Soldering stove with stannum-spilled port thin wall type kettle port

A soldering furnace and overflowing tin technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of pressure fluctuation affecting the welding area and welding quality, inconvenience for the pot mouth to be close to the PCB board, mis-welding or missing soldering of the pot mouth, etc. The effect of reducing solder surface spread, enhancing applicability, and reducing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

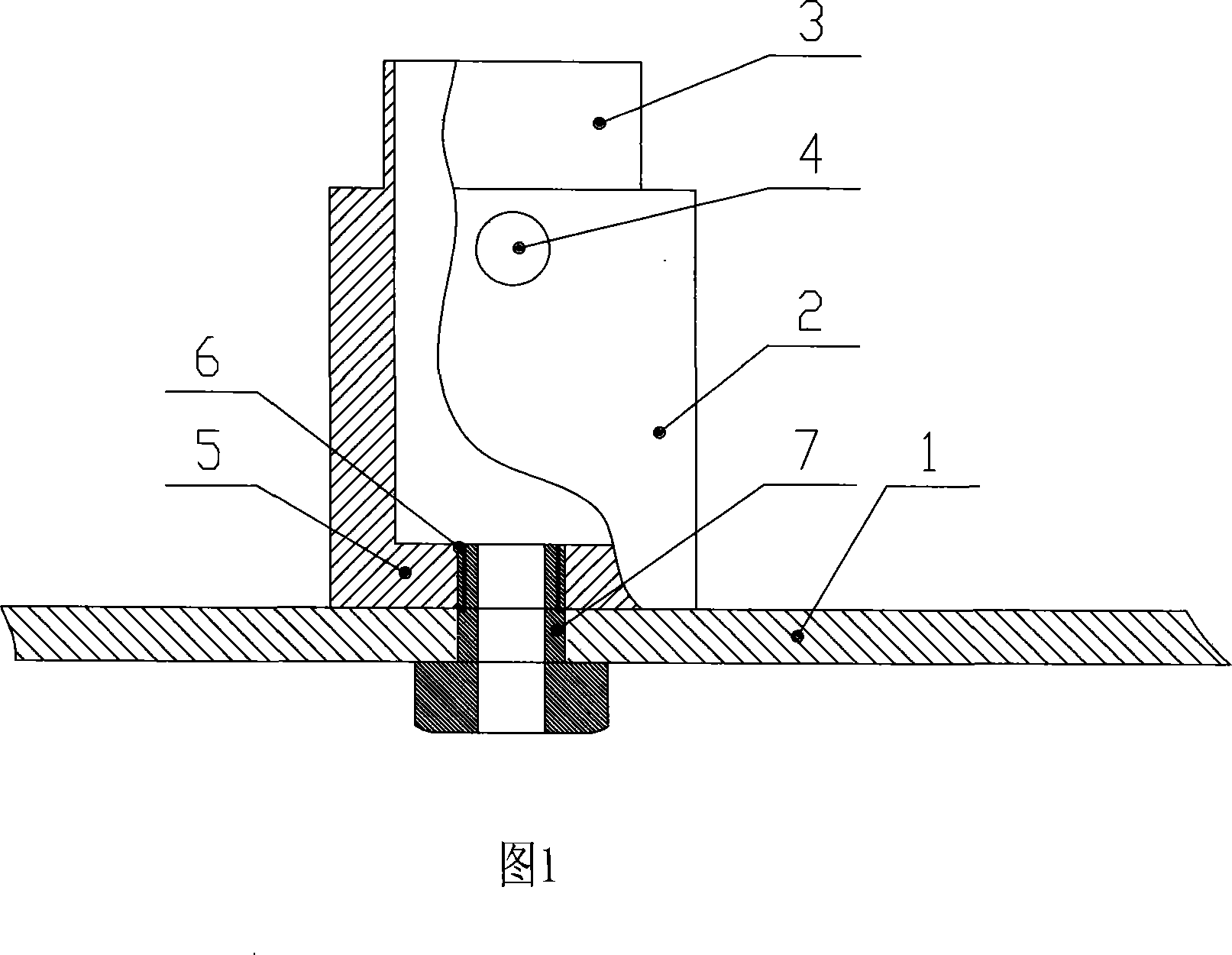

[0010] The thin-walled spout of the soldering furnace with tin overflow hole as shown in Figure 1 is composed of a pot body 2 and a tin outlet 3 arranged on the spout installation panel 1, and the wall thickness of the tin outlet 3 is 0.5- 3mm, the pot body 2 wall thickness is 3 ~ 8mm, on the side wall of the pot body 2 is provided with overflow tin hole 4. A bottom plate 5 is arranged at the bottom of the pot body 2, and a tin inlet hole 6 is arranged on the bottom plate 5. The tin inlet hole 6 is internally threaded and connected with a hollow nut 7, and the hollow nut 7 fixes the bottom plate 5 and the spout mounting panel 1 and twists them together. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com