Tool clamping apparatus for operations of tin-plating and welding leads of wire-welded type components and parts

A technology for fixtures and components, applied in manufacturing tools, welding equipment, auxiliary devices, etc., can solve problems such as low production efficiency and difficulty, reduce the impact of welding quality, improve assembly reliability, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described;

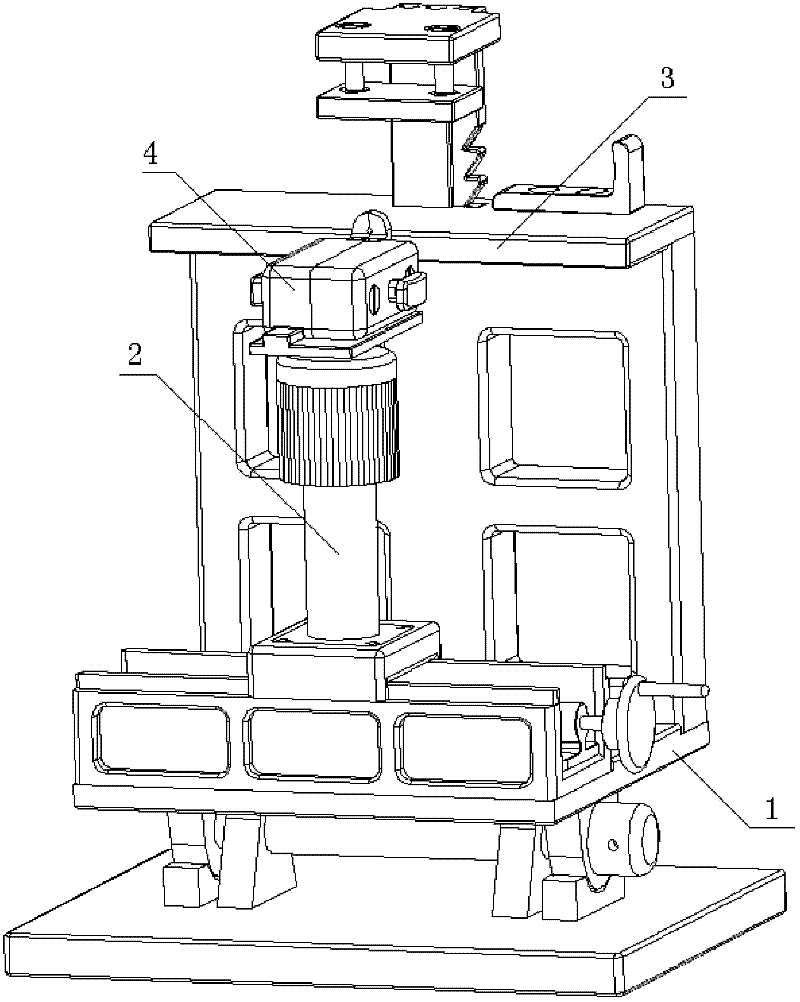

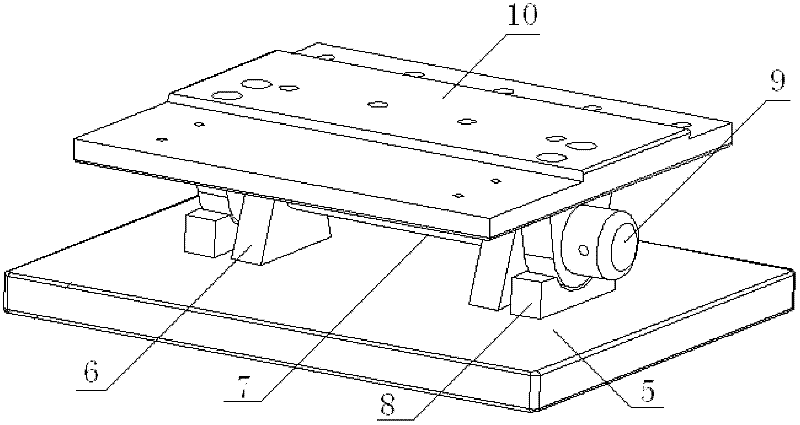

[0030] as attached figure 1 As shown, the tooling and fixture of wire-bonding type component wire tinning and welding operation of the present invention includes turntable 1, horizontal and vertical adjustment mechanism 2, device fixing mechanism 3 and anti-seepage tin fixture 4; figure 2 As shown, the turntable 1 includes a base 5, a support 6, a rotating shaft 7, an angle plate 8, a gland 9 and a seat plate 10. The upper surface of the base 5 is fixed with two supports 6, and the support 6 has a penetrating shaft mounting hole. , the outer sides of the two supports are fixed with an angle plate 8, and the middle part of the angle plate has an arc-shaped groove with a scale. The arc-shaped groove corresponds to the arc-shaped support body under the seat plate 10, and the seat plate 10 is supported by its arc The body is installed in the arc groove of the angle plate 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com