A Welding Method of Discontinuous Lattice Matrix and Core Double-skin Shell Structure

A double skin and skin technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problem of not being able to fundamentally guarantee welding quality, etc., and achieve the effect of high degree of automation, high precision and efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

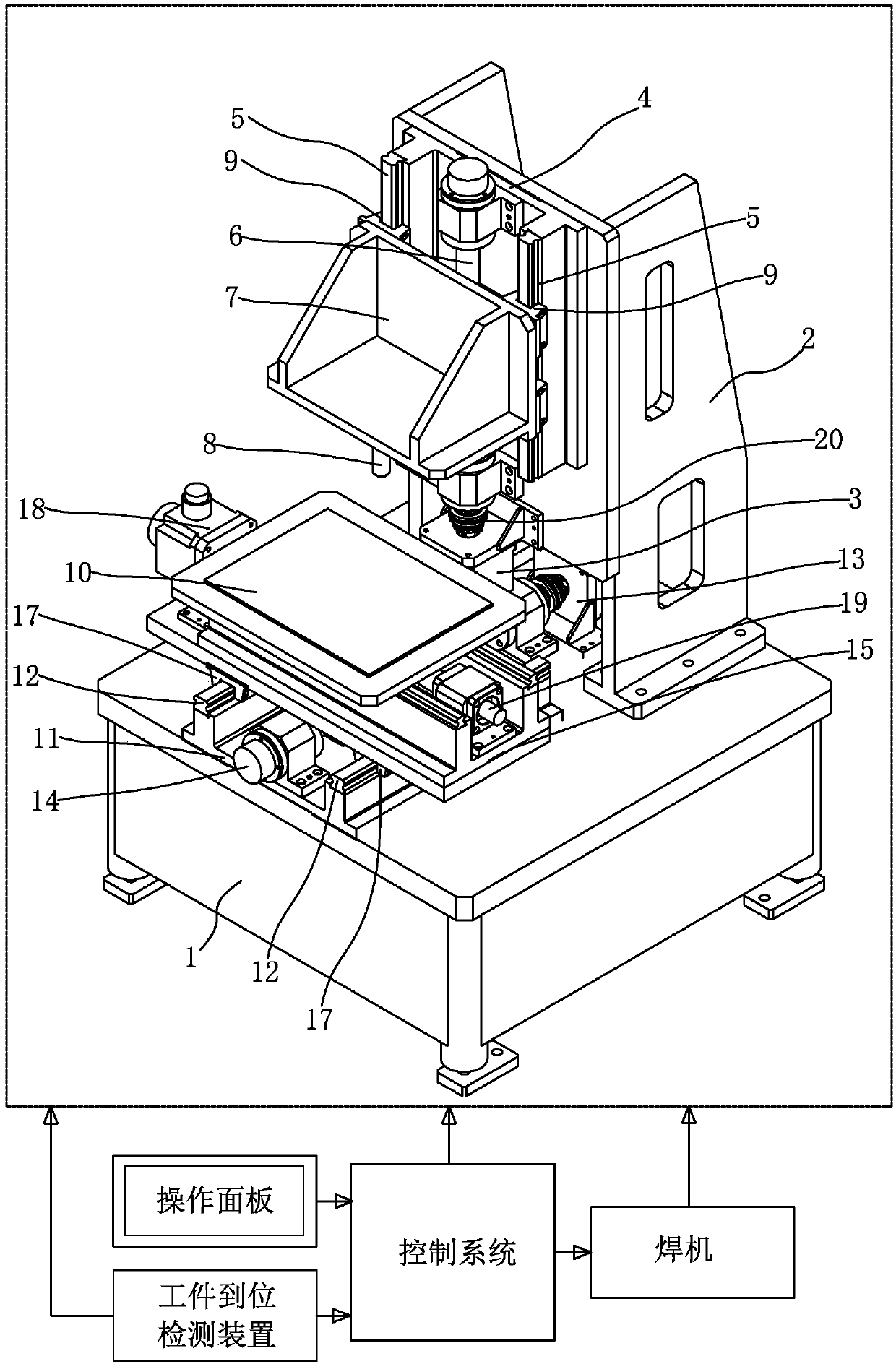

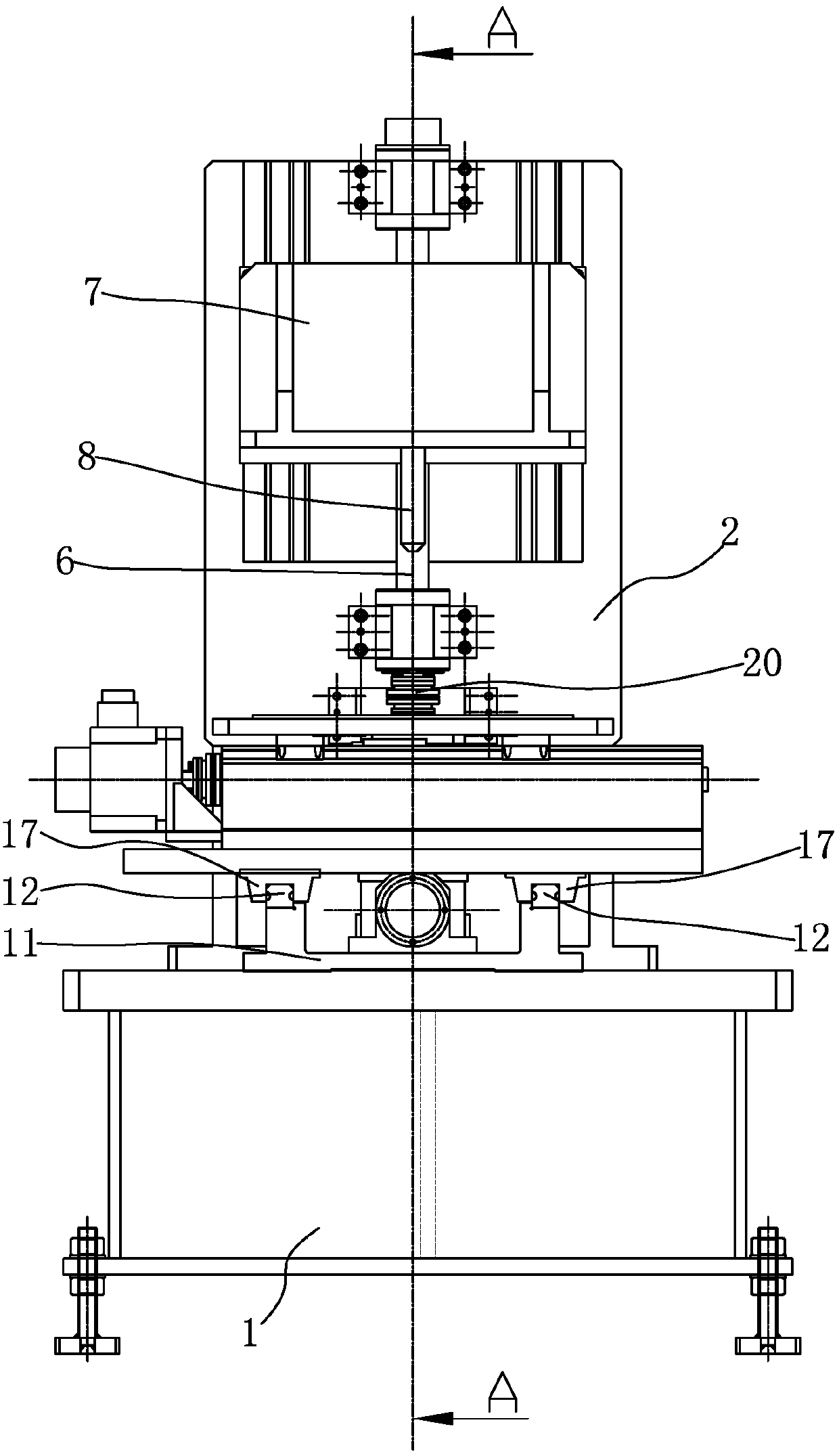

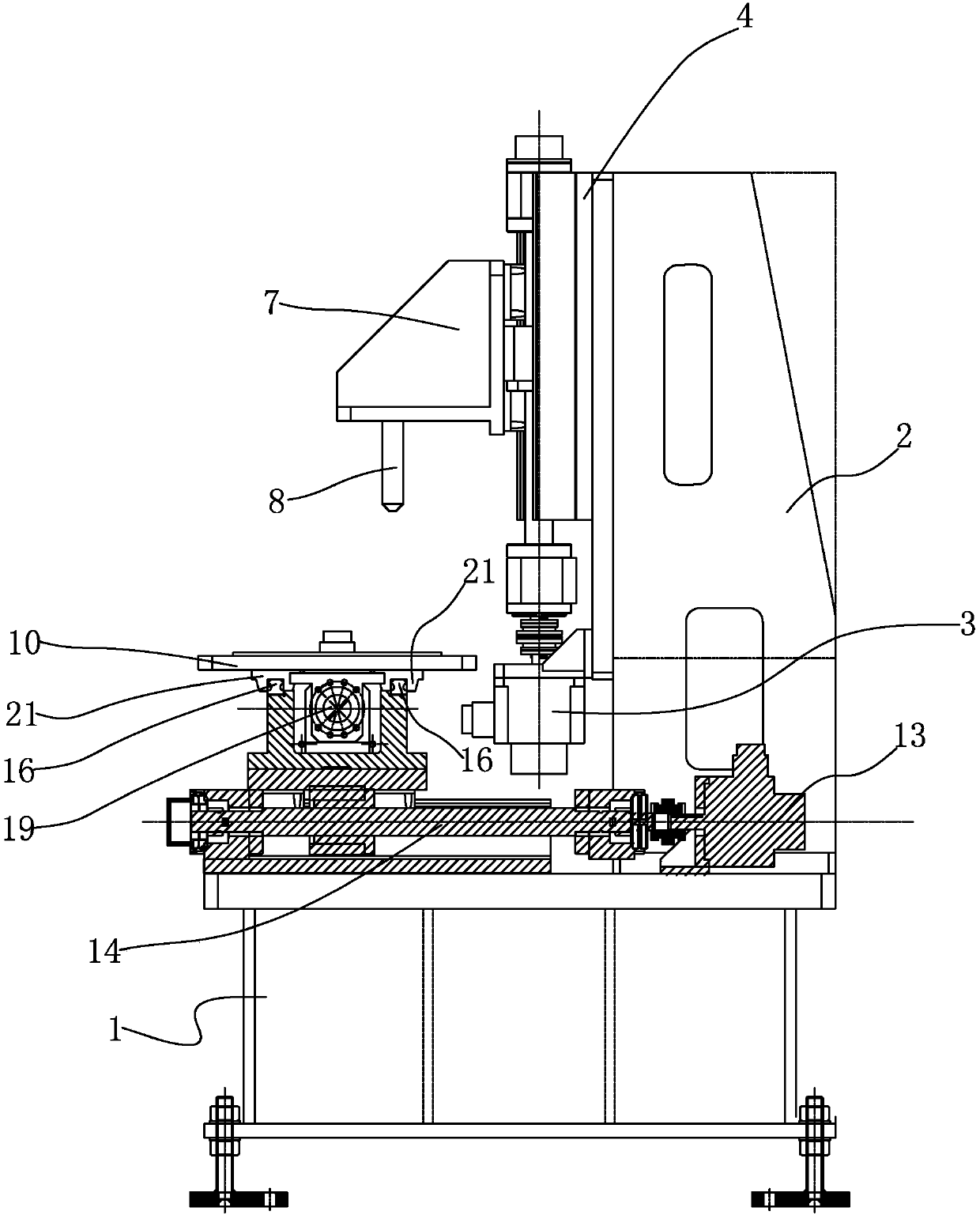

[0045] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Shown is a kind of welding equipment suitable for aerospace with a discontinuous lattice and cored double-skinned shell structure. The welding equipment includes: a bed 1, a welding mechanism placed on the bed 1, and a workpiece positioning Mechanism; the welding mechanism includes: Y-axis bracket 2; Y-axis servo motor 3 and Y-axis slide rail seat on the Y-axis bracket 2; the Y-axis slide rail seat includes a Y-axis slide rail bottom plate 4 and a The Y-axis slide rail 5 on the axis slide rail bottom plate 4; the Y-axis screw 6; one end of the Y-axis screw 6 is connected to the Y-axis servo motor 3, and the other end is supported on the Y-axis slide rail bottom plate 4; Place the welding torch bracket 7 on the Y-axis slide rail seat; a welding torch 8 is installed on the welding torch bracket 7, and the welding torch 8 is connected with the welding machine; The chute 9 is connected to the Y-axis slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com