Patents

Literature

98results about How to "Easy to assemble and weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

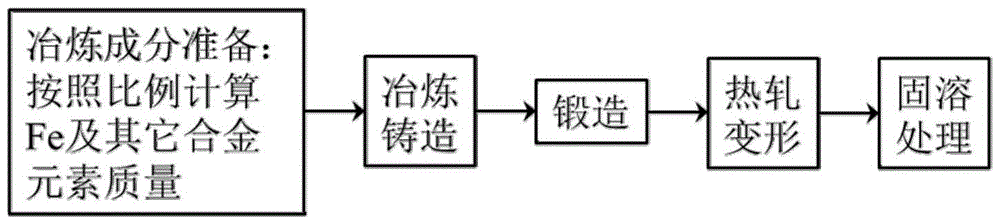

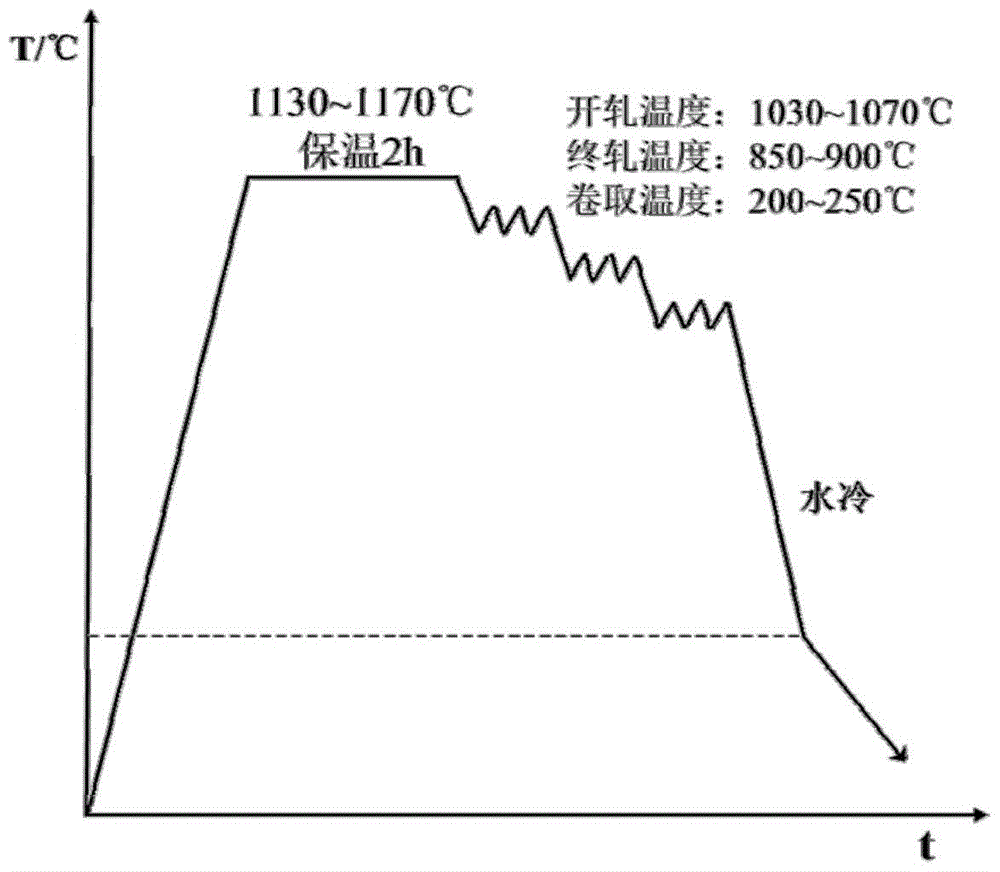

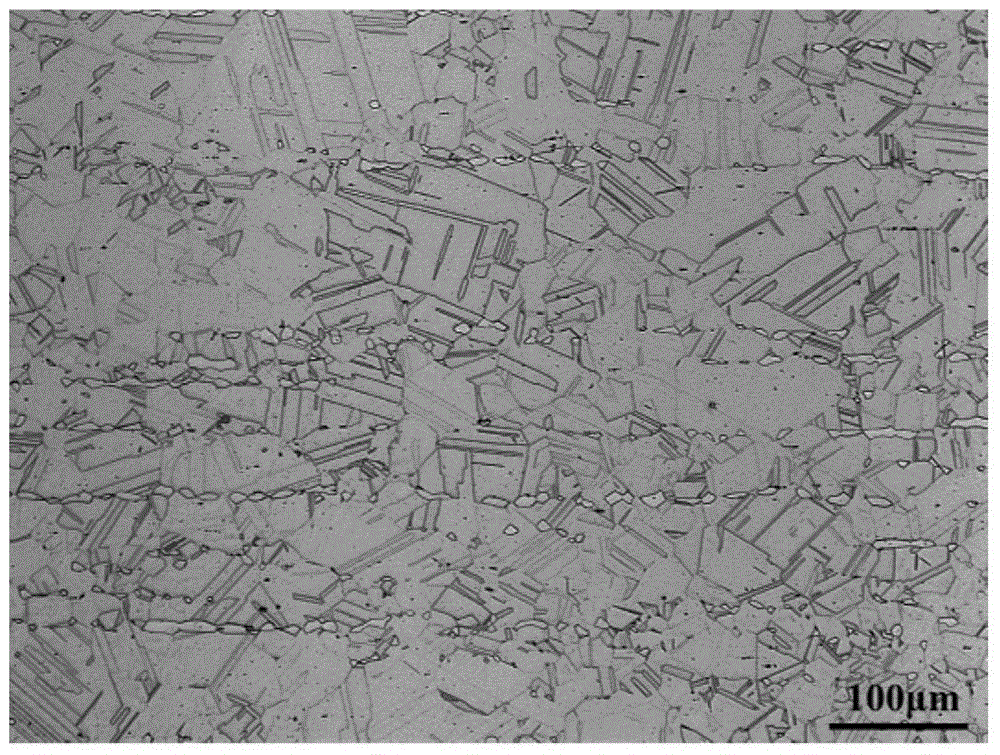

Low-density and high-toughness automobile-used steel board and preparation process

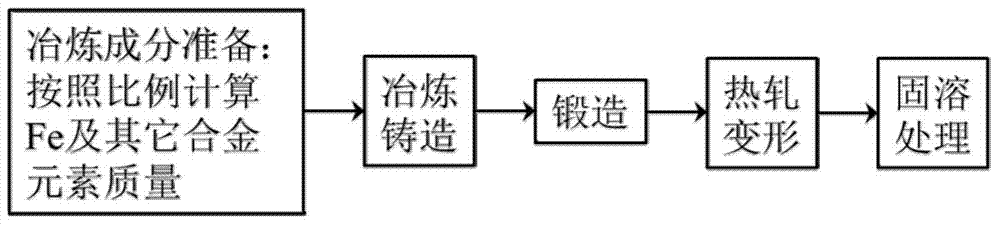

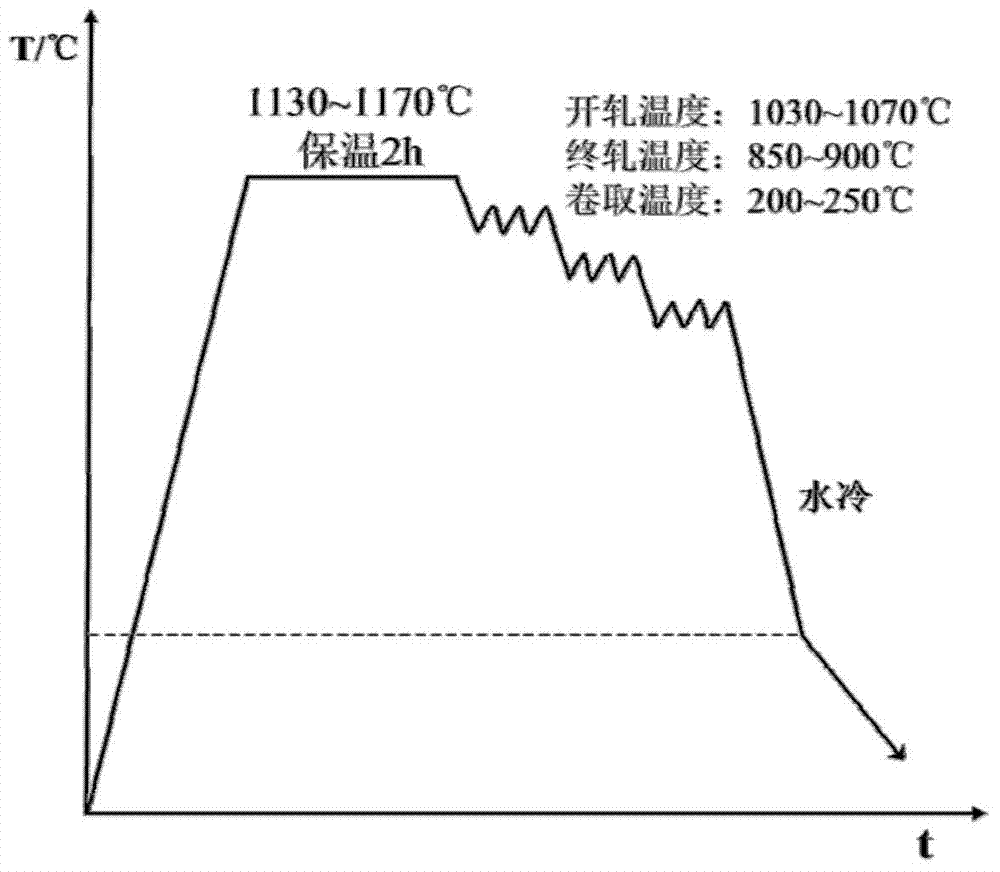

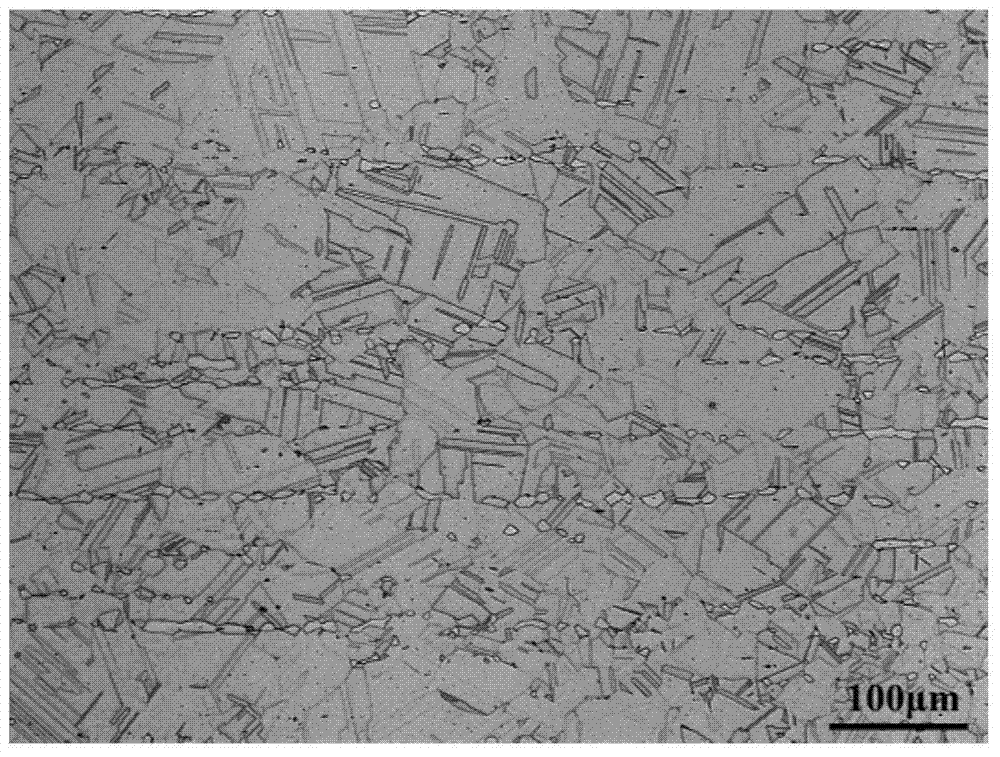

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

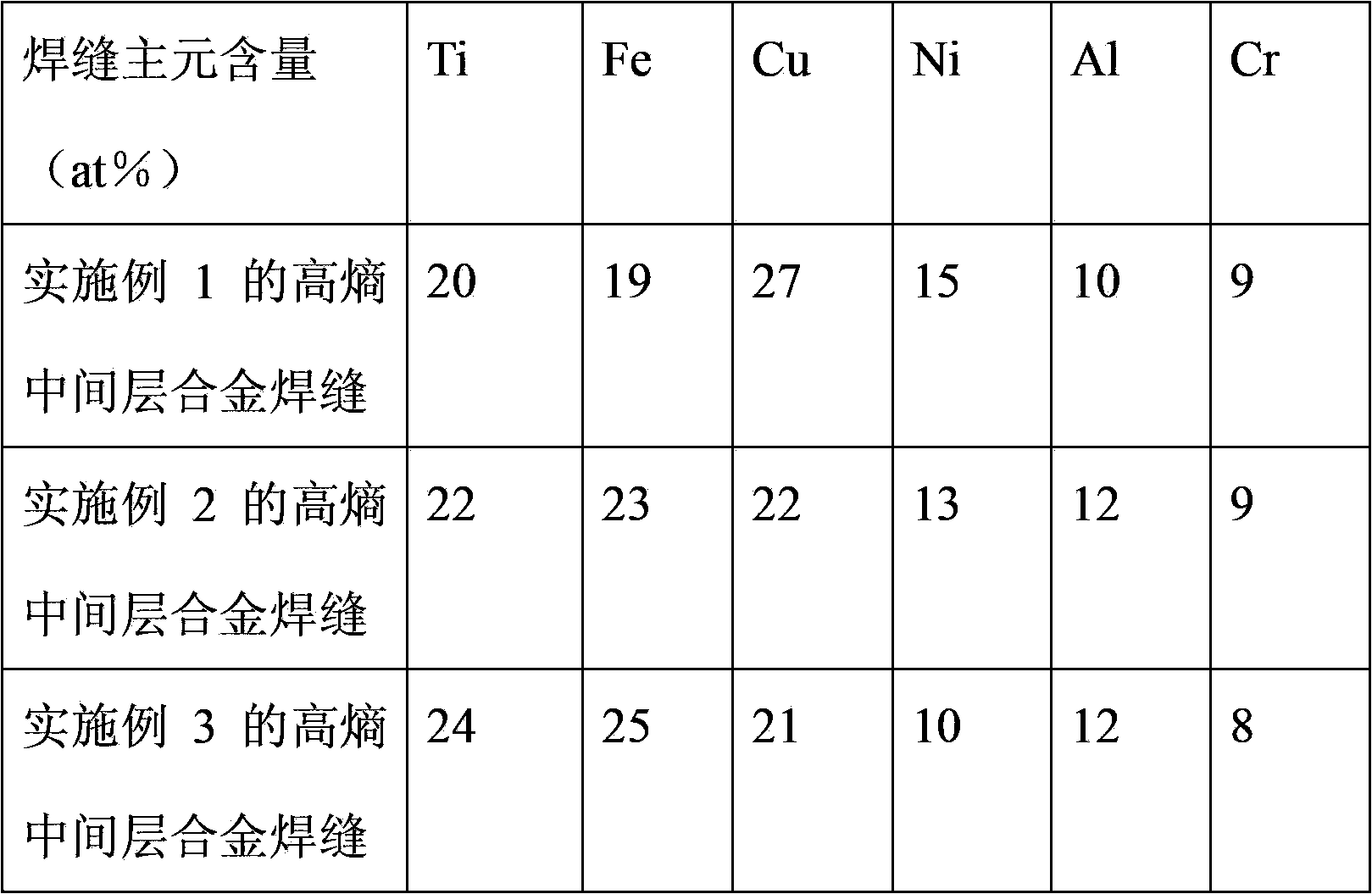

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AGood strengthImprove performanceWelding/cutting media/materialsSoldering mediaCorrosionSpot welding

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

Method for welding titanium and steel by applying high-entropy effect and welding material

InactiveCN102672328AWide adaptabilityEasy to processWelding/cutting media/materialsSoldering mediaWeld seamTitanium

The invention discloses a method for welding titanium and steel by applying the high-entropy effect. A folded middle-layer alloy foil is arranged between a titanium plate to be welded and a steel plate to be welded, and the welding operation is carried out by adopting a resistance spot-welding mode, then the interface resistance heat melts the middle-layer alloy and local base materials, and the molten metals are mixed, so that the high-performance welding of titanium and steel is realized. The invention also discloses a middle-layer alloy and a preparation method of the middle-layer alloy. The middle-layer alloy comprises the following components in the terms of atomic percent: 20-30% of Al, 35-40% of Ni and 35-40% of Cu, wherein the total percent is 100%. The invention has the advantages that the middle-layer alloy is well matched with the titanium and the alloy steel in welding, welding seams (nugget) are single-phase fcc solid-solution structures, and the comprehensive mechanical performance of joints is obviously improved. The preparation method of the middle-layer alloy foil is simple in process and low in manufacturing cost.

Owner:XIAN UNIV OF TECH

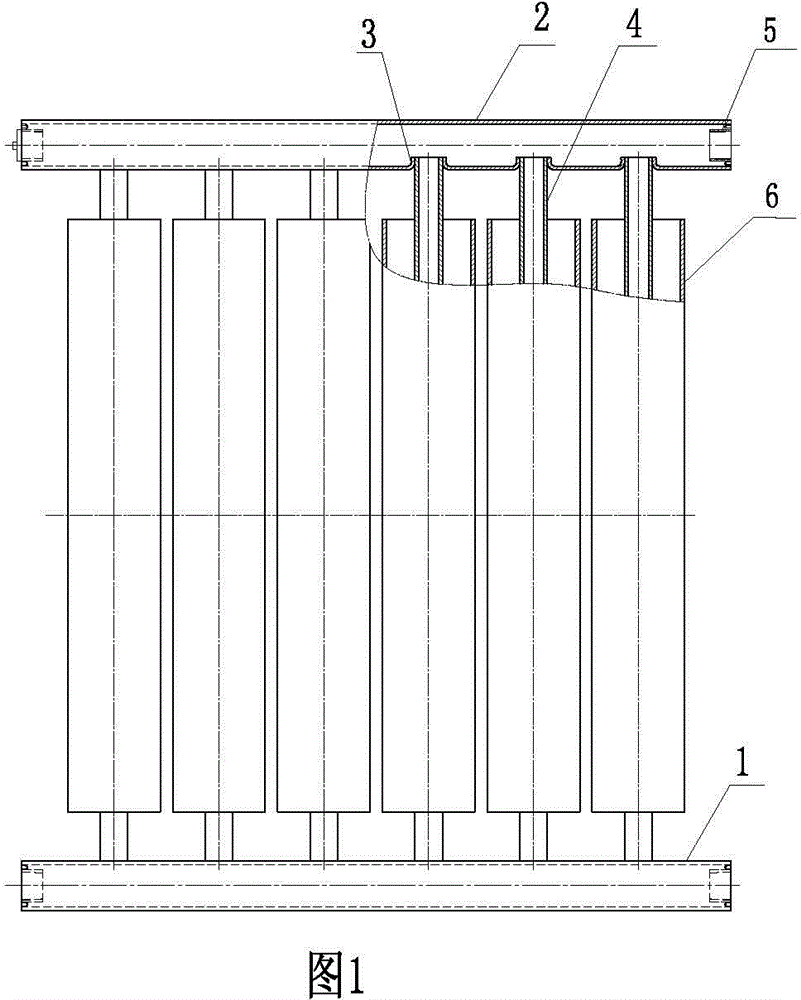

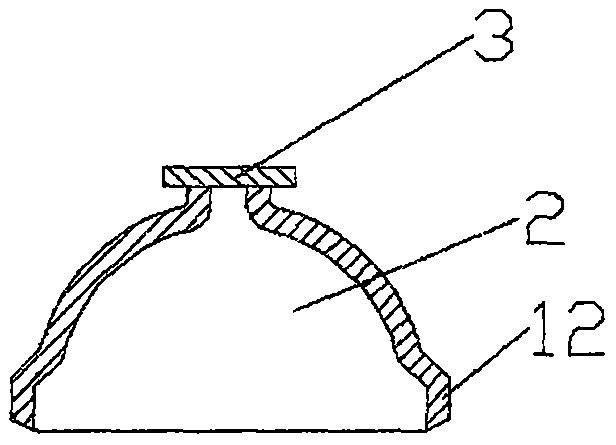

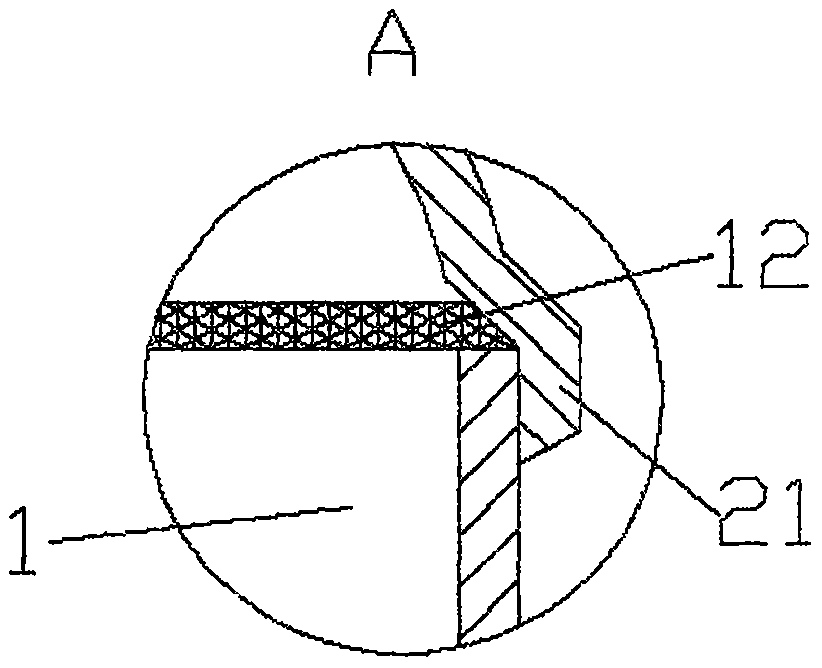

Stainless steel component for heating radiator and manufacturing method thereof

ActiveCN104625632AEliminate gapsUniform weldingSpace heating and ventilation detailsHeat exchanger casingsVertical tubeEngineering

The invention relates to an auxiliary pressure plate for hot water radiators, in particular to a thin-wall radiator used for indoor heating and employing hot water or steam as a heat source, and belongs to indoor heaters. Two rolled drawn transverse tubes and more than two vertical tubes are welded into a rectangle or square; two ends of each vertical tube are punched into concave arc shapes; each rolled drawn transverse tube is evenly provided with concave arc shapes and drawn turnup steps in the lengthwise direction by punching; the concave arc shapes and the drawn turnup steps of the rolled drawn transverse tubes fit the concave arc shapes of the two ends of the vertical tubes. Aiming to the defects that the copper-aluminum or aluminum-plastic radiators are high in manufacturing cost and that the steel-aluminum low-carbon steel radiators easily leak due to corrosion, the radiator is in the unique stainless steel ultra-thin design and is uniquely welded through a fixture; arc U-shaped openings are ingeniously used in welding, edges are aligned and tightly kneaded so that service life is ensued, work efficiency is improved, costs are saved, and the radiator is attractive in price and quality.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

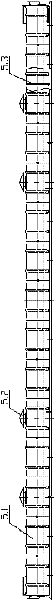

Erecting welding technological method for single-upper-ring type large segmented stand ring with sole plates

ActiveCN105057855AReduce weightReduce difficultyArc welding apparatusProcessing costWelding deformation

The invention relates to an erecting welding technological method for a single-upper-ring type large segmented stand ring with sole plates. A sole plate positioning template and positioning pipes are used for precise positioning; and after splice welding of a lower guide plate, fixed guide vane mounting holes are perforated in a matched mode, and then fixed guide vanes are inserted. The key process problems of stand ring welding deformation, sole plate assembly positioning, sole plate combining through hole processing cost, the production cycle and the like are solved through an auxiliary lower ring, the sole plate positioning templates and the positioning pipes, and the production cost and the production cycle are reduced. According to the stand ring manufactured through the technological method, the problems of assembly positioning, the production cost, welding deformation and the like are effectively solved, and construction site installation requirements are met; the subsequent production cycle and processing cost are greatly reduced, economy and practicability are both considered, and the purposes of lowering cost and improving effects are achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

Advanced integrated network cabinet welding tool platform capable of disassembling and assembling angle iron easily

ActiveCN107309592AAvoid displacementEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPhysics

The invention provides an advanced integrated network cabinet welding tool platform capable of disassembling and assembling angle iron easily. Through the welding tool platform, a wall-mounted bracket or a box base embedded part can be welded and assembled more conveniently and quickly, and the size precision of the wall-mounted bracket or the box base embedded part is improved. The welding tool platform comprises a welding platform. The welding platform comprises an upper platform. Threaded holes formed in an array mode are distributed in the upper platform, and the distances between the adjacent threaded holes of each group are equal. The welding platform further comprises a plurality of positioning bolts, supporting blocks and clamps. The positioning bolts comprise the corner positioning bolt and the side edge positioning bolt. The supporting blocks comprise the side supporting blocks and the welding supporting blocks. The welding supporting blocks are used for inner side positioning of the angle iron and perpendicular positioning of round steel of the base embedded part. The side supporting blocks are used for inner side positioning of angle iron, in the non-round-steel position, of the base embedded part. The clamps comprise the downward pressing type clamp and the forward jacking type clamp. The positioning bolts are used for outer side positioning abutting grids of angle iron of the wall-mounted bracket.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

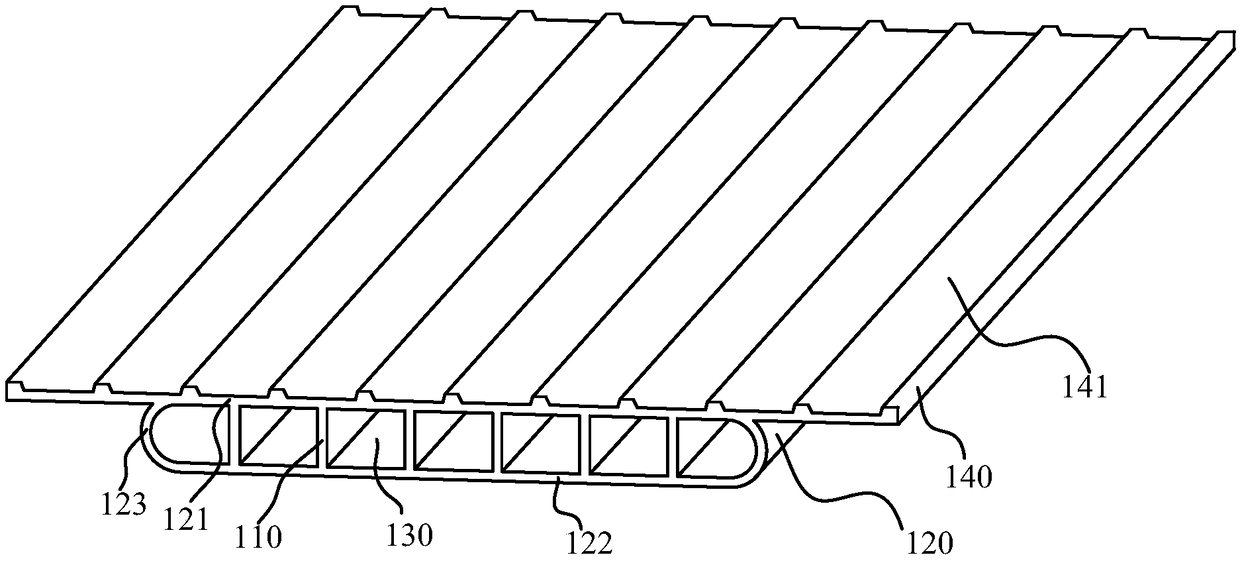

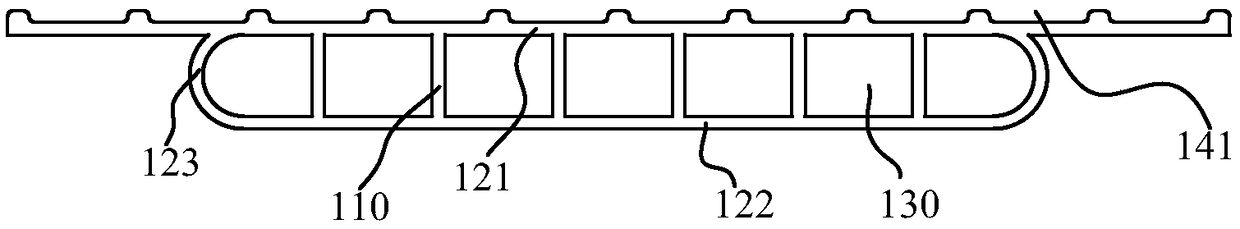

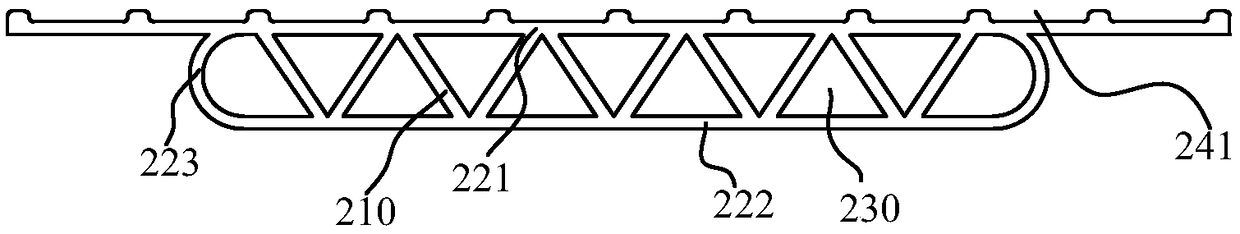

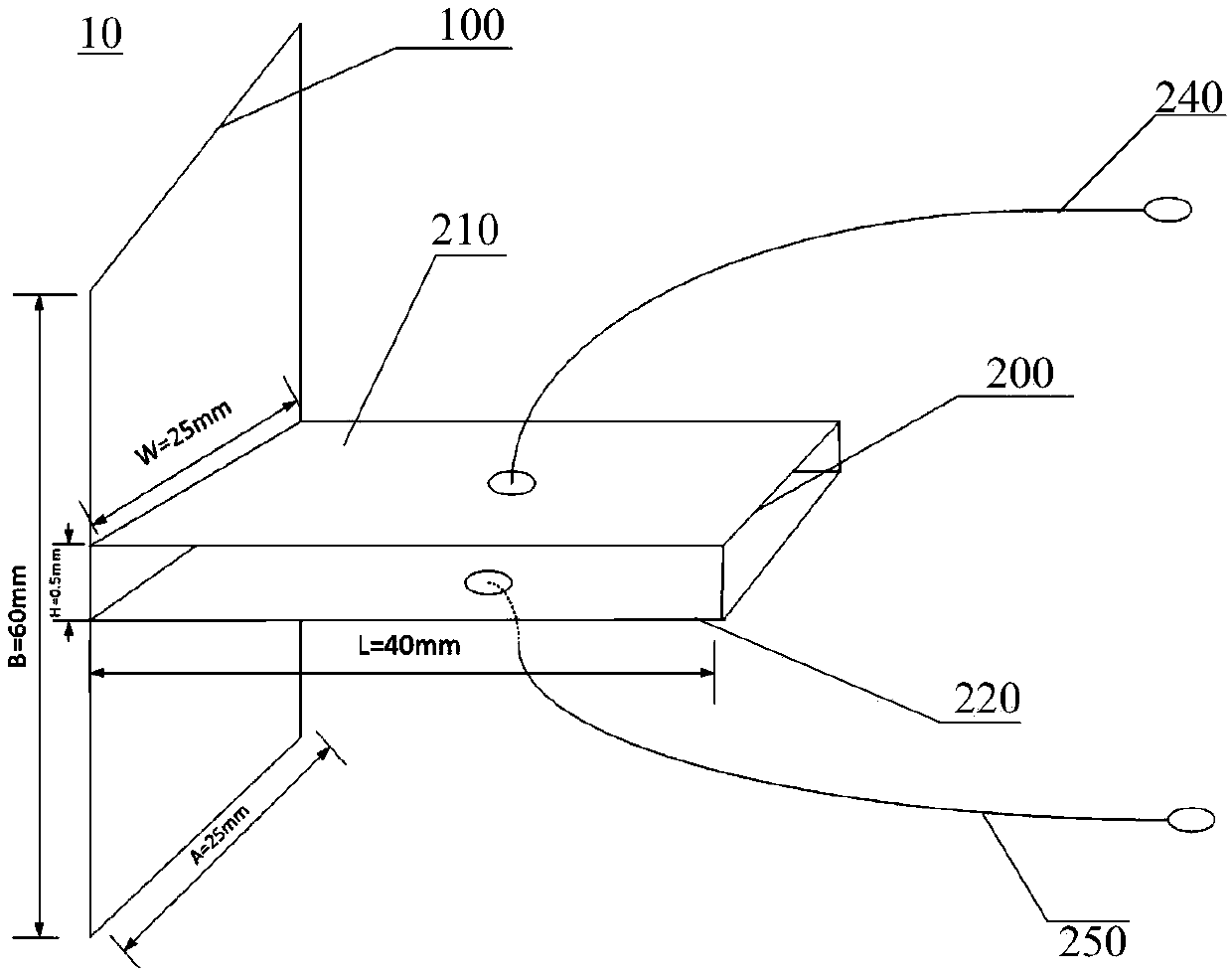

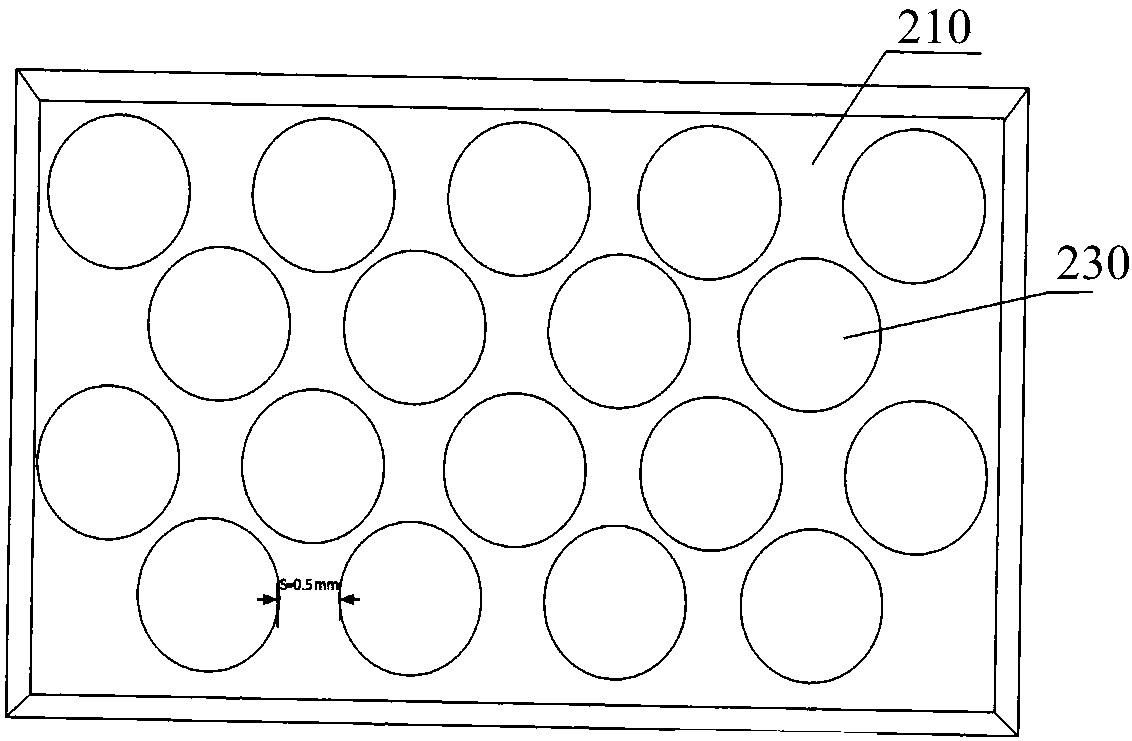

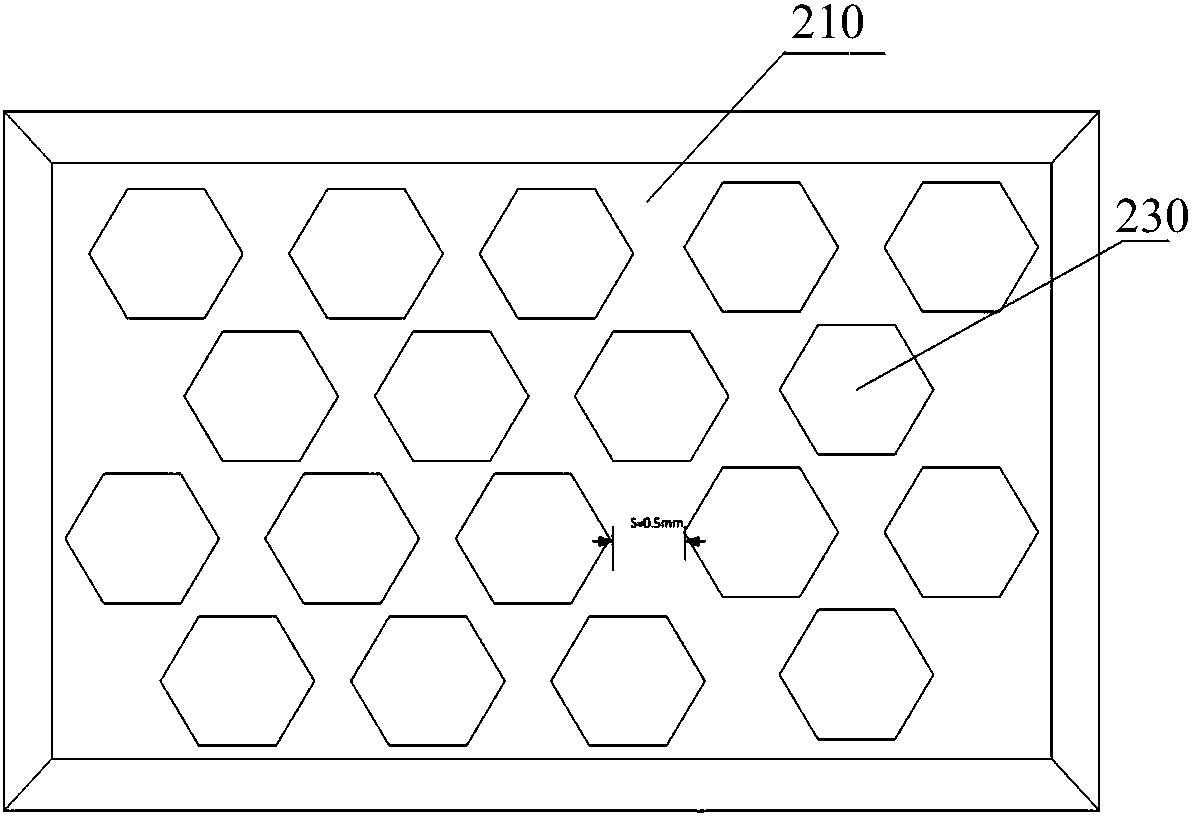

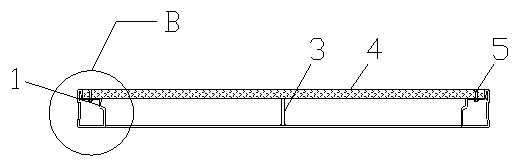

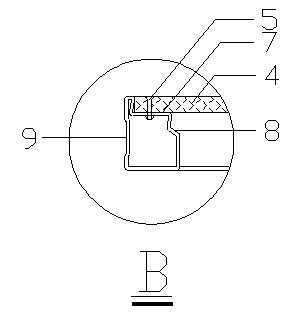

Liquid cooled pipe and battery system

PendingCN108963385ALight in massCompact structureSecondary cellsBatteriesEngineeringMechanical engineering

A liquid cool pipe and battery system are disclosed. The liquid-cooled pipe comprises a flat pipe and a plurality of flow channels arranged inside the flat pipe; A soaking plate having a lower surfaceat least partially covering an outer wall of the flat tube, and an upper surface of the soaking plate for contacting the battery module and having an area greater than an area covered by the soakingplate. The soaking plate of the present invention covers a plurality of flow channels, is in contact with the battery module and has an area larger than the area covered by the soaking plate on the outer wall, so that the heat exchange area between the battery module and the liquid-cooled pipe on the soaking plate of the liquid-cooled pipe is increased, and a groove is arranged on the upper surface, so that the heat conduction gel can be placed, and the heat dissipation performance of the liquid-cooled pipe is greatly improved. Moreover, the soaking plate and the flat tube are integrated, so that the structure of the liquid cooling pipeline is compact and stable.

Owner:江苏和中普方新能源科技有限公司

Four-arm helical antenna of novel feed structure

ActiveCN105119047AStable structureEasy to assemble and weldRadiating elements structural formsAntennas earthing switches associationReturn lossPrinted circuit board

The invention discloses a four-arm helical antenna of a novel feed structure, which comprises a ceramic pillar, an upper printed circuit board (PCB), a lower PCB and a PCB printed connection board. The axis of the ceramic pillar is provided with a through hole. The lower part of the outer side surface of the ceramic pillar is provided with BALUN lines along the circumferential direction. Four metal helical arms are wound onto the outer side surface of the ceramic pillar at intervals. The upper surface and the lower surface of the upper PCB are respectively printed with a fan-shaped upper conductive layer and a fan-shaped lower conductive layer. The metal adjustment regions of the first and second metal helical arms of the four metal helical arms are electrically connected with the fan-shaped upper conductive layer through the welding process. The third and fourth metal helical arms of the four metal helical arms are coupled to the fan-shaped lower conductive layer. The front side surface of the PCB printed connection board is provided with a grounding metal region and an input end region at the upper part of the PCB printed connection board. The fan-shaped lower conductive layer is electrically connected with the grounding metal region of the PCB printed connection board. According to the invention, the return loss is smaller than -25 dB, and the vertex gain is greater than -2 dB. Therefore, the overall size of an antenna is effectively reduced, and the antenna is good in circularly-polarized performance.

Owner:SEMITEL ELECTRONICS

High-capacity pallet transport boxcar

The invention discloses a high-capacity pallet transport boxcar and belongs to the technical field of wagon manufacture. The high-capacity pallet transport boxcar comprises a draw gear buffering device, a bogie, a side wall, an underframe, a car roof, a car door, an air braking device and an end wall. The car roof is of a grid beam structure. The side wall is of a corrugated plate structure capable of installing a pallet. The underframe is of a fish-bellied beam structure. The car door is of a structure with a container locking device. The end wall is of a broken-line-shaped beam structure shaped like a Chinese character feng. The railway vehicle limit is fully utilized, the cross-sectional area in a boxcar body is expanded, the space utilization rate is high, and the self weight of the vehicle is reduced while the internal volume is increased. The goods loading environment in the boxcar is improved, pallet goods can be transported, the mechanical operation requirements of a forklift and the like are met, and the goods loading and unloading efficiency is improved. The strength and rigidity of the whole boxcar conform to the standard requirements, the vehicle load is high, the varieties of goods suitable for transportation are increased, and the comprehensive goods transportation capability is improved.

Owner:CRRC MEISHAN

Piezoelectric energy collector

ActiveCN107819410AImprove conductivityReduce volumePiezoelectric/electrostriction/magnetostriction machinesHoneycomb structureElectricity

The invention relates to a piezoelectric energy collector, which is characterized in that two flexible circuit boards are adopted to clamp piezoelectric ceramic pieces so as to form a piezoelectric unit. The piezoelectric energy collector adopts the flexible circuit board to serve as a substrate of the piezoelectric unit, thereby being high in flexibility, having good conductivity and being convenient for installation and welding. The flexible circuit board can be freely bent, wound and folded, can also stretch and move at will and has the characteristics of light weight and thin thickness, thereby being capable of greatly reducing the size and the weight of the whole piezoelectric energy collector. The flexible circuit board is flexible and high in sensitivity for vibration and can perceive the shake as long as the shake exists, thereby significantly improving the sensitivity of the piezoelectric energy collector for vibration. The piezoelectric unit is provided with a plurality of piezoelectric ceramic pieces and forms a honeycomb structure, so that the piezoelectric energy collector has a plurality of resonant frequency points, can sense the vibration energy of different frequencies in the environment, is wide in bandwidth and facilitates to improving the output voltage of the whole piezoelectric energy collector.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

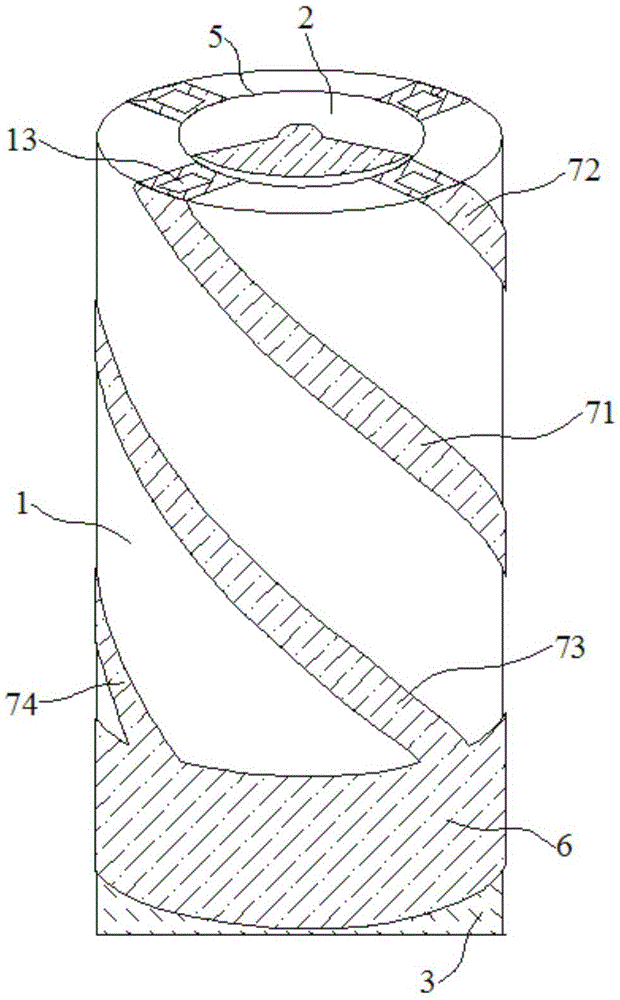

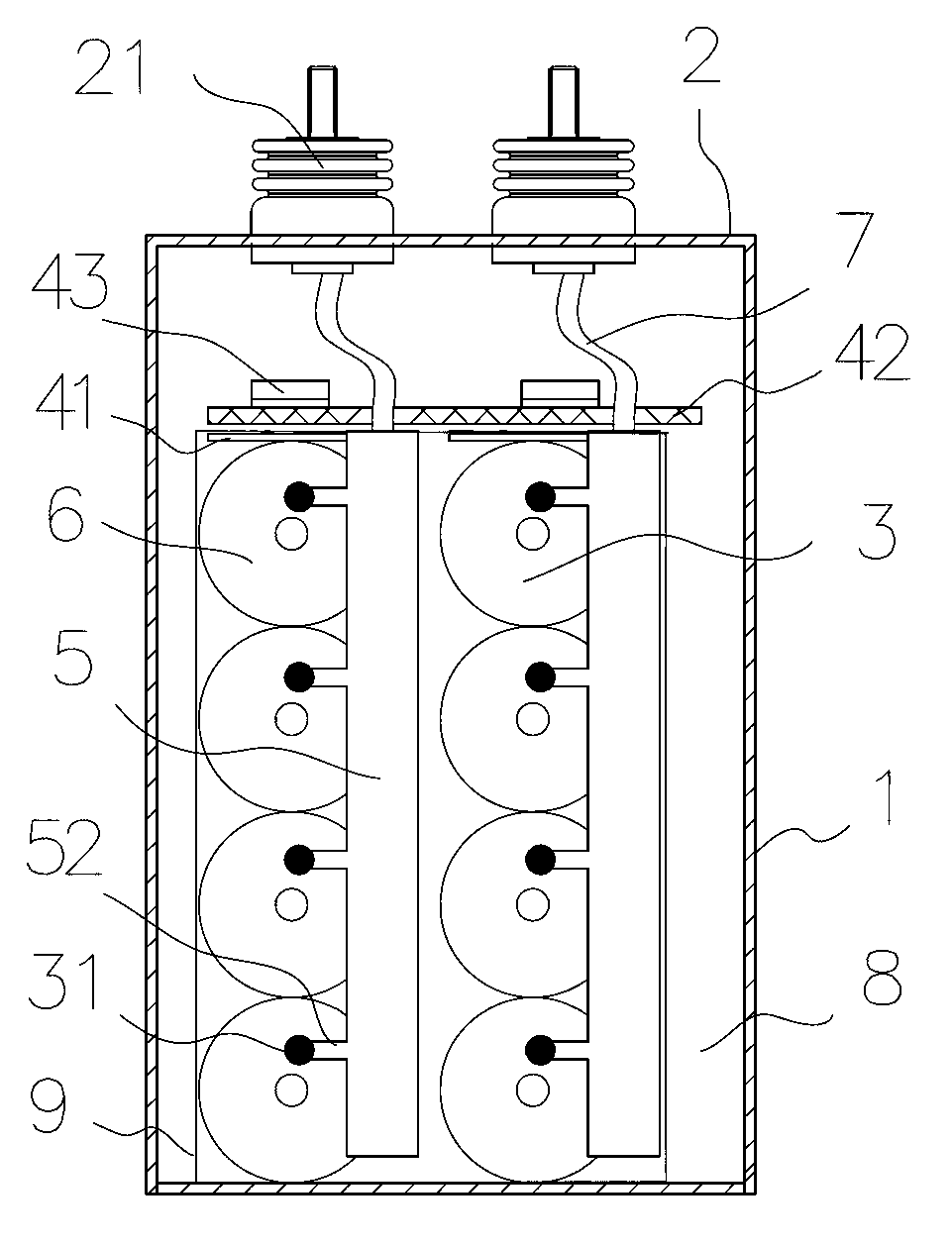

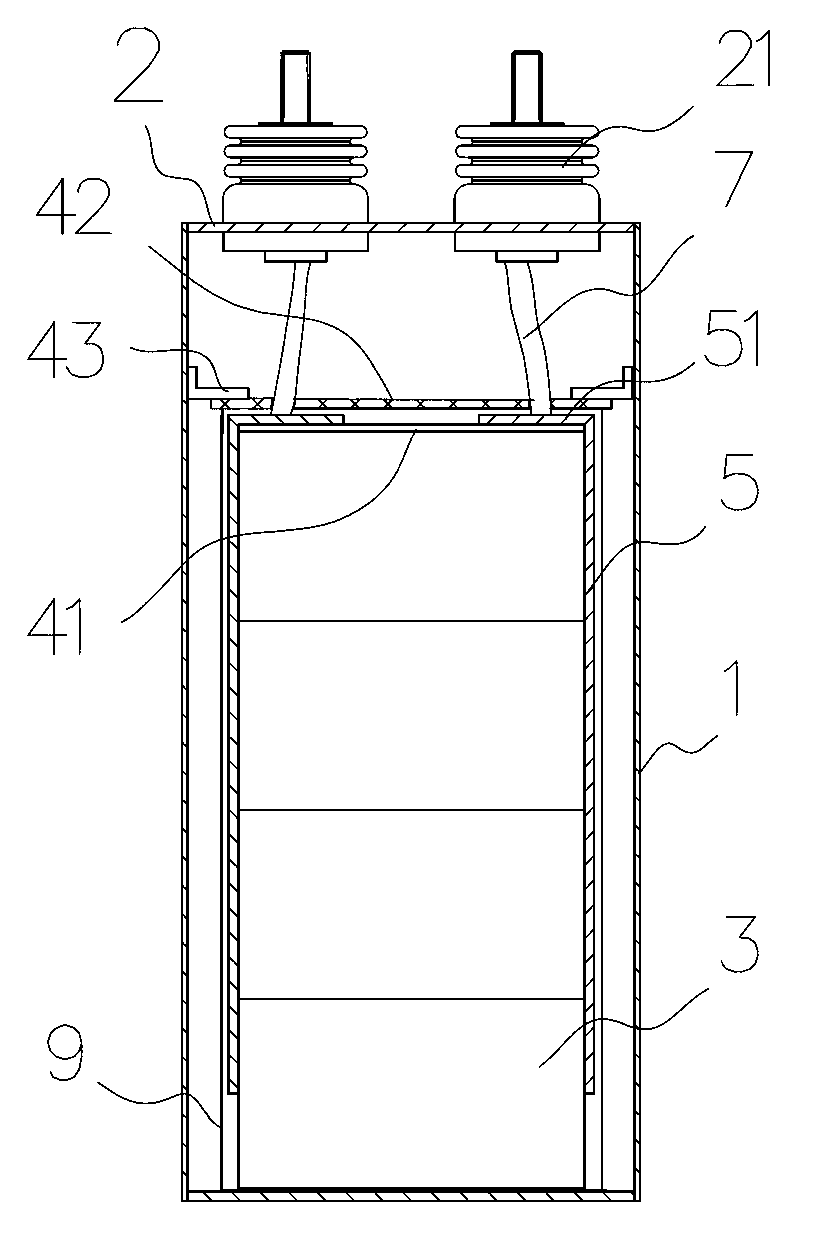

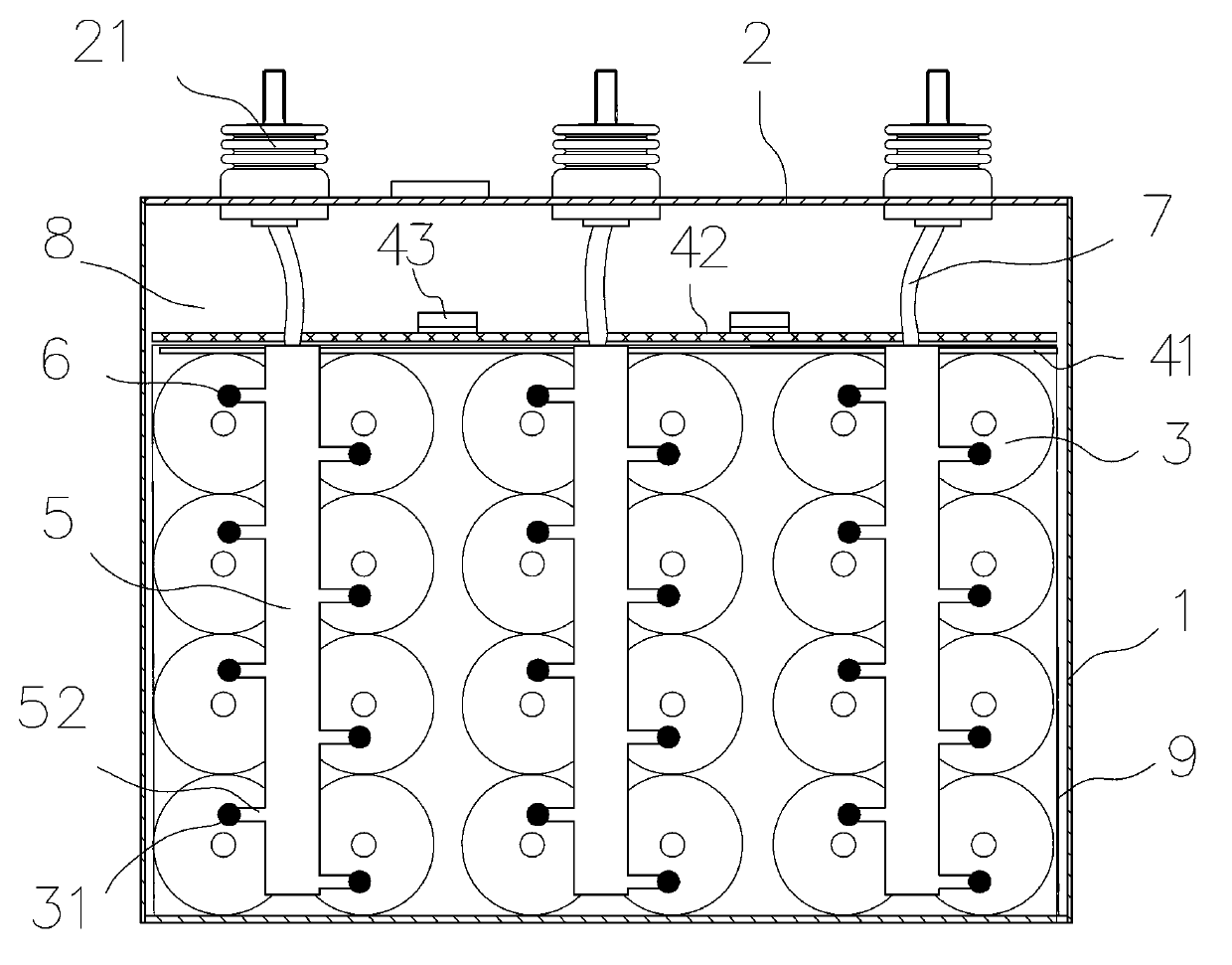

High-power power electronic capacitor for elastic connection among core sets and copper bars

The invention relates to a high-power power electronic capacitor for elastic connection among core sets and copper bars. The high-power power electronic capacitor comprises a cover plate assembly, an outer shell and the core sets. The core sets are fixed in the outer shell, leading-out copper strips are arranged on the two metal sprayed faces of each core set respectively, and bent leading-out electrodes are arranged at the upper ends of the leading-out copper strips and used for being electrically connected with leading-out terminals of the cover plate assembly through welding. Elastic conducting plates are arranged on the leading-out copper strips and extend to all capacitor core metal sprayed faces of the core sets, and the tail end of each elastic conducting plate is electrically connected with the corresponding capacitor core metal sprayed face through the welding. The core sets are connected with the leading-out copper strips in an elastic mode. The force, adhering to the elastic conducting plates, of welding points is strengthened. The situation that the leading-out copper strips have sufficient properties of current passing can be guaranteed, and in addition, the situation that the displacement of the core sets causes the welding points to be strained can be eliminated, so that the welding points are not prone to loosening and disengaging.

Owner:ANHUI TONGFENG ELECTRONICS

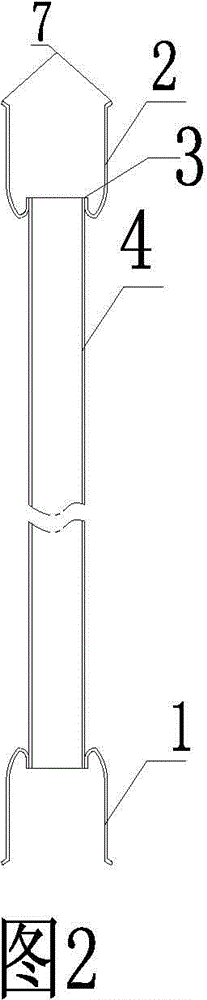

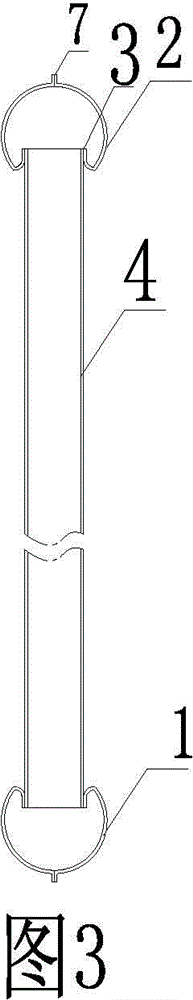

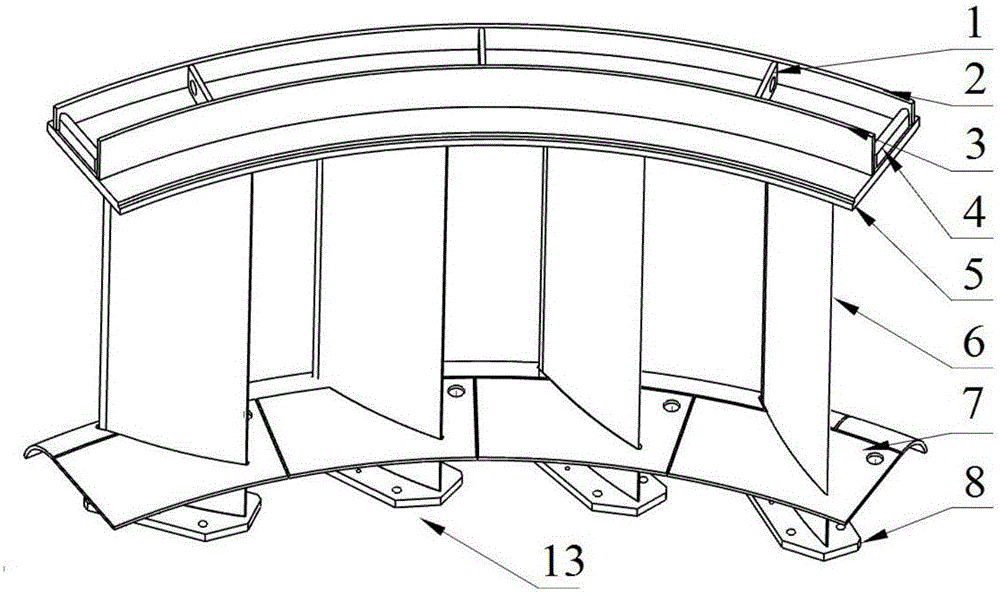

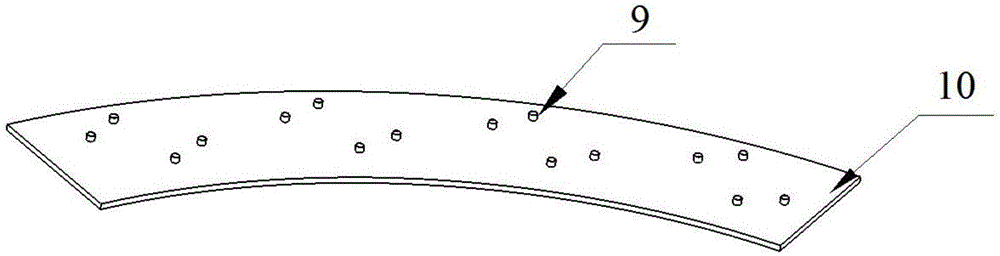

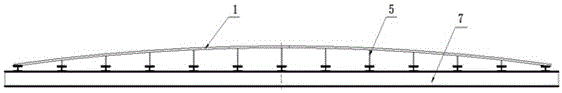

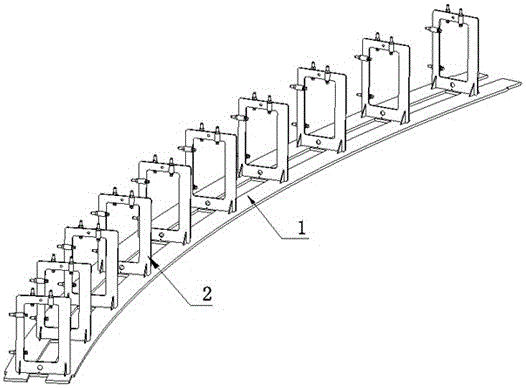

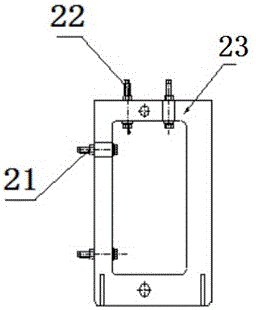

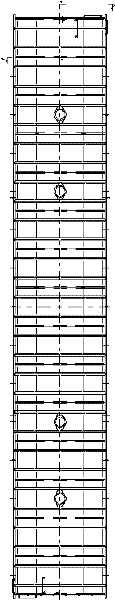

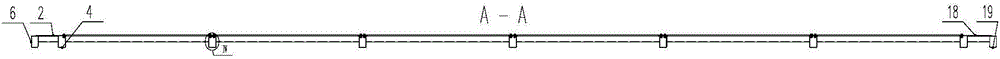

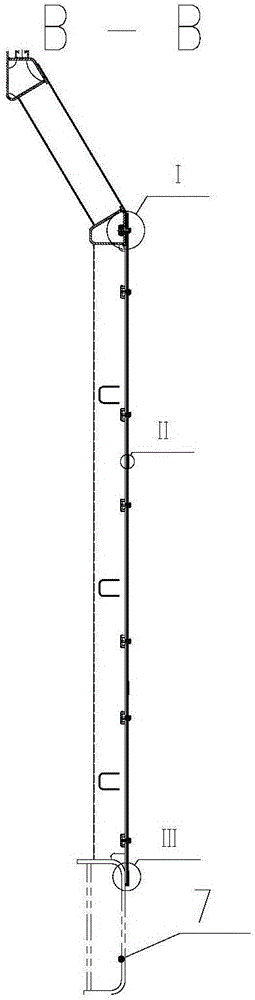

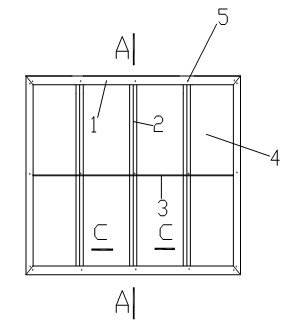

Suspension type train track beam, manufacturing method thereof and technical partition plates for track beam

InactiveCN106736198AHigh dimensional accuracy of cross-sectional structureFast weldingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringCanis lupus familiaris

The invention discloses a suspension type train track beam, a manufacturing method thereof and technical partition plates for the track beam. The track beam is composed of an upper cover plate, a lower cover plate, webs and rib plates. Limiting stop dogs are arranged between the bottom of the lower cover plate and a platform, and the camber curve of the track beam is ensured by the height of the limiting stop dogs. The technical partition plates are arranged in the length direction of the lower cover plate. A first adjusting screw is arranged on one side of each technical partition plate, and a second adjusting screw is arranged on the top of each technical partition plate. The webs are installed on the two sides of the technical partition plates. The bottom edges of the webs are fixedly welded to the lower cover plate. The upper cover plate is fixedly welded to the tops of the webs. The rib plates are welded outside the webs and the upper cover plate. When the upper cover plate, the lower cover plate and the webs perform discharging, dimensional allowance is reserved in the length direction, the track beam is marked in the length direction after welding so that the allowance can be cut off, and the length dimension of the track beam is ensured; and a tank opening fixing device is arranged, the track beam forms a closed structure in the assembly welding and transportation processes, deformation of a non-closed tank type track beam is effectively controlled, and the dimension precision of the track beam is ensured.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

A kind of low-density, high-strength and toughness automobile steel plate and its preparation process

The invention belongs to the field of metal materials, and relates to a novel high strength steel board low in density, high in strength and good in anti-corrosion performance, in particular to component design and a preparation method of the novel automobile-used steel. The automobile-used steel board is characterized by comprising the following specific chemical compositions by mass percentage: 0.60-0.70 percent of C, 0.30-0.40 percent of Si, 10.0-15.0 percent of Mn, 5.0-10.0 percent of Al, less than 0.005 percent of P, less than 0.003 percent of S and Fe and unavoidable impurities in balancing amount. The preparation process comprises the following steps: performing smelting according to the chemical compositions, and forging casting blank material into a steel blank; heating the steel blank to 1,130-1,170 DEG C, keeping the temperature for 2 hours, and performing multi-pass hot-rolling deformation, wherein the rolling starting temperature ranges from 1,030-1,070 DEG C, the rolling stopping temperature ranges from 850-900 DEG C, the accumulated deformation amount ranges from 80 percent to 85 percent, and the rolling temperature is from 200 DEG C to 250 DEG C; after hot rolling, further performing solution treatment of the steel board, keeping the temperature at 1,000-1,050 DEG C for 0.5-1 hour, and performing water quenching treatment; taking a dual-phase organization combining austenite and ferrite, and obtaining the lower density and high toughness automobile-used steel board.

Owner:UNIV OF SCI & TECH BEIJING

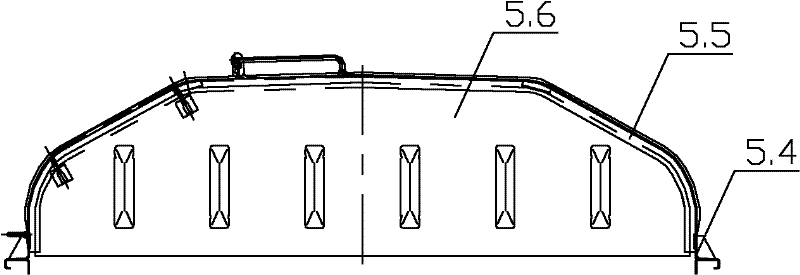

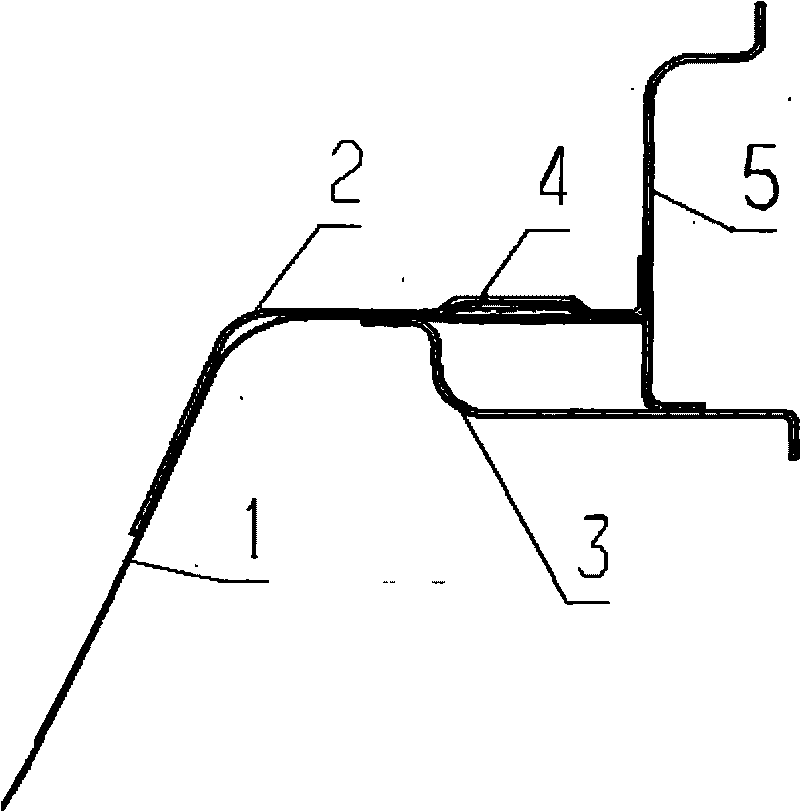

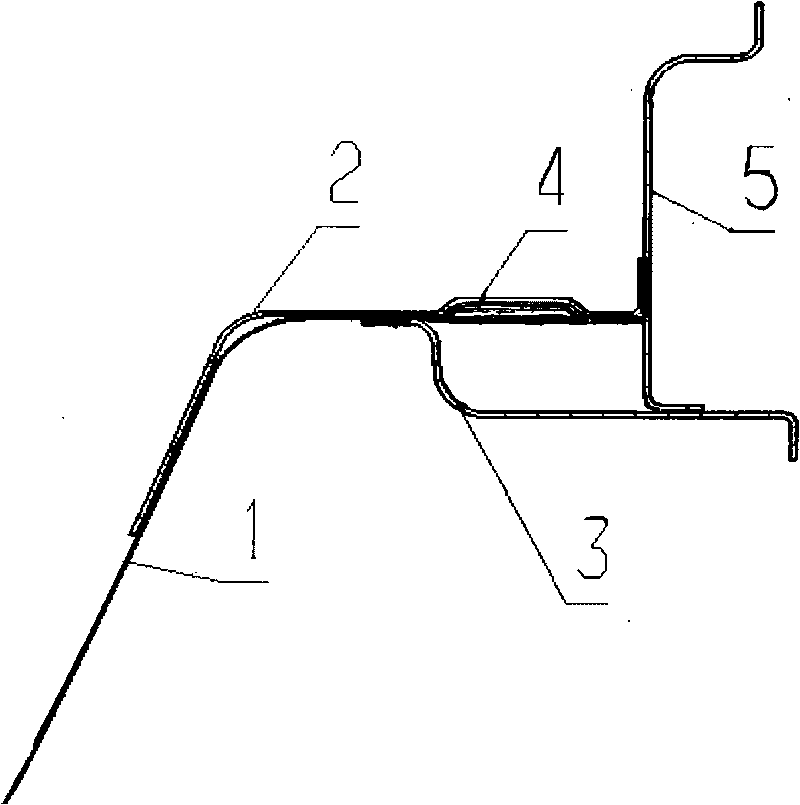

Dog-legged roof for railway boxcars

The invention discloses a dog-legged roof for railway boxcars, which belongs to the technical field of rail wagon manufacturing. The dog-legged roof disclosed by the invention comprises a roof panel, a ventilator, a roof carline, a roof cant rail, a roof end carline and a roof end panel, wherein the roof panel is in a pressed convex rib folding-pressing structure, the roof carline is in a flat steel folding-pressing structure, and the roof cant rail and the roof end carline are both made of cold-bending angle steel; the two sides of the roof panel in the middle are in lap joint with the roof carline, and the roof panel at ends is respectively in lap joint with the roof carline and the roof end carline; the two ends of the whole roof panel are in lap joint with the roof cant rail; and the roof end panel is in a steel-plate pressed convex rib structure, and the upper part of the roof end panel is in lap joint with the roof end carline. The profile of the dog-legged roof disclosed by the invention follows rolling stock clearance for railway, therefore, the rolling stock clearance for railway is used fully, so that the area of an internal section of a vehicle can be effectively expanded, the volume of the vehicle can be increased, the length of the vehicle can be shortened, and the dead weight of the vehicle can be reduced.

Owner:CRRC MEISHAN

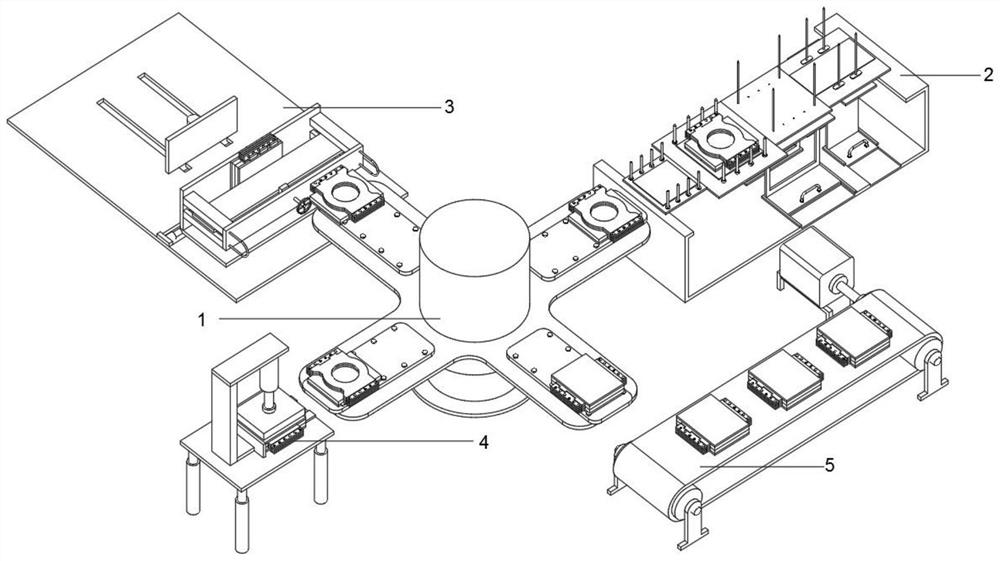

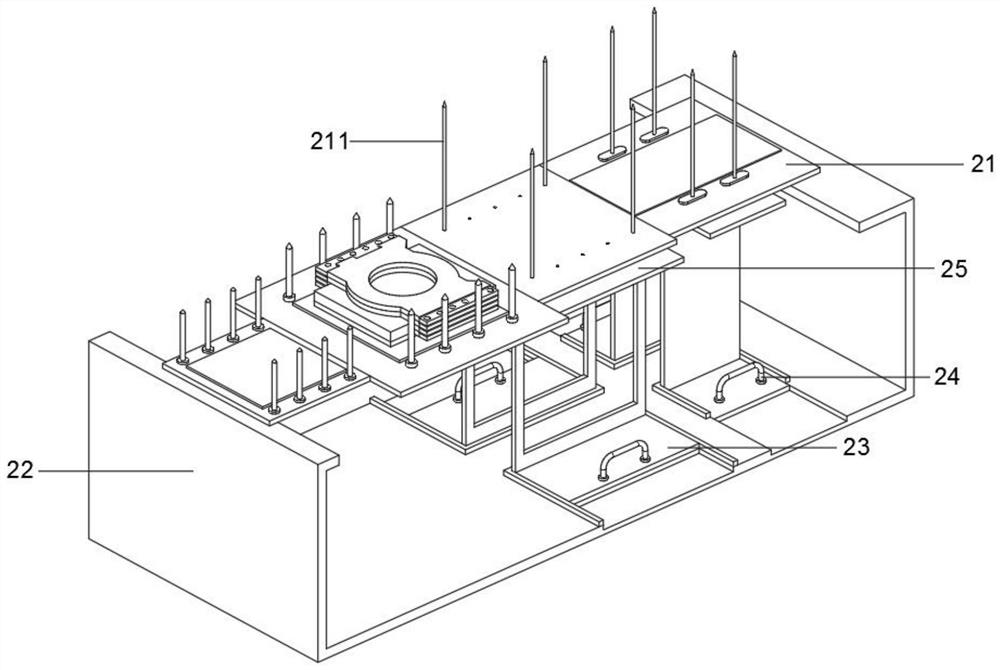

Large-current planar transformer assembling equipment and assembling method

PendingCN114284051AReduce the difficulty of assemblyImprove assembly efficiencyCoils manufactureOutput transformerStructural engineering

The invention provides a large-current planar transformer assembling device and method, and relates to the technical field of transformer assembly.The assembling device comprises a four-station rotary table, a coil clamp, a coil pin clamp and an overall alignment clamp, and a conveying belt for outputting transformer finished products is arranged on one side of the four-station rotary table; the coil clamps, the coil pin clamps, the overall alignment clamps and the conveying belt are clockwise arranged at equal intervals with the four-station rotating disc as the circle center, and clamping structures with multiple limiting functions are arranged in the coil pin clamps, so that coil pins can be conveniently connected. Corresponding clamp devices are adopted in the assembling processes of the composite coil body, the composite coil leading-out ends and the transformer body, the assembling difficulty can be reduced, the assembling efficiency can be improved, the assembling yield and consistency can be improved, clamping structures in the coil pin clamps provide pressing and limiting for the top and the two sides of a composition, and the assembling efficiency can be improved. The pins can be conveniently welded and assembled through 90-degree rotation limiting, and the multiple limiting structures enable the pins to be accurately and rapidly assembled.

Owner:无锡兰迪电子有限公司

Method for welding titanium and steel by applying high-entropy effect and welding material

InactiveCN102672328BWide adaptabilityEasy to processWelding/cutting media/materialsSoldering mediaWeld seamTitanium

The invention discloses a method for welding titanium and steel by applying the high-entropy effect. A folded middle-layer alloy foil is arranged between a titanium plate to be welded and a steel plate to be welded, and the welding operation is carried out by adopting a resistance spot-welding mode, then the interface resistance heat melts the middle-layer alloy and local base materials, and the molten metals are mixed, so that the high-performance welding of titanium and steel is realized. The invention also discloses a middle-layer alloy and a preparation method of the middle-layer alloy. The middle-layer alloy comprises the following components in the terms of atomic percent: 20-30% of Al, 35-40% of Ni and 35-40% of Cu, wherein the total percent is 100%. The invention has the advantages that the middle-layer alloy is well matched with the titanium and the alloy steel in welding, welding seams (nugget) are single-phase fcc solid-solution structures, and the comprehensive mechanical performance of joints is obviously improved. The preparation method of the middle-layer alloy foil is simple in process and low in manufacturing cost.

Owner:XIAN UNIV OF TECH

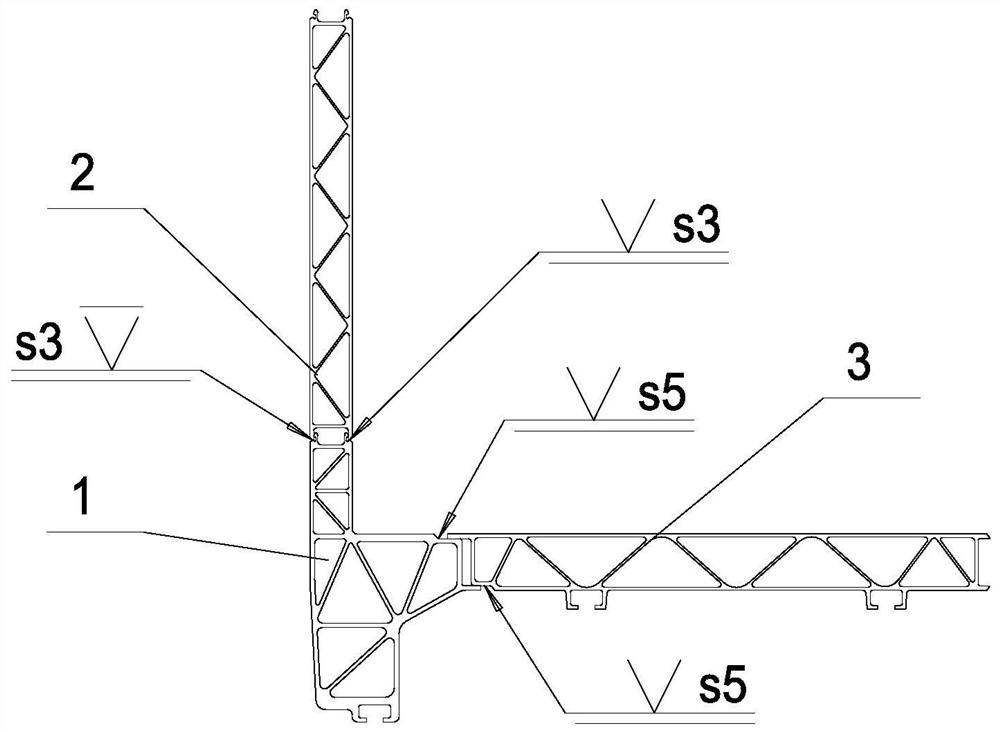

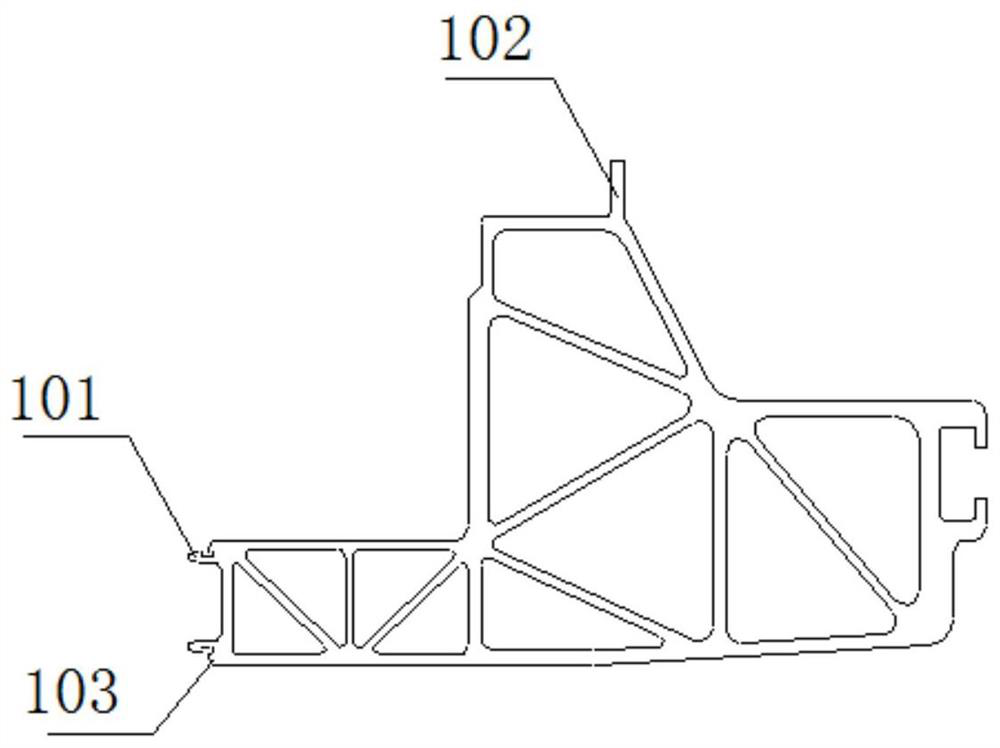

Connecting structure for underframe edge beam and side wall of straddle-type monorail vehicle body

PendingCN112061162AImprove carrying capacityMeet the design requirements for hoistingMonorailsUnderframesLap jointWeld seam

Disclosed is a connecting structure for an underframe edge beam and a side wall of a straddle-type monorail vehicle body. The connecting structure for the underframe edge beam and the side wall of thestraddle-type monorail vehicle body is capable of improving the structural strength of an underframe structure, simplifying the manufacturing process, and greatly reducing the arc welding quantity. The whole structure is formed by combining and welding hollow double-wall large aluminum alloy extrusion profiles, and the structure is designed to be lightweight. The longitudinal full-length arrangement of an underframe edge beam profile ensures that the strength and rigidity of the vehicle body satisfy the requirements under the action of longitudinal, vertical, torsional and other loads. An insertion connector is designed at the connecting position of the underframe edge beam profile and the side wall so as to simplify the connecting form of the side wall and an underframe, improve the assembly precision of the side wall and the underframe, reduce the assembly difficulty, reduce the amount of welding seams at the connecting position of the side wall and the underframe, and improve the overall quality and precision. A lap joint connector is designed at the position where the underframe edge beam profile is connected to an aluminum bottom plate in the horizontal direction, and the structure is convenient to be assembled and welded to the aluminum bottom plate. The overall width of the underframe aluminum structure can be adjusted during underframe final assembly, and the requirement for manufacturing precision is satisfied.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

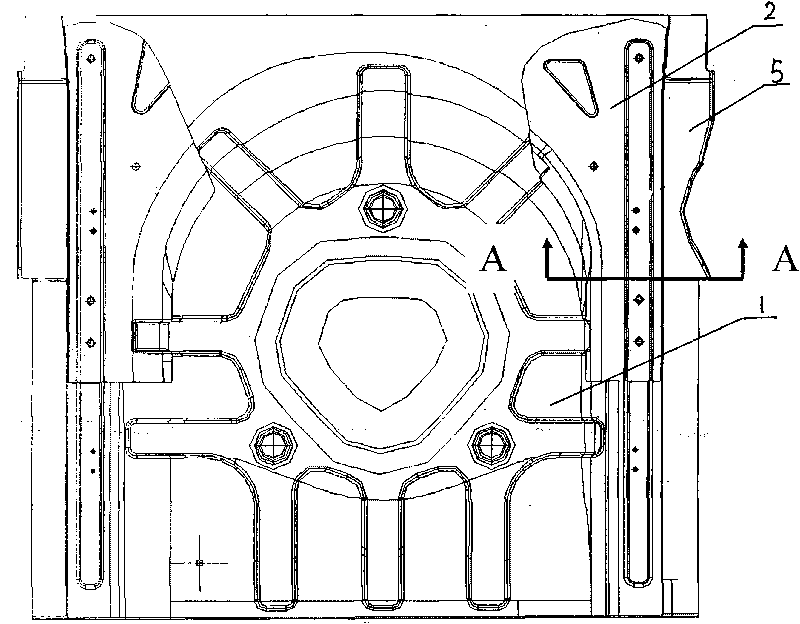

Automobile rear floor bearing structure

InactiveCN101700789AImprove carrying capacityGood workmanshipSuperstructure subunitsMechanical engineeringEngineering

The invention relates to an automobile rear floor bearing structure, comprising a rear floor of an automobile, rear longitudinal beams, rear floor side boards, rear floor reinforcing parts and rear floor nut boards. The two rear floor reinforcing parts are welded onto the front half part of the rear floor, namely near to the upper parts of the left and the right of one side in the automobile; the outer side edges of the two rear floor reinforcing parts as well as the left side and the right side of the rear floor are welded onto the rear floor side boards, and the inter side edges extend to the edge of the tire placing groove of the rear floor and are in welded connection with the rear floor; and the rear floor nut boards are in the shape of a stripe and are clamped between the rear floor and the rear floor reinforcing parts and welded onto the rear floor and the rear floor reinforcing parts. The automobile floor rear part bearing structure has reasonable design and good strength, is easy to assemble and weld and can be suitable for the automobile whose trunk needs to be provided with a gas tank.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904BImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor in a resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

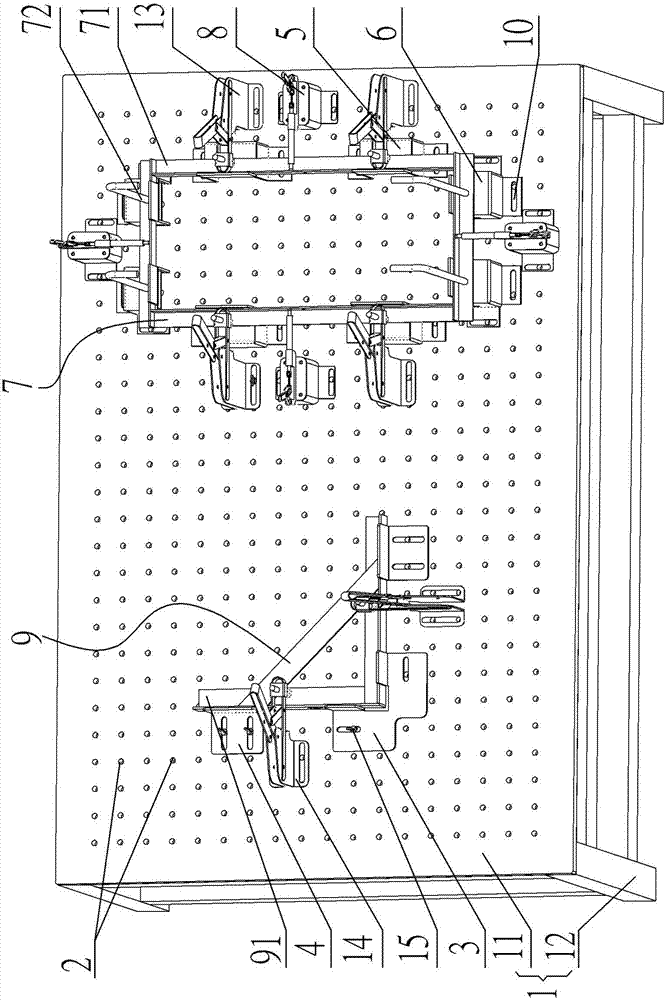

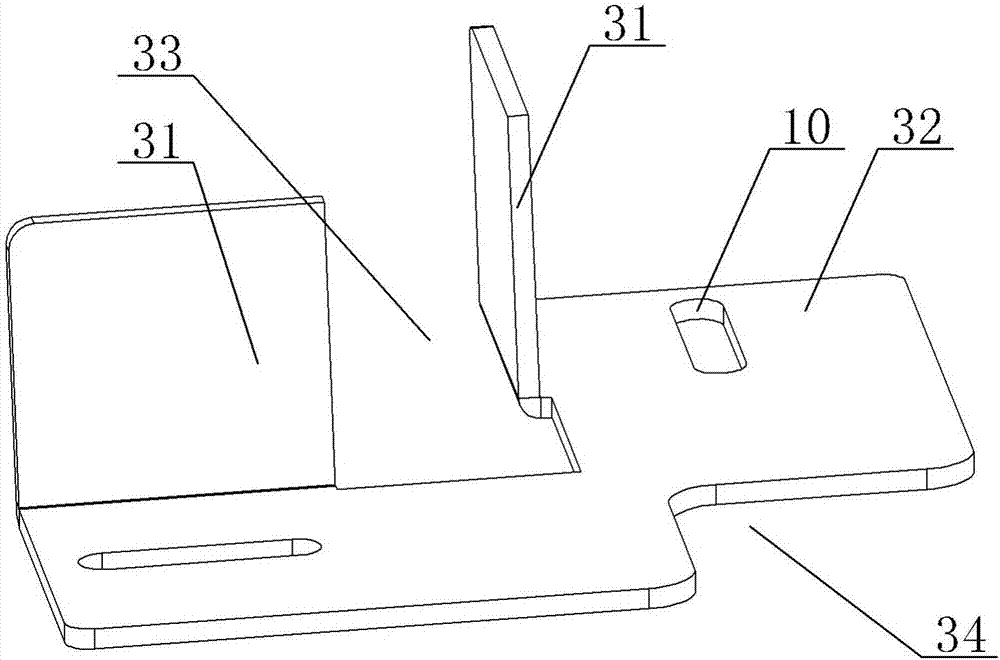

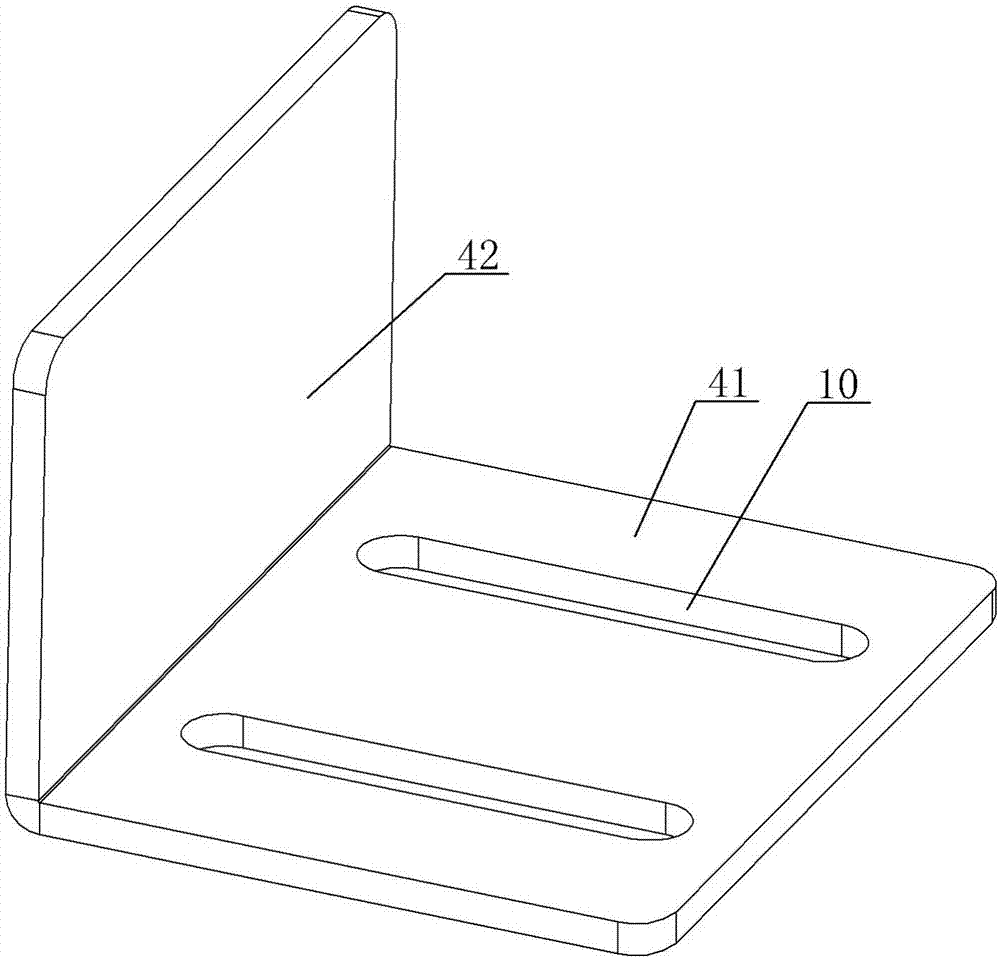

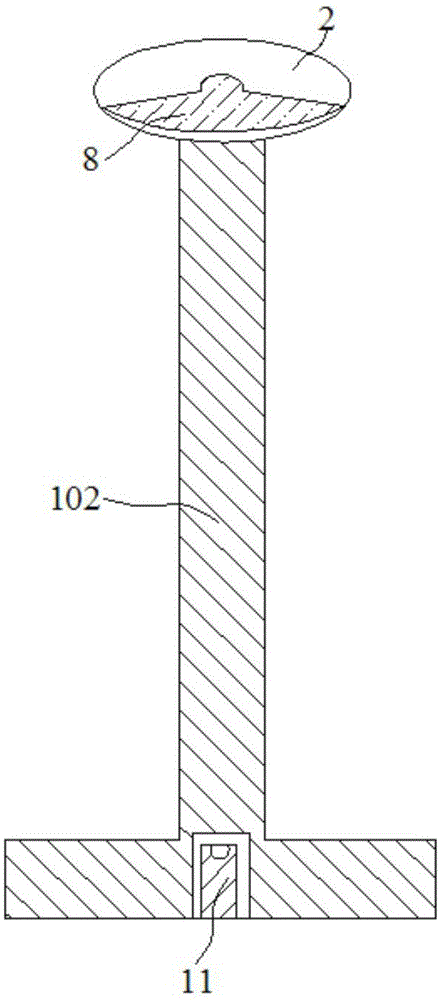

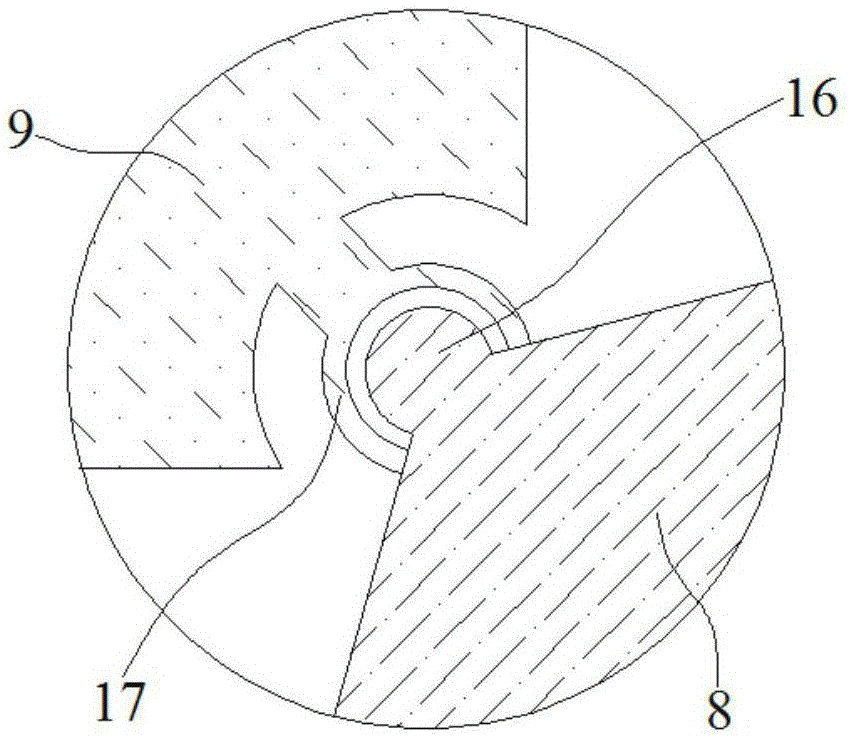

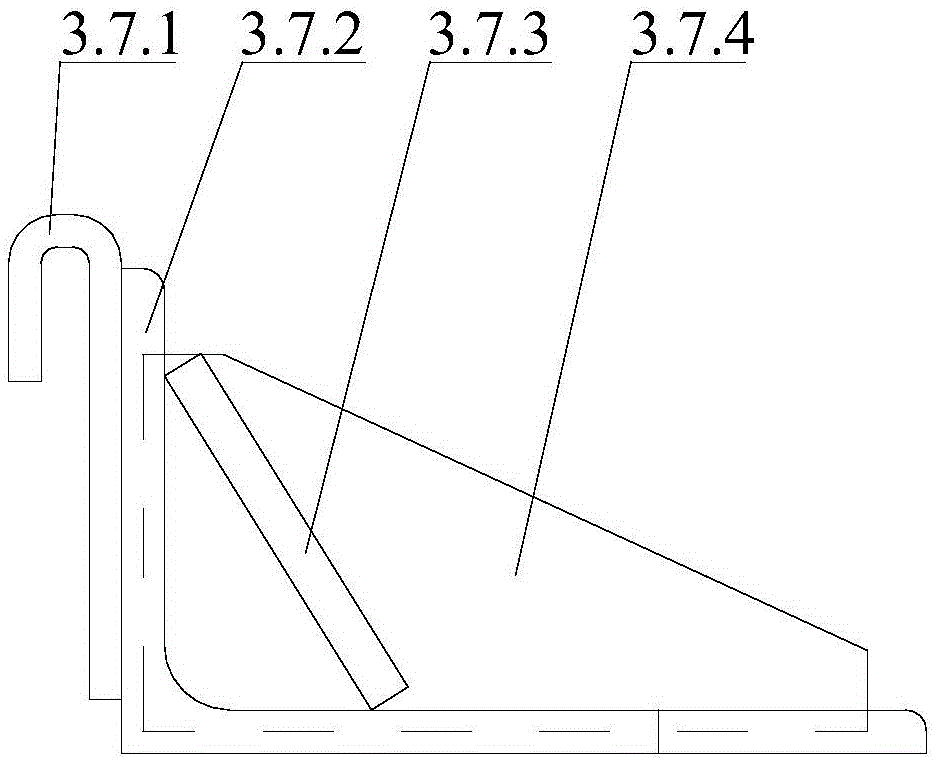

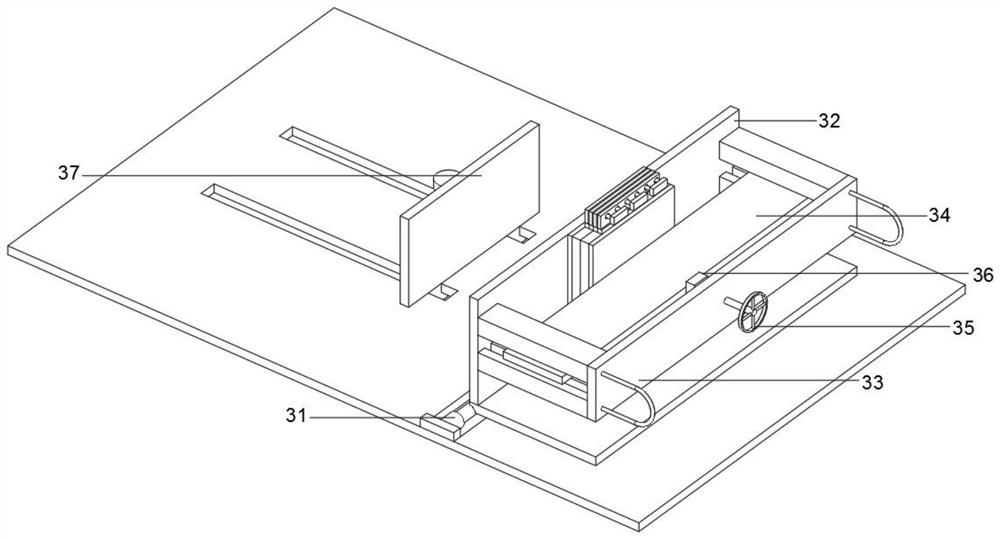

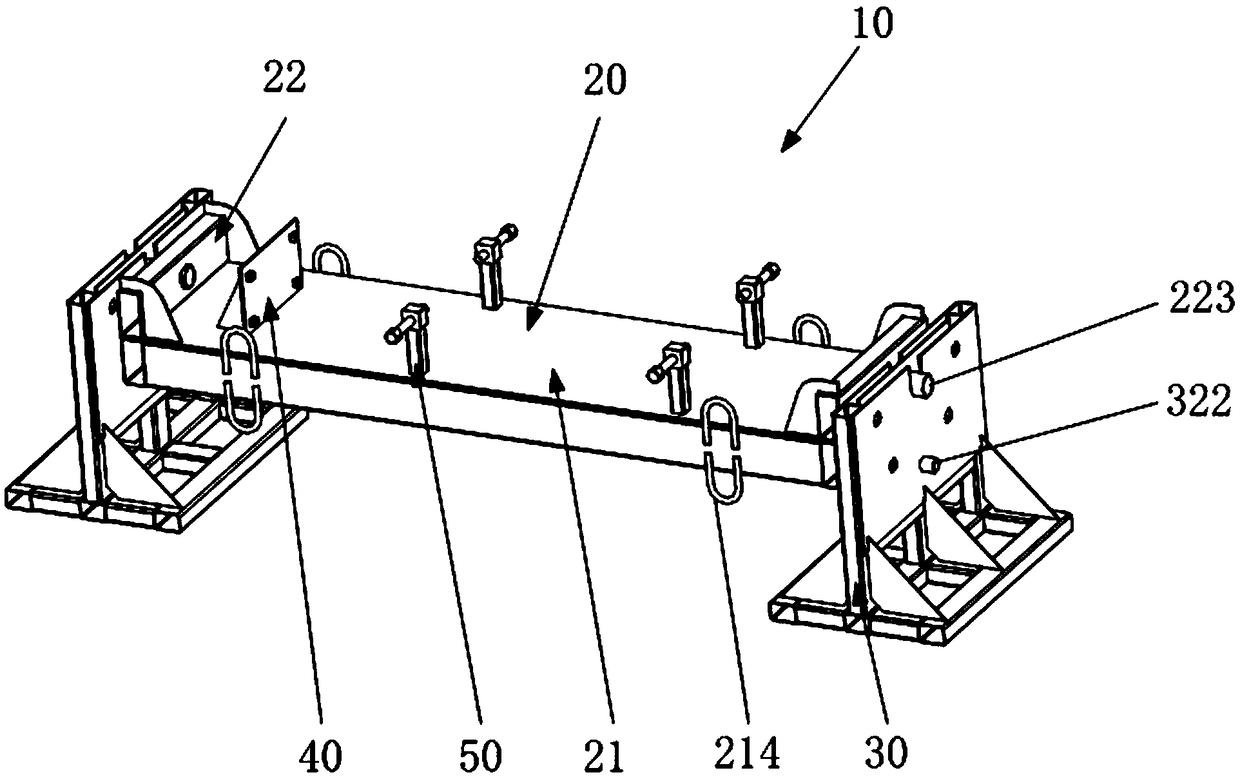

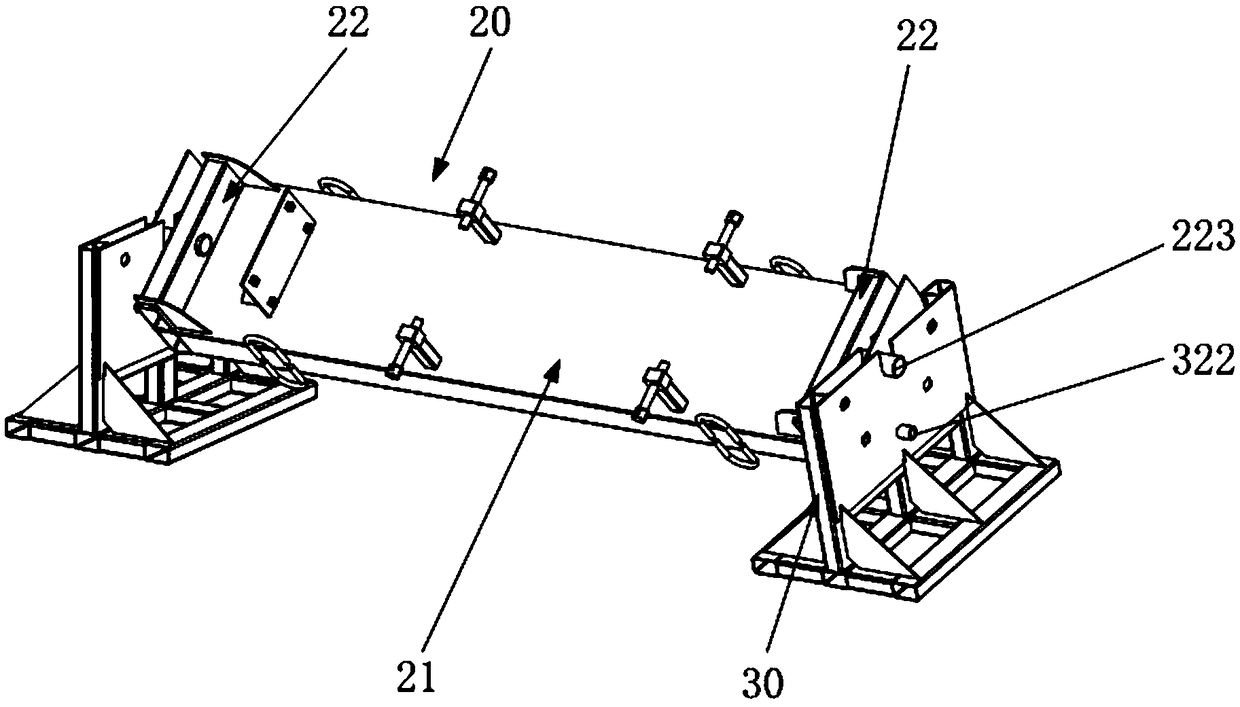

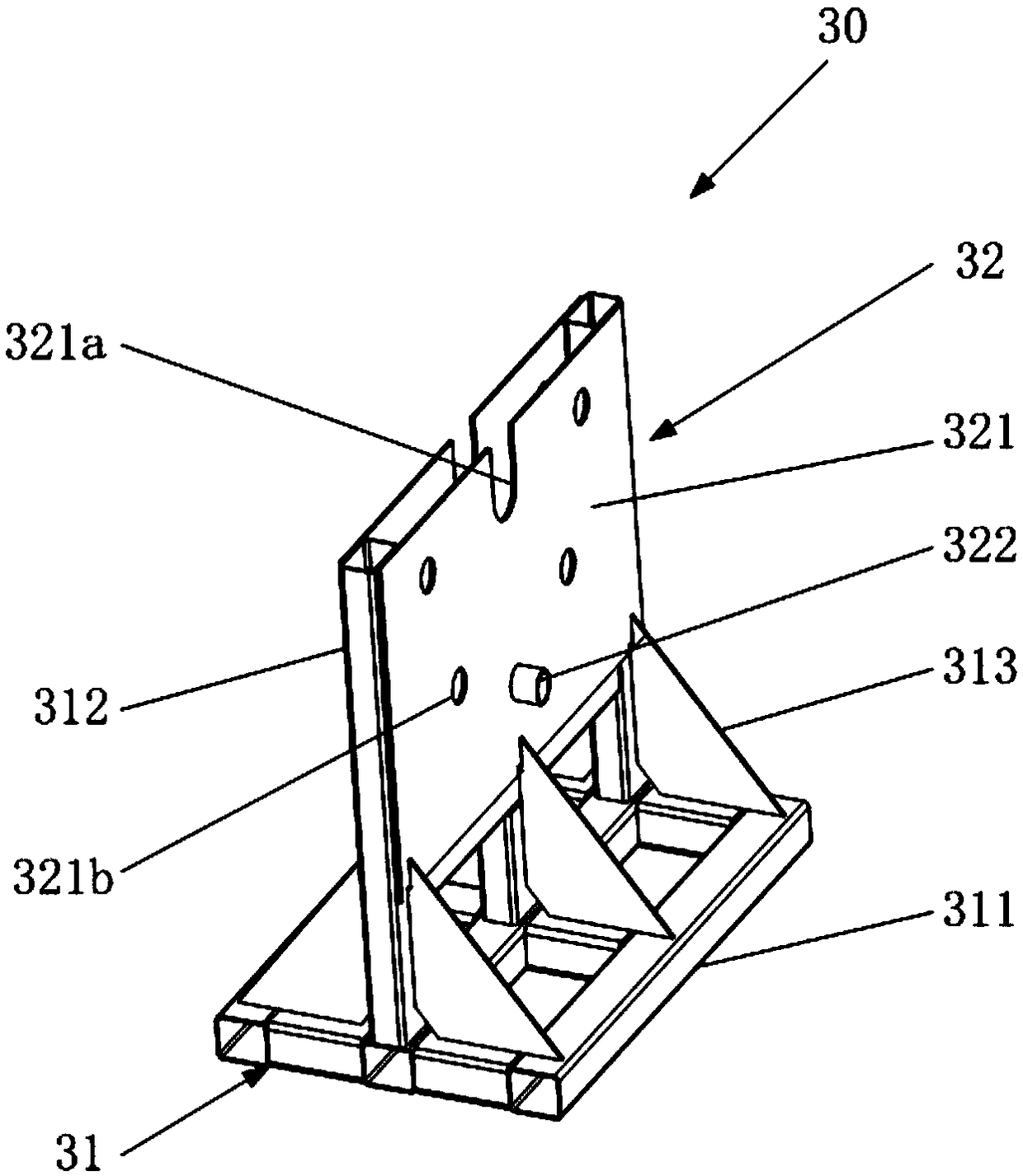

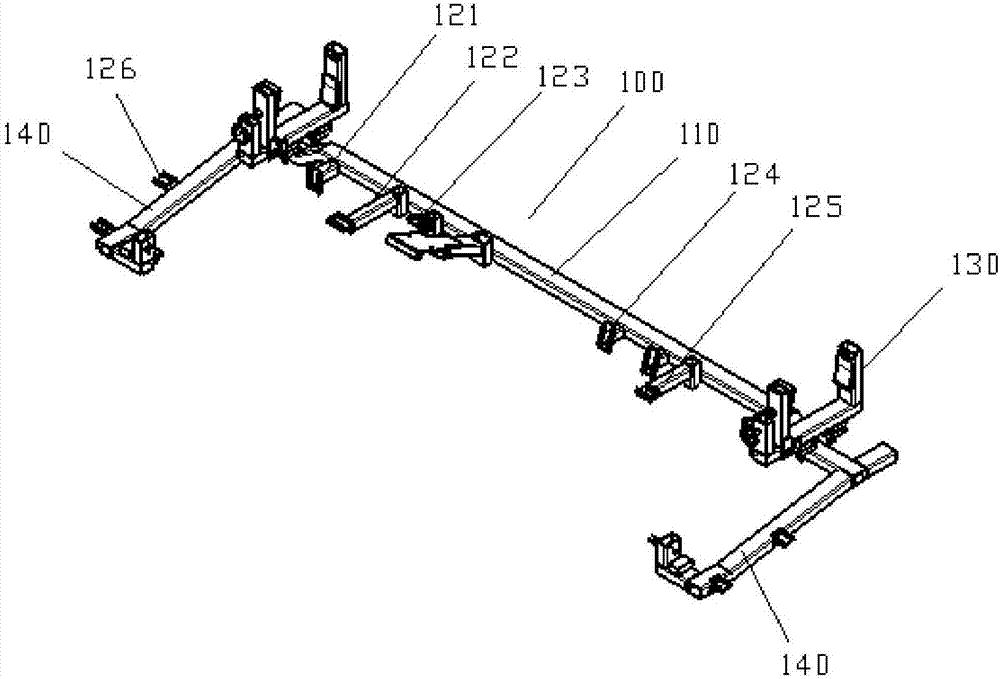

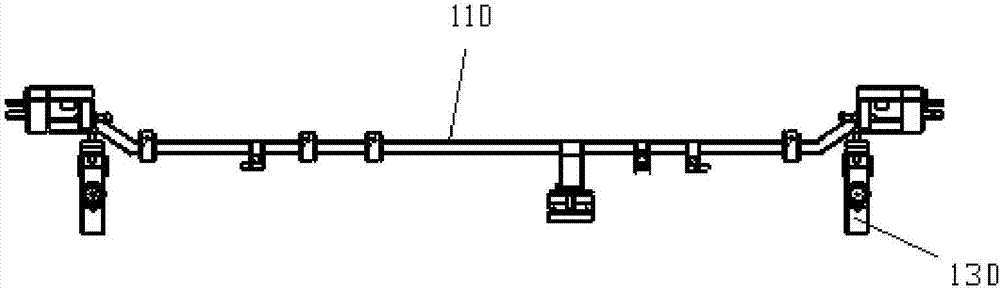

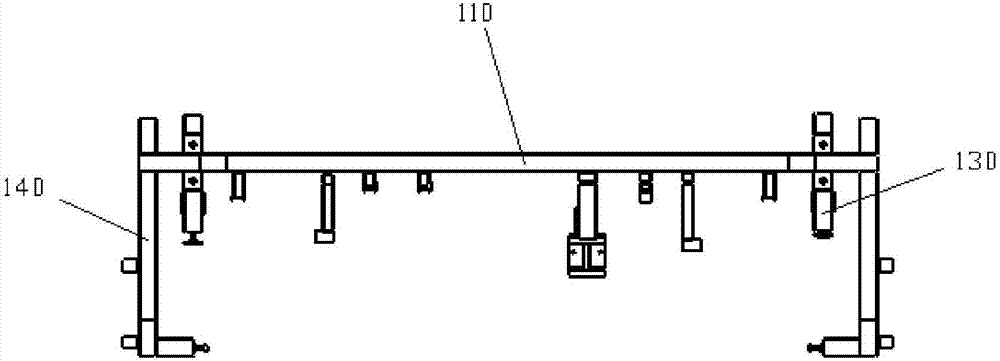

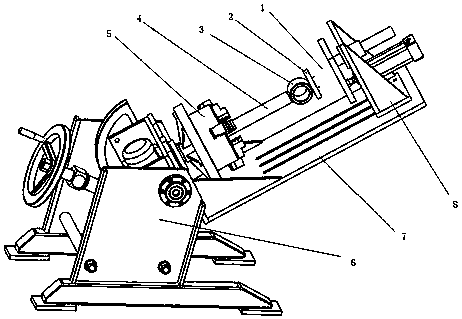

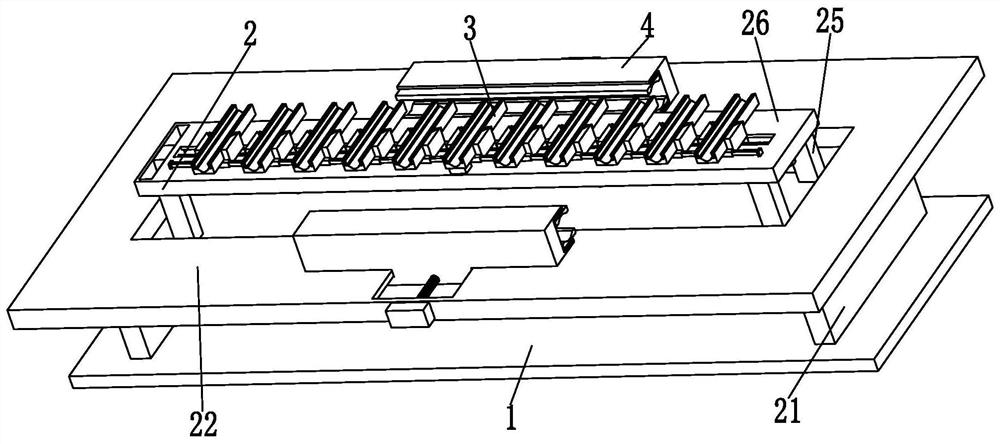

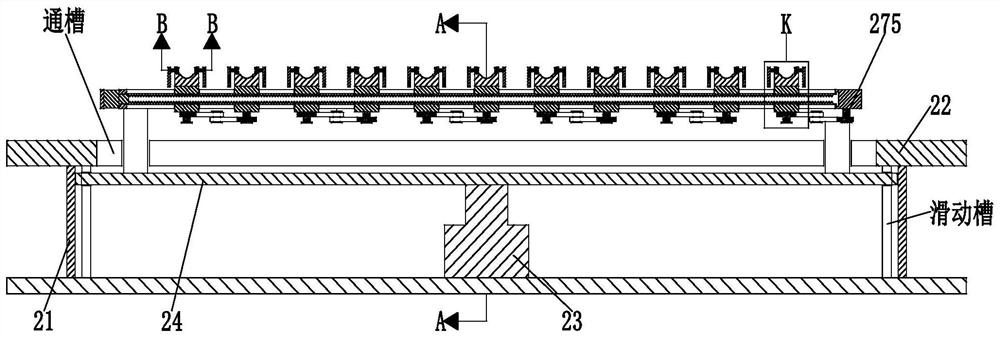

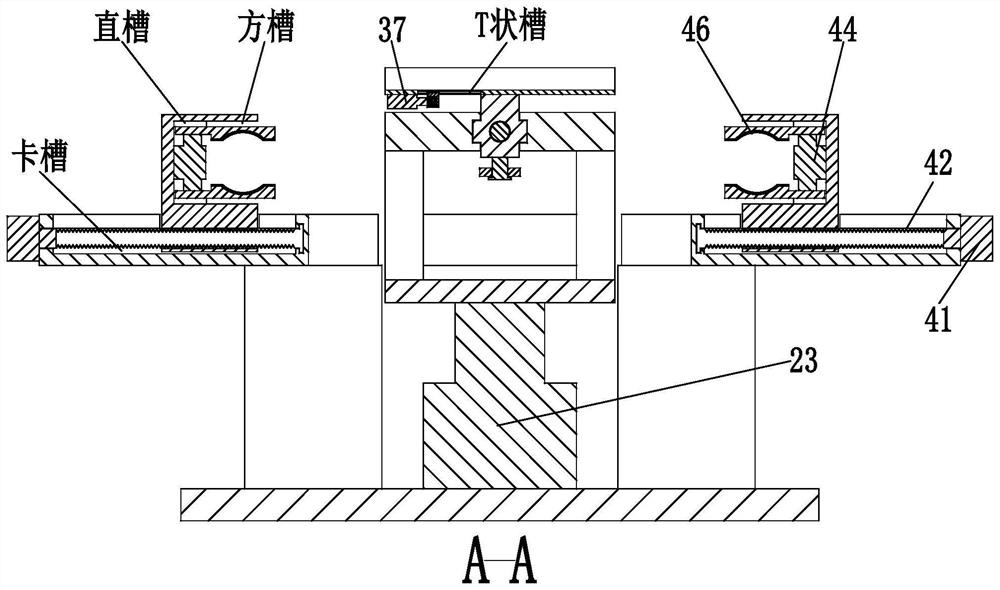

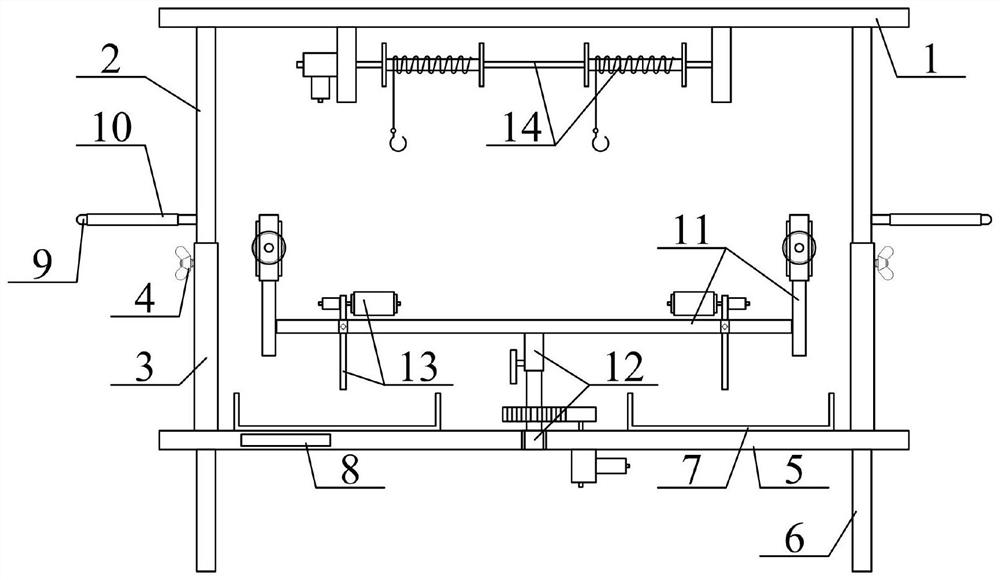

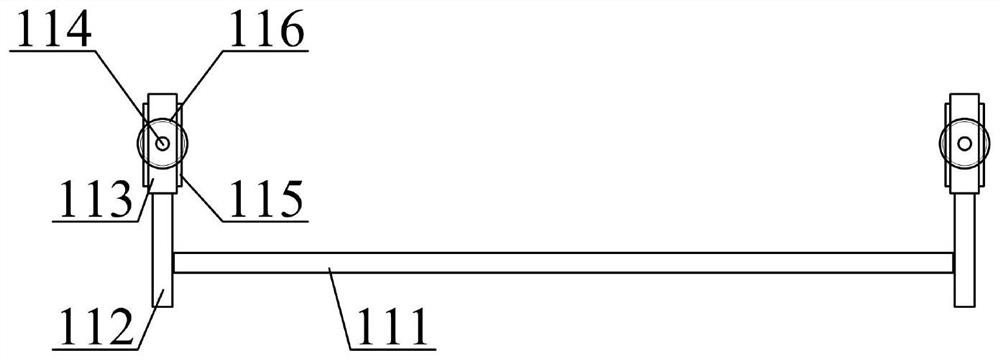

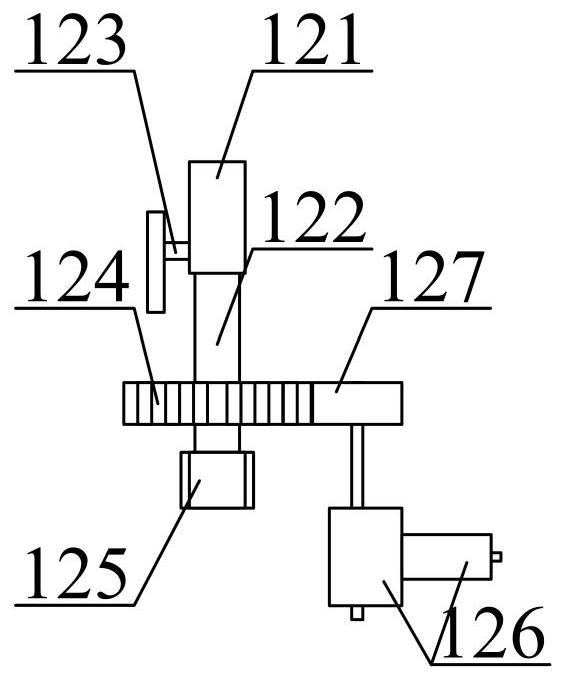

Assembling and welding clamp

PendingCN108723676ALow costEasy to assemble and weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an assembling and welding clamp. The assembling and welding clamp comprises a platform working unit, a rotary supporting unit for supporting the platform working unit and a clamping unit mounted on the platform working unit, wherein the platform working unit is provided with a working platform for carrying out assembling and welding work and rotating mechanisms mounted at two end sides of the working platform; the rotating mechanisms and the working platform can be integrally supported through the rotary supporting unit in a manner of rotating relative to the rotary supporting unit, and can be positioned in a specified angle in a rotation range of the rotating mechanisms and the working platform. The assembling and welding clamp disclosed by the invention can be used for carrying out assembling and welding production on medium-size and small-size steel structure parts in a low-cost and high-reliability manner.

Owner:BAOTOU NORTH VENTURE

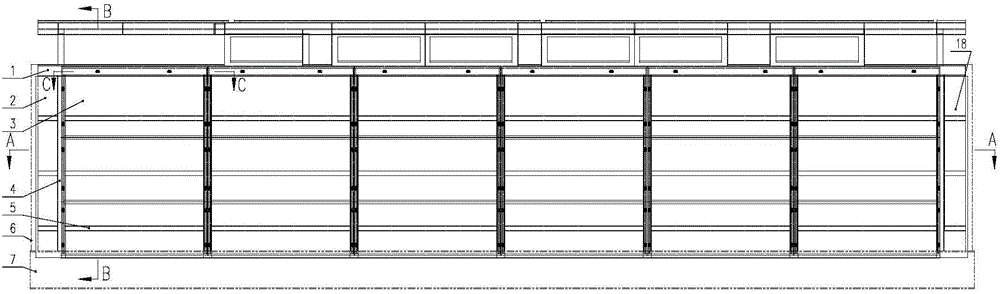

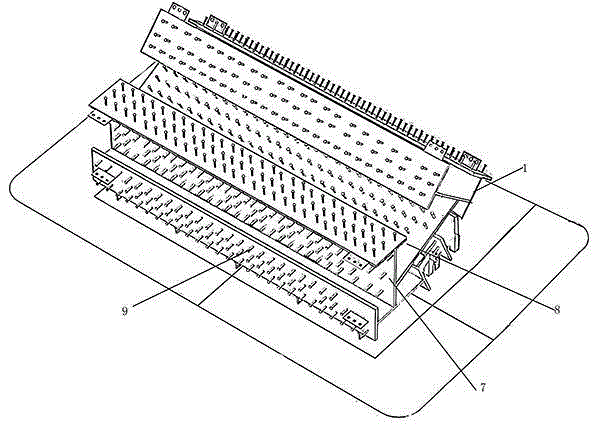

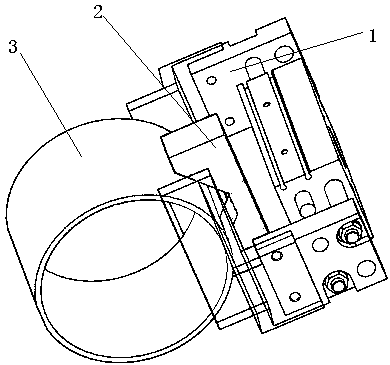

Pipeline installing and welding tool

ActiveCN106881550AEasy to assemble and weldAchieve positioningWelding/cutting auxillary devicesPipeline systemsEngineeringPipe support

The invention provides a pipeline installing and welding tool. The pipeline installing and welding tool comprises a wire pipe installing and welding device. The wire pipe installing and welding device comprises a first main beam. The first main beam is provided with a plurality of installing parts for fixing a wire pipe to be installed and welded. The multiple installing parts are arranged at intervals in the extending direction of the first main beam so as to fix the corresponding parts of the wire pipe. The pipeline installing and welding tool solves the problem that the procedures of a pipe support assembling technology in the prior art are complex.

Owner:CSR TIANJIN METRO VEHICLES +1

Side-wall structure of railway vehicle

ActiveCN106347388AEasy to assemble and weldEasy to assemble and disassembleAxle-box lubricationRailway bodiesWeld seamChassis

The invention discloses a side-wall structure of a railway vehicle. The side-wall structure comprises a side-wall skeleton, wherein the side-wall skeleton is used for being fixed on a bottom-frame boundary beam, and comprises a plurality of side-wall vertical columns, a plurality of intermediate longitudinal beams and a side-wall upper-chord beam; a side-wall fixing skin is respectively arranged between the vertical column at the front end part of the side wall and a wall-partitioning vertical column of a driver cab and between the vertical column at the rear end part of the side wall and a vertical column of the rear-end wall; and detachable side-wall movable skins are arranged in the area enclosed by the vertical column at the front end part of the side wall, the vertical column at the rear end part of the side wall, the side-wall upper-chord beam and the bottom-frame boundary beam. The side-wall structure disclosed by the invention has the advantages that the side-wall skeleton is assembled and welded on the bottom-frame boundary beam, so that the welding can be carried out on welding seams between the side-wall vertical columns and the bottom-frame boundary beam outside a vehicle body. In addition, great convenience is brought for installation, overhauling and maintenance of equipment in a machine room.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

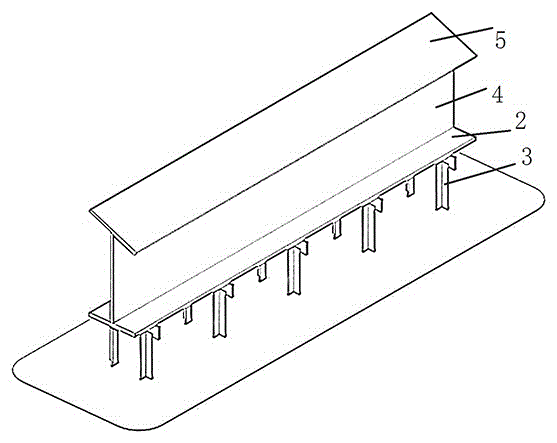

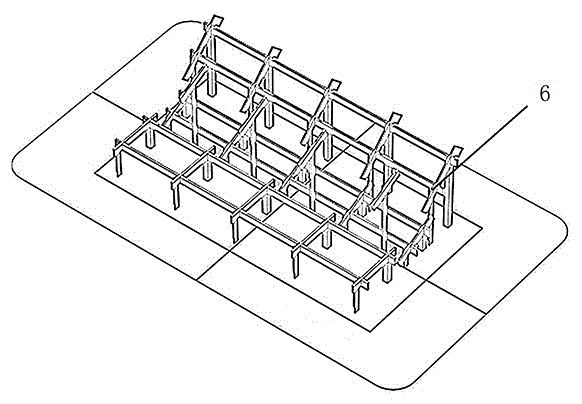

Steel rib double-T-shaped column and manufacturing method thereof

The invention discloses a steel rib double-T-shaped column. The steel rib double-T-shaped column comprises a baseplate, a scaffold, a support plate, an upper cover plate, a support jig frame, a T-shaped unit, a connecting plate and a cotter, wherein the baseplate is arranged on the scaffold; the support plate is arranged on the baseplate; and the upper cover plate is arranged above the support plate to form an H-shaped unit. In the steel rib double-T-shaped column, the H-shaped unit and the T-shaped unit are combined for use to form the steel rib double-T-shaped column, so that the steel rib column structure is largely optimized, the connecting capacity of all steel structures is enhanced, the support force is largely increased, the use safety of the whole steel structure building is improved, and the construction demands are preferably satisfied; and meanwhile, the support jig frame consists of three sets of jig frames, and is arranged in an incremental manner to preferably satisfy the steel structure building demands, so that the preferable assembly welding of the whole steel rib double-T-shaped column is effectively guaranteed, and the quality of the steel rib double-T-shaped column is guaranteed.

Owner:JIANGSU JINGHU HEAVY IND

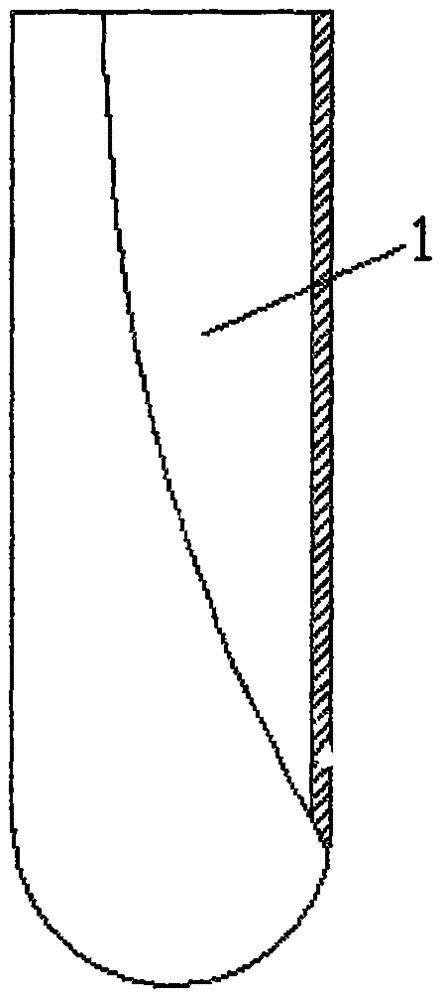

Natural gas cylinder liner for drawing process forming

InactiveCN106704821AReduce the amount of weldingReduce processing costsContainer filling methodsContainer discharging methodsGas cylinderProcessing cost

The invention discloses a natural gas cylinder liner for drawing process forming. The liner comprises a cylinder body (1) and an end enclosure (2). The liner is characterized in that the cylinder body (1) and the end enclosure (2) are matched by welding to form a closed annular inner cavity, wherein the cylinder body (1) and the end enclosure (2) are of an integral structure. The cylinder body (1) disclosed by the invention is improved to the integral structure through a middle rotating plate and a structure of being welded to a barrel in the prior art, so that the welding amount is reduced, the processing cost is lowered, and problems such as welding deformation and solder skips and the like of the cylinder body (1) caused by large-area welding are further avoided. Meanwhile, the key problems that the liner fails as fatigue cracks are generated weld joints in the prior art and the like are solved.

Owner:温州深拉防爆设备有限公司

High-speed railcar ring-structure hydraulic damper piston rod assembling welding fixture

PendingCN109623242ASolve positioning difficultiesEasy to assemble and weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention relates to a high-speed railcar ring-structure hydraulic damper piston rod assembling welding fixture. The fixture comprises a large-bore finger air cylinder, a V-shaped positioning block, a single-axis servo positioner, a chuck, a fixture seat and a fixture installing seat, wherein the chuck and the fixture installing seat are arranged on the single-axis servo positioner so that orientation change of the chuck and the fixture installing seat can be achieved; the chuck is provided with gripper jaw so that a piston rod can be fixed; the fixture seat and the fixture installing seatare slidably connected so that the position of the fixture seat can be adjusted to adapt to the length of the piston rod; the fixture seat is provided with the large-bore finger air cylinder, the large-bore finger air cylinder is connected with the V-shaped positioning block, and the V-shaped positioning block is used for positioning a lifting ring; and after positioning of the piston rod and thelifting ring are completed, the single-axis servo positioner rotates, and welding is conducted. According to the high-speed railcar ring-structure hydraulic damper piston rod assembling welding fixture, the problem that the piston rod and a connection ring are difficult to position is solved, assembling welding is convenient, and the yield is high.

Owner:ZHUHAI YECHENG RAIL TRANSPORTATION EQUIP TECH

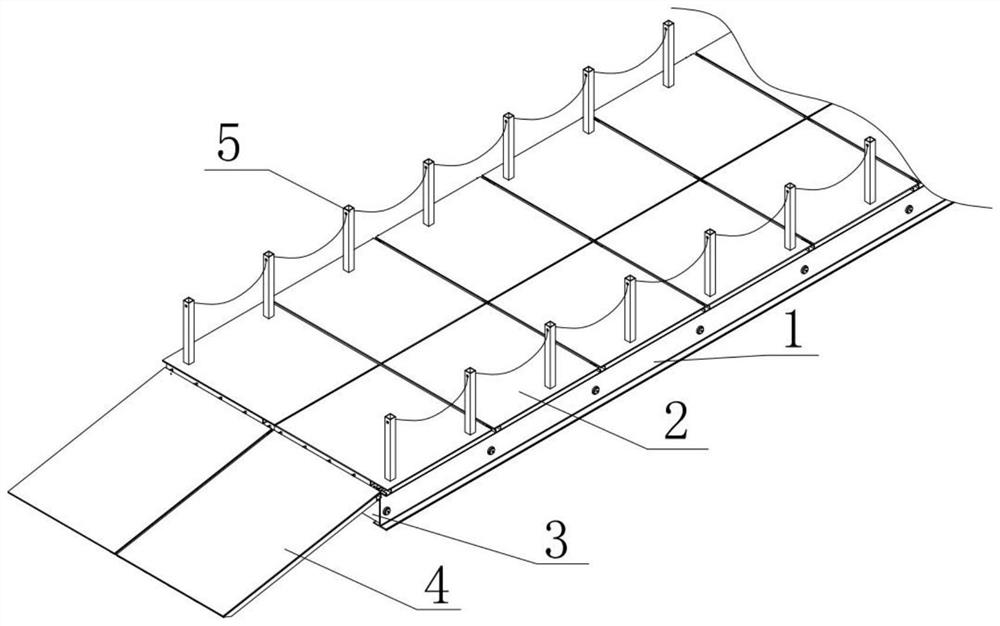

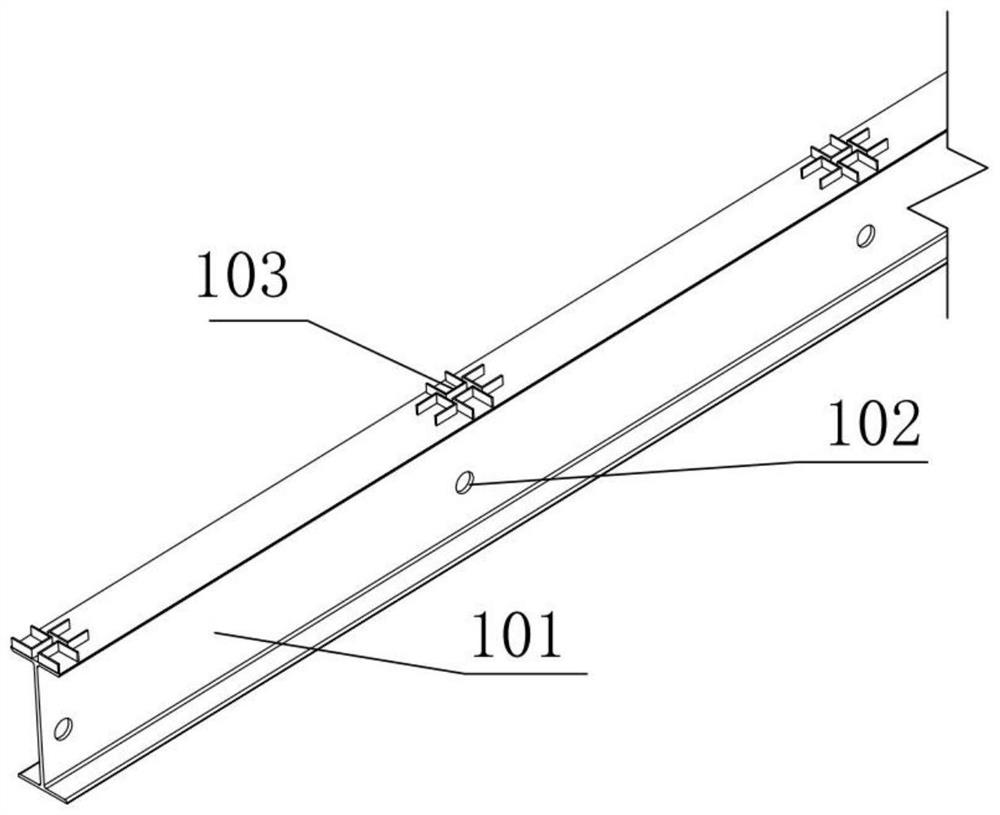

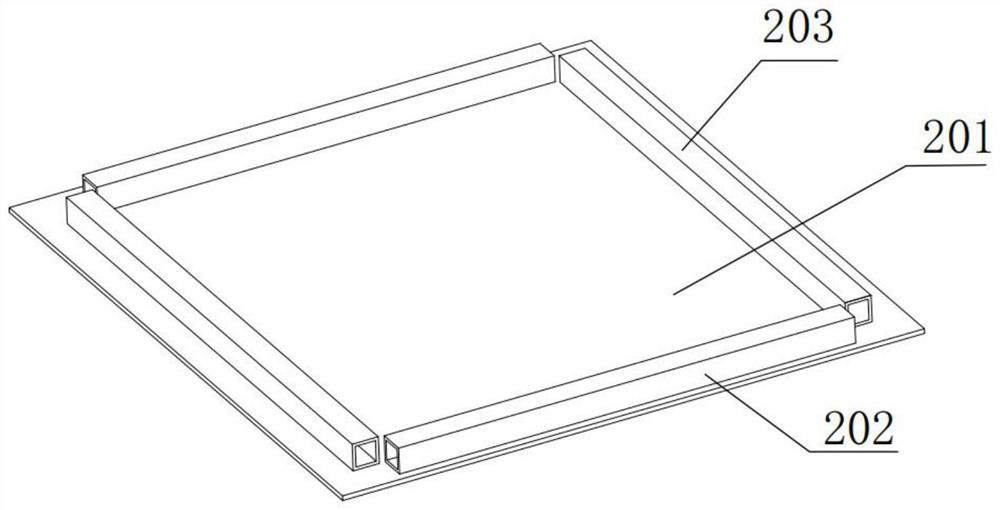

Light empty steel frame plywood formwork and assembling method

The invention relates to a light empty steel frame plywood formwork being suitable for manual assembling and disassembling in construction engineering. An empty steel side rib adopts a step section, a first step is convenient for inserting, laying and fixing a glued board with 9 mm or 12 mm, and a second step is conveniently connected with a hook-on clamping apparatus of moldboard blocks to clamp; and a 'Z' shape or 'single ' shape section is adopted for a true stomach steel rib, an end part and the empty steel side rib are welded to form a bearing strength steel frame, a rivet or a countersunk rivet is fixedly connected with inner and outer steel ribs through a plywood panel, and the moldboard blocks are connected by the hook-on clamping apparatus to form a large area moulding board. The light empty steel frame plywood formwork provided by the invention is accompanied with the advantages of portability and flexible assembly of the traditional combined steel moulding plate with cross-sectional height of 55 mm, and can be mixed with a general glued board and a wood beam formwork manner; and the weight of each square meter moulding board is less than 25 kilos, the rigidity of a steel frame is improved, and the reduplicate turnover utilized times of the moulding board are increased.

Owner:郭正兴

Municipal traffic isolation guardrail manufacturing and assembling auxiliary tool

ActiveCN113352045AImprove welding efficiency and qualityAvoid welding qualityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention relates to a municipal traffic isolation guardrail manufacturing and assembling auxiliary tool. The municipal traffic isolation guardrail manufacturing and assembling auxiliary tool comprises a bottom plate, an adjusting device, a clamping device and a positioning device. The adjusting device is installed on the bottom plate, and the clamping device and the positioning device are installed on the adjusting device. The municipal traffic isolation guardrail manufacturing and assembling auxiliary tool can solve the following problems existing when an existing traffic isolation guardrail is assembled and welded: firstly, when a traditional traffic isolation guardrail is assembled and welded, guardrail cross beams and guardrail vertical beams need to be assembled together by workers, one worker needs to hold connecting and welding positions, the other worker needs to conduct welding operation, and the welding and assembling mode is low in efficiency and wastes labor force; and secondly, when the existing traffic isolation guardrail is welded, due to the fact that manual positioning is unstable, the traffic isolation guardrail is dislocated in the welding process, and the welding quality of the traffic isolation guardrail is reduced.

Owner:CHUZHOU UNIV

Axle assembling and welding tool

PendingCN112872676AEnsure welding efficiencyMeet the needs of useWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringBolt connection

The invention provides an axle assembling and welding tool. The axle assembling and welding tool comprises a top frame, adjusting rods, supporting pipes, adjusting screws, a rack, machine legs, collecting boxes, a control panel, adjusting handles and protective sleeves, wherein the top frame is transversely connected to the upper end between the adjusting rods through bolts; and the adjusting rods are longitudinally inserted into the upper sides of the insides of the supporting pipes and fixedly connected through the adjusting screws. According to the axle assembling and welding tool, through the arrangement of a supporting frame, connecting bases, U-shaped placing bases, adjusting screw rods, clamping bases and rotating hand wheels, automobile axles of different models can be placed and clamped conveniently, and assembling and welding operation can be conducted conveniently; the automobile axles are placed inside the U-shaped placing bases, and the rotating hand wheels are held by hands to rotate and adjust the adjusting screw rods to act in the U-shaped placing bases, so that the clamping bases clamp the automobile axles, the assembly welding operation is carried out, the assembly welding efficiency is ensured, and the use requirements are met.

Owner:山东东岳永盛车桥股份有限公司

Split mounting type emergency combined bridge

PendingCN114016379AReduce protection requirementsMeet emergency security requirementsPortable bridgeBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a split mounting type emergency combined bridge, and relates to the technical field of rapid construction and erection of emergency bridges; the split mounting type emergency combined bridge comprises a main beam structure, a plurality of bridge floor structures arranged above the main beam structure in parallel and bridge end transition slabs located at the two ends of the bridge floor structures, and the main beam structure comprises a main beam frame and a plurality of supporting structures. According to the invention, the section steel is spliced on site, universal profiles such as H-shaped steel, square tubes and steel plates are selected, modular design is adopted, the structure is simple, machining is convenient, and on-site welding and assembling are easy. According to the emergency combined steel bridge, on-site welding, assembling and erecting can be completed through a small amount of manpower and mechanical equipment, the personnel guarantee requirement is lowered, the installing and erecting efficiency is improved, and thus, the emergency guarantee requirement of small and medium-span bridges can be better met.

Owner:巨力索具研究院(天津)有限公司 +1

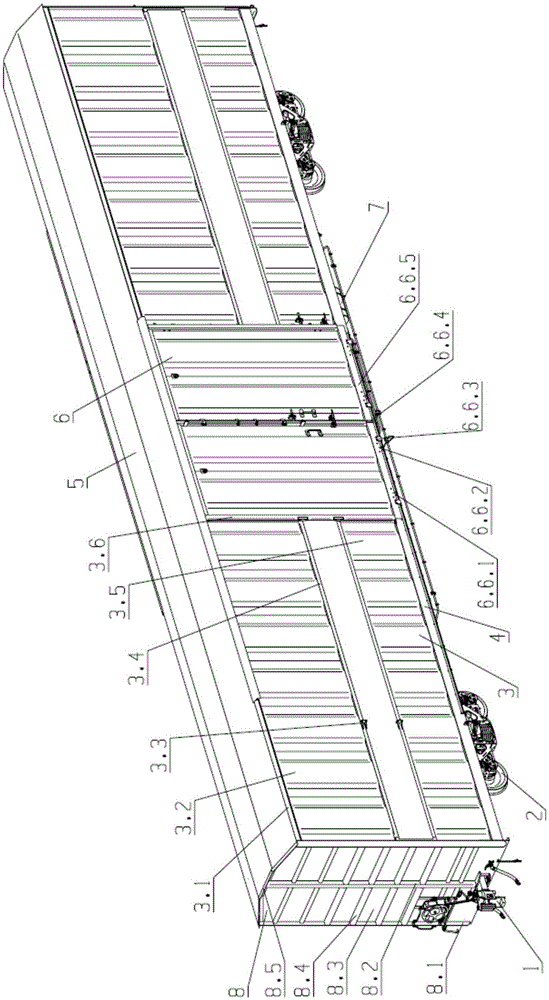

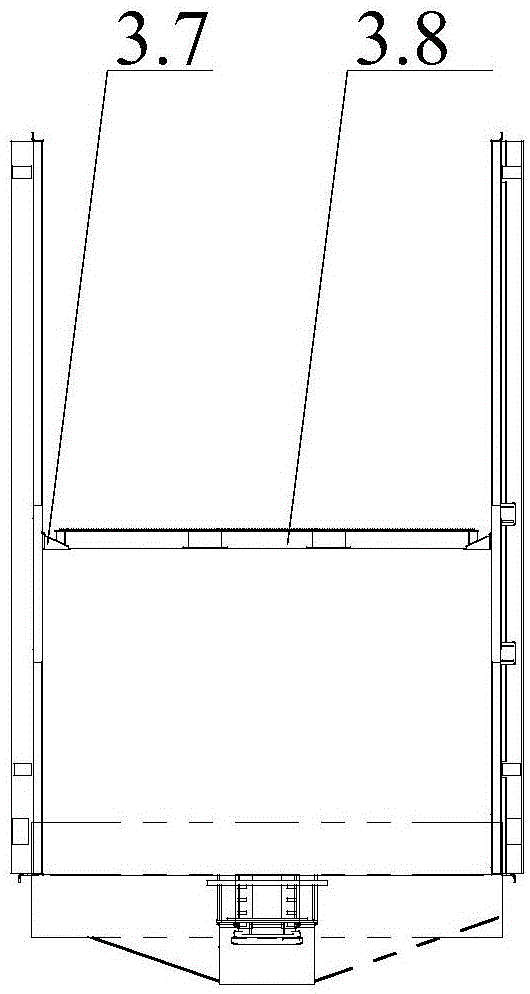

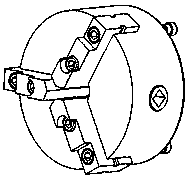

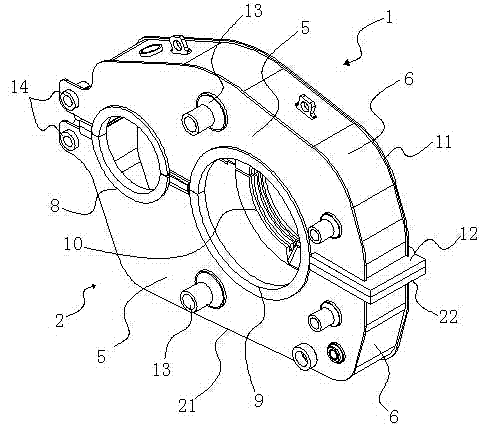

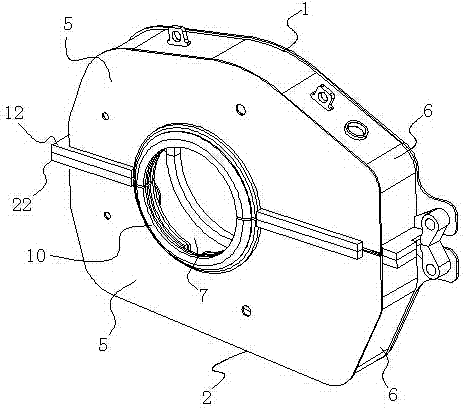

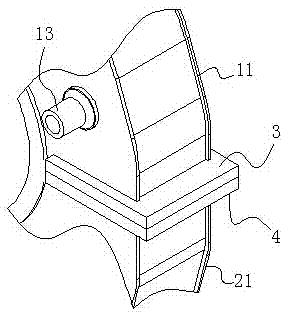

Rotary assembly welding tool capable of improving welding quality of gear cases of locomotives and assembly welding method implemented by rotary assembly welding tool

ActiveCN104493407AReduce distortionReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a rotary assembly welding tool capable of improving the welding quality of gear cases of locomotives. The rotary assembly welding tool comprises a support frame, a rotator, at least two upper case body connecting plate compressing assemblies, at least two lower case body connecting plate compressing assemblies, upper collar ring compressing assemblies and lower collar ring compressing assemblies. The support frame comprises a first support and a second support, the rotator is arranged between the first support and the second support in a rotationally connected manner and comprises a rotary plate, an upper case module and a lower case module, and the shapes and the contour sizes of the upper case module and the lower case module are matched with the shapes and the contour sizes of upper case bodies of the gear cases and gear case inner cavities of the upper case bodies of the gear cases; the upper case body connecting plate compressing assemblies are used for compressing connecting plates of the upper case bodies of the gear cases on one side of the rotary plate, the lower case body connecting plate compressing assemblies are used for compressing connecting plates of lower case bodies of the gear cases on the other side of the rotary plate, the upper collar ring compressing assemblies are used for compressing collar rings of the gear cases on two sides of the upper case module, and the lower collar ring compressing assemblies are used for compressing the collar rings of the gear cases on two sides of the lower case module. The rotary assembly welding tool has the advantages that the welding quality and the production efficiency can be improved.

Owner:TIANYI IND HUNAN RAILWAY PROFESSIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com