Method for assembling upper support body of overhead cell support of hybrid vehicle and clamp thereof

A technology for hybrid electric vehicles and battery racks, which is applied to battery pack parts, circuits, assembly machines, etc. It can solve the problems of unstable welding quality, inability to realize automatic and mechanized welding, and low welding accuracy, so as to avoid processing difficulties, Reduces the incidence of product mismatch and eliminates the effects of heat distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

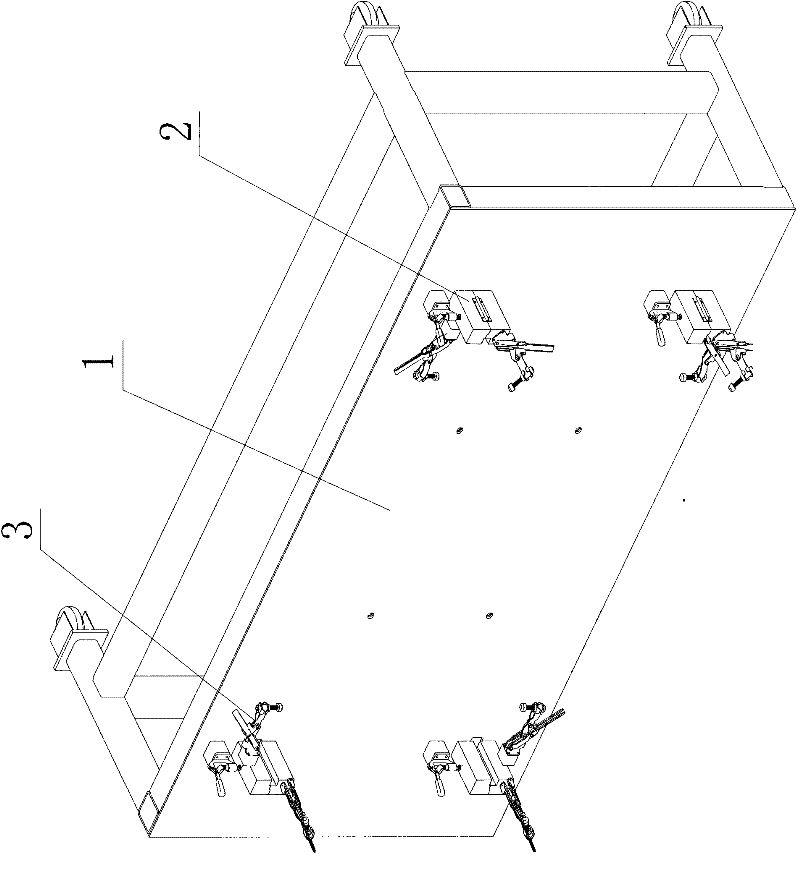

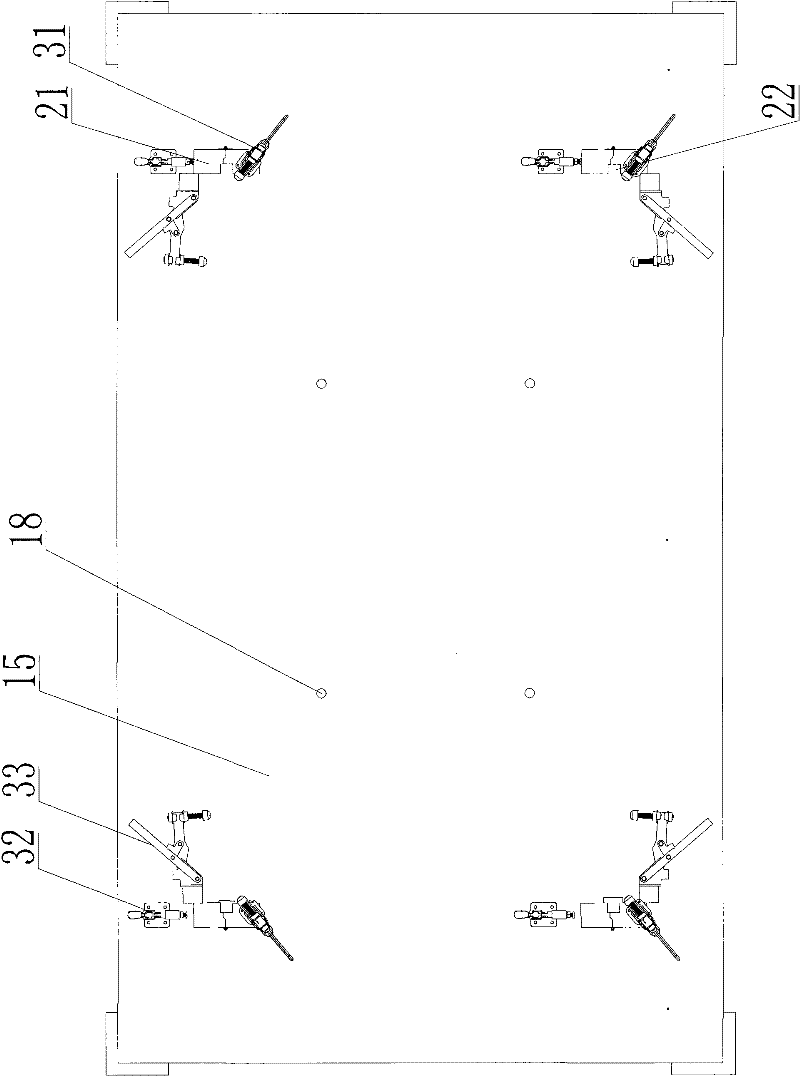

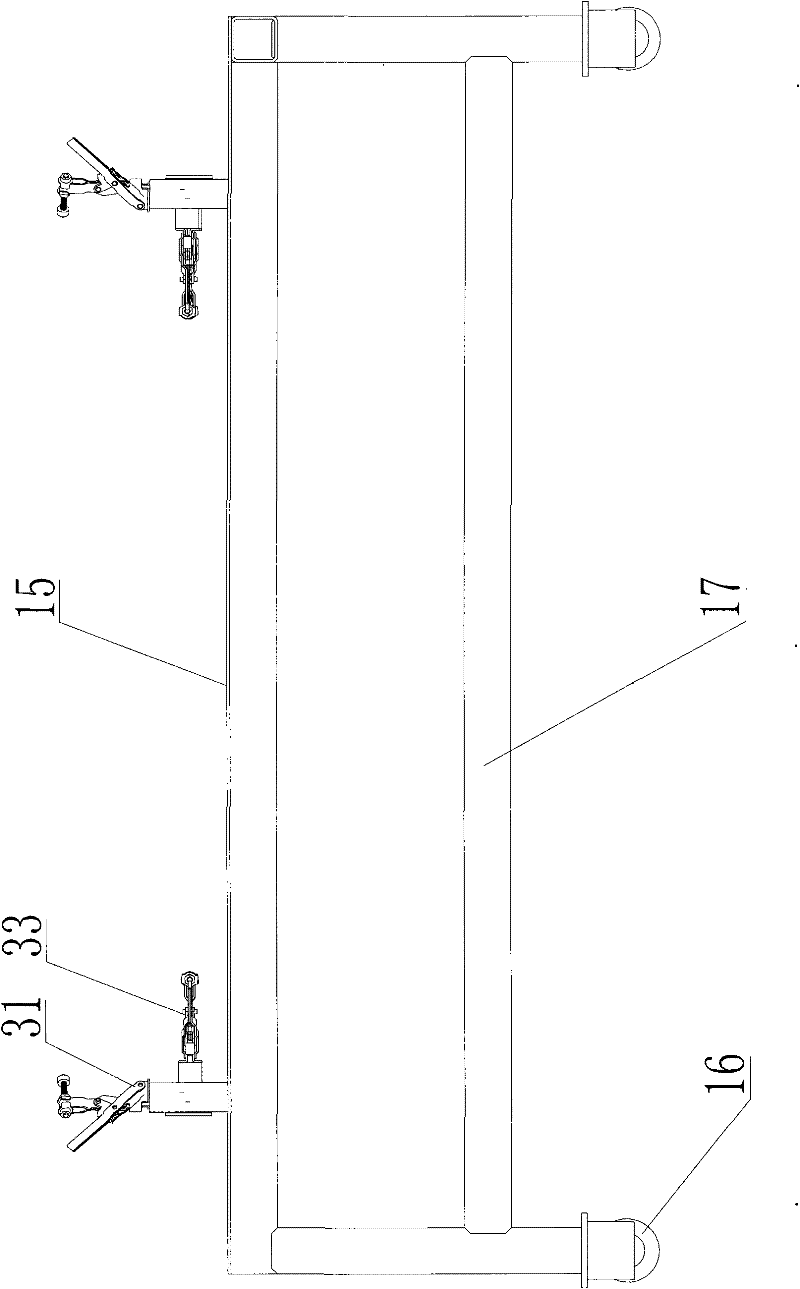

[0047] Example Figure 1~3 , is a welding tool fixture for the upper body of the battery rack on the top of the hybrid electric vehicle, including a clamp body 1, a positioning element 2 is fixedly arranged on the upper end of the clamp body, and a clamping device 3 is arranged on the outside of the positioning element 2, and the positioning element is horizontal Limiting the components of the upper frame body of the top battery rack of the hybrid electric vehicle, the clamping device horizontally and vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com