Patents

Literature

36results about How to "Improve assembly and welding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

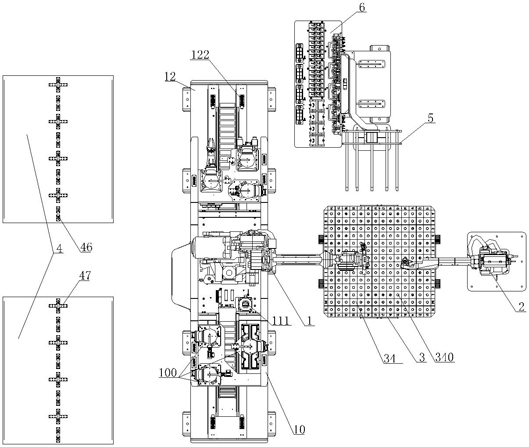

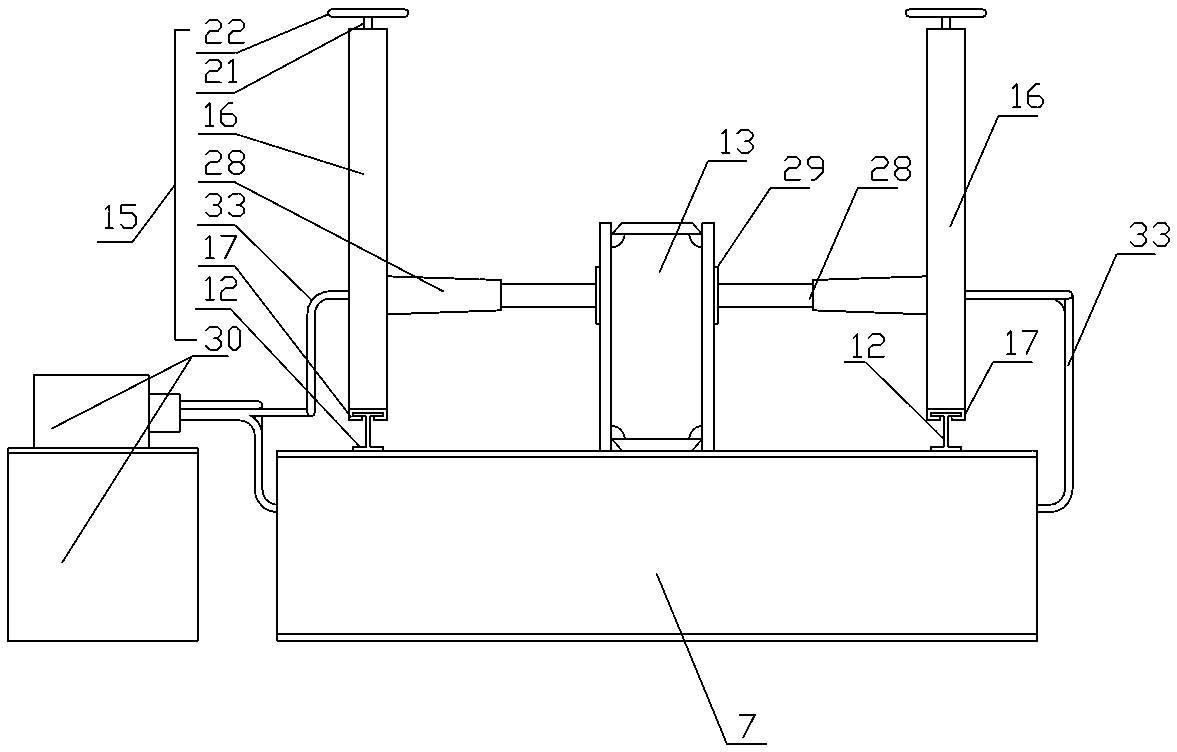

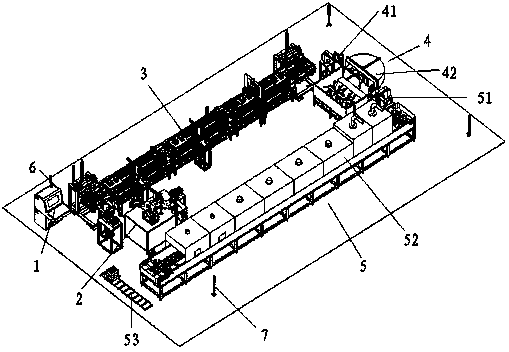

Electric heating rod assembly machine

ActiveCN105855897AImprove assembly and welding efficiencyImprove production stabilityAssembly machinesOther manufacturing equipments/toolsElectricityGrating

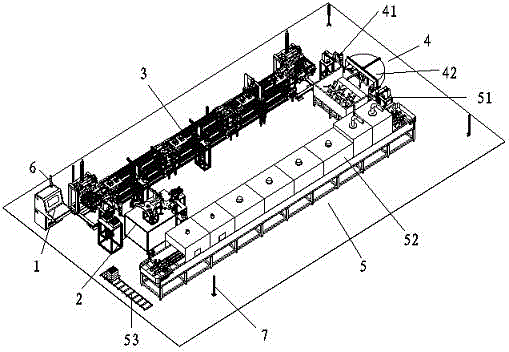

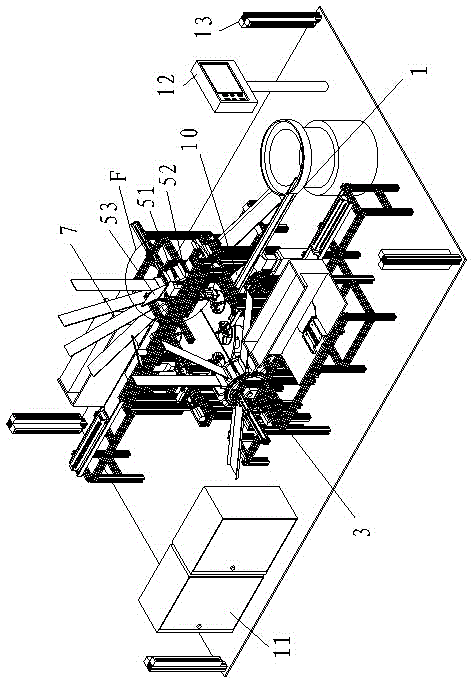

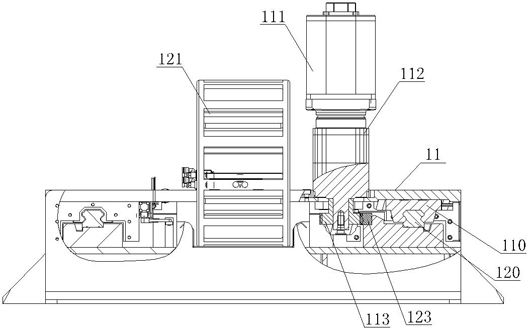

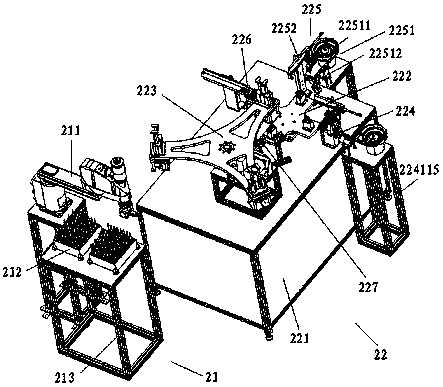

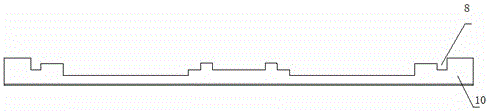

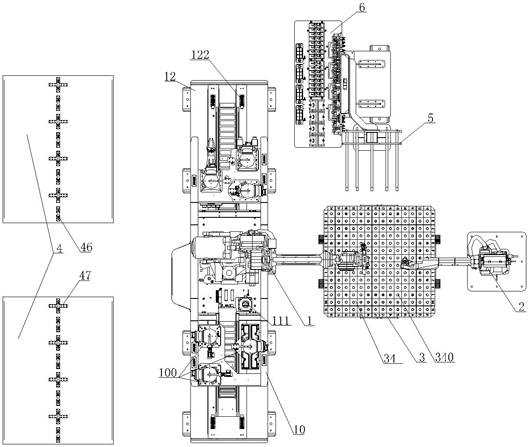

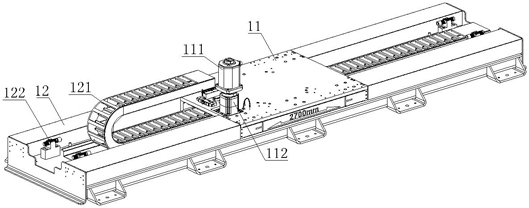

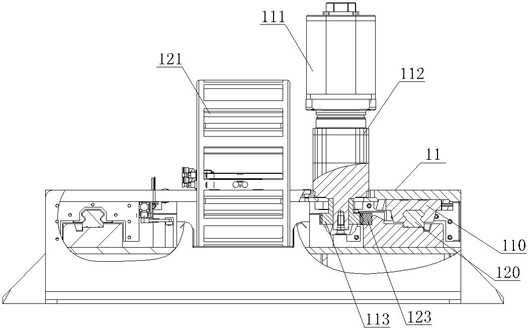

The invention discloses an electric heating rod assembly machine. The electric heating rod assembly machine comprises an electric control box, a rotary assembly mechanism, a chain assembly line, a coating mechanism, a drying mechanism, an indicator lamp tower and area safety gratings, wherein the indicator lamp tower is mounted on the top plate of the electric control box; the front side of the electric control box is provided with the rotary assembly mechanism; the rotary assembly mechanism is used for conveying a workpiece assembled for a first time to the chain assembly line at the rear side of the rotary assembly mechanism; the chain assembly line is used for conveying a wokpiece assembled for a second time to the coating mechanism at the front right side of the chain assembly line; the coating mechanism is used for conveying an assembled electric heating rod to the drying mechanism at the front side of the coating mechanism; and the area safety gratings are arranged around in a rectangular manner. In this way, the assembly welding efficiency is high, the production stability is good, the product scrap rate is low, and the overall production efficiency is high.

Owner:南通江海港建设工程有限公司

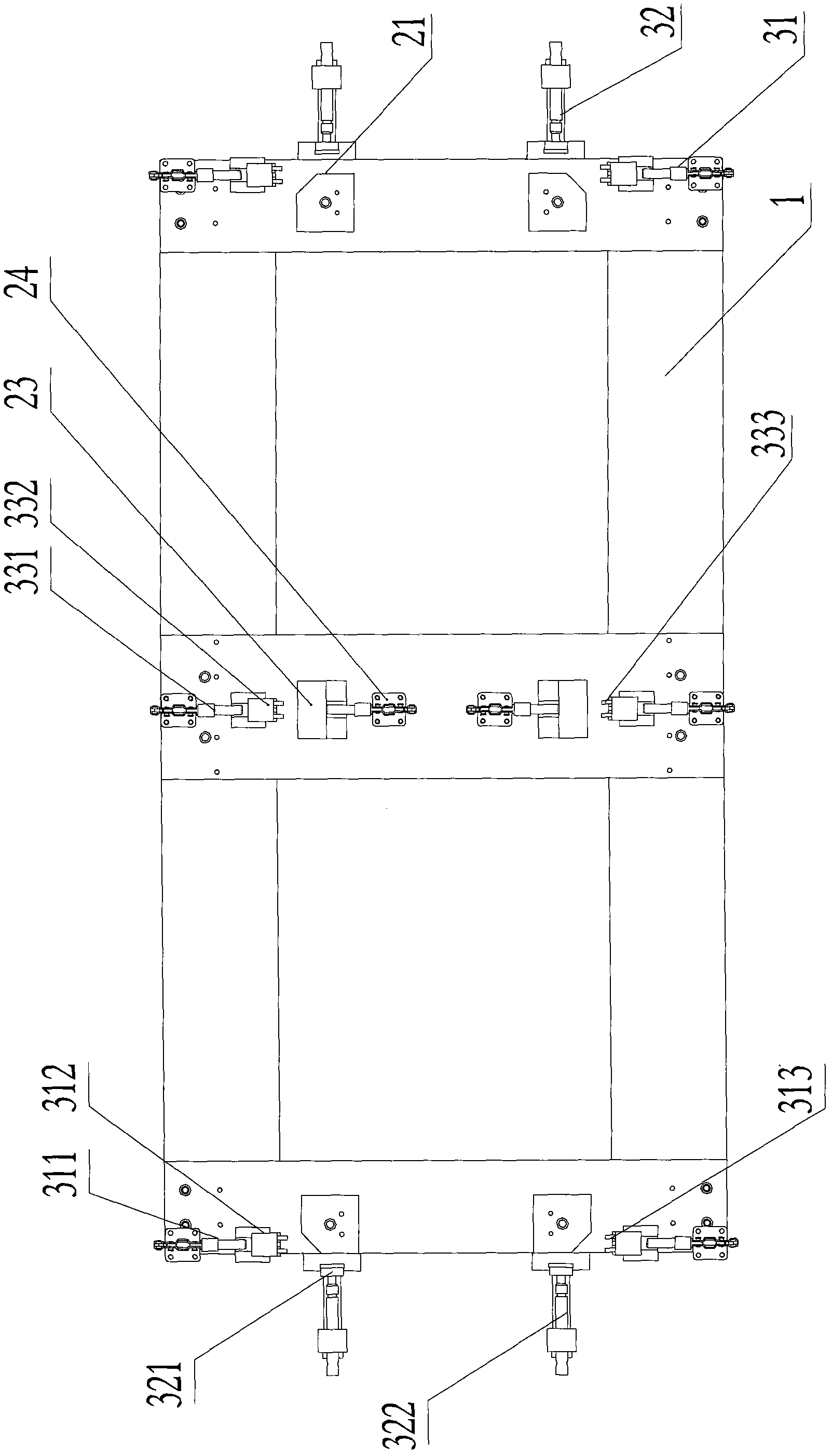

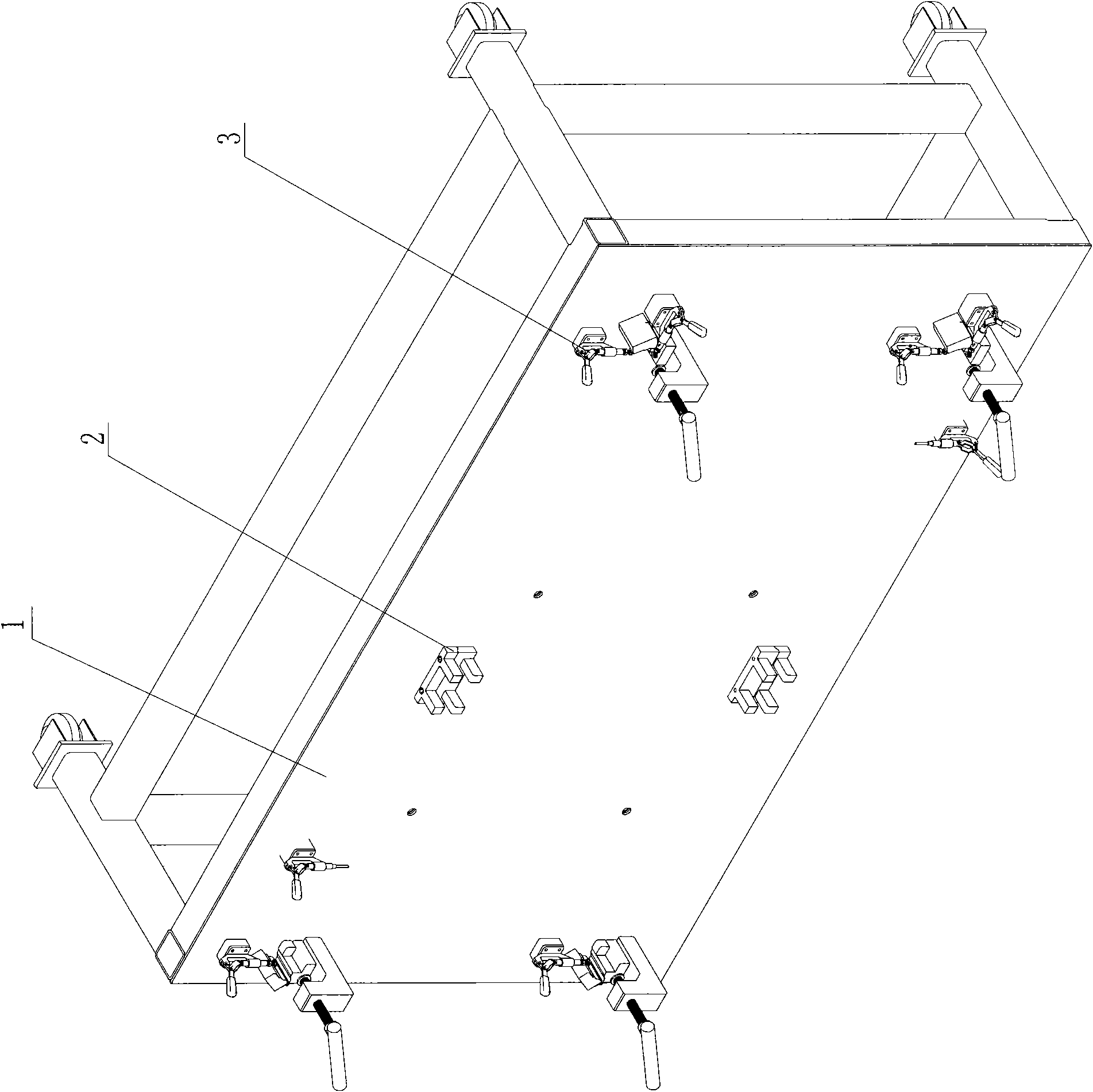

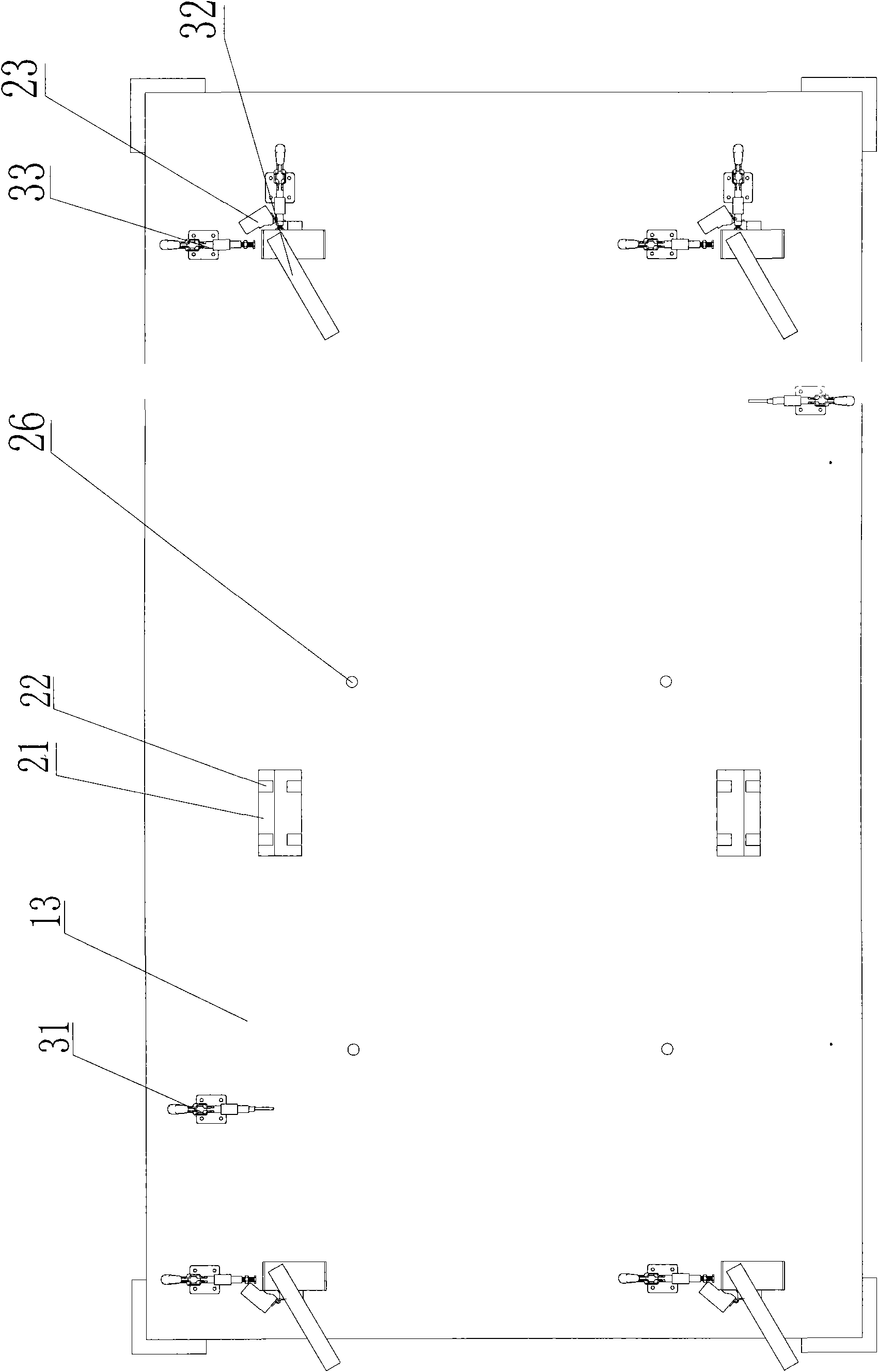

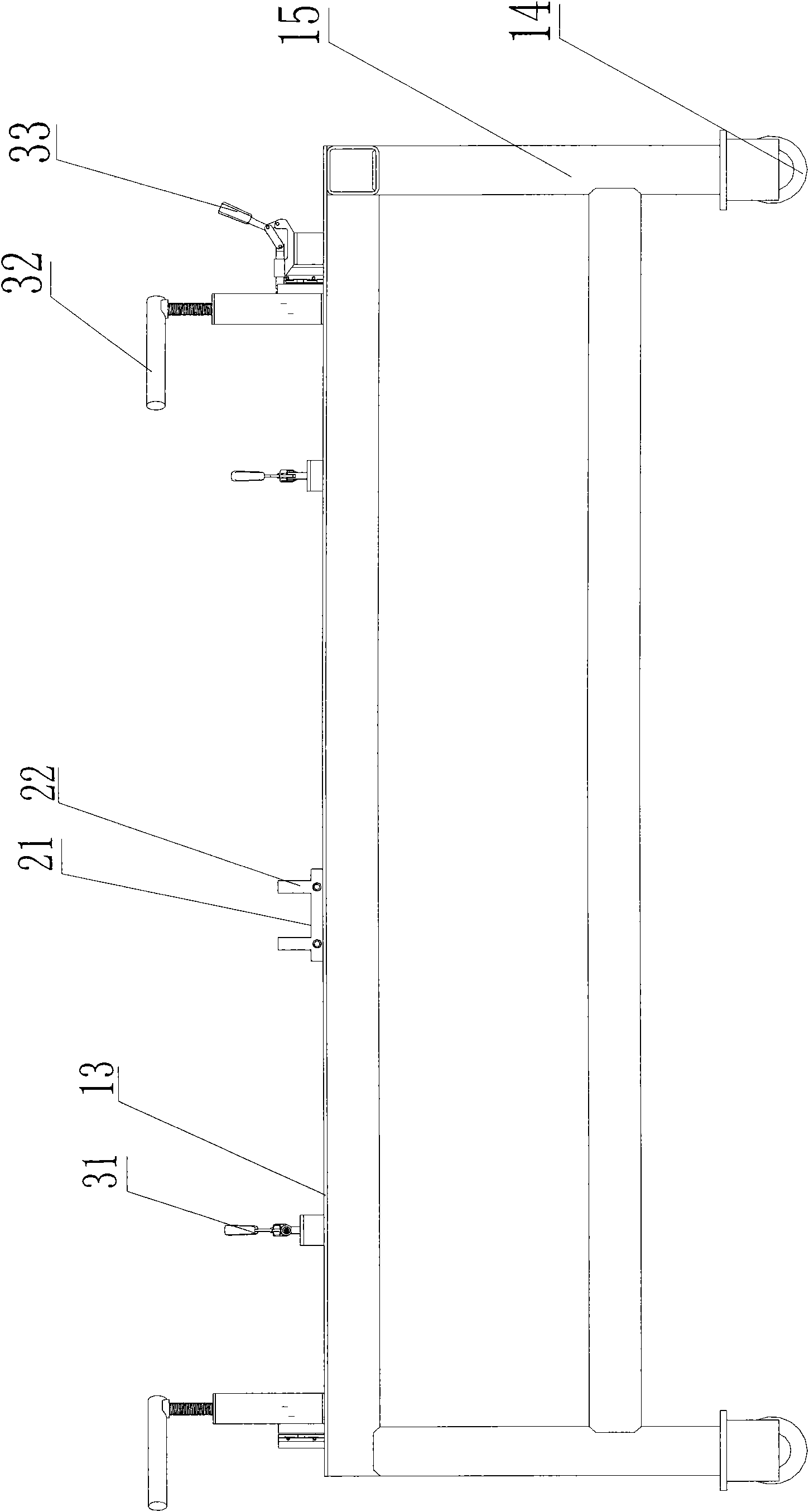

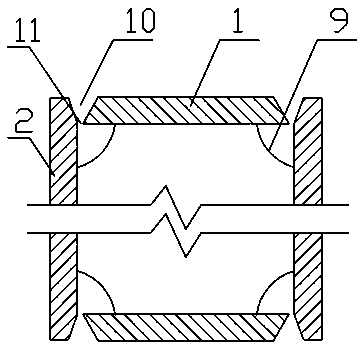

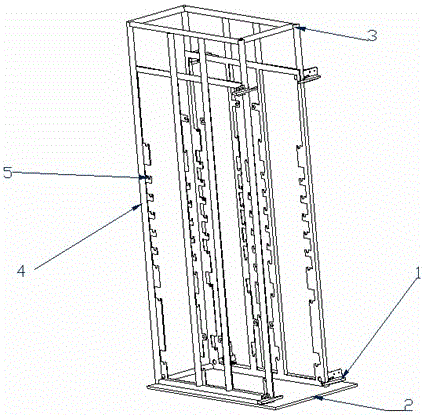

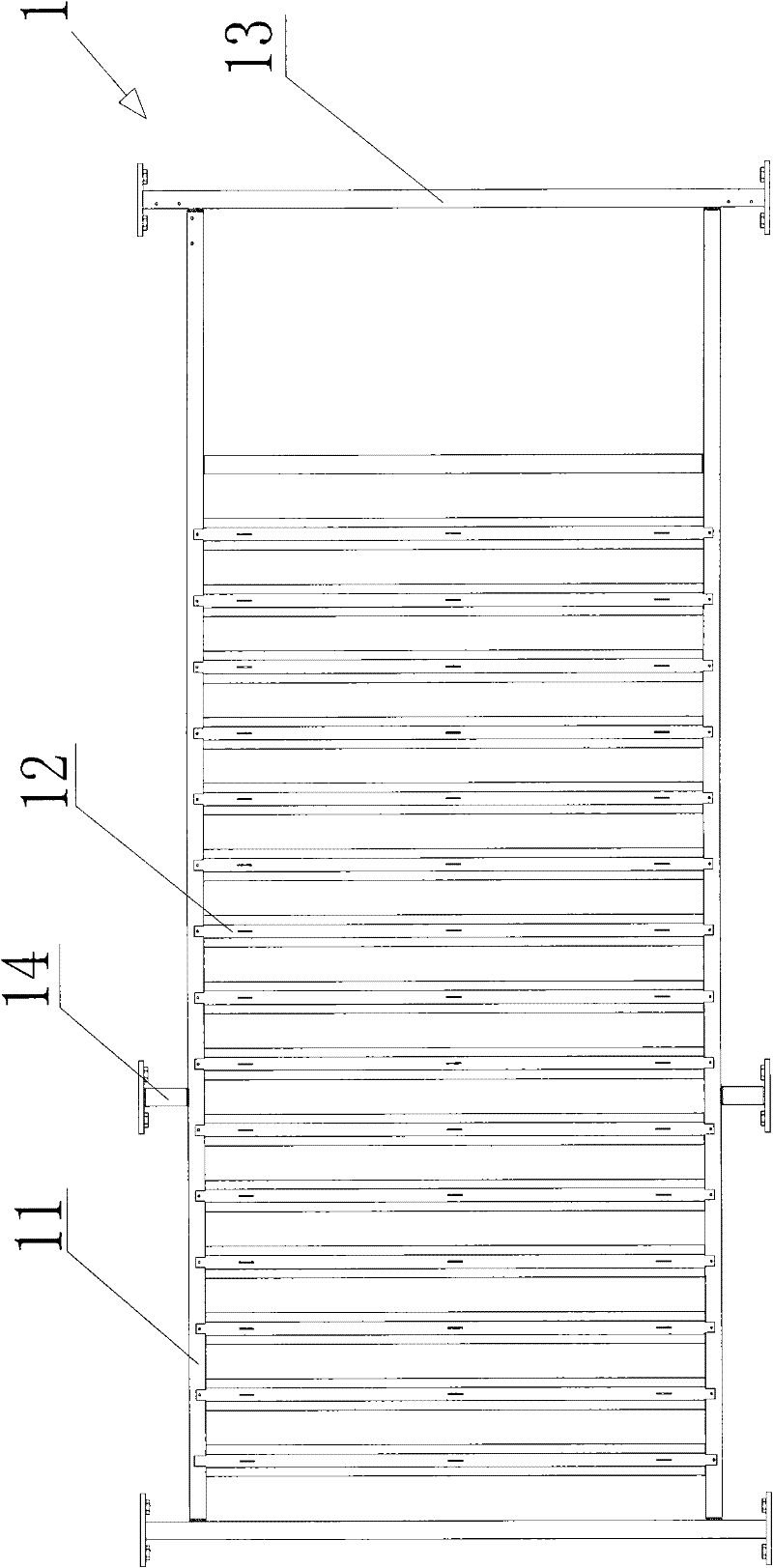

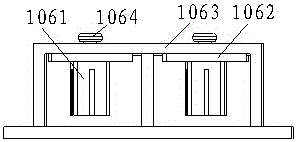

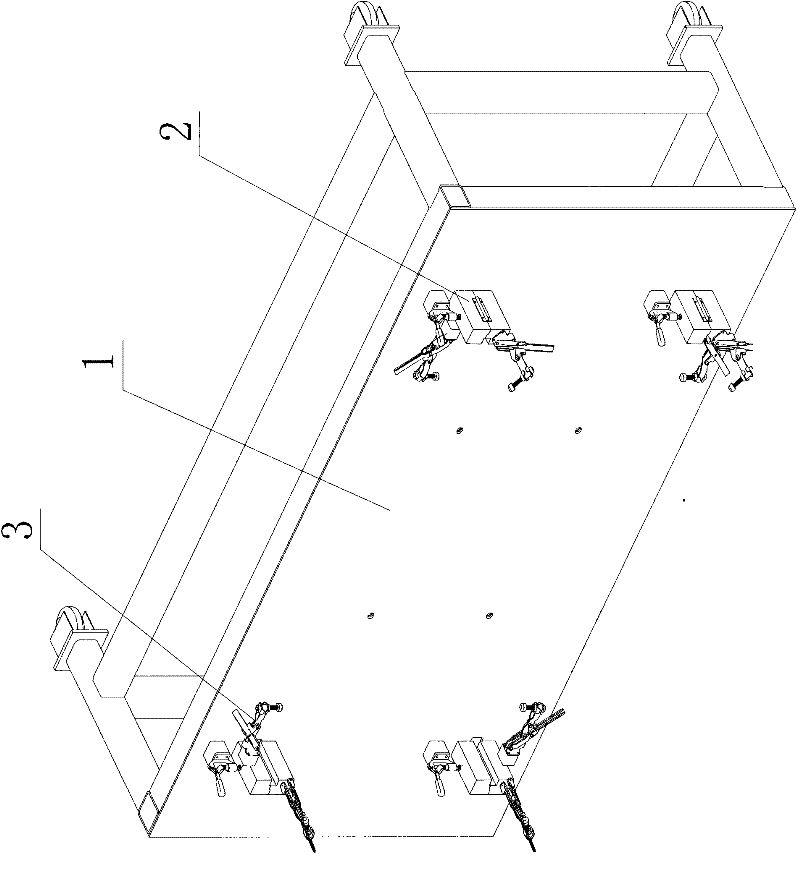

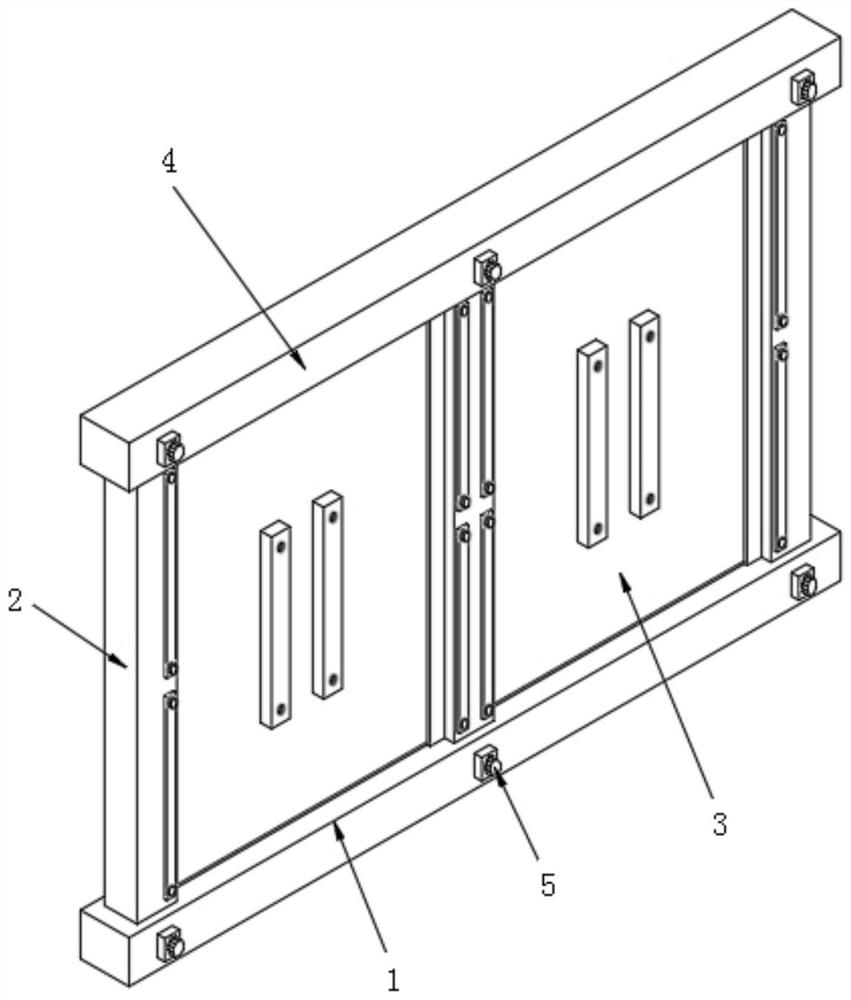

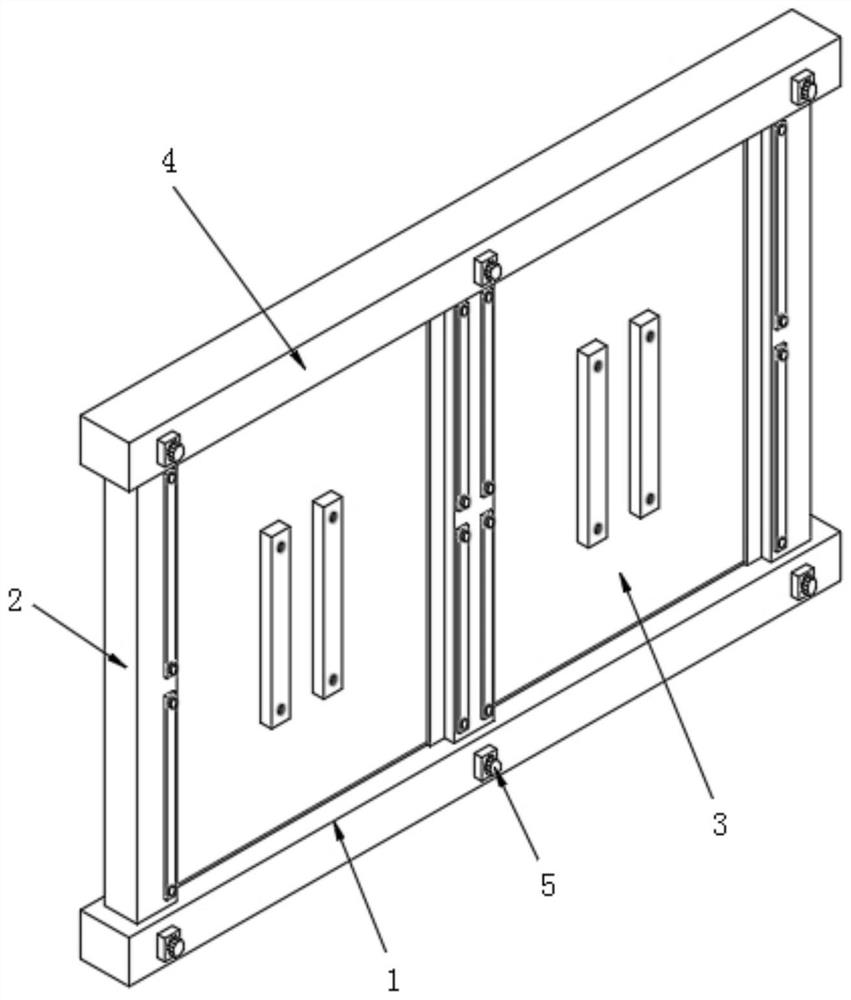

Welding tooling device for pillar frame of machine cabinet and assembly method of device

InactiveCN102029497AReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAuxillary welding devicesInstabilityEngineering

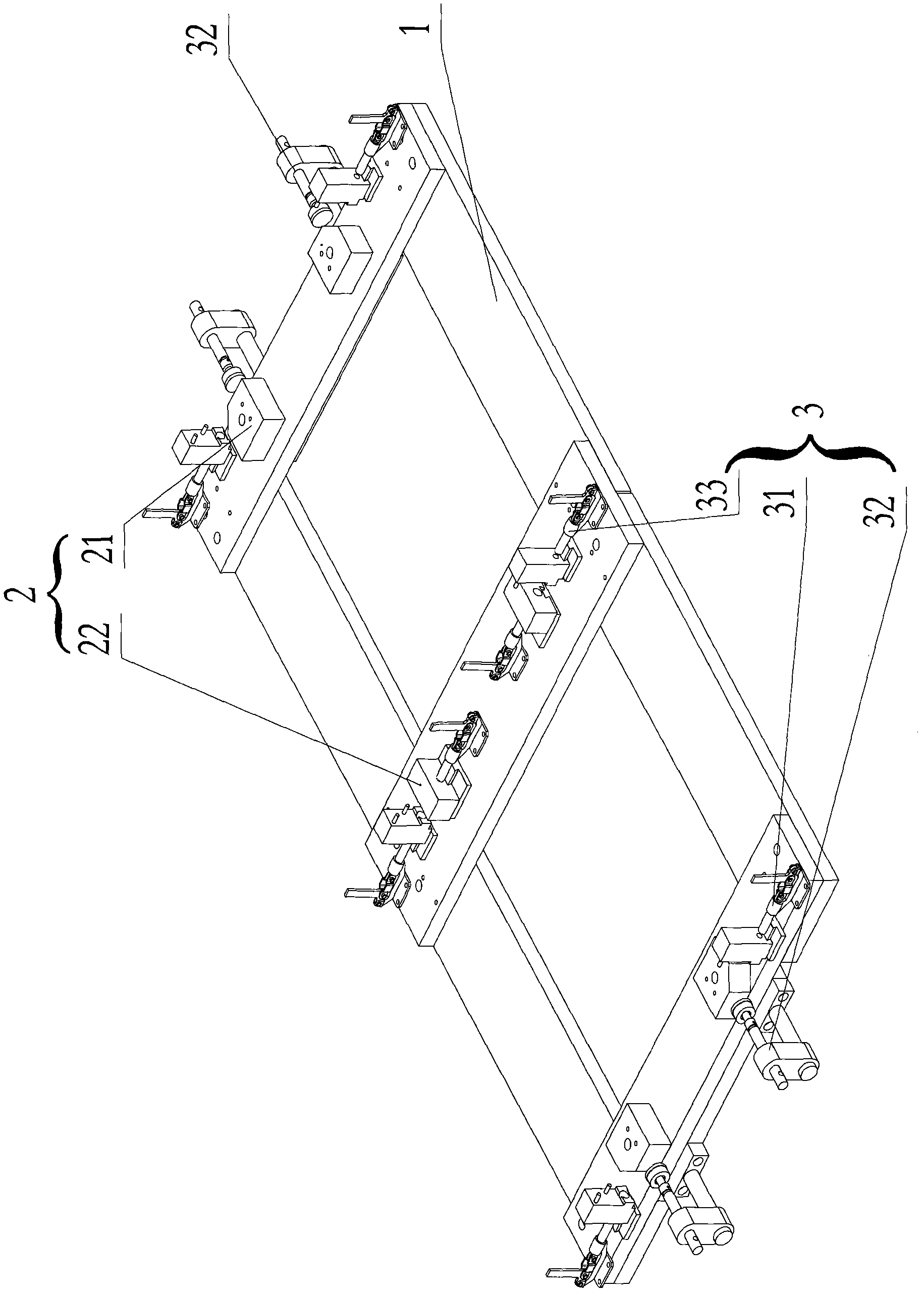

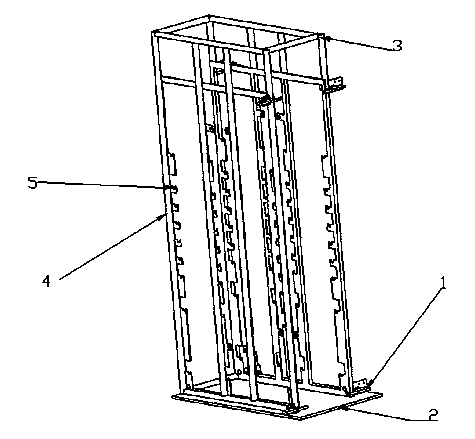

The invention discloses a welding tooling device for a pillar frame of a machine cabinet and an assembly method of the device, wherein the device comprises a clamp body (1) and is characterized in that a positioning element (2) and a clamping device (3) are fixedly arranged on the clamp body, the positioning element (2) is used for horizontal position limitation of all parts of the pillar frame of the machine cabinet, and the clamping device (3) is matched with the positioning element (2) for clamping all the parts of the pillar frame of the machine cabinet in the horizontal direction. By adopting the device and the method disclosed by the invention, the physical labor of operation staff can be greatly reduced, and the assembly and welding efficiency can be improved; and the welding thermal deformation of a workpiece can be controlled or eliminated, and the instability of manual welding can be reduced.

Owner:Jiangsu Boamax Technologies Group Co Ltd

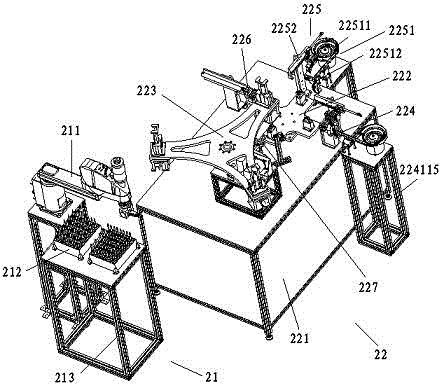

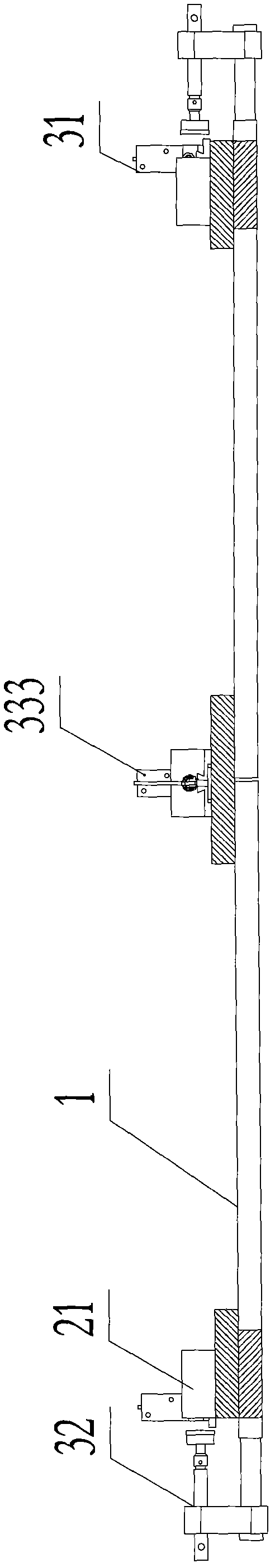

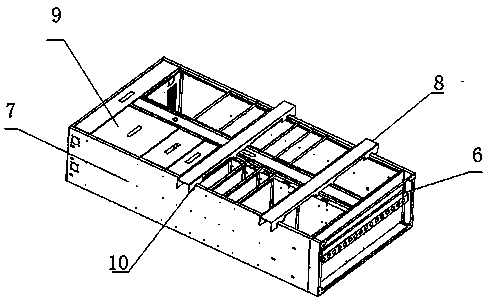

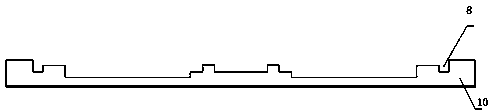

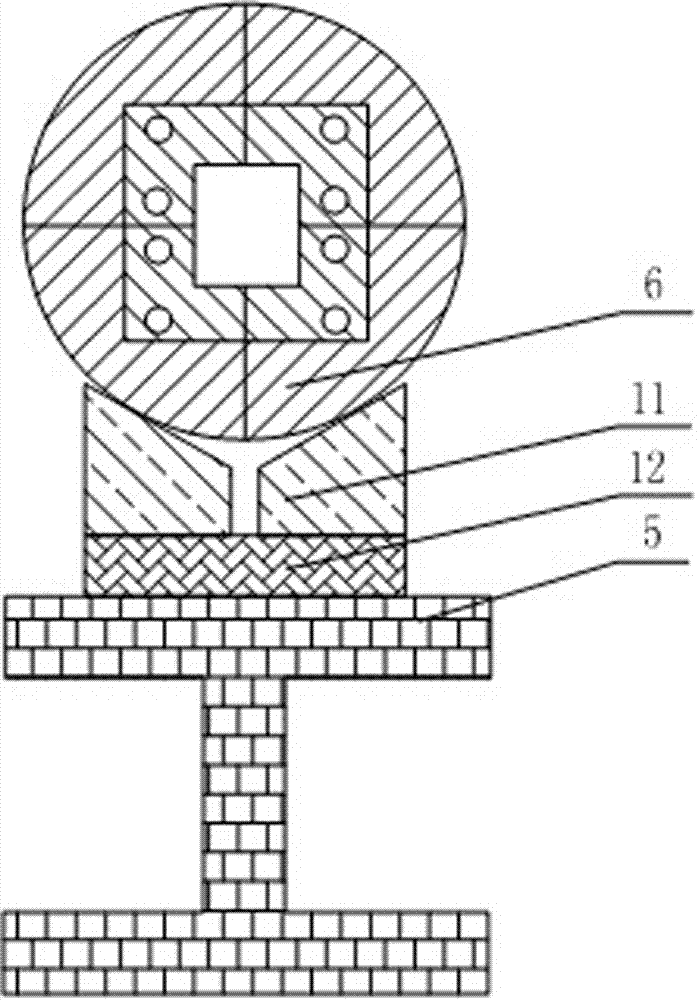

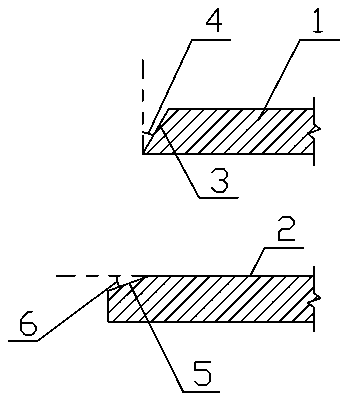

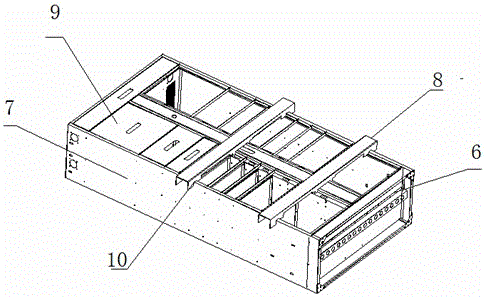

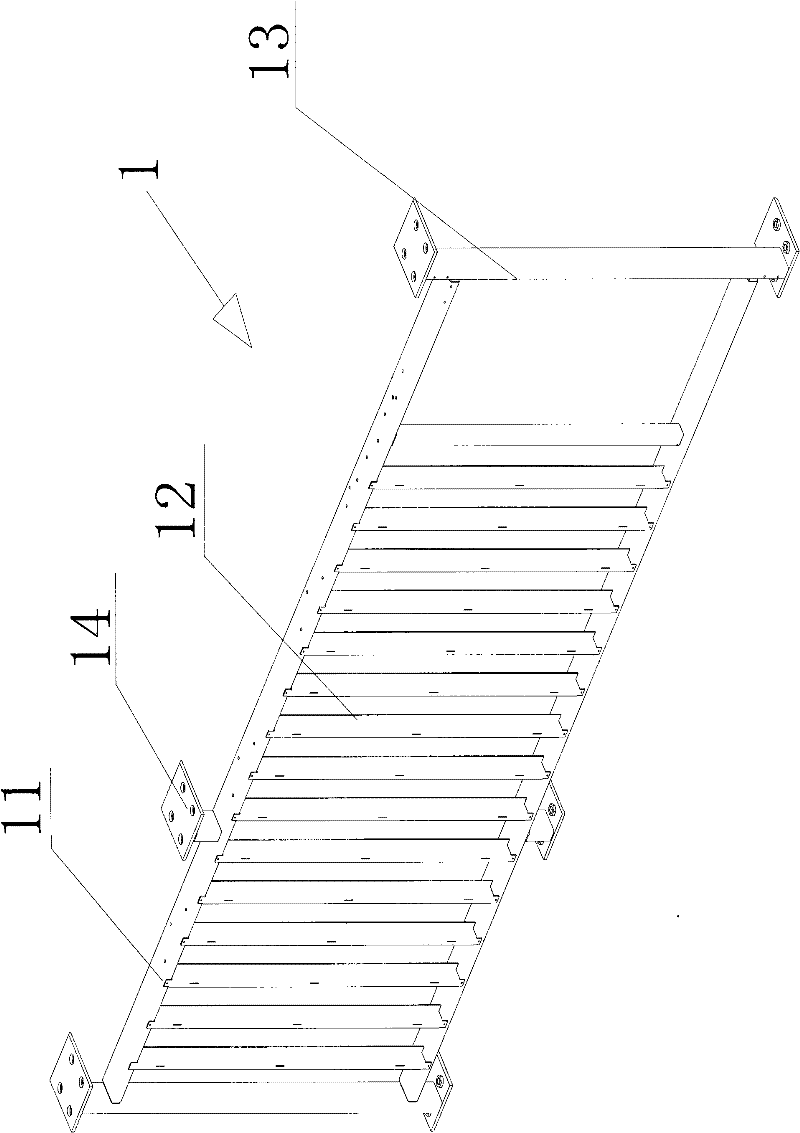

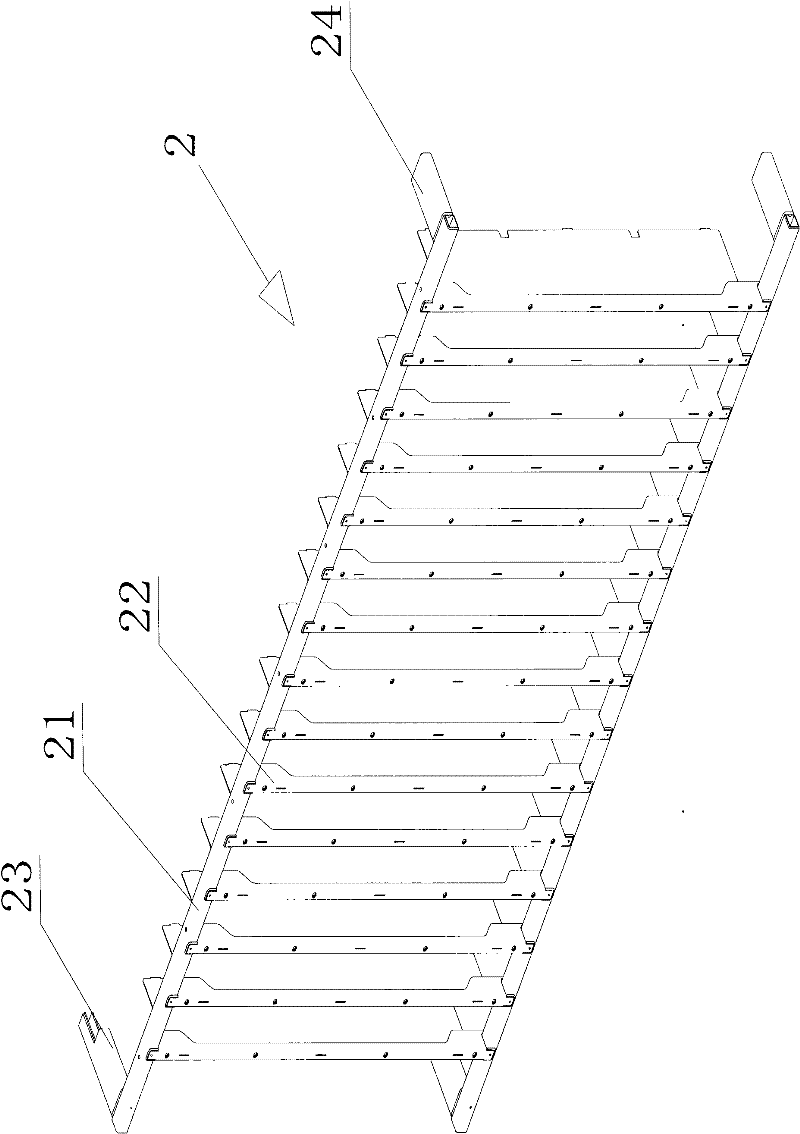

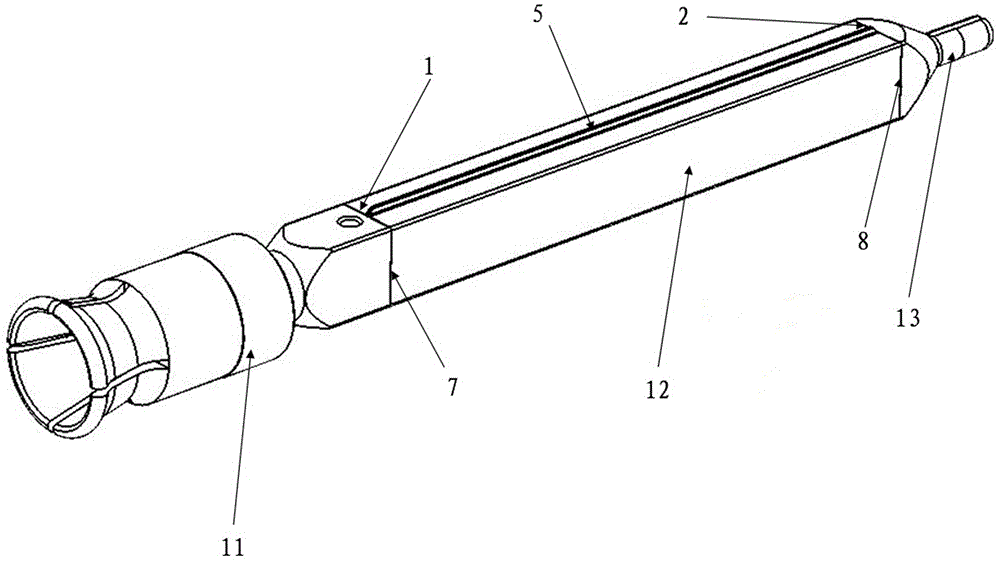

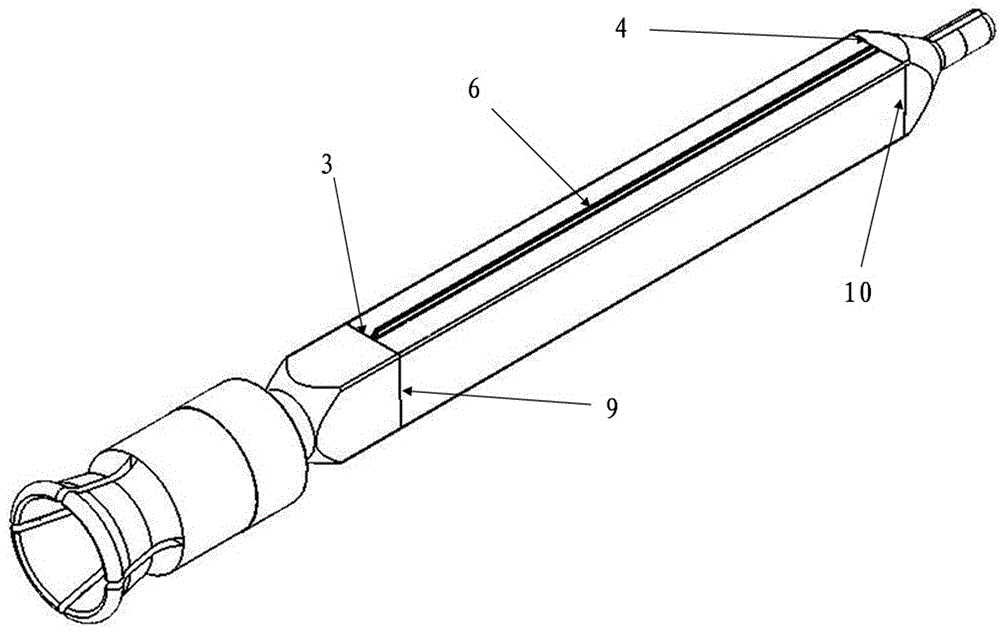

Method for assembling pedestal body of overhead cell support of hybrid vehicle and clamp thereof

ActiveCN101618493AReduce physical laborImprove assembly and welding efficiencyWelding/cutting auxillary devicesAssembly machinesInstabilityThermal deformation

The invention discloses a method for assembling a pedestal body of an overhead cell support of a hybrid vehicle and a used welding frock clamp thereof. The welding tool clamp comprises a clamp body (1), and the pedestal body of the overhead cell support of the hybrid vehicle comprises two pedestal crossbeams (11) and a plurality of middle supporting plates (12); the clamp is characterized in that a positioning element (2) is fixedly arranged at the upper end of the clamp body and horizontally limits the positions of the pedestal crossbeams (11), and a clamping device (3) is arranged at the outer sides of the pedestal crossbeams (11) and clamps the two pedestal crossbeams (11) and the middle supporting plates (12) arranged between the two pedestal crossbeams. The clamp greatly lightens the physical work of the operating staff, improves the assembling and welding efficiency, controls or eliminates the thermal deformation of workpieces caused by welding, and reduces the instability of manual welding.

Owner:苏州宝馨智能制造有限公司

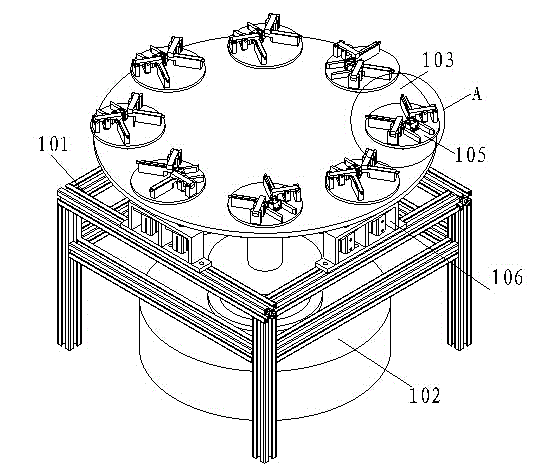

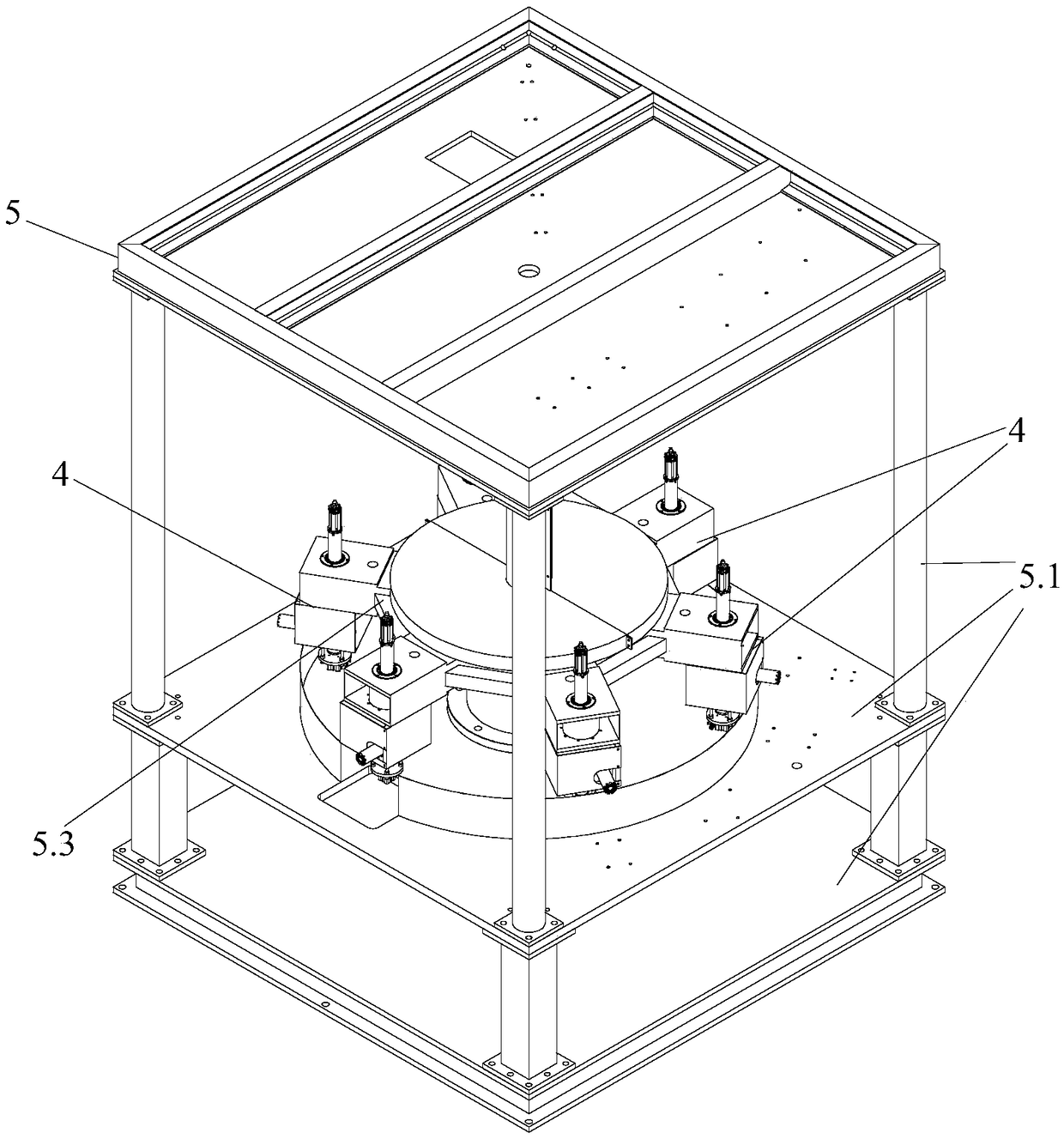

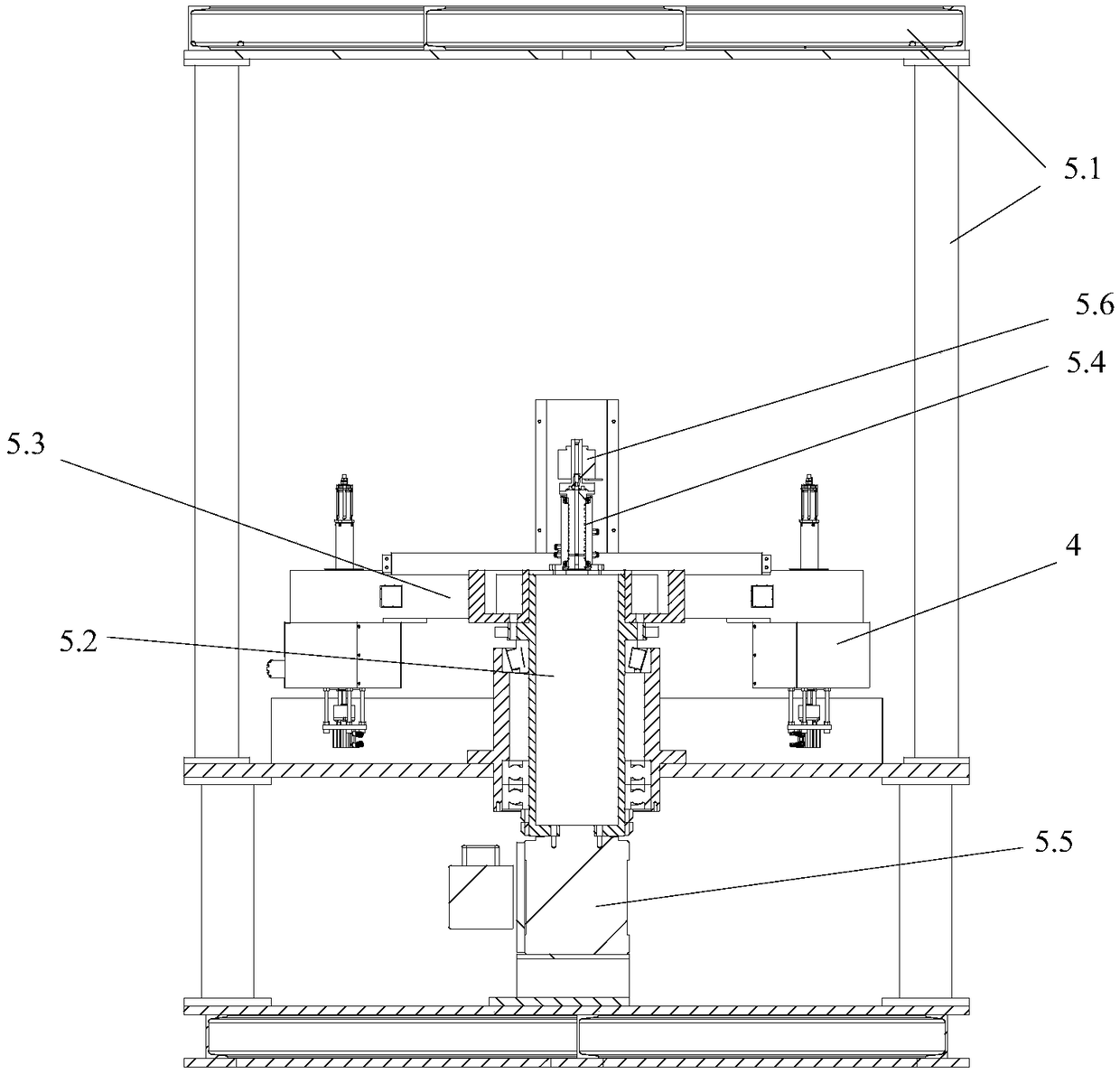

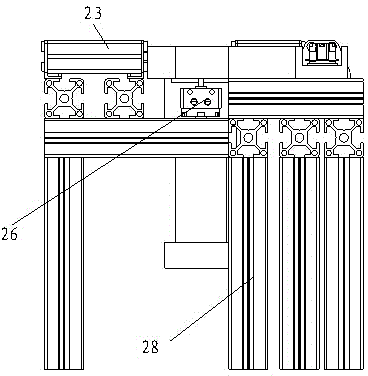

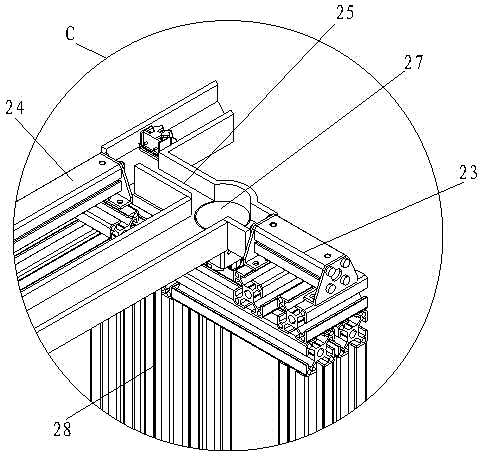

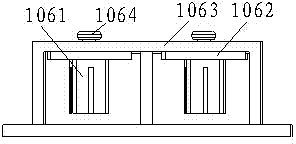

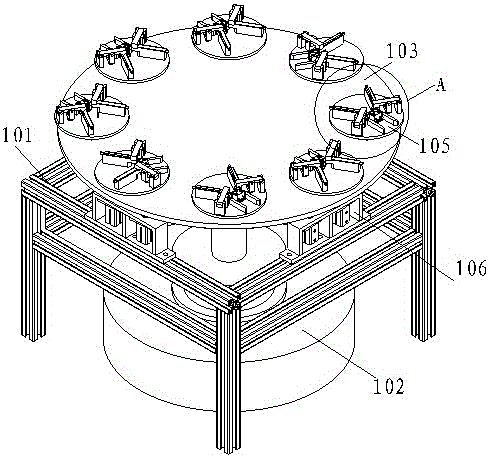

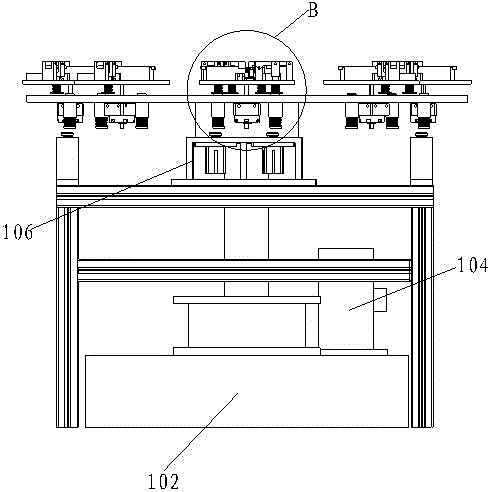

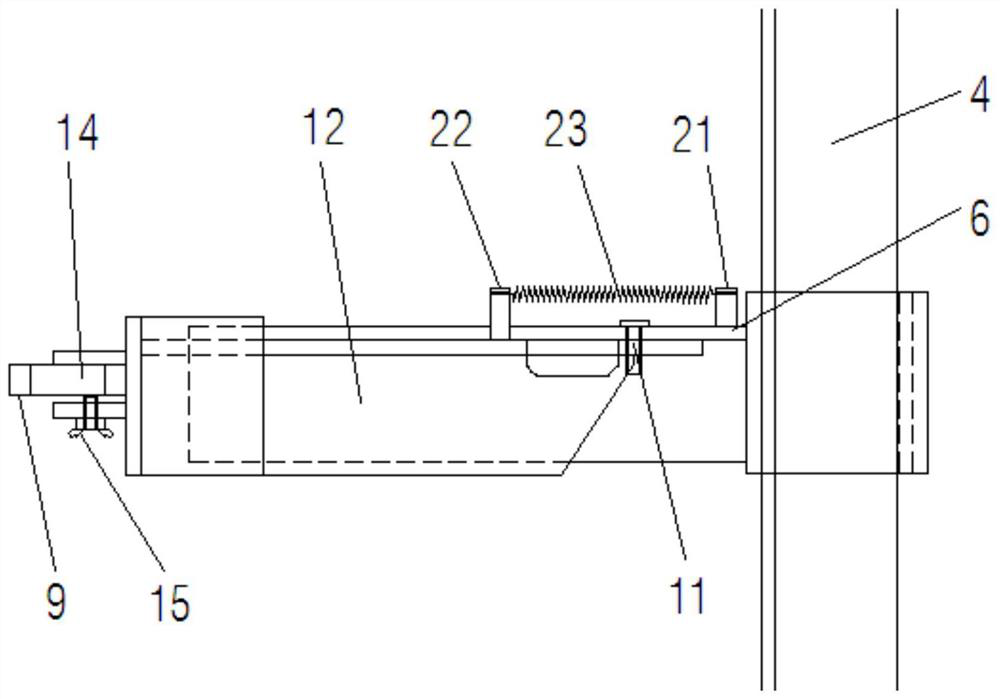

Eight-station welding table of plug welding machine

ActiveCN104668866AImprove assembly and welding efficiencyGood production stabilityWelding/cutting auxillary devicesAuxillary welding devicesMechanical indexElectricity

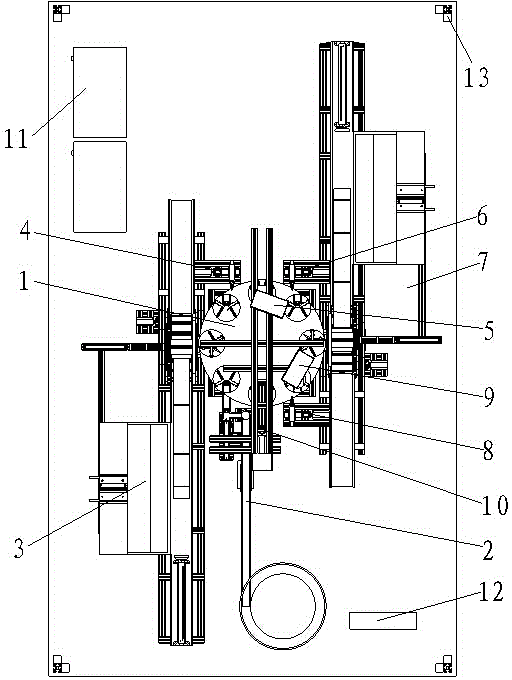

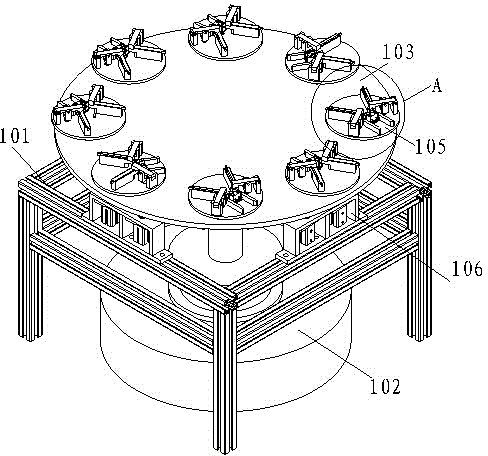

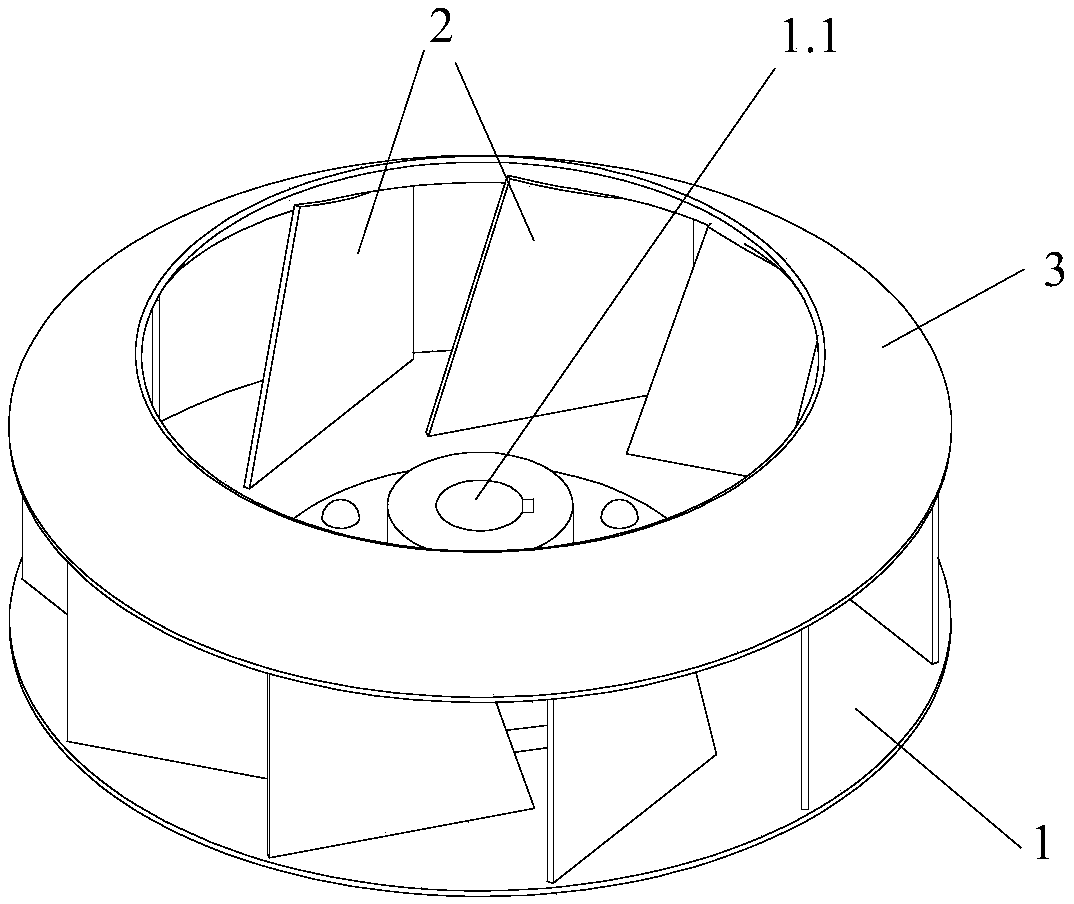

The invention discloses an eight-station welding table of a plug welding machine. The eight-station welding table of the plug welding machine comprises an aluminium alloy welding rack, a floor type mechanical index plate, a working turntable, an index plate rotating motor, a plurality of welding clamps and a plurality of line clamping and driving devices; the floor type mechanical index plate is arranged in the middle of the aluminium alloy welding rack; the index plate rotating motor is arranged on the input of the floor type mechanical index plate; the working turntable is arranged on the upper end of the floor type mechanical index plate; eight welding clamps distributed annularly are arranged on the upper plane of the working turntable; four line clamping and driving devices are arranged on the lower plane of the working turntable; and all the line clamping and driving devices are fixed on the aluminium alloy welding rack. By utilizing the above manner, the assembling welding efficiency is high, the production stability is attractive, the product rejection rate is low, and the total production efficiency is high.

Owner:南通东晨重型机床有限公司

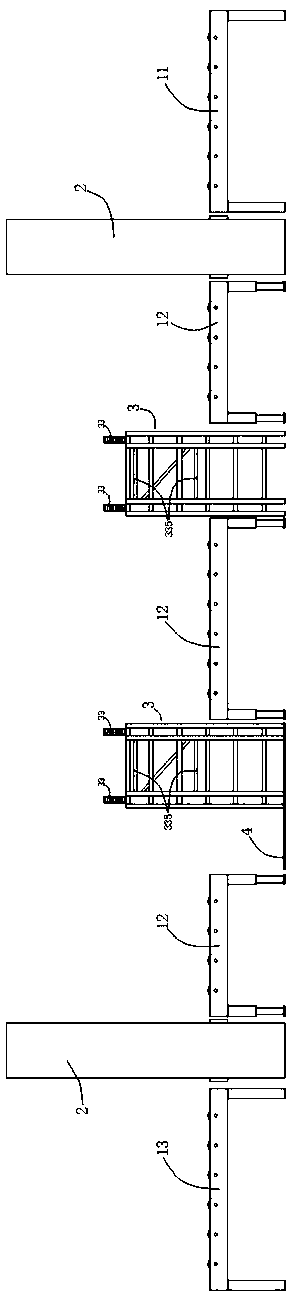

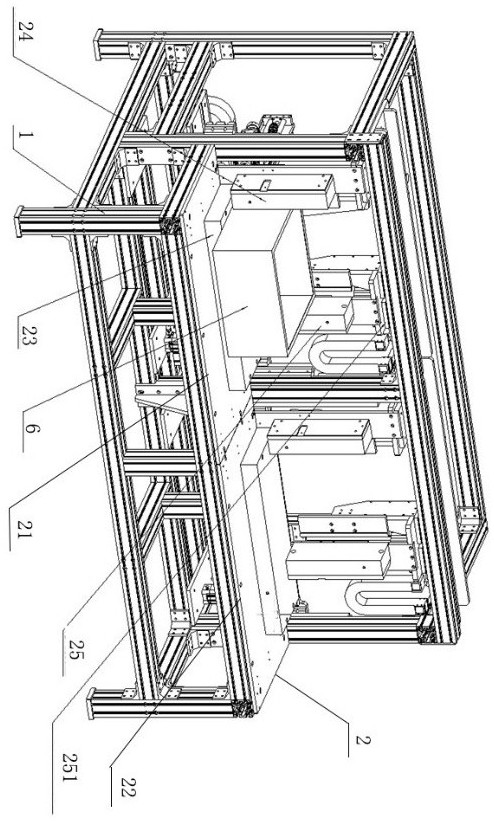

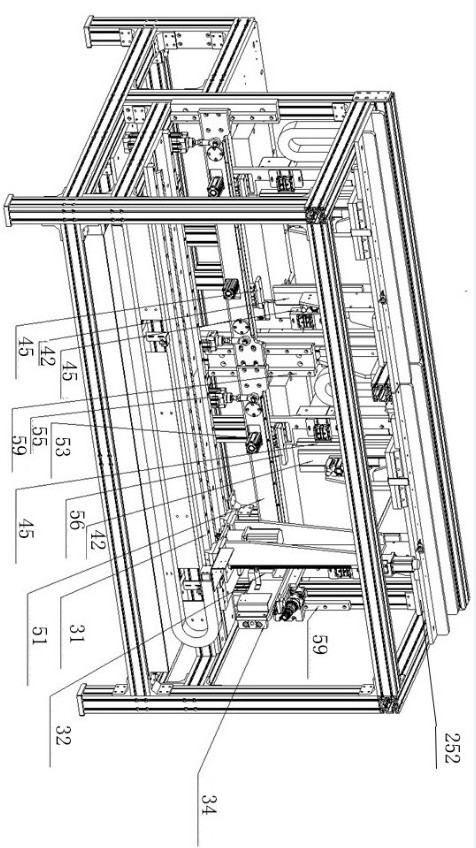

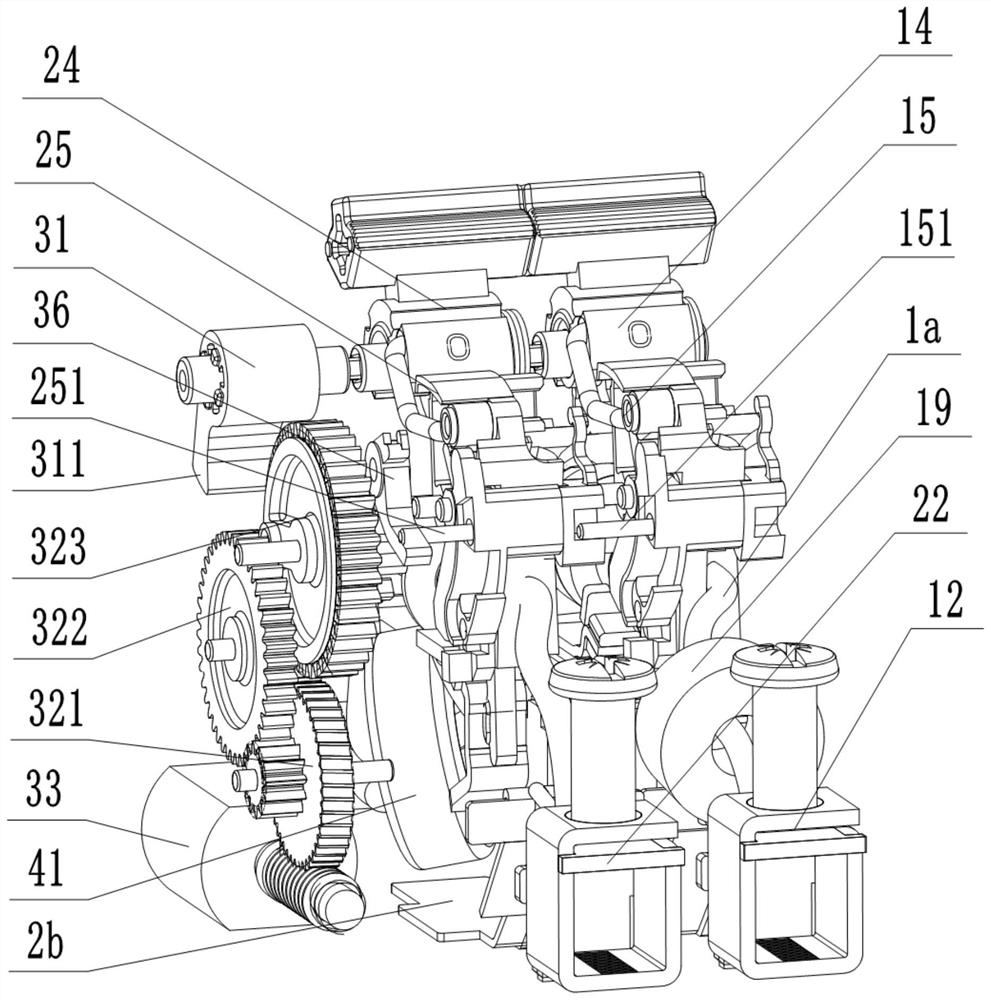

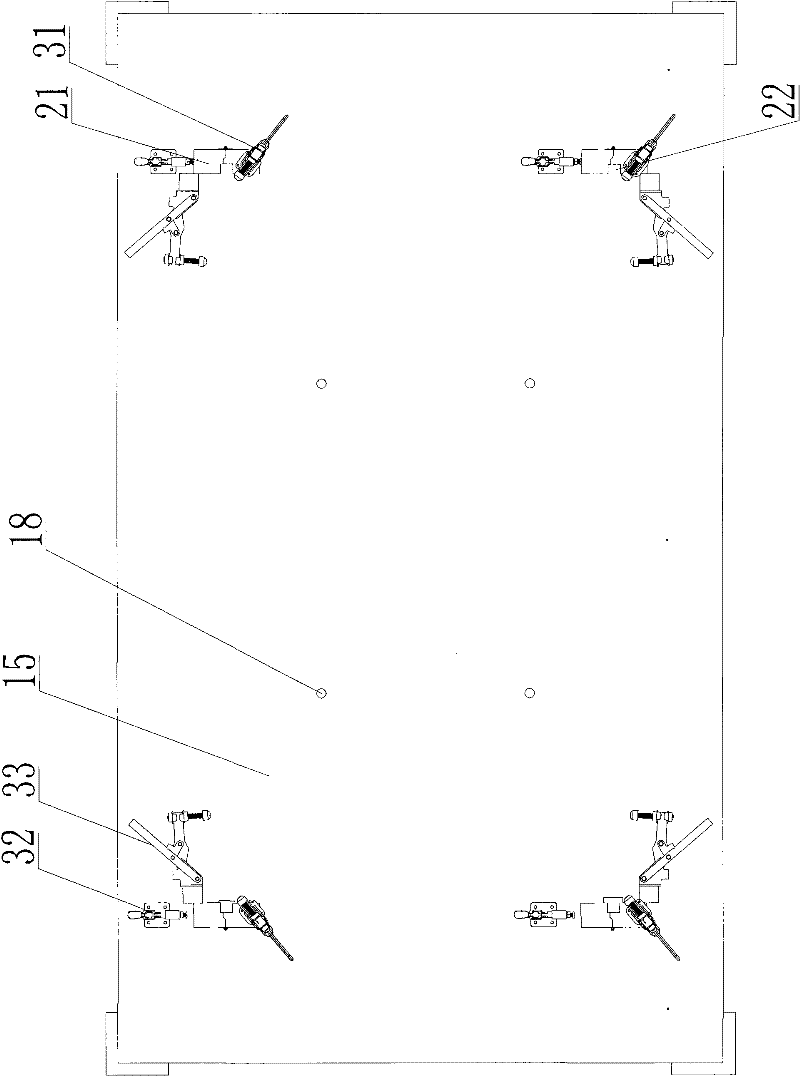

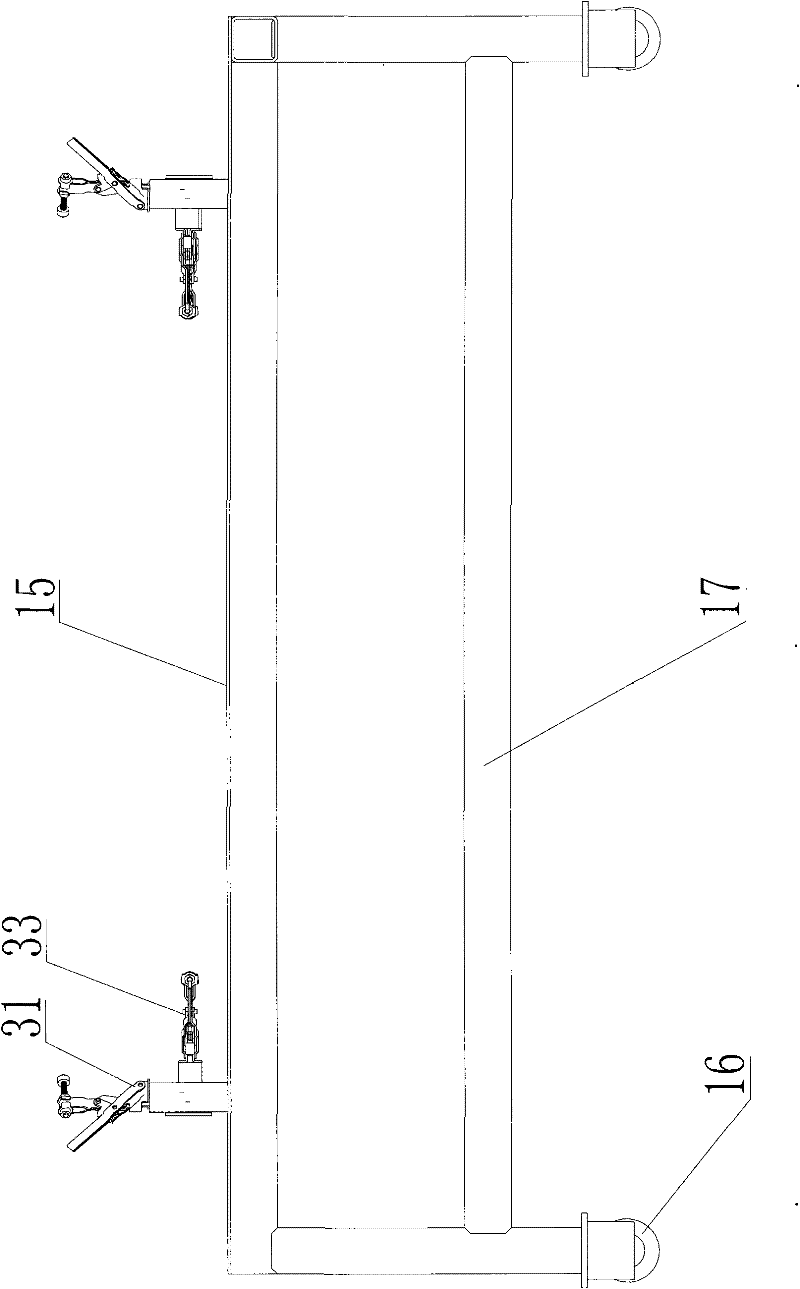

Plug welding machine

ActiveCN104668802AImprove assembly and welding efficiencyImprove production stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectricityGrating

The invention discloses a plug welding machine. The plug welding machine comprises an eight-station welding table, a body feeding mechanism, a first weld line feeding mechanism, a first servo welding mechanism, a first image detecting device, a servo repairing welding mechanism, a second weld line feeding mechanism, a second servo welding mechanism, a second image detecting device, a finished product discharge mechanism, an electric cabinet, a human-machine controller and a regional security grating which are all arranged on a factory floor; the body feeding mechanism, the first weld line feeding mechanism, the first servo welding mechanism, the first image detecting device, the servo repairing welding mechanism, the second weld line feeding mechanism, the second servo welding mechanism and the finished product discharge mechanism are distributed sequentially on each station of the eight-station welding table; the second image detecting device and the second servo welding mechanism are arranged on the same station of the eight-station welding table. By utilizing the above manner, the assembling welding efficiency is high, the production stability is attractive, the product rejection rate is low, and the total production efficiency is high.

Owner:安徽鹏洋传动科技有限公司

Assembling installing method for express cabinet

ActiveCN104384785AHigh welding technology requirementsLabor intensiveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses an assembling installing method for an express cabinet. According to the method, firstly, express cabinet plates are integrally assembled and spliced together, and then, connecting parts between the plates are welded. The assembling installing method has the advantages that the production and installing mode has low requirements on the welding skill of workers, the work intensity of the workers is reduced, the assembling and welding efficiency is improved under the condition of ensuring the assembling and welding precision, and further, the production efficiency of the finished product of the express cabinet is improved.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

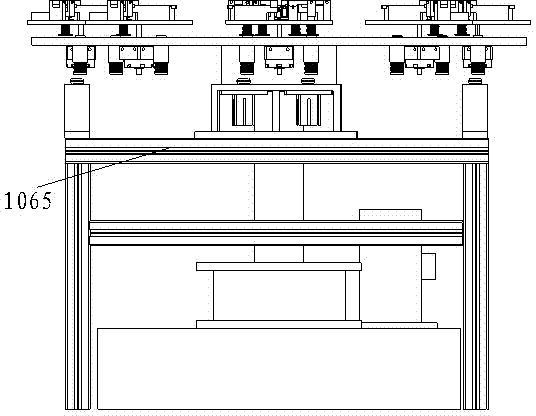

Multi-station full-automatic welding equipment for fan impeller machining

PendingCN109262189ASolve efficiency problemsImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesImpellerWork in process

The invention provides multi-station full-automatic welding equipment for fan impeller machining. The multi-station full-automatic welding equipment comprises chassis positioning mechanisms, a main frame mechanism, a blade and chassis assembling positioning mechanism located at a second machining station, a first welding mechanism used for welding blades and a chassis at a second machining station, a top cover feeding mechanism located at a third machining station, a second welding mechanism used for conducting spot welding on top covers and the blades on the third machining station, a turningmechanism located on a fifth machining station, a third welding mechanism used for conducting all welding on the turned top cover welding semi-finished products and turned blade welding semi-finishedproducts on the fifth machining station, so that a fan impeller finished product is obtained and a discharging mechanism. The chassis positioning mechanisms are separately connected with the main frame mechanism. According to production demands, full-automatic welding can be conducted on the fan impeller to replace a traditional manual welding technology, and therefore welding efficiency, weldingquality and welding precision are improved.

Owner:FOSHAN GOOGOL AUTOMATION TECH

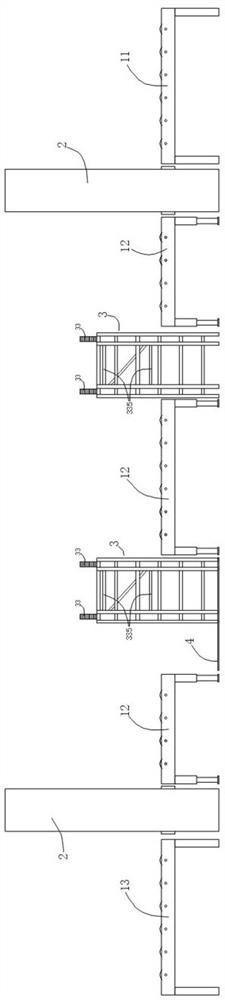

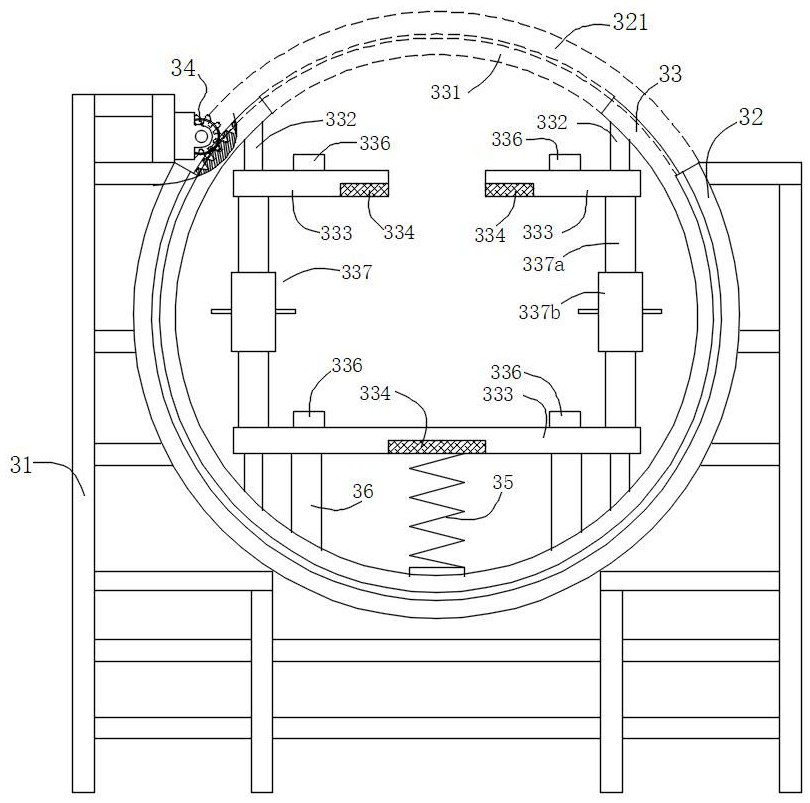

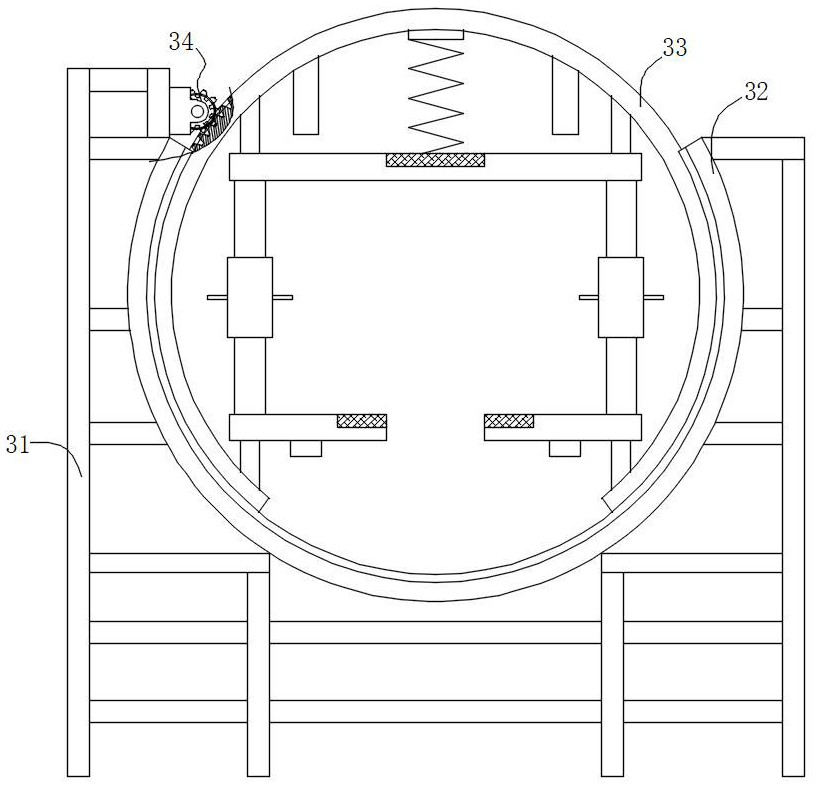

Production system for welding H-shaped steel

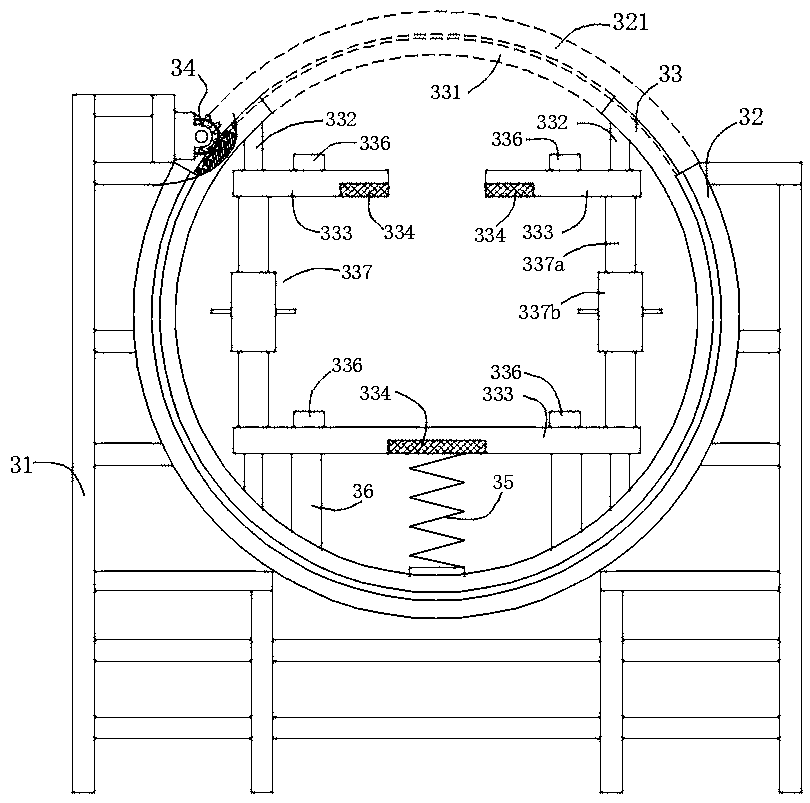

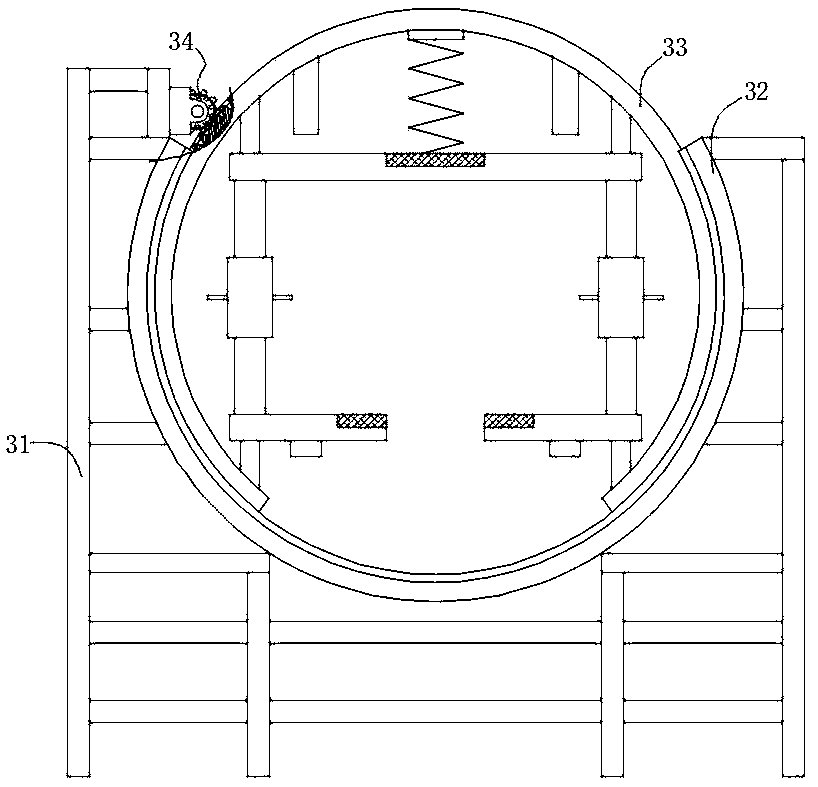

ActiveCN111515590AReasonable structural designEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesAssembly machineFlange

The invention discloses a production system for welding H-shaped steel. The production system comprises a roll gang and assembly machines, and further comprises turnover devices which are arranged onthe output side of the assembly machines in a linked manner. Each turnover device comprises a turnover support, wherein two turnover tracks which are in a circular ring shape as a whole and a rollingframe are arranged on the turnover support, a first notch is horizontally formed above the turnover tracks, a second notch is formed in the rolling frame, two sides of the second notch are each provided with a supporting rod perpendicular to the plane where the second notch is located, two ends of the supporting rods are connected to the inner side of the rolling frame and provided with bearing parts perpendicularly arranged inwards, the distance between the bearing parts at the two ends is equal to the width of a web, electromagnets for fixing flanges are installed on the bearing parts, and aturnover driving mechanism for driving the rolling frame to rotate around the turnover tracks is installed on the turnover support. The production system has the advantages of being reasonable in structural design, simple in operation process, beneficial to reducing the labor intensity and improving the assembly welding efficiency, and the like.

Owner:重庆本浩建设工程有限公司

Technology used for assembling and welding irradiating supervision pipe

The invention discloses a technology used for assembling and welding an irradiating supervision pipe. The technology comprises the steps that a, a weld part is prepared and cleaned in an acetone or alcohol solution for 30 min or more ultrasonically; b, assembling is carried out; c, end weld joints of the plane where the truncated edge of one semi-groove shell is located are welded, and then end weld joints of the plane where the truncated edge of the other semi-groove shell is located are welded; d, the long and straight weld joints on the two semi-groove shells are welded, wherein the two weld joints are symmetrically welded at a time in a full-length mode to form the long and straight weld joints; e, end weld joints of two rest side faces of the irradiating supervision pipe are welded. Weld deformation in the length direction and internal concave type deformation of the two sides of a pipe body are effectively controlled, and the weld joints of the intersecting parts of the straight joints of the two ends and circular joints due to welding deformation is avoided. Welding is carried out according to the welding sequence from the step c to the step e, weld penetration is controlled between 1.1 mm and 1.5 mm accurately, and the overall length of the irradiating supervision pipe is 1532 mm, and straightness can be controlled within 0.8 mm.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Flexible assembling and welding system for standard parts and non-standard parts and method

ActiveCN112404783AAvoid flawsReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringIndustrial engineering

The invention relates to a flexible assembling and welding system for standard parts and non-standard parts and a method. The flexible assembling and welding system comprises at least one carrying robot used for carrying positioning bodies and workpieces, at least one welding robot used for tailor-welding and / or welding the standard parts and the non-standard parts, and at least one self-locking rotary positioning platform arranged between the carrying robots and the welding robots and used for splicing, fixing, tailor-welding and welding the workpieces. Double-station flexible positioning rotary platforms for positioning the workpieces are arranged on the outer sides of the carrying robots. Positioning fixture repositories suitable for the self-locking rotary positioning platforms and thedouble-station flexible positioning rotary platforms are arranged at the side parts of the self-locking rotary positioning platforms. The flexible assembling and welding system for standard parts andnon-standard parts and the method have the advantages of being wide in welding object range, low in operation labor intensity, high in splicing and welding efficiency, consistent in fusion depth of workpiece products and capable of effectively guaranteeing the later-period assembling process and the servicing quality.

Owner:HENAN WINNER VIBRATING EQUIP

Device for assembling and welding irradiation monitoring pipe

ActiveCN105436764ASolve technical bottlenecksBreak the technology blockadeWelding/cutting auxillary devicesAuxillary welding devicesCooling effectNeck parts

The invention discloses a device for assembling and welding an irradiation monitoring pipe. The device is characterized in that a supporting seat provided with a V-shaped groove is arranged on a base, wherein an annular rolling seat is arranged on the supporting seat; two neck part supporting blocks, which are positioned at two sides of the supporting seat and symmetrically distributed on one straight line, are arranged on the base; a limiting datum block is arranged between the supporting seat and each neck part supporting block. The device further comprises four centering component pieces which wrap the irradiation monitoring pipe, wherein the four centering component pieces wrap the outer side of the irradiation monitoring pipe, and then one end of each centering component piece is fixed into a rolling assembly on the supporting seat while the other end of the each centering component piece is positioned on the corresponding limiting datum block. According to the device, the tool design is high in compatibility, and the assembling process and the welding process of the radiation monitoring pipe can be synchronously carried out; the cooling effect of a weld joint in the process of welding the radiation monitoring pipe can be effectively ensured, so that the weld joint can be prevented from collapsing; the linearity and coaxiality of the whole radiation monitoring pipe can be effectively ensured; the device can be overturned in 360 degrees, so that the welding efficiency can be effectively improved; the device is convenient to dismount.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

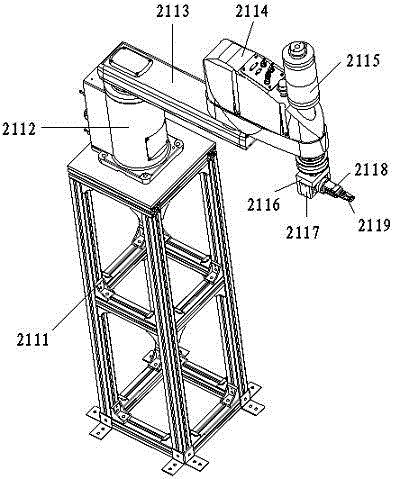

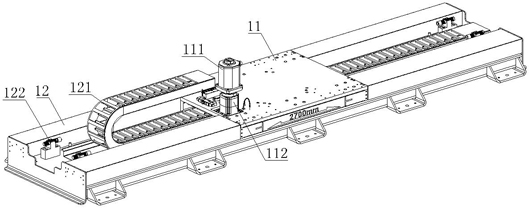

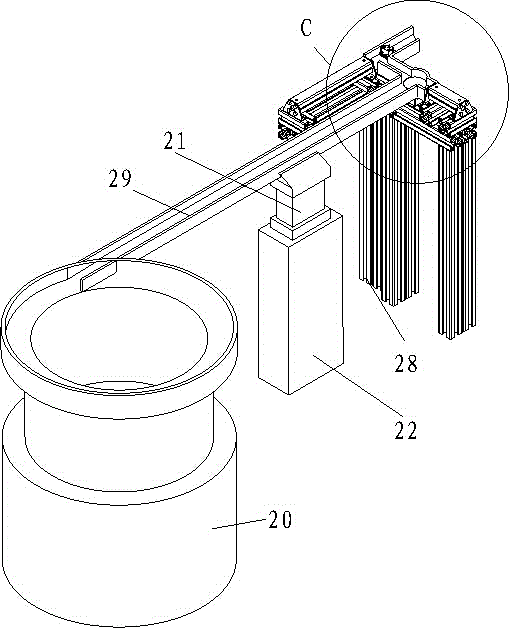

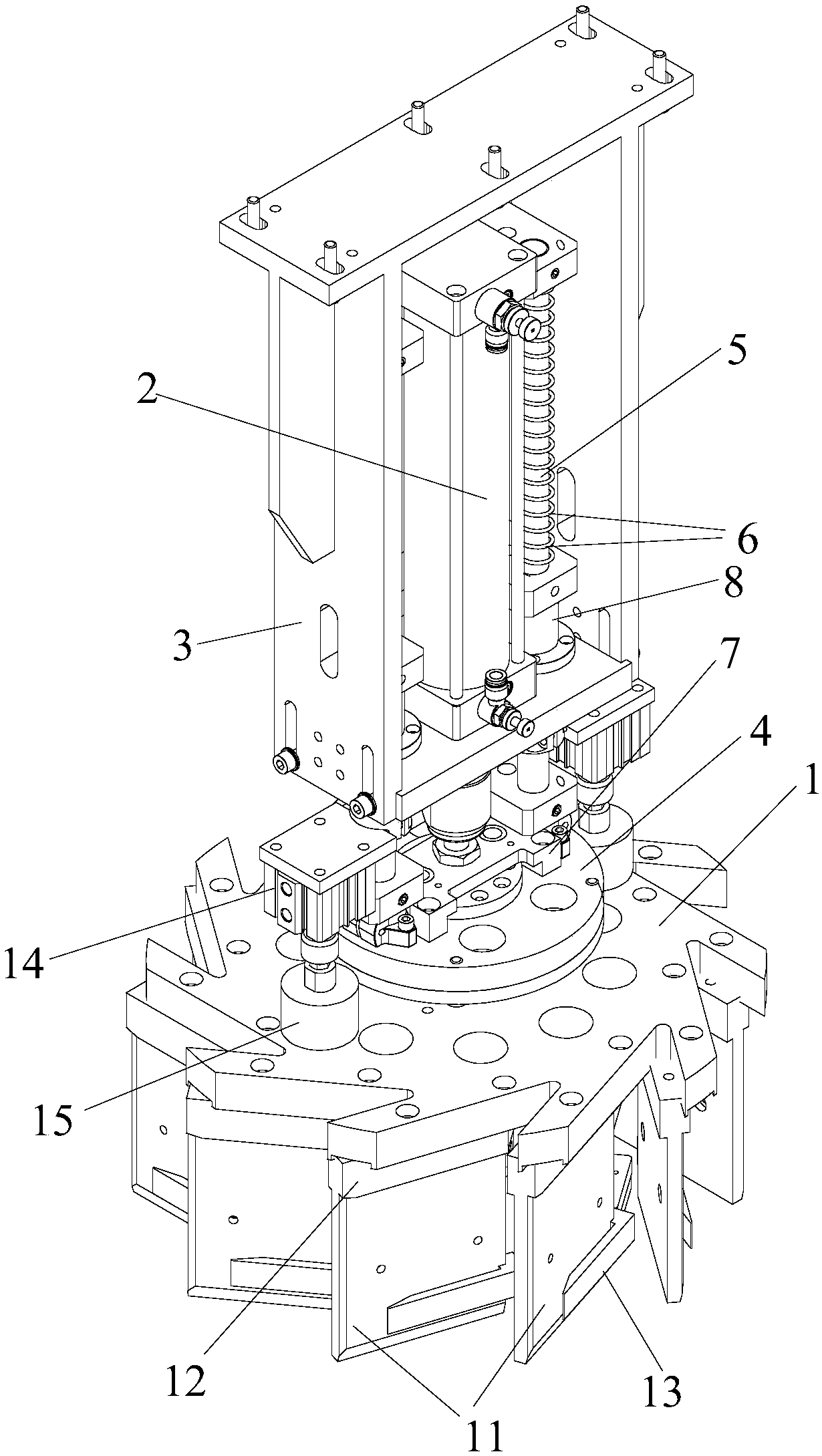

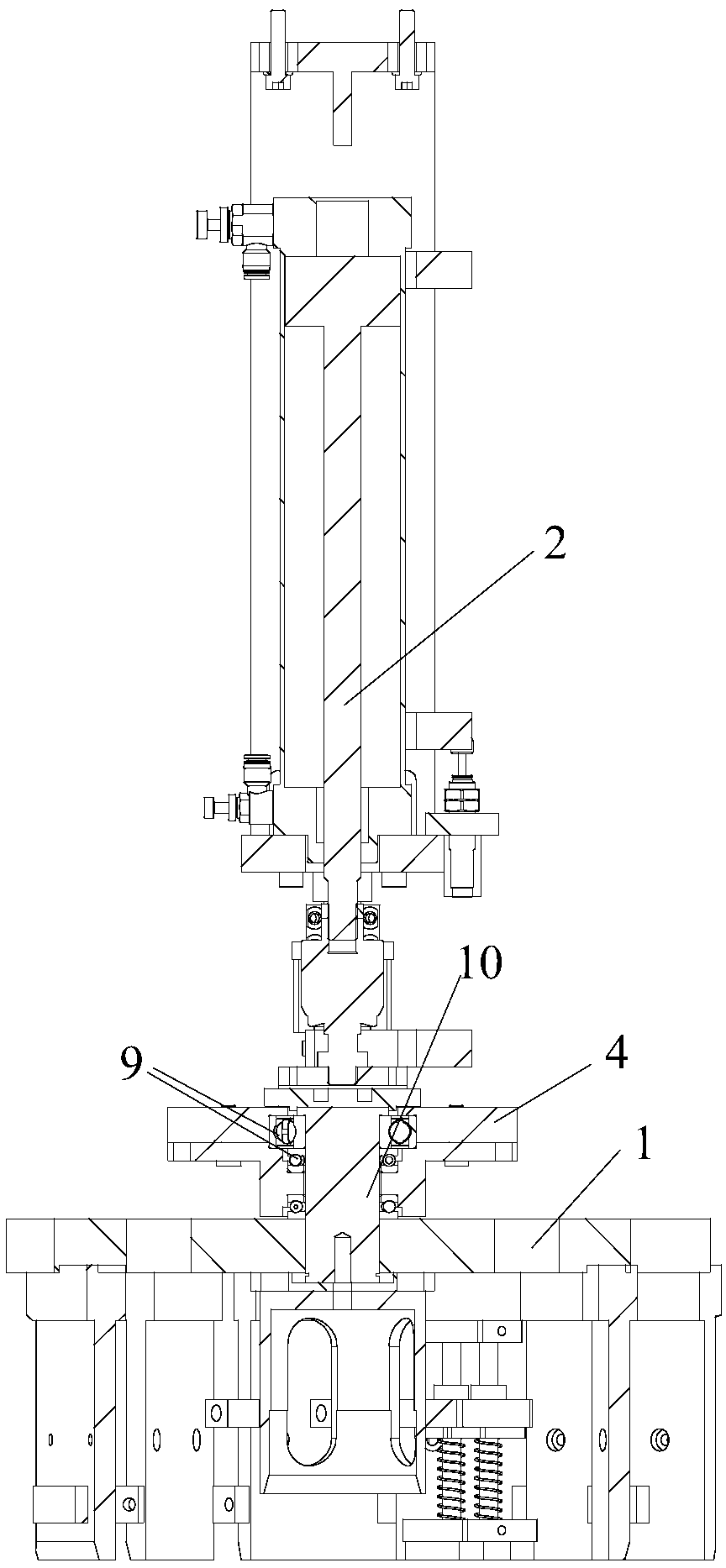

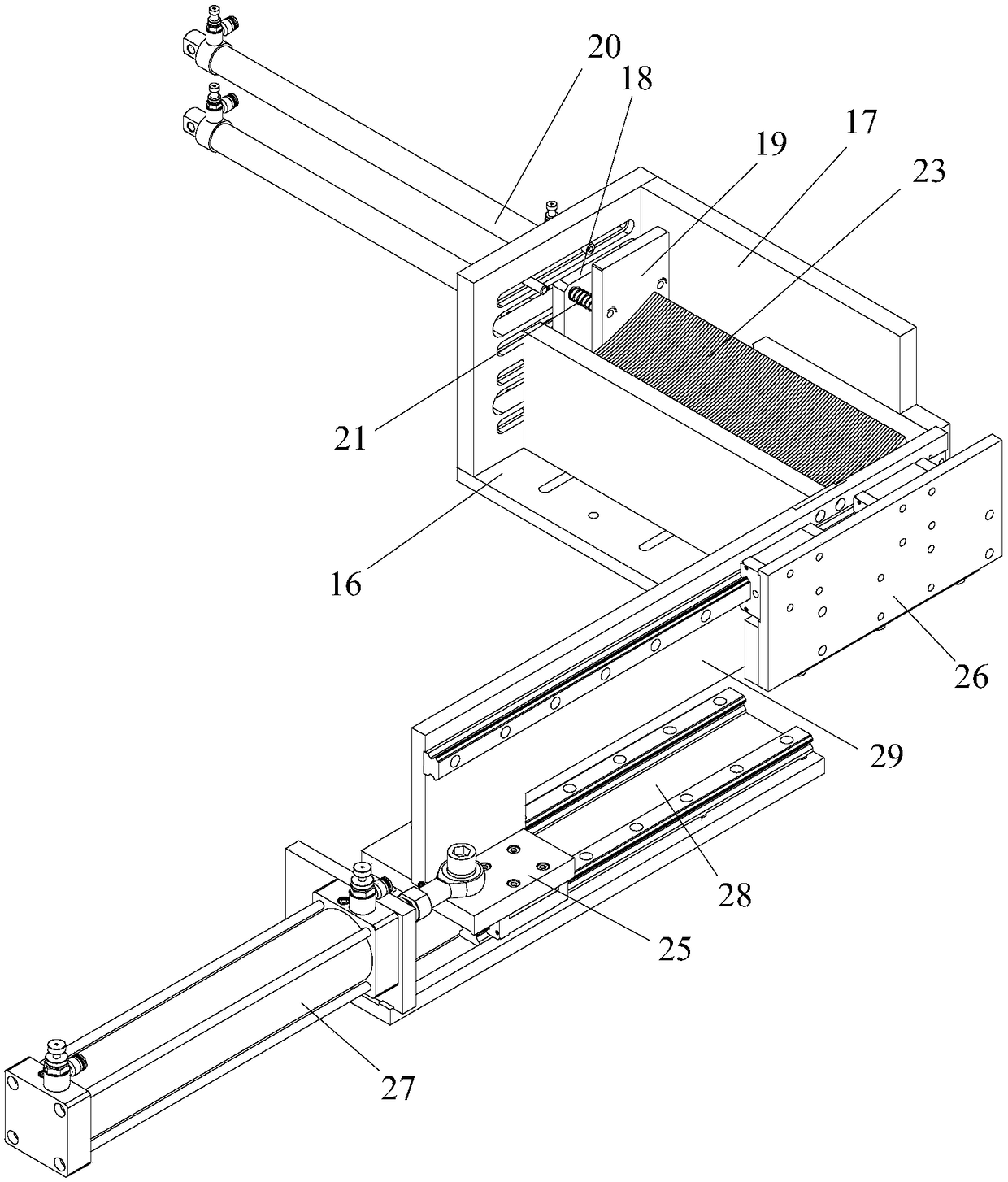

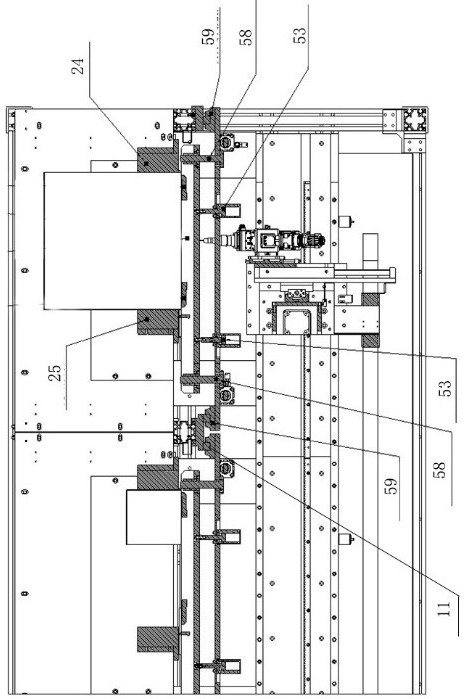

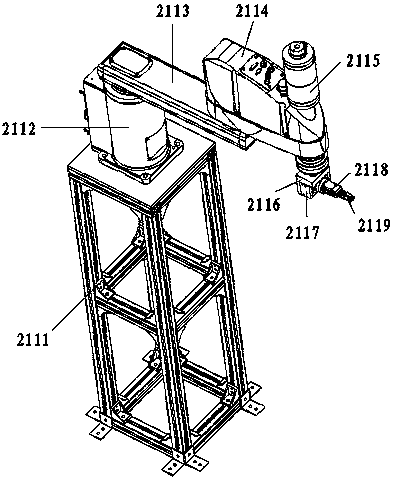

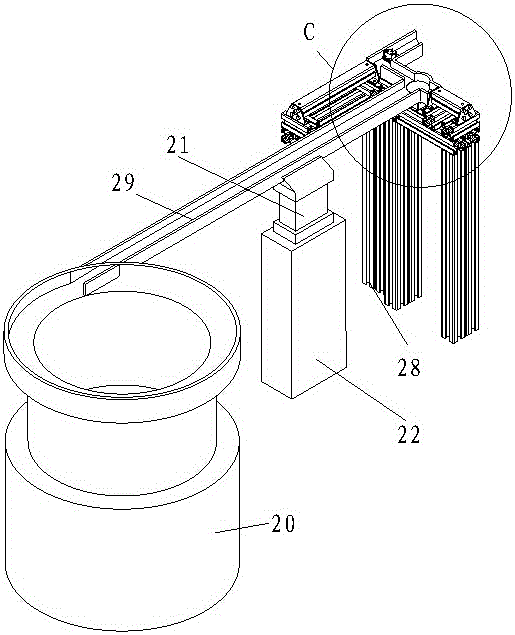

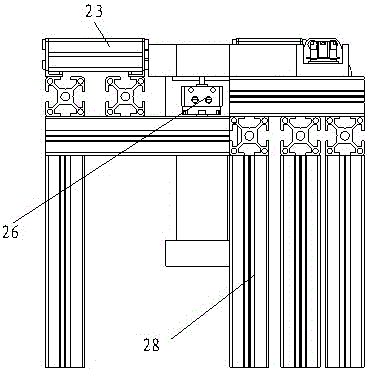

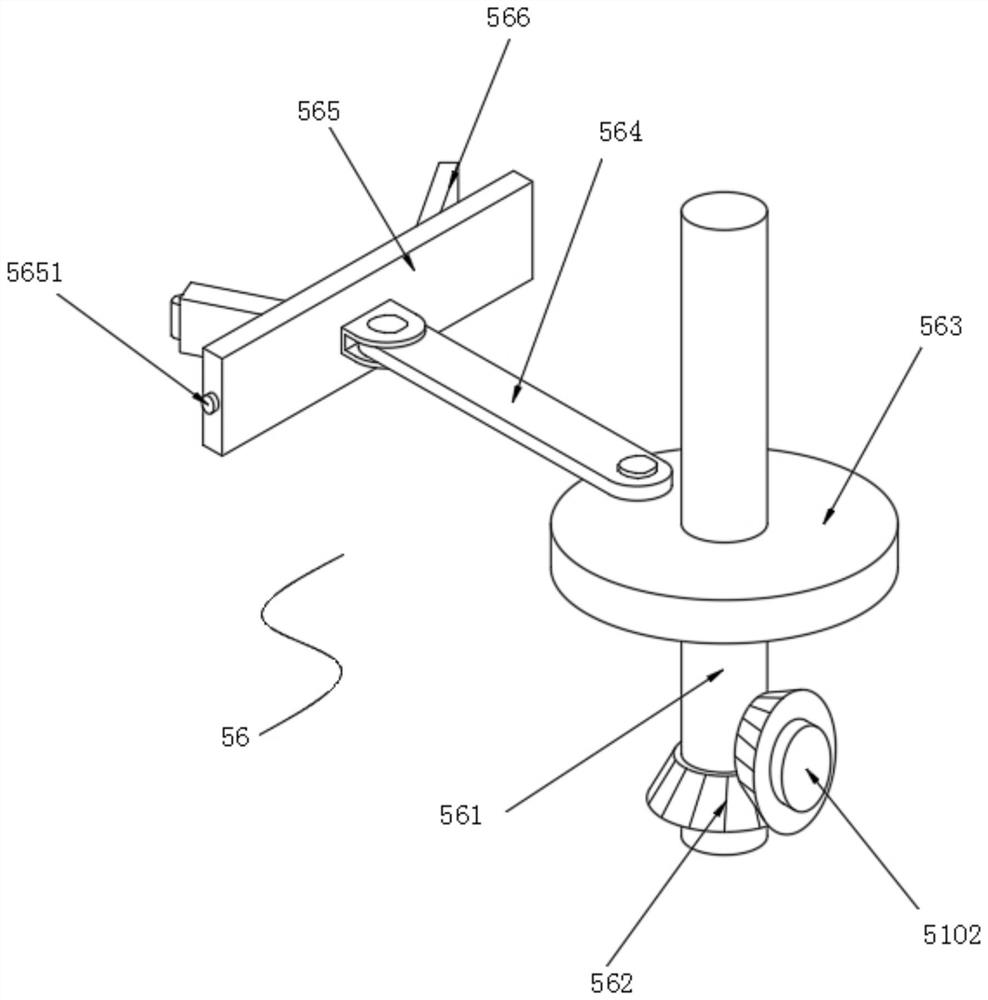

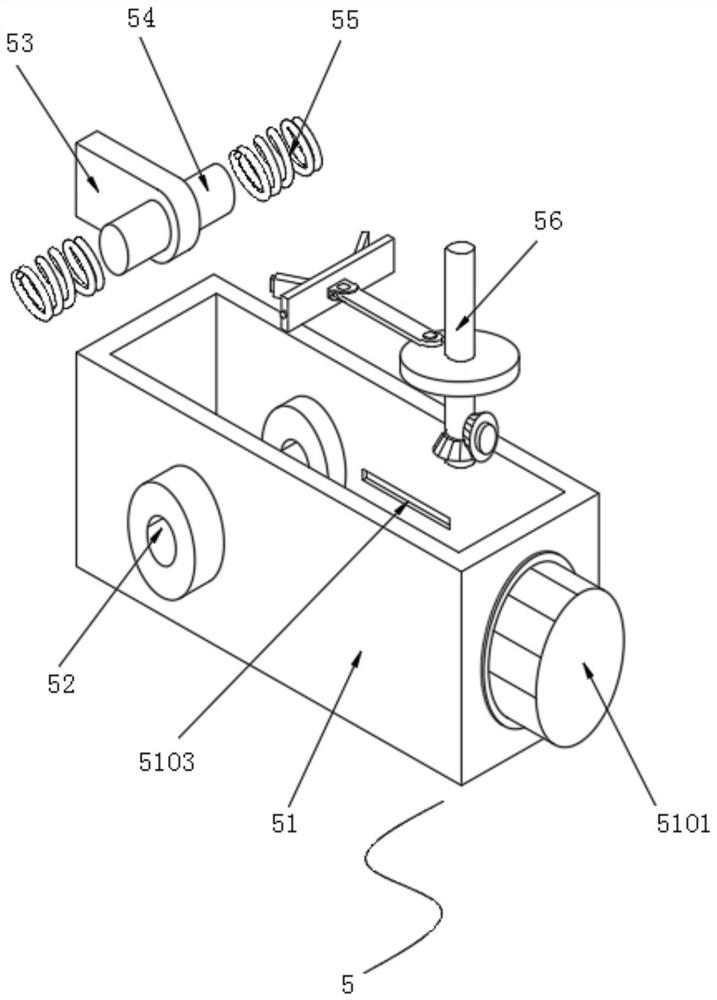

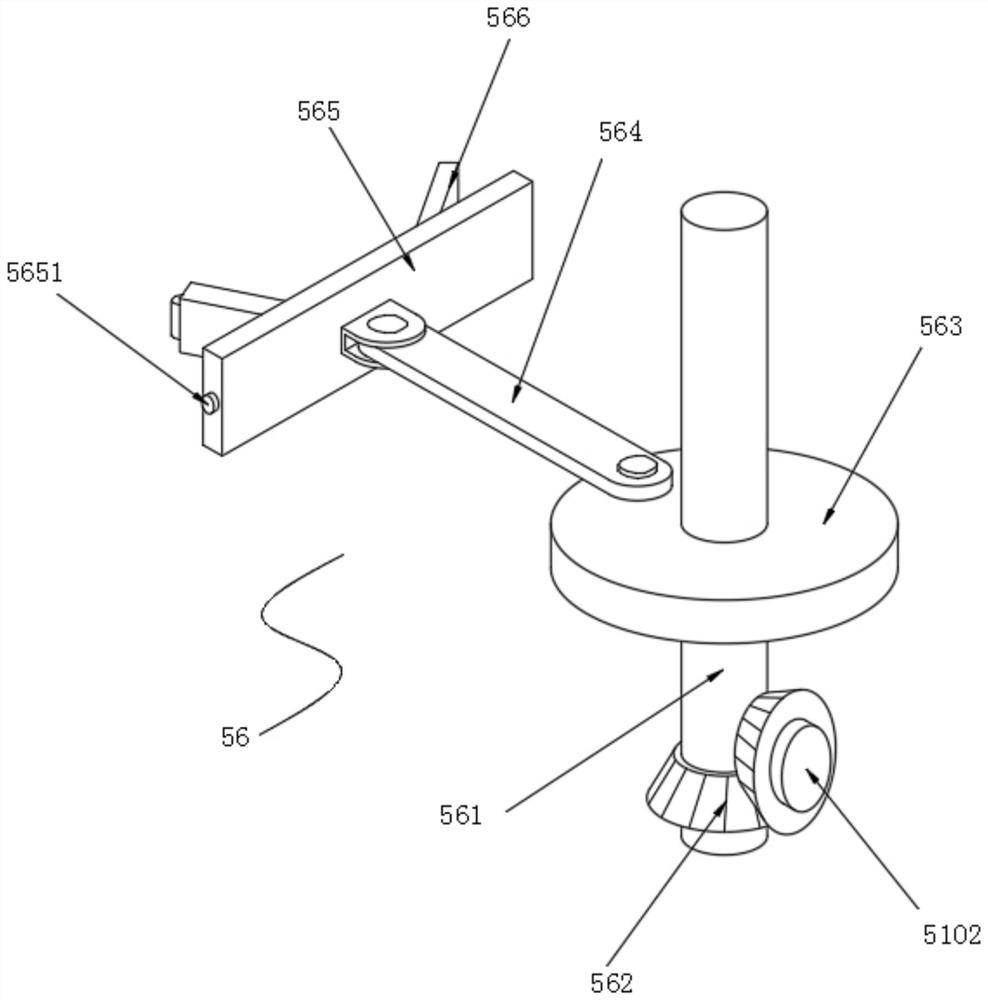

Body feeding mechanism of plug welding machine

ActiveCN104668843AImprove assembly and welding efficiencyImprove production stabilityWelding/cutting auxillary devicesAuxillary welding devicesRotary stageFactory floor

The invention discloses a body feeding mechanism of a plug welding machine. The body feeding mechanism of the plug welding machine comprises a vibrating plate and a linear vibrating feeder seat both of which are fixed on a factory floor; a linear vibrating feeder is arranged on the linear vibrating feeder seat; one end of a feeding tank of the linear vibrating feeder is connected with the vibrating plate, and the other end of the feeding tank of the linear vibrating feeder is connected with one end of an L-shaped intake chute; the end, arranged against the linear vibrating feeder, of the L-shaped intake chute is provided with a first body material pushing cylinder; the part, arranged against the first body material pushing cylinder, of the L-shaped intake chute is provided with a rotating table; the rotating table is arranged on a rotating transposition cylinder; the upper plane of the rotating table and the inner bottom of the L-shaped intake chute are arranged on the same plane; and a second body material pushing cylinder is arranged on the corner of the L-shaped intake chute. By utilizing the above manner, the assembling welding efficiency is high, the production stability is high, the product rejection rate is low, and the total production efficiency is high.

Owner:威海高新园区运营管理有限公司

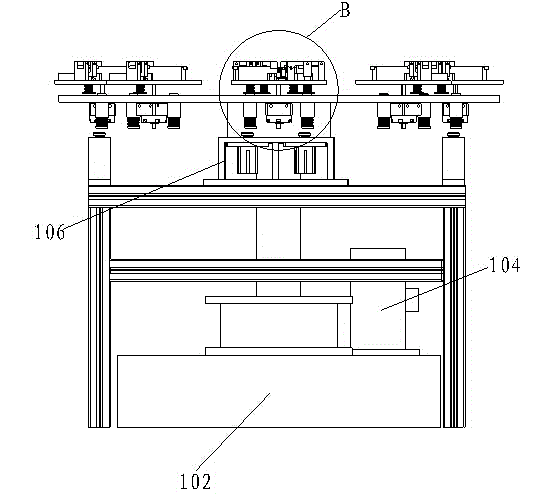

Assembling positioning mechanism and method of draught fan impeller blades and draught fan impeller chassis

ActiveCN109262181AEnsure positioning consistencyImprove assembly and welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesImpellerEngineering

The invention provides an assembling positioning mechanism and method of draught fan impeller blades and a draught fan impeller chassis. The assembling positioning mechanism comprises a pressing positioning device and a blade pushing device; the pressing positioning device is used for pressing, holding and positioning the chassis, making the chassis rotate, and correcting the blades and positioning the blades on the chassis, the blade pushing device is used for arraying the blades and pushing the blades to an output working station, and pushing the blades on the output working station to the pressing positioning device piece by piece; the pressing positioning device is located above a chassis positioning working station and comprises a fixed mould and a pressing holding part, wherein the fixed mould is used for correcting and positioning the blades, and the pressing holding part is used for pressing the fixed mould on the chassis; the fixed mould and the pressing holding part are connected and located above the chassis positioning working station, the fixed mould is evenly provided with welding working stations of the blades and the chassis, and the number of the welding working stations is equal to that of the blades; the output working stations correspond to the welding working stations one to one. By the adoption of the assembling positioning mechanism and method of the draught fan impeller blades and the draught fan impeller chassis, not only can the assembling welding efficiency of the blades and the chassis be improved, but also the positioning uniformity of each blade and the chassis can be guaranteed, and thus the welding precision and quality of the blades and the chassis are improved.

Owner:FOSHAN GOOGOL AUTOMATION TECH

A semi-automatic liner-free penetration welding process for steel box columns

ActiveCN106493459BImprove assembly accuracyElimination of manual steel backing processWelding/cutting auxillary devicesArc welding apparatusSemi automaticStructural engineering

The invention relates to the field of welding technologies, in particular to a semi-automatic gasket-free penetration welding technology for a steel box column. The steel box column is of a frame-shaped structure formed by welding two webs and two wing plates in a mutually perpendicular mode. The welding technology of the frame-shaped structure at least comprises the steps of groove preparing before welding, wherein two groove surfaces A are symmetrically prepared at the ends of the two sides of each web, two groove surfaces B are symmetrically prepared at the ends of the two sides of each wing plate, and V-shaped grooves are formed through the groove surfaces A and the groove surfaces B; assembling before welding, wherein the steel box column is assembled by sequentially adopting the processes of web installing, process partition plate partitioning, wing plate installing, tool membrane platform fixture clamping and web covering; main welding seam welding, wherein preparation of the steel box column is completed by mainly adopting bottoming, channel filling and cover surface welding in sequence. Compared with a traditional technology, the assembly precision is improved, and the one-time ultrasonic flaw detection qualified rate is increased; meanwhile, due to the fact that parameterized welding is adopted by a welding trolley, the welding stability is improved, and the technology has a good application value.

Owner:HUBEI XINSUO CONSTR

A sheet metal box laser welding machine

ActiveCN111185669BGuaranteed accuracyHigh beam qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A sheet metal box laser welding machine, including a frame, the frame is equipped with an operating platform and a sheet metal positioning device for pressing the box cover to ensure the accuracy of the assembly and positioning of the sheet metal box cover at the rear of the operating platform The device and the welding mechanism reduce the pre-point time, greatly save the time for clamping and waiting, improve the welding efficiency, and reduce the cost. The customized suction cup is used to fix the workpiece to ensure the flatness, perpendicularity and parallelism of each surface. The suction cups are arranged on the bottom and both sides, which not only play a positioning role, but also can fix the workpiece; the suction cups on both sides, one side is fixed installation, and the other side is movable installation, so that it can be arbitrary within the designed size range according to the size of the sheet metal box. The size of the opening is adjusted, and the left, right and bottom sheet metal positioning devices are designed to ensure the accuracy of the assembly and positioning of the sheet metal box cover, thereby reducing the cost of manpower and material resources.

Owner:ZHEJIANG JIATAI LASER SCI & TECH CO LTD

Electric heating rod assembly machine

ActiveCN105855897BImprove assembly and welding efficiencyImprove production stabilityAssembly machinesOther manufacturing equipments/toolsElectricityGrating

The invention discloses an electric heating rod assembly machine. The electric heating rod assembly machine comprises an electric control box, a rotary assembly mechanism, a chain assembly line, a coating mechanism, a drying mechanism, an indicator lamp tower and area safety gratings, wherein the indicator lamp tower is mounted on the top plate of the electric control box; the front side of the electric control box is provided with the rotary assembly mechanism; the rotary assembly mechanism is used for conveying a workpiece assembled for a first time to the chain assembly line at the rear side of the rotary assembly mechanism; the chain assembly line is used for conveying a wokpiece assembled for a second time to the coating mechanism at the front right side of the chain assembly line; the coating mechanism is used for conveying an assembled electric heating rod to the drying mechanism at the front side of the coating mechanism; and the area safety gratings are arranged around in a rectangular manner. In this way, the assembly welding efficiency is high, the production stability is good, the product scrap rate is low, and the overall production efficiency is high.

Owner:南通江海港建设工程有限公司

A method for assembling and installing an express cabinet

ActiveCN104384785BHigh welding technology requirementsLabor intensiveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an assembling installing method for an express cabinet. According to the method, firstly, express cabinet plates are integrally assembled and spliced together, and then, connecting parts between the plates are welded. The assembling installing method has the advantages that the production and installing mode has low requirements on the welding skill of workers, the work intensity of the workers is reduced, the assembling and welding efficiency is improved under the condition of ensuring the assembling and welding precision, and further, the production efficiency of the finished product of the express cabinet is improved.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

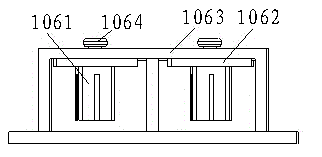

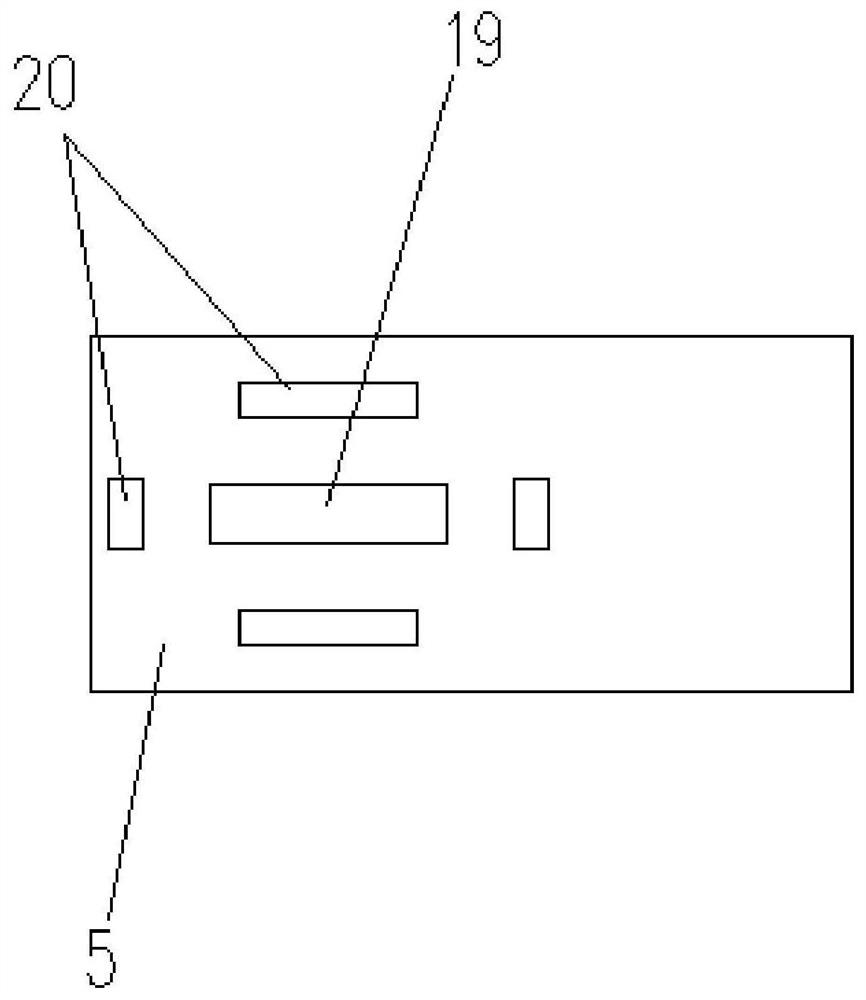

Wire clamping driving device for electrical plug welding machine

InactiveCN104708254AImprove assembly and welding efficiencyGood production stabilityWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention discloses a wire clamping driving device for an electrical plug welding machine. The device comprises wire clamping driving cylinders, wire clamping driving cylinder front flange plates, a wire clamping driving cylinder fixing frame and driving ejector heads, wherein the two wire clamping driving cylinders are fixed to the wire clamping driving cylinder fixing frame through the wire clamping driving cylinder front flange plates, the wire clamping driving cylinder fixing fame is fixed to an aluminum alloy welding rack, and each driving ejector head is installed at one end of a piston rod of the corresponding wire clamping driving cylinder. In this way, assembling and welding efficiency is high, production stability is high, the rejection rate of products is low, and overall production efficiency is high.

Owner:苏州市吴中区木渎华利模具加工店

Assembling method and fixture used for roof battery rack of hybrid electric vehicle

ActiveCN101618490BReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAssembly machinesThermal deformationInstability

Owner:苏州宝馨智能制造有限公司

Body feeding mechanism of electric plug welding machine

ActiveCN104668843BImprove assembly and welding efficiencyImprove production stabilityWelding/cutting auxillary devicesAuxillary welding devicesRotary stageFactory floor

The invention discloses a body feeding mechanism of a plug welding machine. The body feeding mechanism of the plug welding machine comprises a vibrating plate and a linear vibrating feeder seat both of which are fixed on a factory floor; a linear vibrating feeder is arranged on the linear vibrating feeder seat; one end of a feeding tank of the linear vibrating feeder is connected with the vibrating plate, and the other end of the feeding tank of the linear vibrating feeder is connected with one end of an L-shaped intake chute; the end, arranged against the linear vibrating feeder, of the L-shaped intake chute is provided with a first body material pushing cylinder; the part, arranged against the first body material pushing cylinder, of the L-shaped intake chute is provided with a rotating table; the rotating table is arranged on a rotating transposition cylinder; the upper plane of the rotating table and the inner bottom of the L-shaped intake chute are arranged on the same plane; and a second body material pushing cylinder is arranged on the corner of the L-shaped intake chute. By utilizing the above manner, the assembling welding efficiency is high, the production stability is high, the product rejection rate is low, and the total production efficiency is high.

Owner:威海高新园区运营管理有限公司

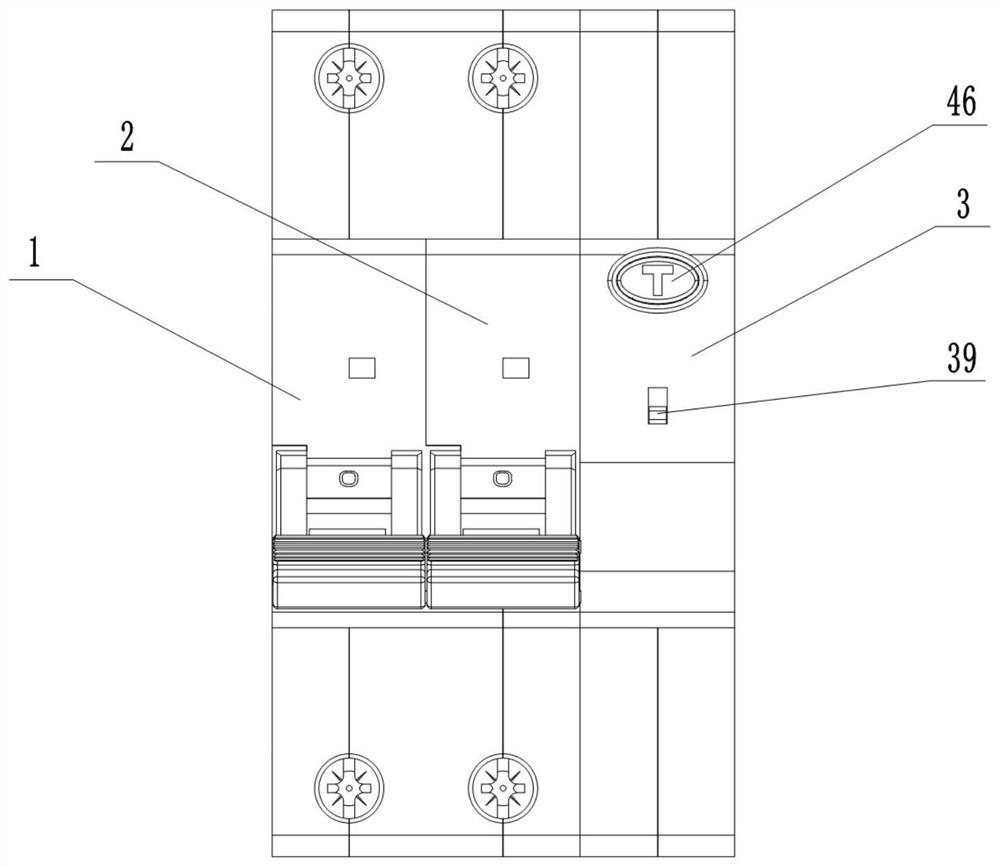

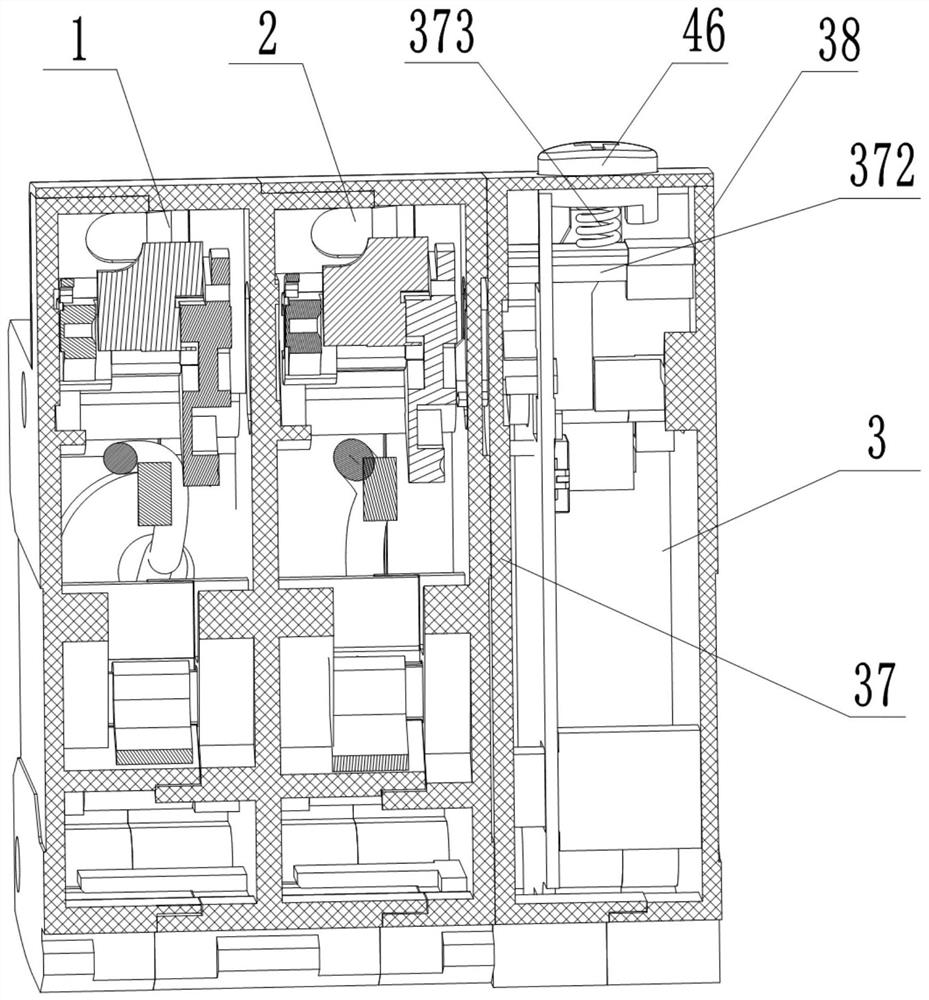

Electric leakage circuit breaker

PendingCN113889381AMove quicklyImprove performanceCircuit-breaking switch detailsProtective switch operating/release mechanismsCurrent sensorRecloser

The invention provides an electric leakage circuit breaker, which comprises an L-phase pole module, an N-phase pole module, a reclosing pole module and an electric leakage protection module, wherein an L-pole handle structure and an L-pole operating mechanism are arranged between the L-pole wire inlet terminal and the L-pole wire outlet terminal of the L-phase pole module, an L-pole moving contact of an L-pole contact mechanism is connected to the L-pole operating mechanism, a current transformer is arranged between the L-pole moving contact and the L-pole wire inlet terminal, a connecting conducting wire connected between the L-pole moving contact and the L-pole wire inlet terminal penetrates through the current transformer, the current transformer is connected with the circuit board of the reclosing pole module and used for feeding back current signals of a main circuit, and when overload occurs, the controller of the circuit board drives the reclosing pole module to act to realize automatic opening. According to the invention, the current sensor senses the overload current to enable the reclosing pole module to act to realize the opening of the circuit breaker, and the circuit breaker has the advantages of quick action, stable performance and high detection precision.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD +1

A process for assembling and welding of radiation supervisory tube

ActiveCN105499803BAvoid Weld CollapseEasy to adjustLaser beam welding apparatusWelding deformationWeld penetration

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Eight-station welding station for electric plug welding machine

ActiveCN104668866BImprove assembly and welding efficiencyImprove production stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectricityMechanical index

The invention discloses an eight-station welding table of a plug welding machine. The eight-station welding table of the plug welding machine comprises an aluminium alloy welding rack, a floor type mechanical index plate, a working turntable, an index plate rotating motor, a plurality of welding clamps and a plurality of line clamping and driving devices; the floor type mechanical index plate is arranged in the middle of the aluminium alloy welding rack; the index plate rotating motor is arranged on the input of the floor type mechanical index plate; the working turntable is arranged on the upper end of the floor type mechanical index plate; eight welding clamps distributed annularly are arranged on the upper plane of the working turntable; four line clamping and driving devices are arranged on the lower plane of the working turntable; and all the line clamping and driving devices are fixed on the aluminium alloy welding rack. By utilizing the above manner, the assembling welding efficiency is high, the production stability is attractive, the product rejection rate is low, and the total production efficiency is high.

Owner:南通东晨重型机床有限公司

A production system for welding h-shaped steel

ActiveCN111515590BReasonable structural designEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesRolloverIndustrial engineering

Owner:重庆本浩建设工程有限公司

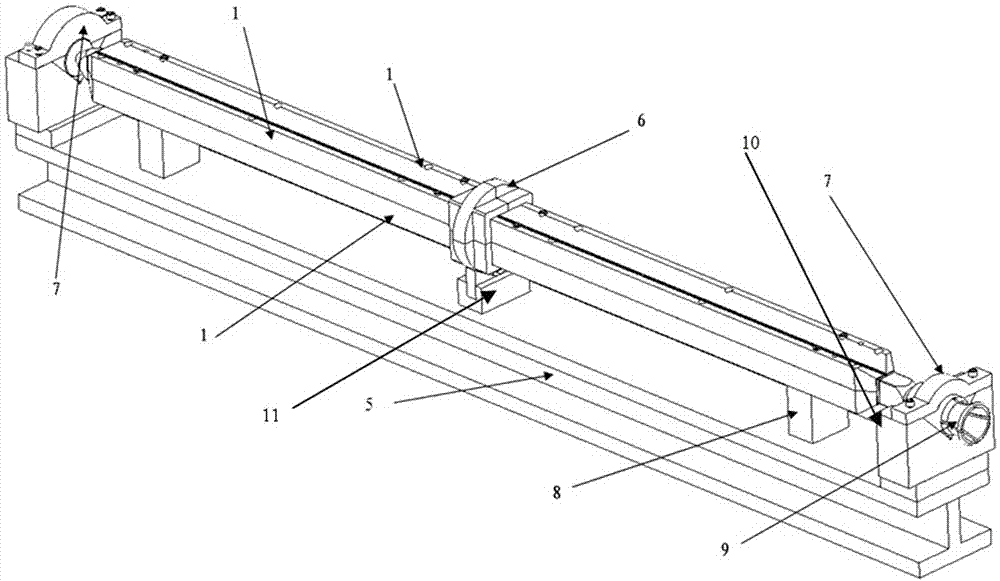

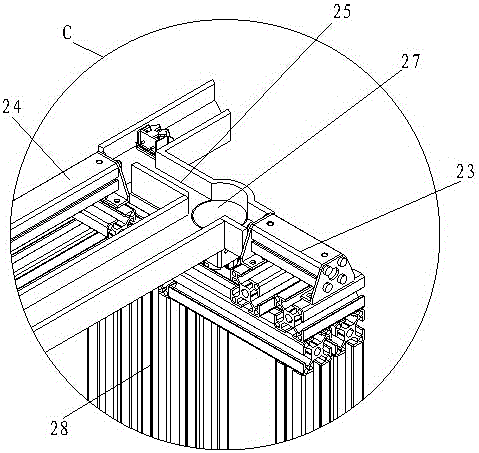

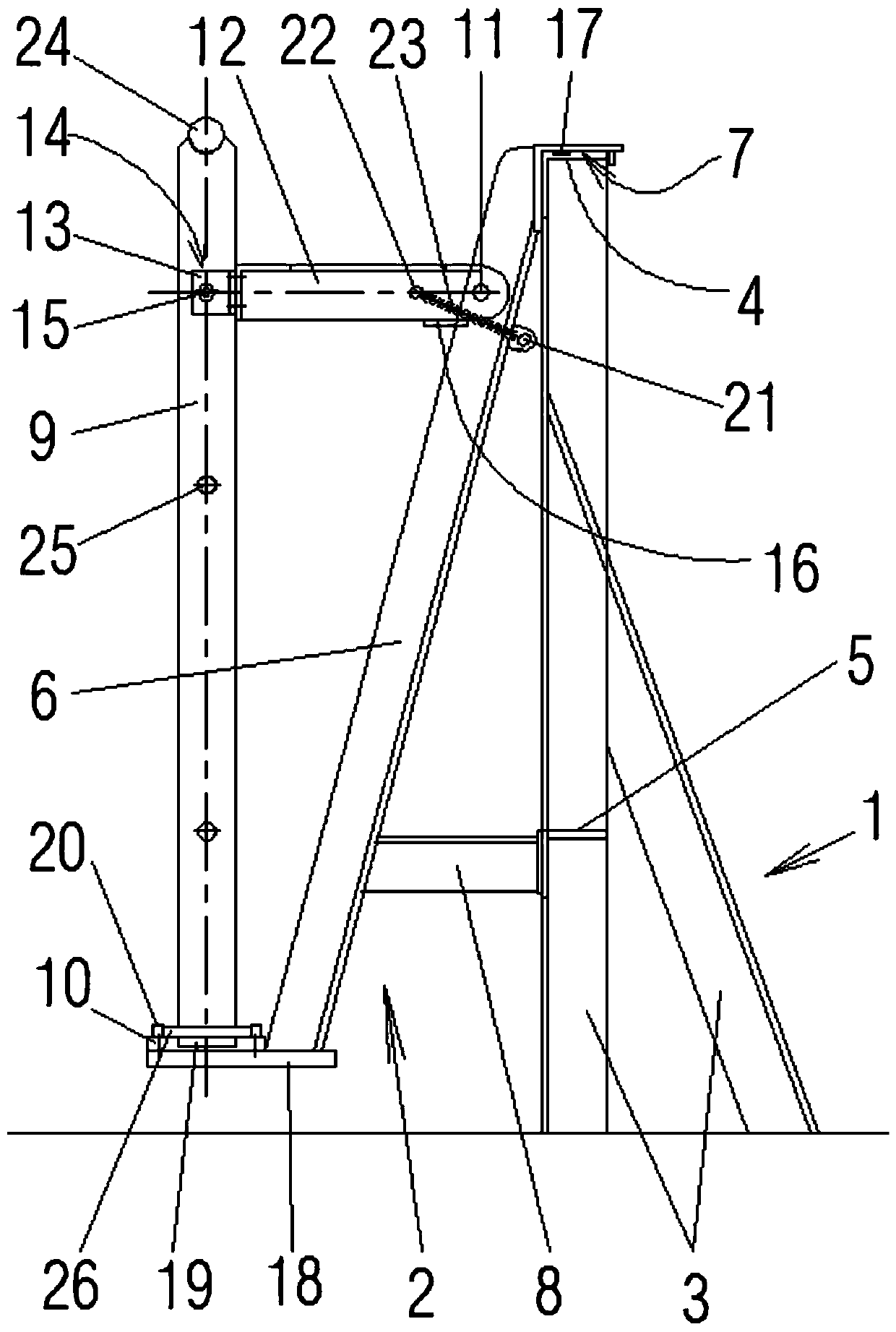

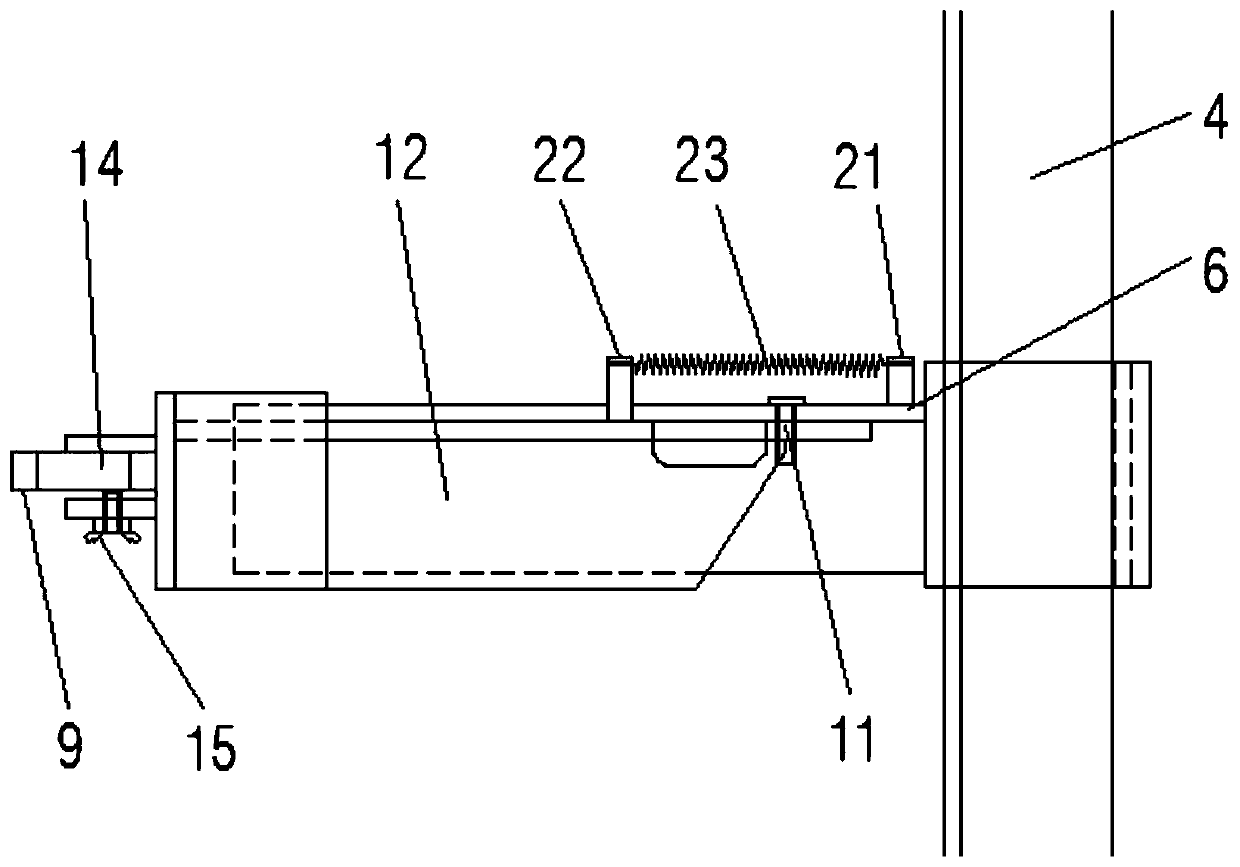

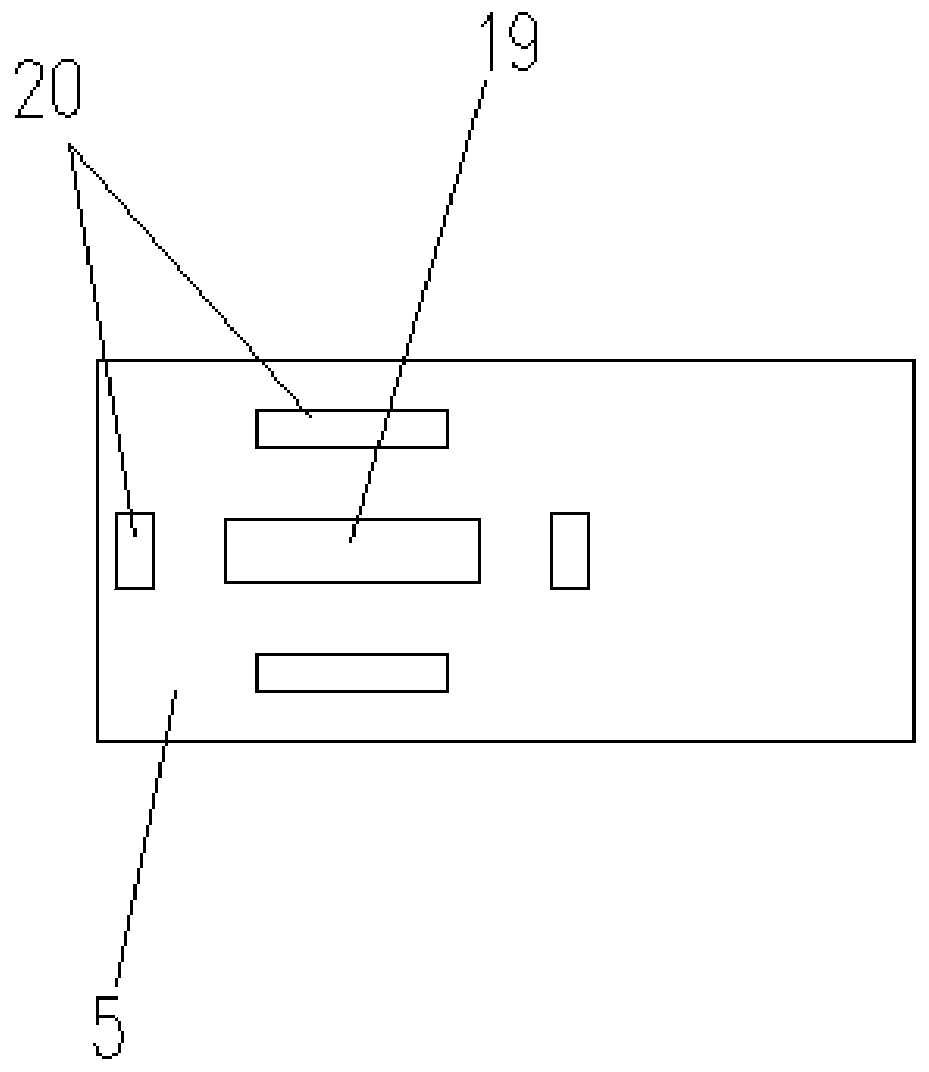

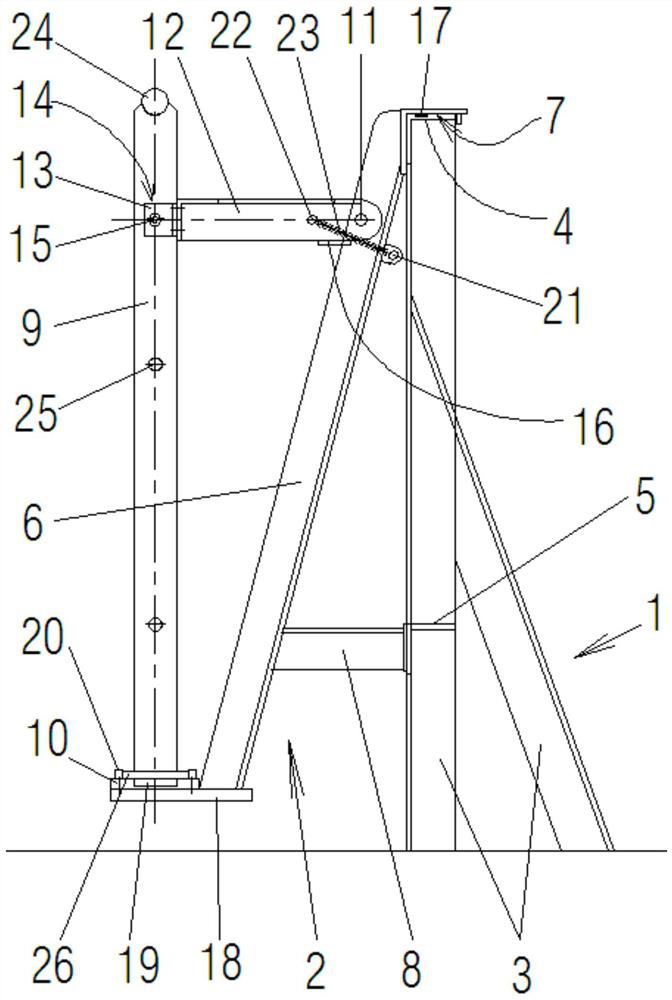

Universal type quick positioning tool for assembly and welding of rails

ActiveCN110153616APrecise positioningEasy to assemble and weldWelding/cutting auxillary devicesAuxillary welding devicesMarine engineeringManufacturing quality

The invention discloses a universal type quick positioning tool for assembly and welding of rails. The tool comprises a fixed support and movable positioning frames, wherein the fixed support comprises a support body as well as an upper positioning beam and a lower positioning beam which are arranged on the support body horizontally; each movable positioning frame comprises a diagonal brace, a sliding groove formed in the upper end of the diagonal brace and used for being matched with the upper positioning beam in a sliding manner, a lateral supporting leg arranged at the lower part of the diagonal brace and a lower positioning base arranged at the lower end of the diagonal brace and used for positioning and fixing the lower end of a rail post, a horizontal positioning arm is rotationallyconnected with the upper part of the diagonal brace through a hinged shaft, an upper positioning base is arranged at the end of the horizontal positioning arm away from the hinged shaft, an open groove used for positioning the upper part of the rail post is formed in the upper positioning base, and a locking device used for fixing the rail post is arranged at the lateral part of the open groove. With the adoption of the tool, the assembly and welding efficiency of rails of a ship is enhanced and the manufacturing quality of the rails of the ship is improved.

Owner:CHENGXI SHIPYARD

Method for assembling upper support body of overhead cell support of hybrid vehicle and clamp thereof

ActiveCN101618492BReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAssembly machinesPhysical hard workPhysical work

The invention discloses a method for assembling an upper support body of an overhead cell support of a hybrid vehicle and a special welding tool clamp used in assembly. The clamp comprises a clamp body (1), and is characterized in that a positioning element (2) is fixedly arranged at the upper end of the clamp body, a clamping device (3) is arranged at the outer side of the positioning element (2), the positioning element horizontally limits the position of each component on the upper support body of the overhead cell support of the hybrid vehicle, and the clamping device clamps the components on the upper support body of the overhead cell support of the hybrid vehicle in a horizontal direction and a vertical direction. The clamp greatly lightens the physical work of the operating staff, improves the assembling and welding efficiency, controls or eliminates the thermal deformation of workpieces caused by welding, and reduces the instability of manual welding.

Owner:苏州宝馨智能制造有限公司

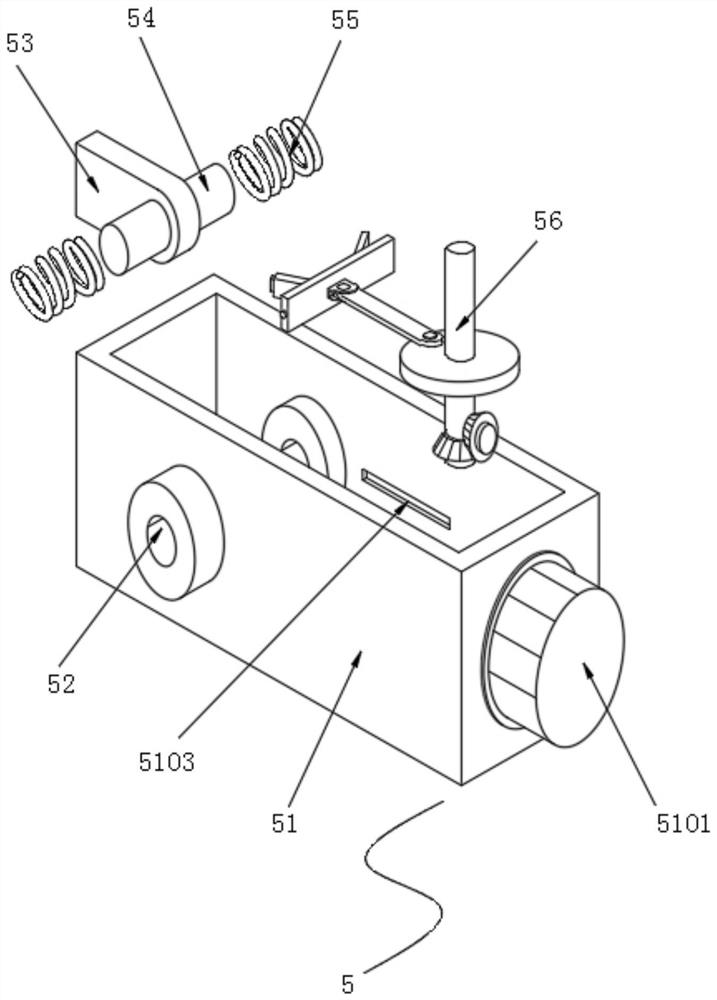

A silicon calcium plate and steel frame combined assembly system and its rapid assembly welding process

ActiveCN113073737BReduce labor intensityQuick fixWelding/cutting auxillary devicesAuxillary welding devicesCalcium silicateEngineering

The invention discloses a combined assembling system of a calcium-silicon plate and a steel frame and a rapid assembling and welding process thereof. The invention relates to the field of construction technology and includes a first beam, and the upper surface of the first beam is vertically and uniformly provided with several vertical beams The upper surface of the first beam is provided with a calcium silicate board at the position between each vertical beam, and a second beam is horizontally arranged between the upper ends of each of the vertical beams, and each vertical beam is connected to the first beam. Both the first beam and the second beam are fixedly connected by mounting parts. The device is provided with an adjustment piece inside the other end of the shell. After the preliminary splicing of each steel frame is completed, the installation piece is used instead of the traditional screw installation method. Under the elasticity of the spring, the user only needs to turn the knob to adjust the steel The frames are quickly fixed, so that the assembly work can be completed quickly, which not only reduces the labor intensity of labor, but also improves the efficiency of assembly and welding.

Owner:潮峰钢构集团有限公司

A universal quick positioning tool for railing assembly and welding

ActiveCN110153616BPrecise positioningEasy to assemble and weldWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringIndustrial engineering

The invention discloses a universal type quick positioning tool for assembly and welding of rails. The tool comprises a fixed support and movable positioning frames, wherein the fixed support comprises a support body as well as an upper positioning beam and a lower positioning beam which are arranged on the support body horizontally; each movable positioning frame comprises a diagonal brace, a sliding groove formed in the upper end of the diagonal brace and used for being matched with the upper positioning beam in a sliding manner, a lateral supporting leg arranged at the lower part of the diagonal brace and a lower positioning base arranged at the lower end of the diagonal brace and used for positioning and fixing the lower end of a rail post, a horizontal positioning arm is rotationallyconnected with the upper part of the diagonal brace through a hinged shaft, an upper positioning base is arranged at the end of the horizontal positioning arm away from the hinged shaft, an open groove used for positioning the upper part of the rail post is formed in the upper positioning base, and a locking device used for fixing the rail post is arranged at the lateral part of the open groove. With the adoption of the tool, the assembly and welding efficiency of rails of a ship is enhanced and the manufacturing quality of the rails of the ship is improved.

Owner:CHENGXI SHIPYARD

A flexible assembly welding system and method for standard parts and non-standard parts

ActiveCN112404783BAvoid flawsReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWorkmanship

Owner:HENAN WINNER VIBRATING EQUIP

Calcium silicate board and steel frame combining and assembling system and rapid assembling and welding process thereof

ActiveCN113073737AReduce labor intensityQuick fixWelding/cutting auxillary devicesBuilding constructionsCalcium silicateEngineering

The invention discloses a calcium silicate board and steel frame combining and assembling system and a rapid assembling and welding process thereof, and relates to the technical field of constructions. The system comprises a first cross beam, a plurality of vertical beam pieces are vertically and evenly arranged on the upper surface of the first cross beam, calcium silicate boards are arranged at the positions, between the vertical beam pieces, of the upper surface of the first cross beam, a second cross beam is horizontally arranged between the upper ends of the vertical beam pieces, and the vertical beam pieces are fixedly connected with the first cross beam and the second cross beam through installation pieces. According to the device, an adjusting piece is arranged inside the other end of a shell, after all the steel frames are preliminarily spliced, a traditional screw installation mode is replaced with the installation pieces, under the elasticity of a spring, a user only needs to rotate a rotary knob, all the steel frames can be rapidly fixed, then the assembling work is rapidly completed, the manual labor intensity is reduced, and meanwhile the assembling and welding efficiency is improved.

Owner:潮峰钢构集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com