Advanced integrated network cabinet welding tool platform capable of disassembling and assembling angle iron easily

A network cabinet and welding tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inaccurate size control and poor fit between the base and the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

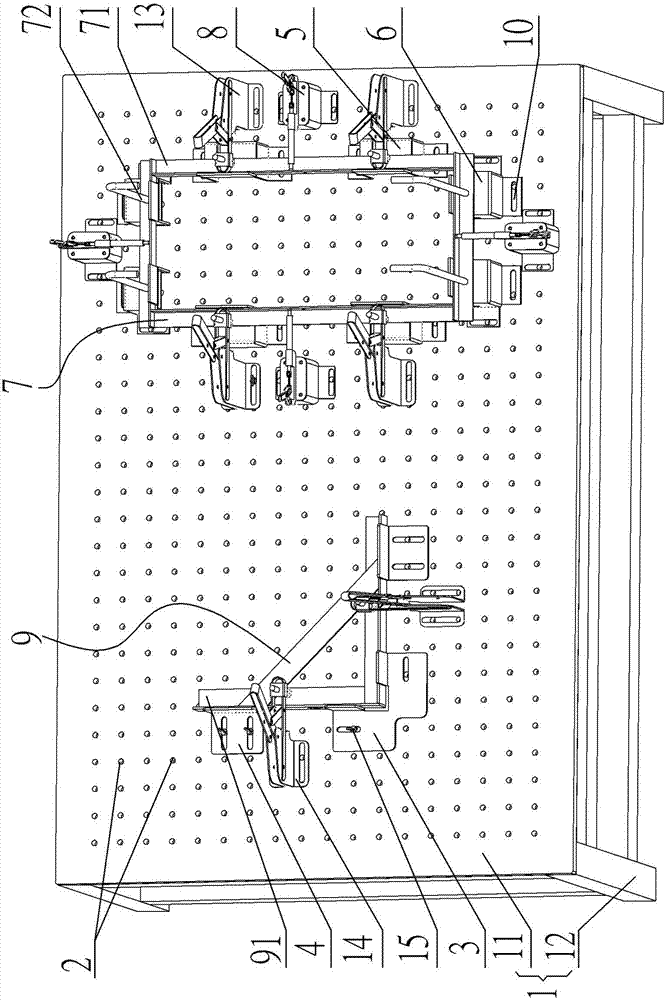

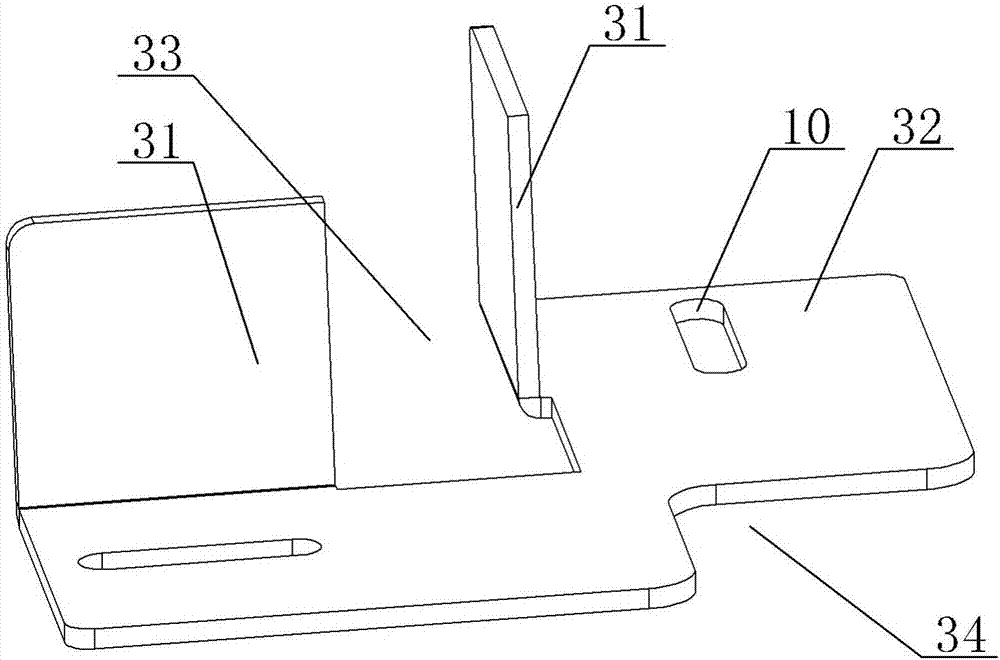

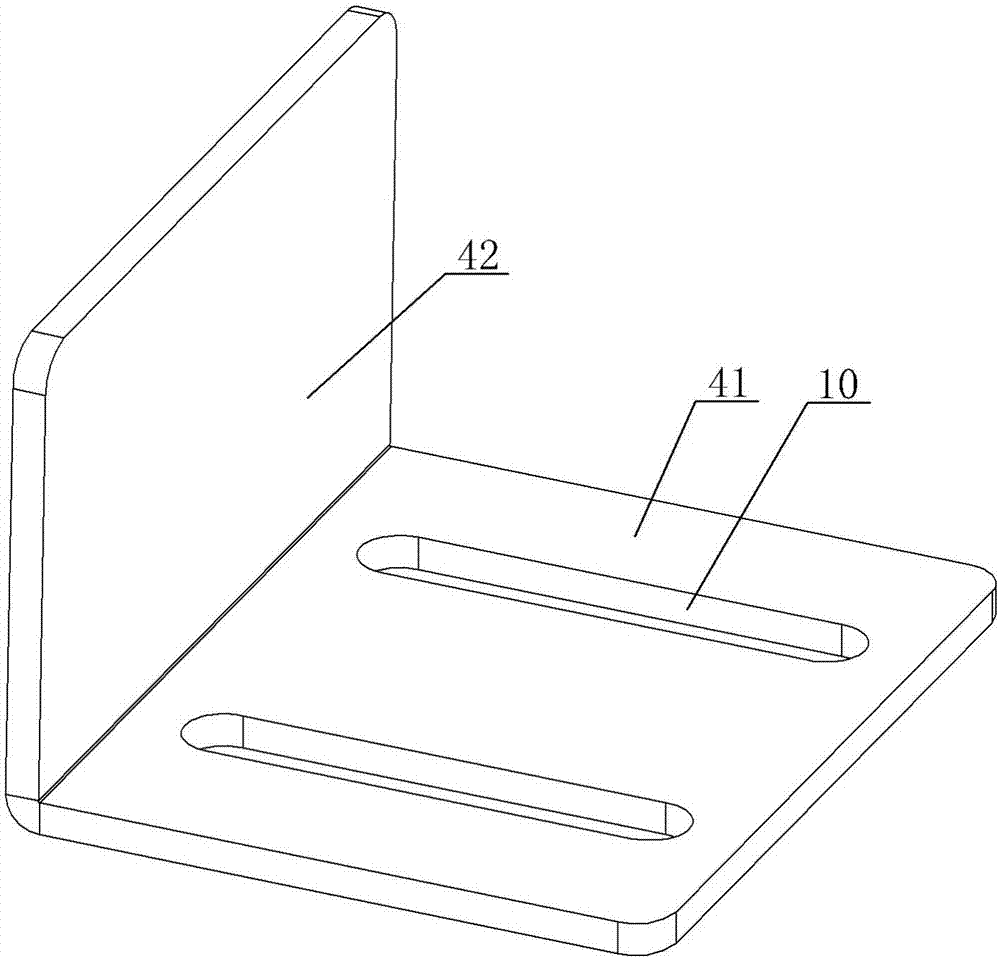

[0027] A welding tooling platform for easy disassembly and assembly of angle irons for advanced integrated network cabinets, see Figure 1-Figure 9 : It includes a welding platform 1, the welding platform 1 includes an upper platform 11, and an array of threaded holes 2 is arranged on the upper platform 11, and the distance between each group of adjacent threaded holes 2 is equal, and it also includes a number of positioning bolts , support block, clamp, positioning bolt includes angle positioning bolt 3, side positioning bolt 4, support block includes side support block 5, welding support block 6, welding support block 6 is used for the inside of angle iron 71 of base embedded part 7 Positioning and the vertical positioning of the round steel 72, the side support block 5 is used for the inner positioning of the angle iron 71 of the non-round steel position of the base embedded part 7; the clamps include a push-down clamp and a front top clamp 8, and the positioning Bolt is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com