Welding method of Q420qE grade ultra-low-carbon bainite steel for bridges

A carbon bainitic steel, welding method technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as the absence of technical solutions

Inactive Publication Date: 2009-08-26

YANSHAN UNIV +1

View PDF2 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing bridge steel welding methods at home and abroad do not have a targeted technical solution that can be completely displaced to solve the above problems, and new research and exploration are needed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

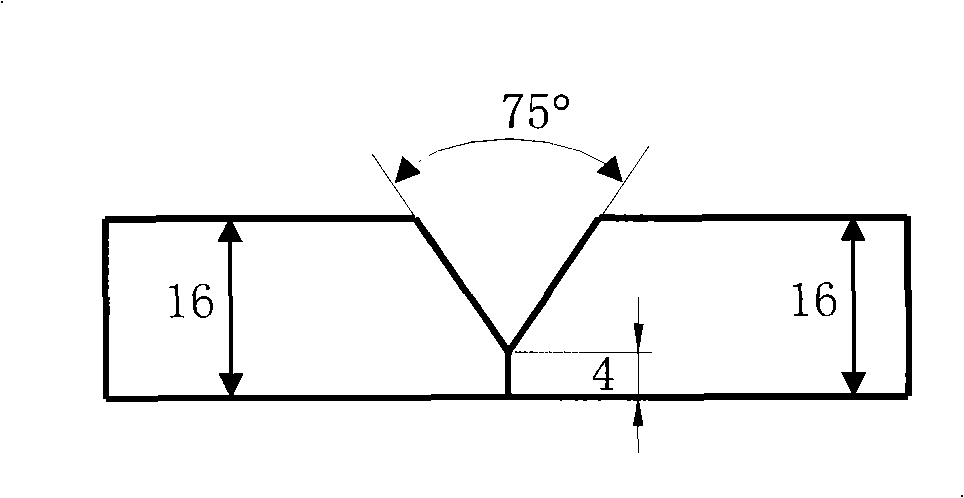

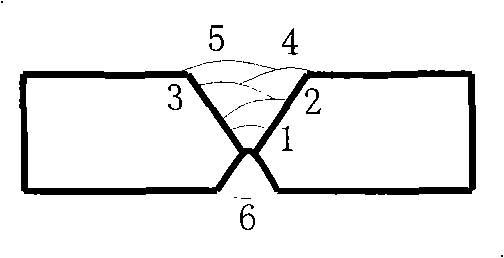

[0082] Example 1 Butt joint of transverse submerged arc welding with plate thickness of 16mm+16mm;

Embodiment 2

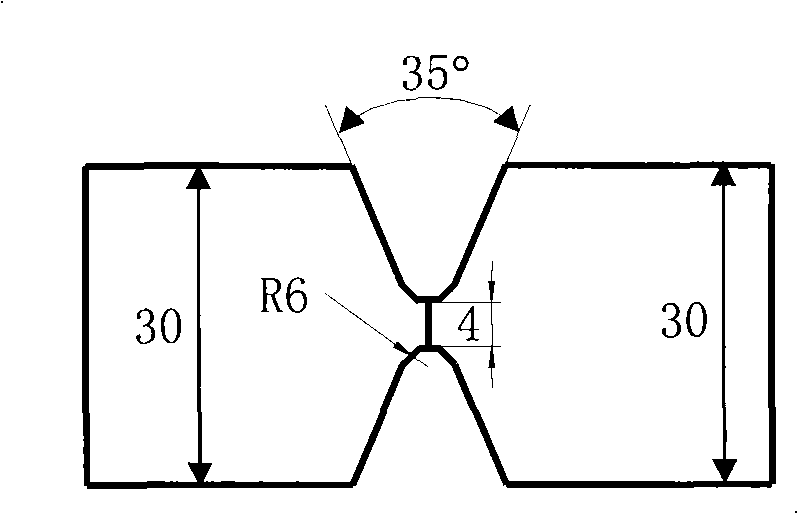

[0083] Example 2 Lateral submerged arc welding butt joint with plate thickness of 30mm+30mm;

Embodiment 3

[0084] Example 3 Butt joint of transverse submerged arc welding with plate thickness of 60mm+60mm;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a welding method of Q420qE grade ultra-low-carbon bainite steel for bridges, comprising the following steps: 1. the special chemical ingredients and technical conditions of Q420qE grade ultra-low-carbon bainite steel for bridges related to the welding method; 2. the pre-heating temperature before welding related to the steel and thickness specification of the steel; 3. welding line energy related to the steel; 4, the groove form and welding method related to the joint form and the plate thickness of the steel; 5. welding materials related to the steel, the joint form, groove form and welding method of the steel; and 6. welding process parameters related to the steel, the joint form, groove form, welding method and welding materials of the steel. The welding method covers the typical joint forms and thickness specifications of the bridge structure, and is simple and practical, the implementation effect of which complies with the related standards of the present bridge steel and the bridge structure, thus being practically applied to welding of the bridge steel structure.

Description

Technical field [0001] The invention belongs to the technical field of steel material welding, and particularly relates to a welding method of Q420qE grade ultra-low carbon bainite steel for bridges. Background technique [0002] At present, my country's railway and highway transportation capacity has been greatly improved, and the construction scale of railways and highway bridges has been continuously expanded, and the technical level has been continuously improved. The function, structure and construction technology of bridges have been adapted to heavy load, high speed, large span, light weight, It has good integrity, high safety, and adopts the direction of full welded joint steel structure. Therefore, the requirements for the strength, low temperature toughness, fatigue, corrosion and other performance and welding performance of bridge steel are getting higher and higher, and the maximum thickness of the bridge steel plate has exceeded 50mm. The strength level of my country...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K31/02B23K101/28

Inventor 王青峰徐向军魏云祥贺富通贝玉成赵苏娟范军旗朱庆菊

Owner YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com