An intelligent welding method for electric fusion pipe fittings

A technology of electric fusion pipe fittings and welding methods, which is applied in the field of intelligent welding of electric fusion pipe fittings, can solve problems such as the inability to ensure the rationality of parameter settings, the inability to guarantee the welding quality of pipe joints, etc., to expand applicability, improve welding efficiency, and improve welding efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

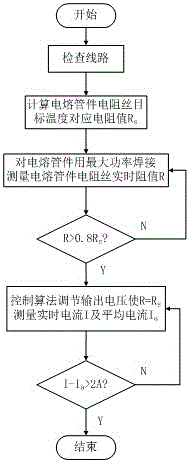

[0029] like figure 1 As shown, the intelligent welding method for electric fusion pipe fittings involved in the present invention includes the following steps:

[0030] Step 1: Preparation for welding:

[0031] a) Line inspection:

[0032] Connect the electric fusion welding machine with the electric fusion pipe fittings. Before the welding starts, control the power supply of the welding machine to output the initial voltage. The initial voltage range is 0-5V, and detect the current output value in the welding circuit under the initial voltage to obtain the initial state. The initial resistance value of the resistance wire of the electric fusion pipe fitting; calculate the deviation between the initial resistance value of the resistance wire of the electric fusion pipe fitting and its standard resistance value, if the above deviation is within ±20% of the standard res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com