Rotary assembly welding tool capable of improving welding quality of gear cases of locomotives and assembly welding method implemented by rotary assembly welding tool

A technology for assembling welding equipment and gear boxes, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the technical problems of this patent are not mentioned, and the technical problems of this patent are not disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

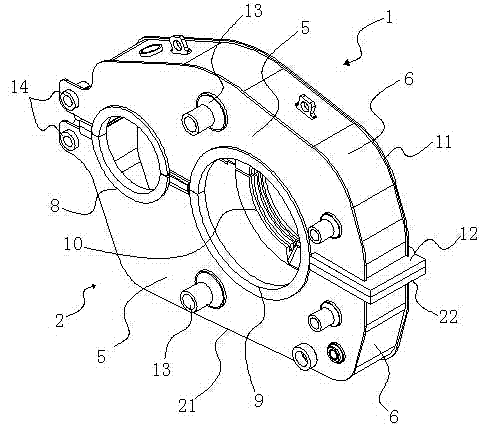

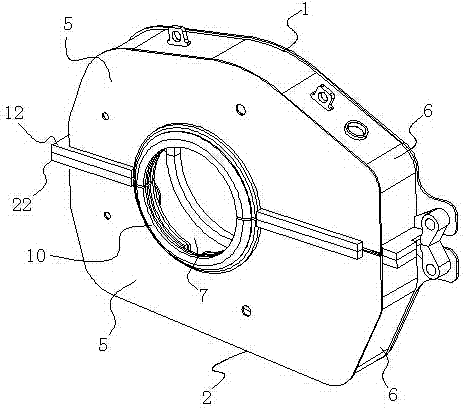

[0058] Embodiment 1: as Figure 4 to Figure 7 As shown, a rotary welding tool that can improve the welding quality of the locomotive gearbox includes a support frame 15 and a rotating body 16 rotatably connected to the support frame 15, and the support frame 15 includes a support frame 151 and a support frame 2 152 , the rotating body 16 is rotatably connected between the first bracket 151 and the second bracket 152, the rotating body 16 includes a rotating plate 161, an upper box mold body 162 vertically arranged on one side of the rotating plate 161, a vertical The lower box mold body 163 arranged on the other side of the rotating plate 161, the outline dimension of the upper box mold body 162 matches the shape outline dimension of the gear box cavity 7 of the upper box body 11 of the gear box, the The outline dimension of the lower box mold body 163 matches the shape outline dimension of the gear box inner cavity 7 of the gear box lower box body 21, and the upper box mold b...

Embodiment 2

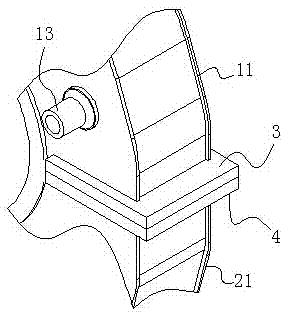

[0091] Embodiment 2: as Figure 13 to Figure 15 As shown, compared with Example 1, the difference is that: the rotary assembly welding tool also includes a gear box upper case coaming plate 6 and a gear box lower case coaming plate 6 respectively pressed into contact with the upper case The mold body surrounding edge portion 18 of the mold body and the surrounding plate pressing part 47 on the mold body surrounding edge portion 18 of the lower box mold body;

[0092] The coaming pressing member 47 includes a U-shaped slider 471, a U-shaped slider 2 (not shown in the figure), a U-shaped pressing rod 472 and a coaming pressing screw 473; the U-shaped sliding block 1 Both 471 and U-shaped slider 2 can be engaged on the side of the rotating plate 161 through its U-shaped opening, and the U-shaped sliding block 1 471 and U-shaped sliding block 2 can move along the side of the rotating plate 161. The side moves back and forth, and a connecting fork edge 48 is provided on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com