Coiled tubing clamping device and injection head using same

A technology of clamping mechanism and oil pipe, which is applied in the direction of drill pipe, casing, earthwork drilling, etc. It can solve the problems that the clamping block cannot slide, reduce the service life of the oil pipe, wear the oil pipe, etc., so as to avoid injury or wear and prolong the use Life and reliability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

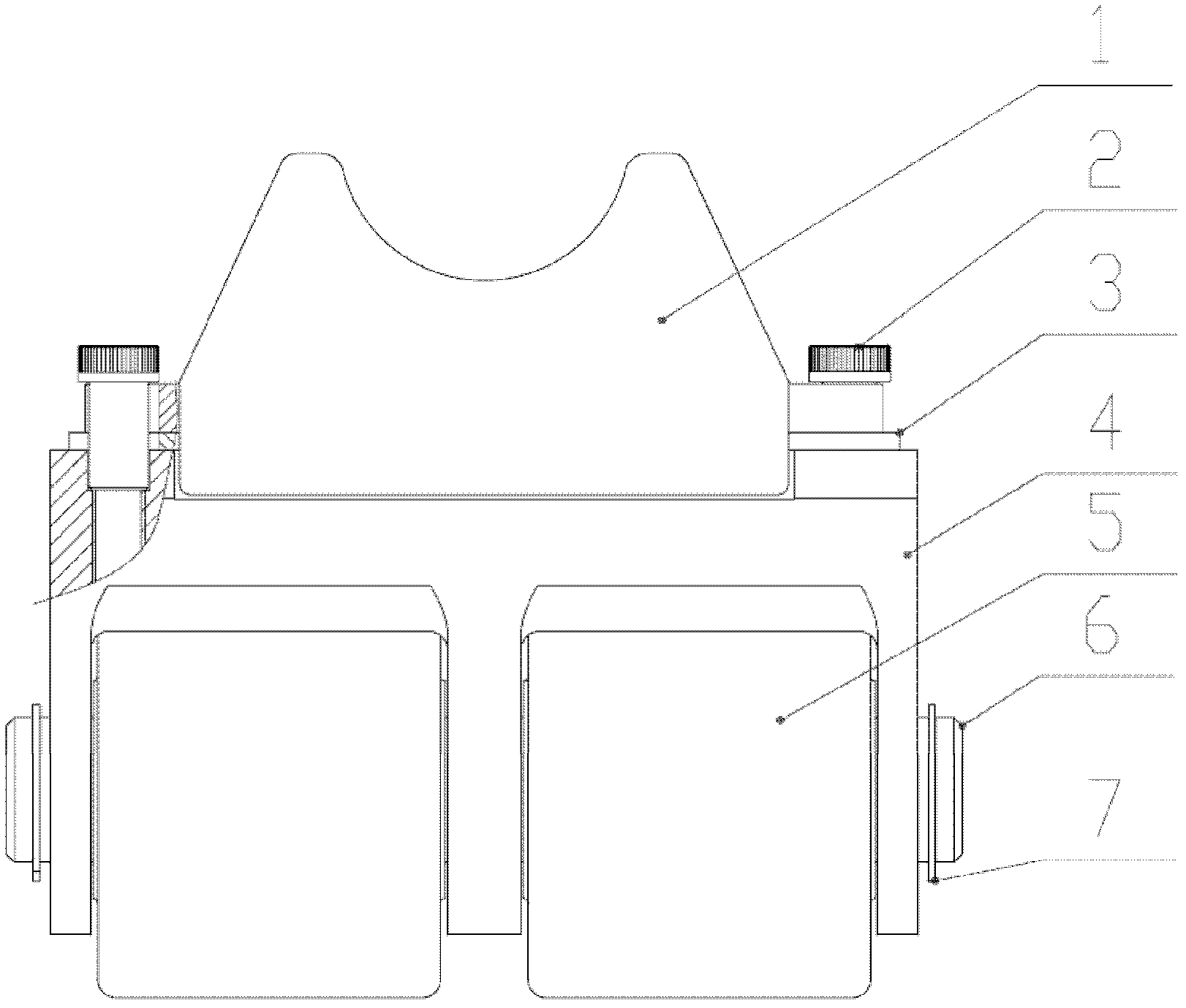

[0033] Such as Figure 1-Figure 7 As shown: a coiled tubing clamping mechanism, including a saddle-shaped clamping block 1 and a clamping block seat 4, the clamping block seat 4 includes a pin shaft 6 and a rolling body 5 sleeved on the pin shaft, the The clamping block seat 4 is provided with two through holes 402 for inserting and connecting the pin shaft with the injection head chain along the direction of the pin shaft 6, and the upper part of the clamping block seat 4 is provided with three partitions 403. The partition 403 is provided with a pin hole 401 for installing the pin 6;

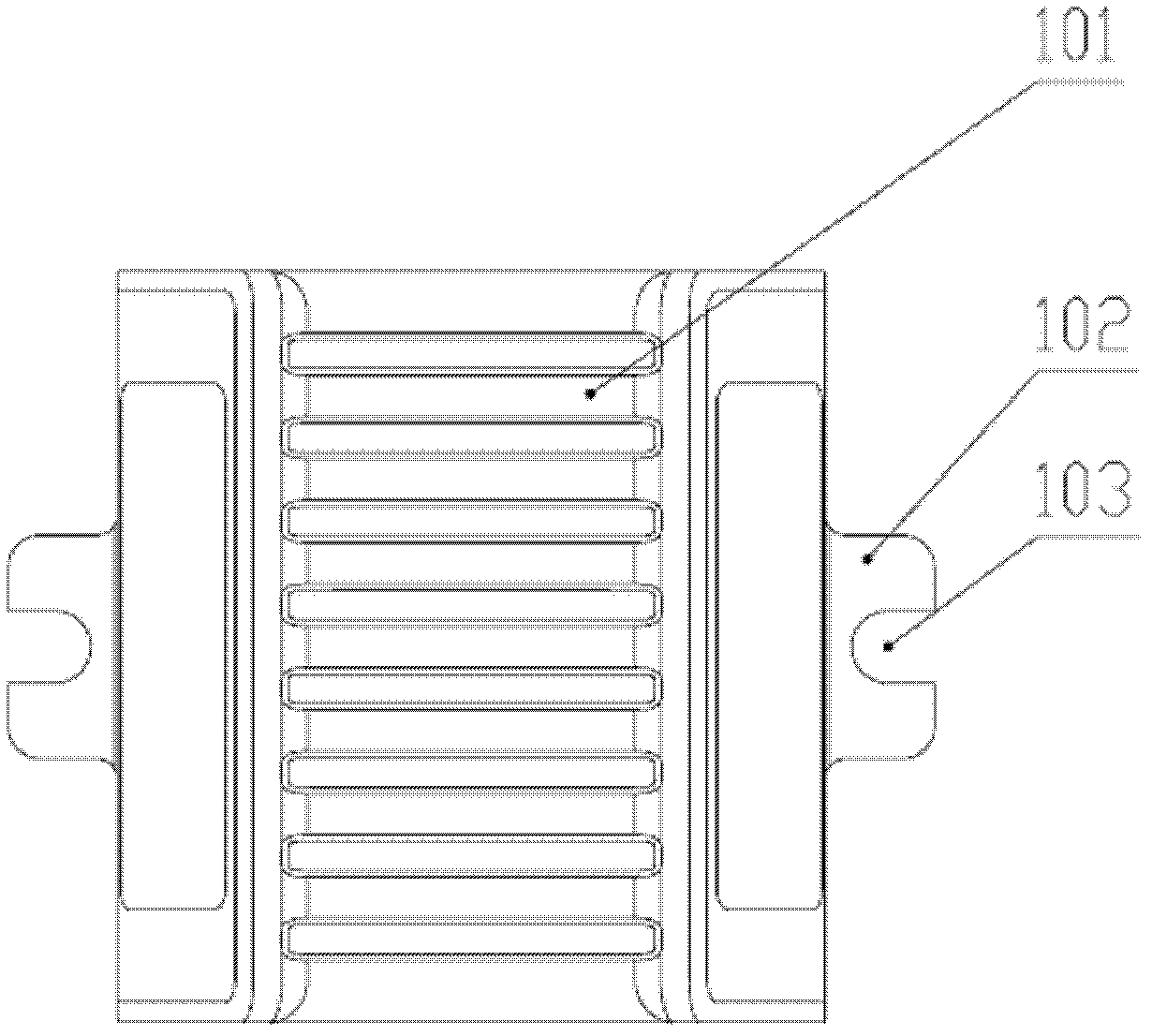

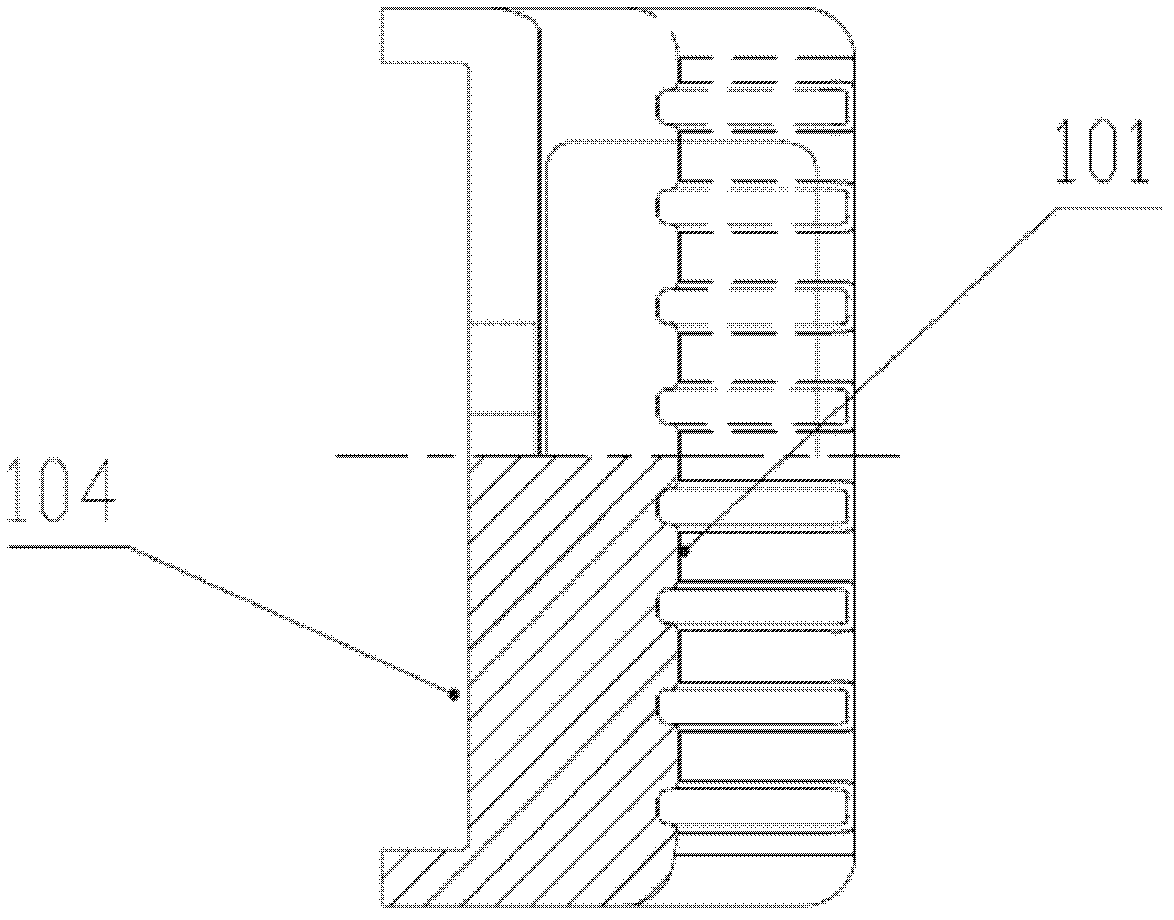

[0034] Both sides of the saddle-shaped clamping block 1 are provided with a tongue table 102, the tongue table 102 is provided with an opening 103, the back of the saddle-shaped clamping block 1 is provided with a groove 104, and the clamping block A pair of bosses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com