Patents

Literature

35results about How to "Reduced impact on weld quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

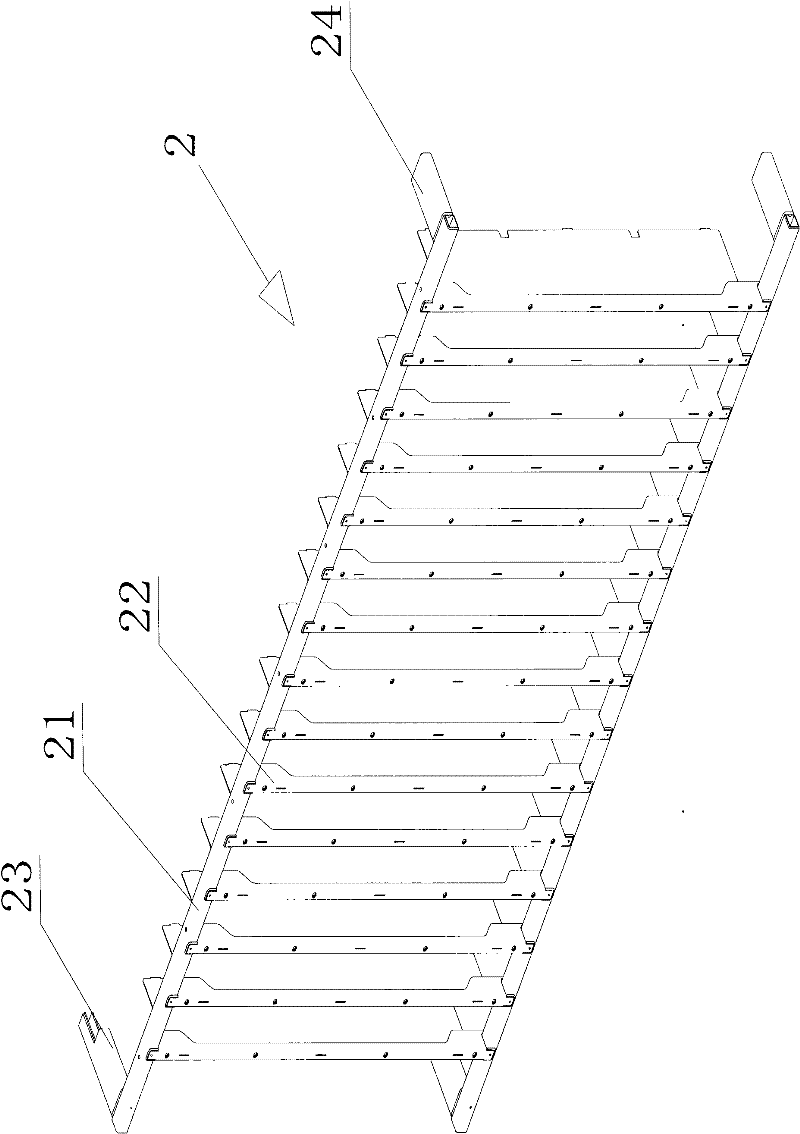

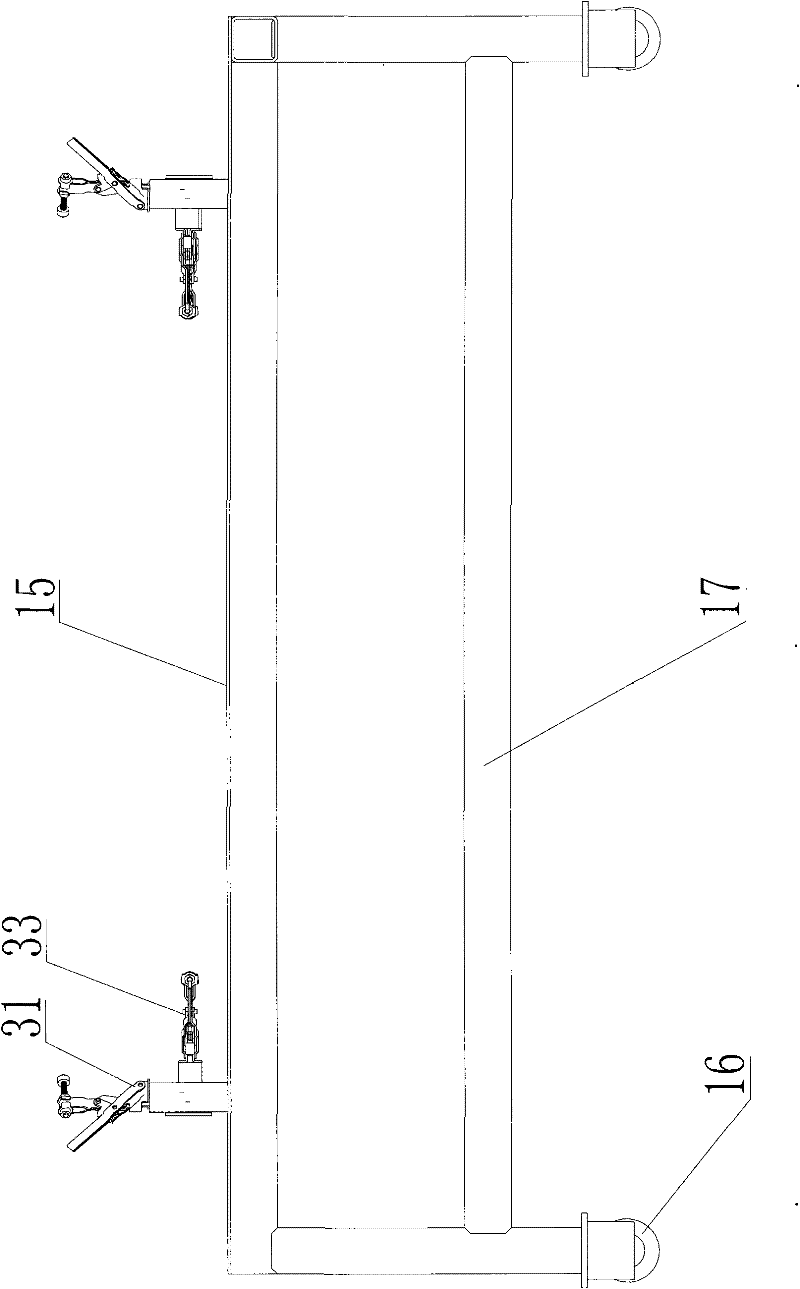

Welding tooling device for pillar frame of machine cabinet and assembly method of device

InactiveCN102029497AReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAuxillary welding devicesInstabilityEngineering

The invention discloses a welding tooling device for a pillar frame of a machine cabinet and an assembly method of the device, wherein the device comprises a clamp body (1) and is characterized in that a positioning element (2) and a clamping device (3) are fixedly arranged on the clamp body, the positioning element (2) is used for horizontal position limitation of all parts of the pillar frame of the machine cabinet, and the clamping device (3) is matched with the positioning element (2) for clamping all the parts of the pillar frame of the machine cabinet in the horizontal direction. By adopting the device and the method disclosed by the invention, the physical labor of operation staff can be greatly reduced, and the assembly and welding efficiency can be improved; and the welding thermal deformation of a workpiece can be controlled or eliminated, and the instability of manual welding can be reduced.

Owner:Jiangsu Boamax Technologies Group Co Ltd

Tool clamping apparatus for operations of tin-plating and welding leads of wire-welded type components and parts

ActiveCN102357699AAchieve fixationAchieve deflectionMetal working apparatusSoldering auxillary devicesTin platingEngineering

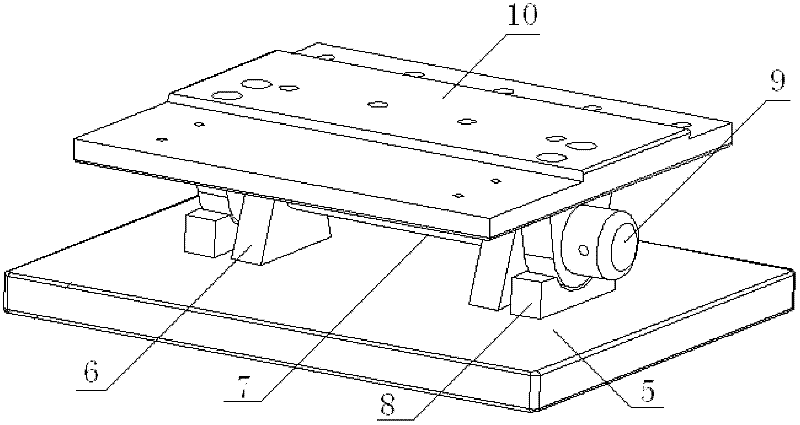

The invention relates to a tool clamping apparatus for the operations of tin-plating and welding the leads of wire-welded type components and parts, belonging to the technical field of welding. The clamping apparatus comprises a turntable, a transverse / longitudinal adjustment mechanism, a component fixing mechanism and a tin-leakage preventing clamp; the bottom face of the tin-leakage preventing clamp is matched with a slide rail of a transverse / longitudinal adjustment mechanism supporting plate; the transverse / longitudinal adjustment mechanism is fixedly mounted on a seat board of the turntable as a whole through a slide rail bottom plate; and the component fixing mechanism is fixedly mounted on the seat board of the turntable through a fixing mechanism body and is opposite to the transverse / longitudinal adjustment mechanism. According to the invention, core wires of the leads are clamped through the tin-leakage preventing clamp so as to exert effects of clamping and tin-leakage preventing, a fixing surface can deflect within 30 DEG towards two sides from the vertical direction through the adjustment of the turntable, and the alignment between the leads and a welding pin (groove)can be realized through adjusting the transverse / longitudinal adjustment mechanism and adjusting the sliding of the tin-leakage preventing clamp on the transverse / longitudinal adjustment mechanism. The tool clamping apparatus can effectively standardize various operations in processes of assembling and connecting and reduces the influence on welding quality caused by human factors.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

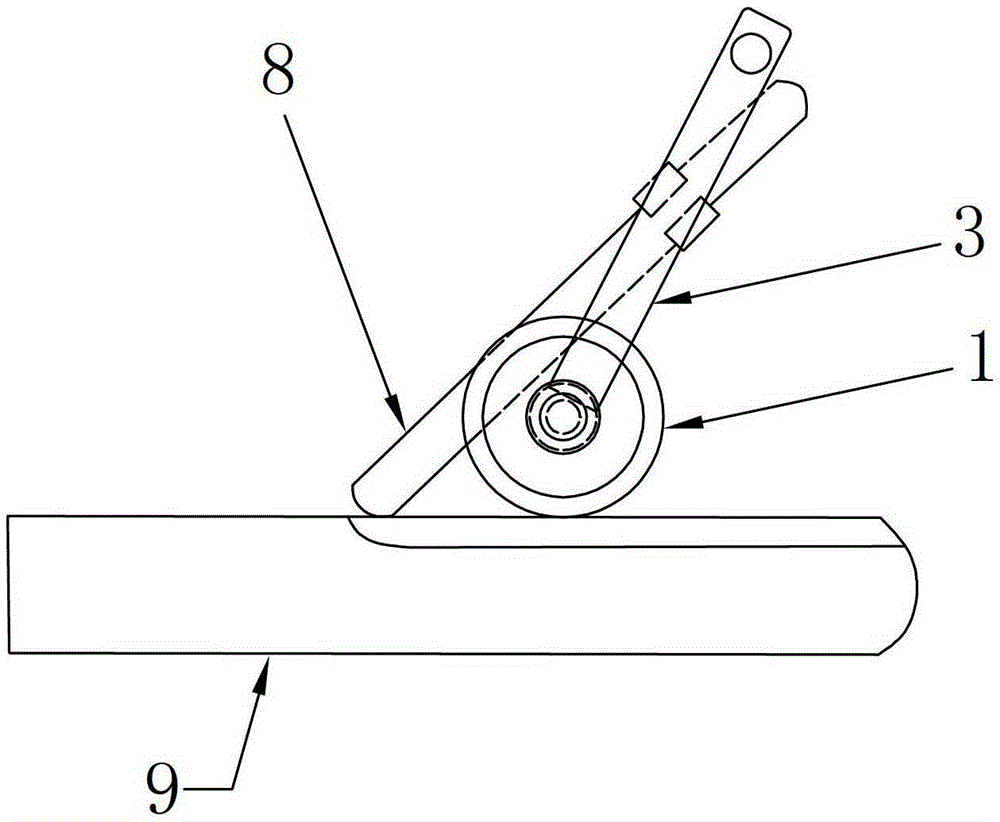

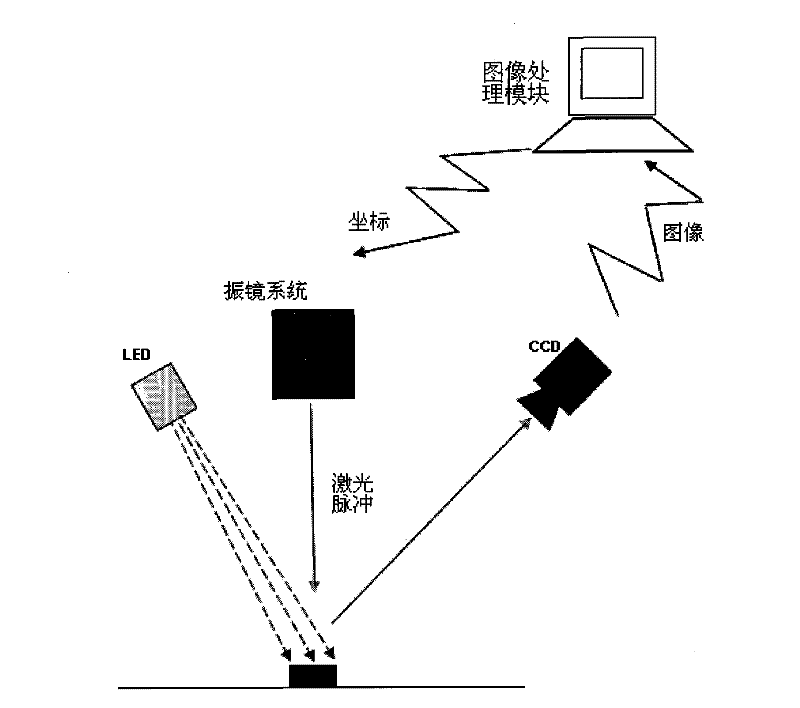

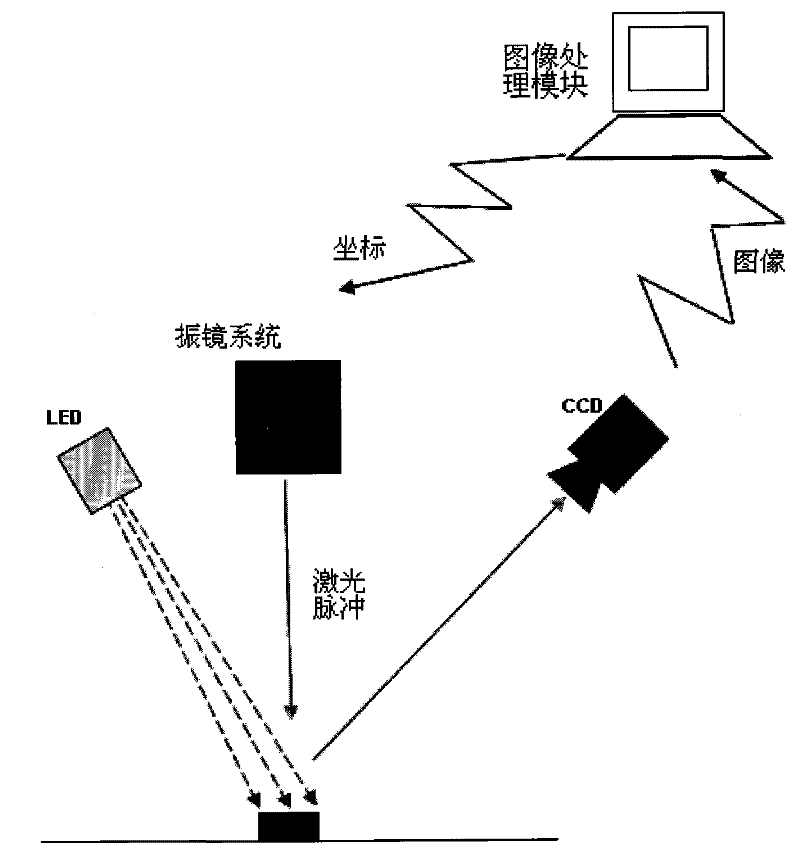

CCD (Charge Coupled Device) galvanometer type laser welding device and method

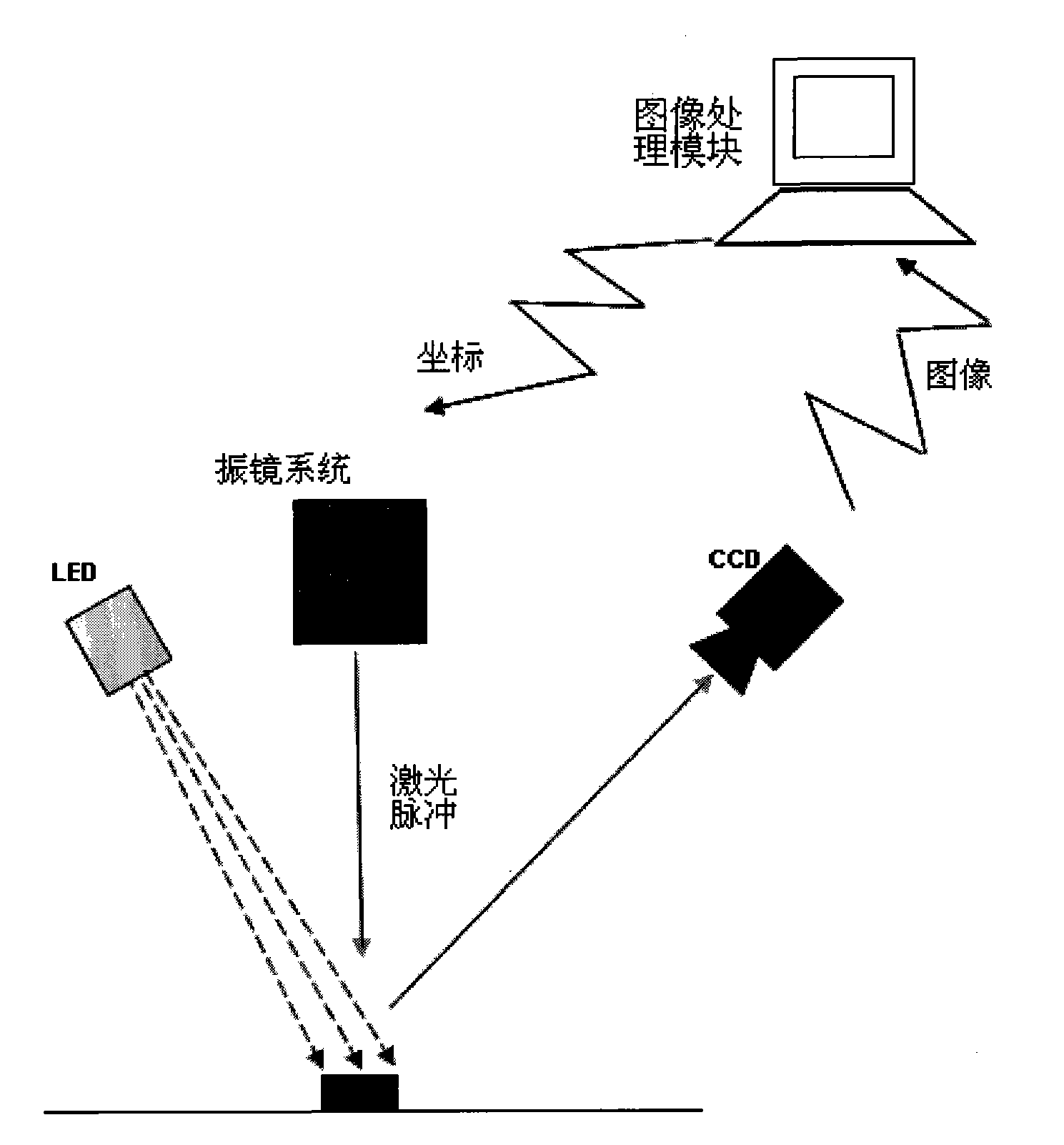

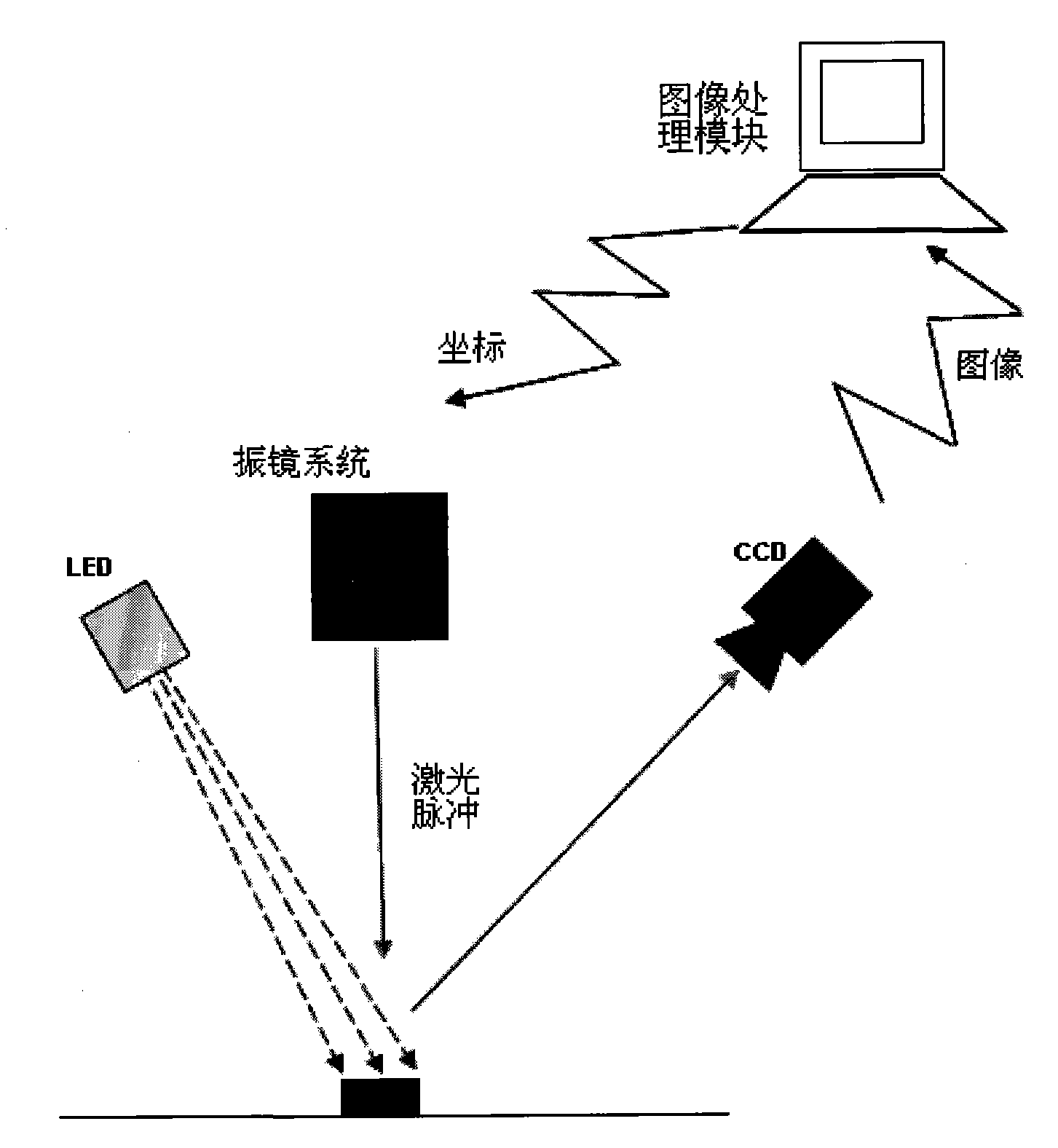

ActiveCN101835348APrecision weldingEasy to controlPrinted circuit assemblingMetal working apparatusImaging processingGalvanometer

The invention discloses a CCD (Charge Coupled Device) galvanometer type laser welding device which comprises an LED lamp, a CCD image acquisition device, an image processing module and a galvanometer system, wherein the LED lamp is used for obliquely irradiating an electronic component pin from the side face of the electronic component pin to project the shadow of the electronic component pin onto a printed circuit board; the CCD image acquisition device is used for acquiring the image data of the electronic component pin through the light and shade contrast on the printed circuit board; the image processing module is used for calculating according to the image data to obtain a welding position coordinate of the electronic component pin and conveying the welding position coordinates to the galvanometer system; and the galvanometer system is used for emitting laser pulses according to the information of the welding position coordinate to smelt the electronic component pin material and form a welding spot on the printed circuit board. The invention also discloses a CCD galvanometer type laser welding method. The invention can dynamically and precisely control the welding position and is not easy to cause pollution.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

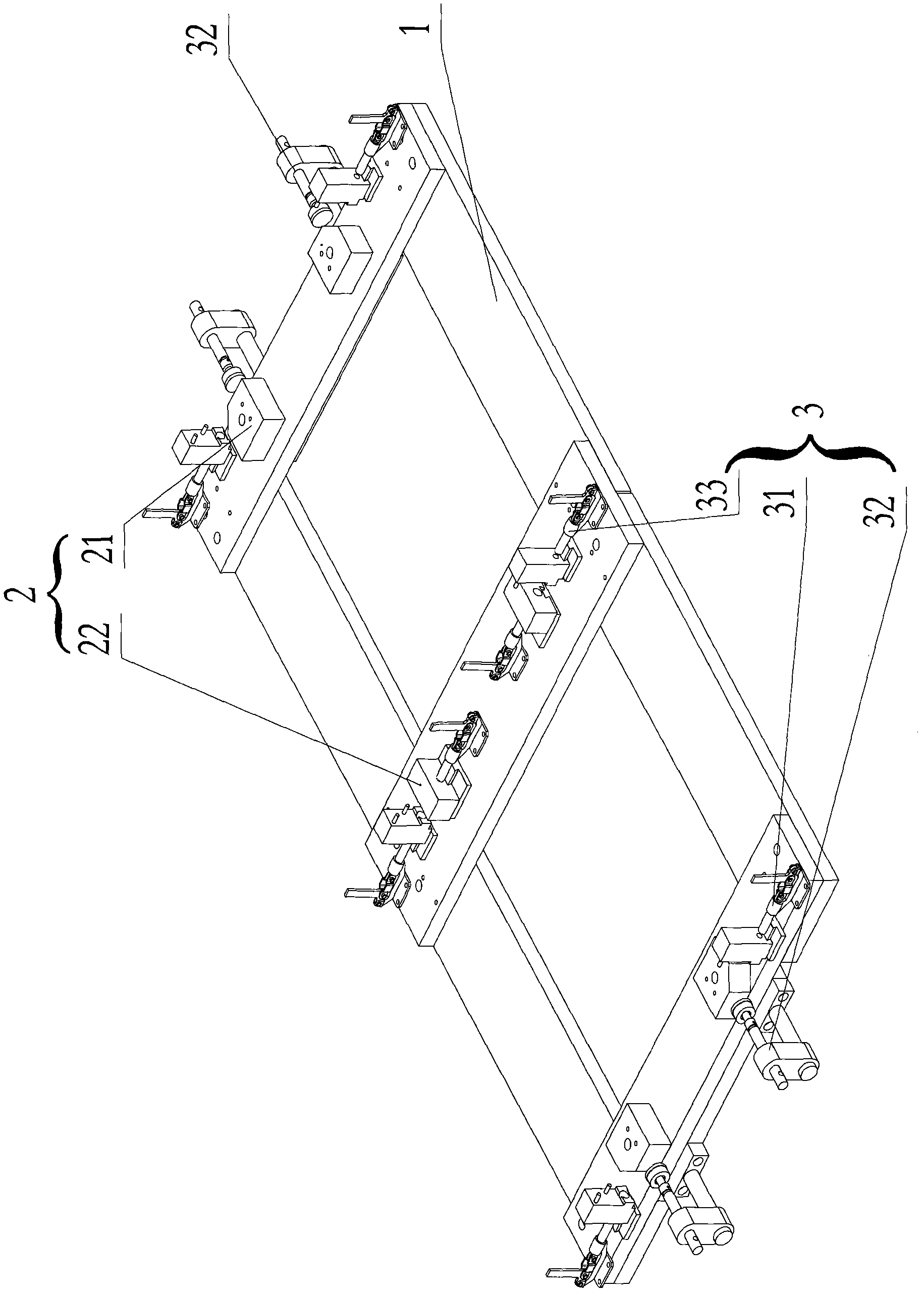

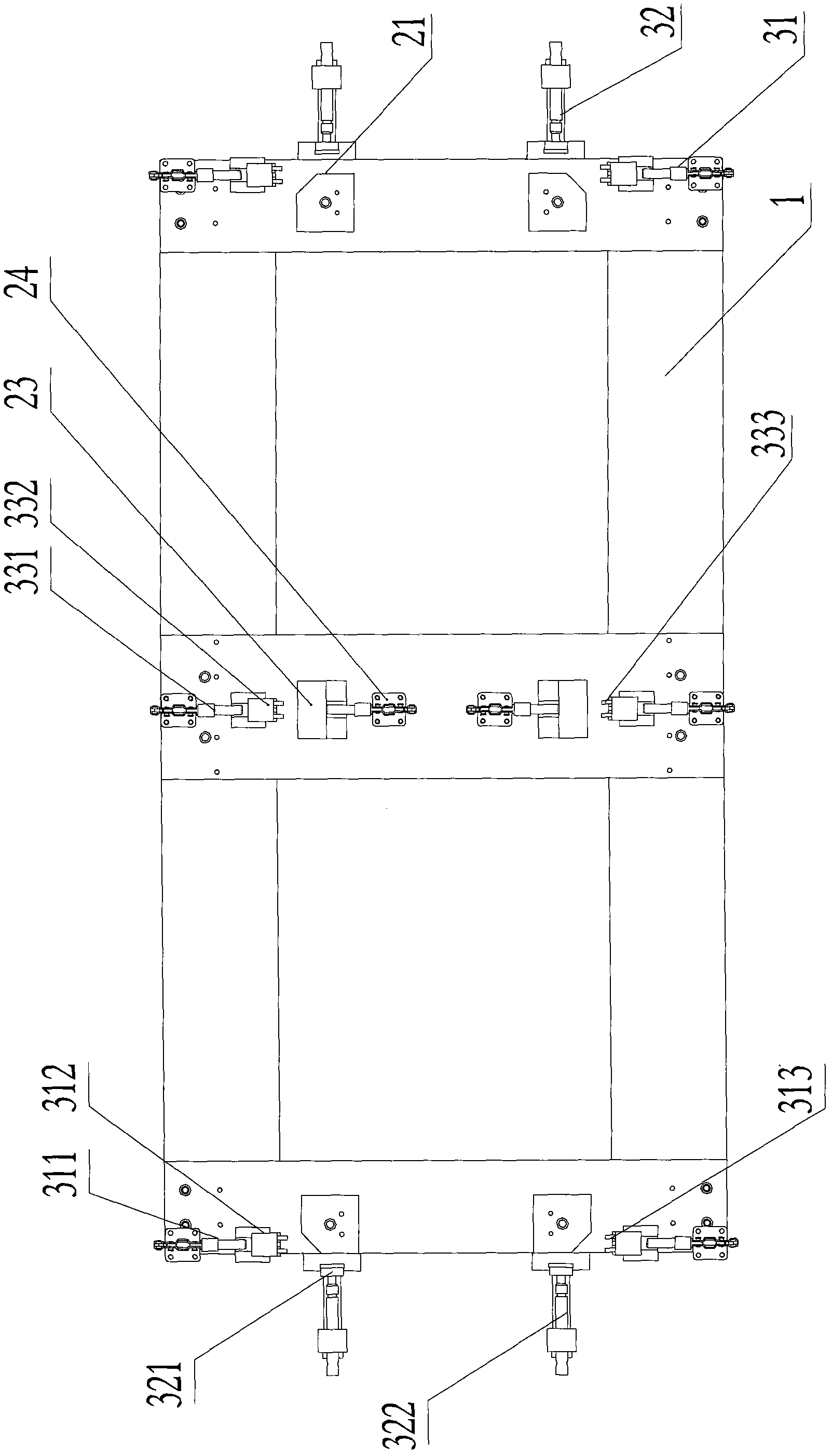

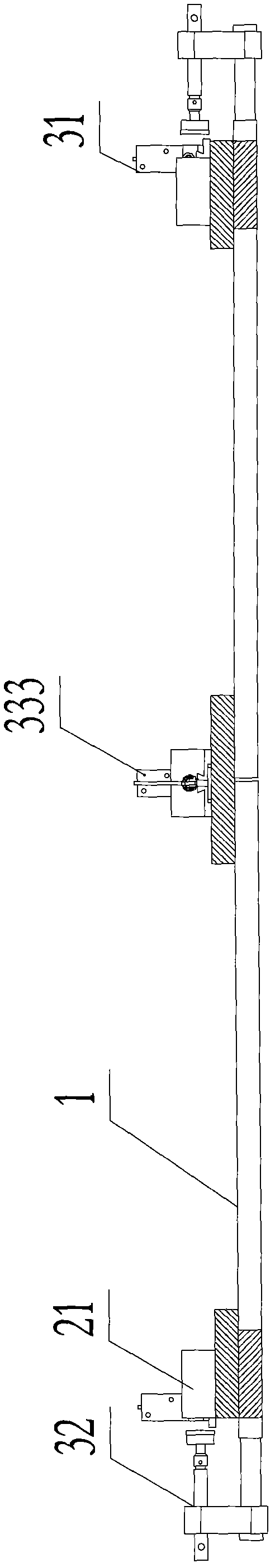

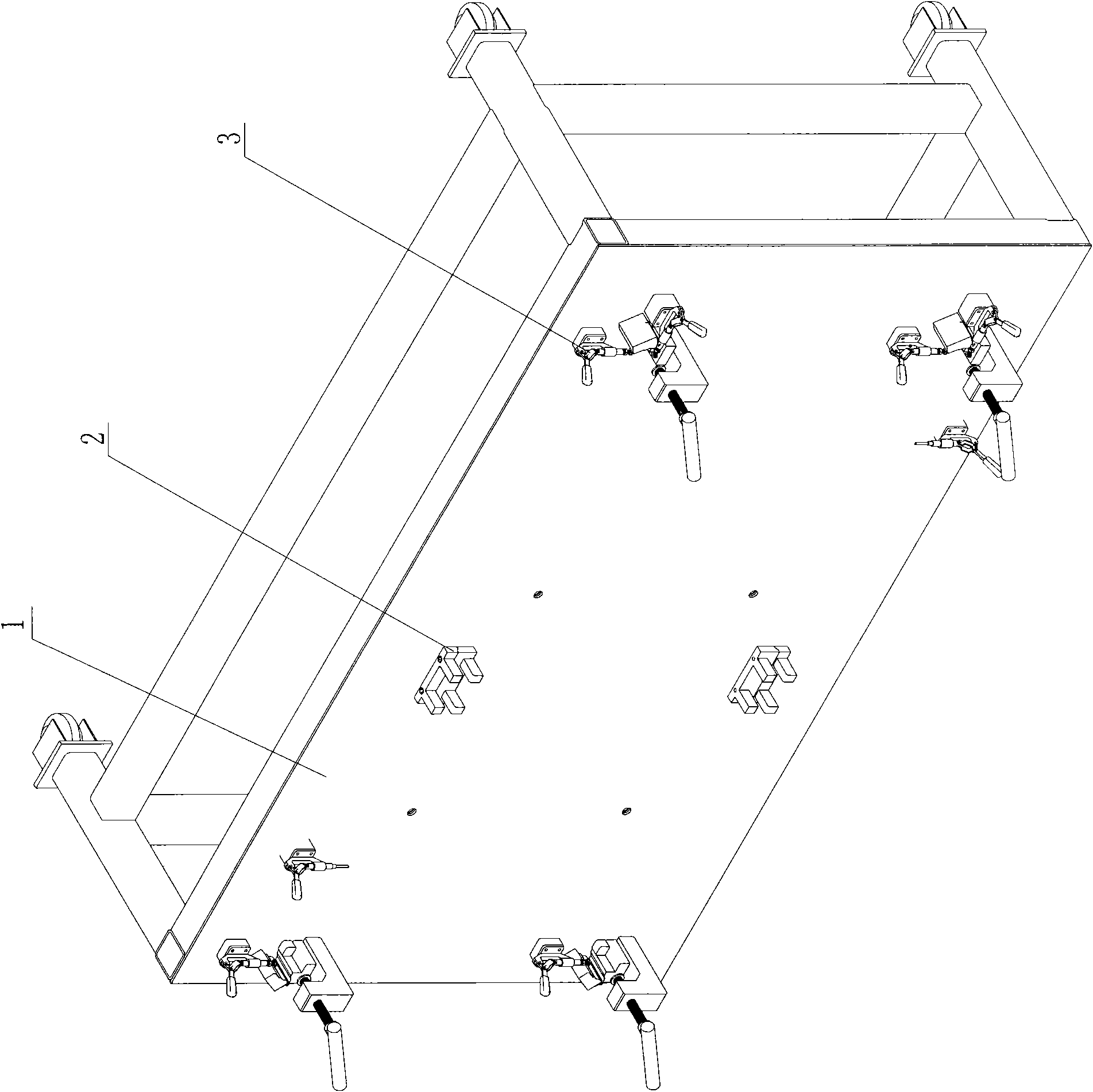

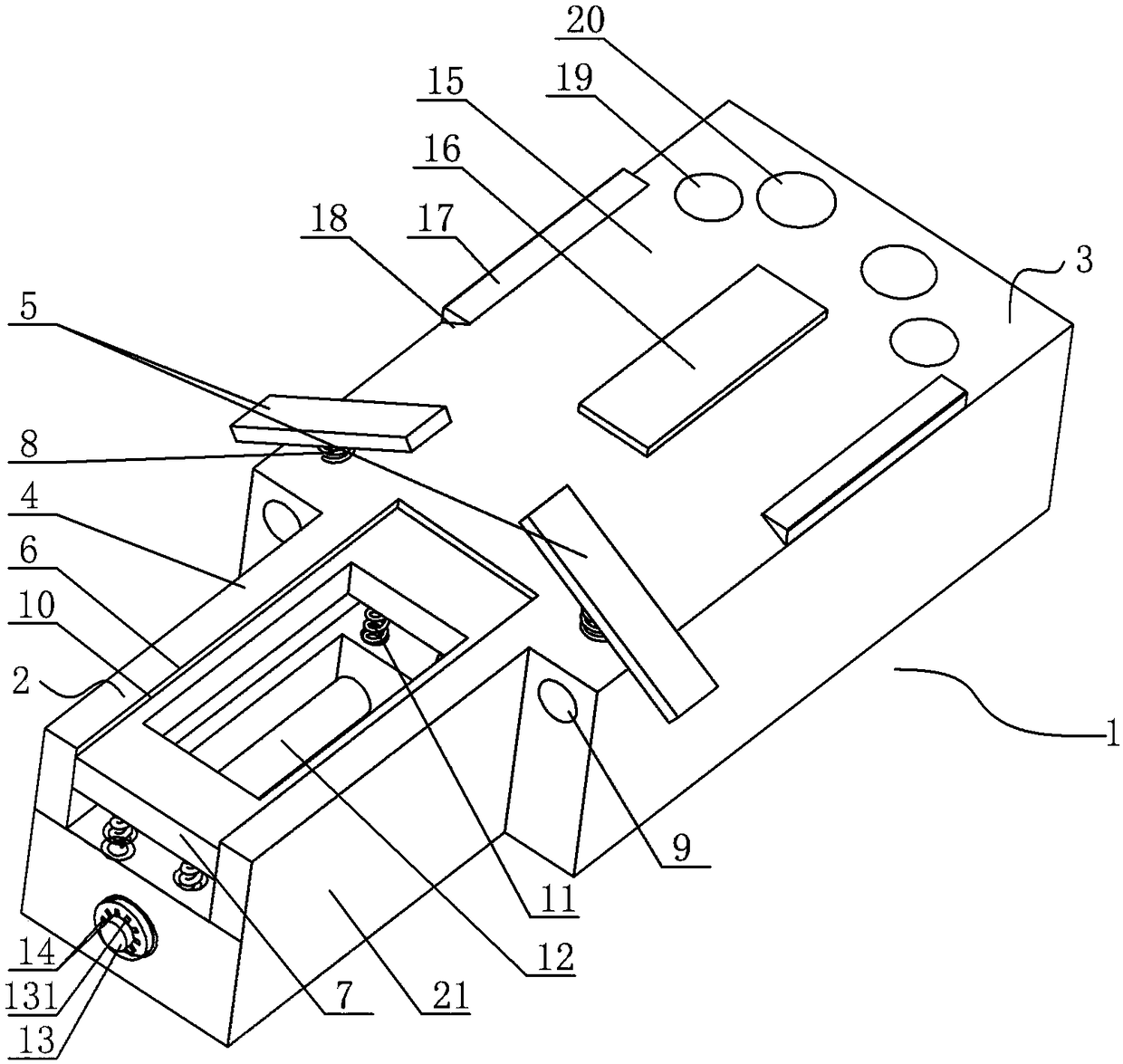

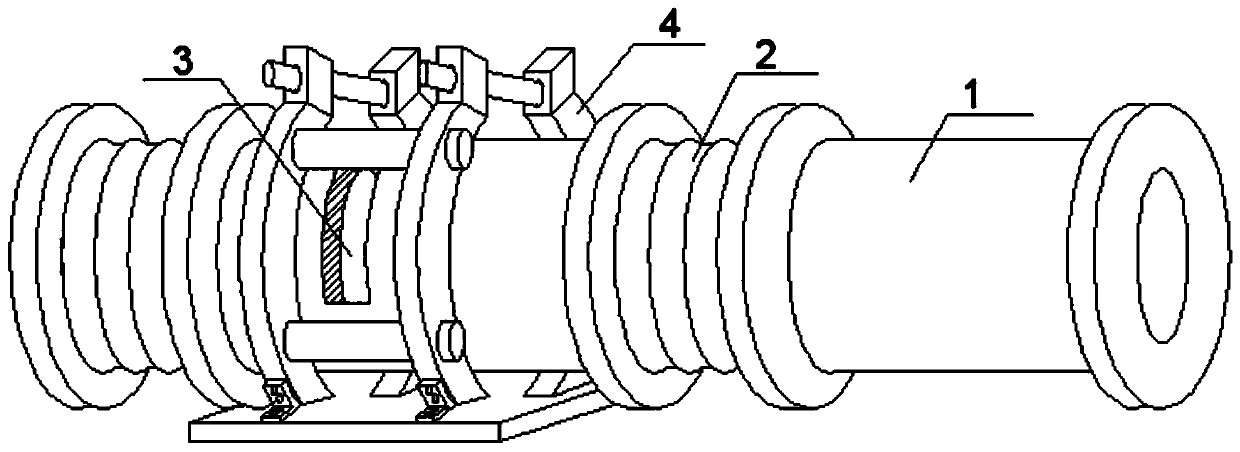

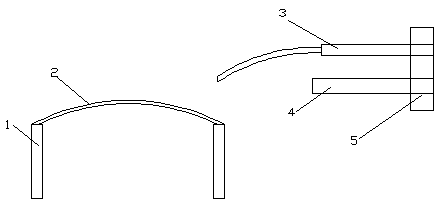

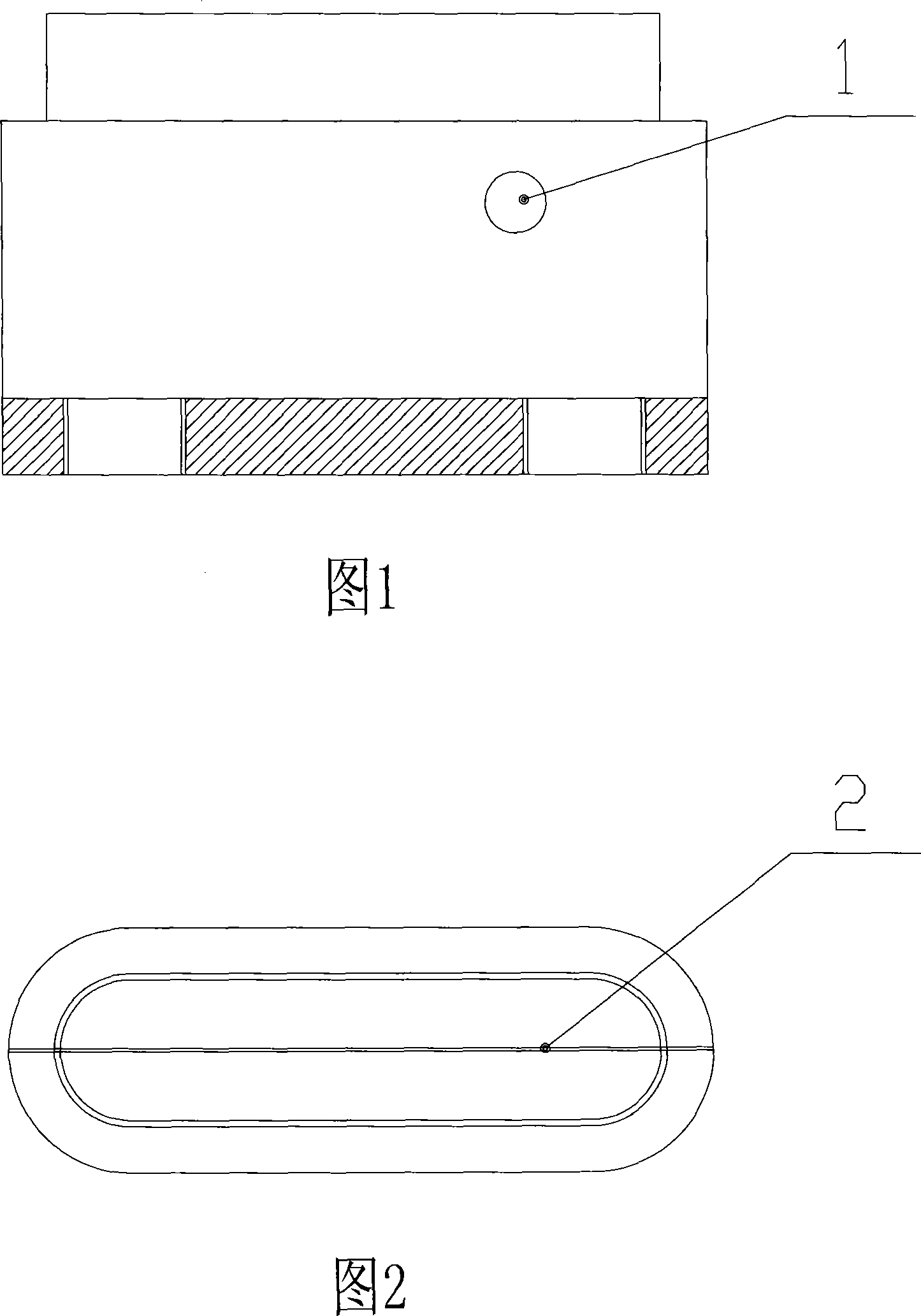

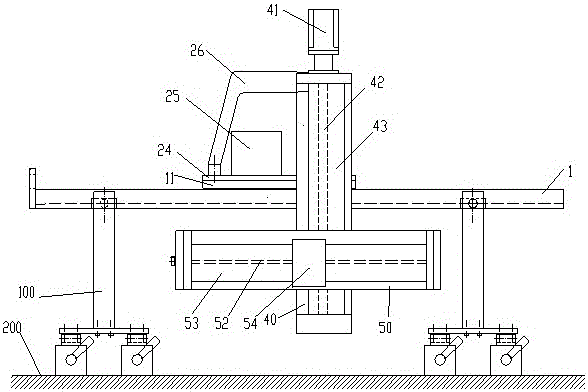

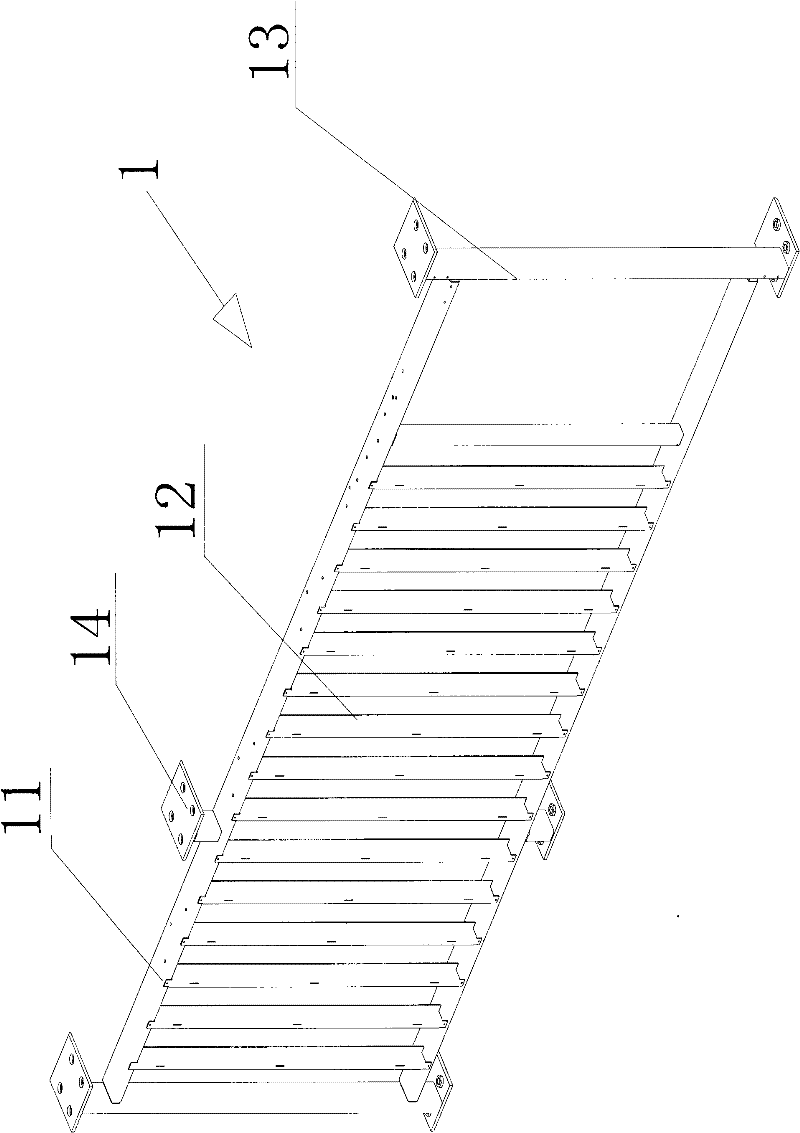

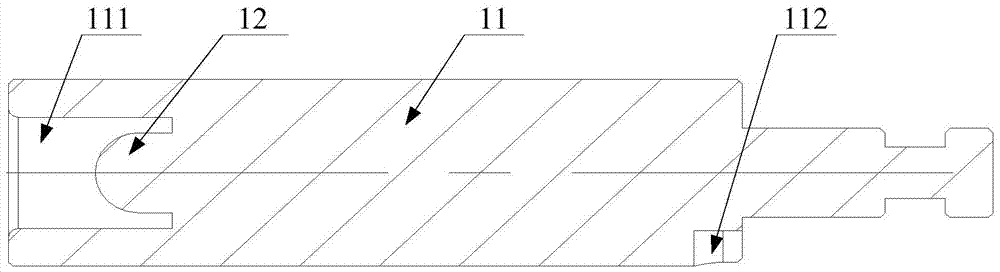

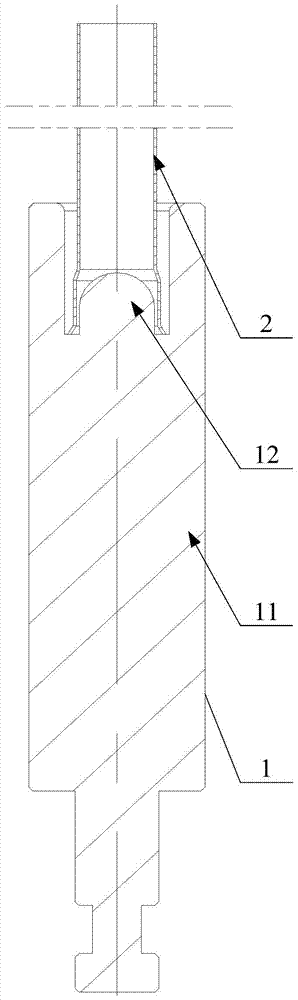

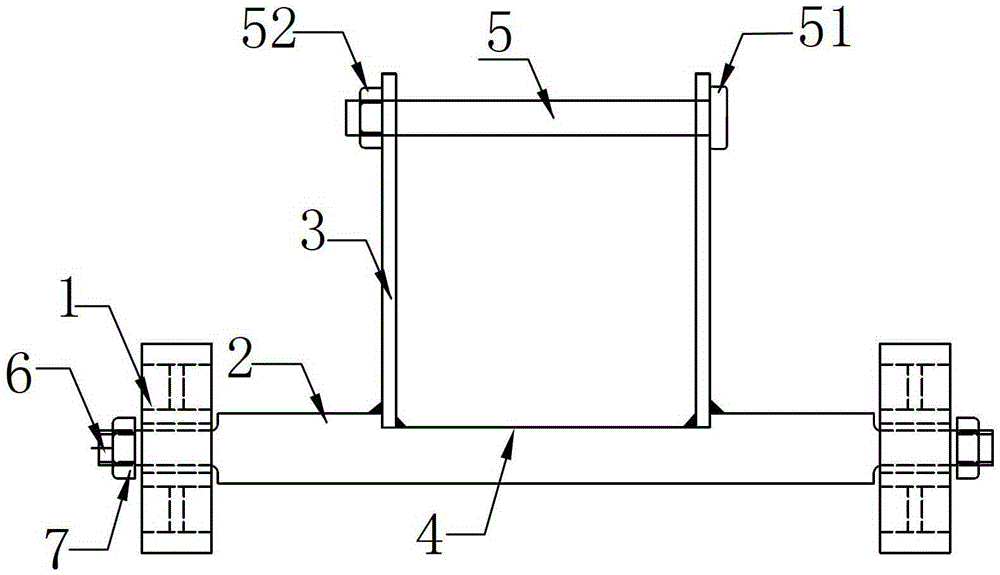

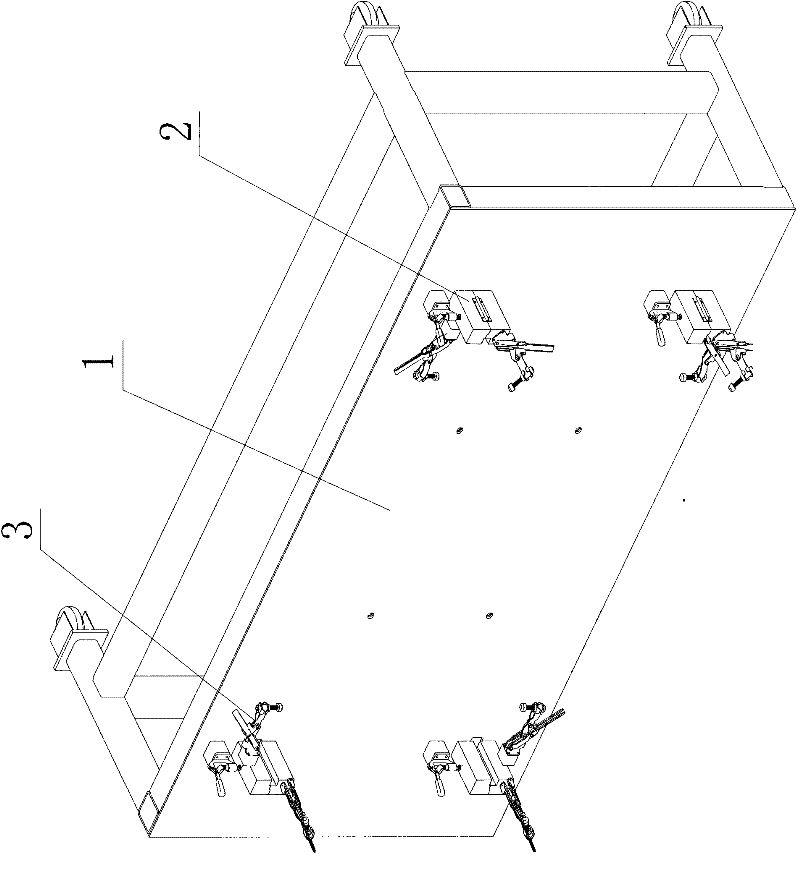

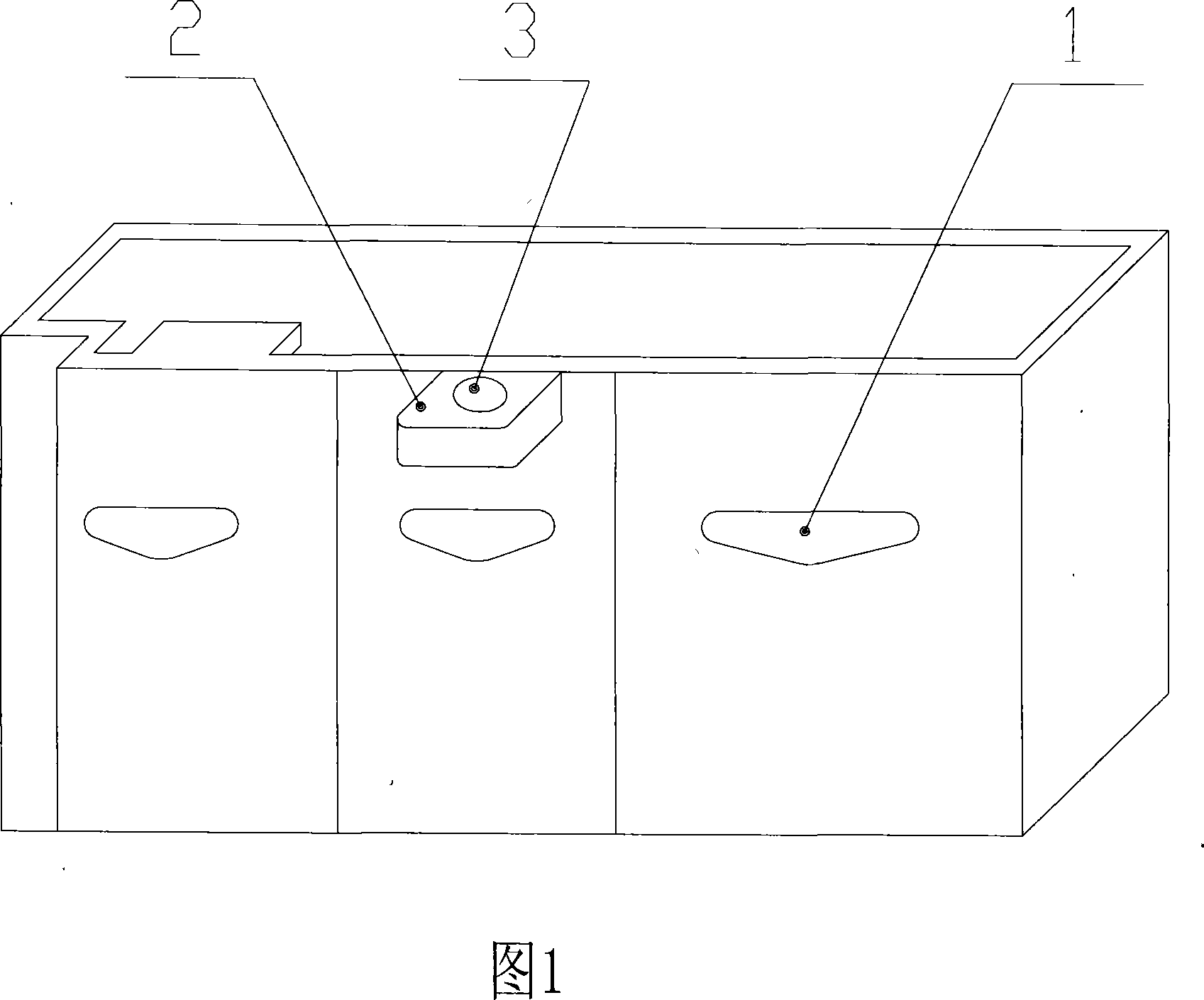

Method for assembling pedestal body of overhead cell support of hybrid vehicle and clamp thereof

ActiveCN101618493AReduce physical laborImprove assembly and welding efficiencyWelding/cutting auxillary devicesAssembly machinesInstabilityThermal deformation

The invention discloses a method for assembling a pedestal body of an overhead cell support of a hybrid vehicle and a used welding frock clamp thereof. The welding tool clamp comprises a clamp body (1), and the pedestal body of the overhead cell support of the hybrid vehicle comprises two pedestal crossbeams (11) and a plurality of middle supporting plates (12); the clamp is characterized in that a positioning element (2) is fixedly arranged at the upper end of the clamp body and horizontally limits the positions of the pedestal crossbeams (11), and a clamping device (3) is arranged at the outer sides of the pedestal crossbeams (11) and clamps the two pedestal crossbeams (11) and the middle supporting plates (12) arranged between the two pedestal crossbeams. The clamp greatly lightens the physical work of the operating staff, improves the assembling and welding efficiency, controls or eliminates the thermal deformation of workpieces caused by welding, and reduces the instability of manual welding.

Owner:苏州宝馨智能制造有限公司

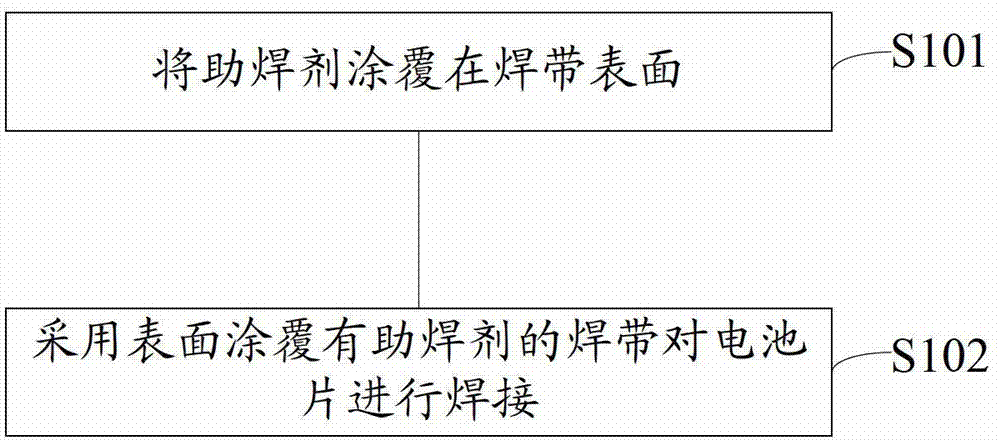

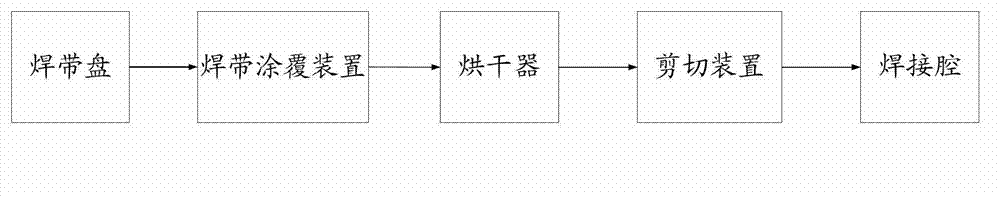

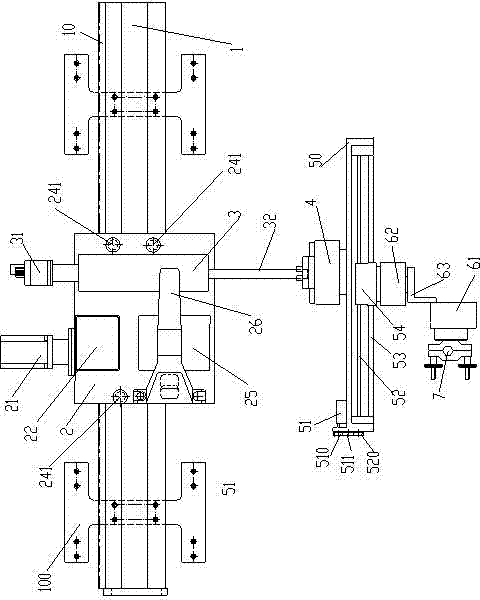

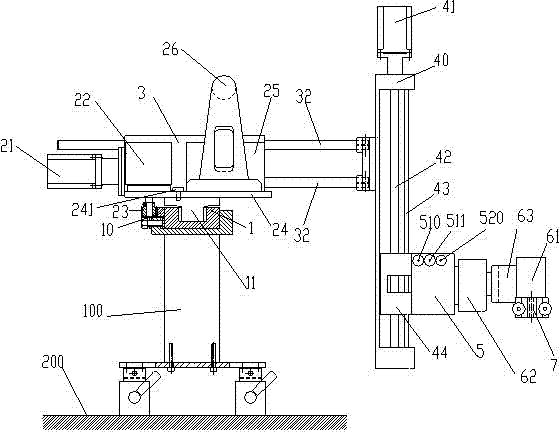

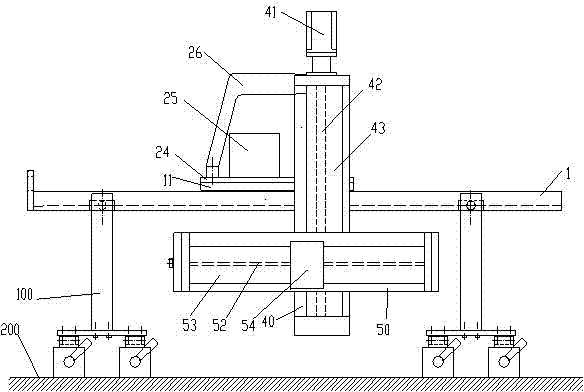

Welding method and welding system

InactiveCN103084685APrevent crystallizationReduced impact on weld qualitySolder feeding devicesMetallurgyImpurity

The invention provides a welding method which comprises coating scaling powder on the surface of a solder strip, and carrying out welding to battery pieces by adopting the solder strip with the scaling powder coated on the surface of the solder strip. The invention further provides a welding system which comprises a solder strip reel with a solder strip installed, a shearing device used for shearing the solder strip and a welding cavity, and further comprises a scaling powder coating device, wherein the first end of the scaling powder coating device is connected with the solder strip reel, the second end of the scaling powder coating device is connected with the shearing device, and the scaling powder is contained inside the scaling powder coating device. On one hand, the welding method and the welding system can reduce the influence of the impurities of the scaling powder to welding quality, avoid a solder skip phenomenon caused by unevenly coated scaling powder, and improve the welding quality between battery pieces. On the other hand, in a scaling powder coating process, the welding method and the welding system remove the turning over operation of the battery pieces, and therefore reduce the fragment risk of the battery pieces.

Owner:LIXIAN YINGLI NEW ENERGY CO LTD

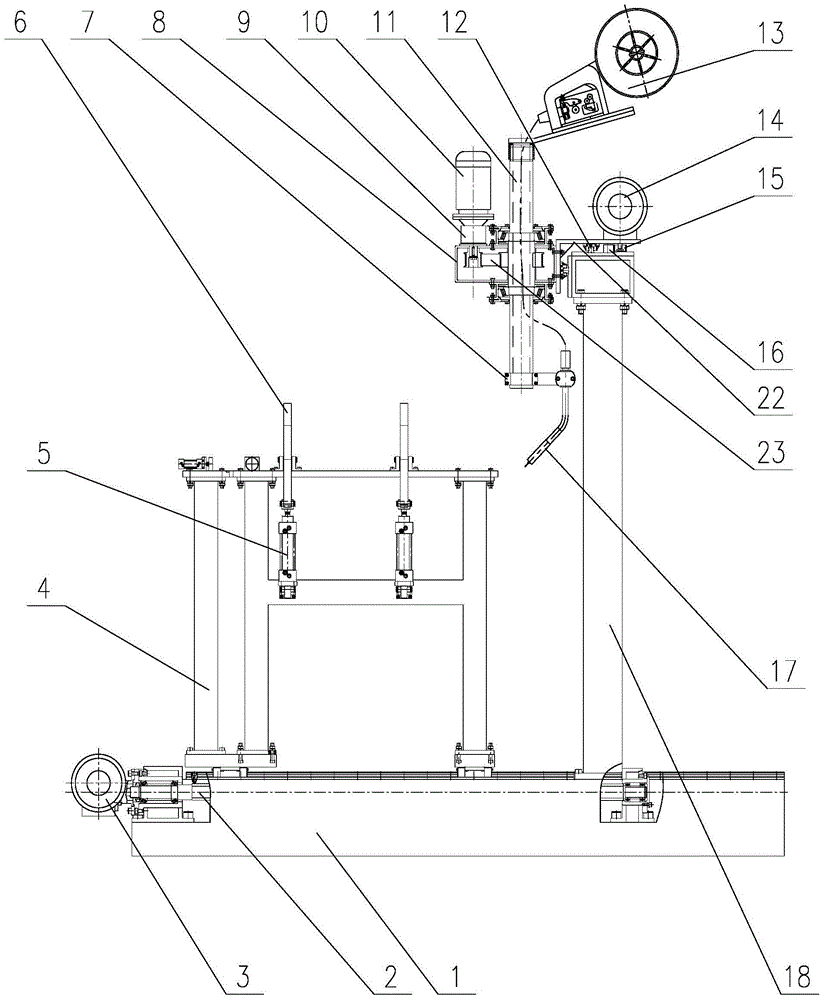

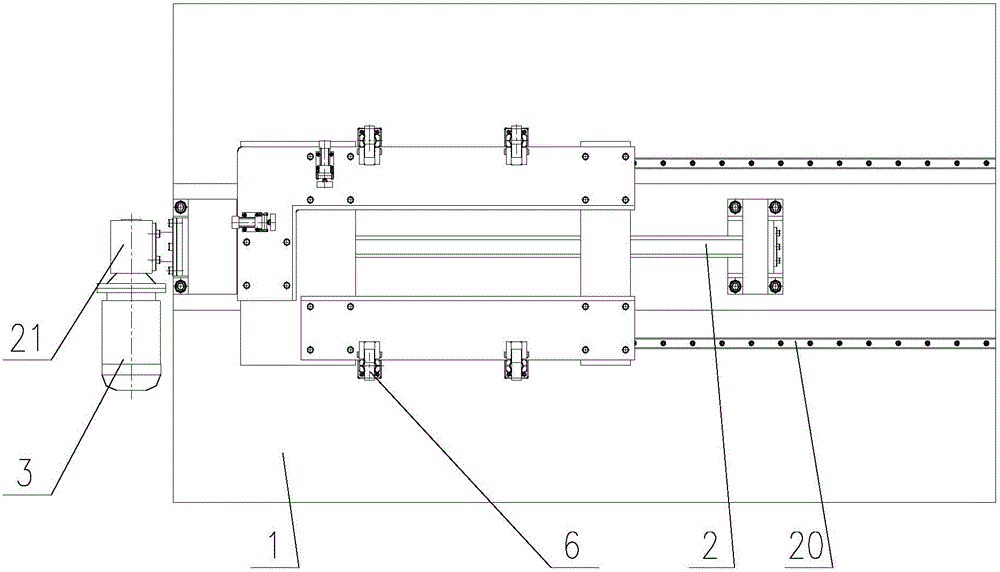

Large combined joist steel girder assembling automatic welding device and automatic welding method

ActiveCN103894747ARealize automatic weldingRealize all-round automatic welding without blind zoneWelding/cutting auxillary devicesAuxillary welding devicesGear wheelReducer

The invention relates to a large combined joist steel girder assembling automatic welding device and automatic welding method capable of achieving the purpose that no blind areas exist in the welding joint direction, and the device and method are used for automatic welding of large combined joist steel girders. A rack is fixed on one side of a rail, a walking trolley is connected with a rail sliding block which is matched with the rail in a sliding mode, a speed reducer is located on the walking trolley and is driven by a walking motor, the speed reducer drives a walking gear which is matched with the rack and drives the walking trolley to move on the rail, the walking trolley is connected with a y-axis adjusting mechanism which is connected with a z-axis adjusting mechanism, and the z-axis adjusting mechanism is connected with an x-axis adjusting mechanism which is connected to a welding gun clamp.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

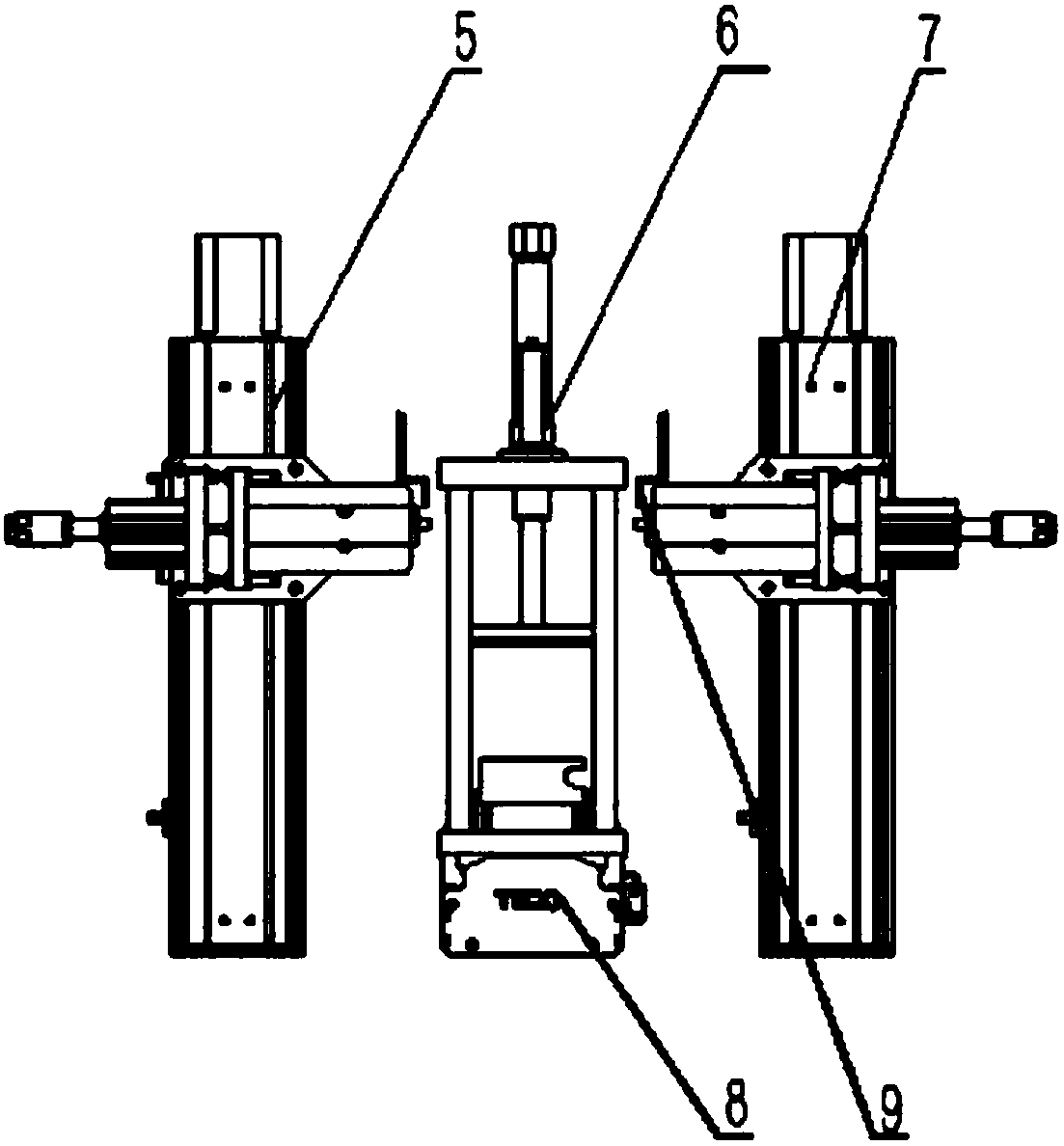

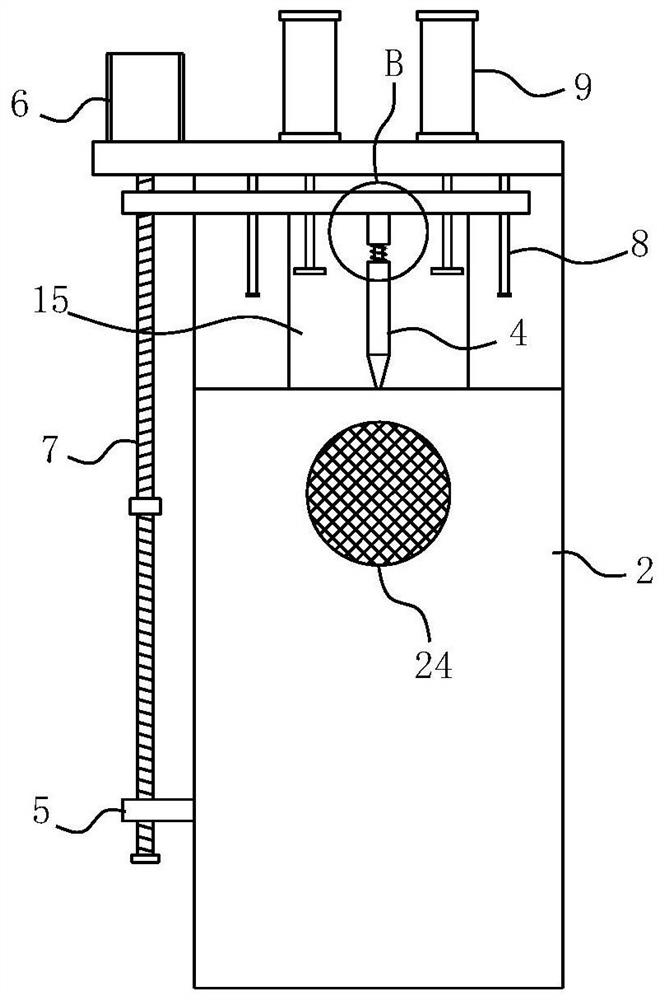

Welding method based on automatic battery electric-welding device

InactiveCN108927592AImprove work efficiencyExtended service lifeResistance electrode holdersWelding/cutting auxillary devicesElectric resistance weldingFastener

The invention relates to a welding method based on an automatic battery electric-welding device. The welding method based on the automatic battery electric-welding device is mainly used for solving the technical problem of low working efficiency in the prior art. According to the welding method based on the automatic battery electric-welding device, the problem is solved by adopting the technicalscheme that the automatic battery electric-welding device comprises a feeding welding mechanism located in a support 1, two electric resistance welding mechanisms and a main air source on the support;the feed welding mechanism comprises a press-assembling part, and Z-direction feeding mechanisms which are symmetrical relative to the press-assembling part; an X-direction servo sliding rail is arranged at the lower end of the press-assembling part; the Z-direction feeding mechanism comprises a Z-direction servo motor, a Z-direction sliding block connected with Z-direction servo motor, a Y-direction driving mounting block located on the front face of the Z-direction sliding block and mounted through a fastener, a stroke-adjustable air cylinder arranged on the Y-direction driving mounting block, an air cylinder push block connected with the stroke-adjustable air through a buffer, and a welding head connected with the air cylinder push block through a welding head mounting block. The welding method can be used for automatic electric welding of batteries.

Owner:张家港市欧微自动化研发有限公司

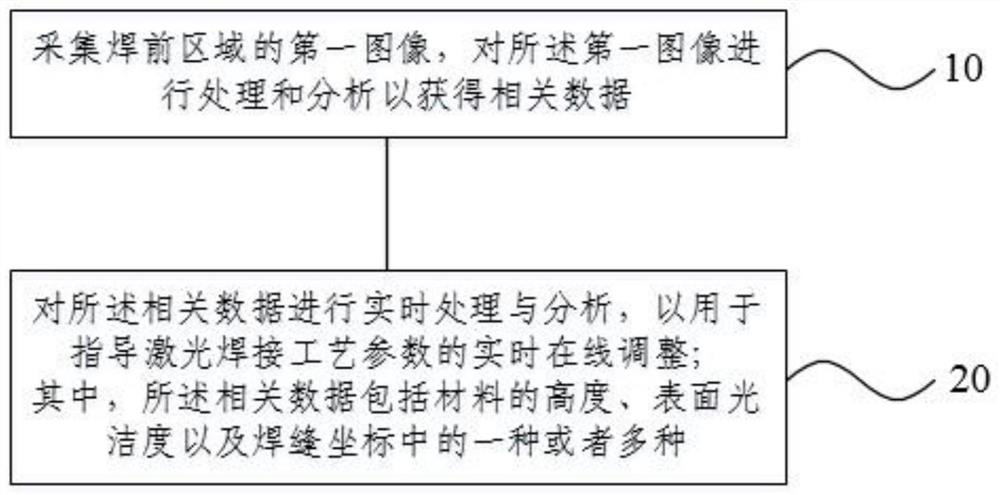

Tab welding method

PendingCN112676676ASolve the problem of welding deviation caused by wrong identificationSolve the problem of welding deviationArc welding apparatusCell component detailsSurface finishImage pair

The invention provides a tab welding method. The tab welding method comprises the following steps: acquiring a first image of a pre-welding area, and processing and analyzing the first image to obtain related data; and carrying out real-time processing and analysis on the related data so as to guide real-time online adjustment of laser welding process parameters, specifically, the related data comprises one or more of the material height, the surface smoothness and weld joint coordinates. The first image of the pre-welding area is processed and analyzed to obtain necessary pre-welding information, so that the laser welding process parameters are adjusted in real time, the influence of material warping on the welding quality is reduced, real-time weld joint tracking is achieved, and the problem of welding deviation caused by wrong identification due to the fact that a liquid injection hole is not assembled in place during welding is solved.

Owner:WUHAN YIFI LASER EQUIP CO LTD

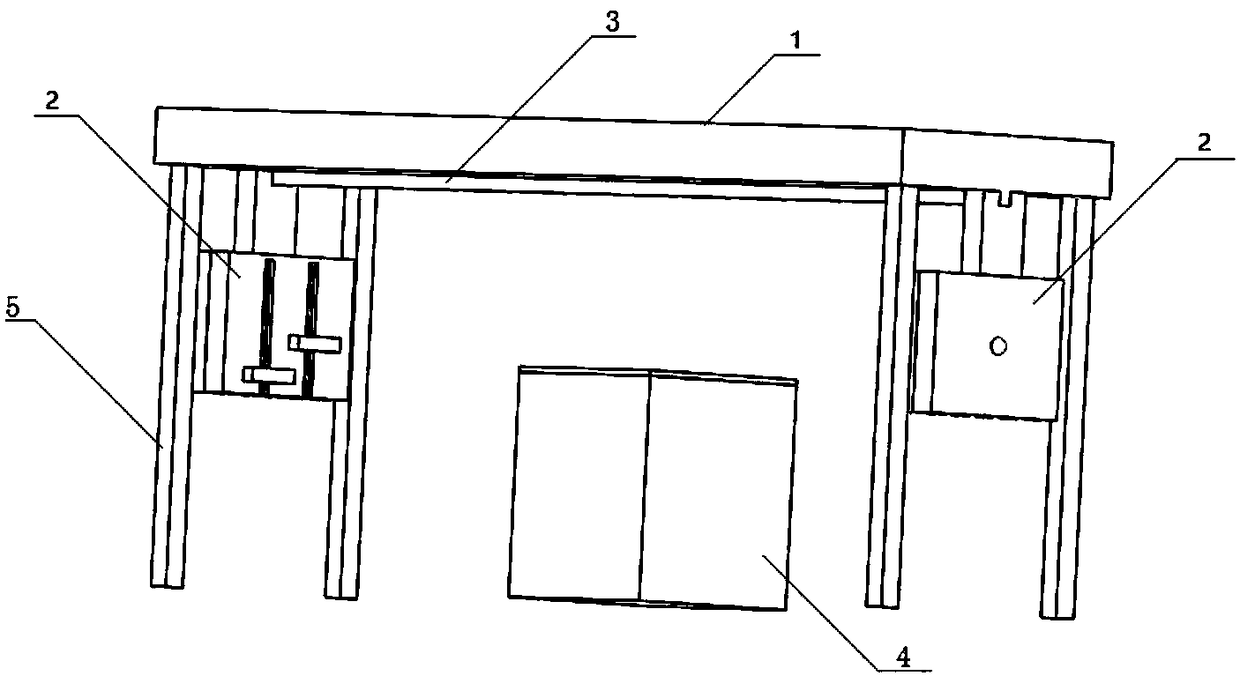

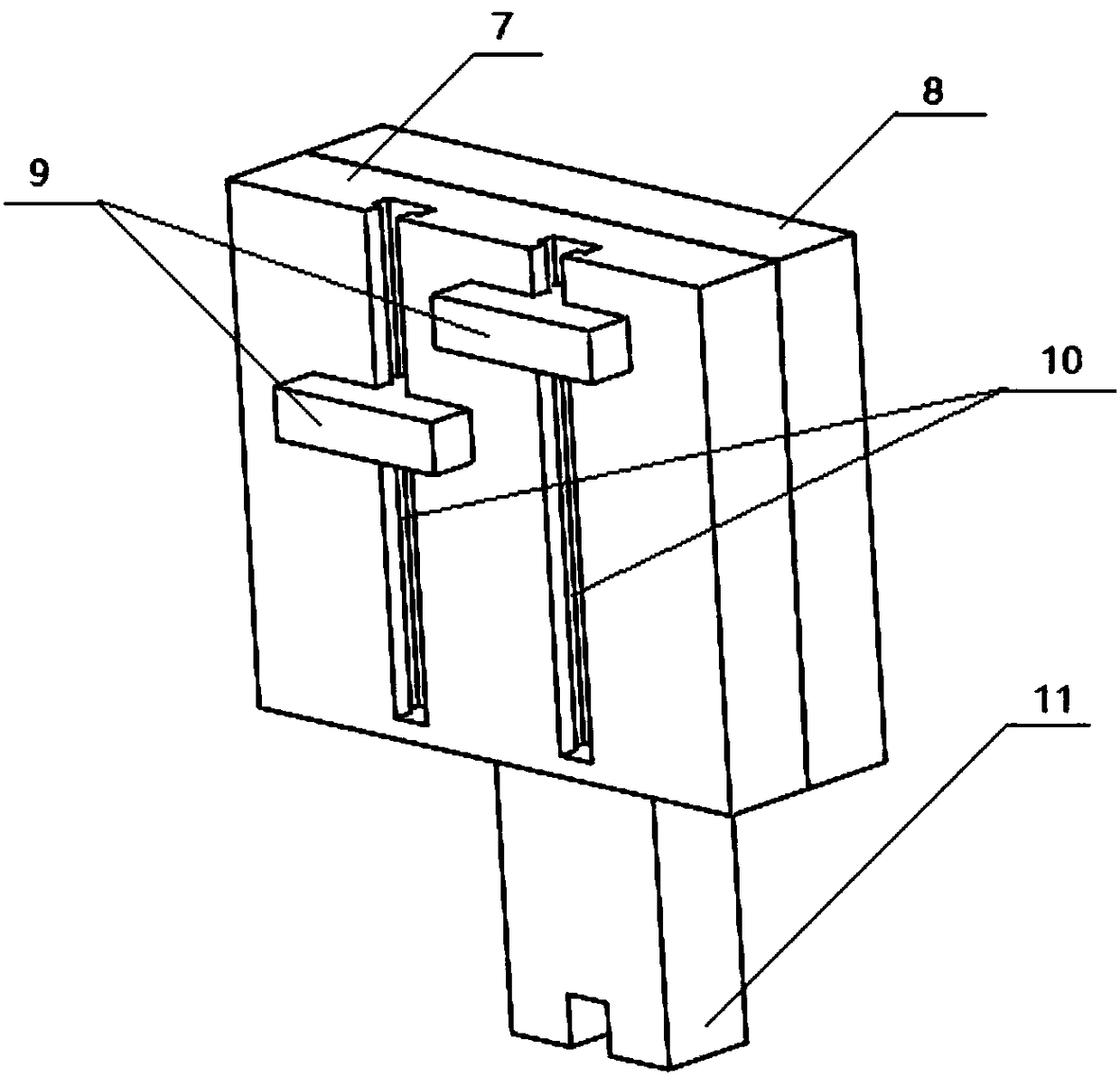

Integrated fixture and welding method for 5G SFP package type optical transceiver module

ActiveCN108907399AEnsure reasonable forceAdjust the tightness in timeWelding/cutting auxillary devicesAuxillary welding devicesTransceiverEngineering

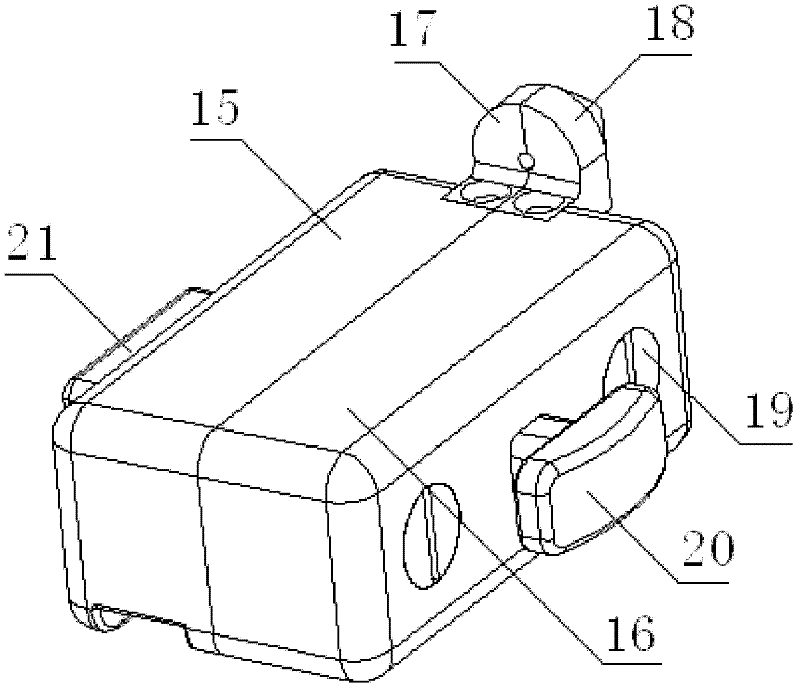

The invention provides an integrated fixture for welding of a 5G SFP package type optical transceiver module. By means of the integrated fixture, the production qualified rate of the 5G SFP package type optical transceiver module is increased to 10% or over, the production cycle is shortened by 90% or over, welding operation is convenient, the welding performance is reliable, and the fixture is easy and convenient to machine. The integrated fixture comprises a working base table; a flexible plate welding part and an optical component welding part are arranged at the upper end positions of thetwo ends of the working base table in the length direction; the flexible plate welding part is used for prefixing and prewelding printed circuit boards (PCBs) and flexible PCBs; and the optical component welding part is used for welding semi-finished components and optical components completed by the flexible plate welding part into complete 5G SFP package type optical transceiver module components.

Owner:HENGTONG ROCKLEY TECHNOLOGY CO LTD

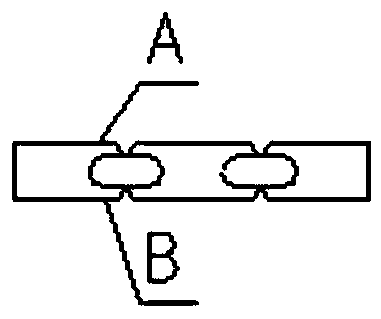

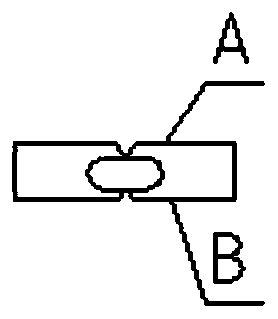

Improved welding process for casting block of tail shield of shield tunneling machine

InactiveCN110666374AEffective control of deflection and deformationReduced impact on weld qualityWelding/cutting auxillary devicesAuxillary welding devicesShield tunnelingRivet

The invention discloses an improved welding process for a casting block of a tail shield of a shield tunneling machine. The improved welding process comprises the following steps that steel plates areassembled according to a drawing to form the casting block; grooves in the two sides of the casting block are machined; and the side A of the casting block is welded through multi-layer single-pass and section-by-section backstep welding under a small current, the casting block is turned over after one layer is welded, the side B of the casting block is welded in the same way, and the step is repeated until two layers are welded on the side B and three layers are welded on the side A, so that welding of the casting block is completed. The improved welding process has the advantages that resources are saved, costs are reduced, and the quality is effectively controlled. Bending deformation of the casting block after welding is reduced, the leveling difficulty is reduced for rivet workers, the welding quality of the casting block is guaranteed, and unnecessary costs are reduced.

Owner:济南重工集团有限公司

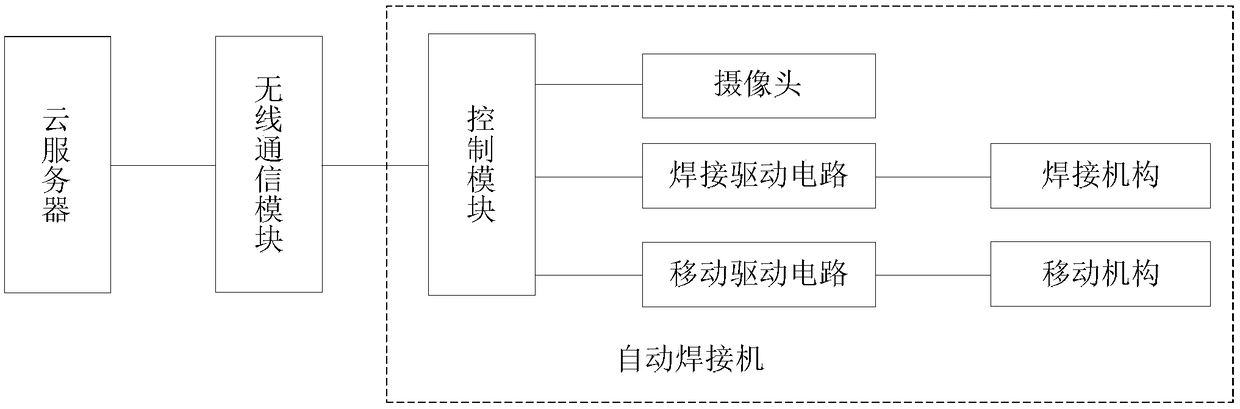

Intelligent welding system and working method thereof

InactiveCN108907536AReduce dependencyReduced impact on weld qualityWelding/cutting auxillary devicesAuxillary welding devicesIntelligent lightingInformation transmission

The invention belongs to the field of intelligent automation, and particularly relates to an intelligent welding system and a working method thereof. The intelligent welding system comprises a cloud server, an automatic welding machine and a wireless communication module, wherein the automatic welding machine is controlled by a control module, and the wireless communication module is used for carrying out information transmission between the cloud server and the automatic welding machine. The intelligent welding system and the working method thereof have the beneficial effects that the controlmodule is suitable for obtaining the welding information of a workpiece from the cloud server through the wireless communication module so as to control the automatic welding machine to conduct welding, so that the dependence degree of the welding process on people is reduced, the influence of human factors on the welding quality is further reduced, and the automation degree and the production efficiency are improved.

Owner:TECH TRANSFER CENT CO LTD NANJING UNIV OF SCI & TECH

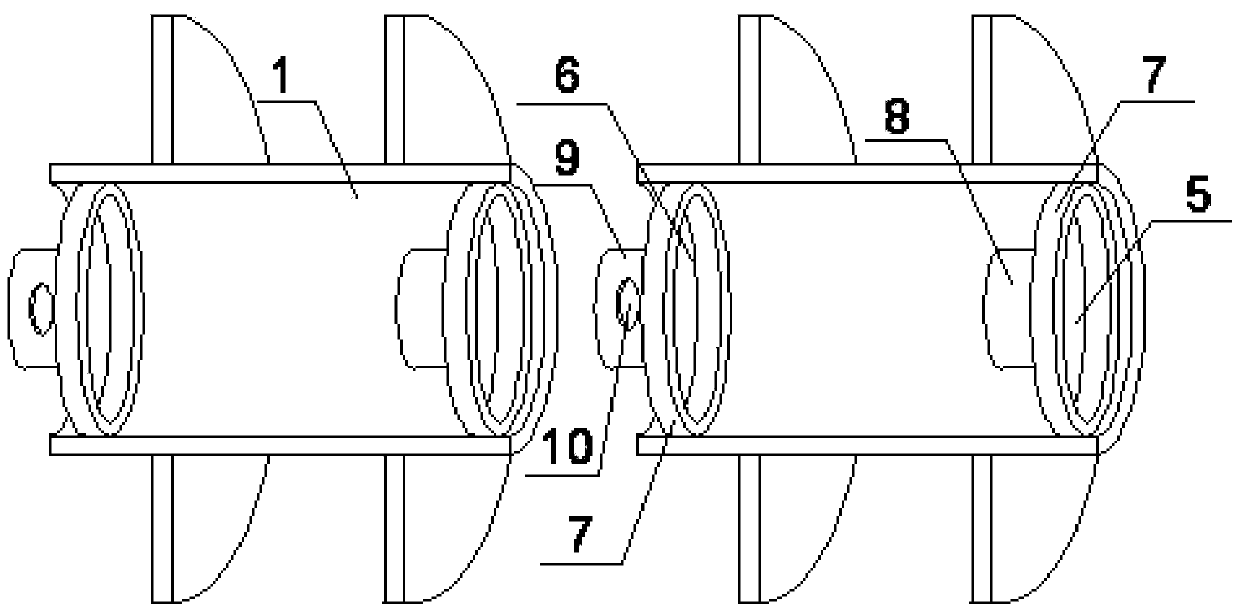

Welding process of natural gas long-distance pipeline

InactiveCN110434436AAchieve a fixed purposeAct as a windshieldWelding/cutting auxillary devicesArc welding apparatusEngineeringWind speed

The invention discloses a welding process of a natural gas long-distance pipeline. The welding process involves long-distance pipelines and a communicating pipe; the communicating pipe is fixedly arranged between two adjacent long-distance pipelines in a sealing manner; a groove is formed in the long-distance pipelines; fixing frames are arranged on the two sides of the groove; each fixing frame comprises a fixing base, a left positioning ring and a right positioning ring; the left positioning ring and the right positioning ring are correspondingly and fixedly arranged on the fixing base through hinges; and the left positioning ring and the right positioning ring are positioned through fixing pins. The fixing frames are additionally arranged on the long-distance pipeline so as to achieve the purpose of fixing the long-distance pipeline, the precision of welding joints of a connecting pipe is improved, and the condition of an interface group is optimized; and in addition, the fixing frames can play a certain wind shielding role, so that the influence of the wind speed on the welding quality can be reduced as much as possible.

Owner:芜湖中燃城市燃气发展有限公司

Welding fixture

ActiveCN105798517BImprove welding efficiencyHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention relates to a welding fixture. The welding fixture comprises a workbench base, double-side welding combined clamping plates and sliding rails which are connected to the workbench base, a welding operating table used for placement of a weldment, brackets connected to the workbench base, a front fixture rotating plate and a rear fixture rotating plate which are connected via a rotating shaft and can rotate around the rotating shaft clockwise or anticlockwise, and slideable fixtures, sliding grooves and liftable supporting rods which are positioned on two sides of the front fixture rotating plate. According to the invention, the automaton of welding turnover is realized through rotation of the double-side welding combined clamping plates, the influence on the welding quality due to turnover originally is reduced, the operation of workers is simplified, only few manual operation is needed, requirements for the degree of proficiency and operating techniques are lower, the quality of welding products is guaranteed, and the welding efficiency and automation degree of double-side welding are improved.

Owner:ANHUI HAODING METAL PROD LIMITED

Tool suspension welding positioning device

InactiveCN107755935ASimple and effective protectionReduced impact on weld qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering gun

The invention relates to a tool suspension welding positioning device. The positioning device includes a tooling, a welding guide, a welding torch, and a limit steel block. The welding guide is arranged on the tool to locate the position of the welding spot in the Y direction, and the limit steel block is arranged at the lower part of the welding torch , to locate the X-direction position of the welding spot, and a nylon block is arranged between the limiting steel block and the welding torch. The welding guide device of the present invention is fixed on the tooling, and the position of the welding spot is determined by combining with the limit steel block, and combined with the nylon block to protect and position the parts more concisely and effectively, greatly reducing the position deviation of the welding point and the impact of human factors on the welding quality Impact.

Owner:YIZHENG TONGZHOU AUTO PARTS CO LTD

Application of vacuum electron beam welding to molybdenum-rhenium alloy welding

InactiveCN112276328AStrong penetrating powerReduced impact on weld qualityElectron beam welding apparatusVacuum electronicsElectron bunches

The invention relates to the field of vacuum electron beam welding in the equipment manufacturing industry, in particular to application of vacuum electron beam welding to molybdenum-rhenium alloy welding. Molybdenum-rhenium alloy is used as a material for powder metallurgy manufacturing, is sensitive to environmental carbon, nitrogen and oxygen, is easy to oxidize under high-temperature conditions, is easy to form pores, brittle phases and cracks in the welding process, and high-quality welding and forming of the molybdenum-rhenium alloy is realized by utilizing the characteristics of variousparameters of vacuum electron beam welding; and the molybdenum-rhenium alloy is a molybdenum alloy which takes molybdenum as a base and is added with 2%-5% of rhenium. Molybdenum is added into rhenium, the plasticity and strength of molybdenum can be improved, and rhenium belongs to a solid solution strengthening type alloy. The molybdenum-rhenium alloy is generally manufactured by a powder metallurgy method, tensile strength, ductility and resistivity of the molybdenum-rhenium alloy are increased along with increase of rhenium content, and the molybdenum-rhenium alloy is generally applied tothermocouple wire materials, structural materials in aerospace or high-temperature structural materials.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

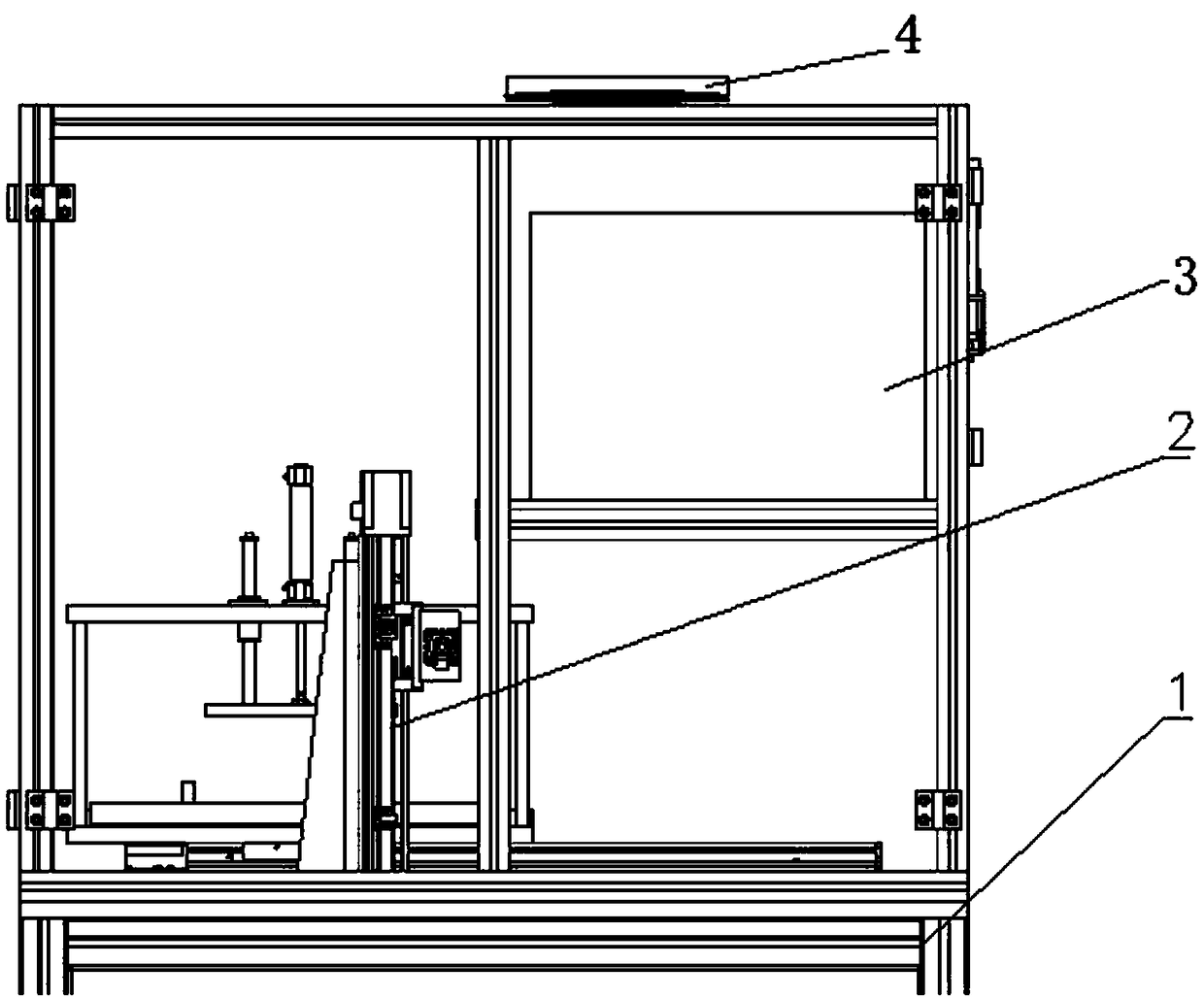

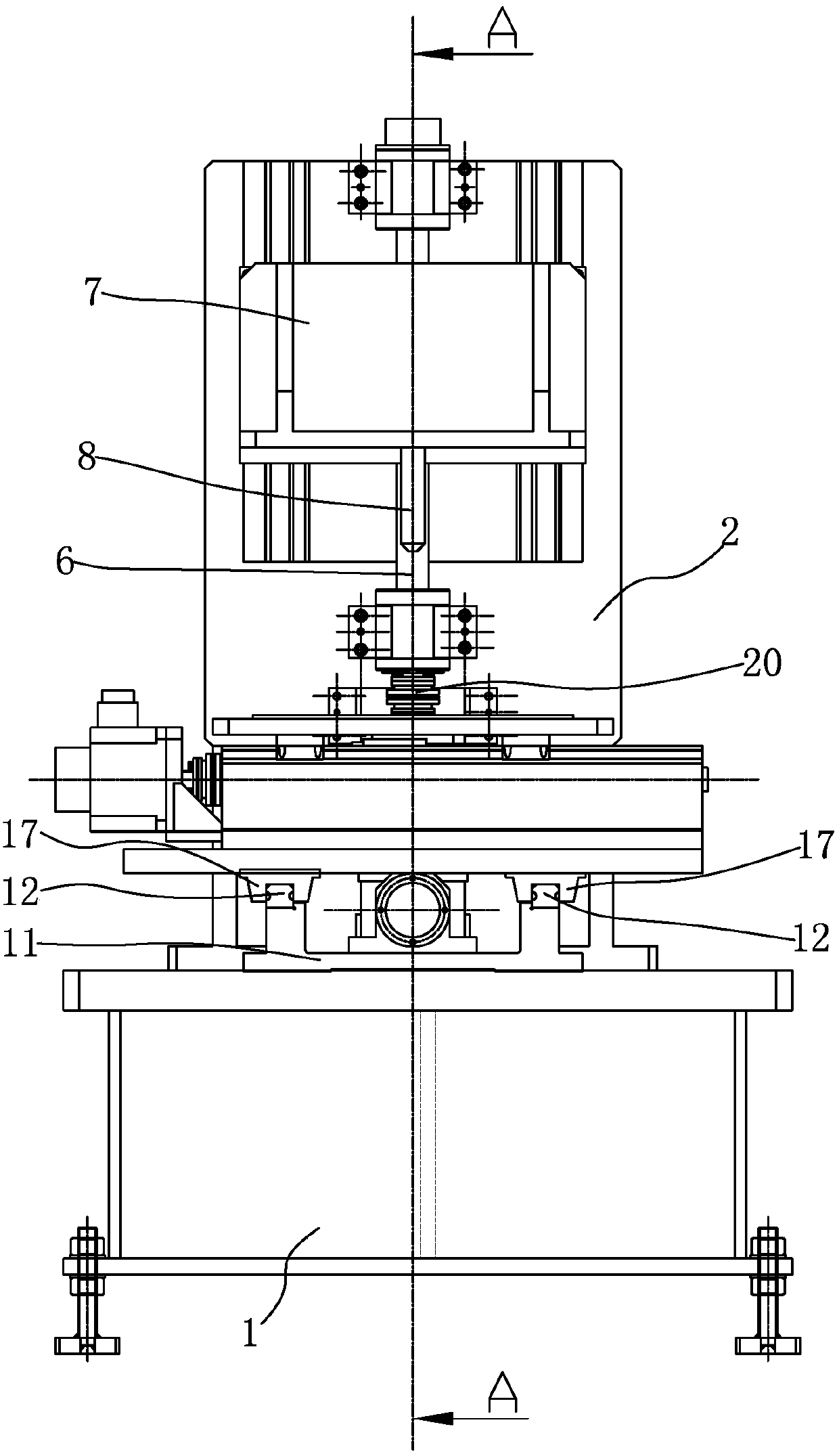

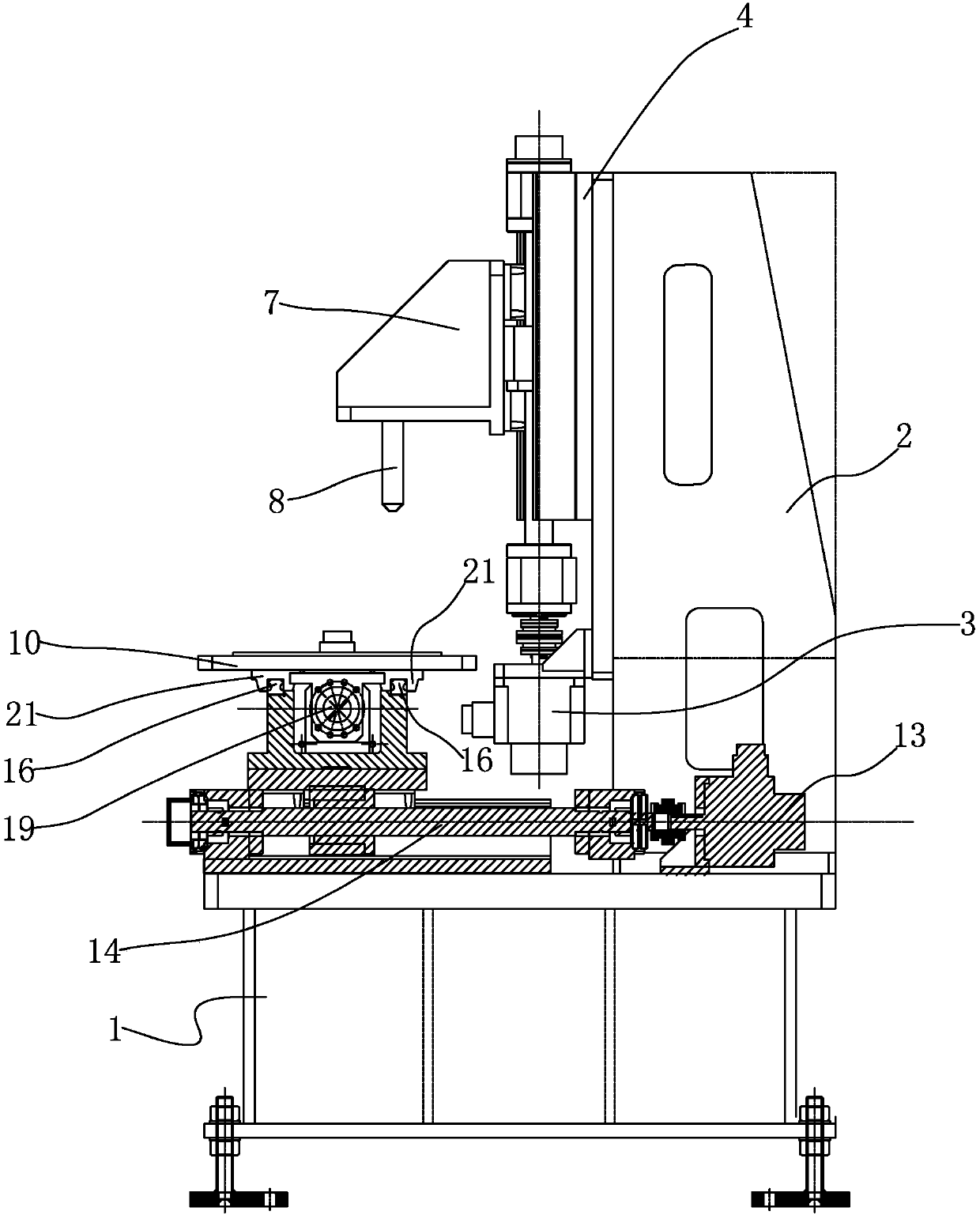

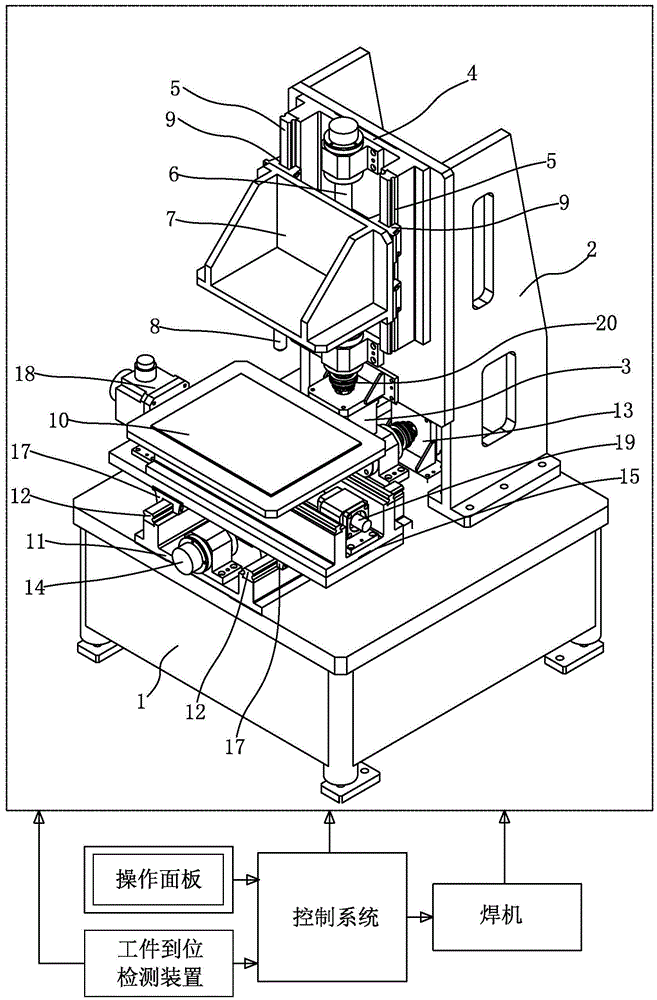

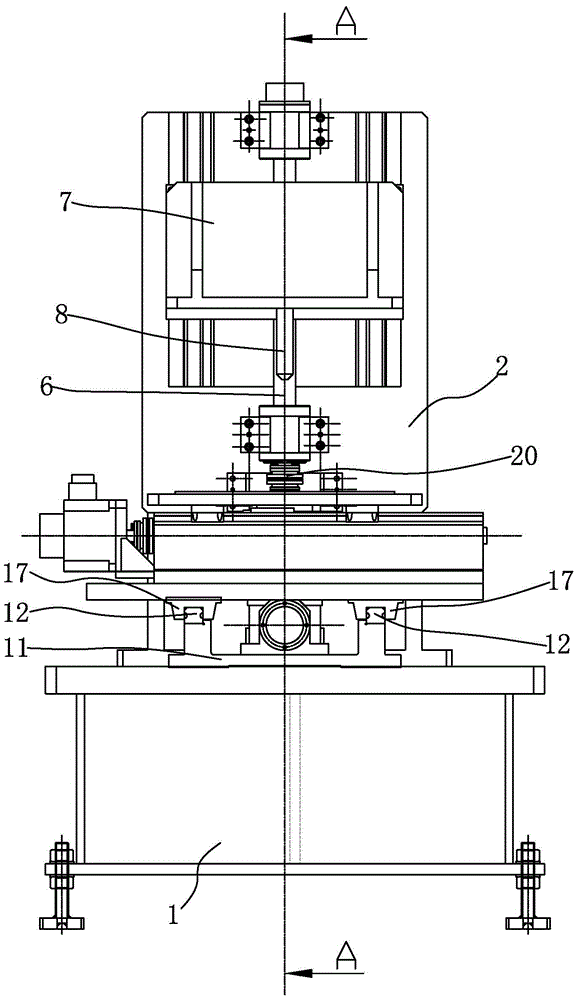

An automatic welding equipment for automobile radiator head

InactiveCN105290662BRealize automatic weldingIdeal welding postureWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentRounded Rectangle

The invention relates to automatic welding equipment for end sockets of an automobile radiator and belongs to the field of automatic welding equipment. The automatic welding equipment is composed of a base, a workbench, pneumatic clamps, a gantry type stand column and a welding mechanism. Compression of the end sockets and a core of the automobile radiator is achieved through the four sets of pneumatic clamps. In the welding process, a control system automatically controls the pneumatic clamps to be pressed and lifted respectively, and therefore the pneumatic clamps are prevented from colliding with a welding gun; besides, the three sets of pneumatic clamps are always kept in a compressed state, and thus welding deformation is reduced. At round corners of a rounded rectangle welding track, the welding mechanism with a rotating shaft achieves continuous welding of the round corners by means of rotation of the rotation shaft, and the welding gun is always kept in the ideal welding posture, so that improvement on the production efficiency and welding quality of a welding procedure of the end sockets of the automobile radiator is facilitated.

Owner:SHANDONG JIANZHU UNIV

Soldering tin stove pot port with separating slice

InactiveCN101198224ALow equipment requirementsImprove work efficiencyPrinted circuit assemblingSolderingHigh pressure

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

An automatic welding device and automatic welding method for the assembly of large-scale composite girder steel main girders

ActiveCN103894747BRealize automatic weldingRealize all-round automatic welding without blind zoneWelding/cutting auxillary devicesAuxillary welding devicesGear wheelReducer

The invention relates to an automatic welding device and an automatic welding method for large-scale composite girder steel main girder assembly that can realize no blind area in the welding seam direction and is used for automatic welding of large composite girder steel main girder. The rack is fixed on one side of the track, and the walking trolley and track slider Connection, the track slider and the track slide and cooperate, the reducer is located on the traveling trolley and is driven by the traveling motor, the reducer drives the traveling gear, the traveling gear matches the rack and drives the traveling trolley to move on the track, the walking trolley and the y-axis are adjusted The mechanism is connected, the y-axis adjustment mechanism is connected with the z-axis adjustment mechanism, the z-axis adjustment mechanism is connected with the x-axis adjustment mechanism, and the x-axis adjustment mechanism is connected with the welding torch clamp.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Method for manufacturing power decentralization and power centralization type transformer oil tank

InactiveCN101465195BReduce the impact of dimensional accuracyControllableTransformers/inductances coolingInductances/transformers/magnets manufactureFuel tankPass rate

The invention provides a manufacturing method for a power decentralization and centralization type transformer tank which comprises a tank body, assembly accessories and non-assembly accessories arranged on the tank body. The manufacturing method comprises the following steps: A, assembling and welding the tank body and the non-assembly accessories; and B, assembling and welding the assembly accessories on the tank body. Optimally, the assembly accessories comprise a mounting seat and an oil circuit connecting pipe; wherein, the mounting seat and the oil circuit connecting pipe are simultaneously welded in the end of the assembling and welding process. Accordingly, the invention minimizes the impact on the welding precision of the mounting seat, the oil circuit connecting pipe and other important assembly accessories caused by welding deformation and ensures the assembly and welding accuracy of the assembly accessories and the tank body so as to improve the passing rate of the products; besides, the invention can reduce the destressing adjustment and repair process after welding, shorten the working procedures and improve the production efficiency, and can easily achieve mass flowline production.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Assembling method and fixture used for roof battery rack of hybrid electric vehicle

ActiveCN101618490BReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAssembly machinesThermal deformationInstability

Owner:苏州宝馨智能制造有限公司

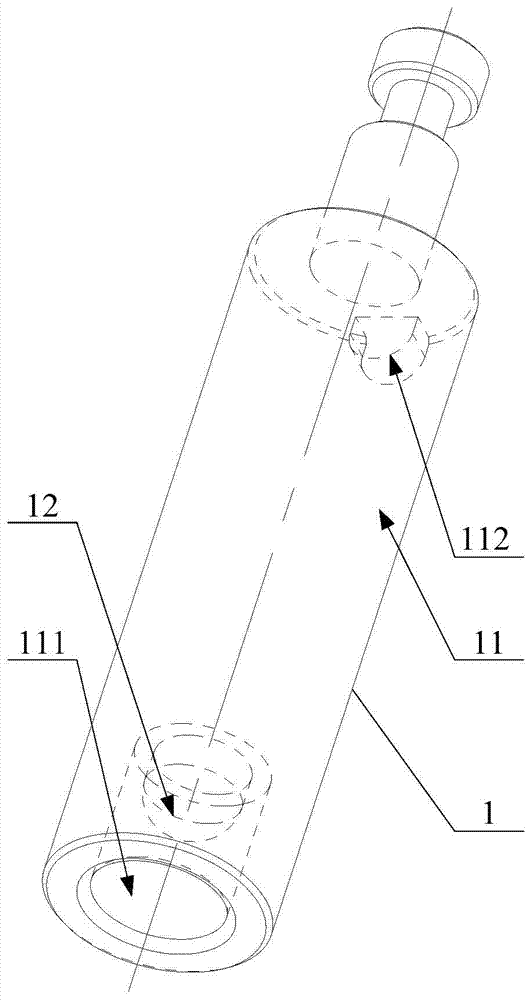

Tube expander and its base, straight tube flaring method

ActiveCN104647796BImprove flaring efficiencyAchieve fixationMetal-working feeding devicesPositioning devicesStraight tubeEngineering

The invention provides a tube expander, a base and a straight tube expansion method. The base of the tube expander provided by the present invention includes: a base body, the base body has a placement groove for placing the flaring end of the straight pipe; a positioning column arranged at the bottom of the placement groove for cooperating with the inner wall of the straight pipe and positioning the straight pipe . The base of the tube expander provided by the present invention realizes the fixing of the flared end of the straight tube by setting a placement groove for placing the flared end of the straight tube, and a positioning column that cooperates with the inner wall of the straight tube and positions the straight tube, so that the straight tube can be fixed The flaring end is fixed on the base of the tube expander, so that the tube expander can simultaneously expand the tube and expand the other end of the straight tube, without first expanding the tube and then manually expanding the tube, which effectively improves the expansion efficiency of the straight tube ; It also avoids manual flaring and manual handling of straight pipes, which effectively reduces the labor intensity of the staff.

Owner:GREE ELECTRIC APPLIANCES INC

Spot welding equipment for aluminum alloy workpiece

ActiveCN113579444AReduced impact on weld qualityRealize automatic controlResistance electrode holdersCleaning using toolsStructural engineeringSpot welding

The invention relates to the technical field of aluminum alloy welding, in particular to spot welding equipment for an aluminum alloy workpiece. The spot welding equipment comprises a rear seat body and a front seat body, a positioning groove is formed in the top wall of the end, close to the rear seat body, of the front seat body, a top plate is horizontally mounted at the top of the end, close to the front seat body, of the rear seat body, and two air cylinders are mounted on the top wall of the top plate; and output shafts of the two air cylinders extend to the lower side of the top plate and are provided with pressing plates, a mounting groove is formed in the bottom wall of the positioning groove, the interior of the mounting groove and the upper portion of the positioning groove are provided with two opposite elastic welding guns correspondingly, and the opposite ends of the two elastic welding guns are provided with connecting plates. A reciprocating driving mechanism drives a movable brush and a fixed brush to sequentially brush and wipe the aluminum alloy workpiece, the influence of an oxidation film on the welding quality is reduced to the maximum extent, the two elastic welding guns are arranged, a synchronous driving mechanism is used for controlling the two elastic welding guns to move in the opposite directions or the reverse directions, and the elastic welding guns can stably apply pressure to the workpiece, so that the welding quality is ensured.

Owner:福建科源新材料股份有限公司

An auxiliary device for carbon arc gouging of flat welds

ActiveCN103418883BReduce work intensityReduced impact on weld qualityElectrode supporting devicesArchitectural engineeringTorch

The invention discloses an auxiliary device for flat weld joint carbon arc air gouging and a use method thereof. The auxiliary device comprises a bracket for supporting a carbon arc air gouging torch and traveling wheels on the two sides of the brackets, wherein the bracket comprises a piece of supporting transverse steel and two pieces of vertical flat steel connected with the supporting transverse steel; the traveling wheels are arranged at the two ends of the supporting transverse steel; the upper ends of the two pieces of vertical flat steel are provided with mounting holes; a piece of round steel with external thread is connected with the two pieces of vertical flat steel through the mounting holes; one end of the round steel is provided with a pin cap, and the other end of the round steel is fixed through a fastening nut. According to the auxiliary device for flat weld joint carbon arc air gouging, the center of a gouging groove is overlapped with the center of a weld joint, so that the width and the depth of the gouging groove along the length of the entire weld joint are uniform, the influence of a non-uniform carbon gouging weld joint on the welding quality is effectively reduced, meanwhile, the working intensity of the carbon gouging workers can be reduced and the labor productivity is improved.

Owner:JIANGMEN NANYANG SHIP ENG

Soldering stove with stannum-spilled port thin wall type kettle port

InactiveCN101184370AReduced impact on weld qualityReduce weld spreadPrinted circuit assemblingEngineeringSoldering

The invention relates to a tinning furnace component for soldering tin on a PCB plate, in particular to a kettle spout of solder furnace, which comprises a kettle body and a tin outlet which are arranged on a kettle spout installation panel, wherein, the wall thickness of the tin outlet is 0.5 to 3mm; the wall thickness of the kettle body is 3 to 8mm; a tin overflow hole is arranged on the sidewall of the tin outlet; a bottom plate is positioned at the bottom of the kettle body; a tin inlet hole is arranged on the bottom plate; the internal threads of the tin inlet hole are connected with a hollow nut; the bottom plate and the kettle spout installation panel are fixed and screwed together via the hollow nut. The invention has the advantages that: as the tin is overflowed through the tin overflow hole, the PCB plate can be arranged at the kettle spout directly, so as to reduce the influence to the welding quality of PCB plate because of the pressure oscillation of the kettle spout; and the invention can reduce the quality drawbacks such as soldering surface diffusion and deficient welding which are generated because of the overpressure or undersize pressure when in welding; in addition, the detachable connection between the kettle spout and the kettle spout installation panel can be realized, thereby the applicability can be strengthened.

Owner:苏州明杰自动化科技有限公司

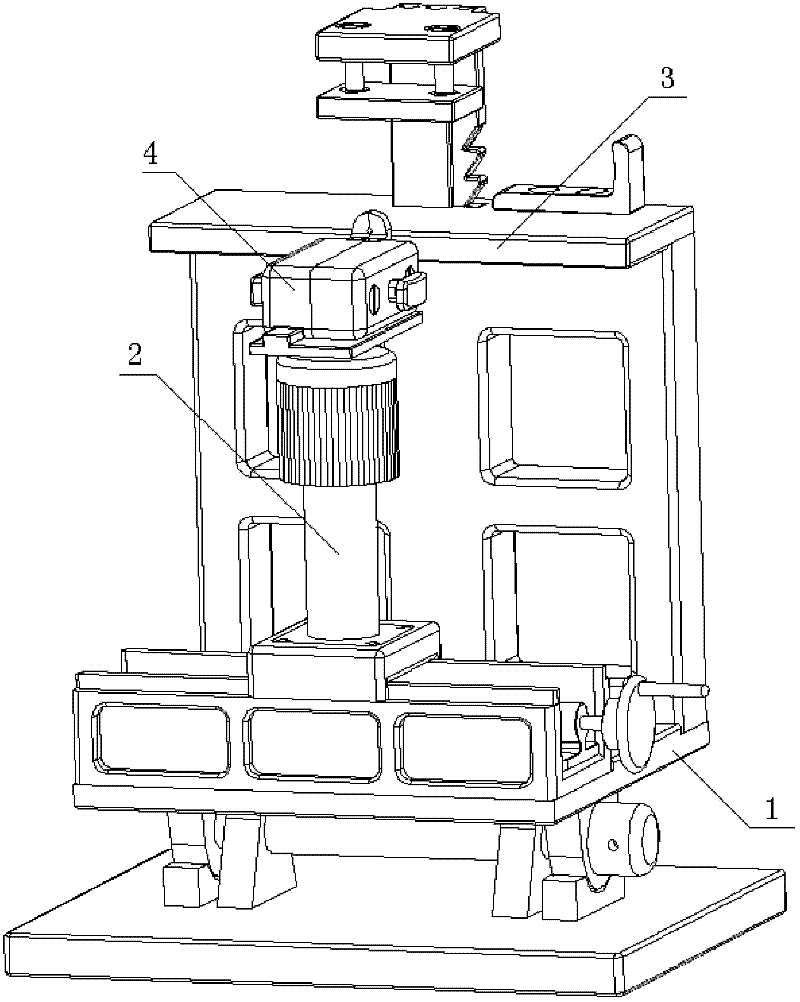

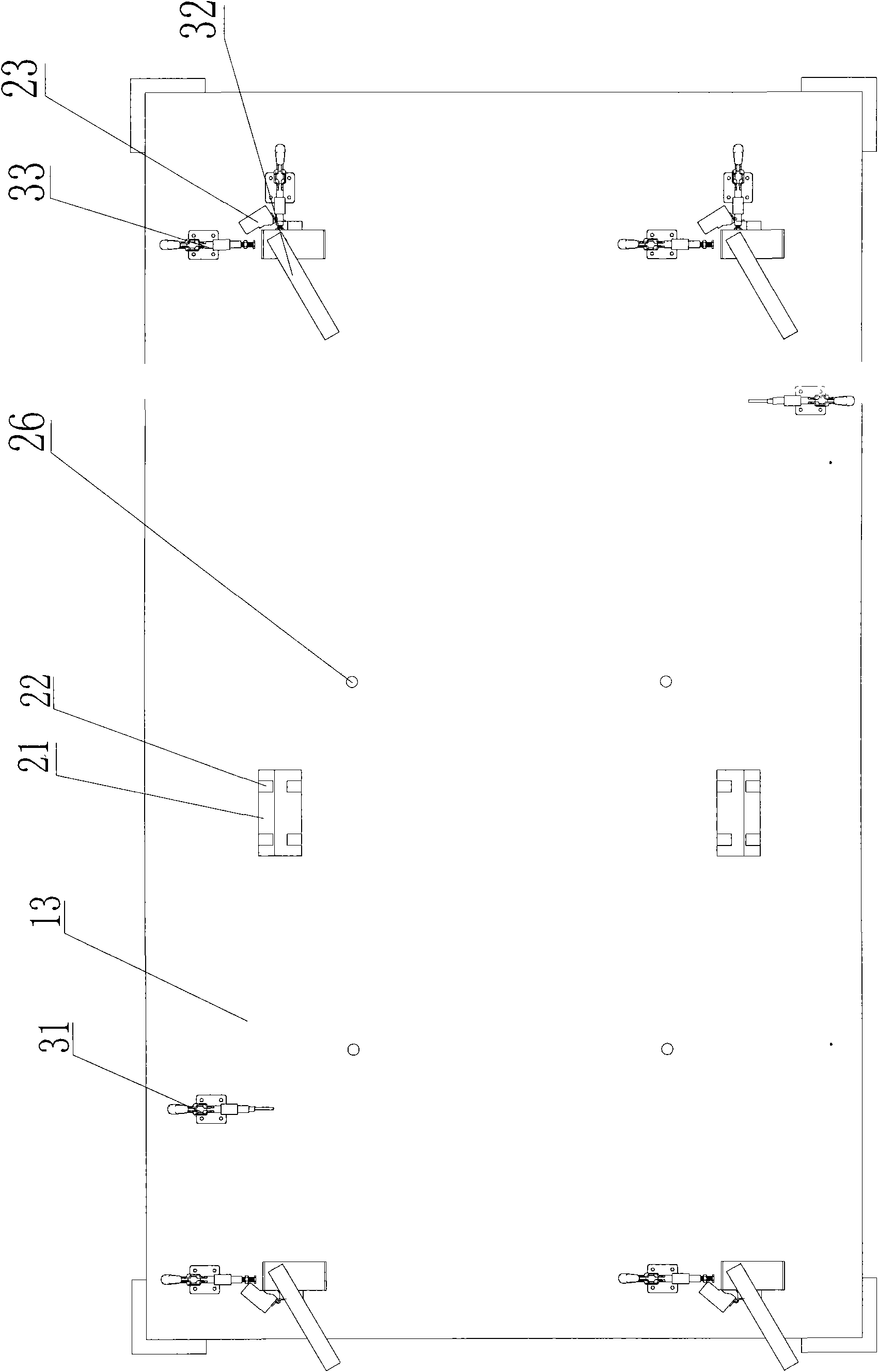

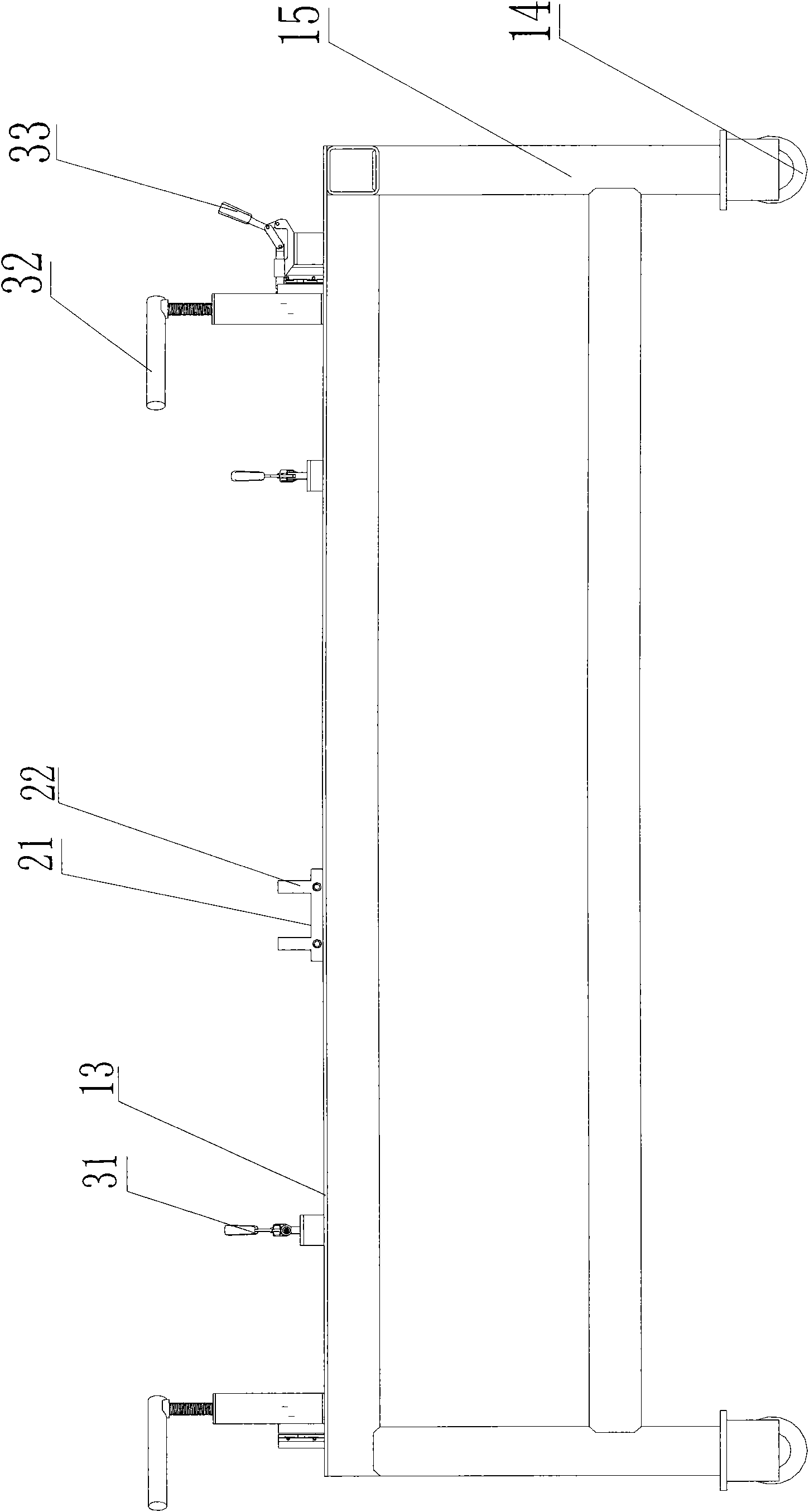

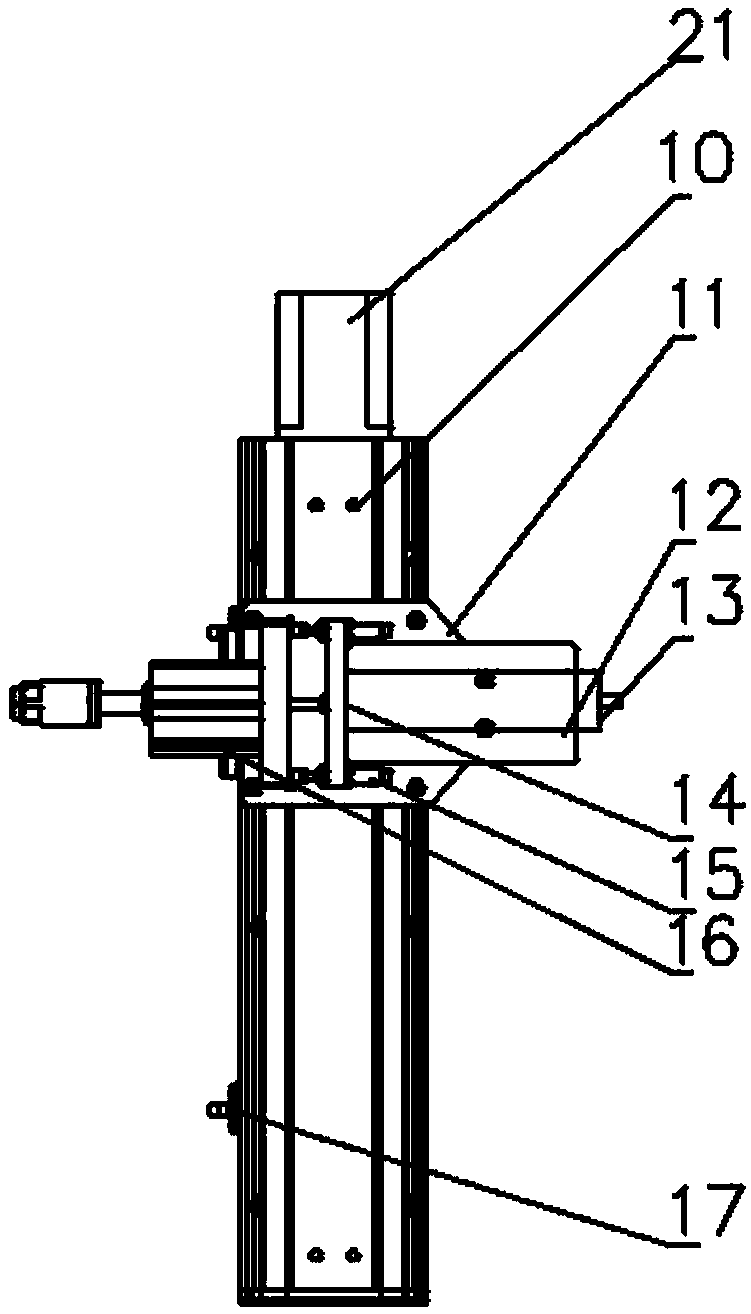

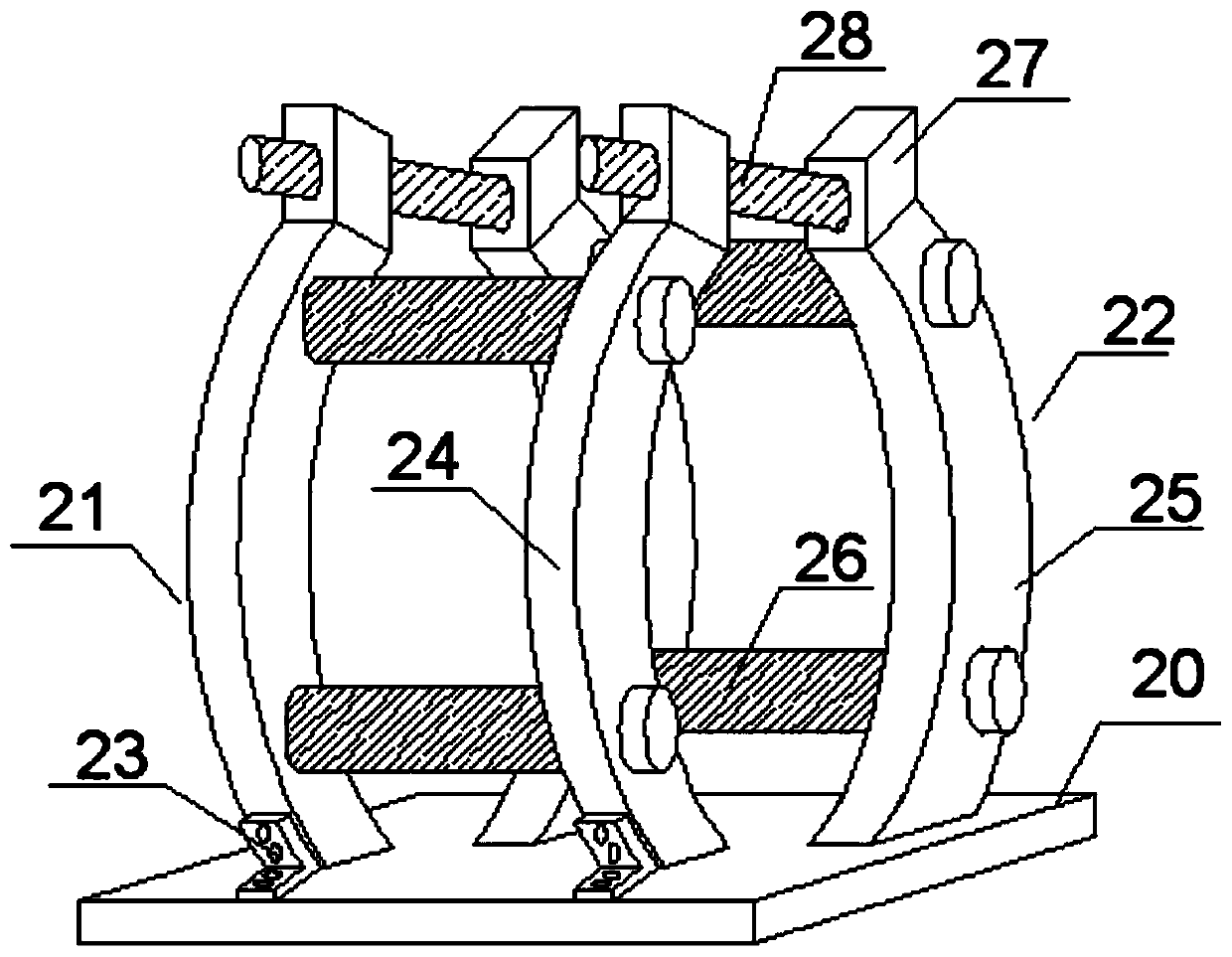

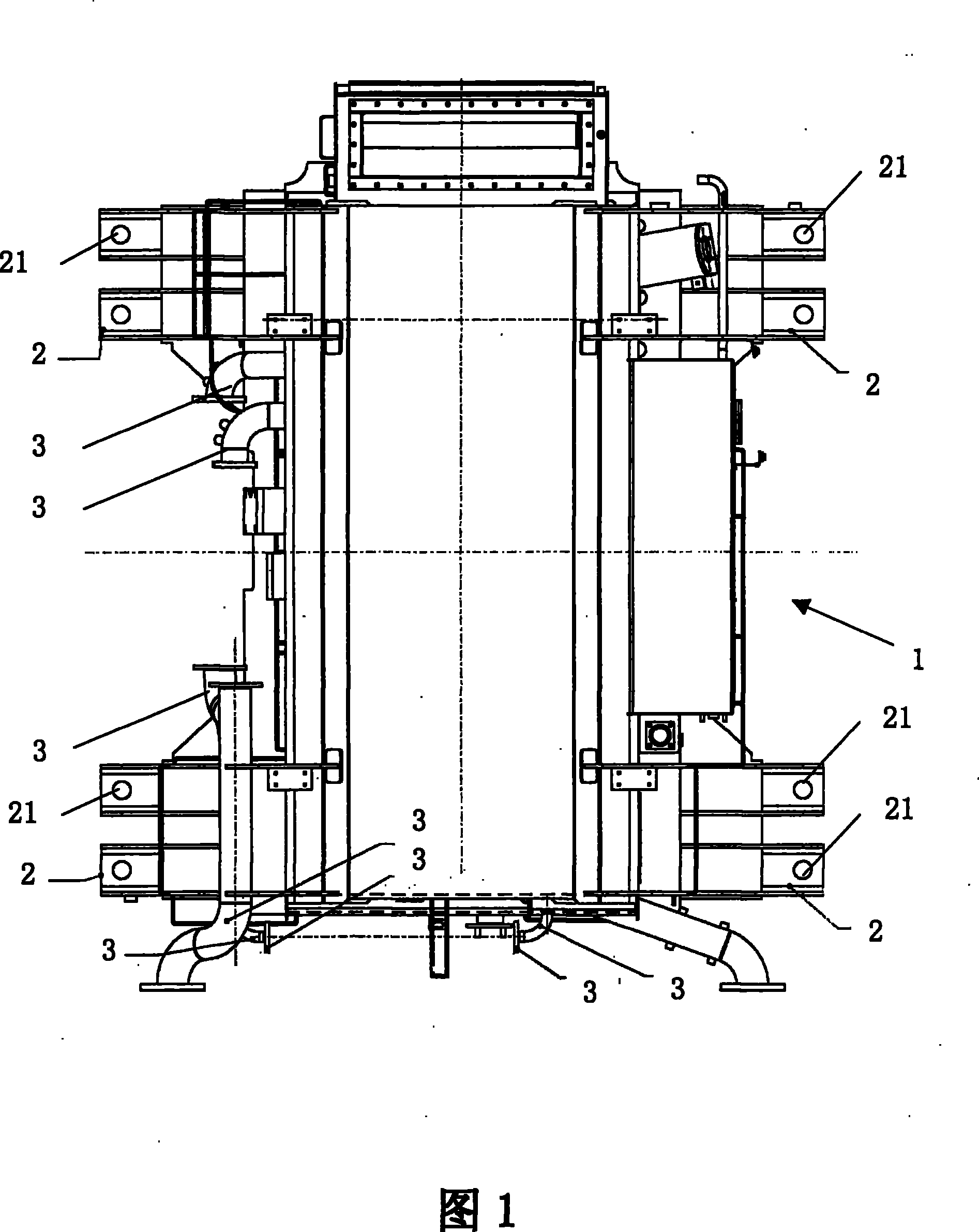

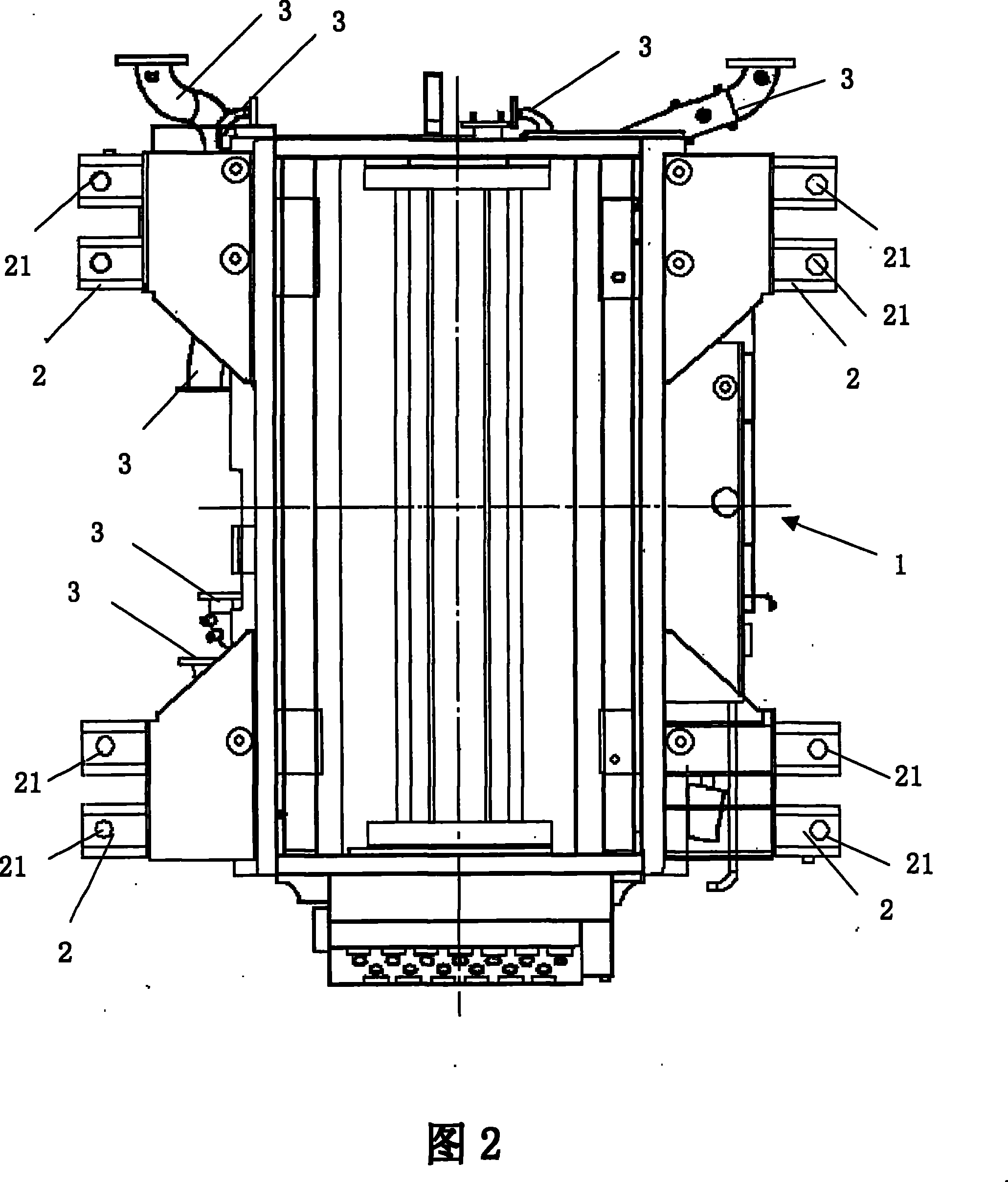

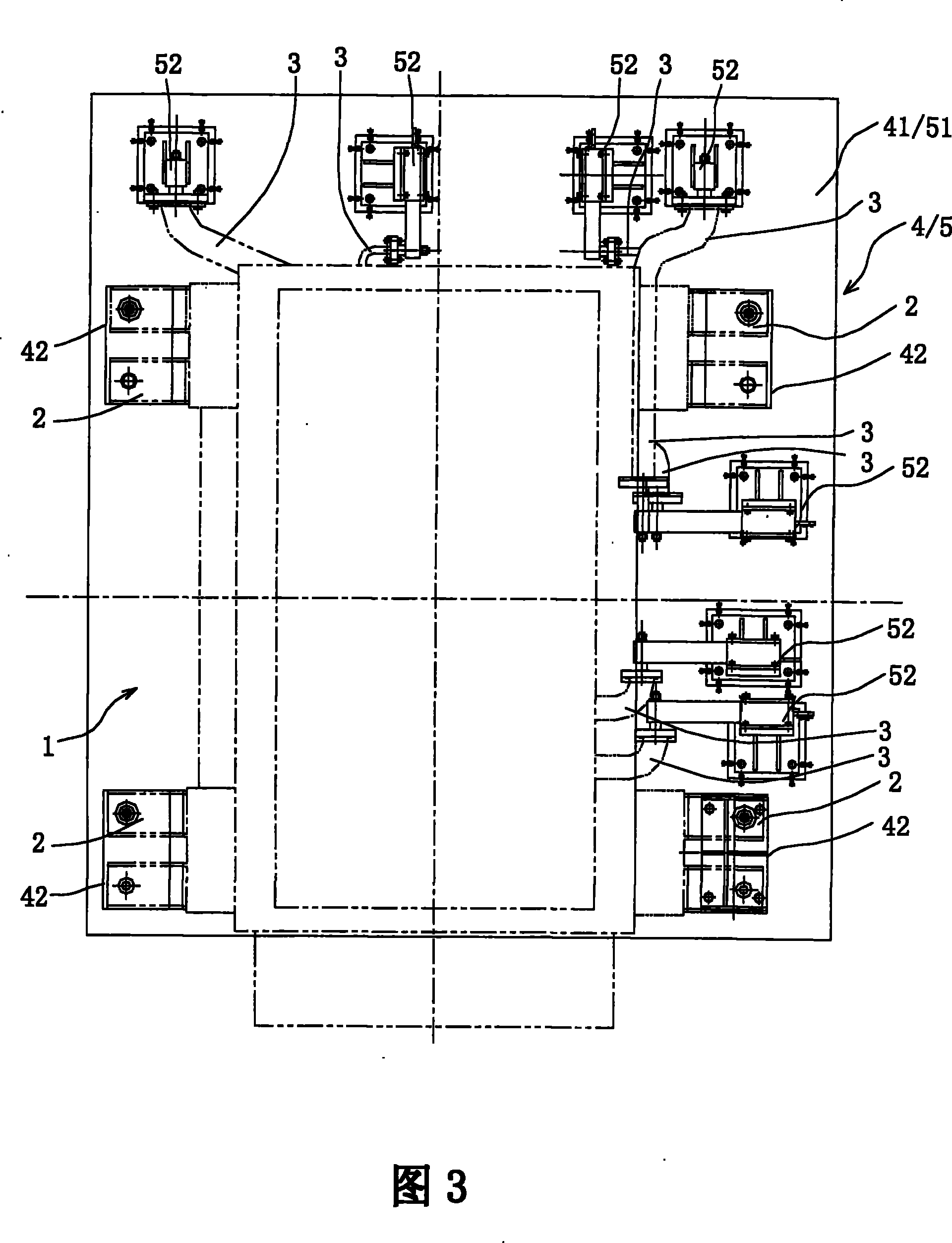

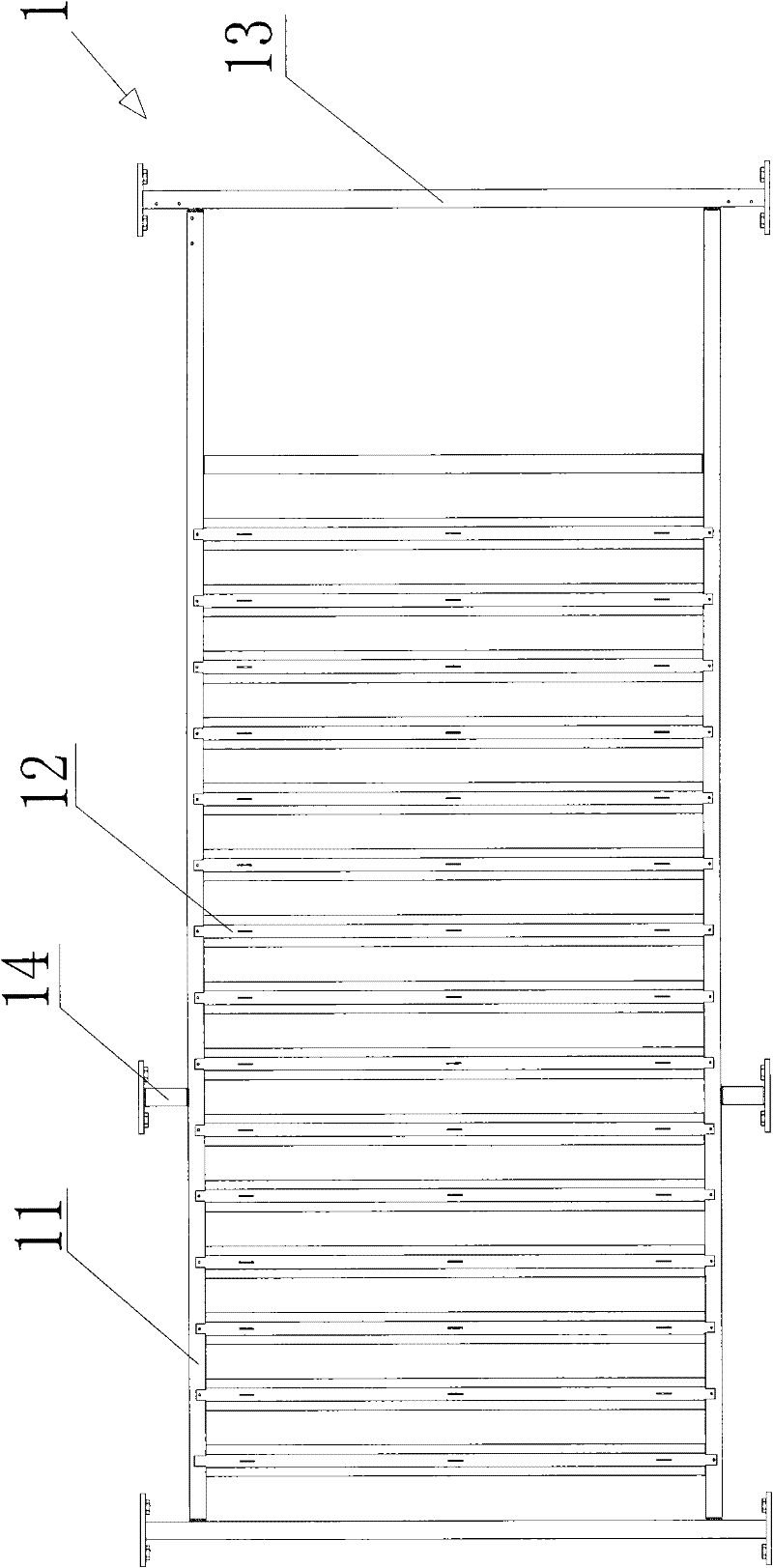

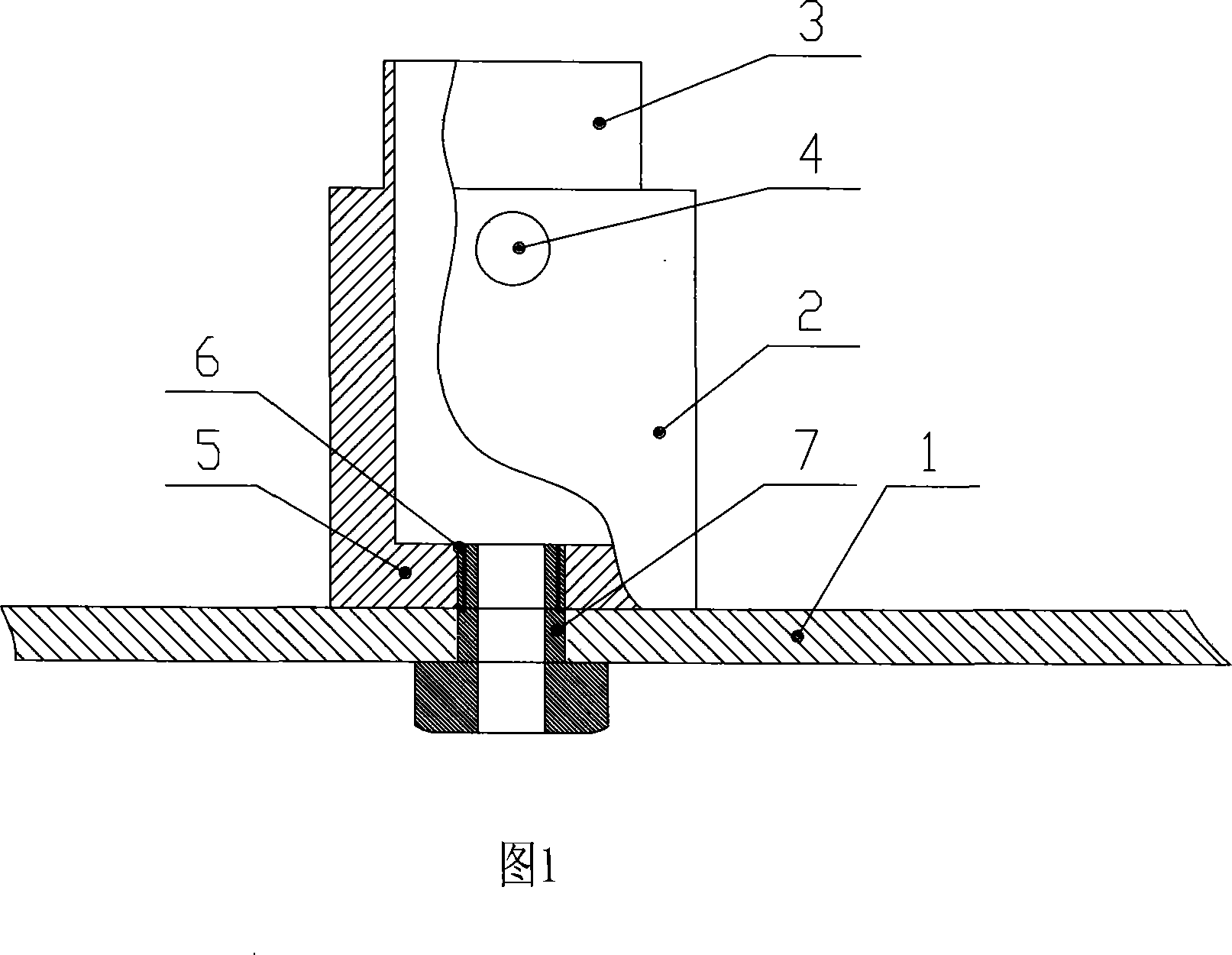

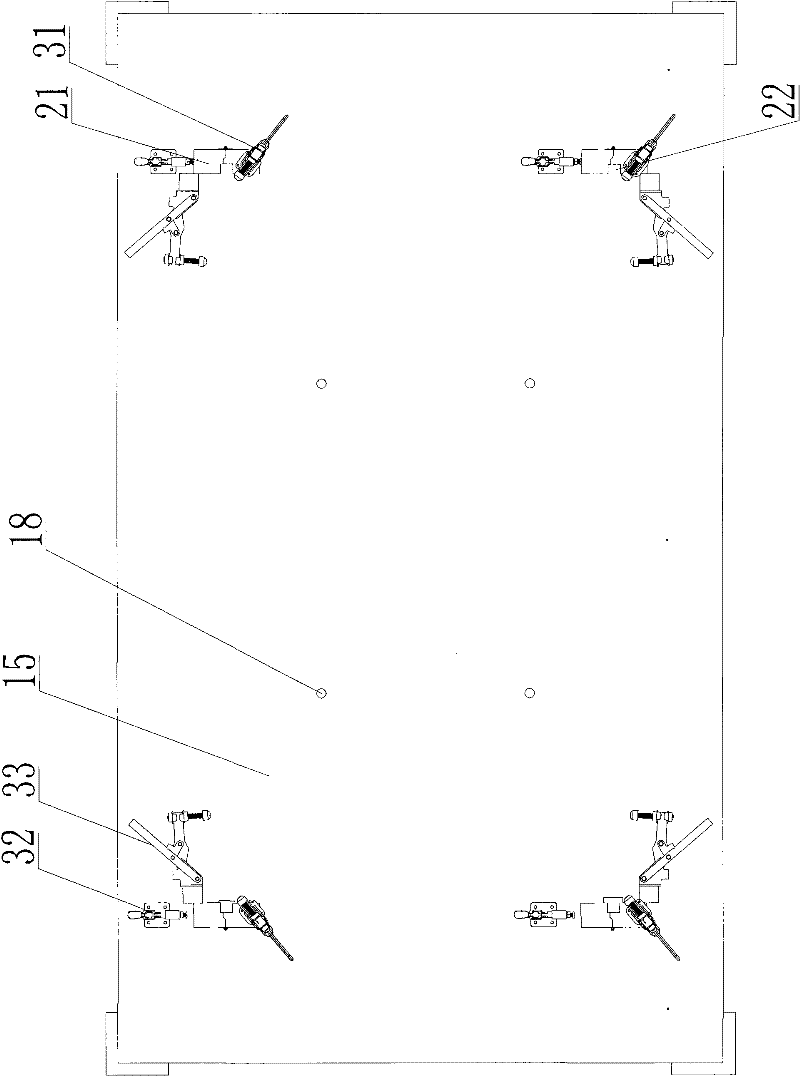

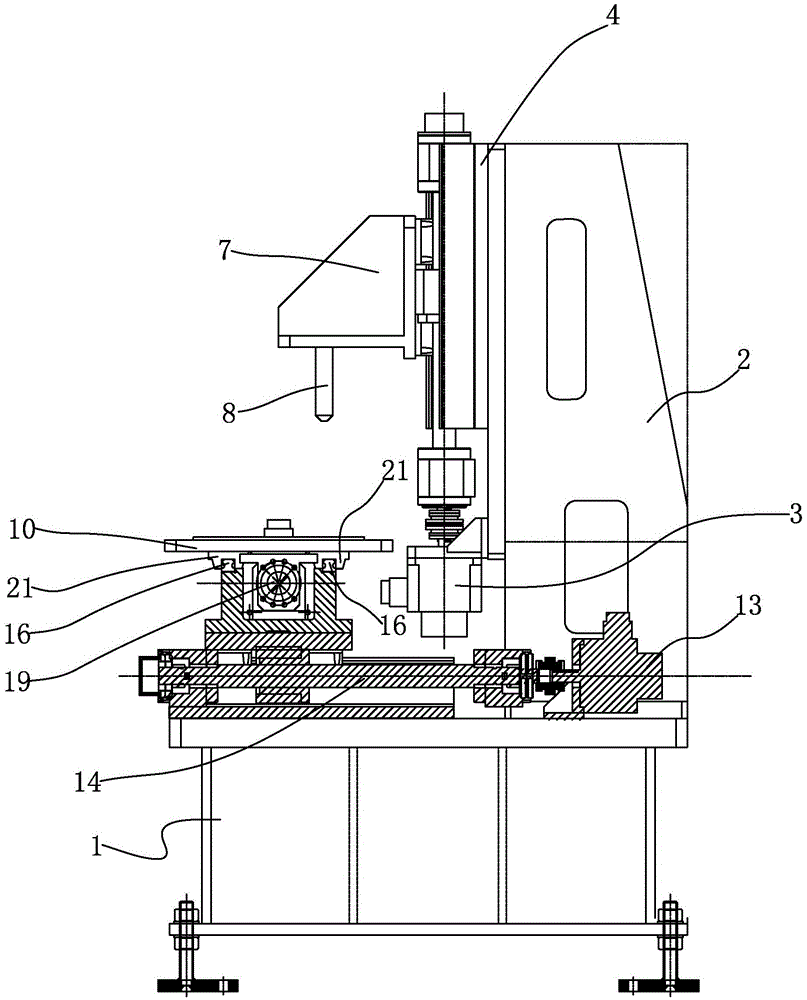

Method for assembling upper support body of overhead cell support of hybrid vehicle and clamp thereof

ActiveCN101618492BReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAssembly machinesPhysical hard workPhysical work

The invention discloses a method for assembling an upper support body of an overhead cell support of a hybrid vehicle and a special welding tool clamp used in assembly. The clamp comprises a clamp body (1), and is characterized in that a positioning element (2) is fixedly arranged at the upper end of the clamp body, a clamping device (3) is arranged at the outer side of the positioning element (2), the positioning element horizontally limits the position of each component on the upper support body of the overhead cell support of the hybrid vehicle, and the clamping device clamps the components on the upper support body of the overhead cell support of the hybrid vehicle in a horizontal direction and a vertical direction. The clamp greatly lightens the physical work of the operating staff, improves the assembling and welding efficiency, controls or eliminates the thermal deformation of workpieces caused by welding, and reduces the instability of manual welding.

Owner:苏州宝馨智能制造有限公司

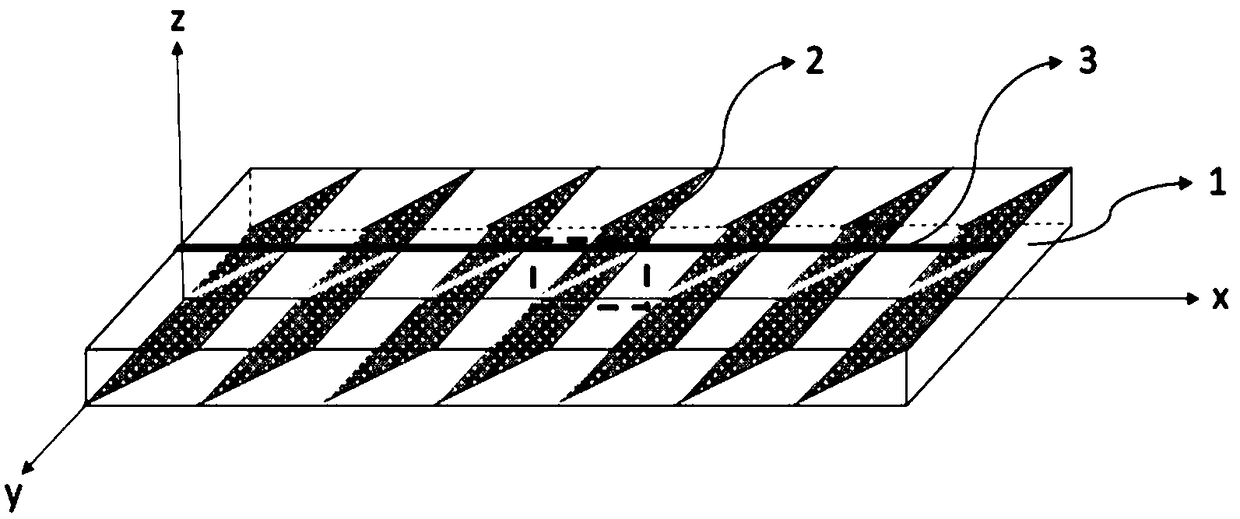

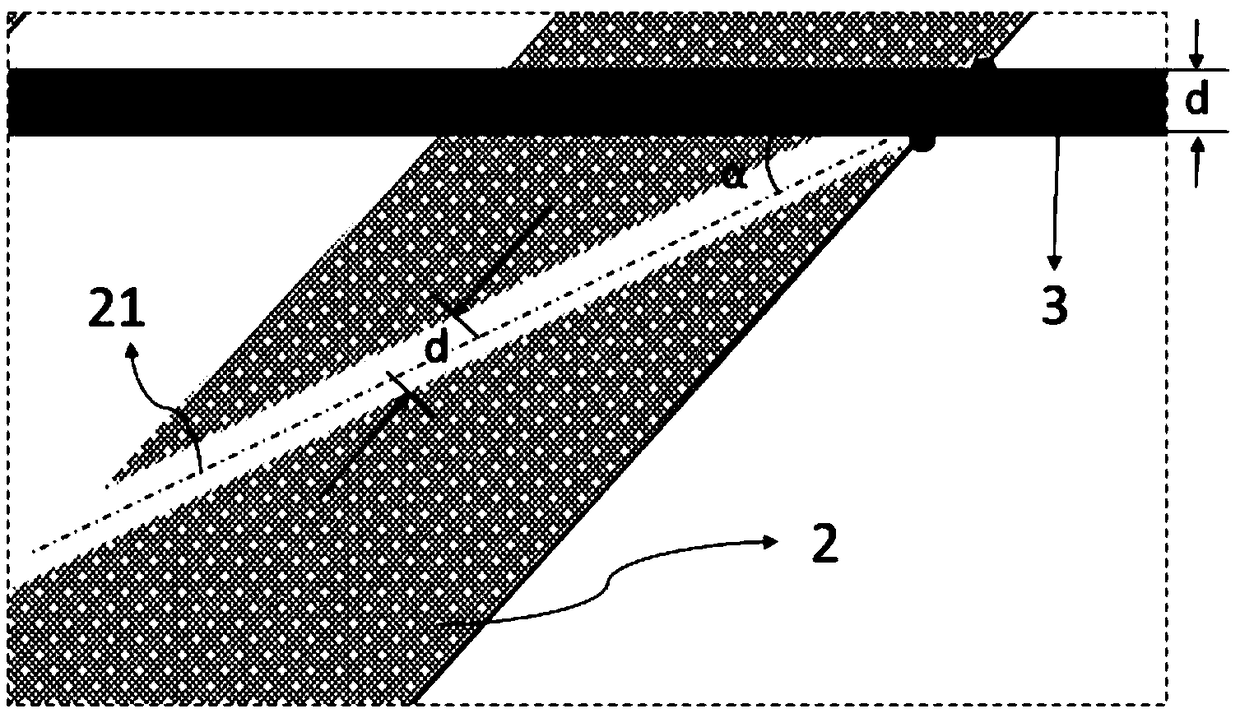

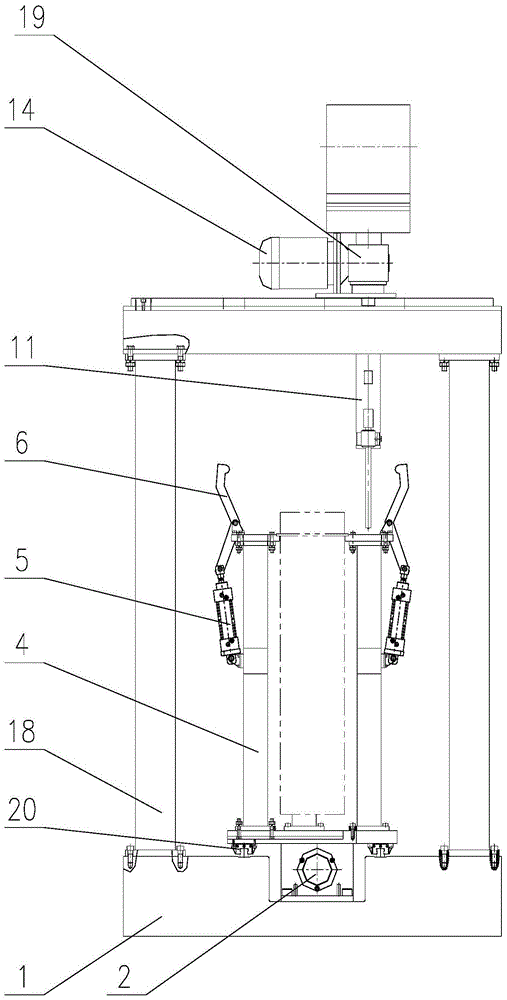

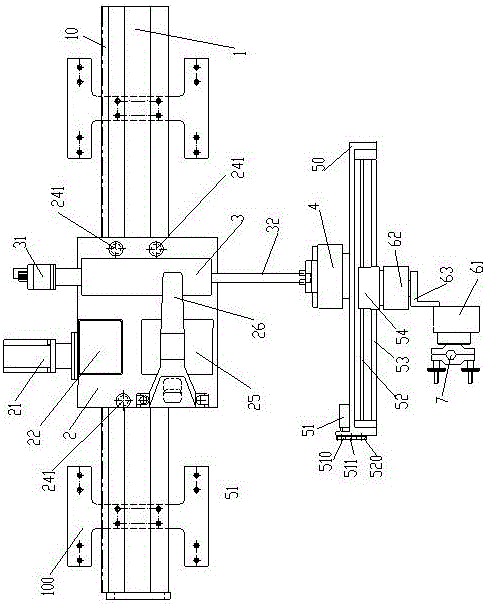

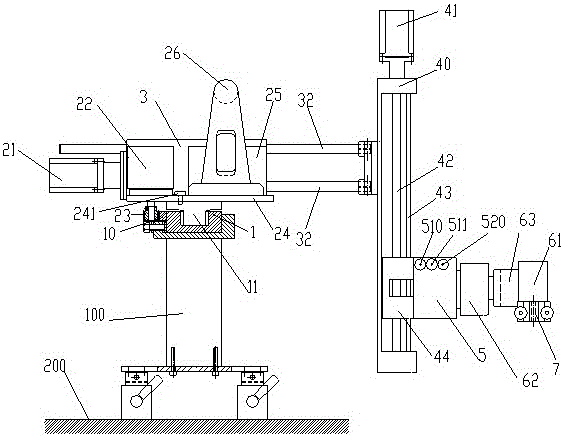

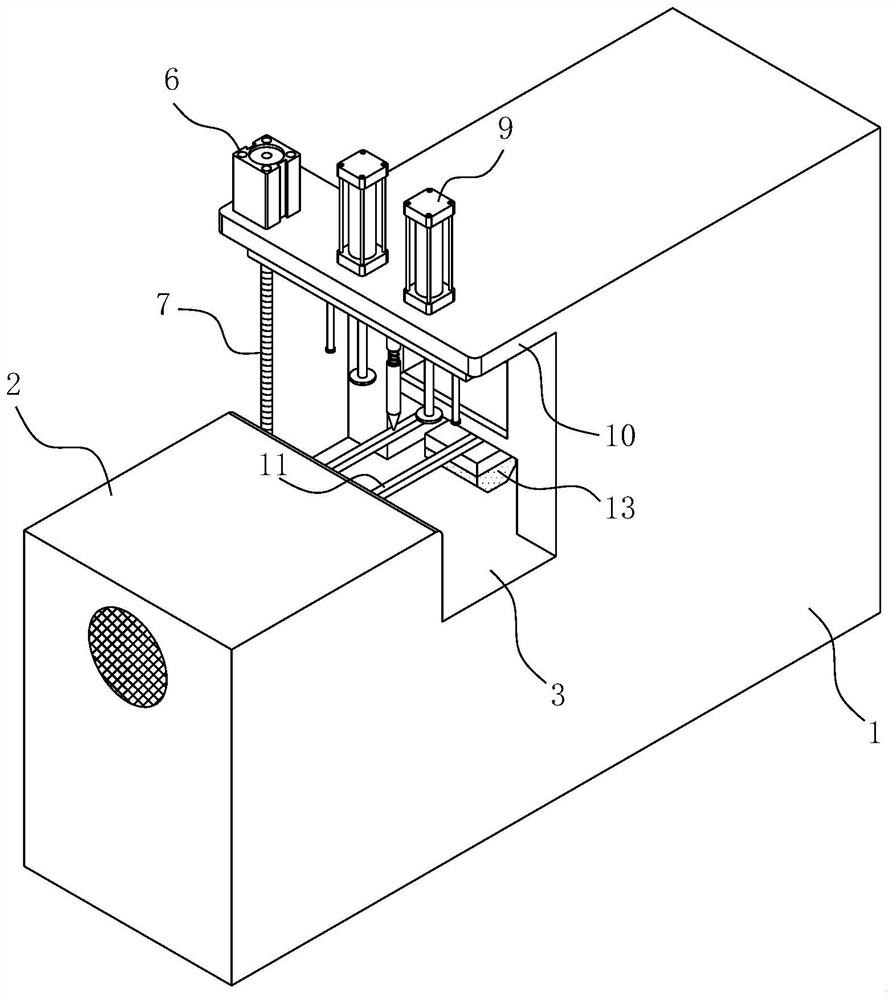

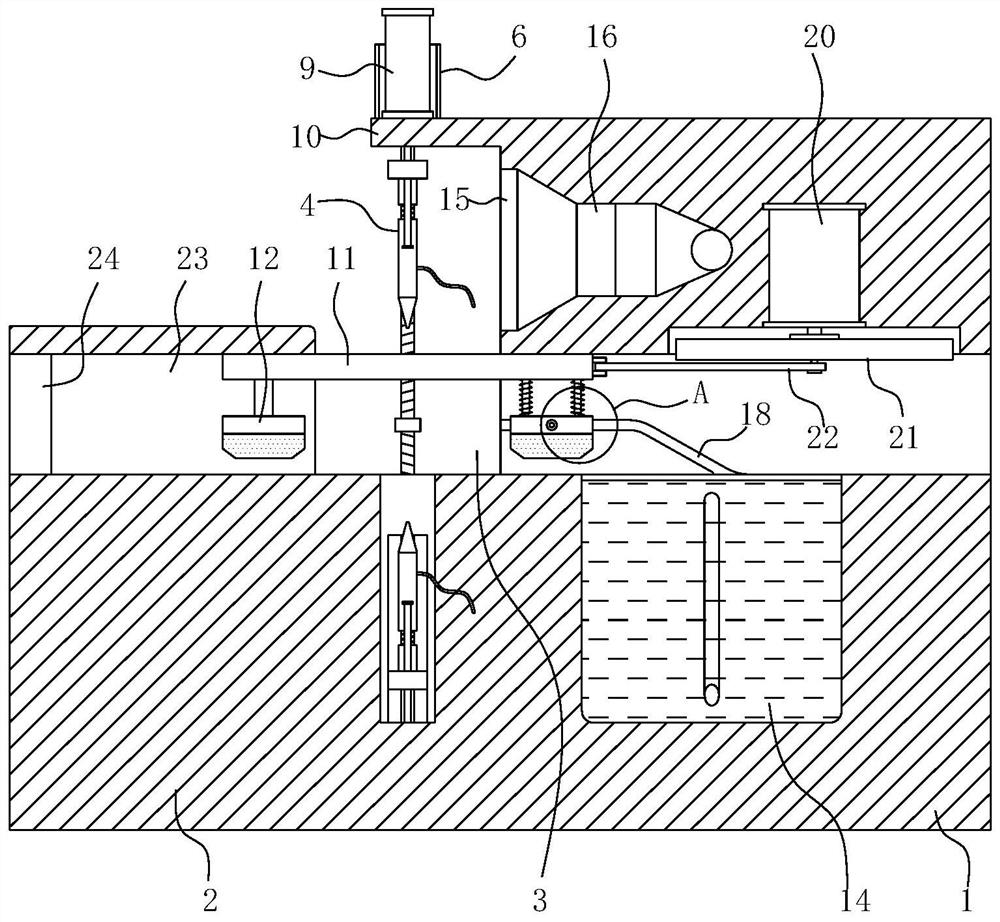

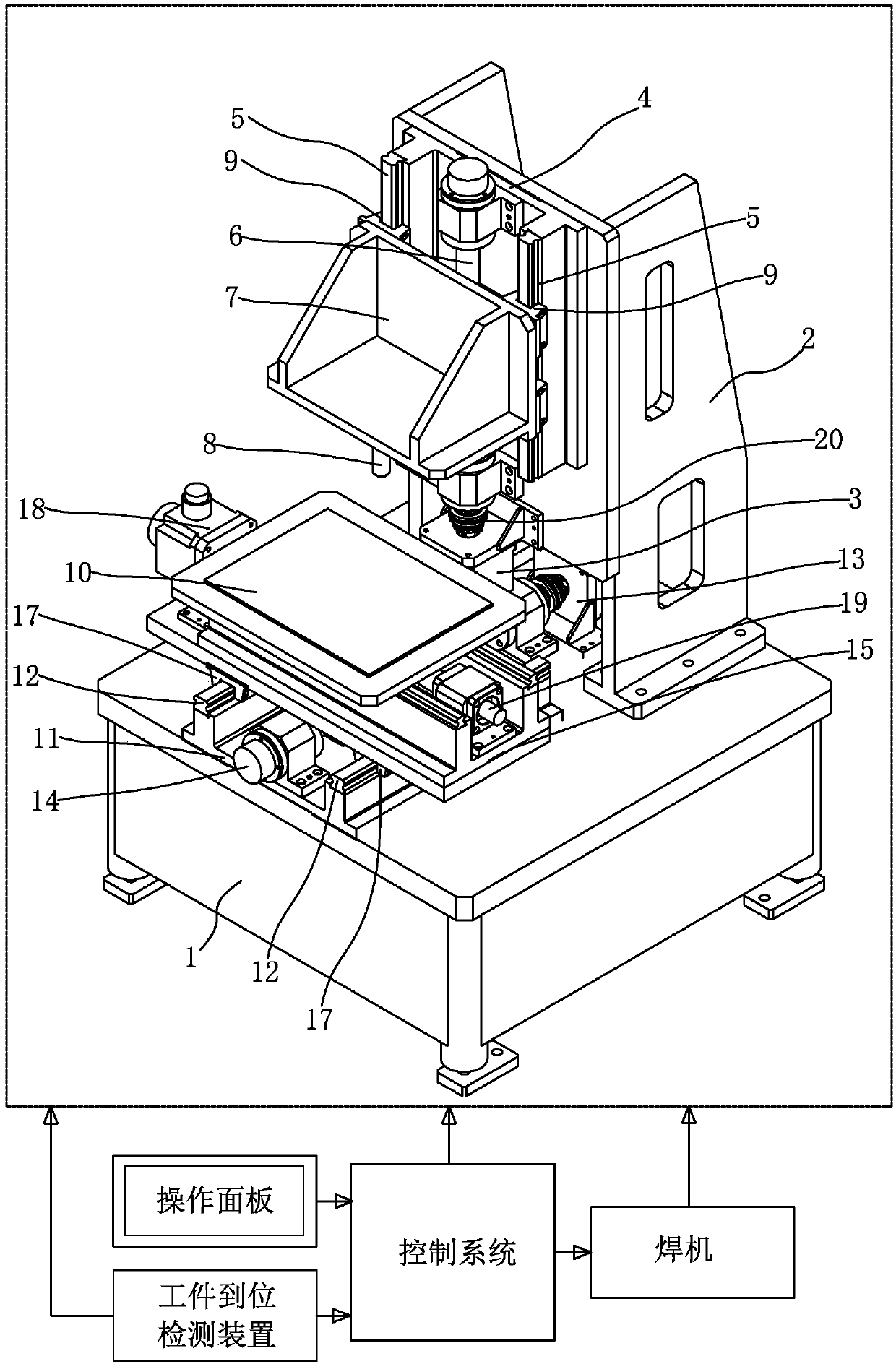

A Welding Method of Discontinuous Lattice Matrix and Core Double-skin Shell Structure

ActiveCN105643056BReduced impact on weld qualityEasy to operateWelding accessoriesControl systemEngineering

The invention discloses a welding device suitable for an aerospace discontinuous lattice core-added double-skin barrel shell structure. The welding device comprises a bed body, and a welding mechanism and a workpiece positioning mechanism which are arranged on the bed body. The welding mechanism comprises a Y-axis support, a Y-axis servo motor, a Y-axis slide rail base, a Y-axis lead screw and a welding gun support, wherein the Y-axis servo motor and the Y-axis slide rail base are located on the Y-axis support, the Y-axis slide rail base comprises a Y-axis slide rail bottom plate and a Y-axis slide rail located on the Y-axis slide rail bottom plate, and the welding gun support is arranged on the Y-axis slide rail base. The workpiece positioning mechanism comprises a cross-shaped slide table and an electromagnetic suction cup arranged on the cross-shaped slide table. The influences of artificial factors on the welding quality are reduced to the maximum extent; by controlling the whole welding process and the whole workpiece automatic positioning process through a control system, the welding device has the advantages of being easy to operate, safe, reliable, high in automation degree, high in precision and efficiency and the like.

Owner:DALIAN UNIV OF TECH

Welding device suitable for aerospace discontinuous lattice core-added double-skin barrel shell structure

The invention discloses a welding device suitable for an aerospace discontinuous lattice core-added double-skin barrel shell structure. The welding device comprises a bed body, and a welding mechanism and a workpiece positioning mechanism which are arranged on the bed body. The welding mechanism comprises a Y-axis support, a Y-axis servo motor, a Y-axis slide rail base, a Y-axis lead screw and a welding gun support, wherein the Y-axis servo motor and the Y-axis slide rail base are located on the Y-axis support, the Y-axis slide rail base comprises a Y-axis slide rail bottom plate and a Y-axis slide rail located on the Y-axis slide rail bottom plate, and the welding gun support is arranged on the Y-axis slide rail base. The workpiece positioning mechanism comprises a cross-shaped slide table and an electromagnetic suction cup arranged on the cross-shaped slide table. The influences of artificial factors on the welding quality are reduced to the maximum extent; by controlling the whole welding process and the whole workpiece automatic positioning process through a control system, the welding device has the advantages of being easy to operate, safe, reliable, high in automation degree, high in precision and efficiency and the like.

Owner:DALIAN UNIV OF TECH

CCD (Charge Coupled Device) galvanometer type laser welding device and method

ActiveCN101835348BPrecision weldingEasy to controlPrinted circuit assemblingMetal working apparatusImaging processingGalvanometer

The invention discloses a CCD (Charge Coupled Device) galvanometer type laser welding device which comprises an LED lamp, a CCD image acquisition device, an image processing module and a galvanometer system, wherein the LED lamp is used for obliquely irradiating an electronic component pin from the side face of the electronic component pin to project the shadow of the electronic component pin onto a printed circuit board; the CCD image acquisition device is used for acquiring the image data of the electronic component pin through the light and shade contrast on the printed circuit board; the image processing module is used for calculating according to the image data to obtain a welding position coordinate of the electronic component pin and conveying the welding position coordinates to the galvanometer system; and the galvanometer system is used for emitting laser pulses according to the information of the welding position coordinate to smelt the electronic component pin material and form a welding spot on the printed circuit board. The invention also discloses a CCD galvanometer type laser welding method. The invention can dynamically and precisely control the welding position and is not easy to cause pollution.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Soldering stove with pin protection block type kettle port

InactiveCN101184372AReduced impact on weld qualityReduce weld spreadPrinted circuit assemblingEngineeringSoldering

The invention relates to a soldering furnace used for welding printed circuit board (PCB), in particular to a mouth for a soldering furnace, which is characterized in that at least a tin spilling hole is arranged at the periphery of the mouth; a pin protection block is arranged at the outer flank of the mouth and a pin perforation is arranged on the pin protection block; the tin spilling hole with a conic multilateral opening at the bottom is 2 to 10mm lower than the tin outlet of the mouth. The invention has the advantages that the PCB can be directly arranged at the mouth by arranging the tin spilling hole to spill tin, lowering the requirement for equipment, improving work efficiency and decreasing effectively the influence of the pressure fluctuation at the mouth on the welding quality of the PCB; the quality drawbacks as wide welding area and deficient welding due to the pressure fluctuation when welding the PCB can be reduced; besides, the welding-free protection of the pin device near the mouth can be achieved.

Owner:苏州明杰自动化科技有限公司

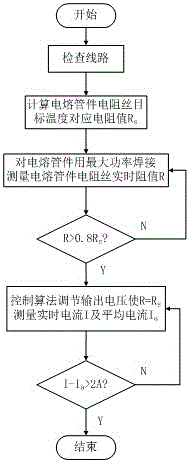

An intelligent welding method for electric fusion pipe fittings

ActiveCN104816467BSave the link of setting parameters in advanceImprove welding efficiencyPipe fittingEngineering

The invention discloses an intelligent welding method for electrofusion pipe fittings. The method includes the steps of welding preparation, temperature rising period, constant-temperature period and welding completion. Resistance values of resistance wires of the electrofusion pipe fittings are controlled to further control temperatures of the resistance wires of the electrofusion pipe fittings so as to realize welding of the electrofusion pipe fittings. The intelligent welding method has the advantages that presetting of welding parameters before electrofusion welding is avoided, welding quality can be effectively improved, and doubling is prevented.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com