Beer bottle sorting machine

A bottle unscrambler and beer bottle technology, applied in the field of bottle unscrambler, can solve the problems of remote use and broken bottles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

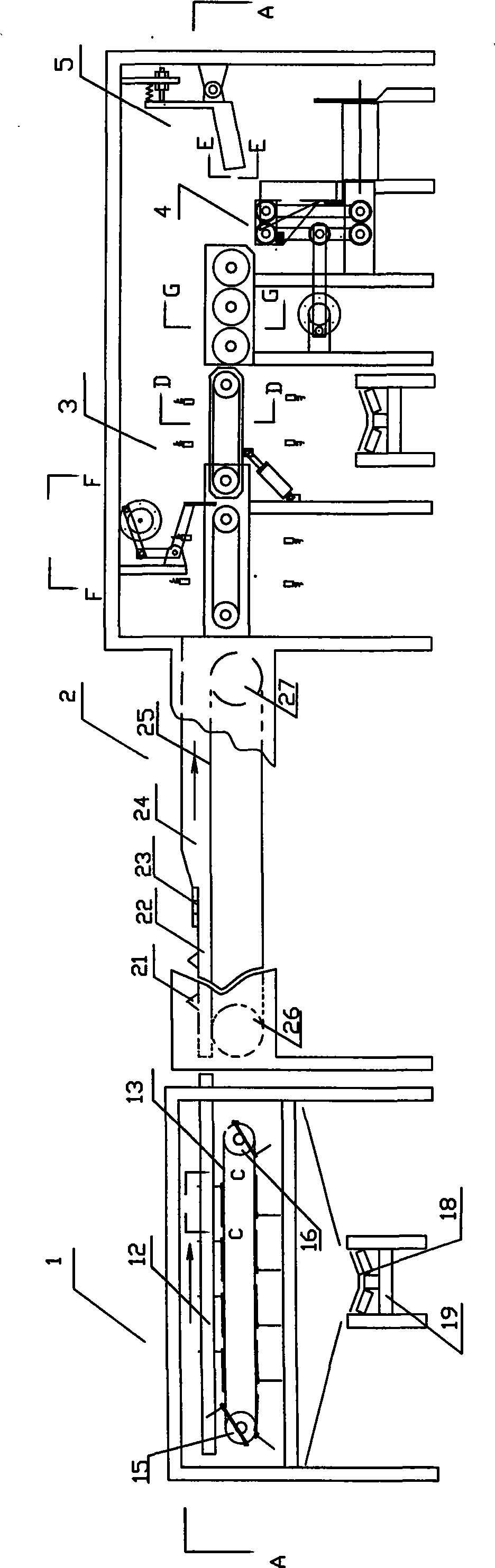

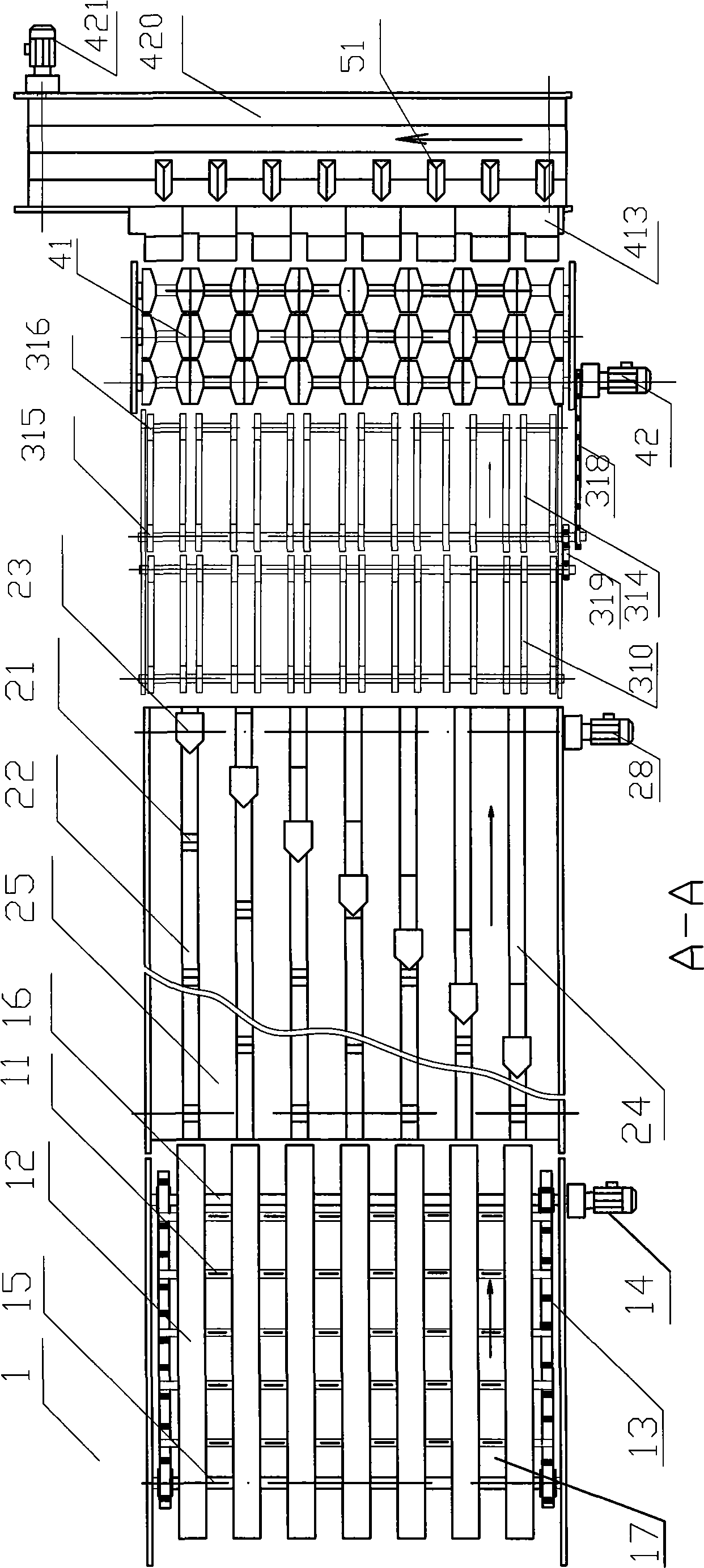

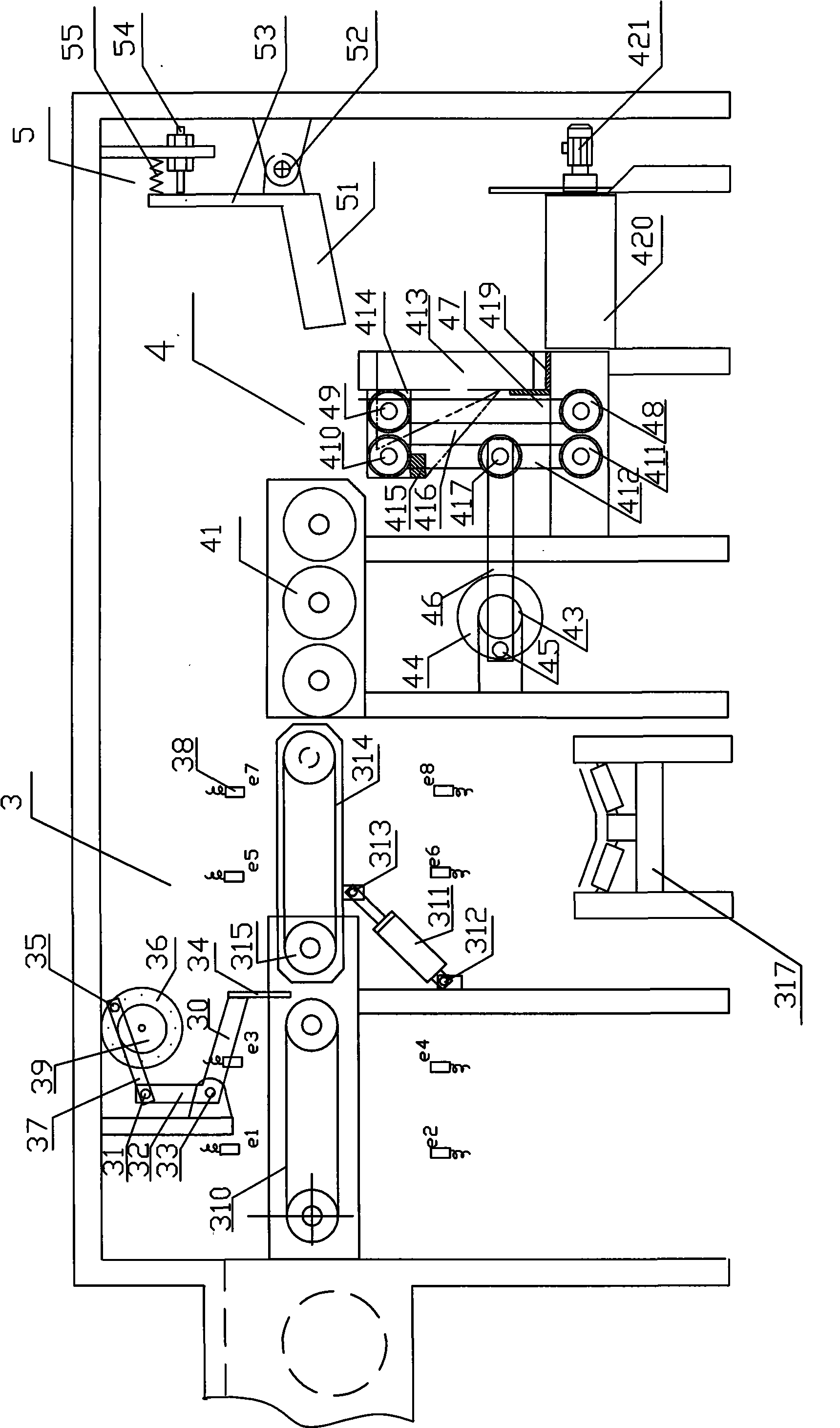

[0019] see Figure 1~2 As shown, the broken bottle mechanism 1 is composed of several grids 12 and driving rods 11 between the grids 12 to form a grid groove 17, and the driving chain 13 drives the glass bottle to move forward, and the broken bottle is moved from the grid. Groove 17 drops broken bottle collection bucket 18 and sends away by broken bottle conveyor belt 19 again. Several groups of gratings 12 form a conveyor belt for removing broken bottles, and the driving rods 11 are equidistantly arranged on the inner side of the driving rod transmission chain 13, and the driving rod transmission motor 14, the driving rod driving front shaft 15, the driving rod driving rear shaft 16 and the driving rod driving chain 13 drives driving lever 11 jointly and promotes glass bottle in grid groove 17 and moves ahead.

[0020] The bottle straightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com