Processing technique capable of processing interior parts of integral differential mechanism casing by one step

A differential case and internal processing technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high physical labor intensity, low precision of differential case, low processing efficiency, etc. Effects of physical labor, improvement of precision, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

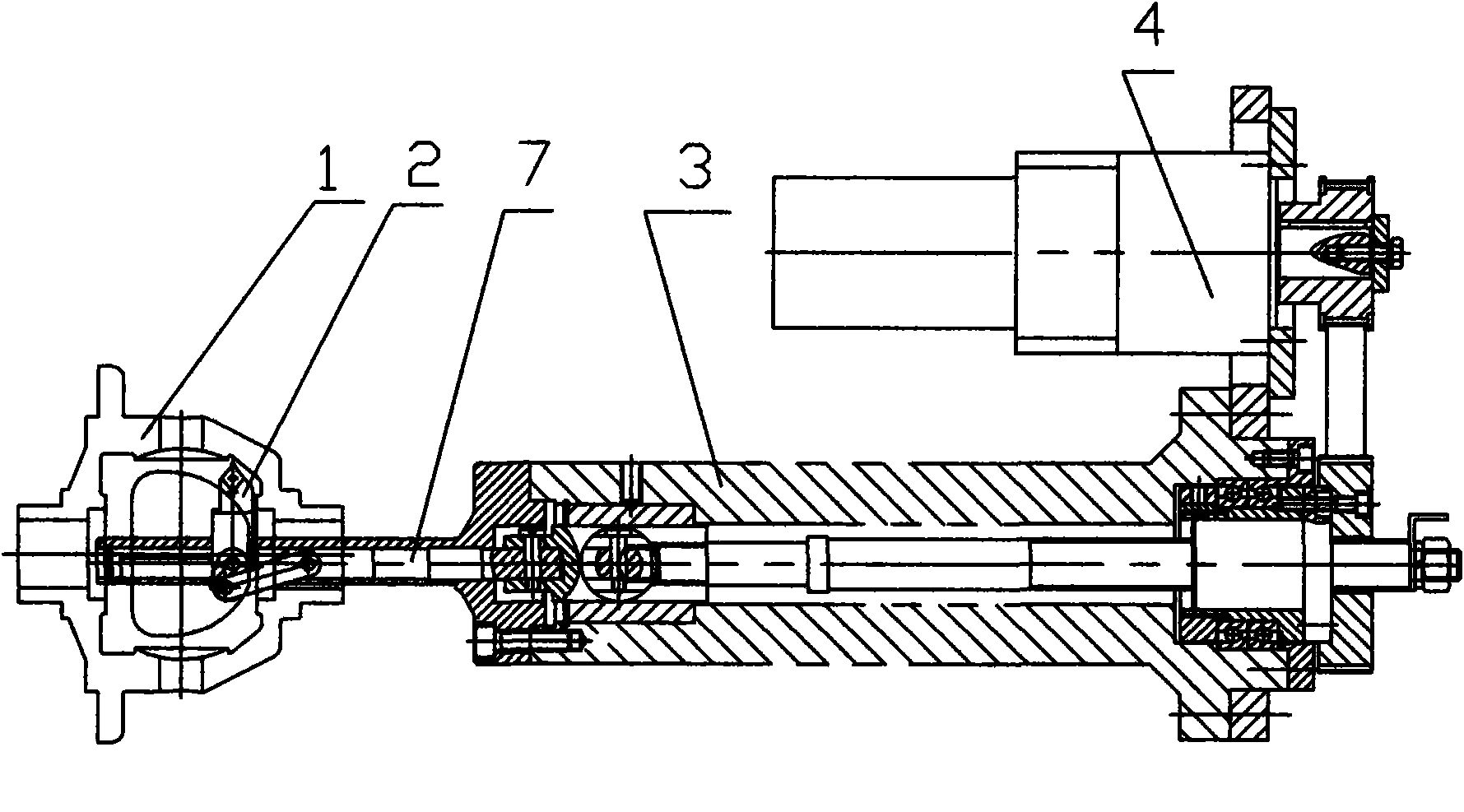

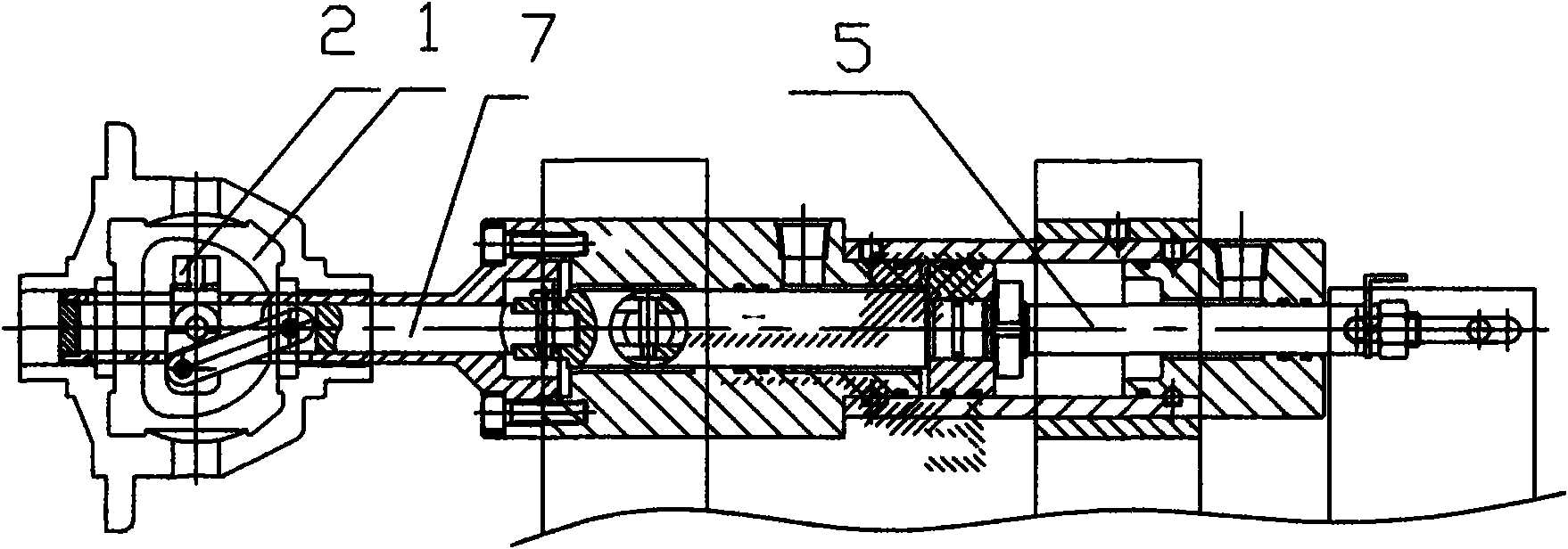

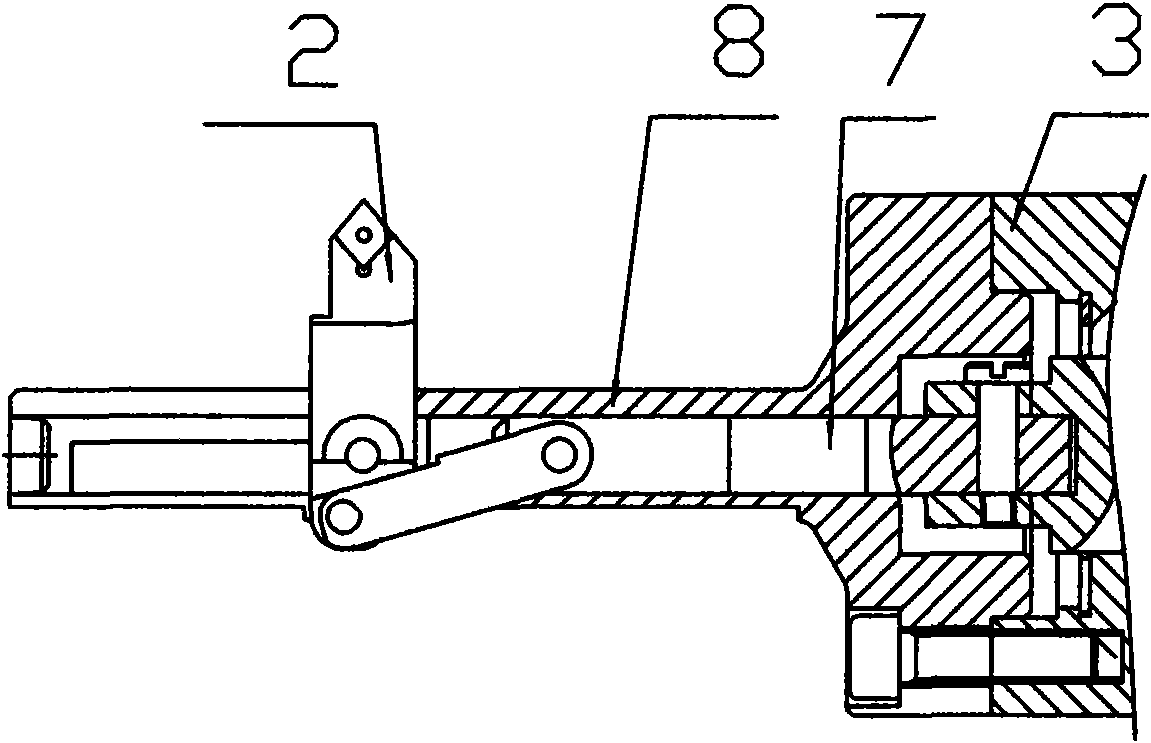

[0019] This embodiment provides a processing technology for one-time completion of the internal processing parts of the overall differential case, which is characterized in that: the processing technology for one-time completion of the internal processing parts of the overall differential case is one-time clamping, using hydraulic pressure The power chuck, equipped with special jaws, directly clamps the positioning surface of the workpiece 1, eliminating the positioning error of the workpiece 1; after the workpiece 1 is clamped, first complete the inner spherical surface of the differential case, and then complete the two inner end surfaces and bearings The key parts of the hole process are processed; the installation error of the workpiece 1 is greatly reduced; now, the force analysis of the tool bar used to process the inner spherical surface of the difference shell or the two inner end surfaces on the special CNC machine tool, the turning spherical cutter 2 and the push rod 7...

Embodiment 2

[0025] This embodiment provides a processing technology for one-time completion of the internal processing parts of the overall differential case, which is characterized in that: the processing technology for one-time completion of the internal processing parts of the overall differential case is one-time clamping, using hydraulic pressure The power chuck, equipped with special jaws, directly clamps the positioning surface of the workpiece 1, eliminating the positioning error of the workpiece 1; after the workpiece 1 is clamped, first complete the inner spherical surface of the differential case, and then complete the two inner end surfaces and bearings The key parts of the hole process are processed; the installation error of the workpiece 1 is greatly reduced; now, the force analysis of the tool bar used to process the inner spherical surface of the difference shell or the two inner end surfaces on the special CNC machine tool, the turning spherical cutter 2 and the push rod 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com