Patents

Literature

513 results about "Saddle shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

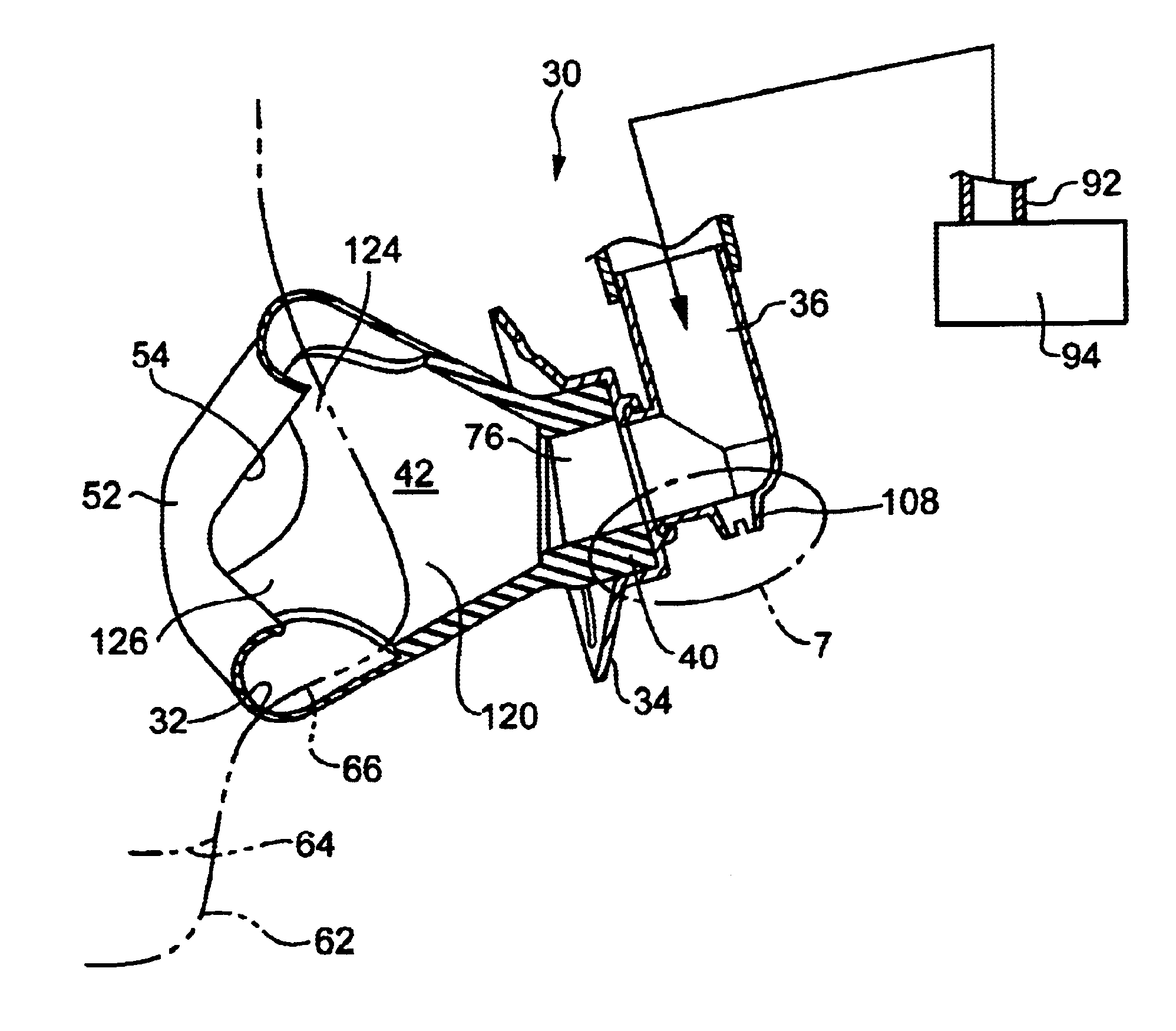

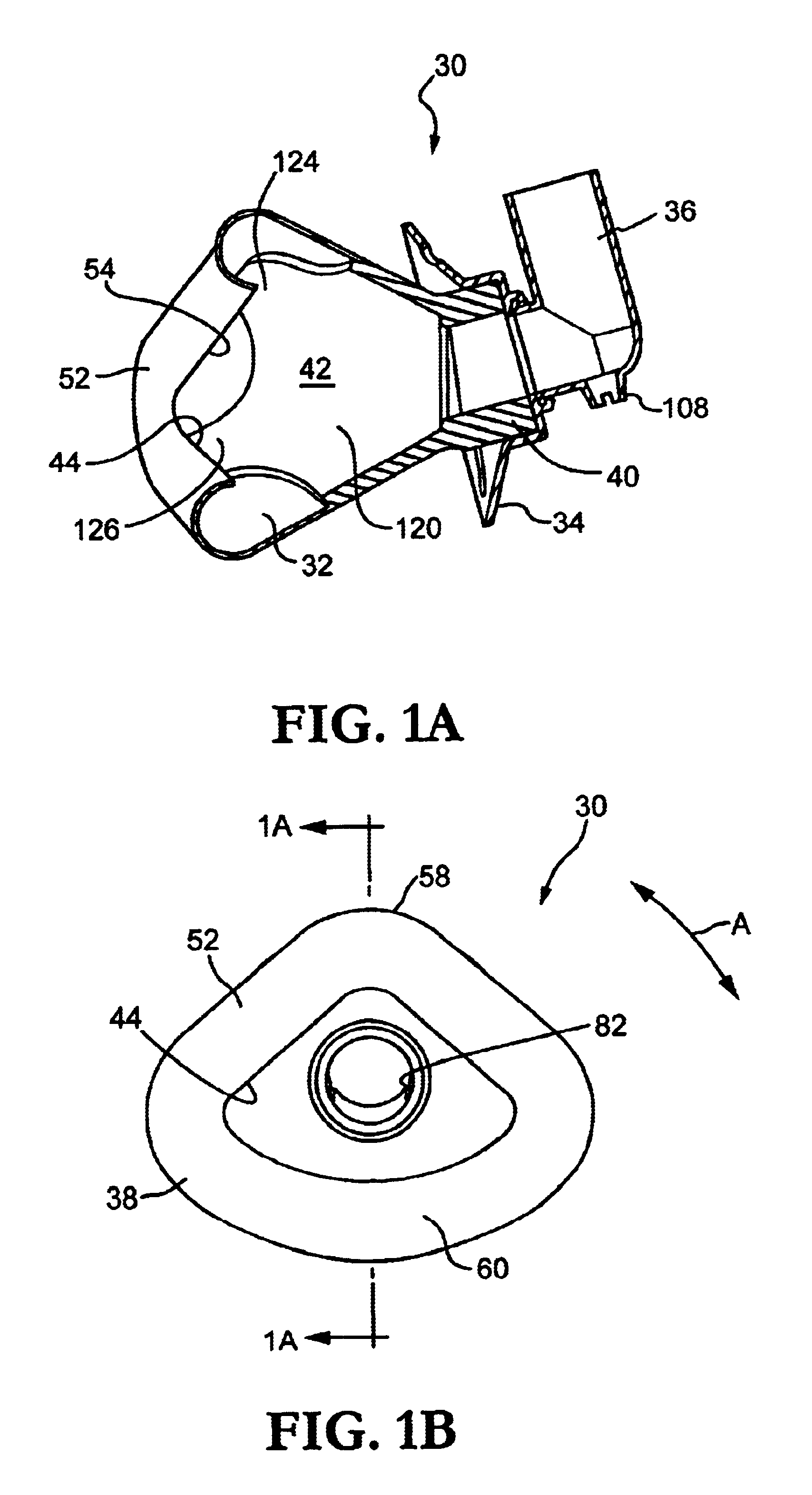

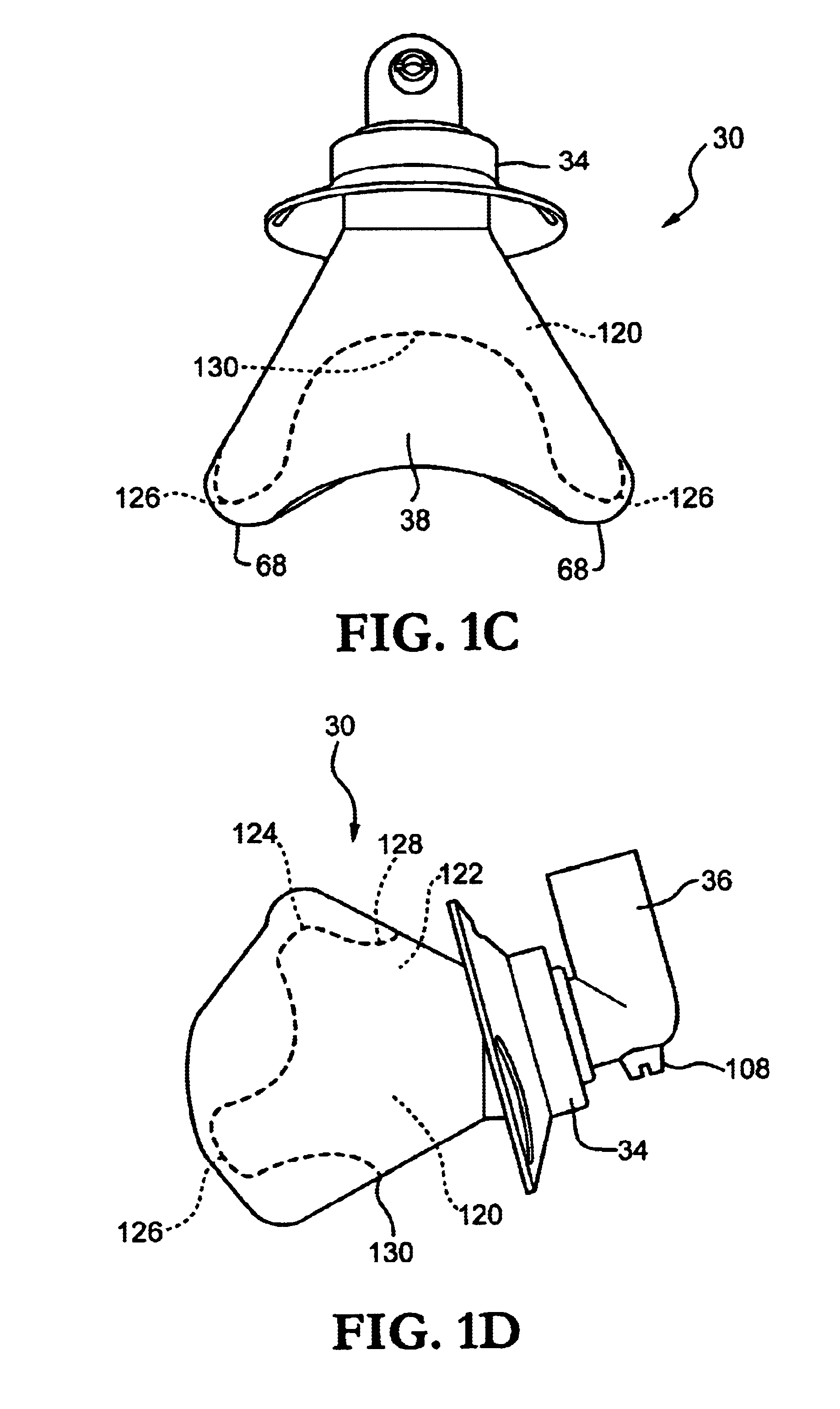

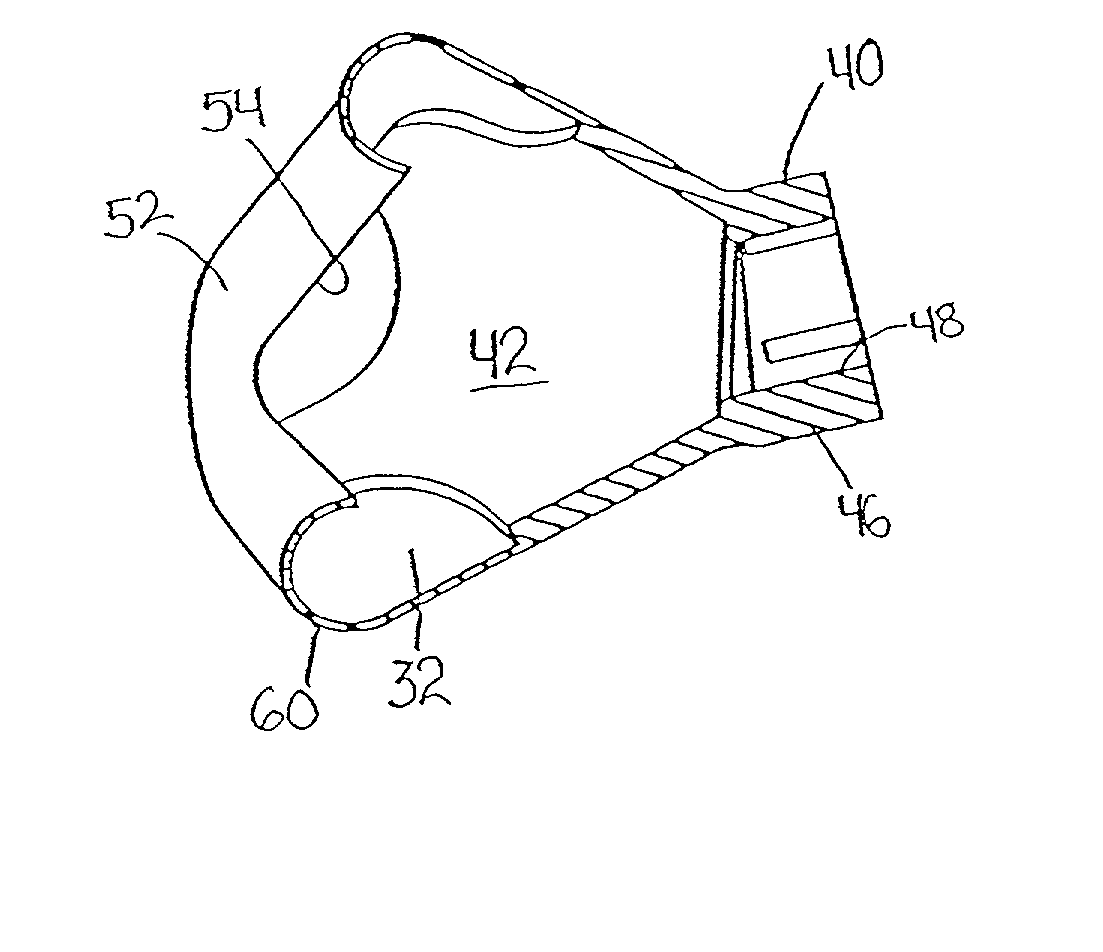

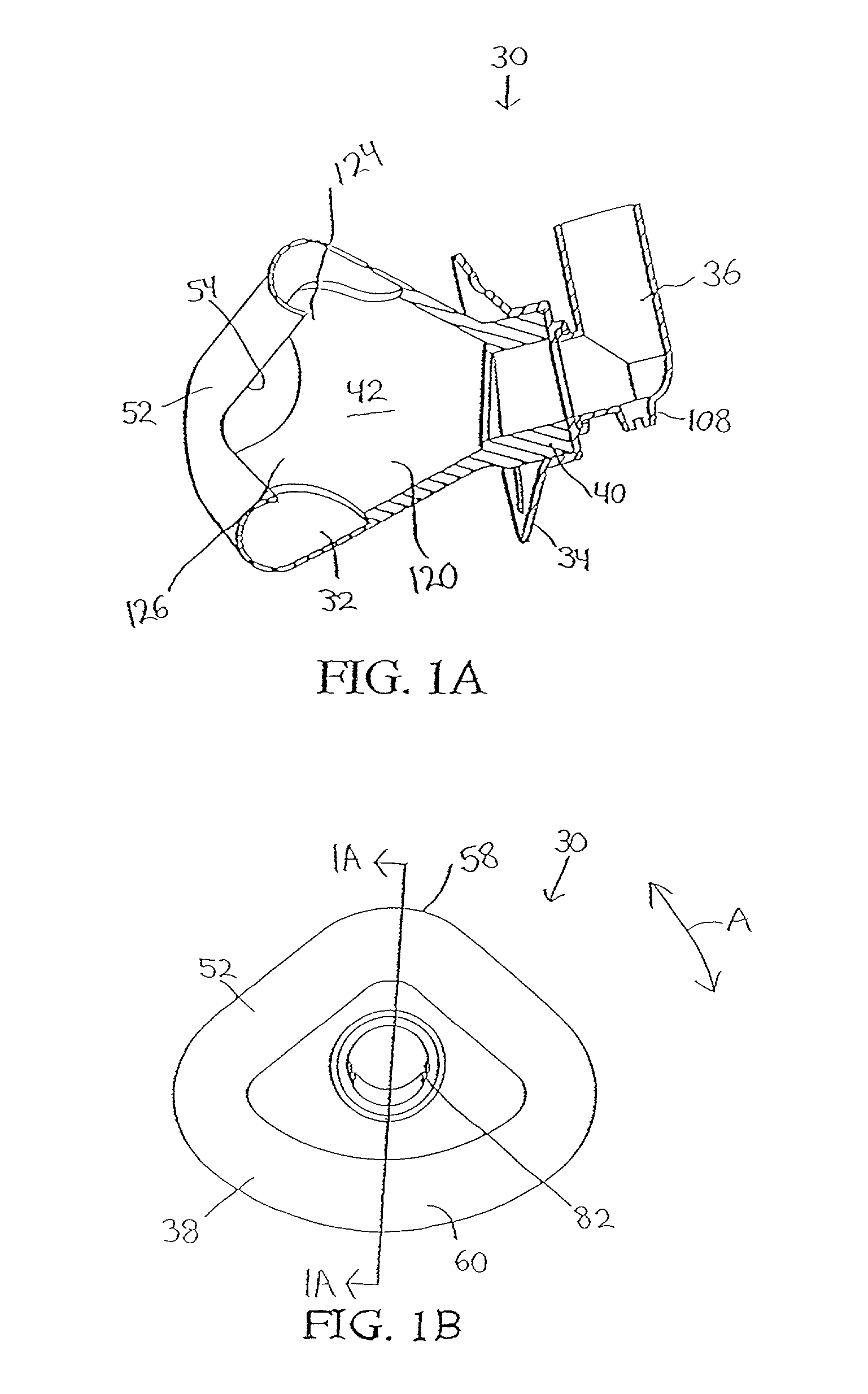

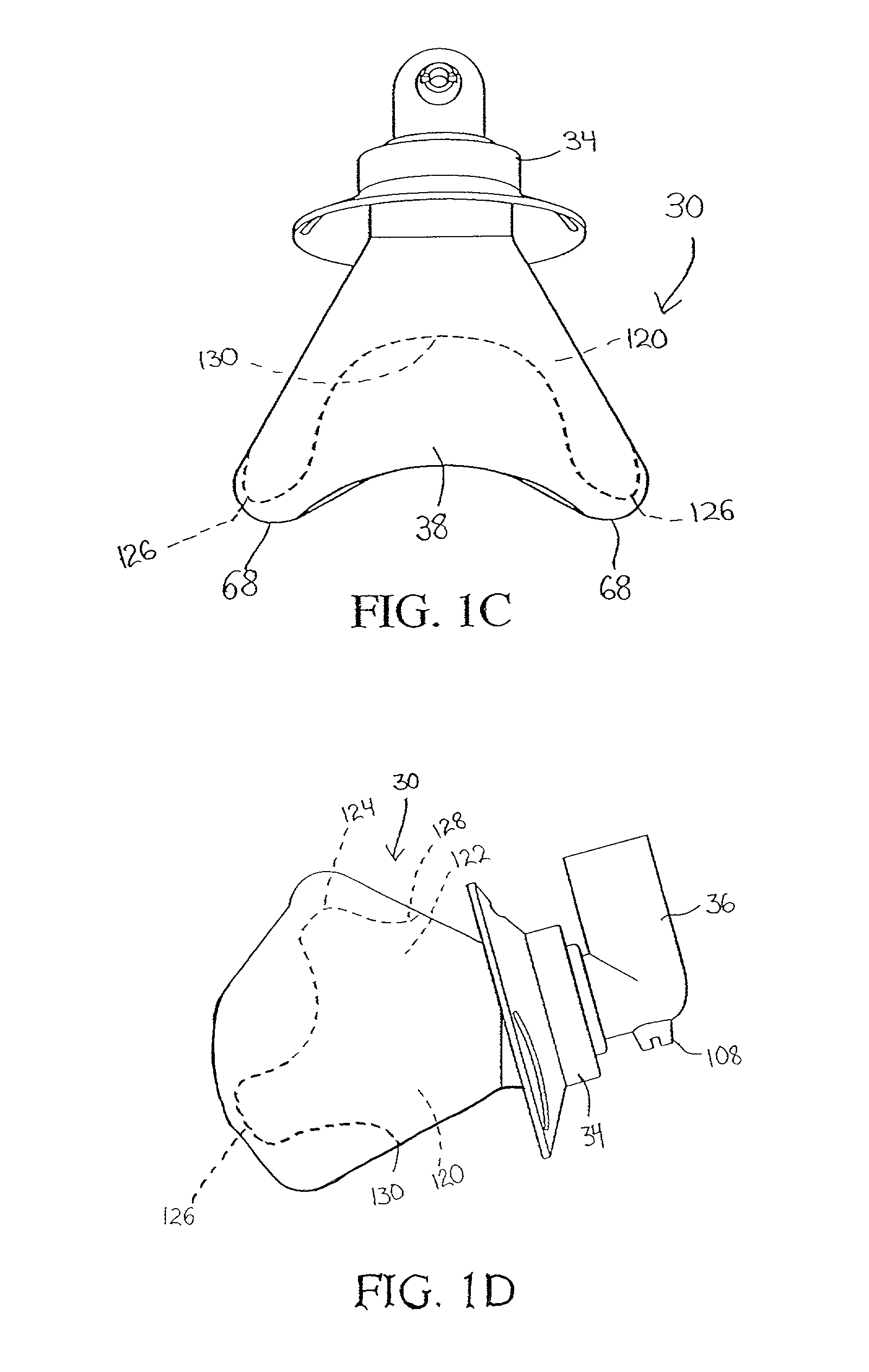

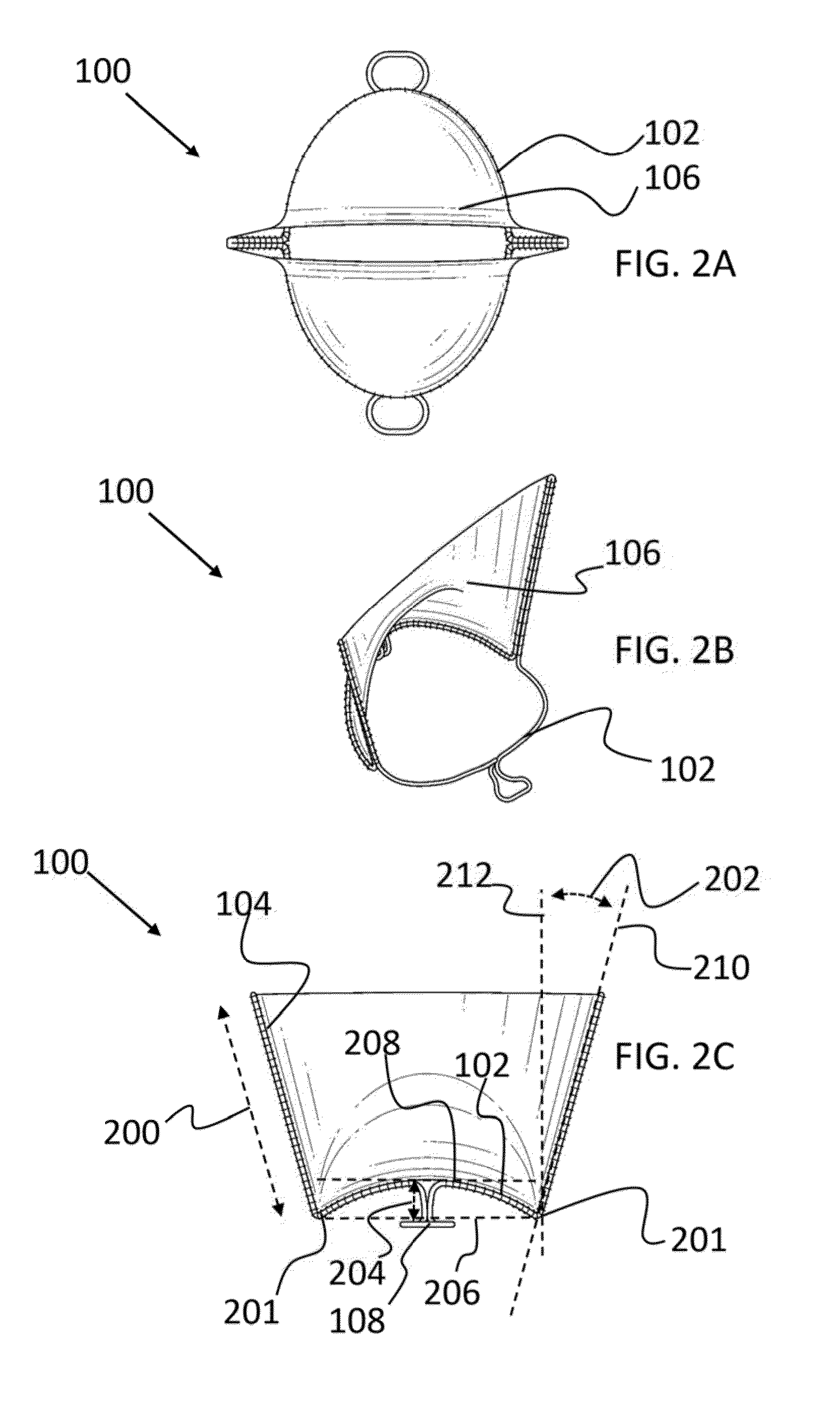

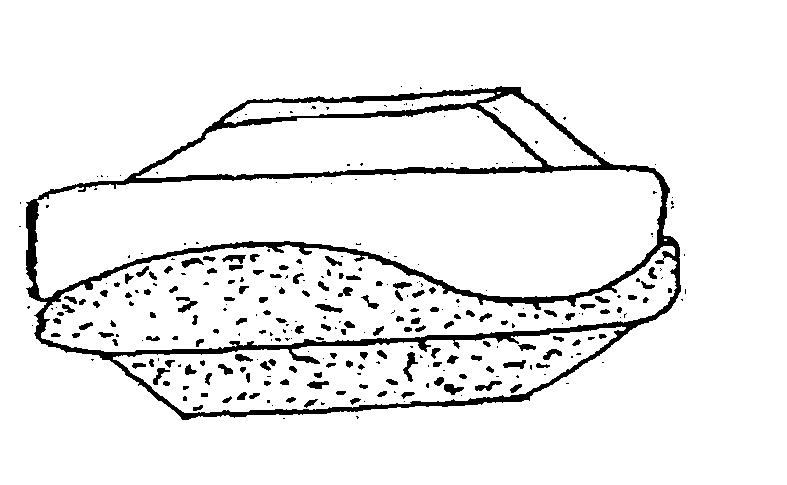

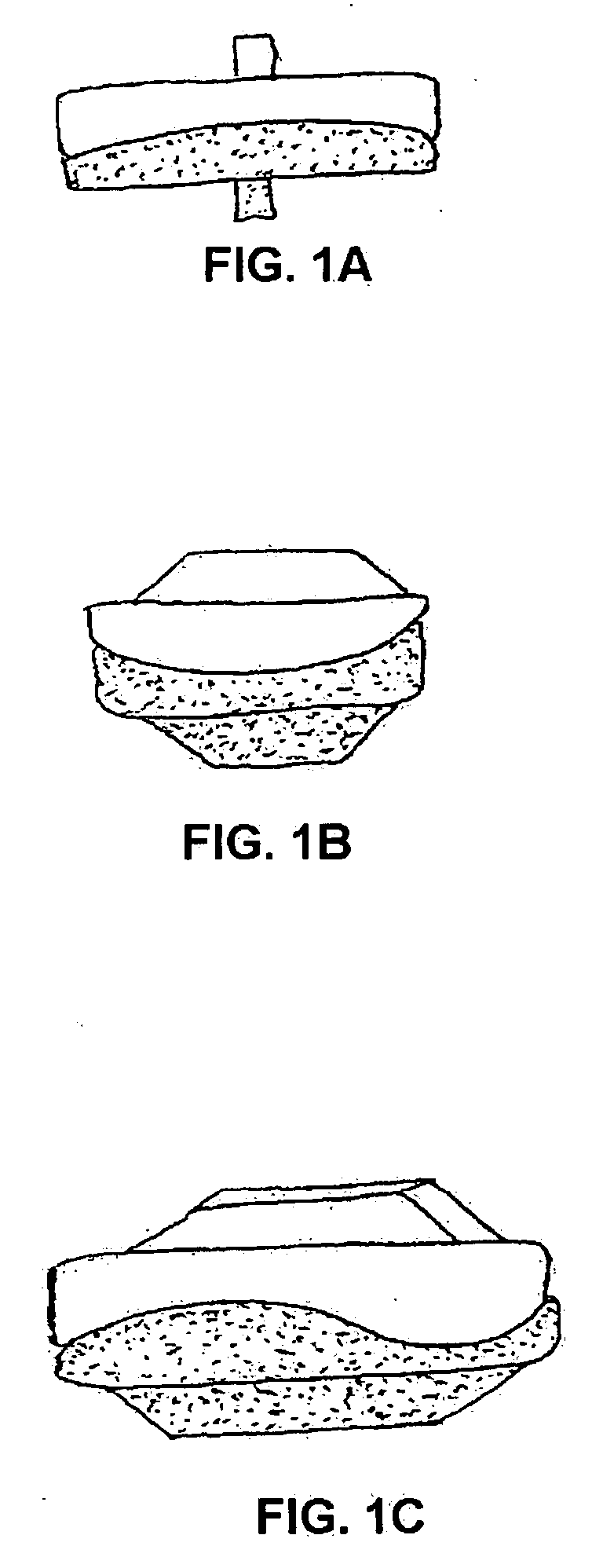

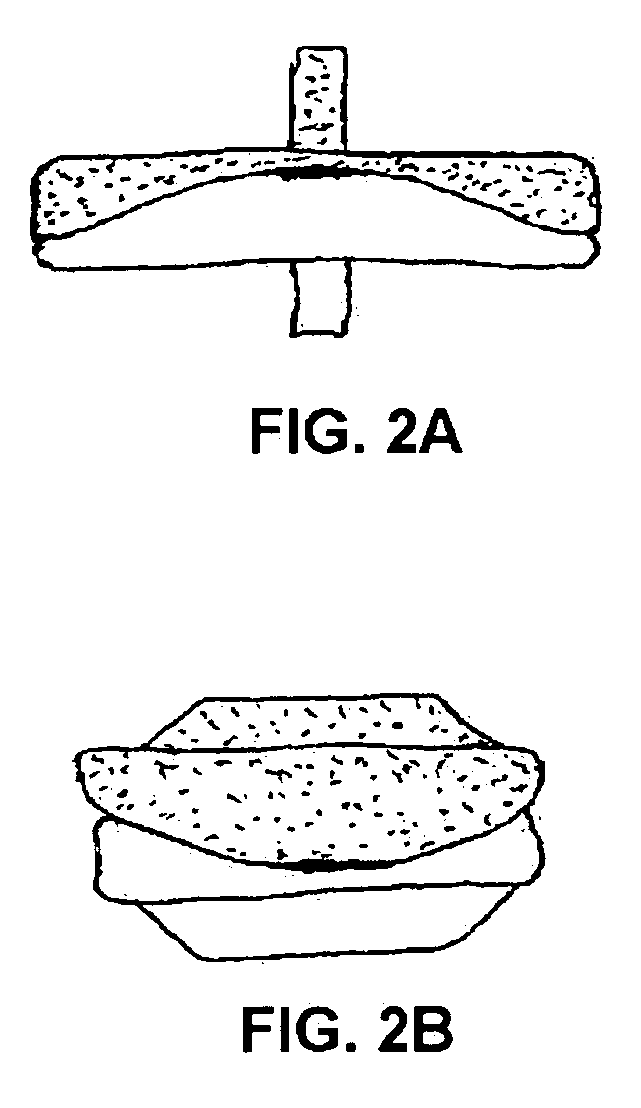

Nasal mask and system using same

A nasal mask assembly that includes a seal member defined from a unitary piece of elastomeric material. The seal member defines a nose receiving cavity and has a first end portion and a second end portion generally opposite the first end portion. A first opening in the first end portion allows at least a portion of a nose to enter the nose receiving cavity such that the nares of the patient communicate with the nose receiving cavity. The seal member includes a neck portion defined in the second end portion and a second opening defined in the neck portion in communication with the nose receiving cavity. A reinforcement area is provided on the side walls of the seal member. The reinforcement area comprises a saddle shaped contoured area on each side of the seal member. Each saddle shaped area has an upper and a lower protrusion portion for providing supporting contact with the face.

Owner:RIC INVESTMENTS LLC

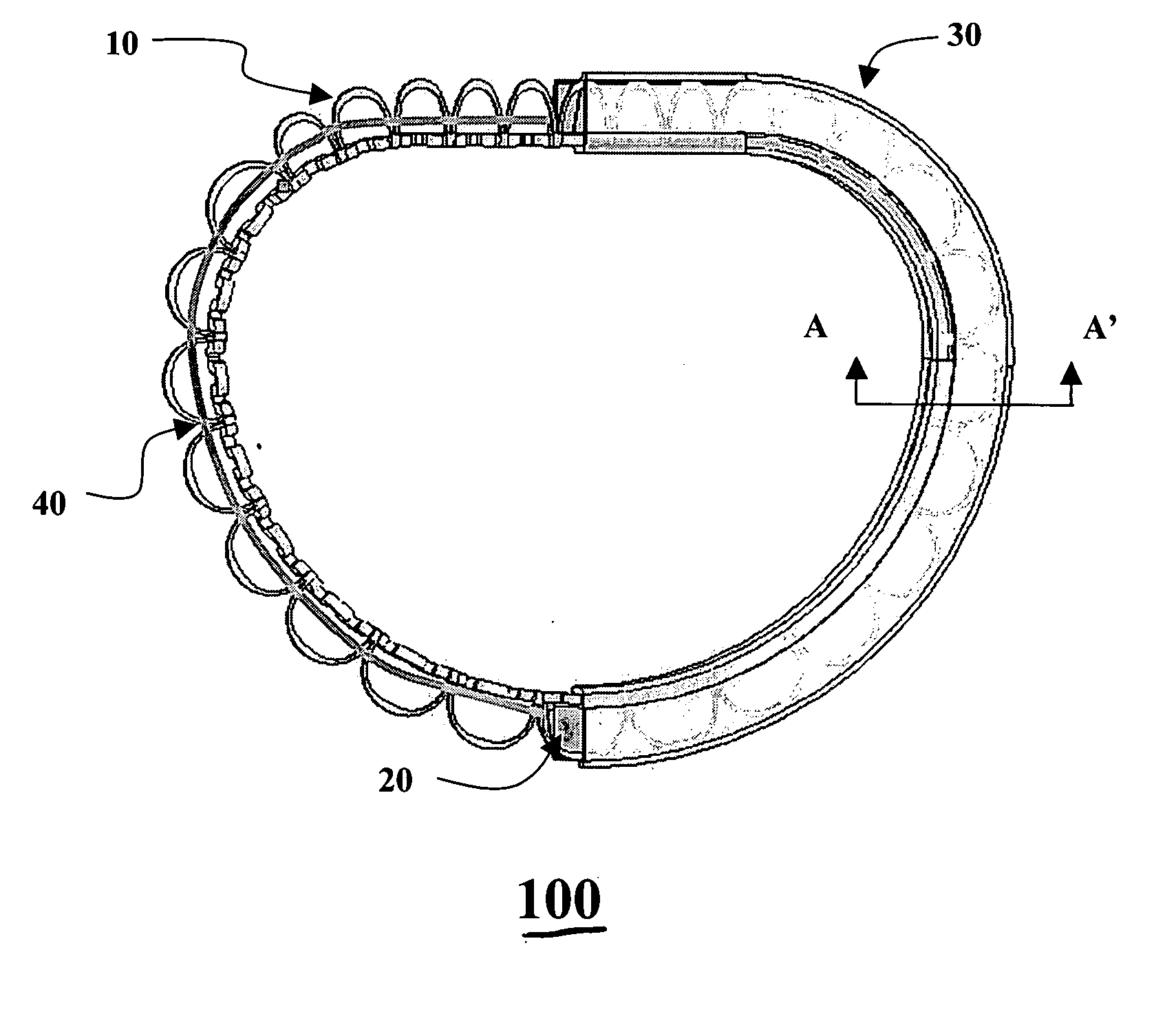

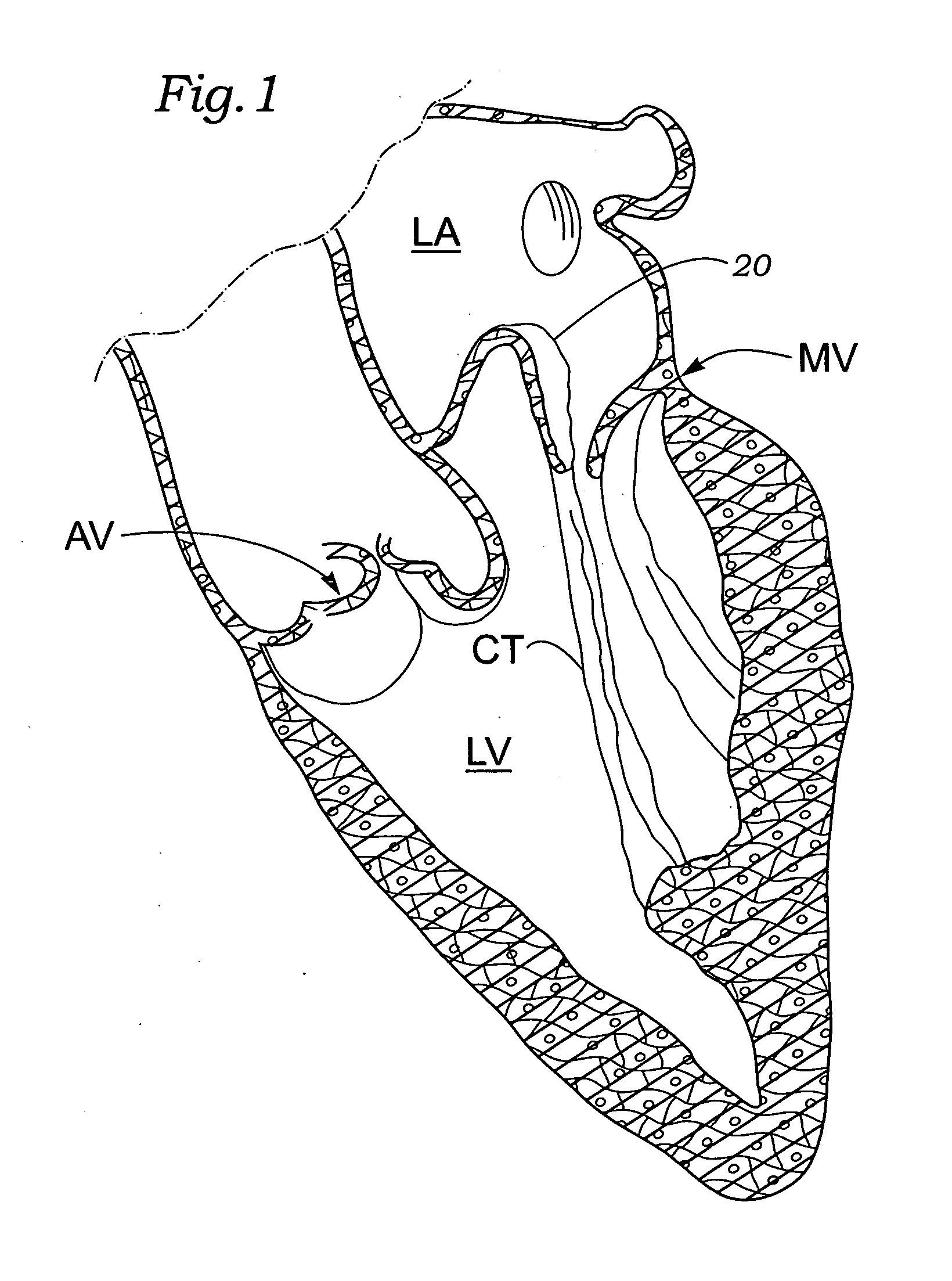

Valvular support prosthesis

InactiveUS20060206203A1Certain flexibilityFlexible processStentsAnnuloplasty ringsProsthesisMitral valve leaflet

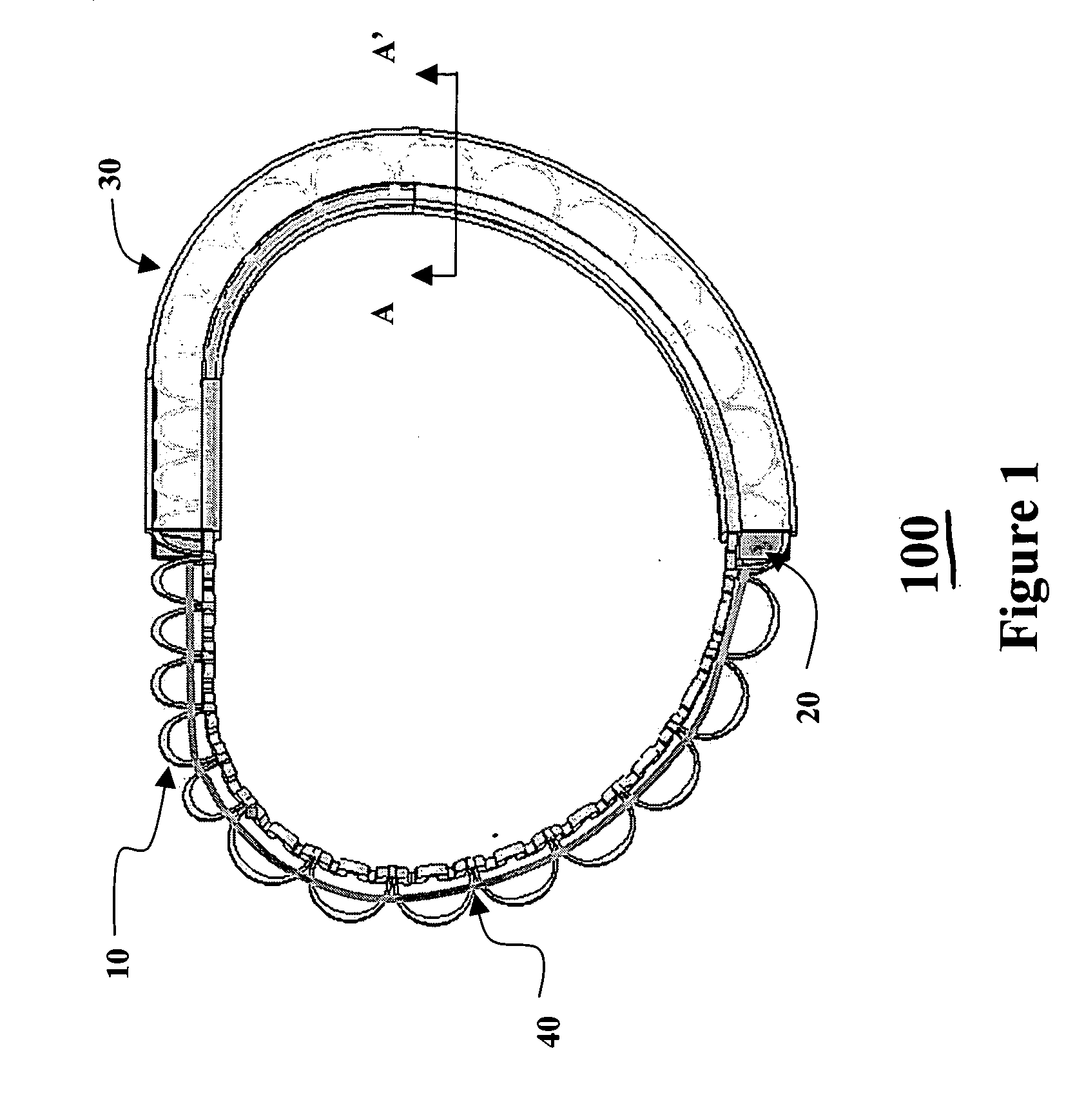

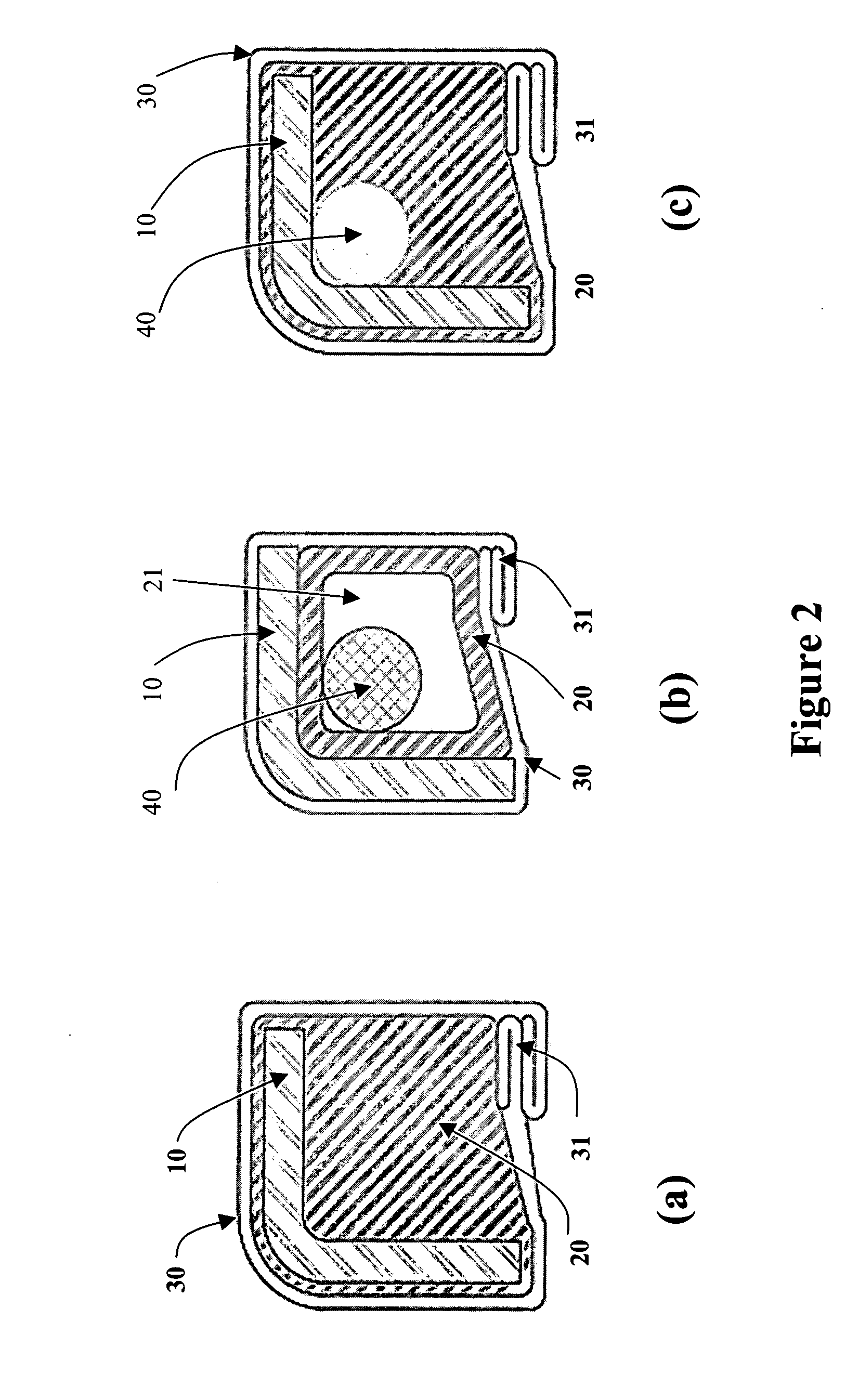

A ring prosthesis provides suitable flexibilities / stiffness three-dimensionally at various points about the circumference of an associated heart valve, and is shaped proportionally to fit about the annulus of the associated heart valve. The ring prosthesis also provides a certain flexibility to conform to the natural non-planar shape of the annulus (e.g., saddle shape for mitral valve surface) with or without preformation of the ring prosthesis. The prosthesis can also be used as an artificial annulus for further valve anchoring.

Owner:YANG JUN +1

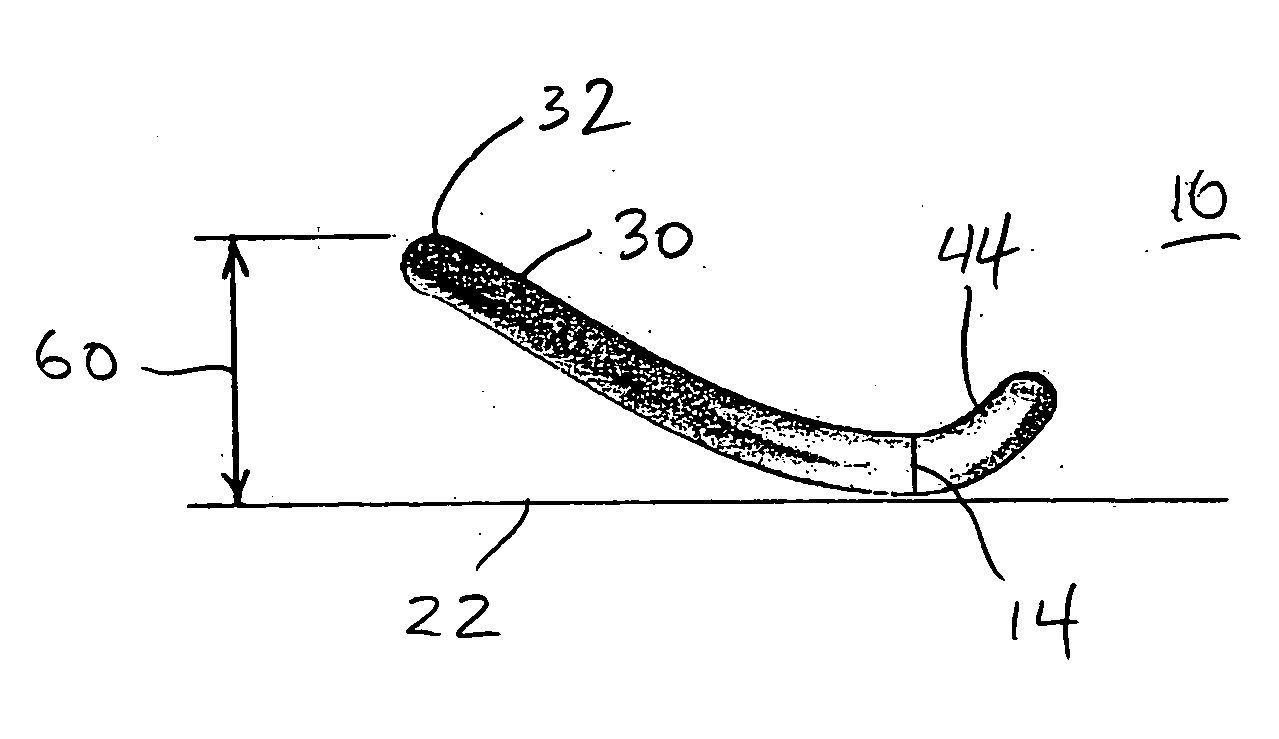

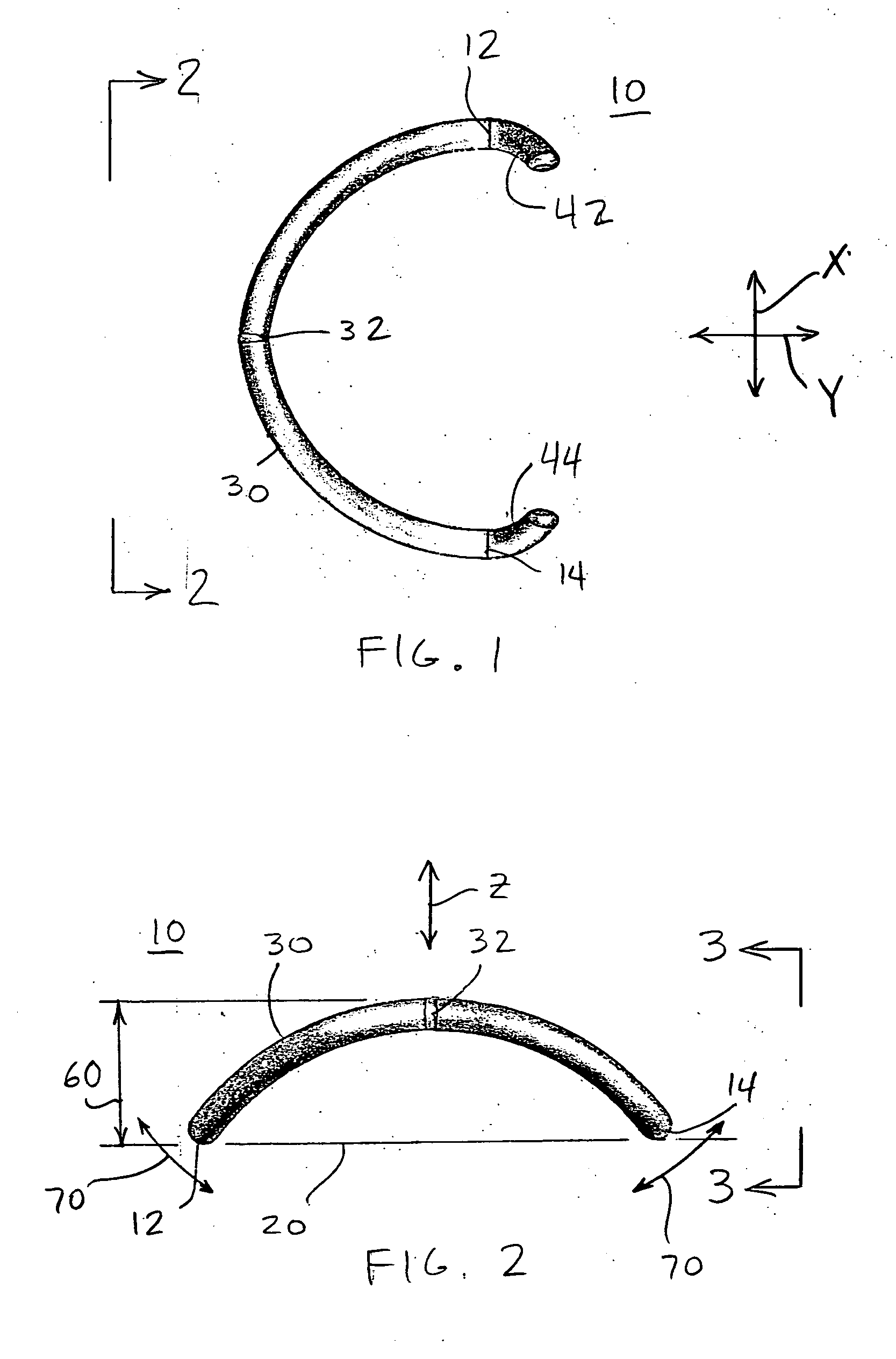

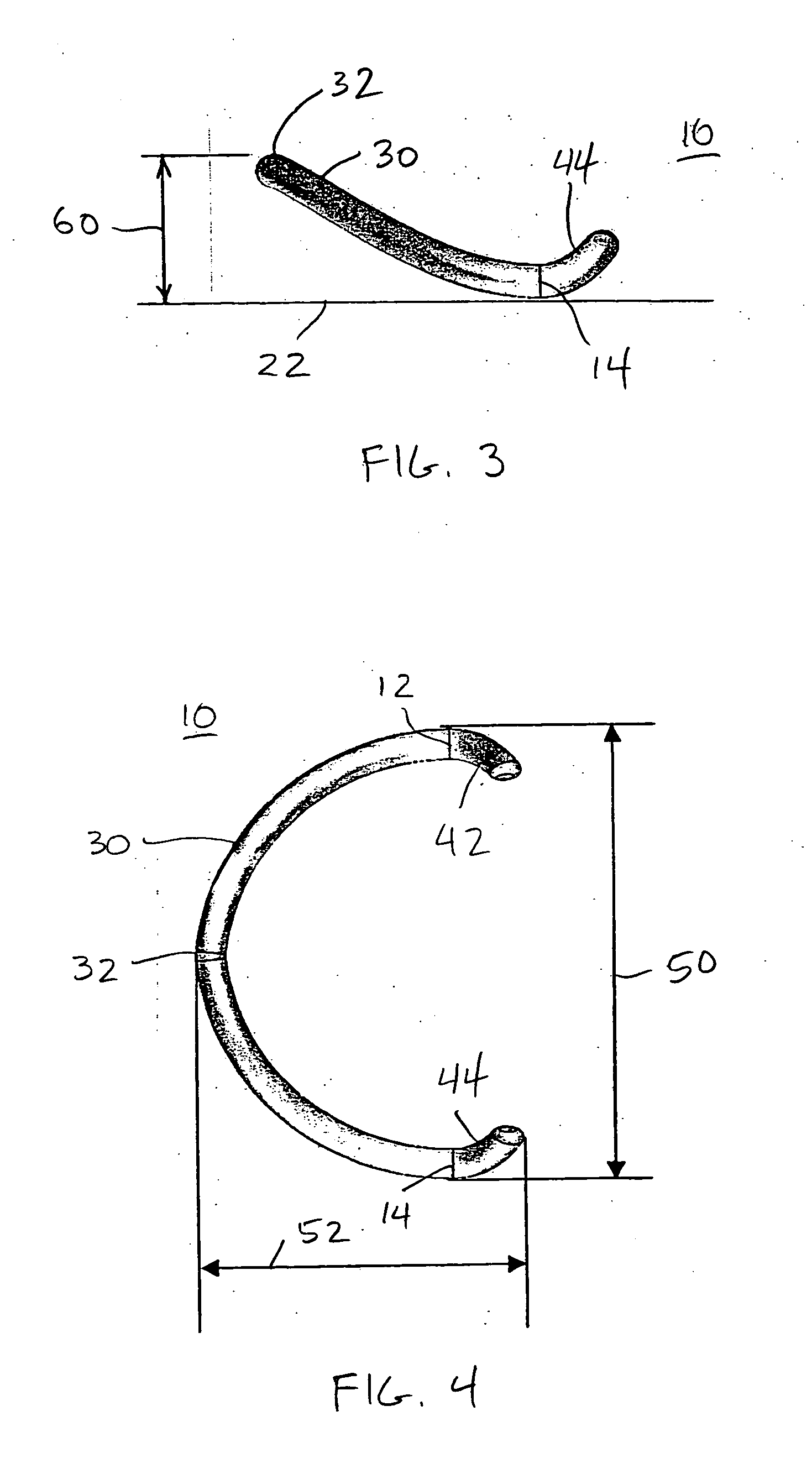

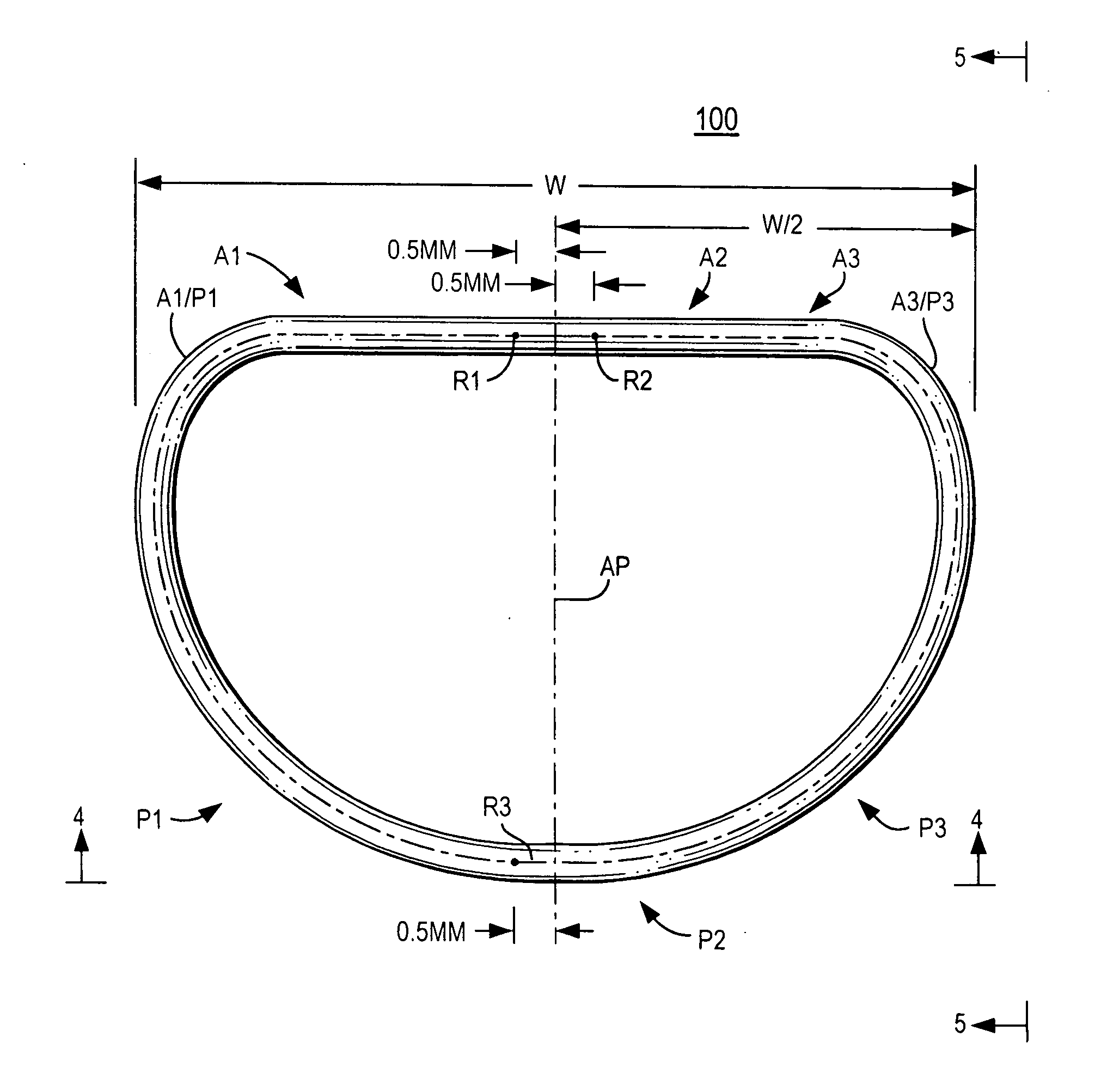

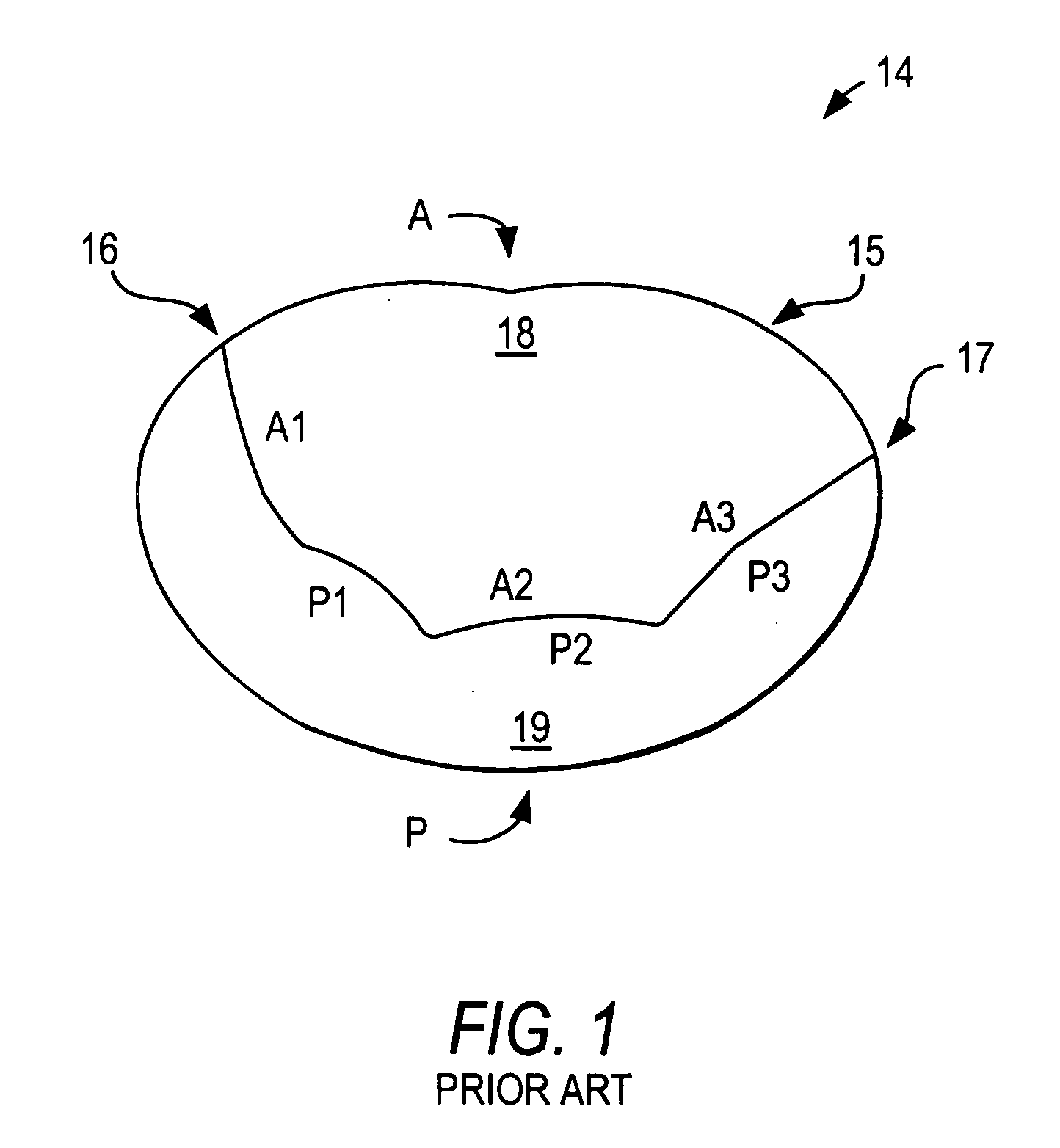

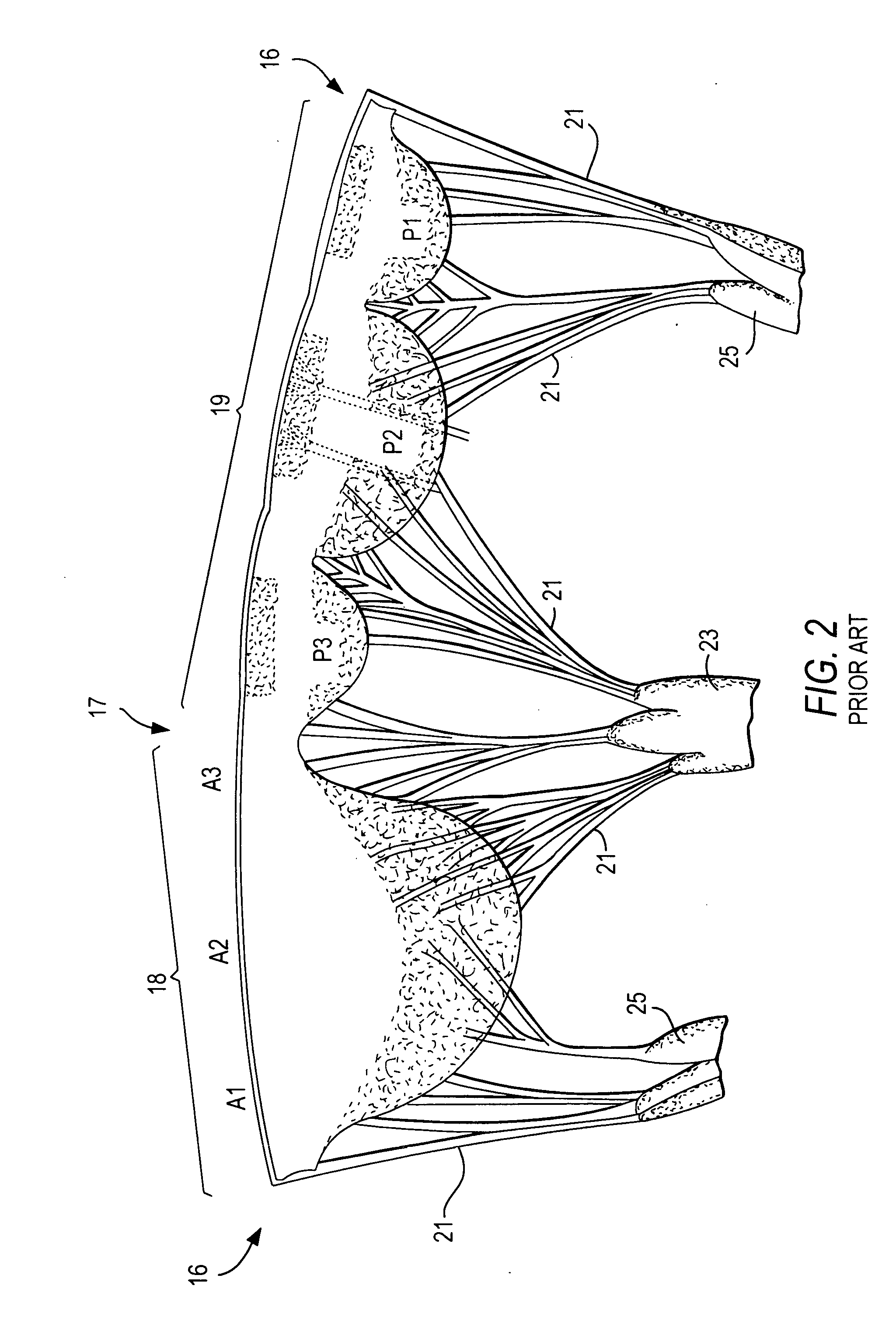

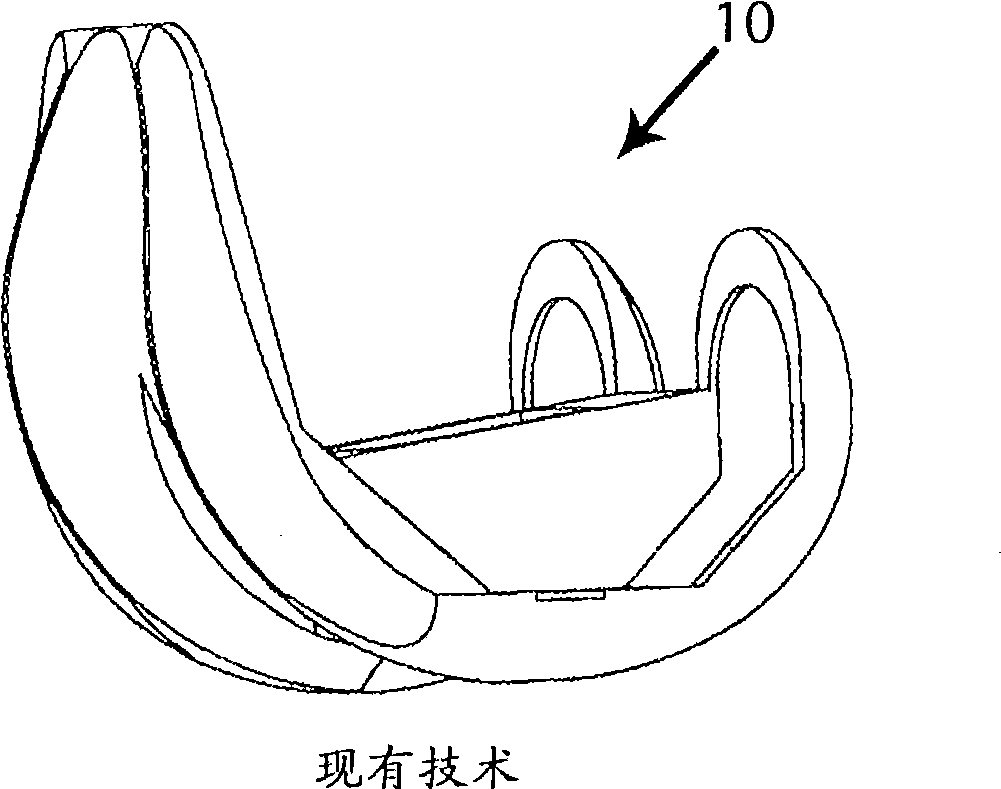

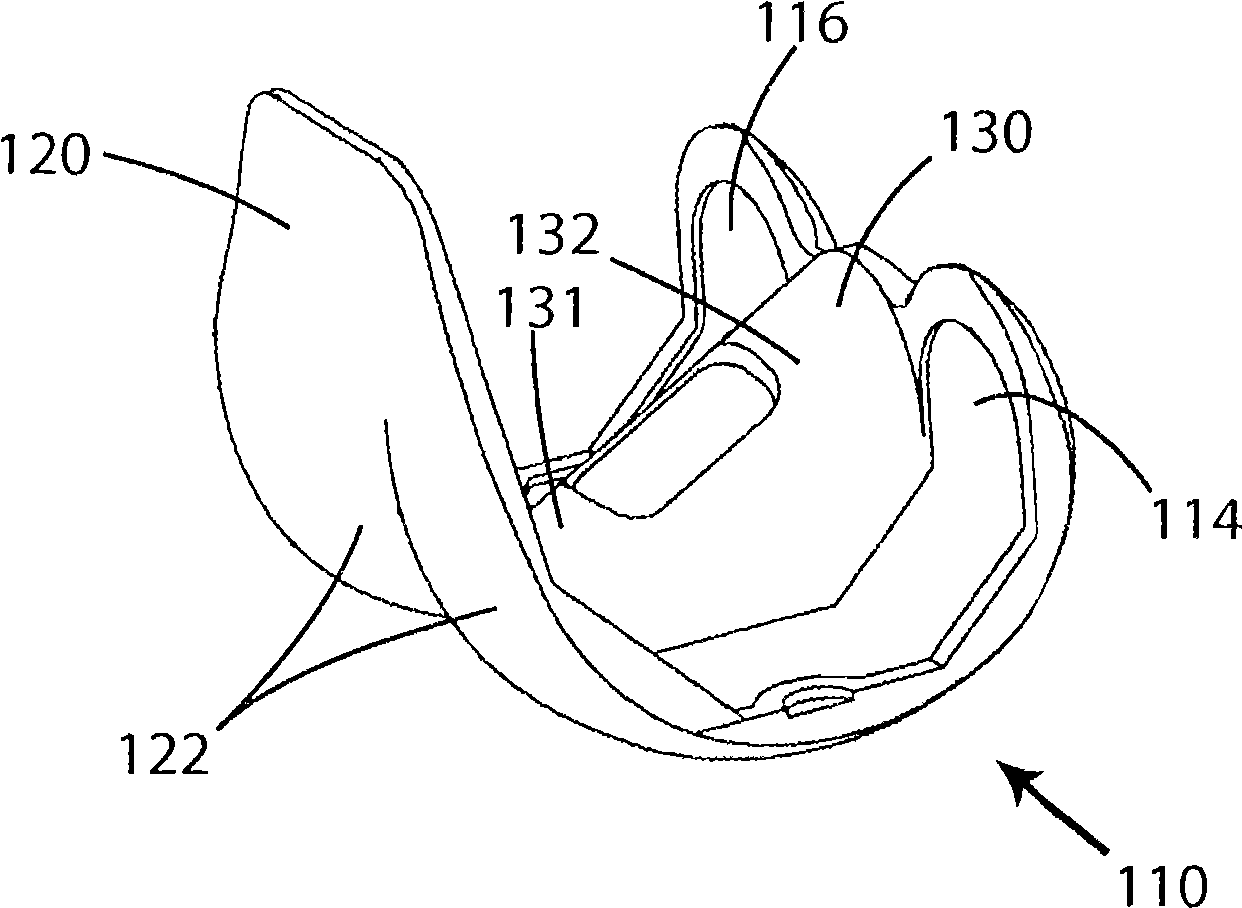

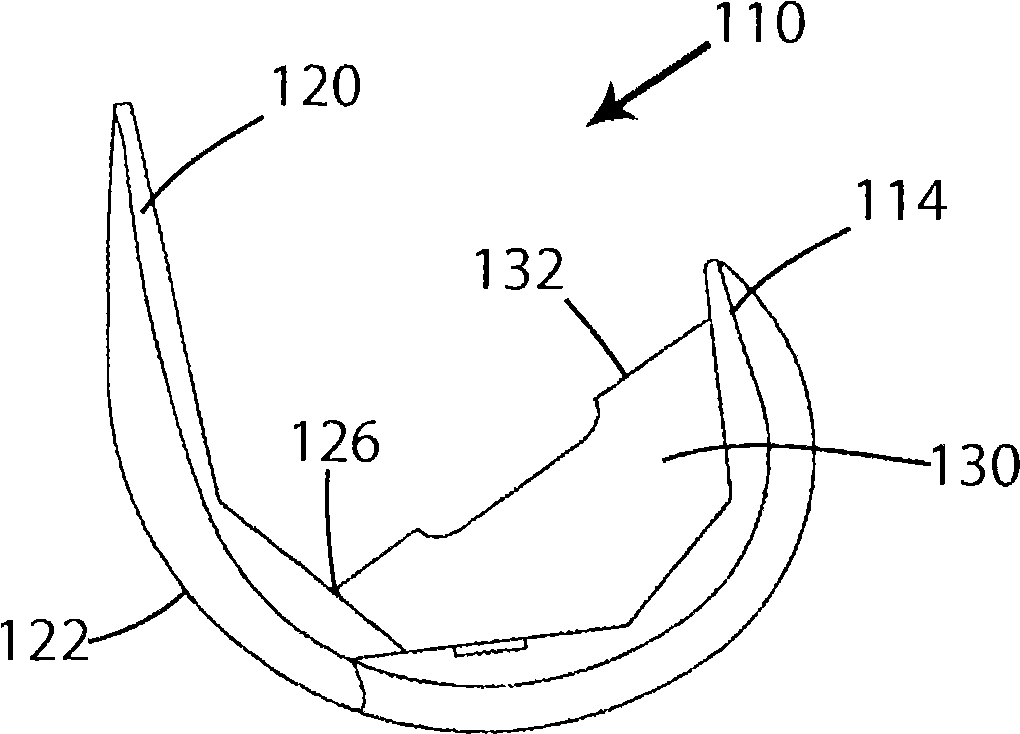

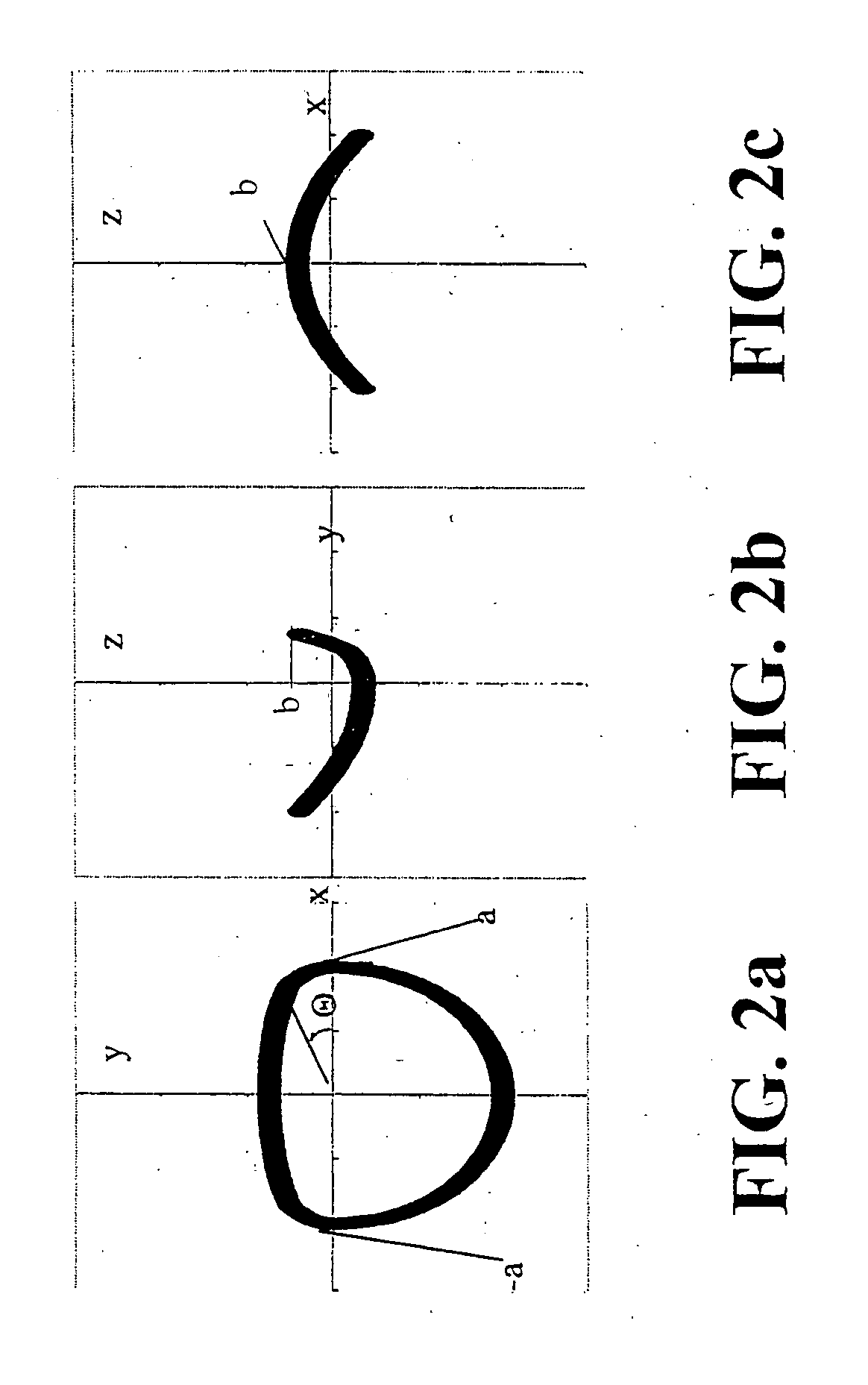

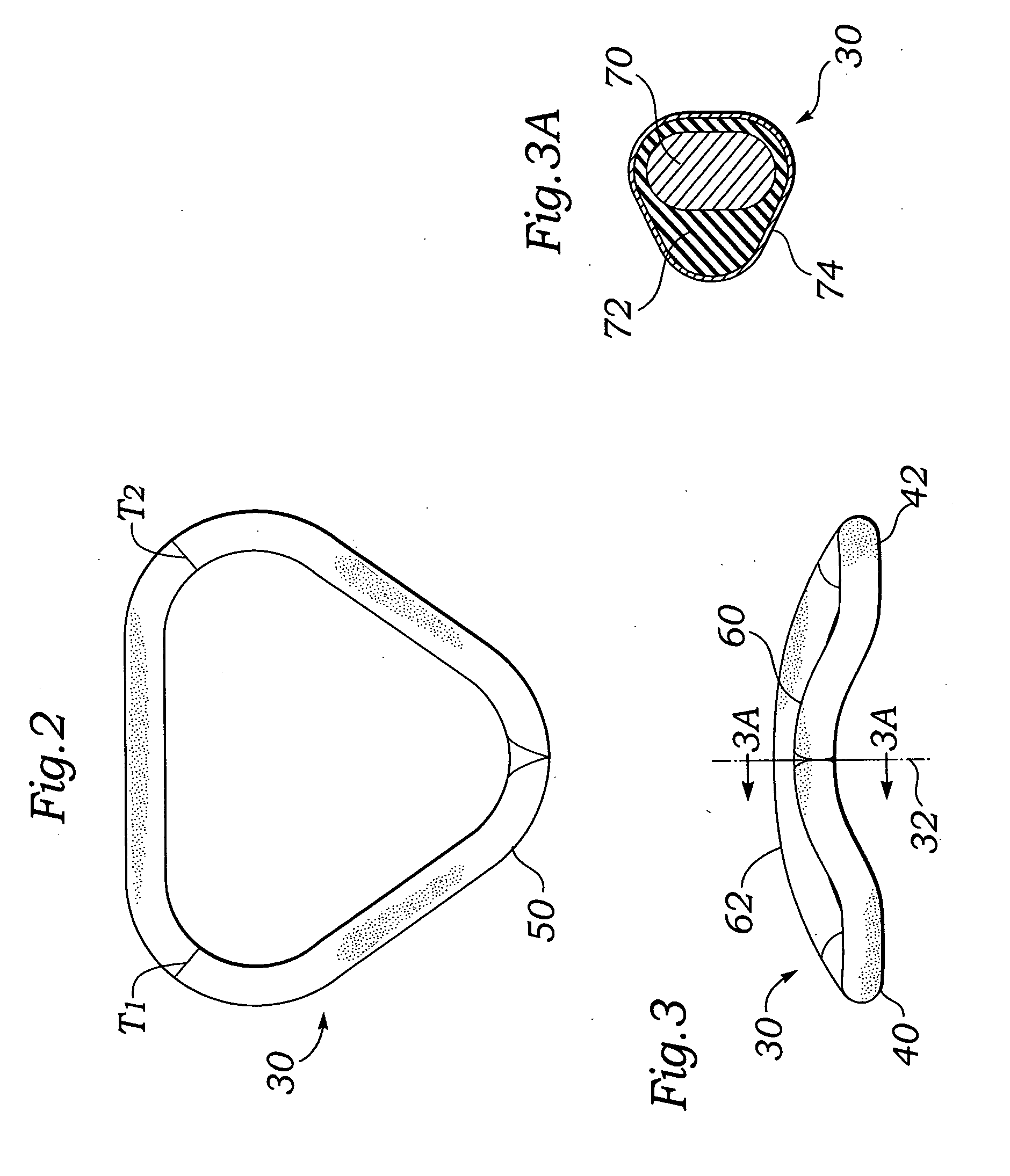

C-shaped heart valve prostheses

A prosthesis for a heart valve (e.g., the mitral valve) is generally C-shaped in plan view. Points at the top and bottom of the C lie in a plan view plane. The back of the C rises above the plan view plane between the top and bottom points. Free end portions of the C may also rise above the plan view plane. The prosthesis is accordingly saddle-shaped. The back of the C may have an indentation that extends toward the open side of the C. In use as a mitral valve prosthesis the top and bottom of the C are respectively adjacent the commissures of the valve, and the back of the C is adjacent the posterior section of the valve. The prosthesis may be rigid or semi-rigid.

Owner:ST JUDE MEDICAL LLC

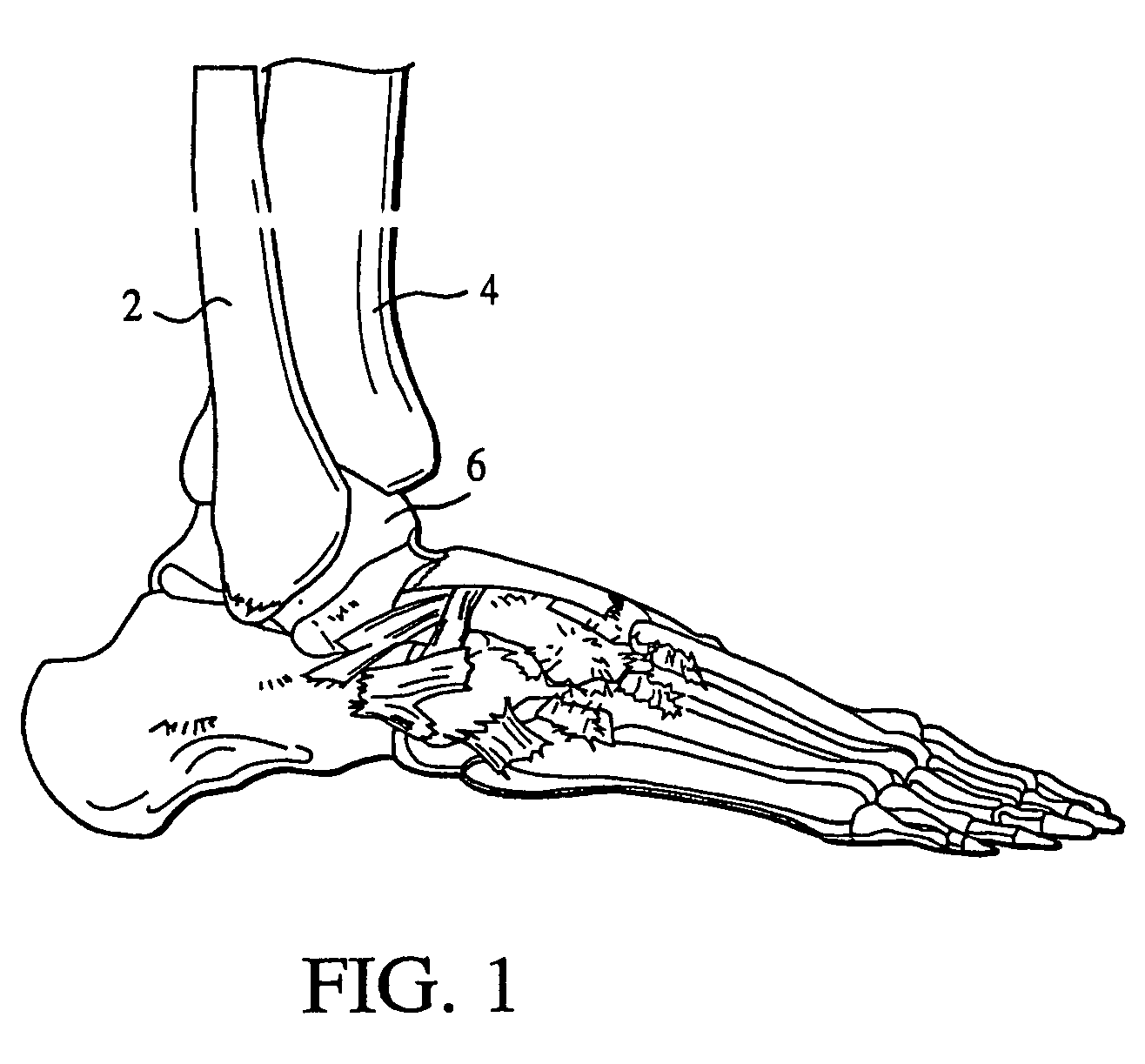

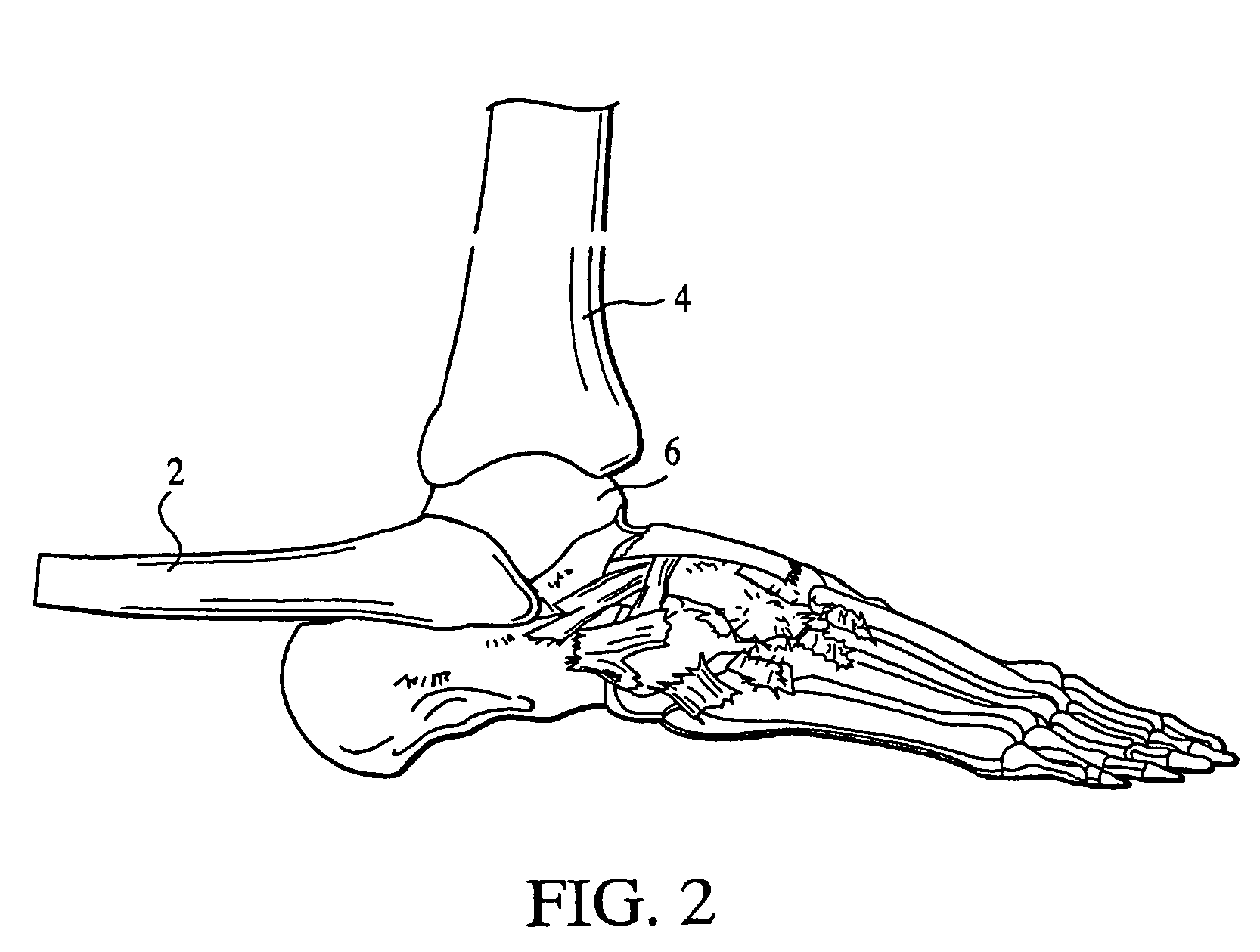

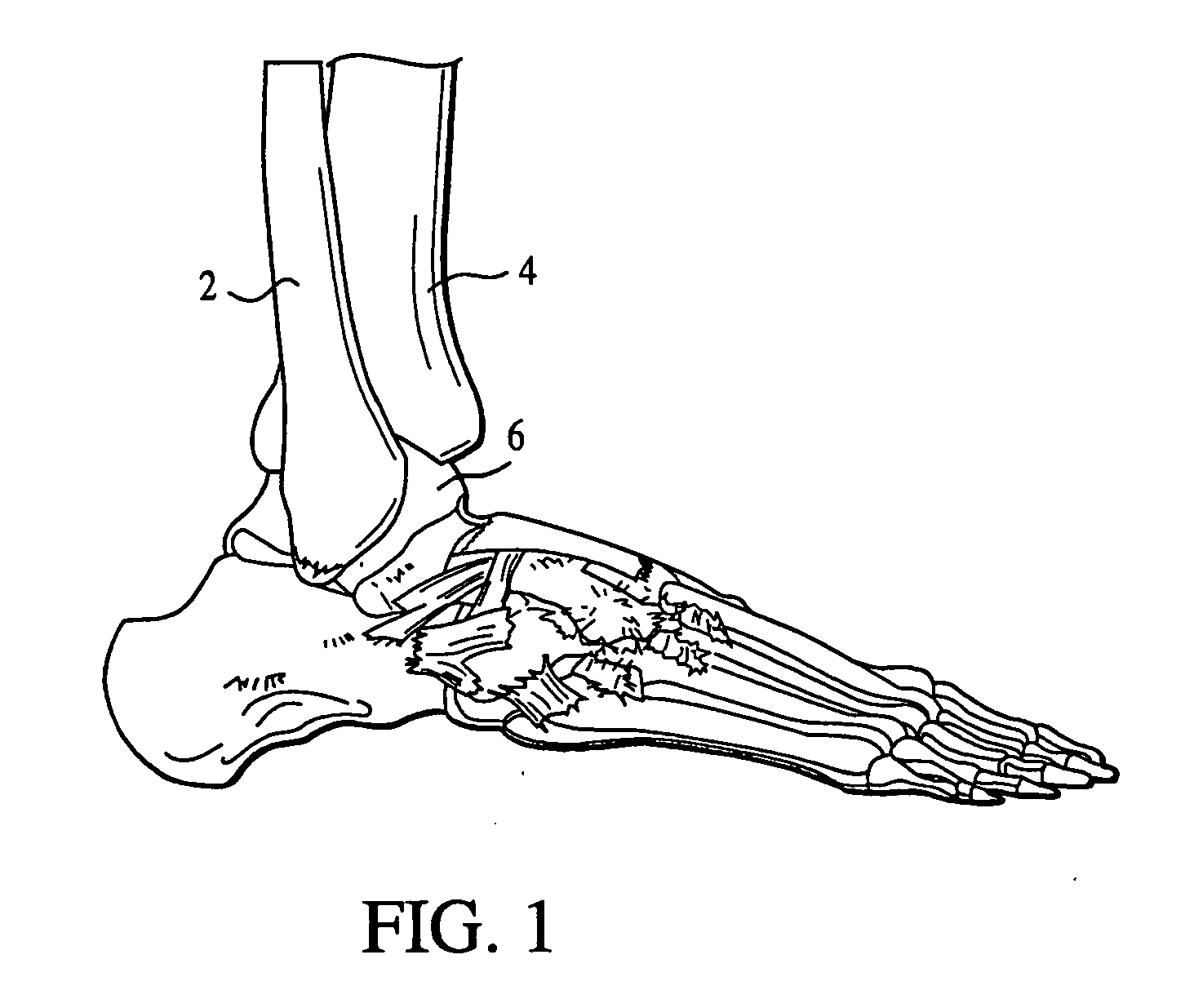

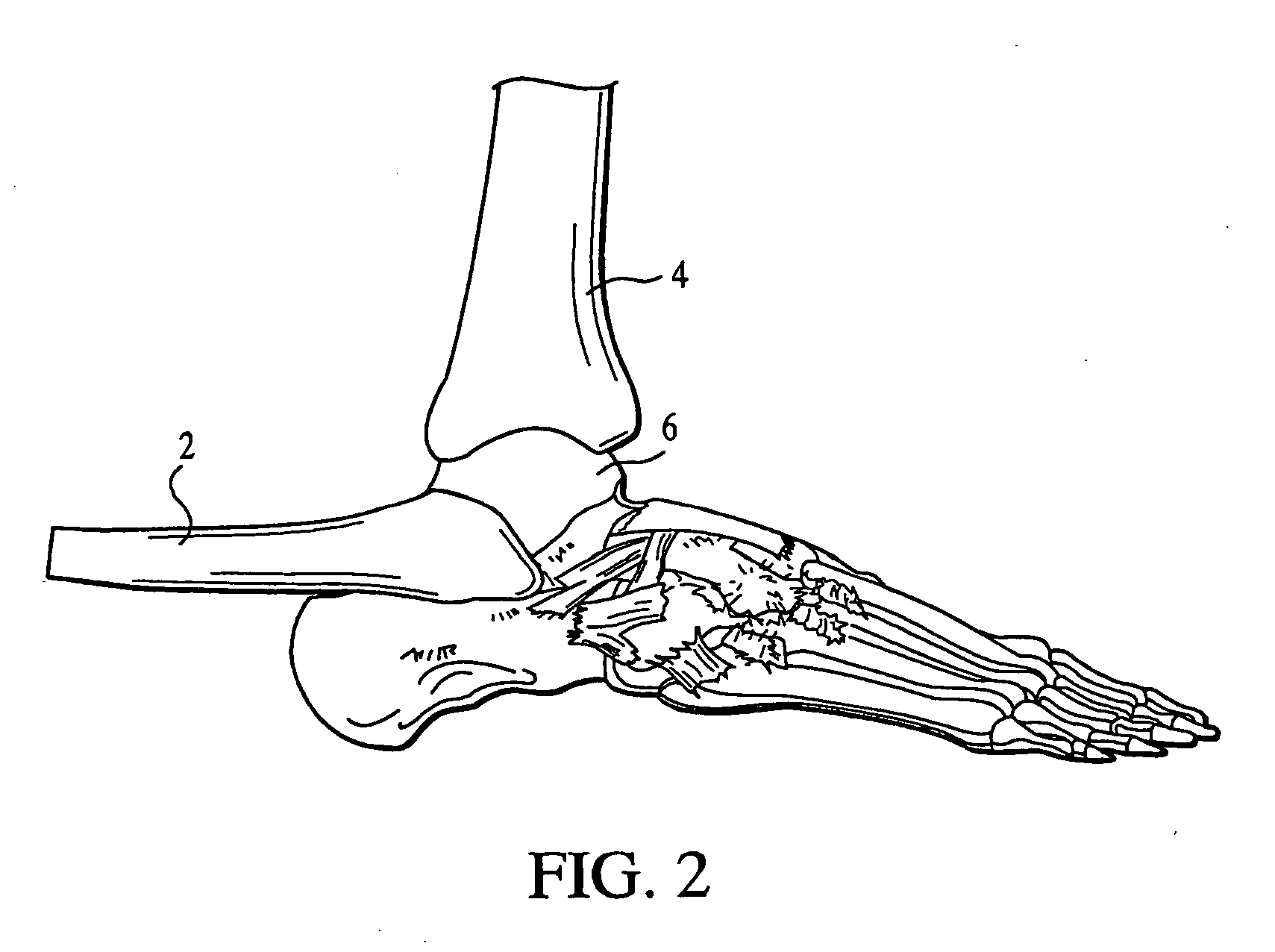

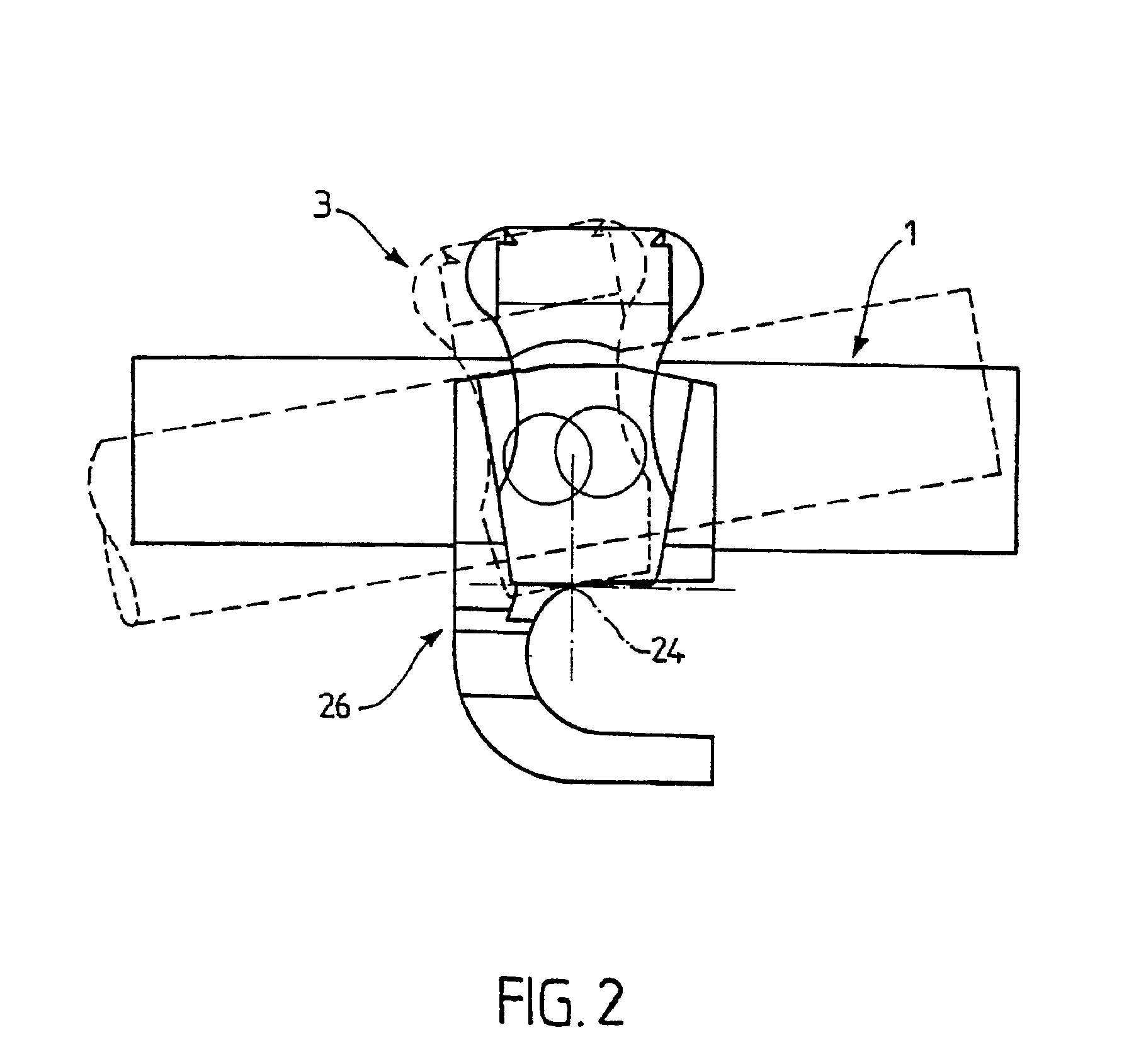

Ankle joint prosthesis and its method of implantation

The ankle joint prosthesis adapted to involve the patient's distal tibia and talus has, according to the present invention, tibial, talar and mobile or semi-constrained bearing components that are laterally to medially implanted in the patient. The tibial component's top surface has convex curvature in its anterior to posterior plane and is configured so as to approximate and match with the curvature of a prepared portion of the distal tibia; its bottom surface being approximately flat. The talar component's top surface has saddle-shaped, convex curvature in its anterior to posterior plane, it's bottom surface has concave curvature and is configured so as to approximate and match with the curvature of a prepared portion of the talus. The mobile or semi-constrained bearing components have embodiments that comprise a wide variety of geometric shapes. A method for implanting such a prosthesis is also disclosed.

Owner:CONCEPTS & MEDICINE III

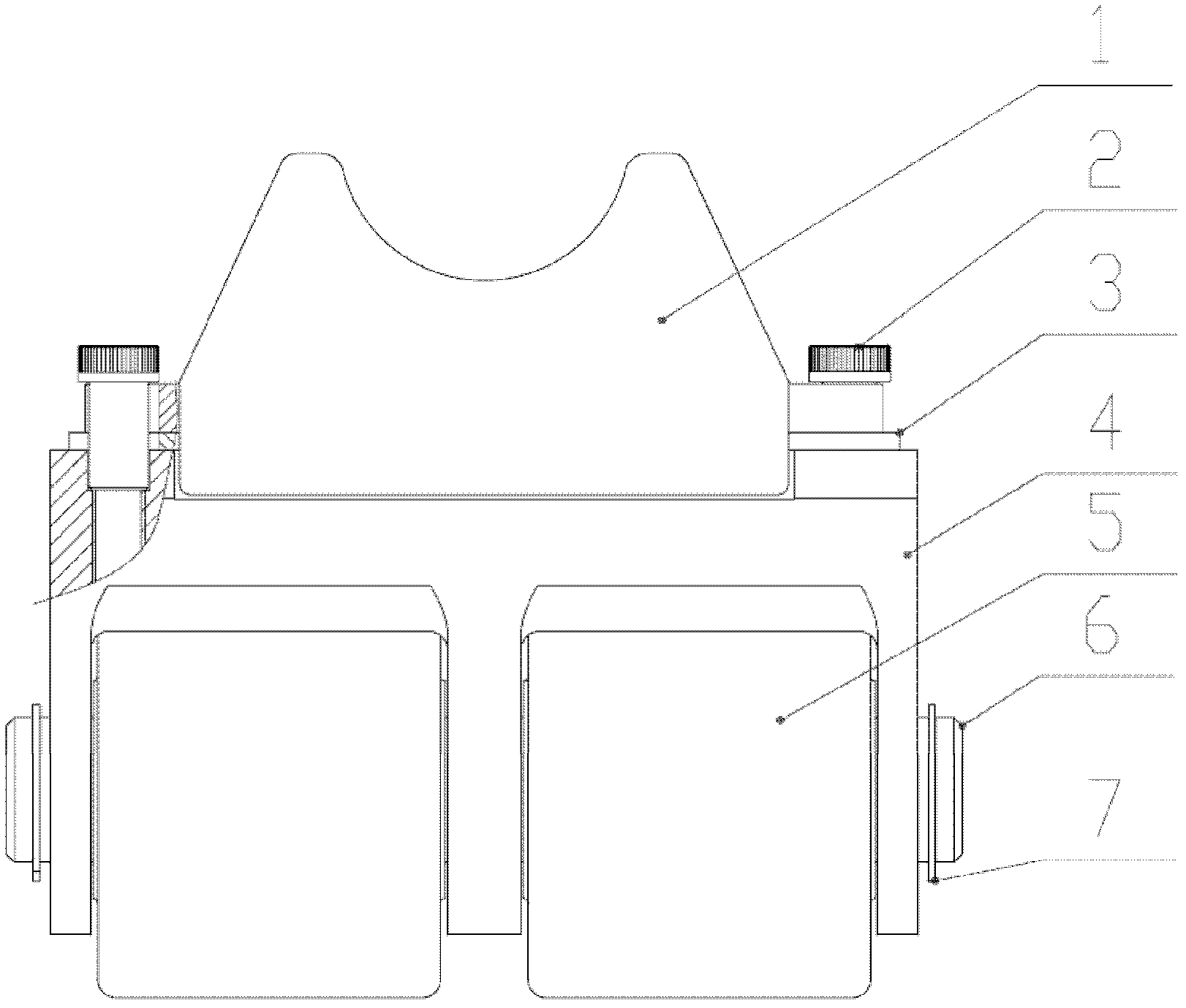

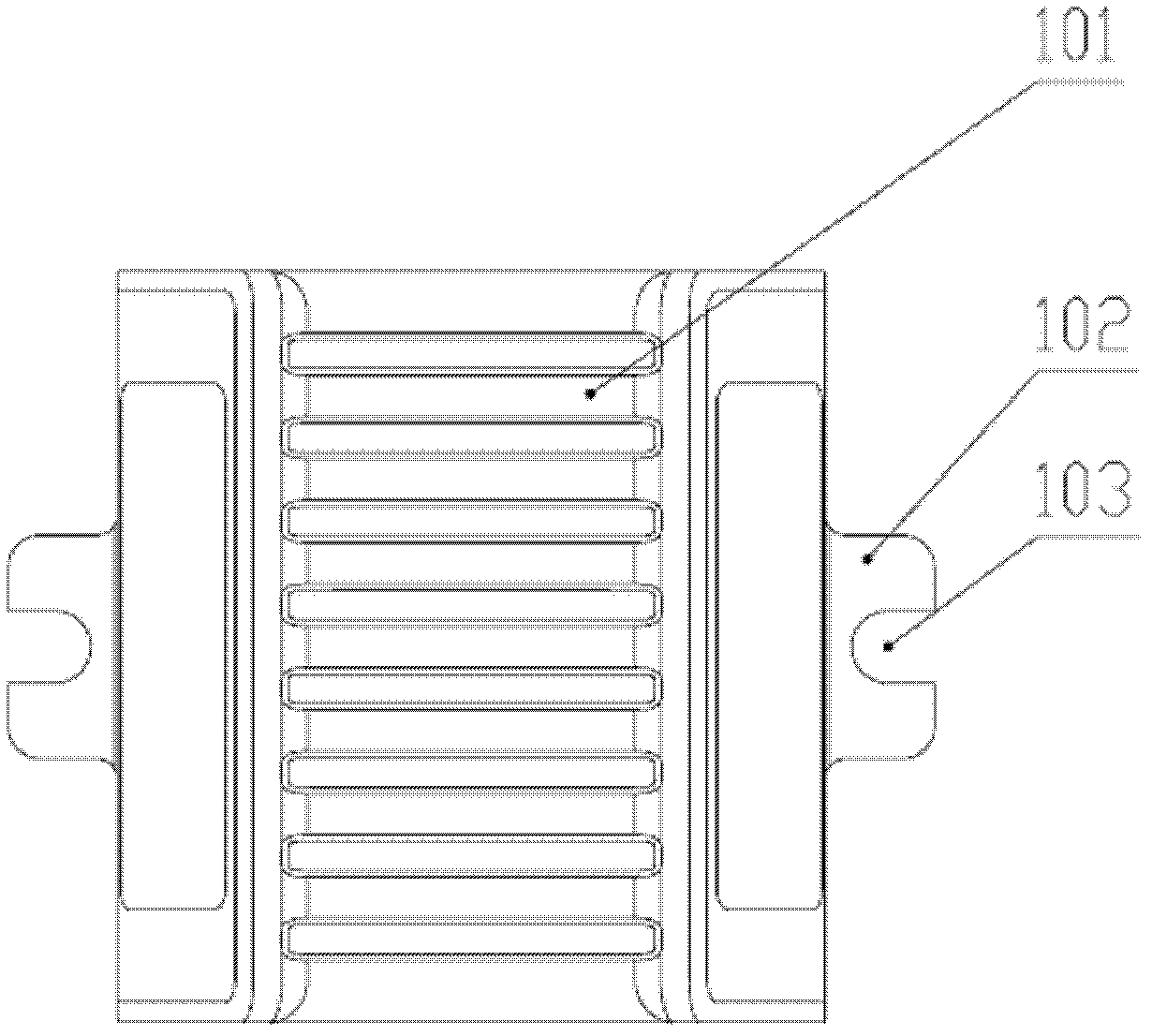

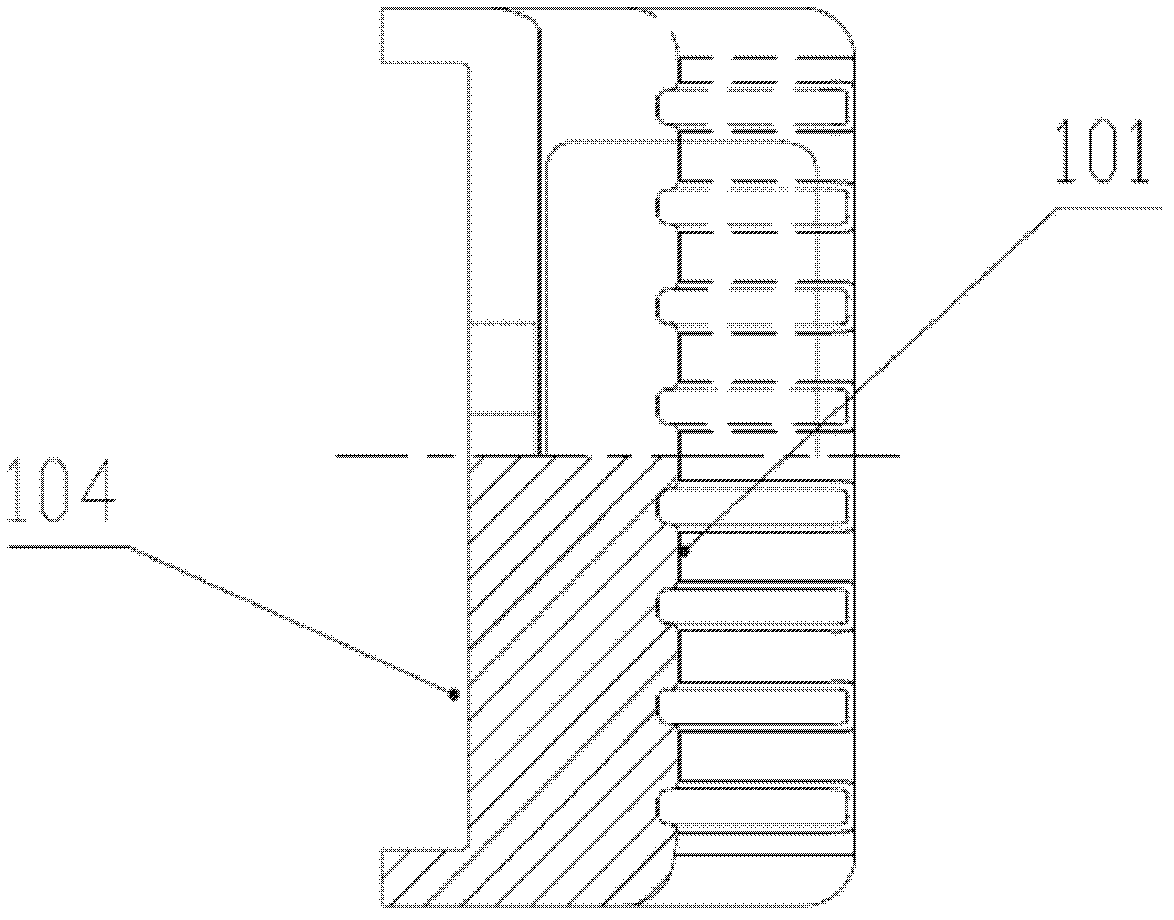

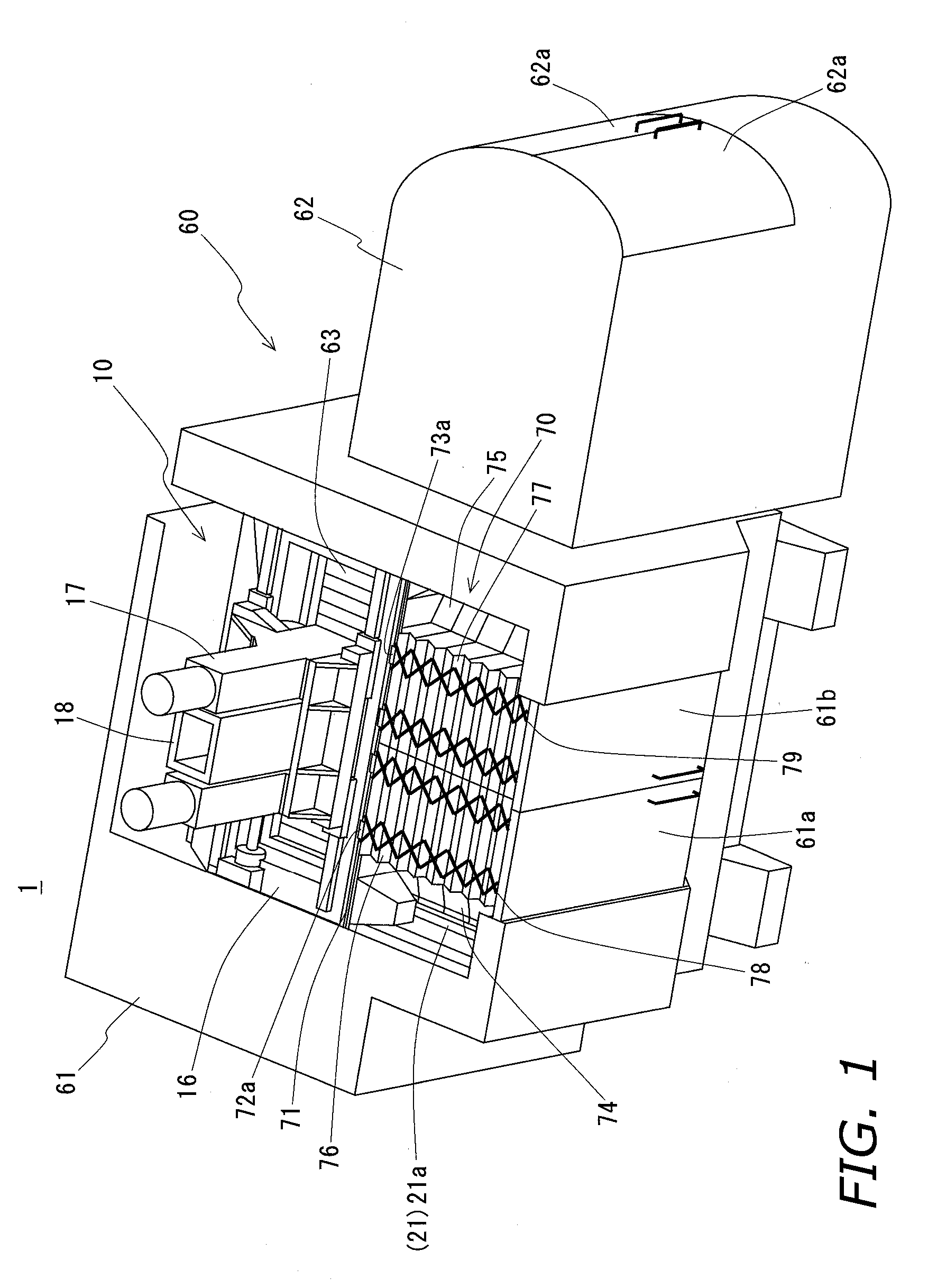

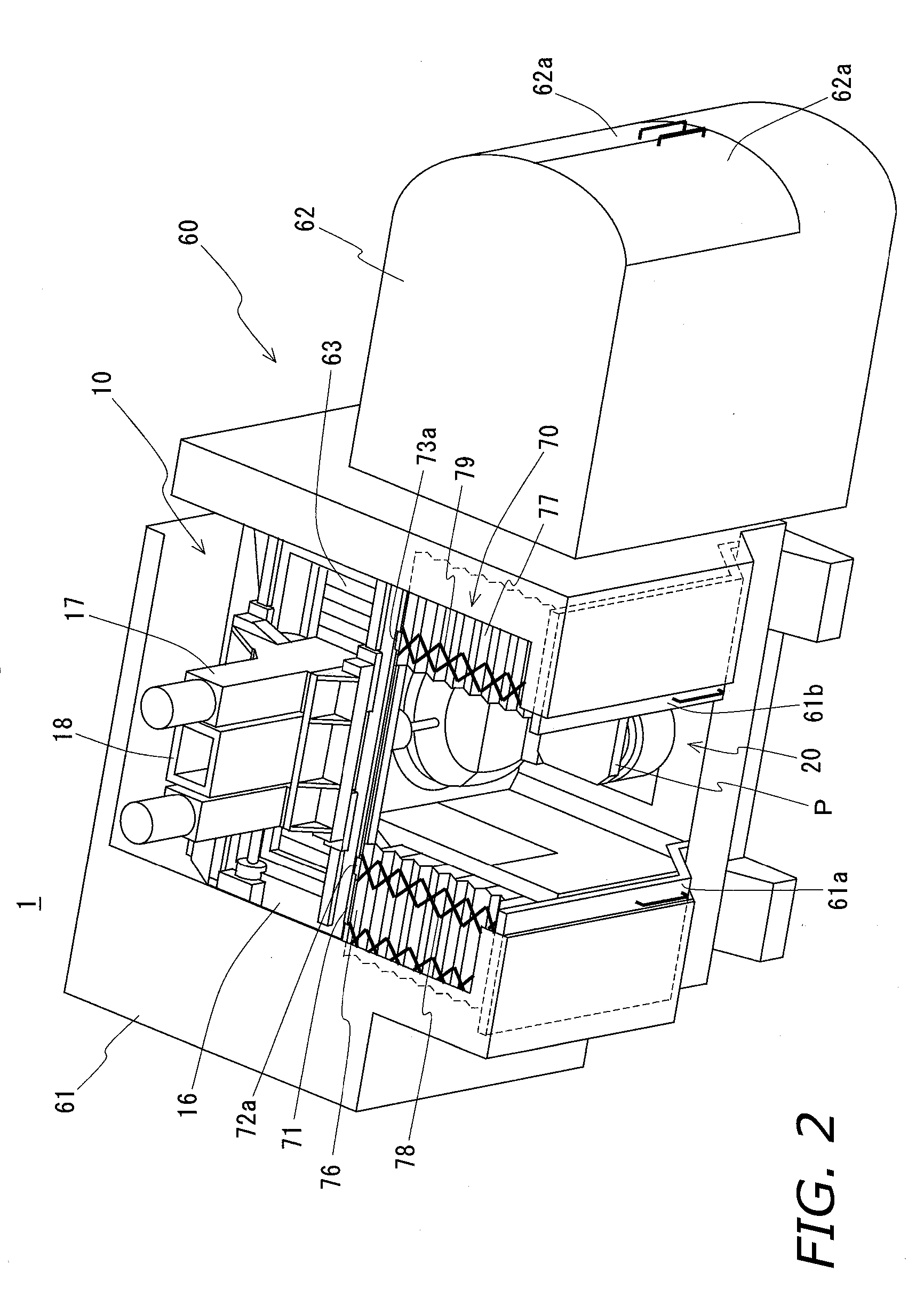

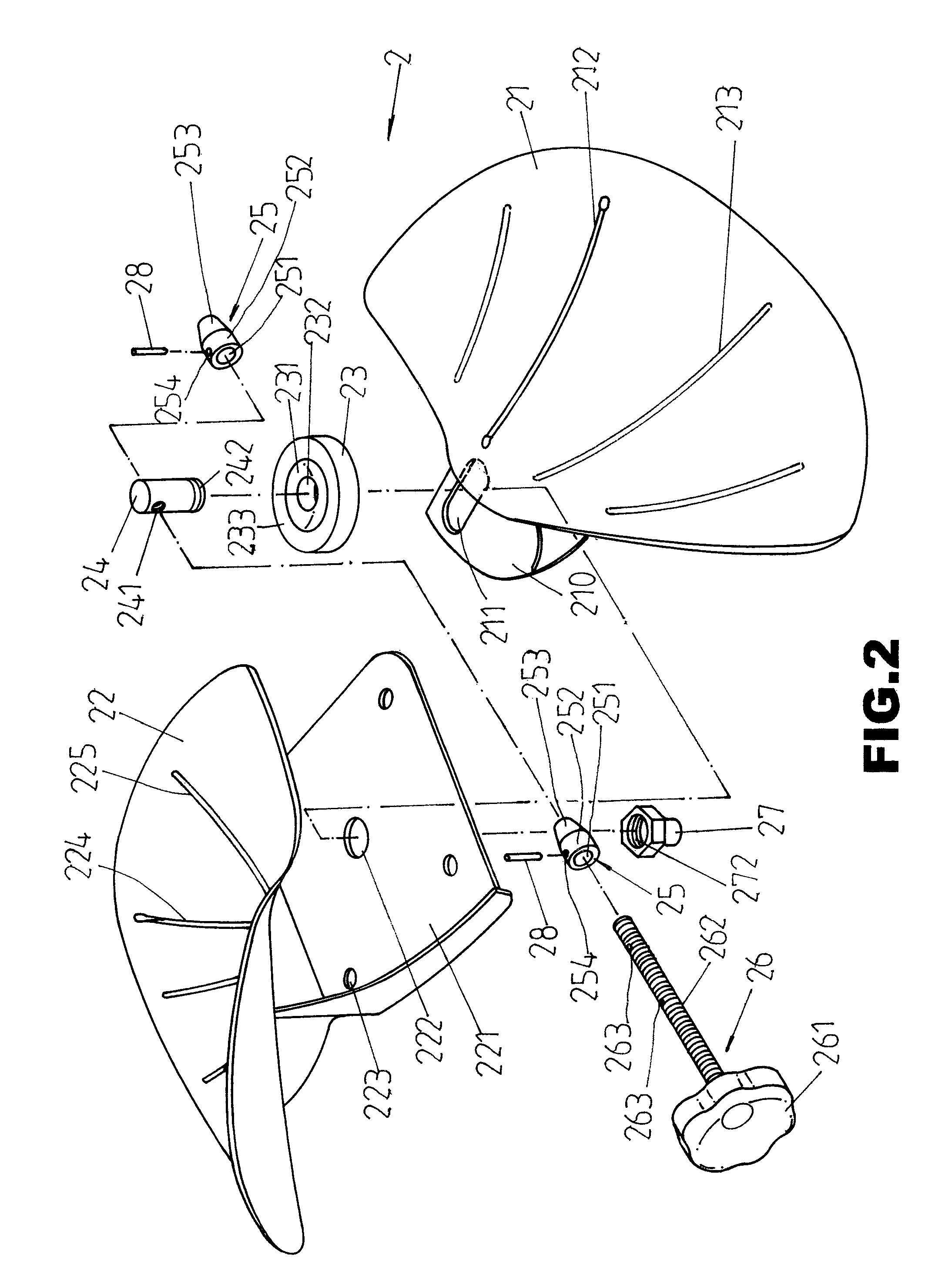

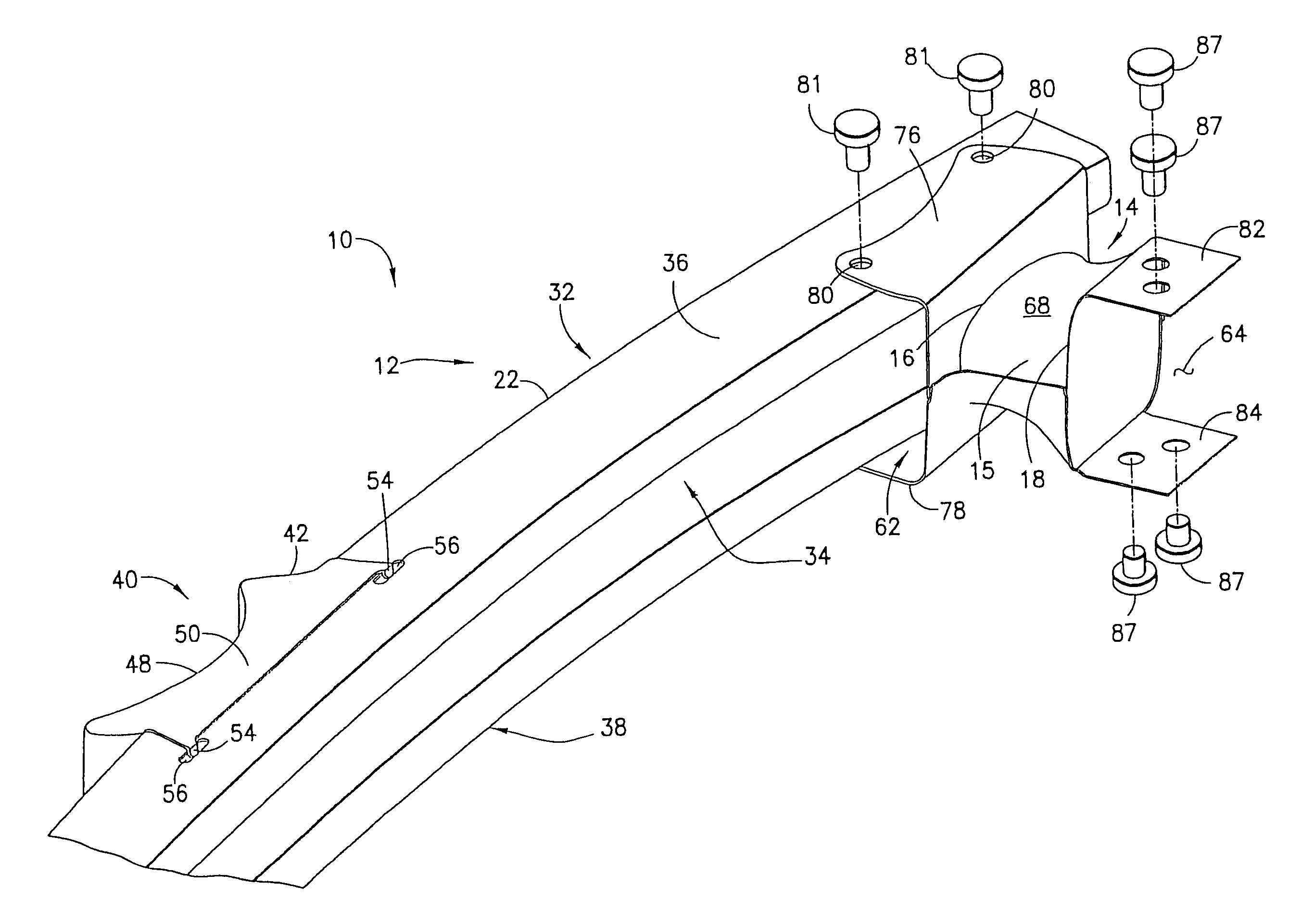

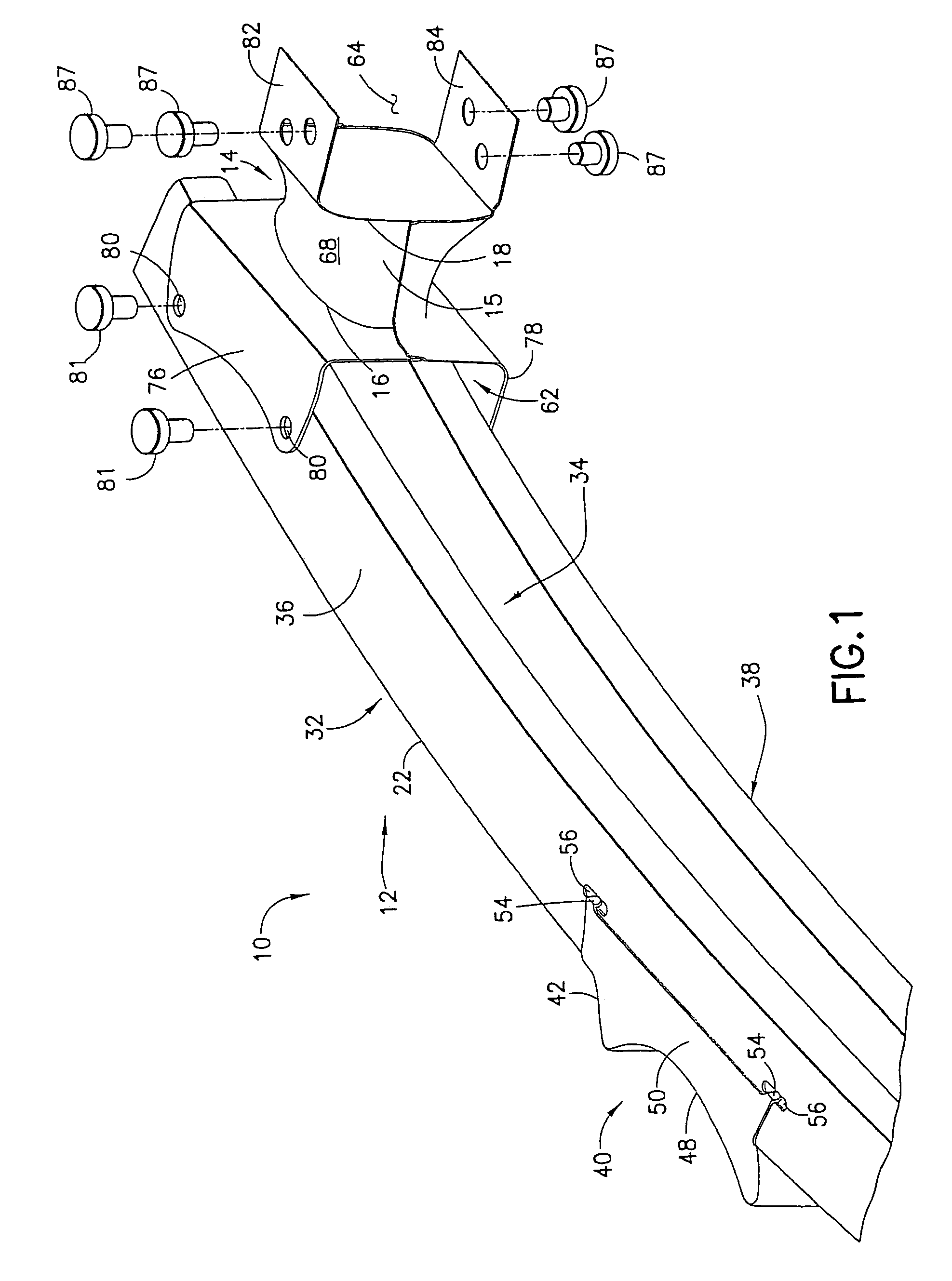

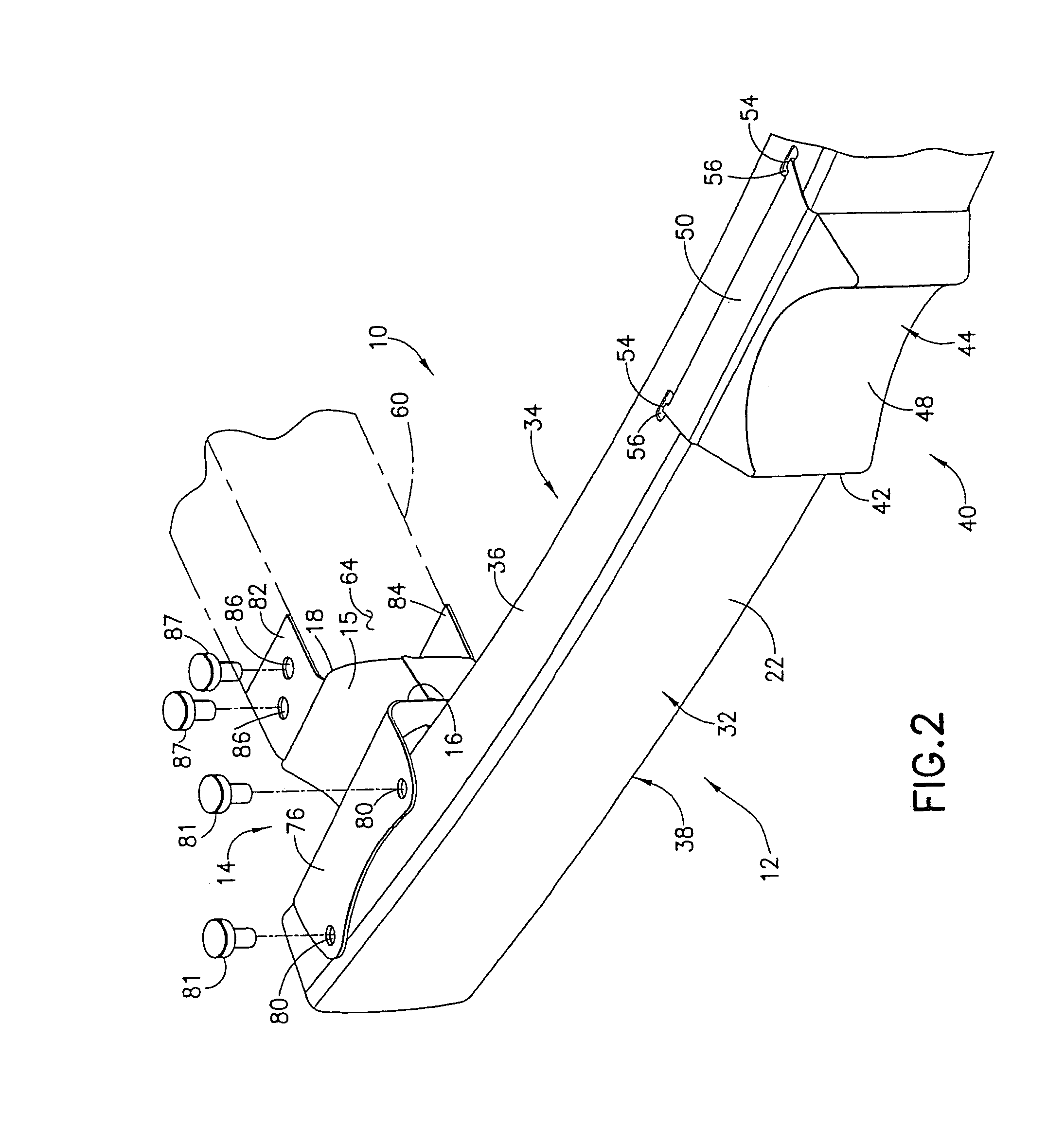

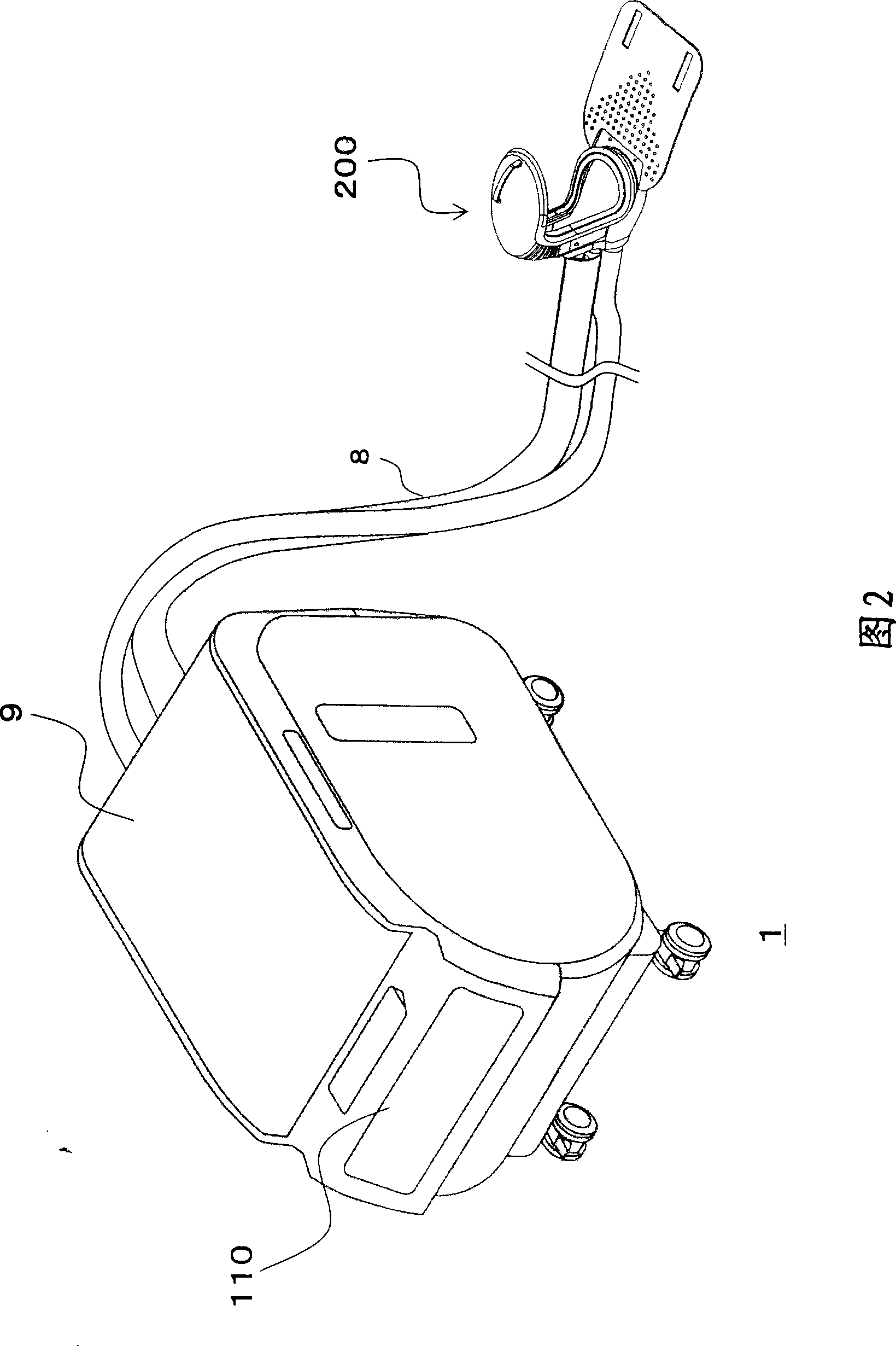

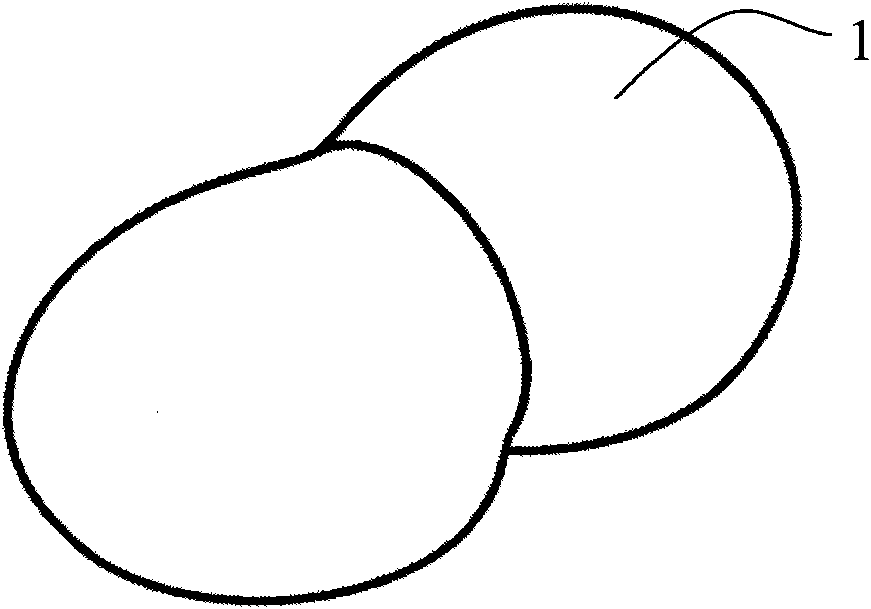

Coiled tubing clamping device and injection head using same

ActiveCN102704870BAvoid wear and tearImprove reliabilityDrilling rodsDrilling casingsCoiled tubingEngineering

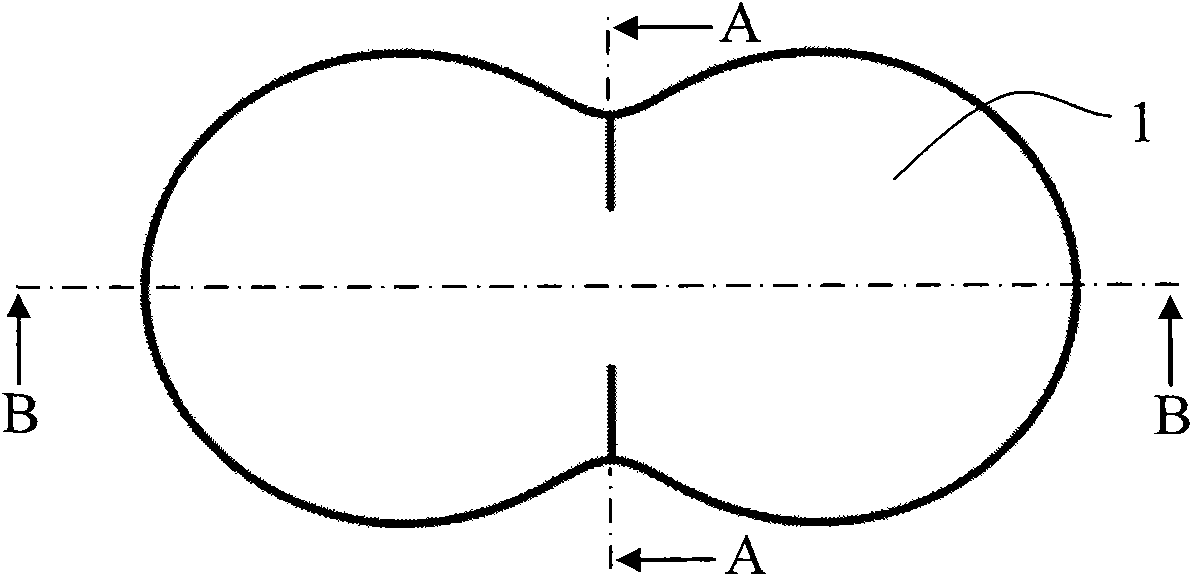

A coiled tubing clamping mechanism comprises a saddle-shaped clamping block (1) and a clamping block seat (4). The saddle-shaped clamping block (1) is connected to the clamping block seat (4). Two sides of the saddle-shaped clamping block (1) are provided with a tongue platform (102). The tongue platform (102) is provided with an open hole (103). The back of the saddle-shaped clamping block (1) is provided with a groove (104). Two sides of the clamping block seat (4) are provided with a pair of bosses (406) respectively. The groove (104) of the saddle-shaped clamping block (1) is inserted in a holding slot (405) formed by the bosses (406) of the clamping block seat. A traverse gap is kept between the groove (104) and the holding slot (405). The clamping block seat (4) is provided with a positioning screw (2) for limiting the position of the saddle-shaped clamping block (1). Also disclosed is an injector head using the coiled tubing clamping mechanism, comprising a tubing clamping mechanism (11) and a drive chain (13). The tubing clamping mechanism (11) is mounted on the drive chain (13) through two pin holes (401) in the clamping block seat (4). The present invention can effectively prevent the tubing from being worn, is reliable in use, and makes it convenient to replace the clamping block.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

Semi-constrained ankle joint prosthesis and its method of implantation

The ankle joint prosthesis adapted to involve the patient's distal tibia and talus has, according to the present invention, tibial, talar and mobile or semi-constrained bearing components that are laterally to medially implanted in the patient. The tibial component's top surface has convex curvature in its anterior to posterior plane and is configured so as to approximate and match with the curvature of a prepared portion of the distal tibia; its bottom surface being approximately flat. The talar component's top surface has saddle-shaped, convex curvature in its anterior to posterior plane, it's bottom surface has concave curvature and is configured so as to approximate and match with the curvature of a prepared portion of the talus. The mobile or semi-constrained bearing components have embodiments that comprise a wide variety of geometric shapes. A method for implanting such a prosthesis is also disclosed.

Owner:SCHON LEW C +4

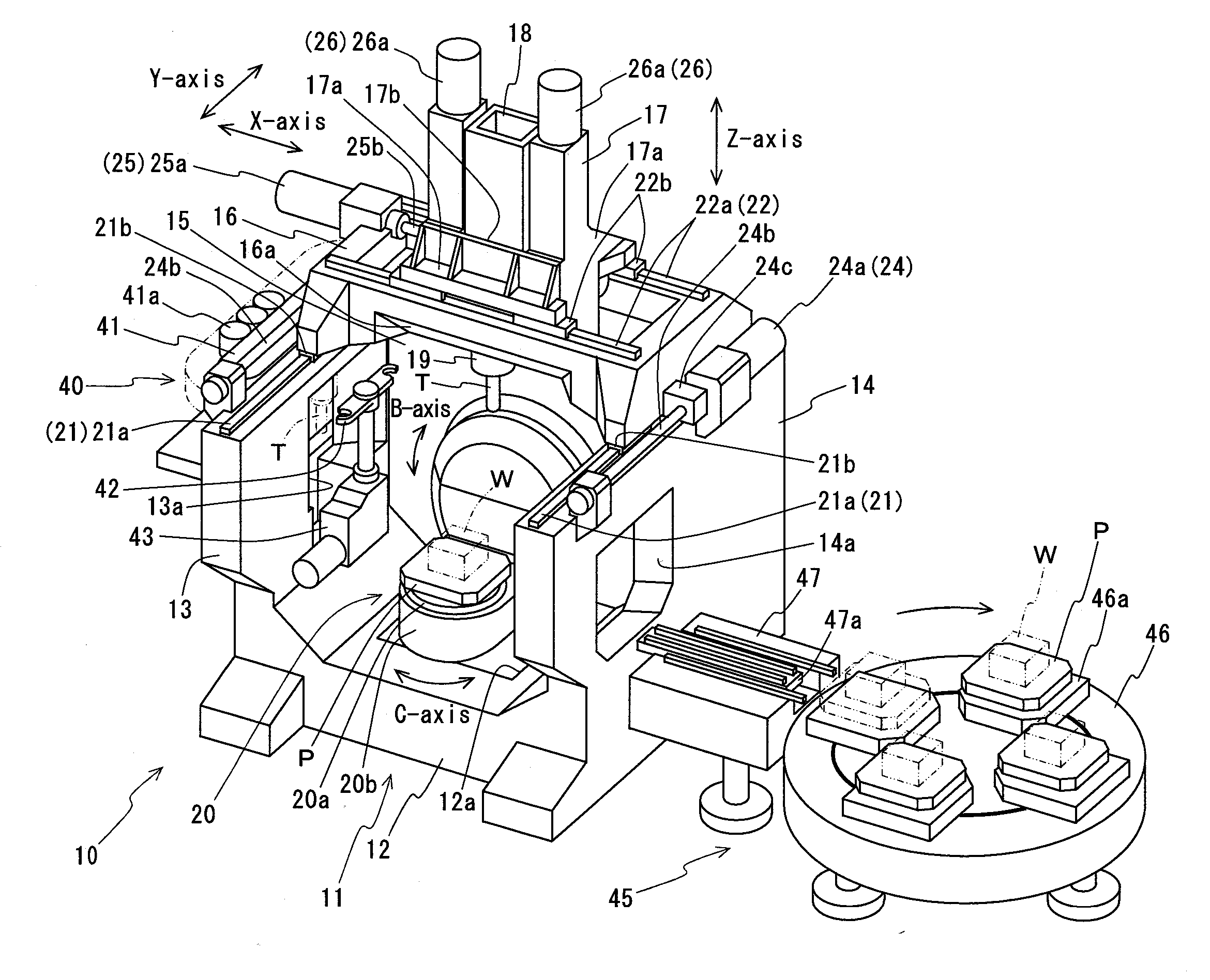

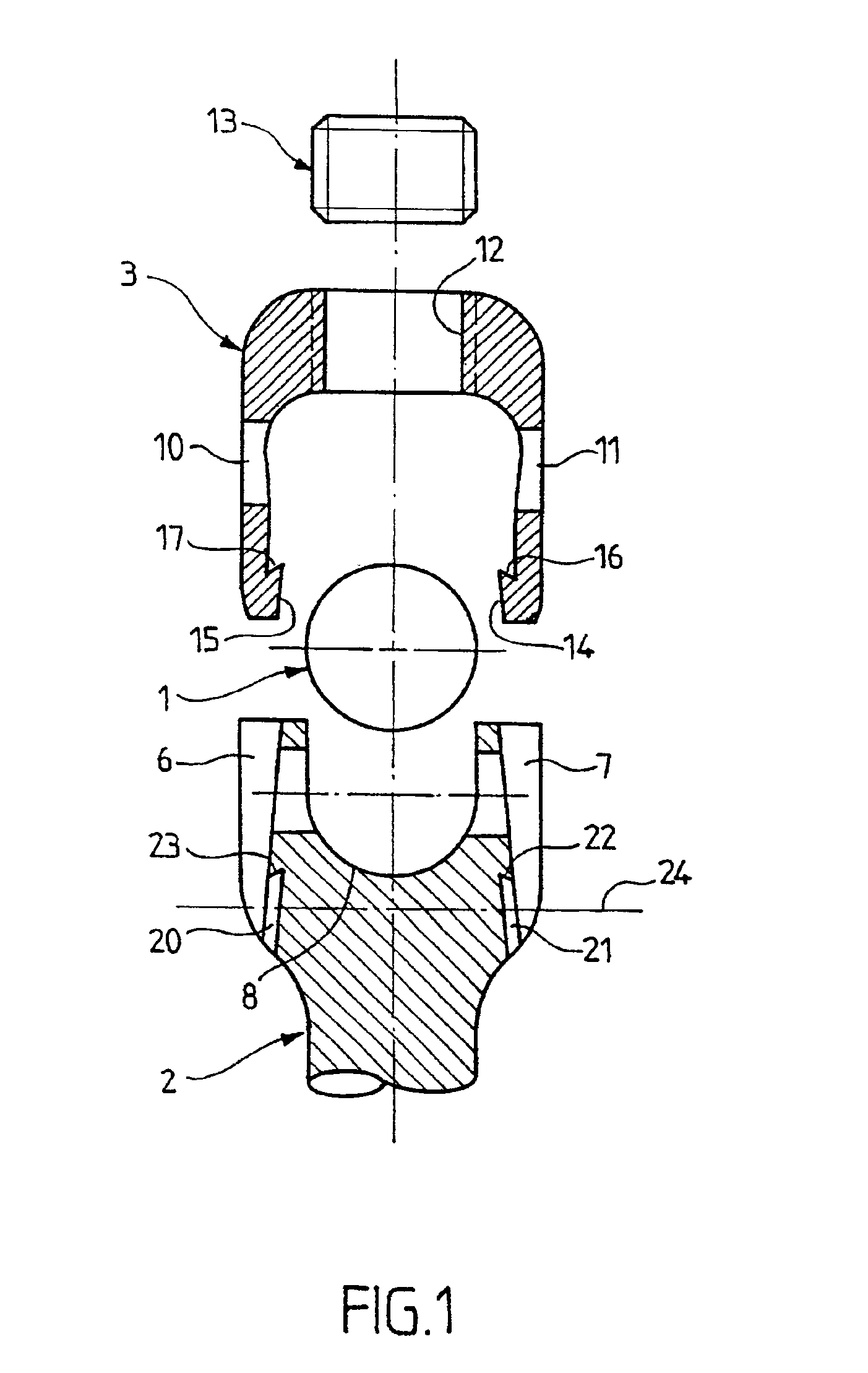

Machine Tool

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

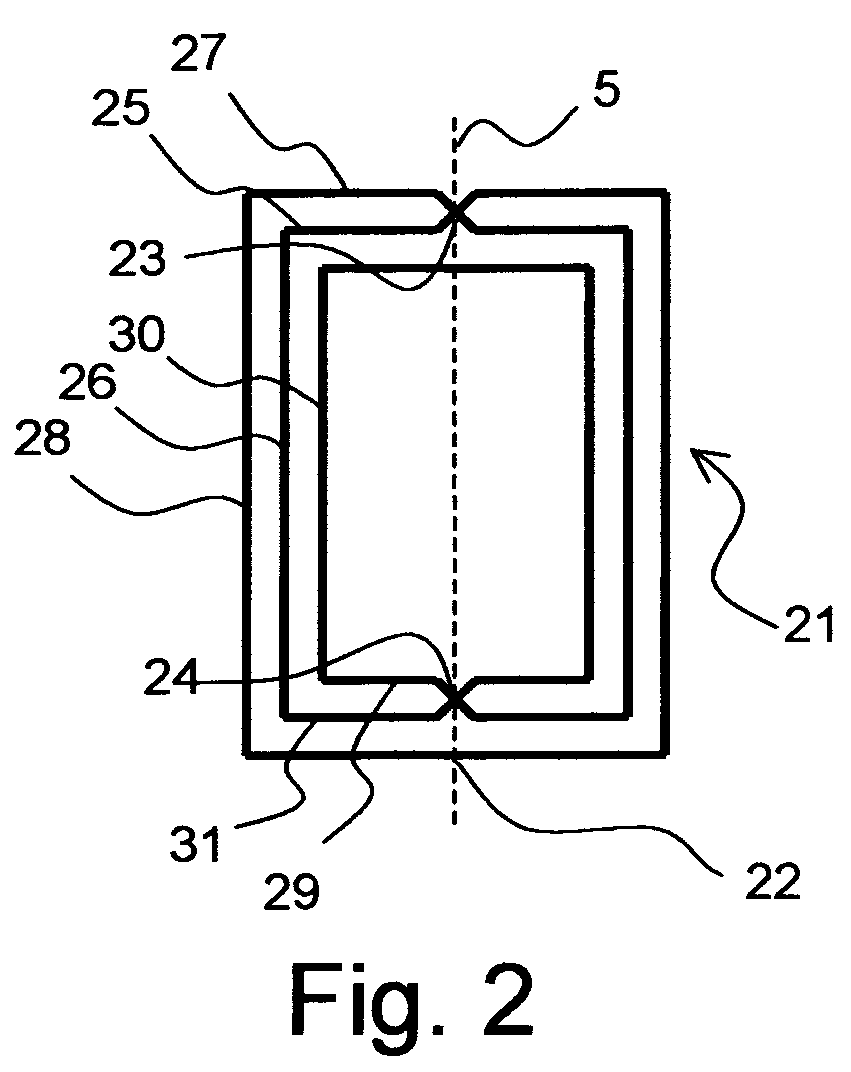

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

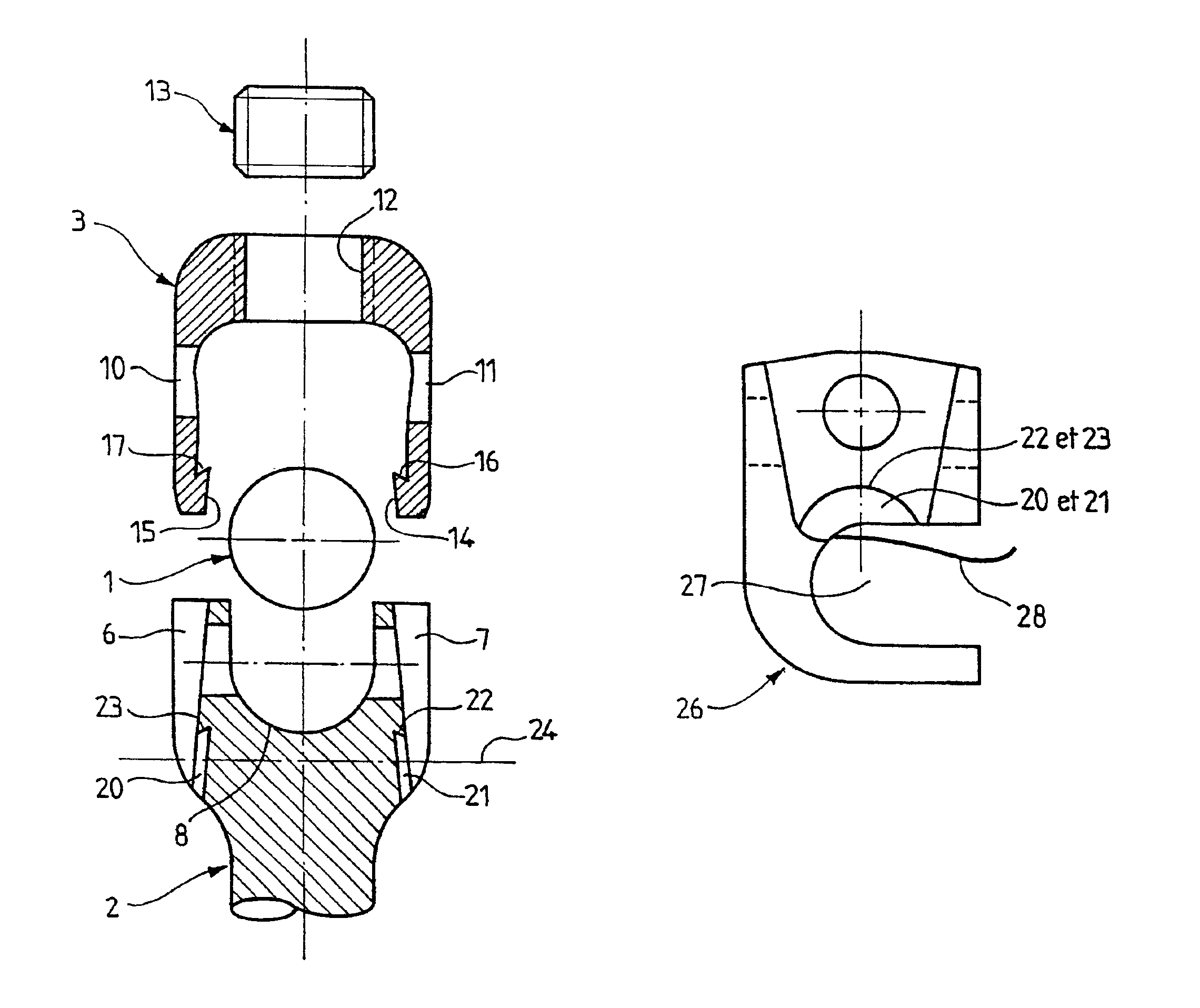

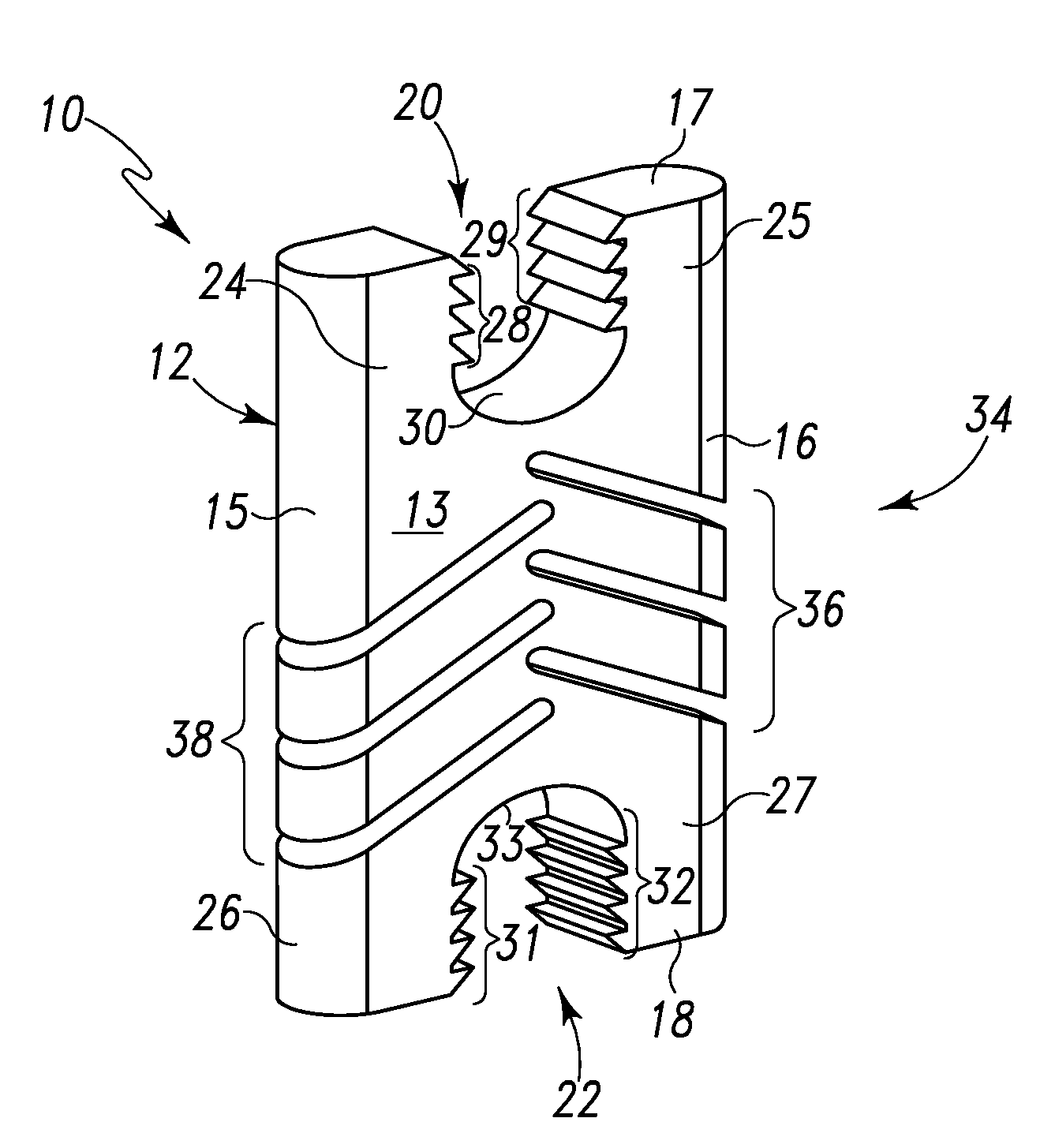

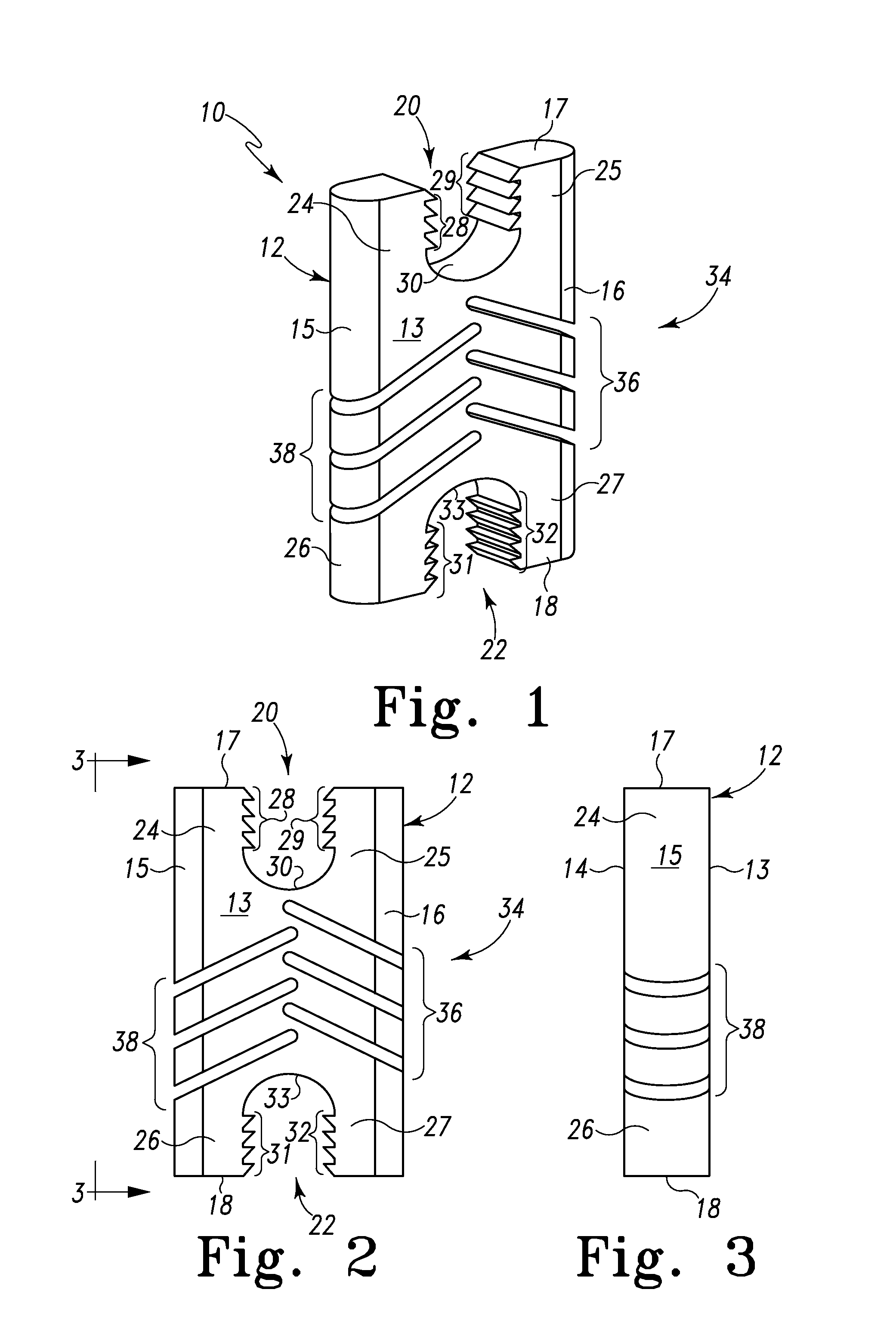

Fixing element and ancillary for stabilizing vertebrae

InactiveUS6911030B1Minimal frictionAvoid inconvenienceSuture equipmentsInternal osteosythesisEngineeringSaddle shape

The invention concerns an osteosynthesis system, comprising at least a linking element in the form of a rod, at least two fixing elements each capable of being anchored in a vertebra, and a locking screw. The invention is characterized in that the base of the head has a general horse-saddle shape, and the head has guide means for an independent closure component designed to be fixed on the head after the linking element has been positioned in the fork of the head, said closure component being generally U-shaped whereof the branches are urged to co-operate with the branches of-the fork-shaped part of the head and whereof the base comprises an internal thread for co-operating with the locking screw and the guide means provided on the head is formed by an arc-shaped shoulder on the outer side surfaces of the fork-shaped part. The invention also concerns an ancillary and an element for fixing such a system.

Owner:SPINEVISION +1

Nasal mask and system using same

A nasal mask assembly that includes a seal member defined from a unitary piece of elastomeric material. The seal member defines a nose receiving cavity and has a first end portion and a second end portion generally opposite the first end portion. A first opening in the first end portion allows at least a portion of a nose to enter the nose receiving cavity such that the nares of the patient communicate with the nose receiving cavity. The seal member includes a neck portion defined in the second end portion and a second opening defined in the neck portion in communication with the nose receiving cavity. A reinforcement area is provided on the side walls of the seal member. The reinforcement area comprises a saddle shaped contoured area on each side of the seal member. Each saddle shaped area has an upper and a lower protrusion portion for providing supporting contact with the face.

Owner:RIC INVESTMENTS LLC

Artificial spinal disc

The present invention relates to prostheses for treating spinal pathologies, and more specifically to an artificial disc implant. The implant includes an inferior implant for placement on an inferior vertebra and a superior implant for placement on a superior vertebra. The implant also includes an articulating interface that is generally saddle-shaped and ramped from the anterior of the vertebrae to the posterior of the vertebrae.

Owner:PAXSON ROBERT DAVID +2

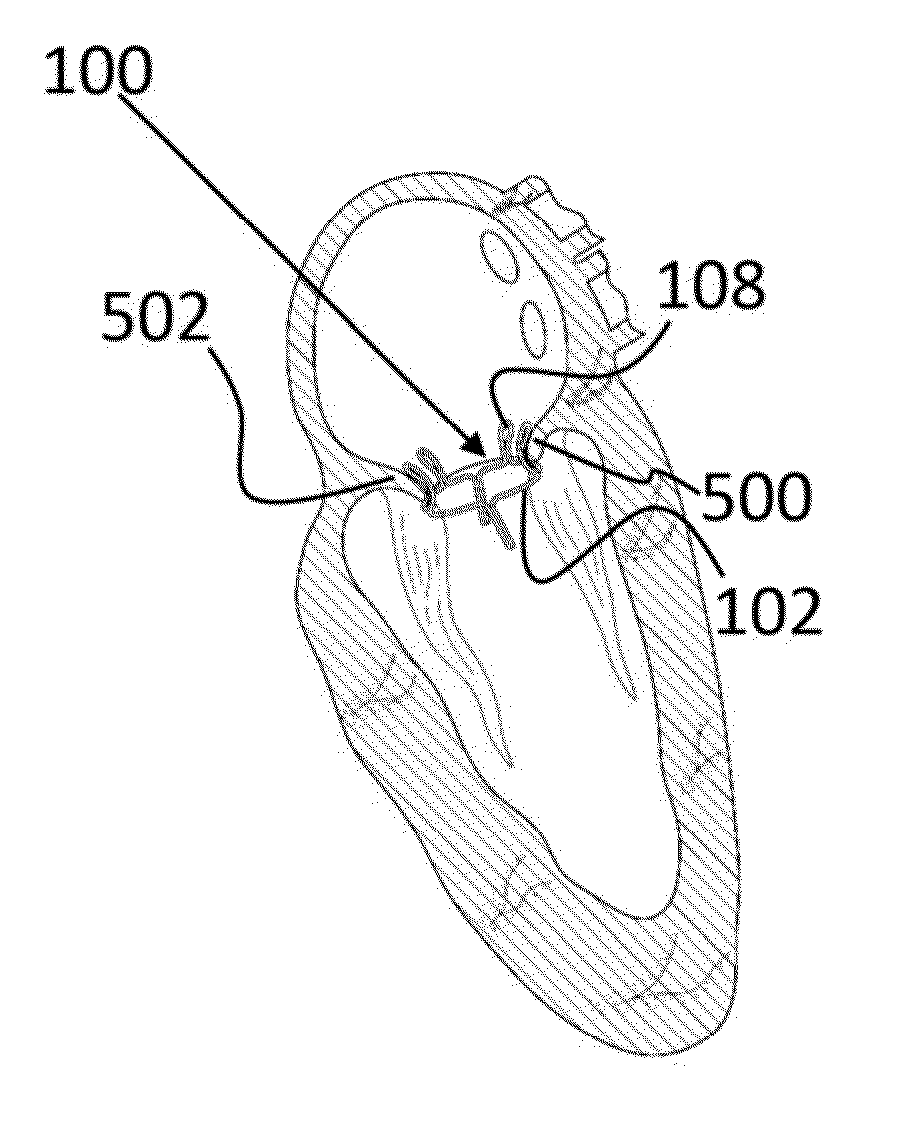

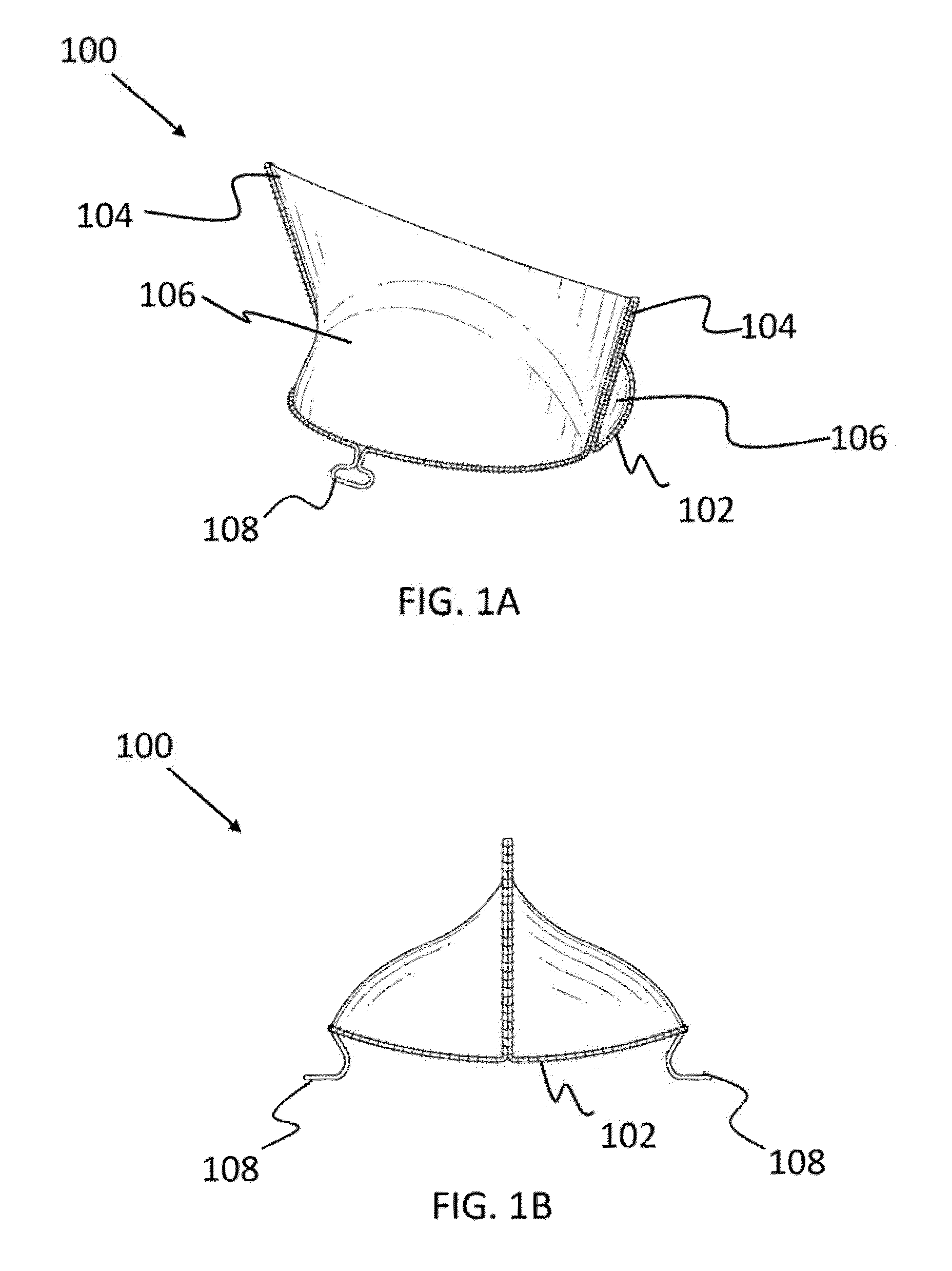

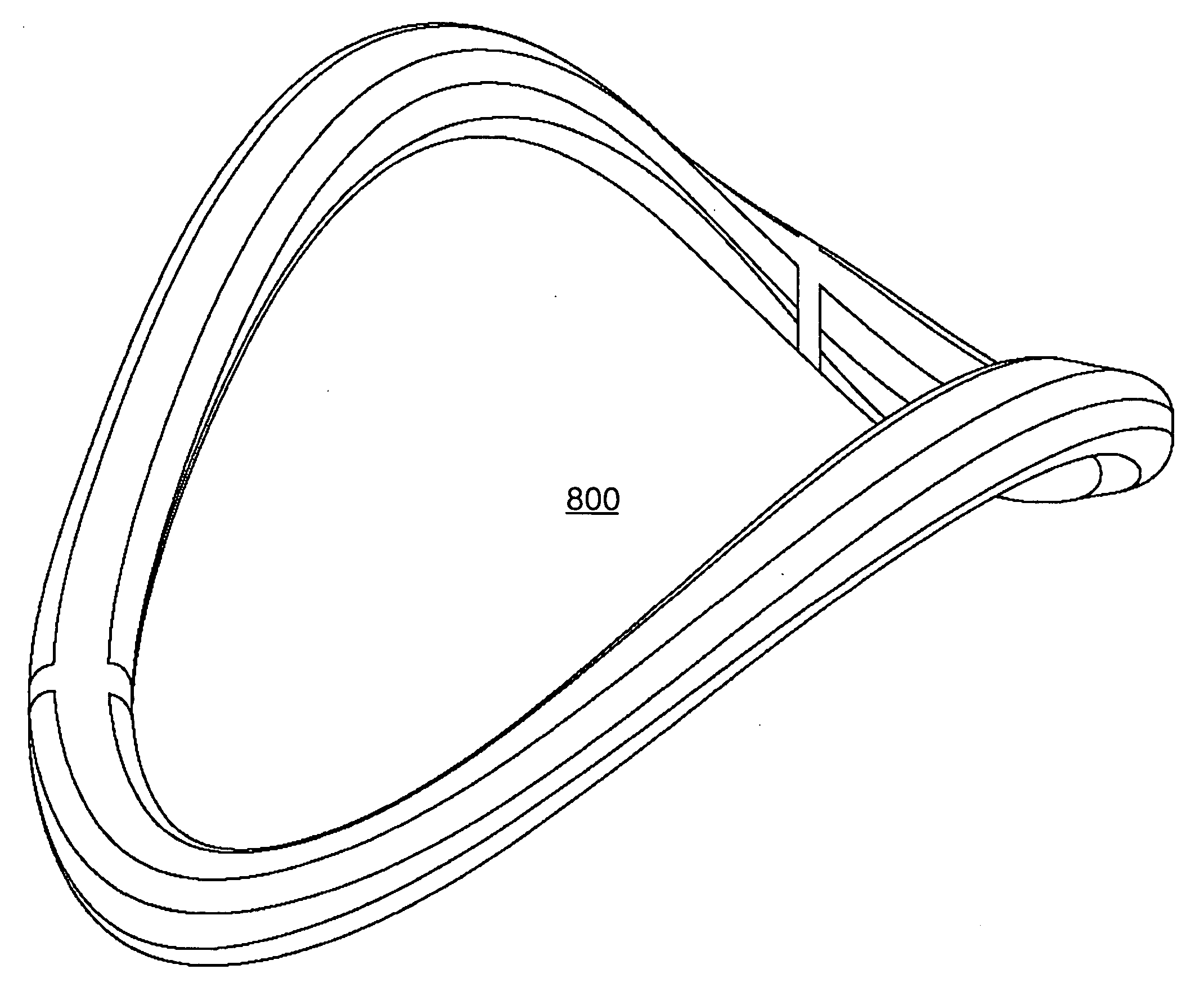

Transcatheter mitral valve

Described is a transcatheter mitral valve. The mitral valve includes a saddle-shaped annulus frame with two prongs extending therefrom. Two leaflets are attached with the frame and prongs to form a bi-leaflet mitral valve. The frame is collapsible to a collapsed configuration that allows for delivery and implantation at a mitral position. When at the mitral position, the mitral valve expands into an open configuration and is secured in place by a fixture, such as clamps that extend from the frame.

Owner:RGT UNIV OF CALIFORNIA

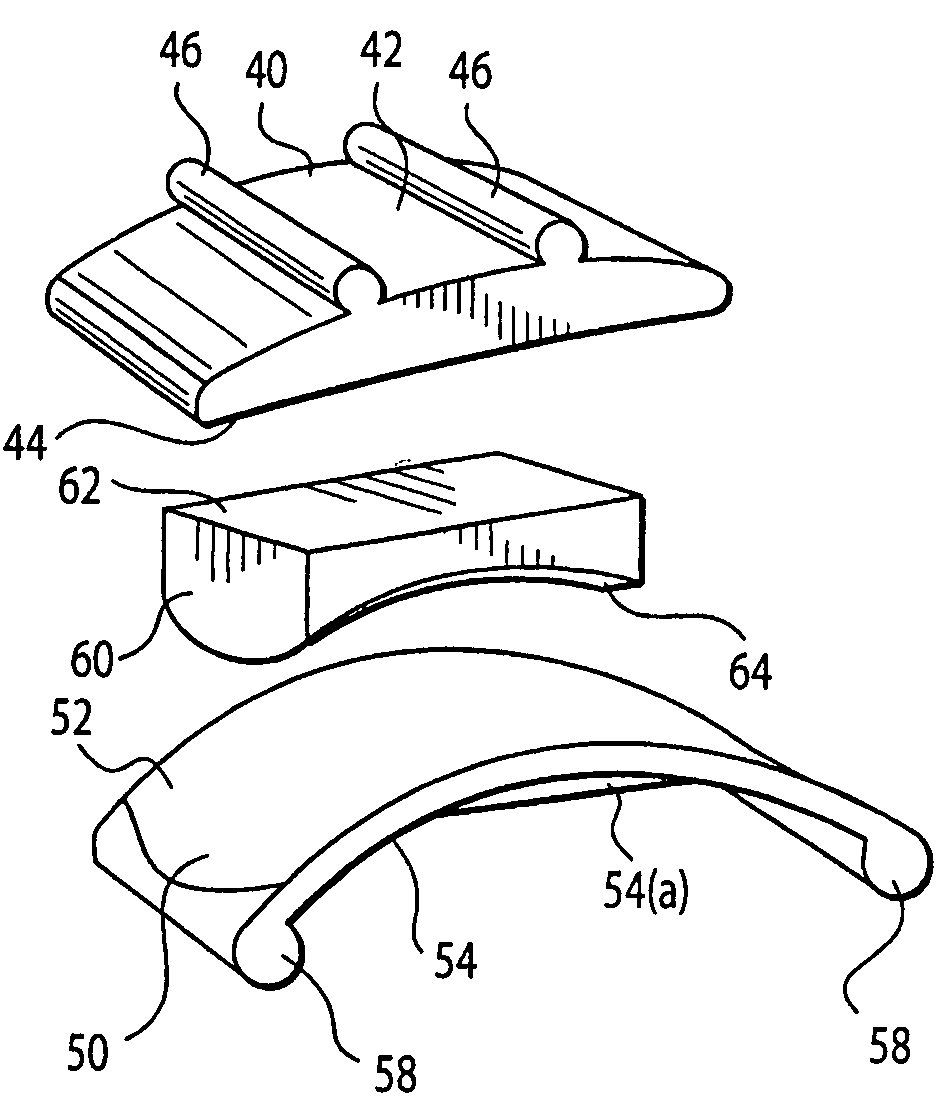

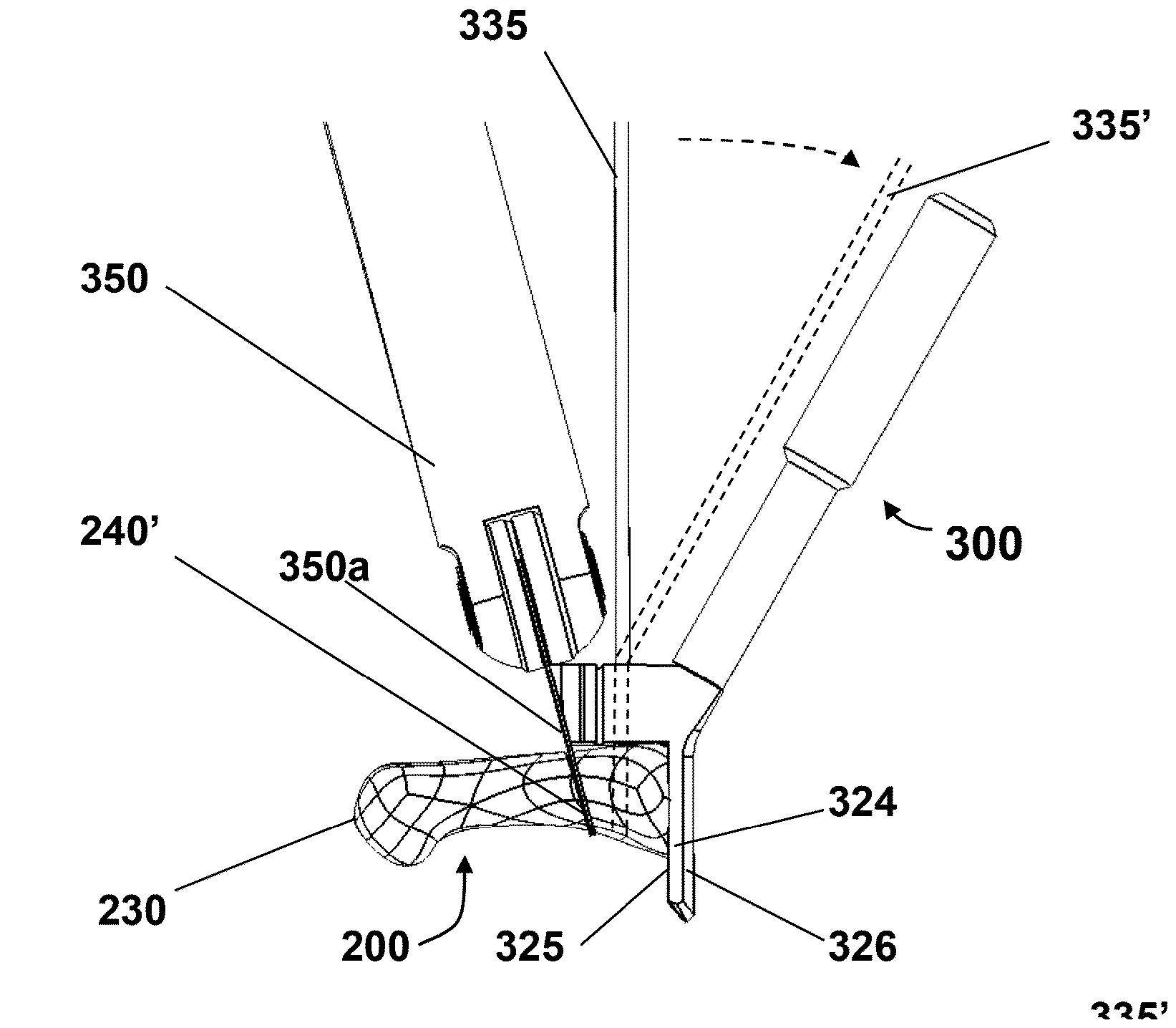

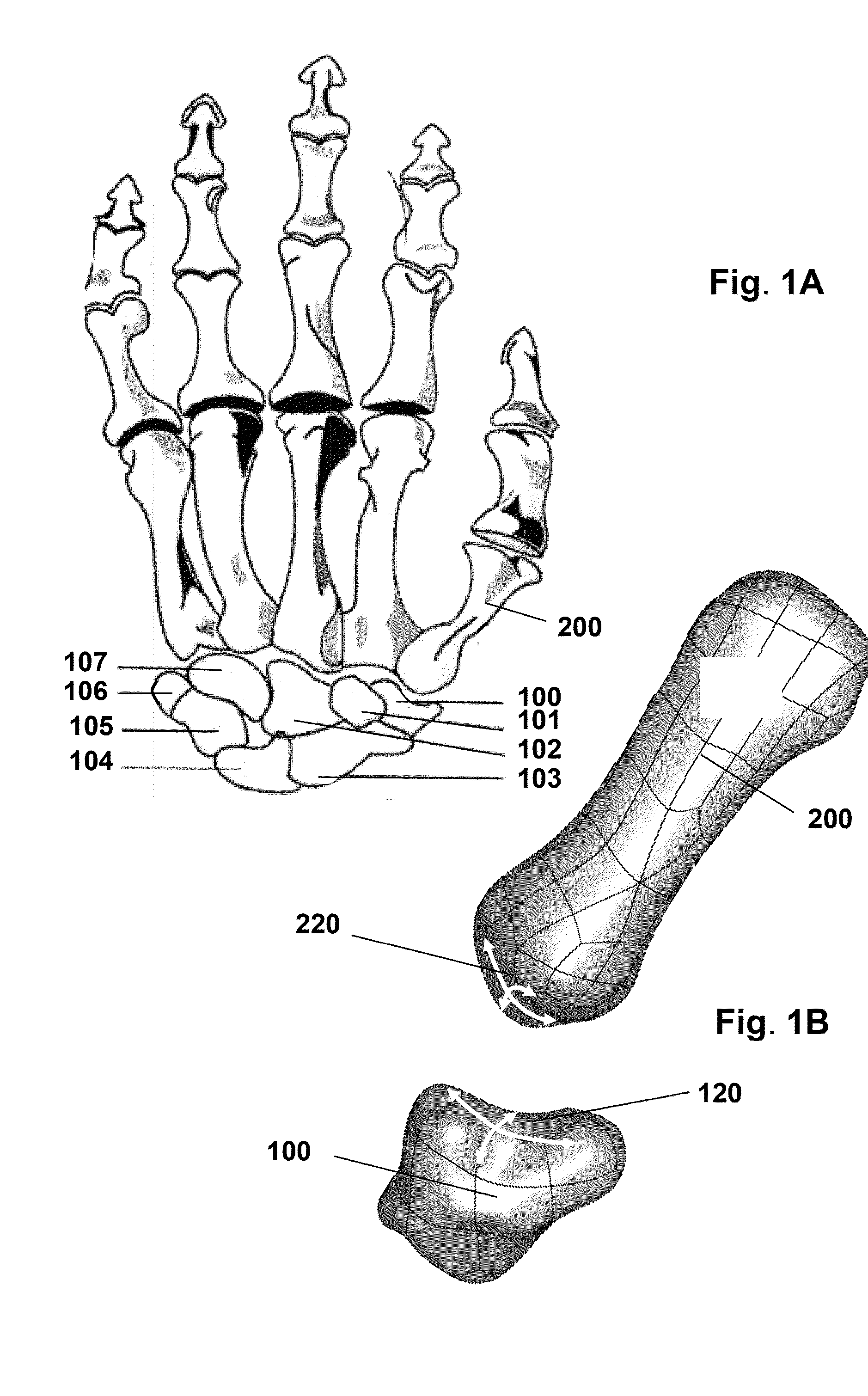

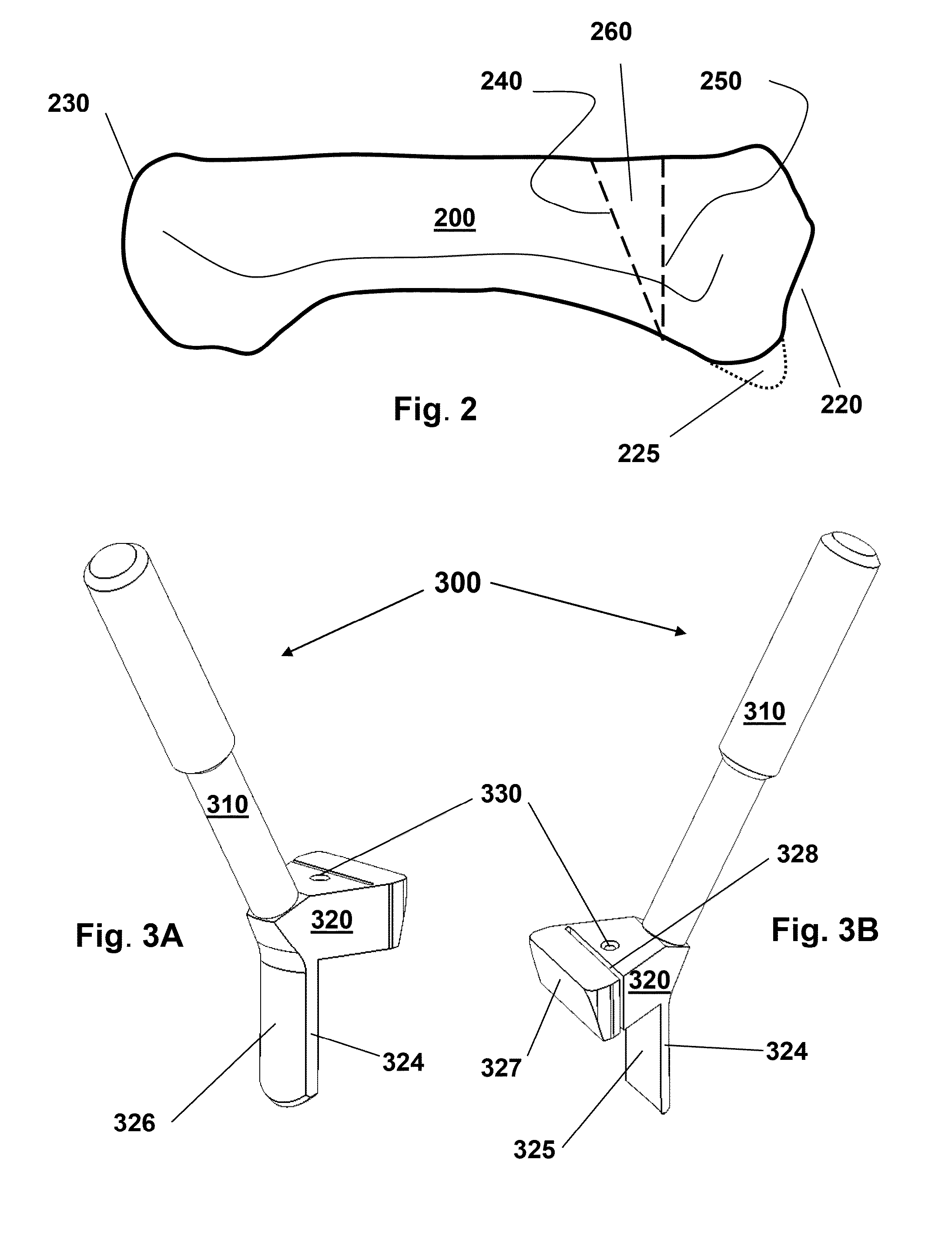

Devices, implements and methods for the treatment of a multi-axis joint

Devices, implements and methods are provided for performing trapezioplasty of the osteoarthritic trapezium. Once a palmar osteophyte has been removed from the trapezium bone, a trapezial rasp is used to shape the central portion of the trapezium bone into an initial saddle shape. A contouring tool having a double curvature reverse saddle shape is used to contour the trapezium bone into a final, smooth saddle shape.

Owner:SKELETAL DYNAMICS LLC (US)

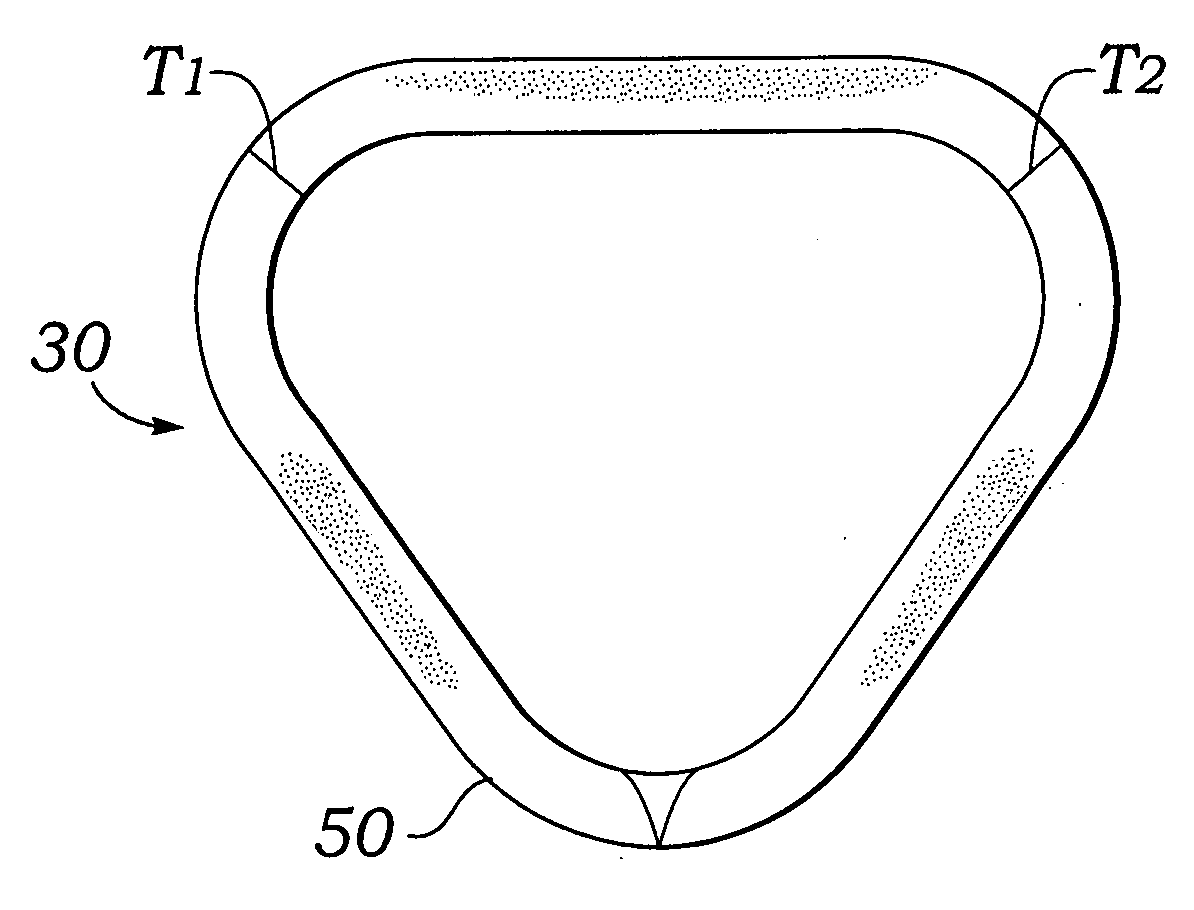

Saddle-shaped mitral valve annuloplasty prostheses with asymmetry, and related methods

A mitral valve annuloplasty prosthesis (ring or C) has a generally saddle shape, i.e., portions of the prosthesis that are or will be adjacent the anterior and posterior commissures of the valve are relatively low as compared to at least some other portions of the prosthesis that are or will be between the commissures. However, the saddle shape is asymmetrical, in that the portion that is or will be adjacent the posterior commissure is lower than the portion that is or will be adjacent the anterior commissure.

Owner:ST JUDE MEDICAL LLC

Semi-sliding hydraulic bulging technology of automobile axle housing part and die thereof

InactiveCN101823096AReasonable distribution of wall thicknessIncreased Strength and RigidityShaping toolsUltimate tensile strengthSaddle shape

The invention discloses a semi-sliding hydraulic bulging technology of an automobile axle housing part and a die thereof. In the invention, the semi-sliding bulging die the body of which is composed of an upper fixed module and a lower fixed module (10,10') in the middle and a left sliding module and a right sliding module (6,6') is adopted to carry out twice hydraulic bulging shaping to a reduced pipe blank (11), wherein, after hydraulic bulging shaping at the first time, the middle of the pipe blank is saddle-shaped; and after being annealed, precise shaping is achieved by secondary hydraulic bulging shaping. The upper fixed module and the lower fixed module keep motionless in the process of bulging and are used for removing the parts after bulging. The left sliding module and the rightsliding module (6,6') adopt an integral structure (or are composed of parts of axial split dies) and are respectively connected with the left sliding module and the right sliding module of a three-dimensional hydraulic machine to perform horizontal movement. The cavity of the fixed module by secondary hydraulic bulging comprises the maximum cross section of a workpiece, and the cavity of the fixed module by first hydraulic bulging is designed according to the saddle-shaped bulging pipe blank. The technology replaces a casting method and a stamping welding method, simplifies manufacturing procedures, lowers cost by 20% and improves strength and rigidity of the workpiece by 30%.

Owner:YANSHAN UNIV

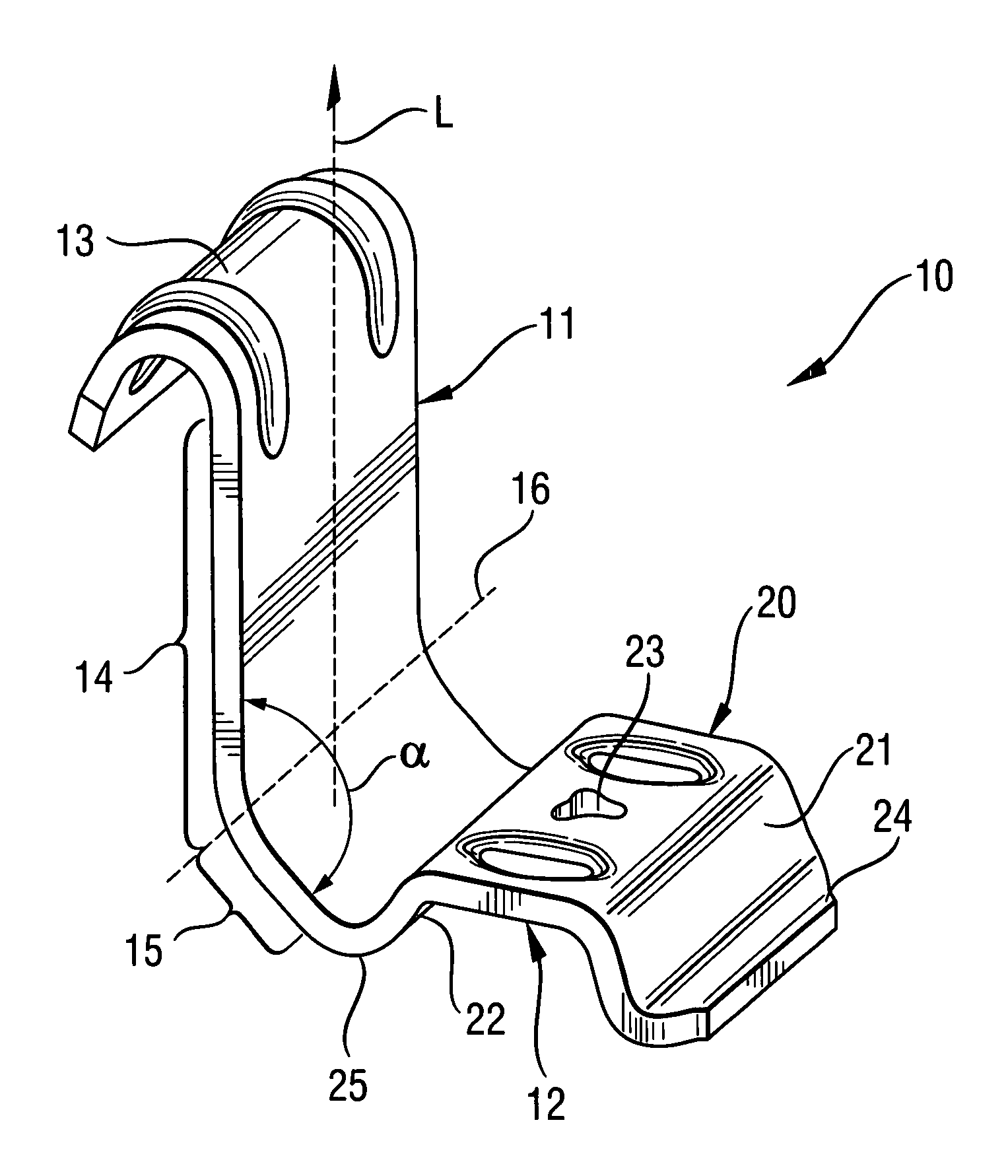

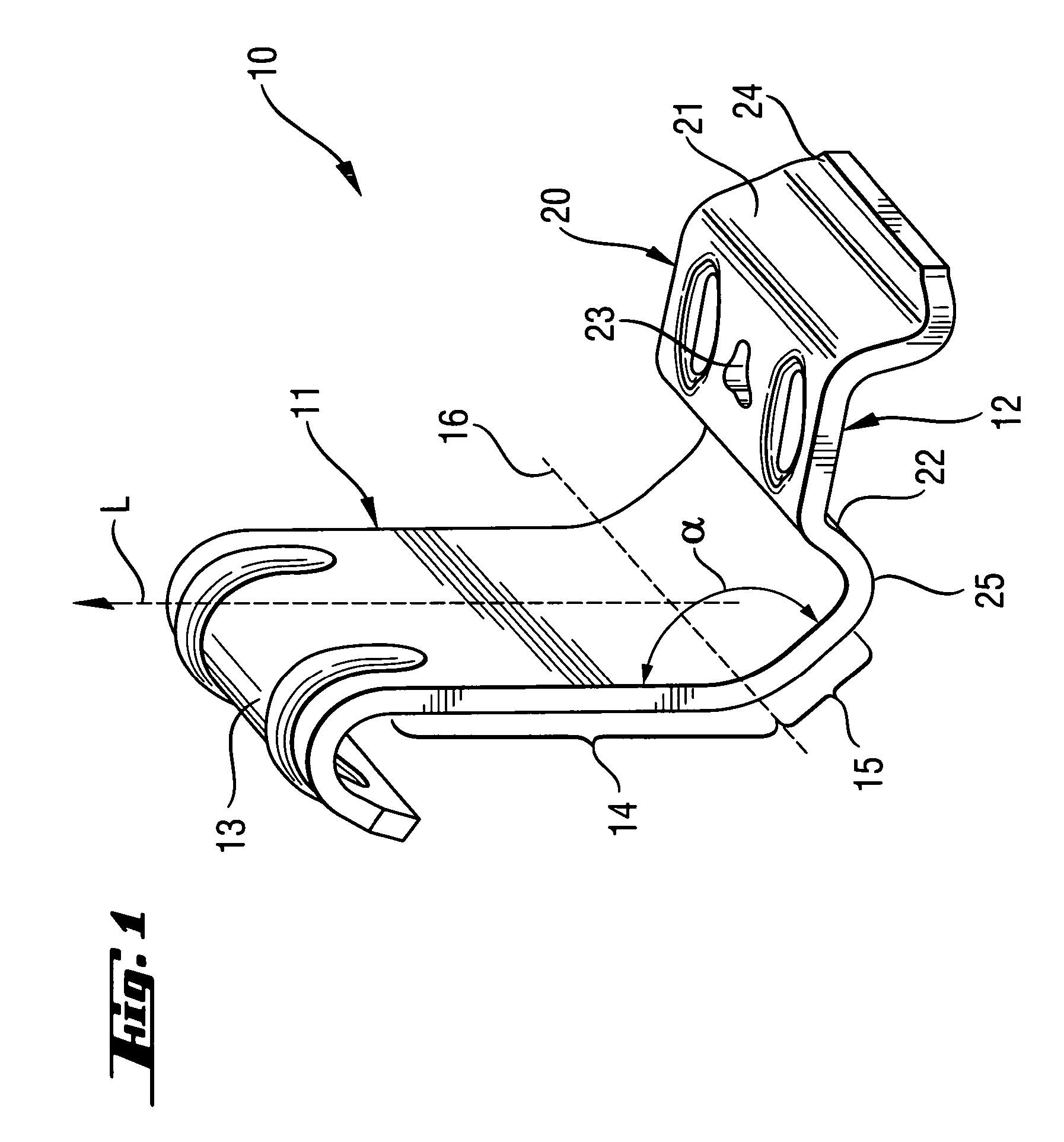

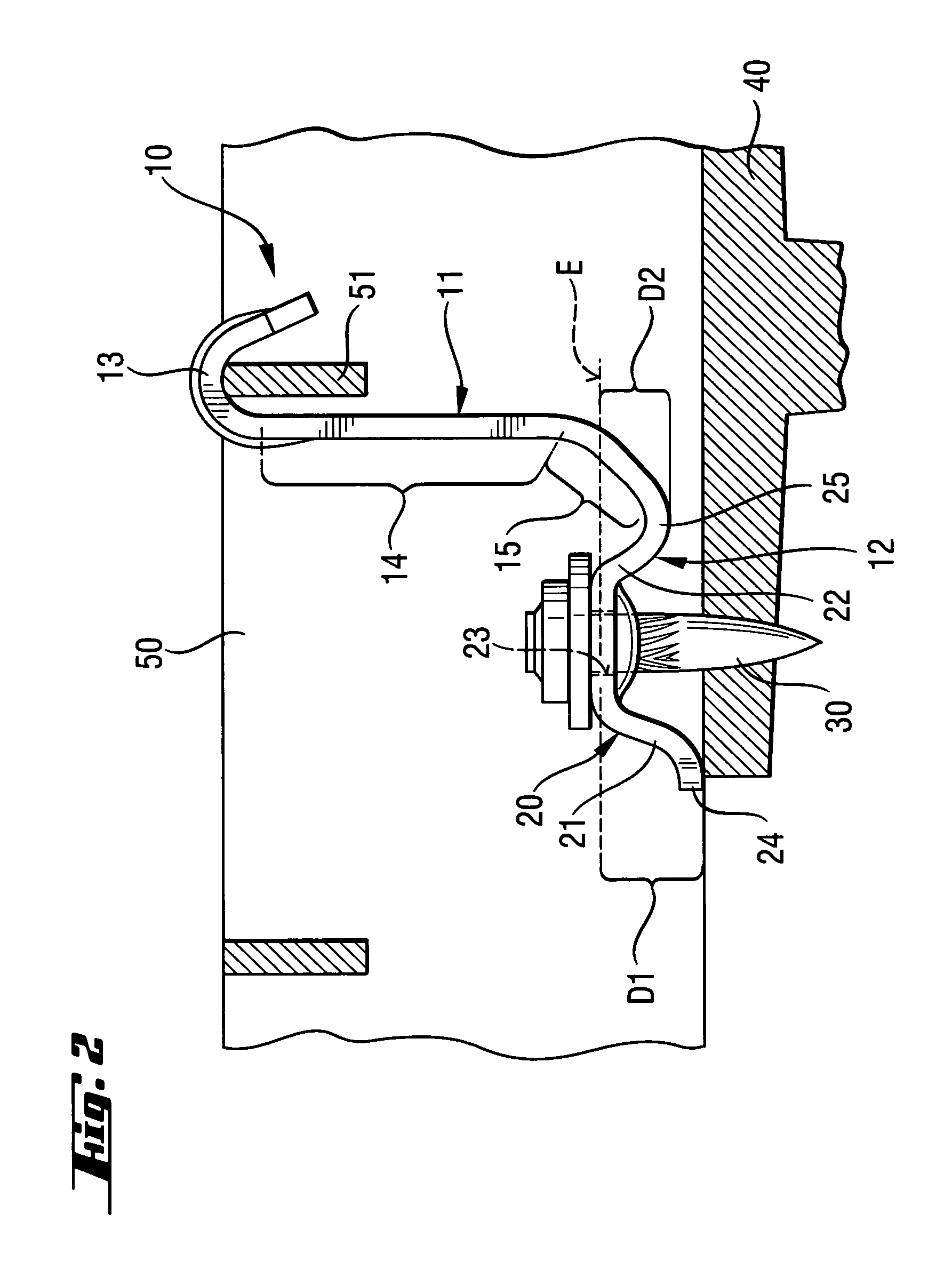

Grid-holding element

ActiveUS7789365B2Certain tolerance rangeEasy to fixCandle holdersLighting support devicesEngineeringSaddle shape

Owner:HILTI AG

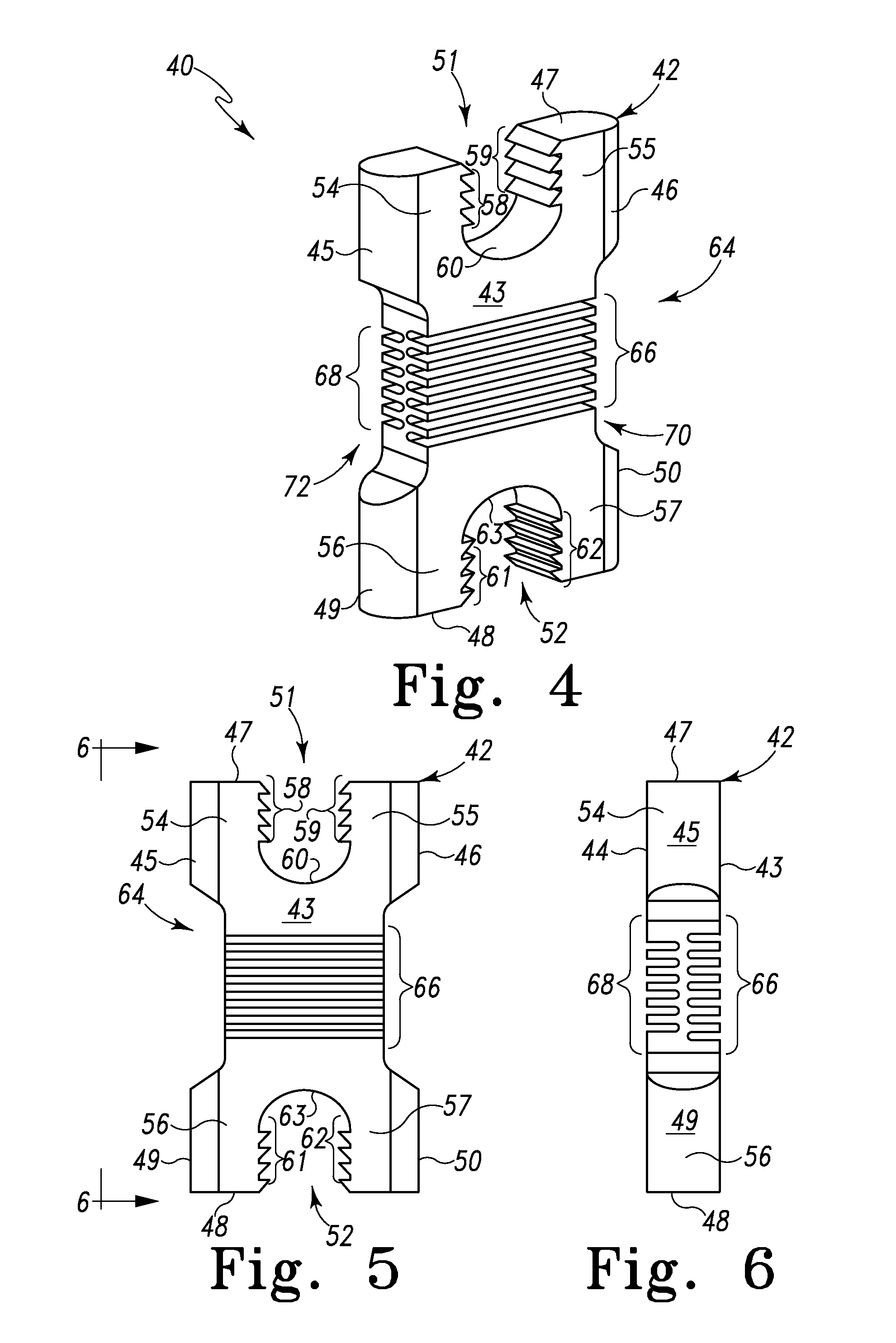

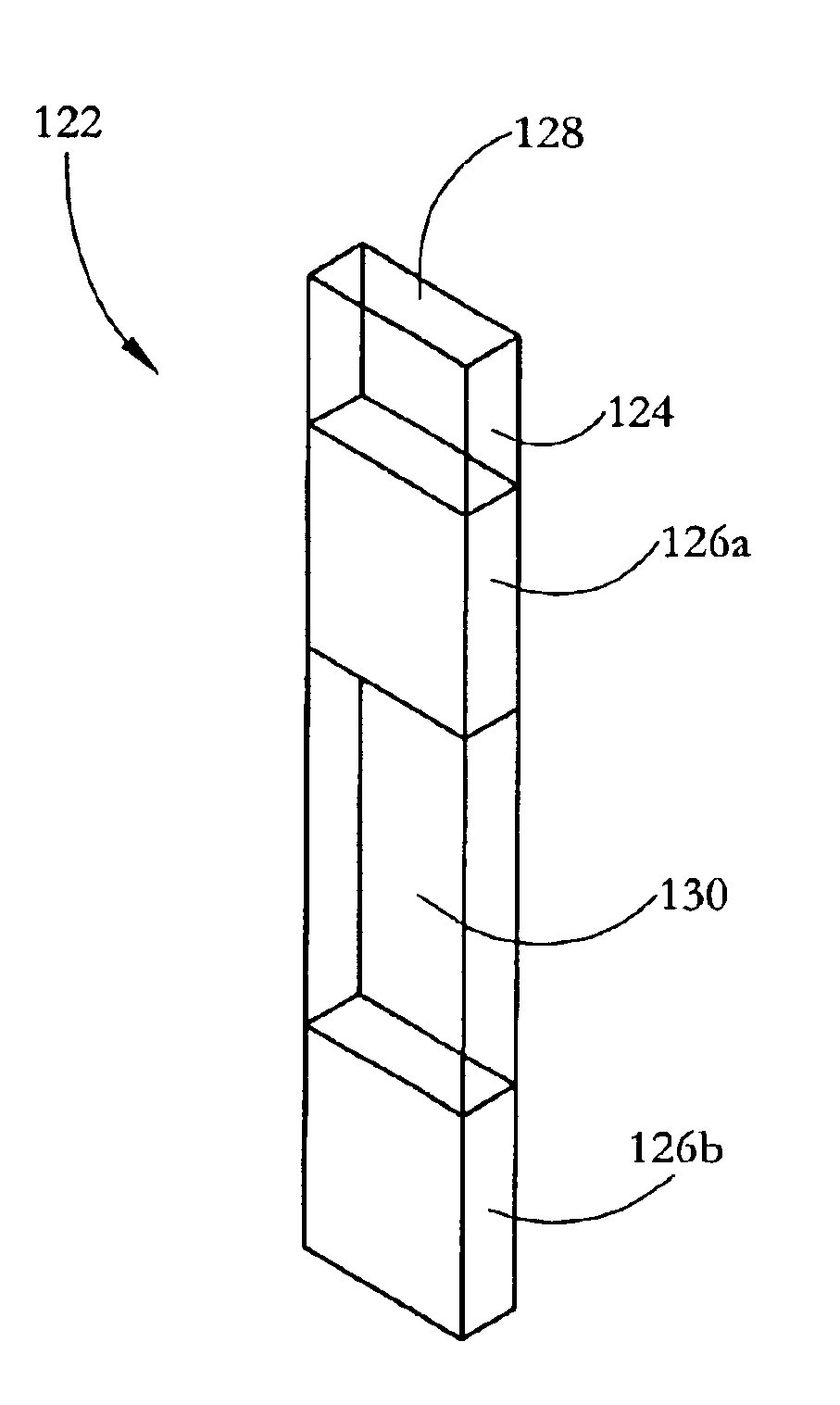

Flexible and Static Interspinous/Inter-Laminar Spinal Spacers

Interspinous / inter-laminar spinal spacers (spinal spacers) are configured to be placed between bony structures (i.e. transverse and spinous processes) of adjacent vertebrae of a spine. In one form, flexible spinal spacers are defined by a unitary body that is configured to be placed between bony structures of adjacent vertebrae of a spine. The unitary body has a flex portion that provides for motion between the adjacent vertebrae to which it is coupled. The flex portion is configurable to provide for various degrees of angulation, flexion, extension and / or compression of the present flexible spinal spacer. In another form, static spinal spacers are defined by a unitary body that is configured to be placed between bony structures of adjacent vertebrae of a spine. The unitary body has saddle-shaped ends each defining a pocket that is configured to receive a bony structure of a vertebra. The pockets may or may not be textured and / or may or may not include teeth, serrations or ridged surfaces to secure the spinal spacer to the bony structure.

Owner:LIFE SPINE INC

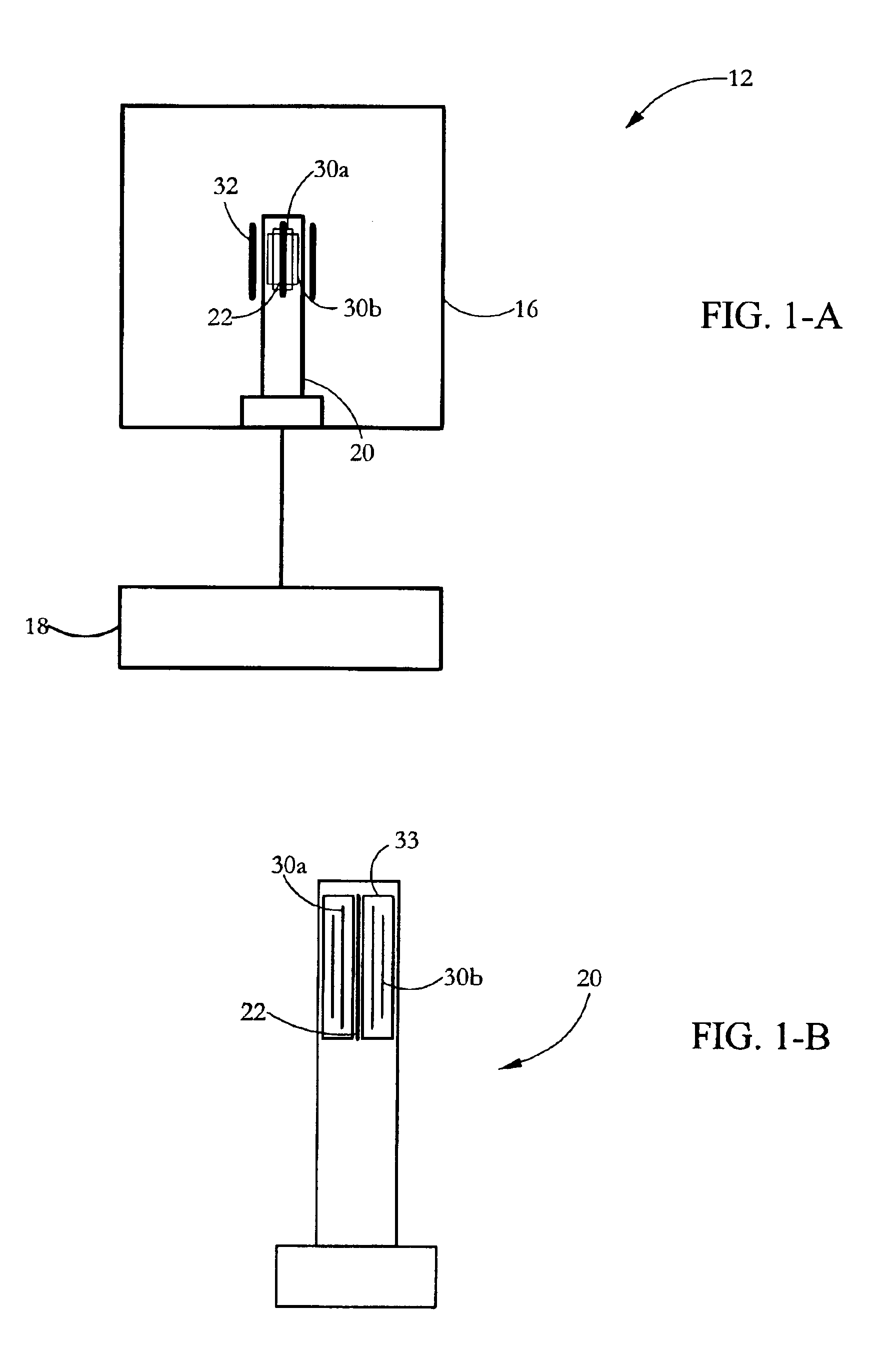

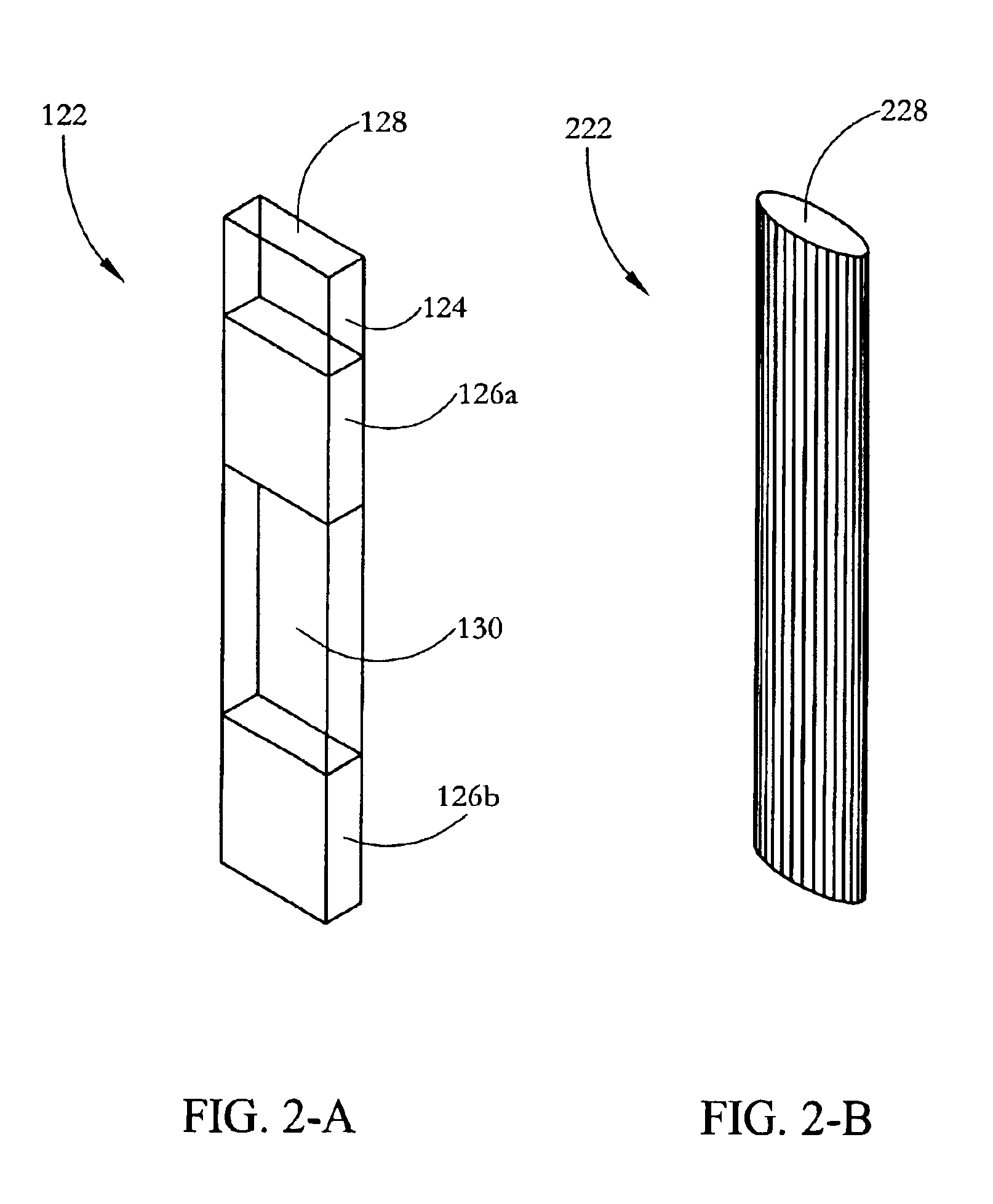

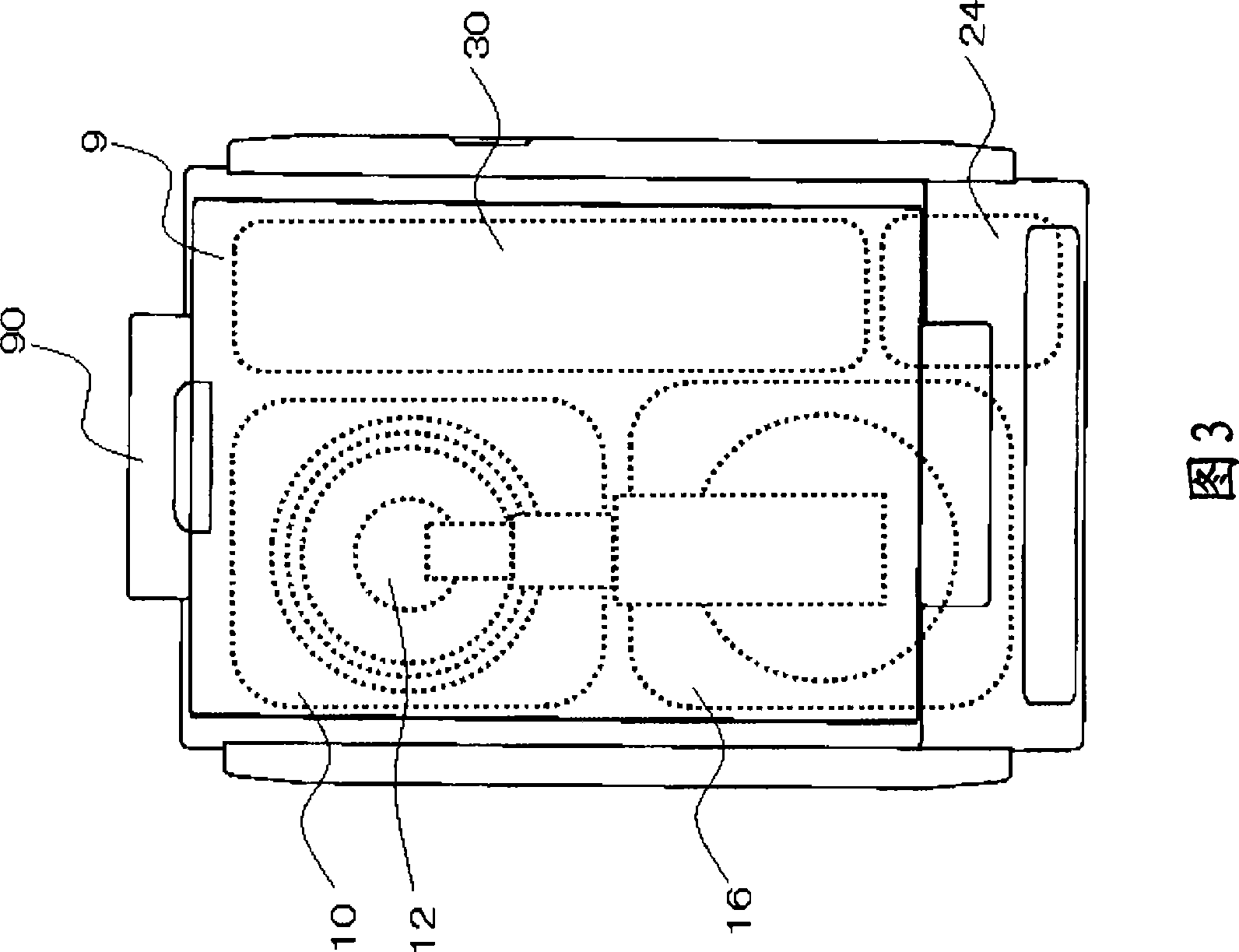

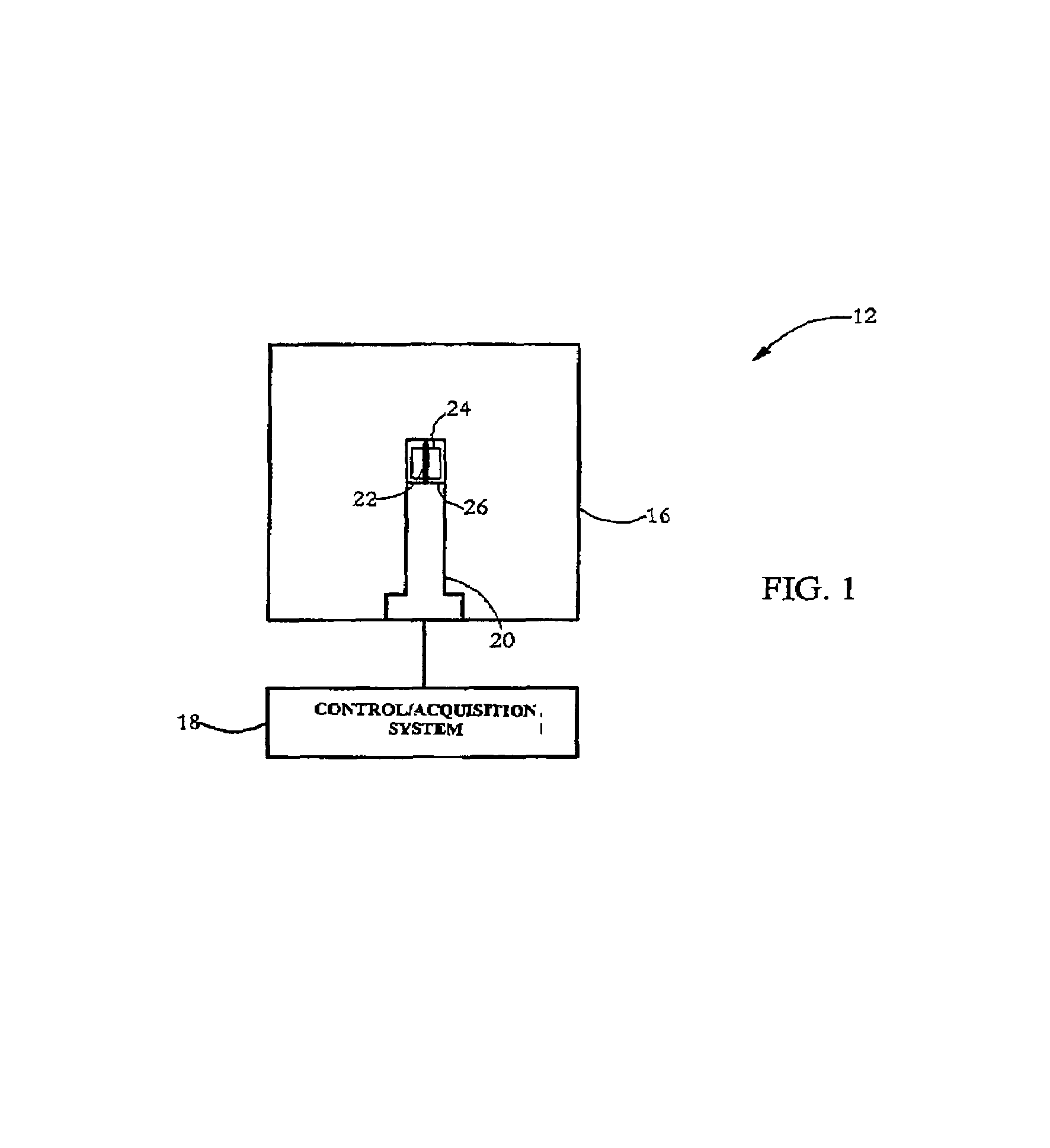

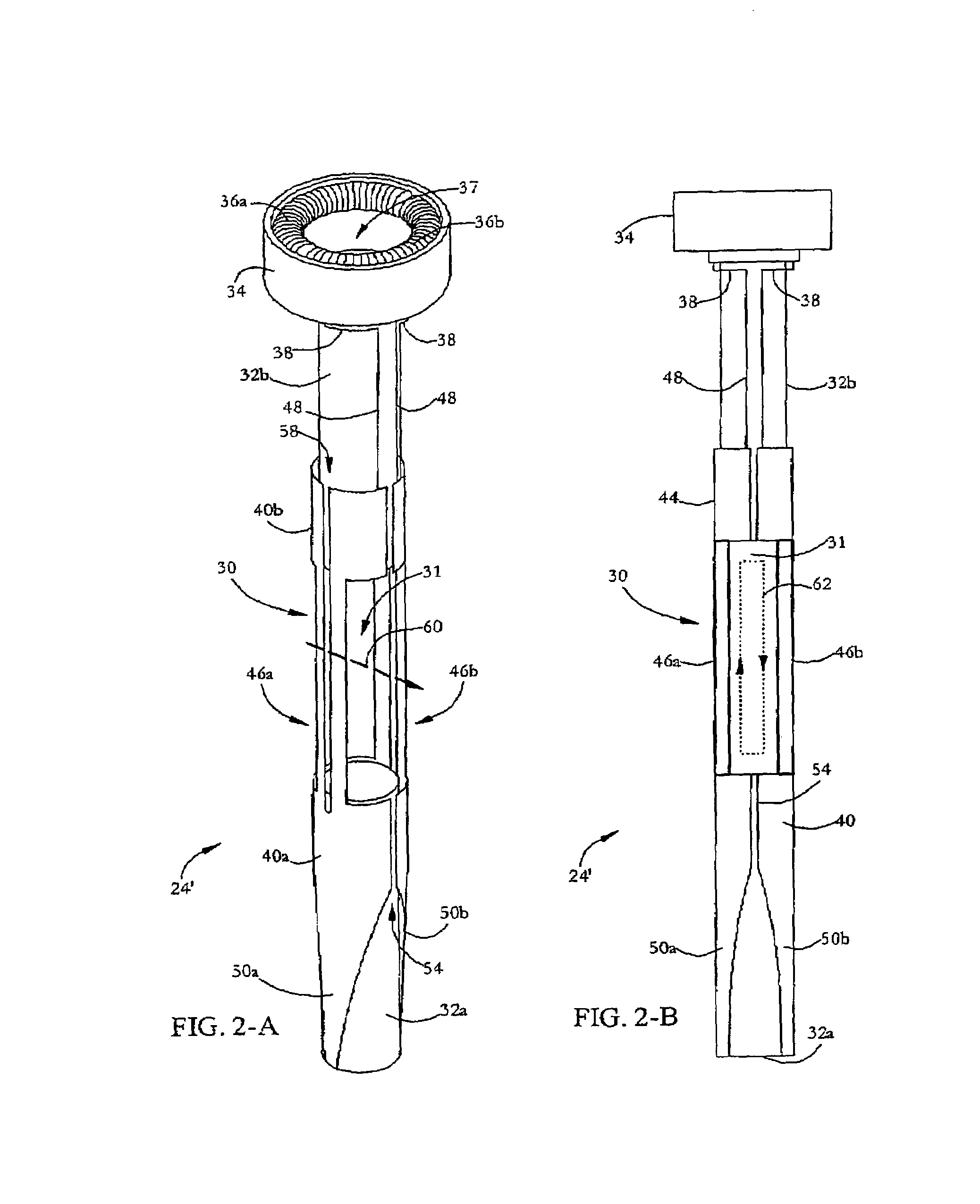

Squashed liquid NMR sample tubes and RF coils

InactiveUS6917201B2Laboratory glasswaresElectric/magnetic detectionNMR - Nuclear magnetic resonanceSaddle shape

Nuclear magnetic resonance (NMR) systems and methods employing squashed (transversely-elongated) sample vessels (sample tubes or flow cells) for holding liquid NMR samples, and matching squashed saddle-shaped RF coils allow reducing sample and / or coil losses and increasing the RF circuit quality factors (Q). In a present implementation, the RF coils and sample vessels have rectangular cross-sections. Rounded (e.g. ellipsoidal) or other squashed cross-sections may also be used. The coil corresponding to the highest sample losses is positioned such that the magnetic field generated by the coil is along the major axis of the sample vessel. Squashed sample vessels may also be used with conventional circular coils, particularly for low-temperature measurements where sample losses dominate.

Owner:AGILENT TECH INC

Seat having a saddle shape to fit a user ergonomically

Owner:CHANG KUO CHYANG

Posterior stabilized knee prosthesis

A knee joint prosthesis includes a femoral component having an anterior side, a posterior side, a pair of laterally spaced condylar portions, and an intercondylar portion joining the condylar portions and including a recess. A cam surface is located adjacent the intercondylar recess on the anterior side of the femoral component and has a saddle shape that is defined by an at least substantially concave first radius of curvature and a convex third radius of curvature that is perpendicular to the concave first radius of curvature. The prosthesis also includes a tibial component including a platform having an upper surface that includes first and second laterally spaced concavities. Each concavity is adapted for receiving one condylar portion of the femoral component. The tibial component has a tibial post for reception in the intercondylar recess of the femoral component. The tibial post has a saddle shaped anterior cam surface that is complementary to the saddle shaped anterior cam surface of the femoral component and is defined by an at least substantially convex second radius of curvature and a concave fourth radius of curvature that is perpendicular to the convex second radius of curvature.

Owner:NEW YORK SOC FOR THE RUPTURED & CRIPPLED MAINTAINING THE HOSPITAL FOR SPECIAL SURGERY

Bumper system for a motor vehicle

Owner:ARCONIC INC

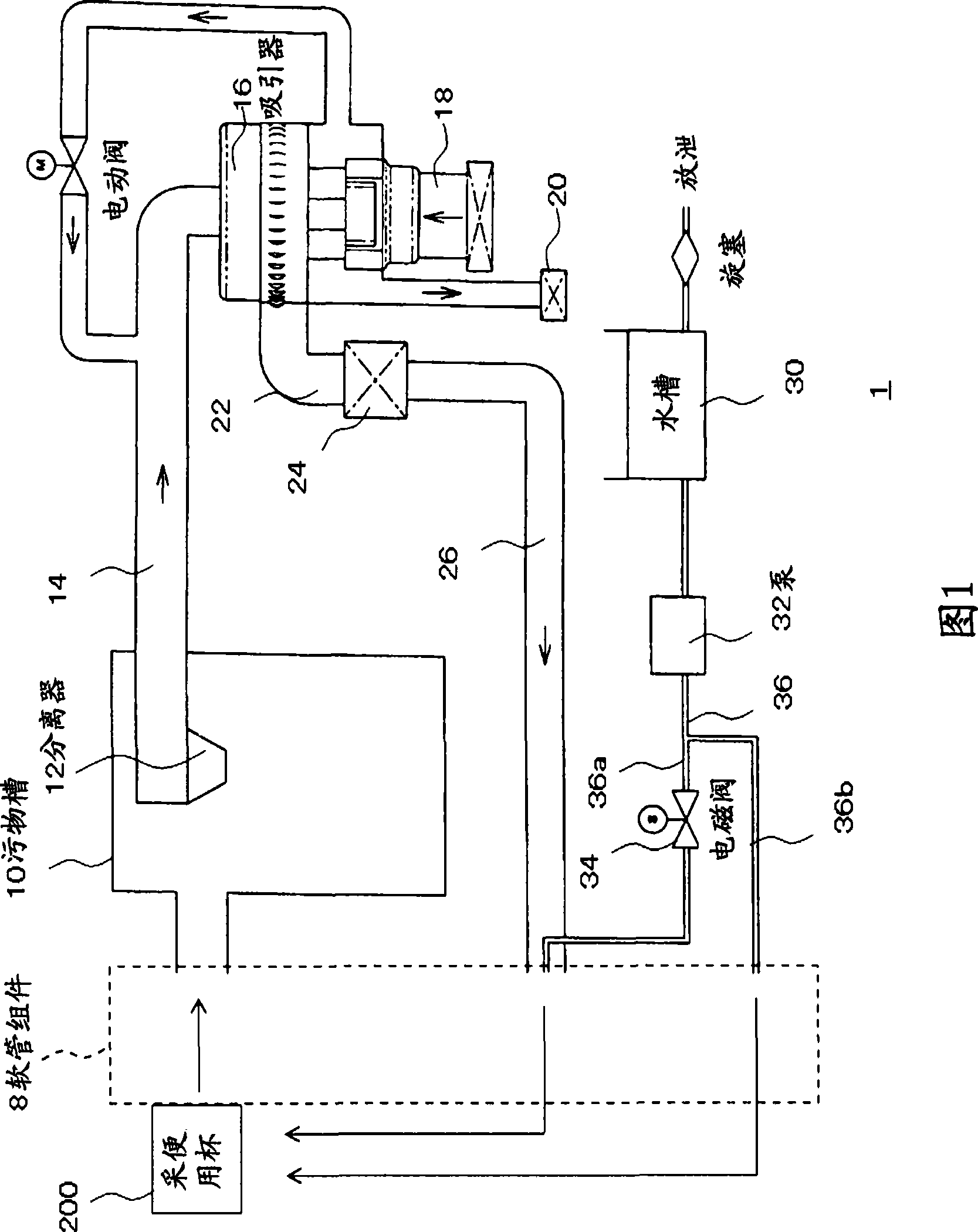

Waste treatment device

InactiveCN101396319APrevent leakageEnhance the outstanding effectMedical transportElastic componentWaste treatment

The invention is related to an excretion processing device for caring capable of performing washing of a caregiver respectively according to shapes of excrement and urine, and an excretion vessel capable of preventing excretion and the like leaking from an edge section of an opening section. The excretion processing device for caring includes a suction connector, an excretion reservoir, a water tank for accommodating the water, injection means and injection control means; the excretion vessel includes a cup section and an elastic component, wherein the cup section is provided with the opening section that surrounds anus and pubes and of which the edge part is a bending saddle shape; and the elastic component provided along the edge section of the opening section includes an flange projecting towards inner side of the opening section.

Owner:HEARTFUL CORP

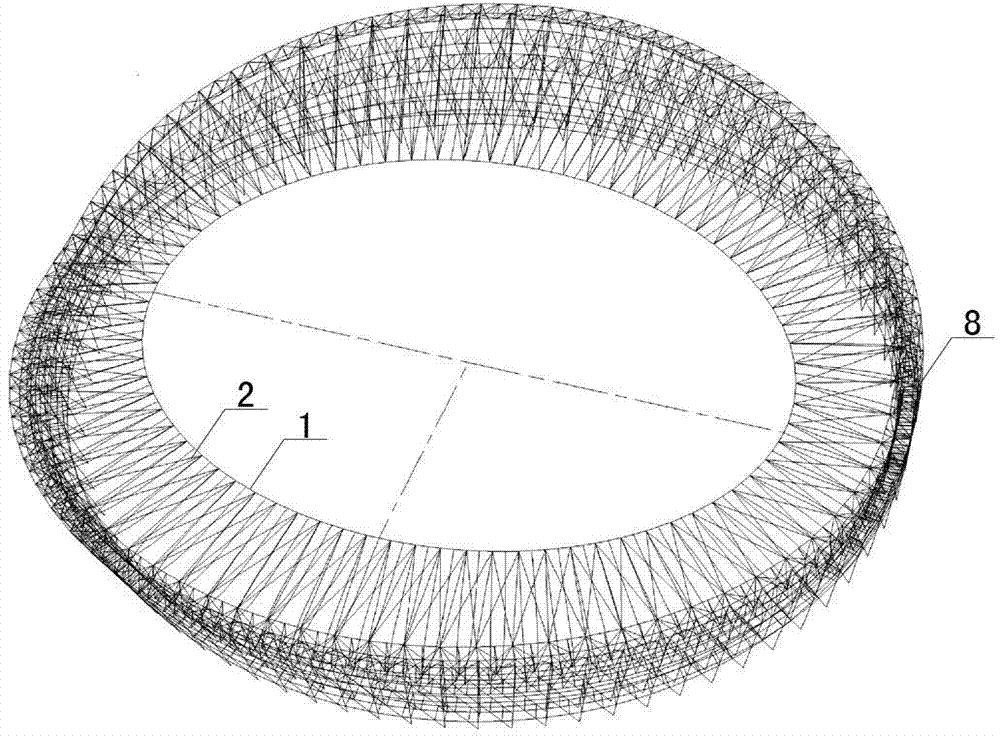

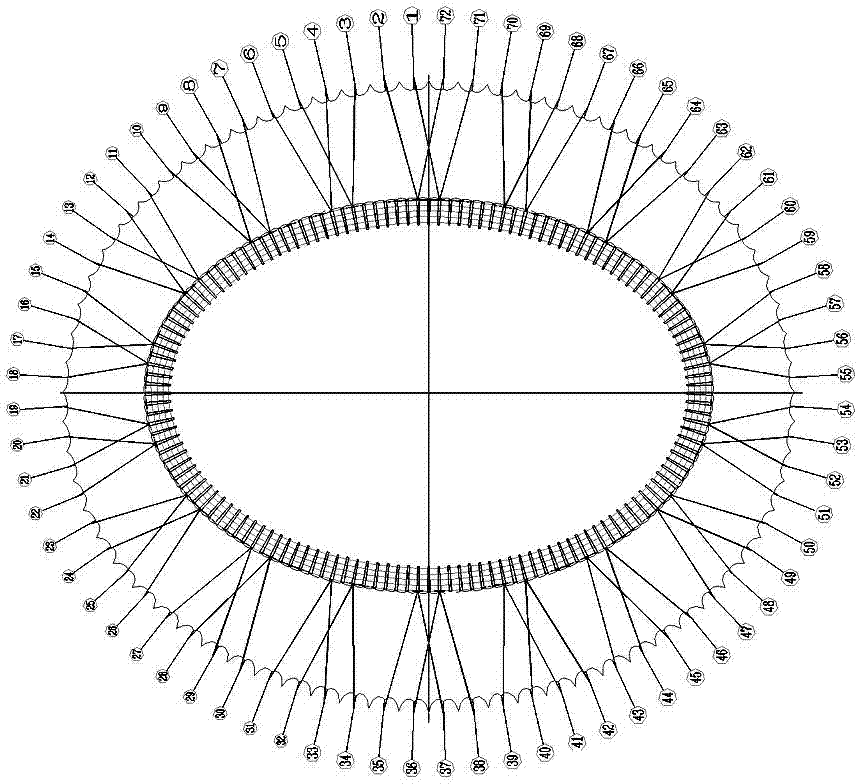

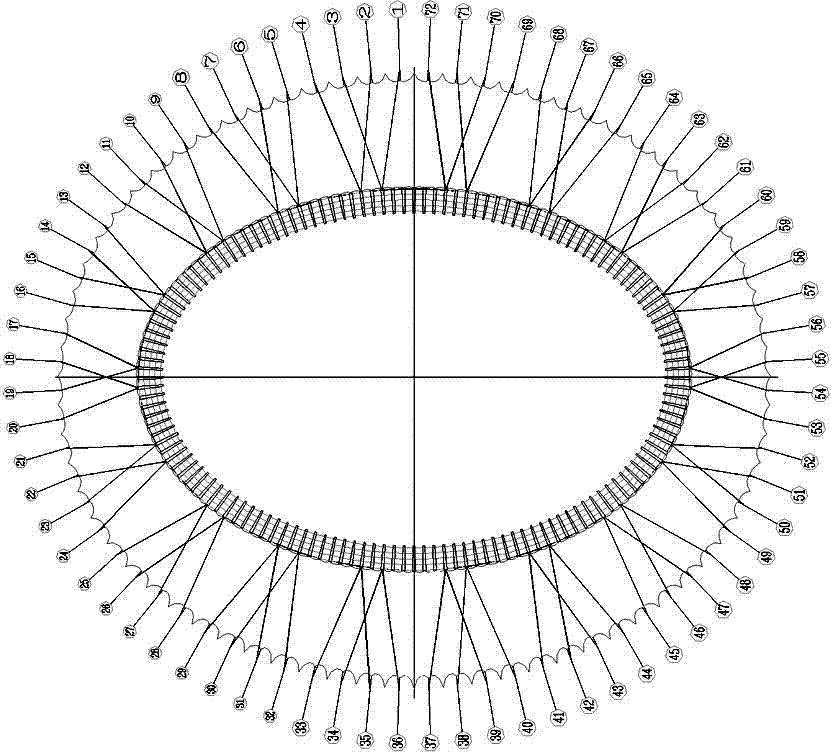

Extra-large-span saddle-shaped flexible network cable tensioning forming construction method

InactiveCN103883125AOvercome the disadvantages of low efficiencyReduce consumptionBuilding material handlingNetwork structureArchitectural engineering

The invention provides an extra-large-span saddle-shaped flexible network cable tensioning forming construction method. A step-by-step lifting overall tensioning method is provided to carry out construction, blanking is carried out on hanging cables and annular cables according to the set length, the hanging cables and the annular cables are assembled on the ground, the hanging cables are selected as tensioning cables, the hanging cables are hoisted in batches in a subsection mode, finally the hanging cables are tensioned and mounted in place, and the whole network cable structure is tensioned and formed. The method solves the problem that construction difficulty is large due to annular cable tensioning, and saves the number of construction personnel and mechanical consumption, due to the fact that the dynamic and continuous construction process is divided into construction periods and each hoisting period is statically controllable, construction quality detection is facilitated better, the whole set of brand-new extra-large-span saddle-shaped flexible network structure construction technology is formed, the construction method is small in high-attitude work quantity, the high-attitude work quantity is reduced by more than 60 percent relative to a traditional tensioning hoisting process, a supporting tower and other auxiliary facilities are removed, the construction period is shortened by 50 percent, and the method can be widely applied to flexible network structure construction.

Owner:BEIJING ACAD OF BUILDING ENG

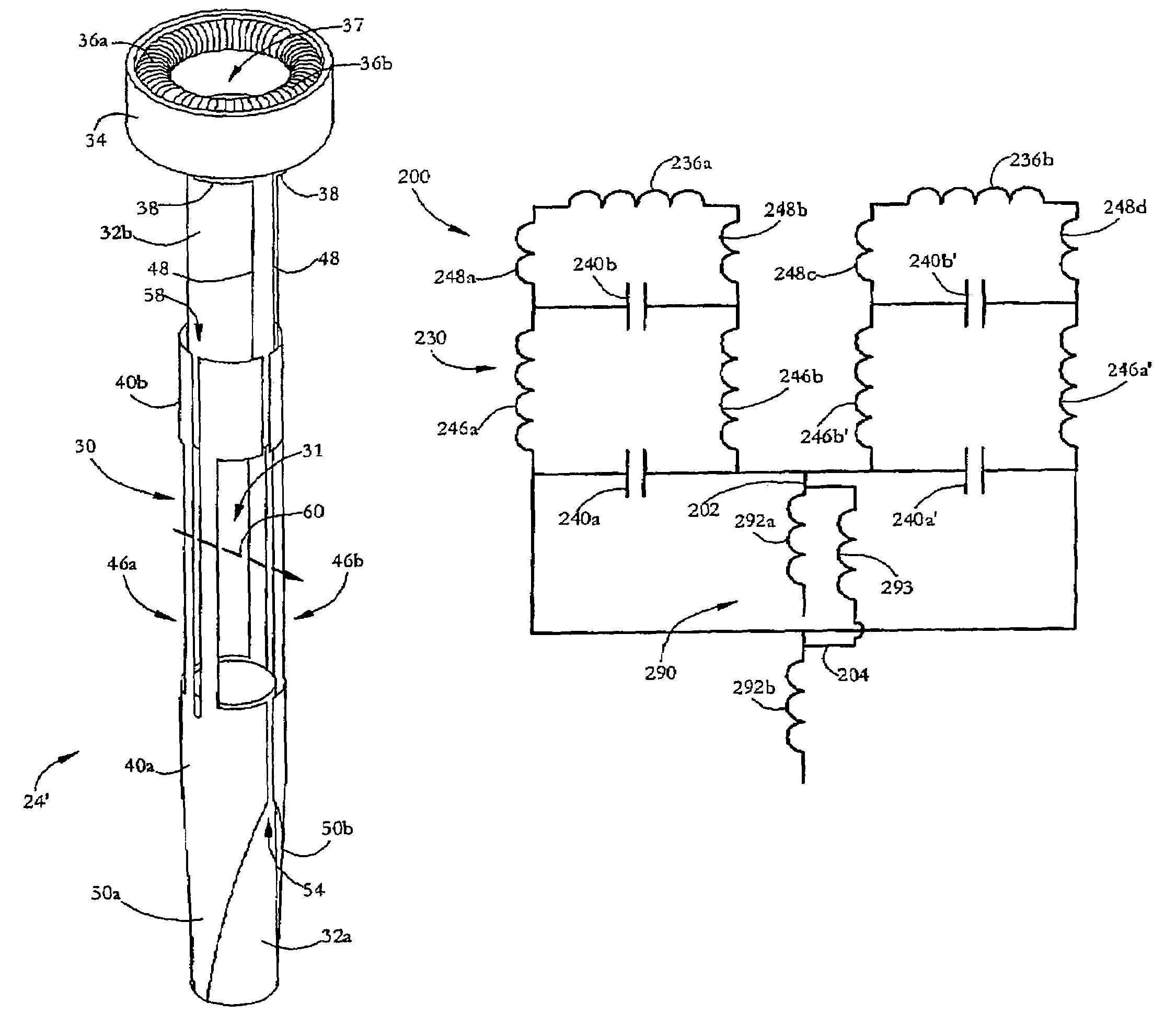

NMR RF coils with improved low-frequency efficiency

InactiveUS7132829B2Magnetic measurementsElectric/magnetic detectionMagnetic susceptibilityCapacitance

According to one aspect, the low-frequency (e.g. lock channel) performance of a nuclear magnetic resonance (NMR) saddle-shaped, distributed-capacitance radio-frequency (RF) coil is improved by connecting a pair of auxiliary inductors across a plurality of leads extending upward from the coil upper ring. The upward-extending leads can be formed from the same foil as a main coil structure. The auxiliary inductors are separated from the coil window, so that magnetic susceptibility discontinuities introduced by the auxiliary inductors can be compensated for. In one embodiment, two half-toroid auxiliary inductors are positioned to form a full toroid shape. Some lost high-frequency performance can be recovered by using a split capacitance band positioned over the lower coil ring. The split capacitance band allows capacitance tuning while maintaining an RF current path close to the coil window.

Owner:AGILENT TECH INC

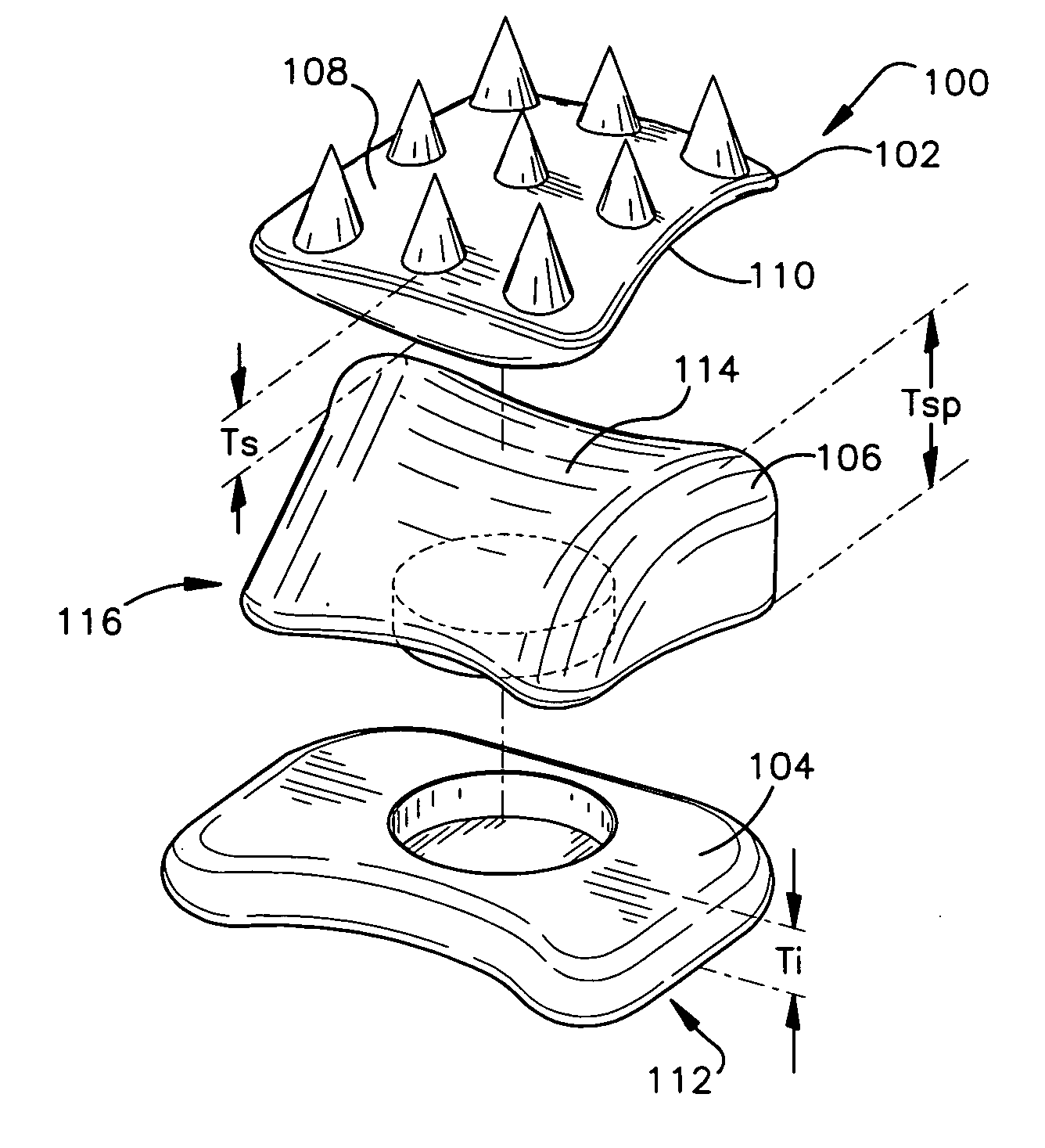

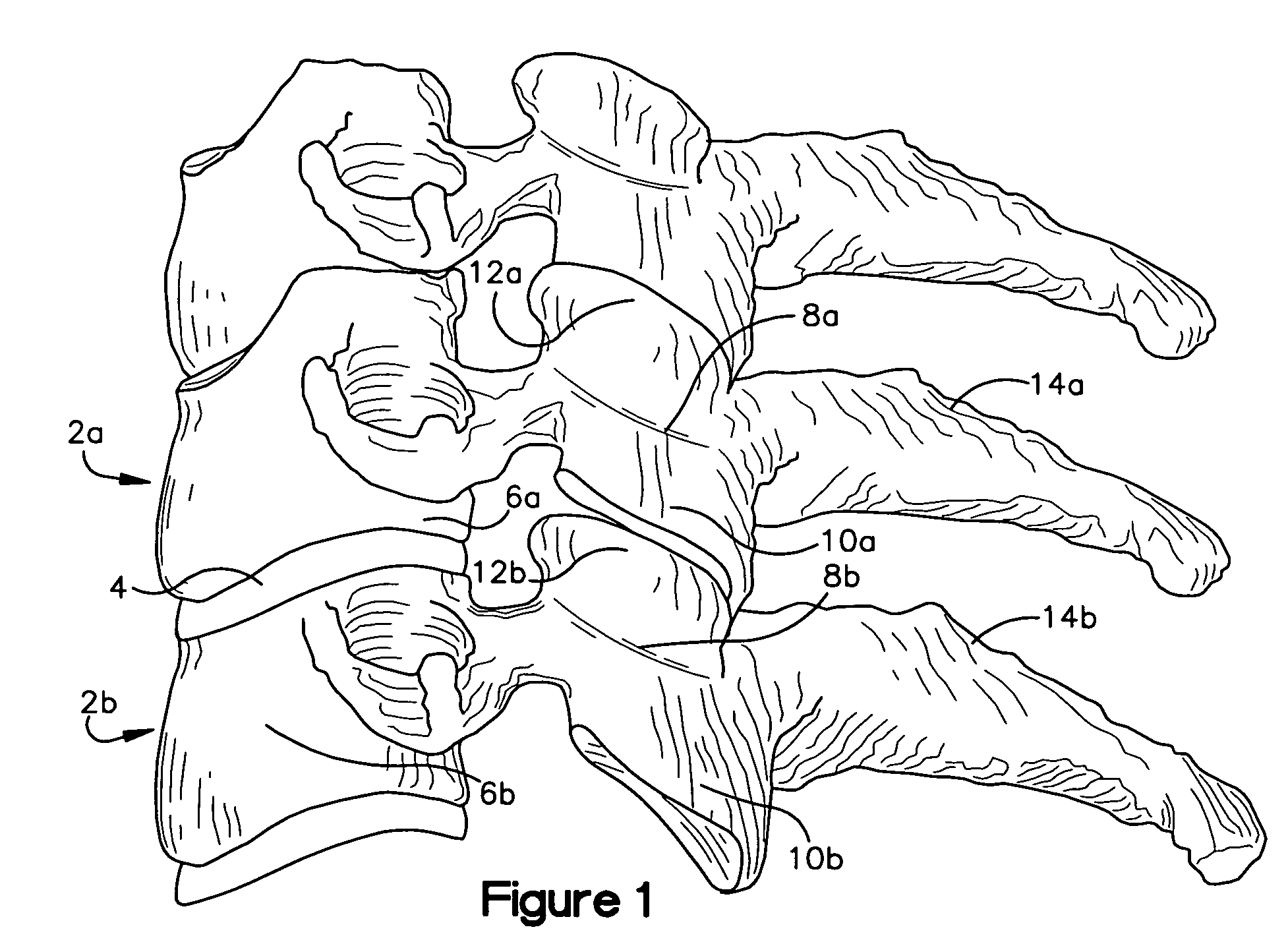

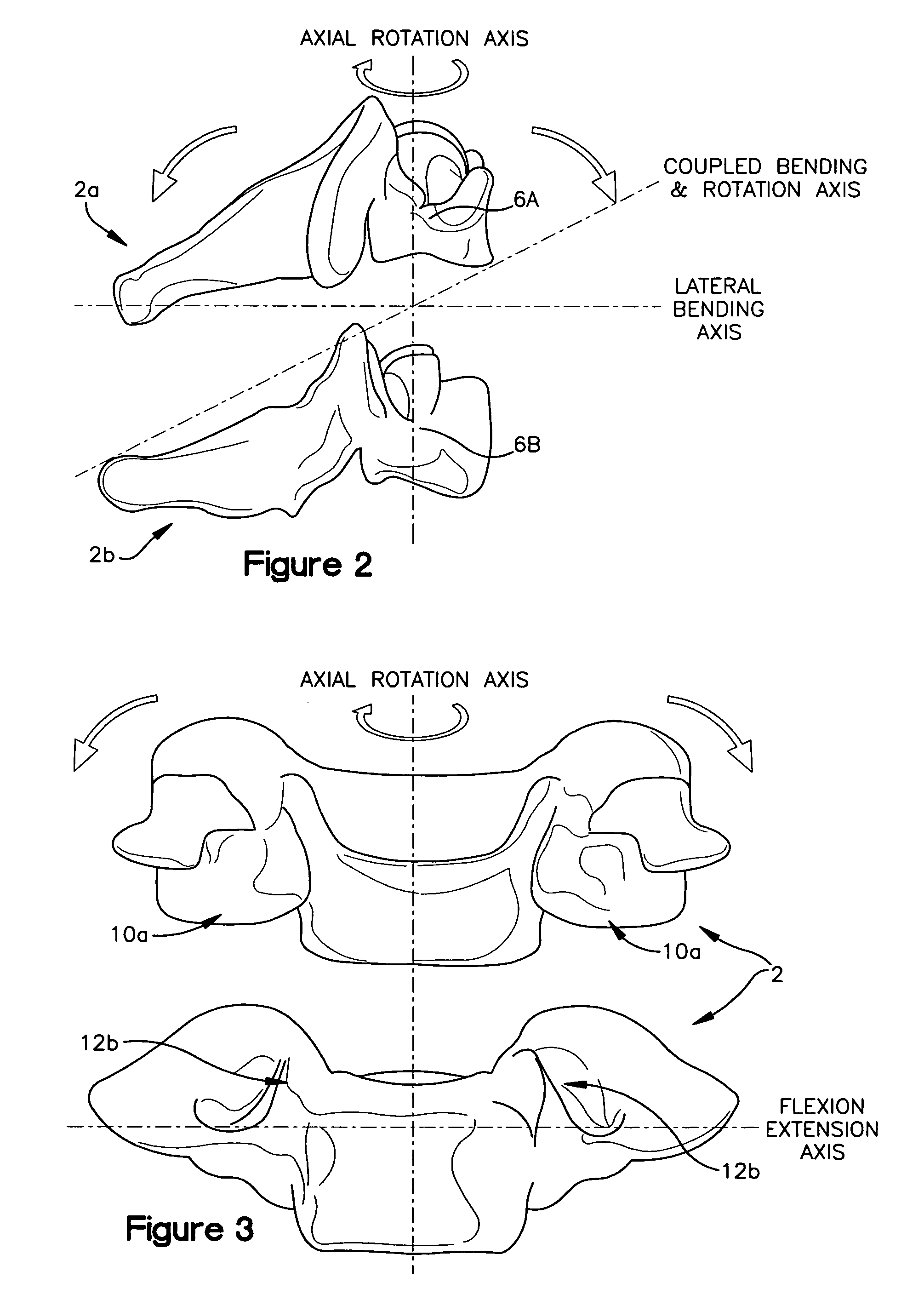

Spacerless artificial disc replacements

InactiveUS20050267582A1More flexiblyPrevent rotationJoint implantsSpinal implantsSpinal columnAxial rotation

Spacerless artificial disc replacements (ADR) are disclosed. One preferred embodiment includes two saddle-shaped components to facilitate more normal spinal flexion, extension, and lateral bending while limit axial rotation, thereby protecting the facet joints and the annulus fibrosus (AF). Either or both of the superior and inferior components are made of a hard material such as chrome cobalt, titanium, or a ceramic including alumina, zirconia, or calcium phosphate. The articulating surfaces of the ADR are also preferably highly polished to reduce friction between the components. Metals, alloys or other materials with shape-memory characteristics may also prove beneficial.

Owner:HOWMEDICA OSTEONICS CORP

Non-planar cardiac vascular support prosthesis

An annuloplasty ring comprising an elongated curved member defining a ring-shape having an at rest size and shape to fit against the annulus of the mitral valve in a heart, the member having a substantial saddle shape wherein the annular height to width ratio is in the range of 5% to 50%.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

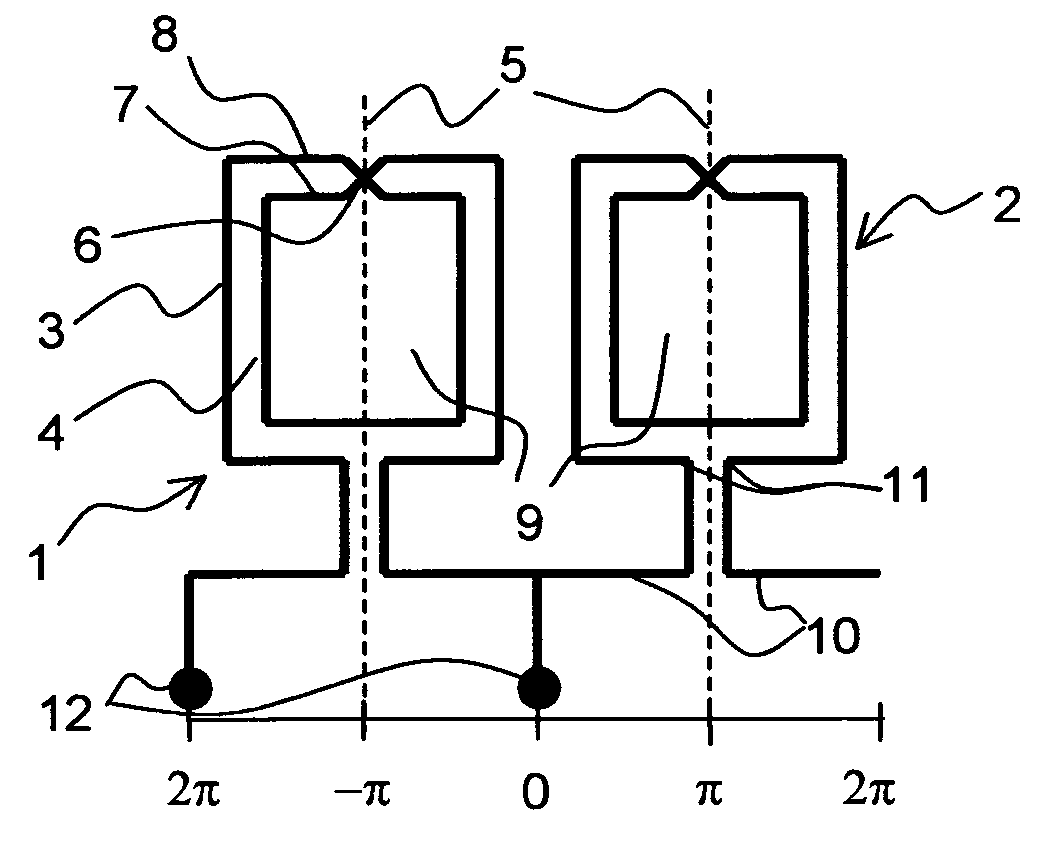

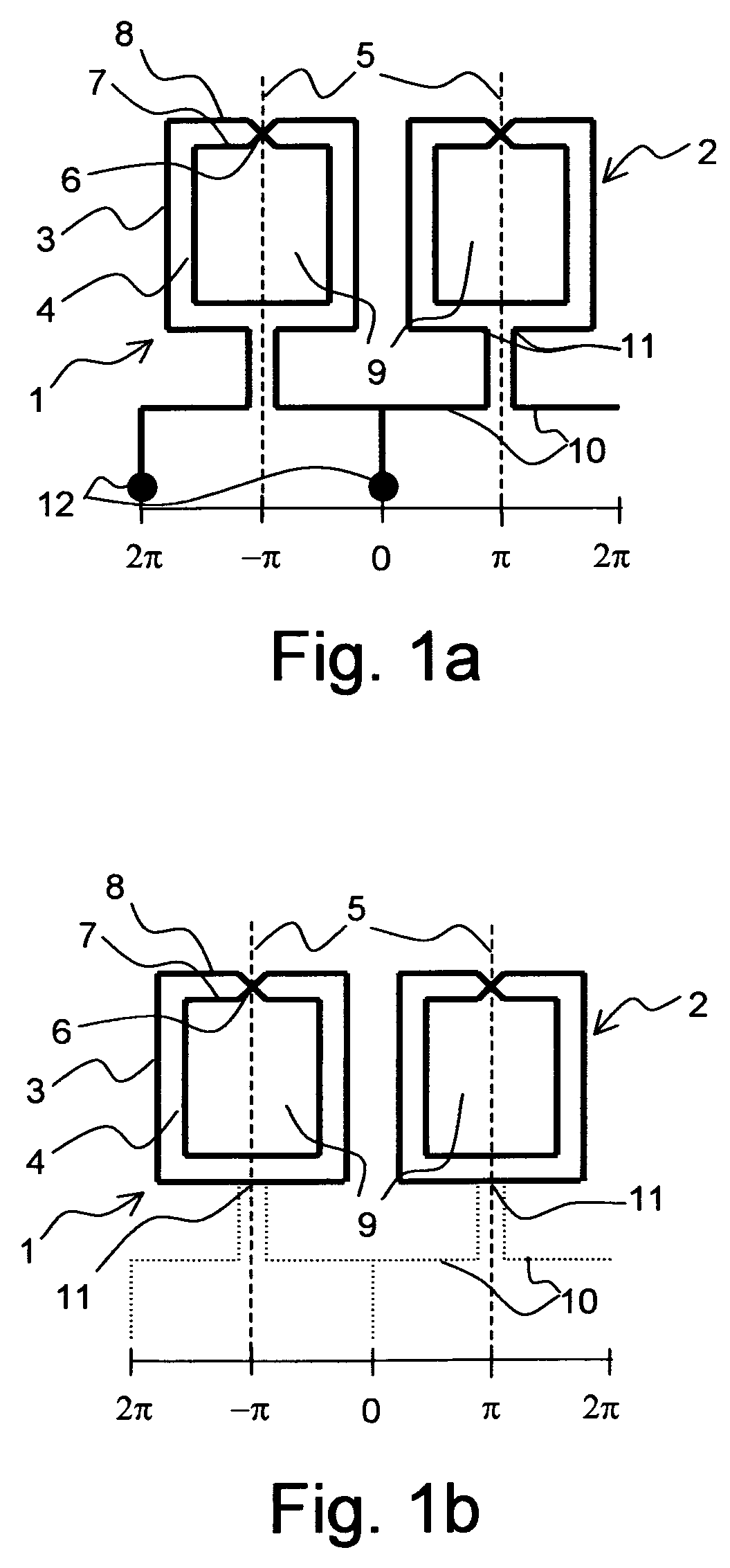

Electrically symmetric NMR coils with a plurality of windings connected in series

ActiveUS7397246B2Reduce couplingHigher resonant modesMagnetic measurementsElectric/magnetic detectionElectromagnetic couplingNMR - Nuclear magnetic resonance

A nuclear magnetic resonance probe head comprising at least two orthogonal coil / resonator configurations A1 and A2 having different resonance frequencies, wherein at feast one of the coil / resonator configurations A1 has two saddle-shaped coils S1 and S2, wherein each coil has a window about which N windings are disposed which are connected in series, wherein N≧2. Each coil S1 and S2 is formed mirror-symmetrically relative to a central plane of the respective coil, which is perpendicular to the window of the respective coil, wherein the central planes of the coils S1 and S2 are identical to minimize the electromagnetic coupling between the two coil / resonator configurations A1 and A2 at the resonance frequency of A2. The NMR probe head reduces coupling between the two coil / resonator configurations.

Owner:BRUKER SWITZERLAND AG

Saddle-shaped annuloplasty ring

A mitral annuloplasty ring that has a saddle shape with an upward bow in both an anterior segment and a posterior portion, with the upward bow being more pronounced in the anterior segment. The ring defines a closed ring body with a rounded isosceles triangular shape and the anterior segment along a long side. The posterior portion bulges outward to create a minor-major axis dimension ratio of between about 3.3:4 to 4:4. An inner ring body is made of a generally rigid material such as titanium that will substantially resist distortion when subjected to the stress imparted thereon after implantation in the mitral valve annulus of an operating human heart. The outward and upward posterior bow of the annuloplasty ring corrects for pathologies associated with mitral valve prolapse, as seen with Barlow's syndrome for instance, in which the leaflets tend to be elongated or floppy. The anterior segment has an enhanced upward bow to conform to systolic mitral annulus shapes, and the upward posterior bow is somewhat lower, for example between 1-2 mm lower, to help reduce the chance of suture pull-out, or dehiscence.

Owner:EDWARDS LIFESCIENCES CORP

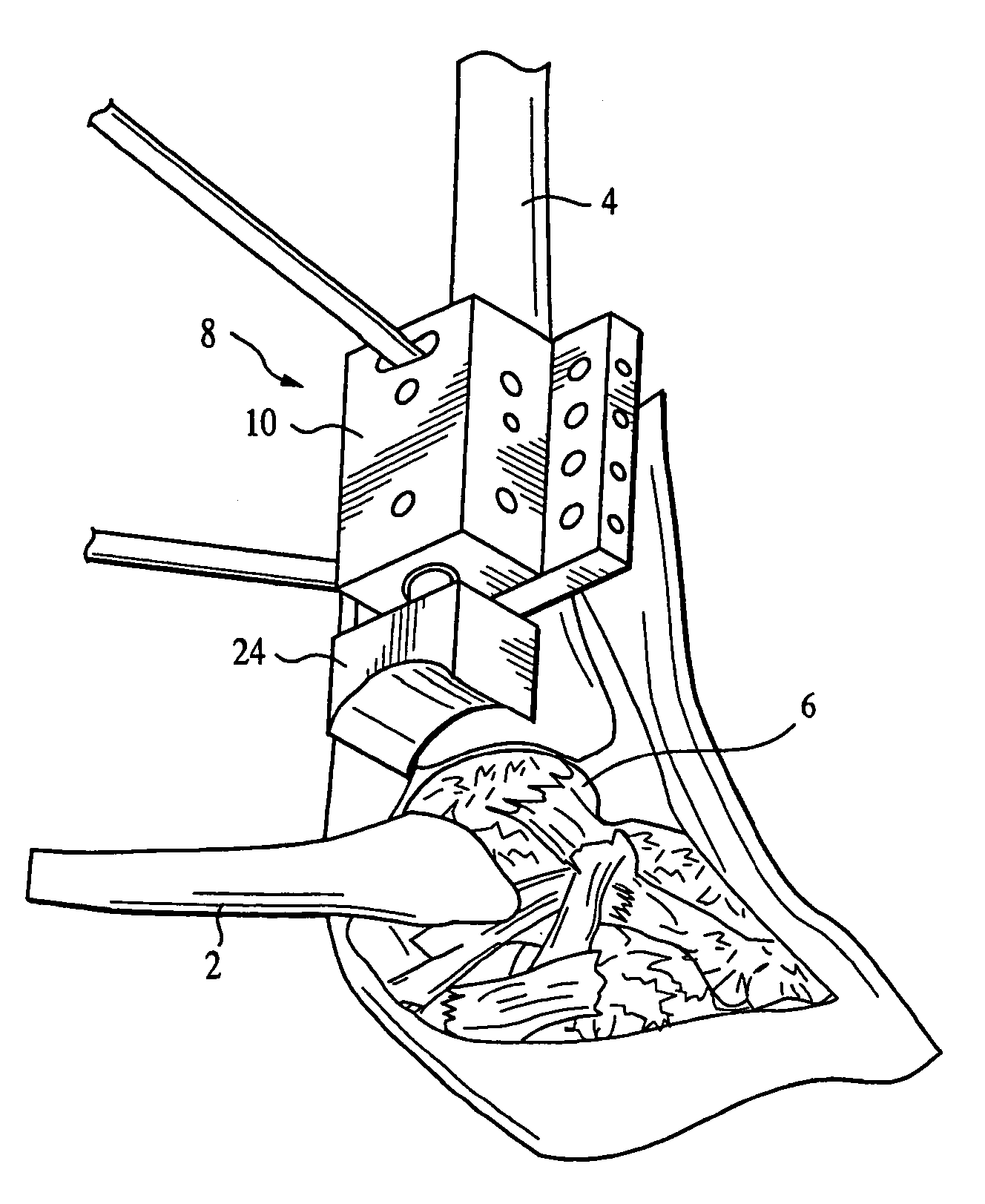

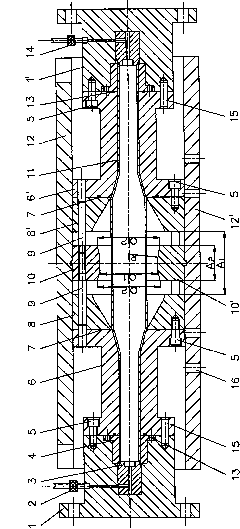

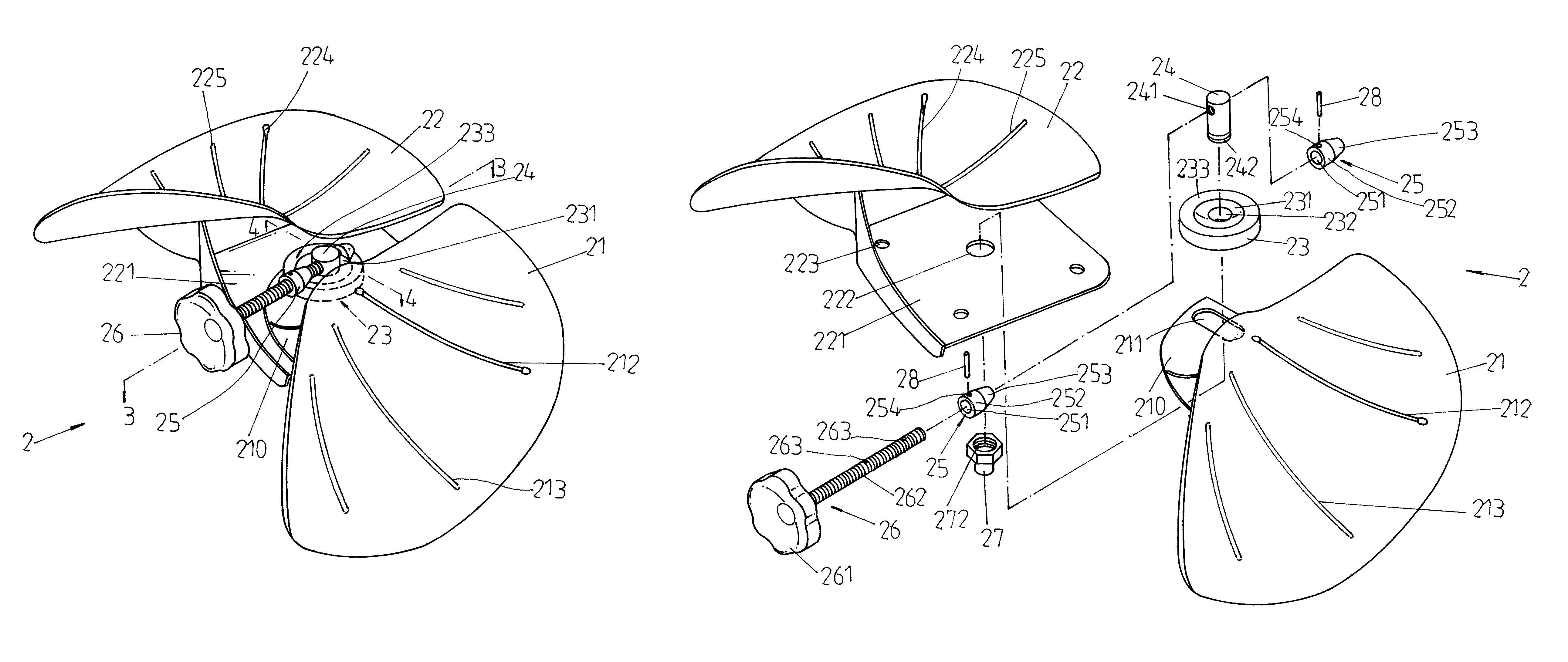

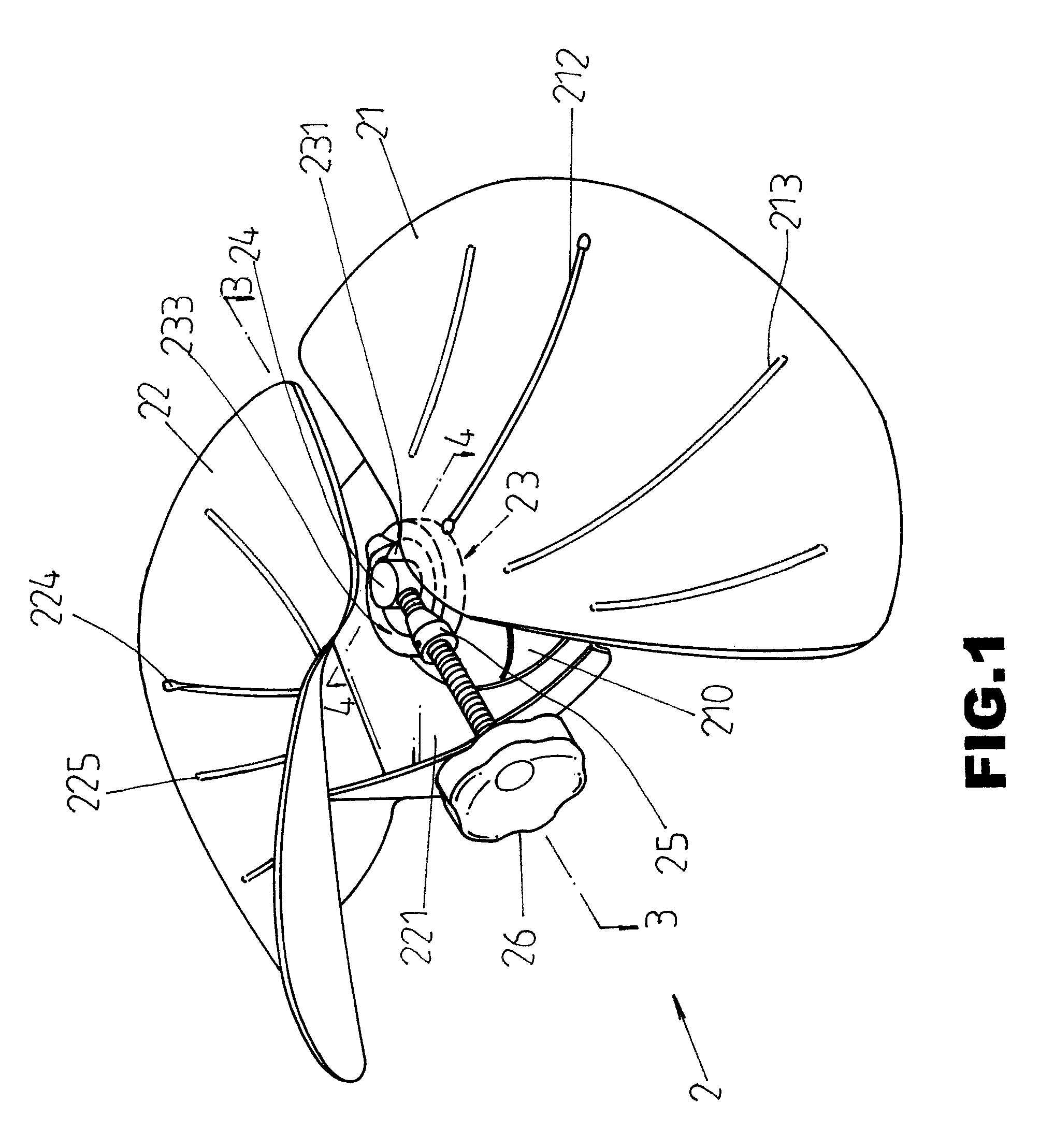

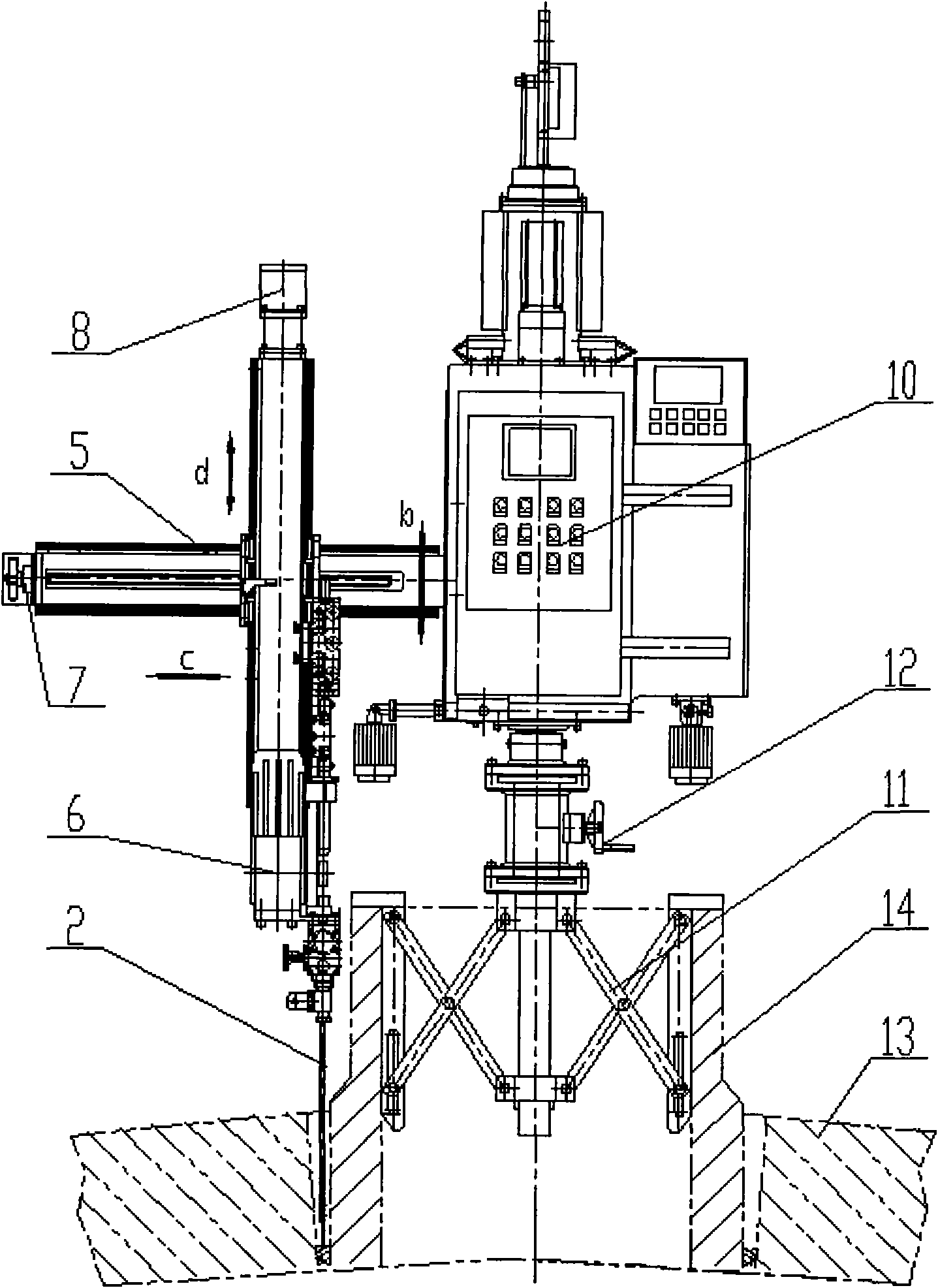

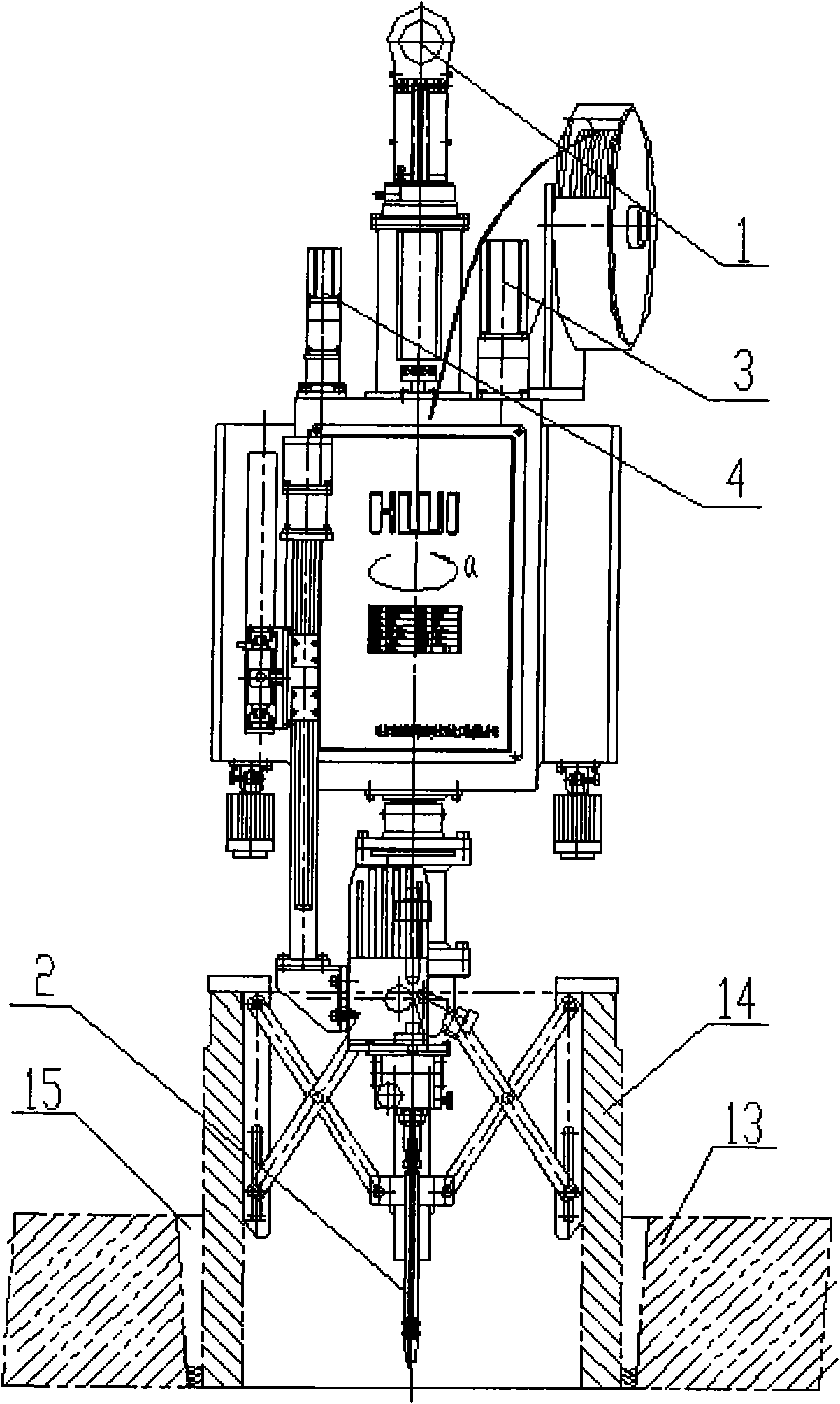

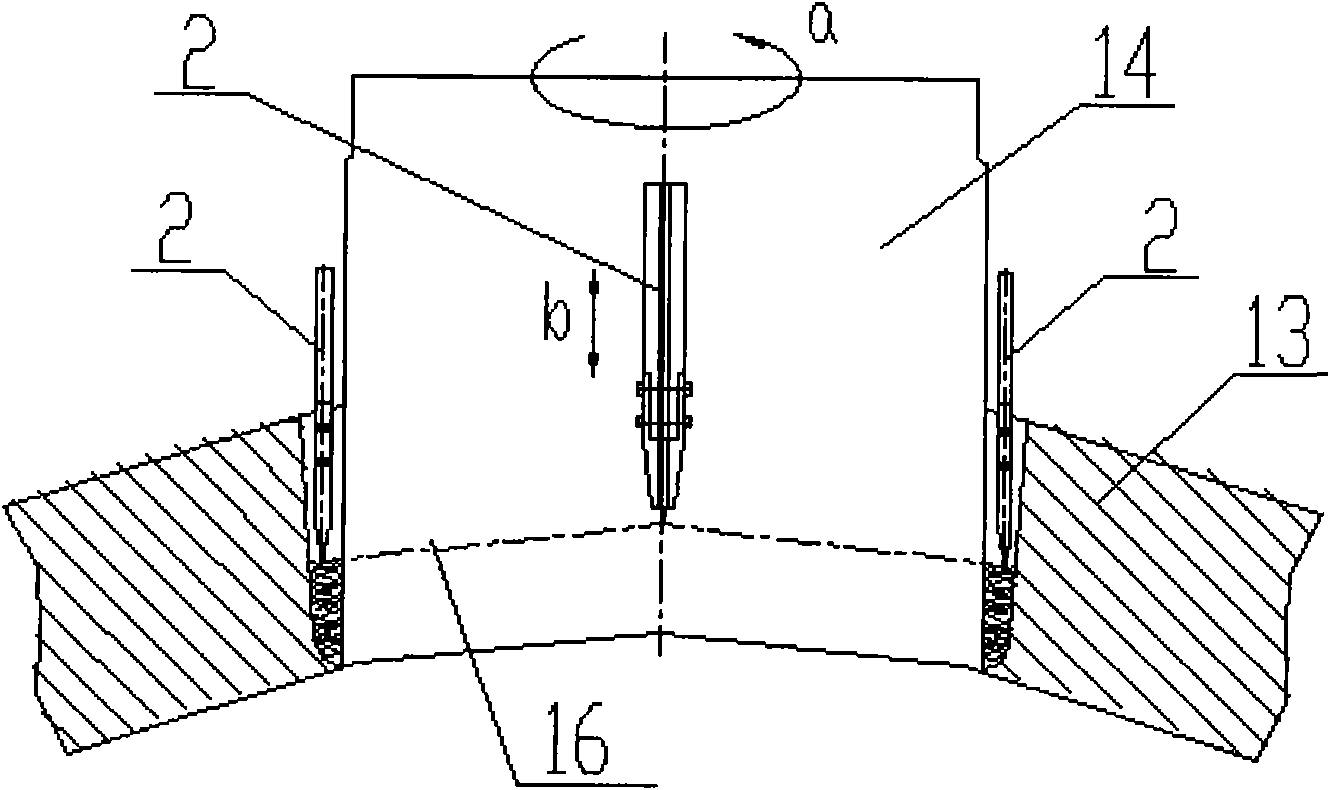

Numerical control submerged automatic arc welding device and numerical control submerged automatic arc welding method for saddle-shaped narrow bevel

InactiveCN101780590AQuality improvementIncrease productivityArc welding apparatusNumerical controlEngineering

The invention provides a numerical control submerged automatic arc welding device and a numerical control submerged automatic arc welding method for a saddle-shaped narrow bevel and belongs to the technical field of non-planar automatic welding. The invention mainly solves the technical problems of low production efficiency and non-assured welding quality of the welding of heavy pressure vessel in the prior art. The automatic welding device and the automatic welding method of the invention mainly comprise that: a rotating motor (3) rotates to drive a welding gun (2) to perform a rotary motion a; meanwhile, a machine head lifting motor (4) makes a welding gun (2) perform a lifting motion b; the two kinds of motions a and b form a resultant motion through a certain numerical control model; and through the numerical control resultant motion, a welding gun head (2-1) can accurately realize the saddle-shaped path welding of a narrow bevel. Meanwhile, the numerical control of the welding times and welding amount of each layer, the number of the welded layers and the thickness of the welding channels in the narrow bevel can be realized. The device and the method are mainly used in the saddle-shaped welding of the narrow bevel between a connecting pipe and a cylinder in the heavy pressure vessel.

Owner:HARBIN WELDING INST LTD

Light distribution lens for LED street lamp

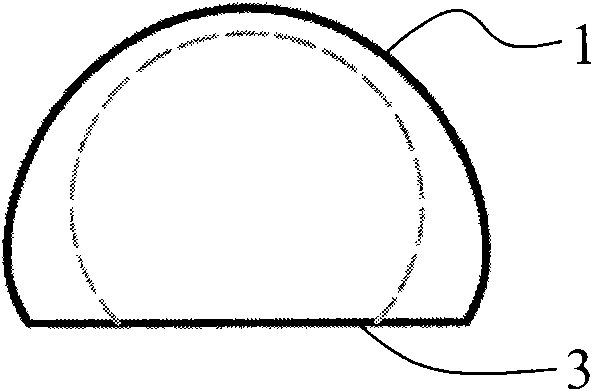

InactiveCN101852385AIncrease profitIncrease light intensityMechanical apparatusPoint-like light sourceIlluminanceOptical axis

The invention relates to a light distribution lens for an LED street lamp. An LED comprises an LED chip, a packaged lens packaged together with the LED chip and an optical axis; and the lens comprises a continuous saddle-shaped light distribution curved surface, a concave semi-sphere and a connecting plane, wherein the light distribution curved surface is symmetrical about the optical axis and used for distributing Lambertian distribution light emitted from the corresponding LED chip into large-angle bat-wing light intensity distribution along the length direction of a road; the concave semi-sphere is positioned at the bottom of the lens and symmetrical about the optical axis and the shape of the concave semi-sphere is matched with that of the corresponding LED packaged lens; and the connecting plane is positioned at the bottom of the lens and used for connecting the light distribution curved surface and the semi-sphere. The lens can distribute Lambertian distribution light emitted from the corresponding LED chip into large-angle bat-wing light intensity distribution along the length direction of the road to form oblong light spots along the length direction of the road. Therefore, the utilization ratio of light rays is enhanced, the intensity of illumination on a road surface between street lamps is enhanced and road surface illumination becomes uniform.

Owner:THE HONG KONG POLYTECHNIC UNIV

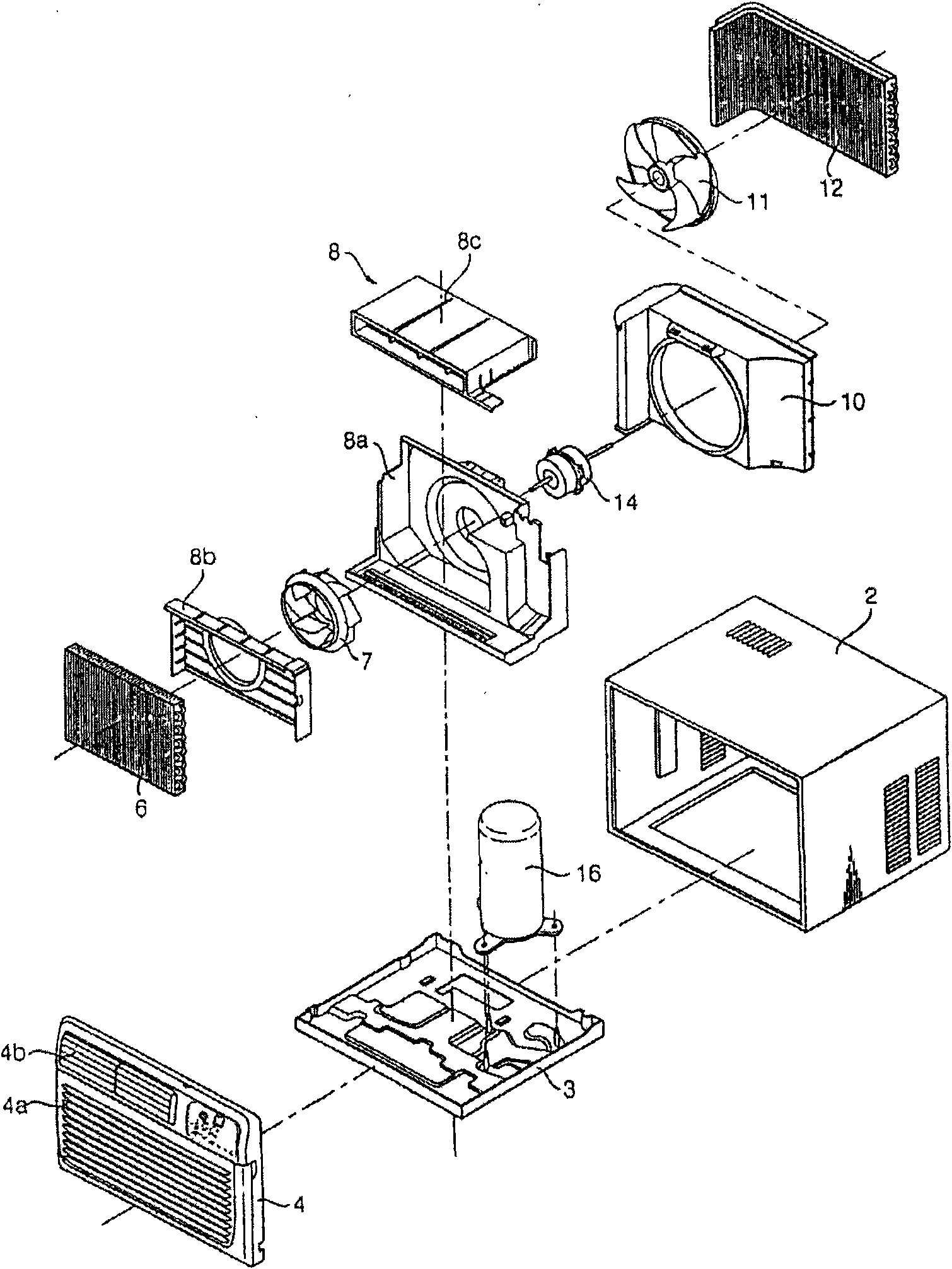

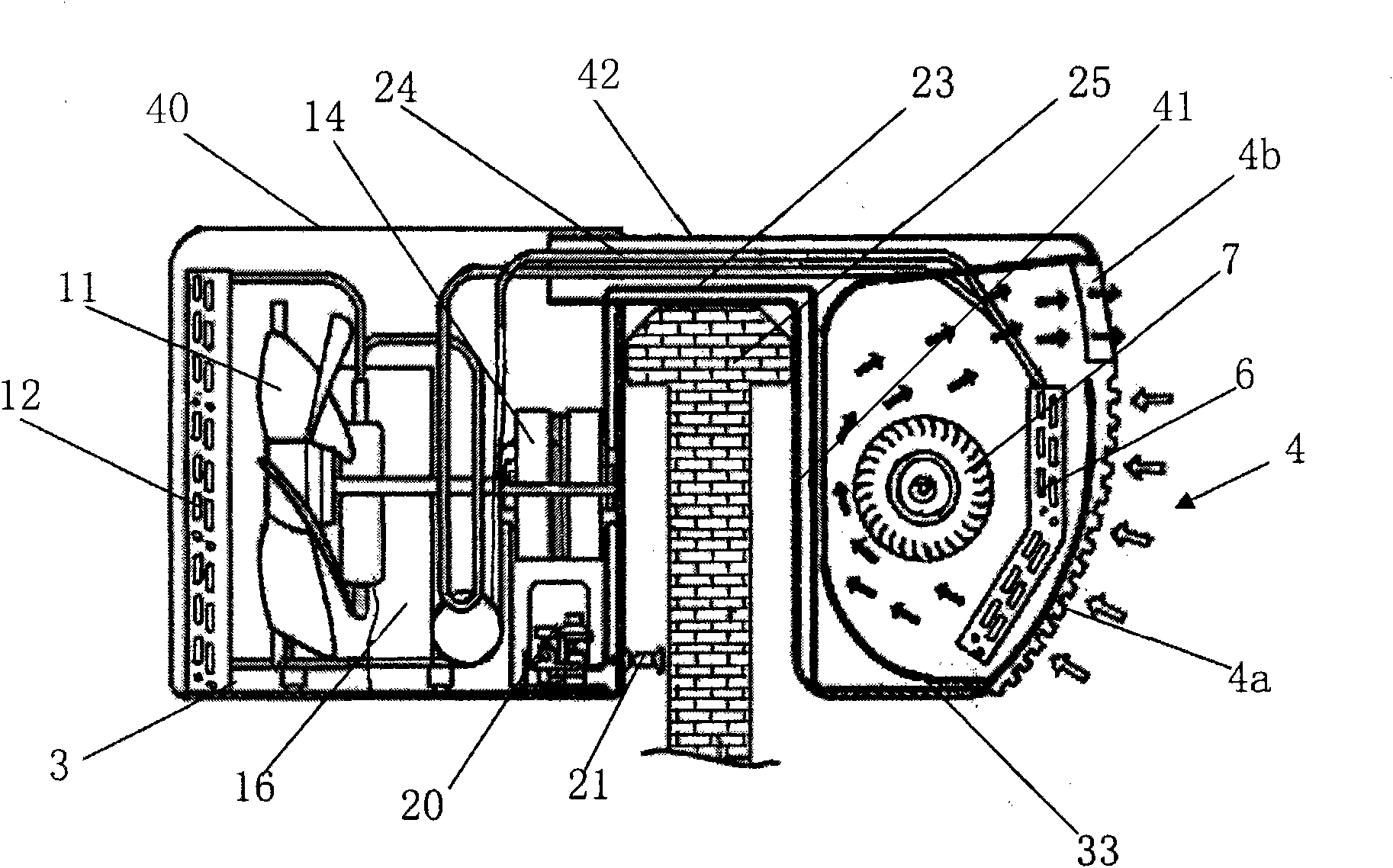

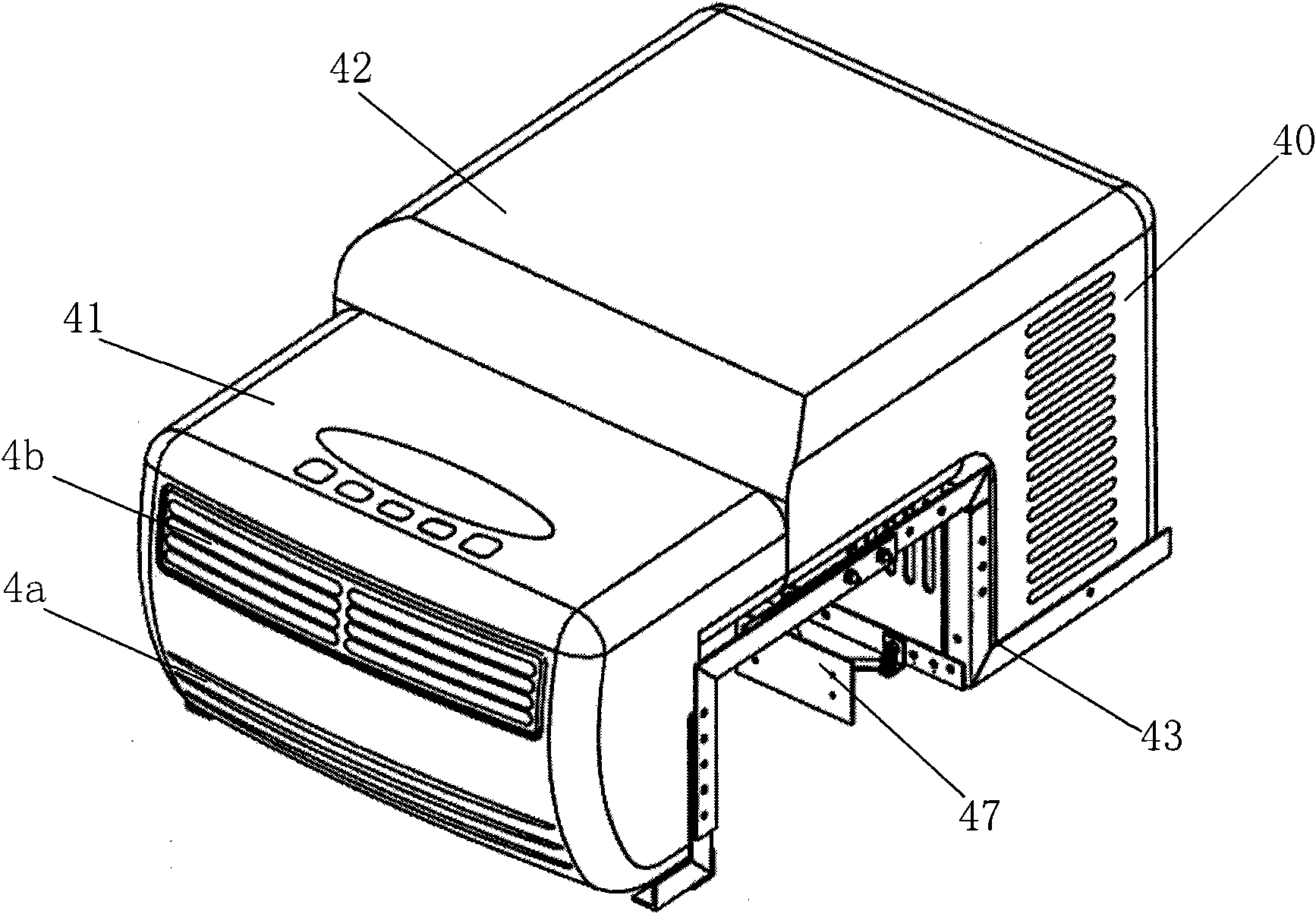

Saddle-shaped window type air-conditioner

InactiveCN101876465AChange heightChange spanLighting and heating apparatusSpace heating and ventilation detailsEngineeringSaddle shape

The invention discloses a saddle-shaped window type air-conditioner, which comprises an indoor panel, a machine case, an evaporator, an indoor fan, a condenser, an outdoor fan, a compressor and a chassis. The machine case includes three parts: an indoor machine shell, an outdoor machine shell and a connecting machine shell, and a mounting bracket is arranged on a saddle-shaped part which is a combining part of the outdoor machine shell, the indoor machine shell and the connecting machine shell and comprises a first mounting part, a second mounting part and a sliding part, wherein the first mounting part and the second mounting part are respectively jointed with buckling outlines of the bottoms of the indoor machine shell and the outdoor machine shell and are fixed with shell bodies, the sliding part is jointed with a bending outline connecting of the bottoms of the machine shells, the indoor machine shell and the vertical side face of the outdoor machine shell, and the height of the mounting bracket and the width of the saddle-shaped position are realized by changing the connecting positions between a regulating part and the first mounting part, the second mounting part as well as a spanning part. Gravity acted on the air-conditioner is uniformly borne by the mounting brackets, thereby avoiding machine case fracture caused by centralized stress on the connecting machine shell.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com