Extra-large-span saddle-shaped flexible network cable tensioning forming construction method

A super-span saddle and construction method technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of waste of manpower and material resources, cost, long tension construction period, low efficiency, etc., and achieve reasonable and economical solutions. Effect of consumption of construction personnel and machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

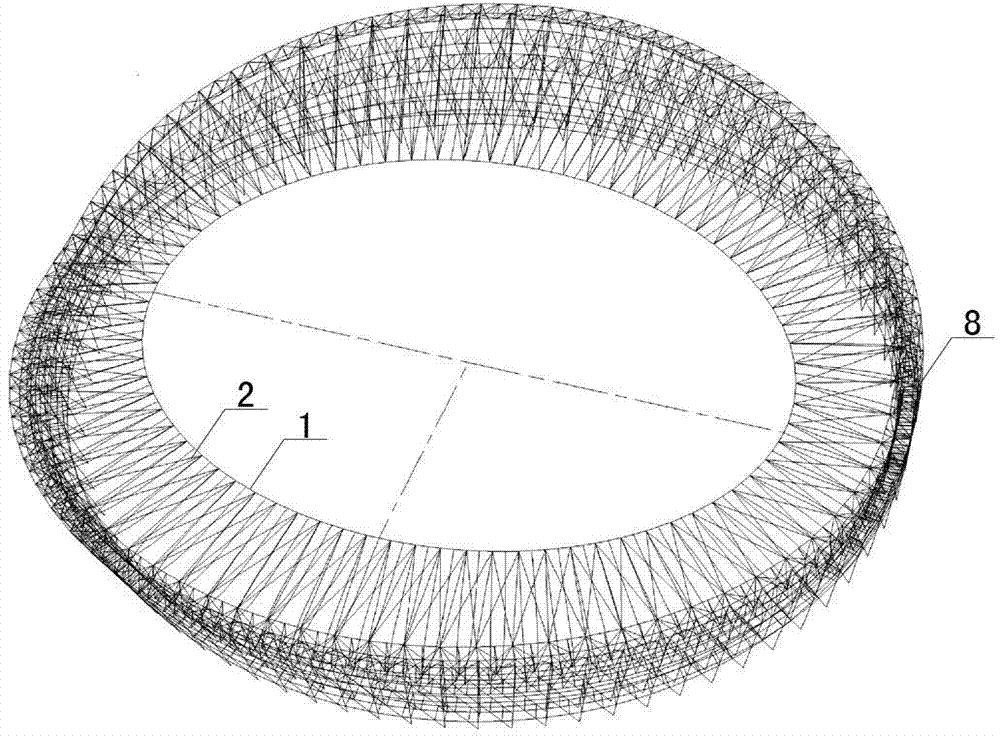

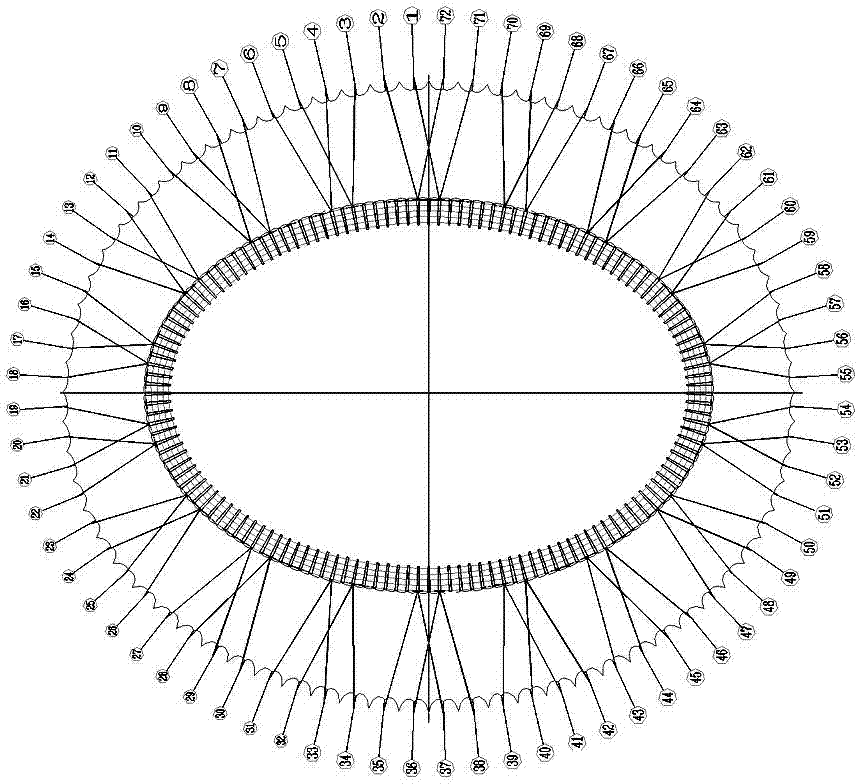

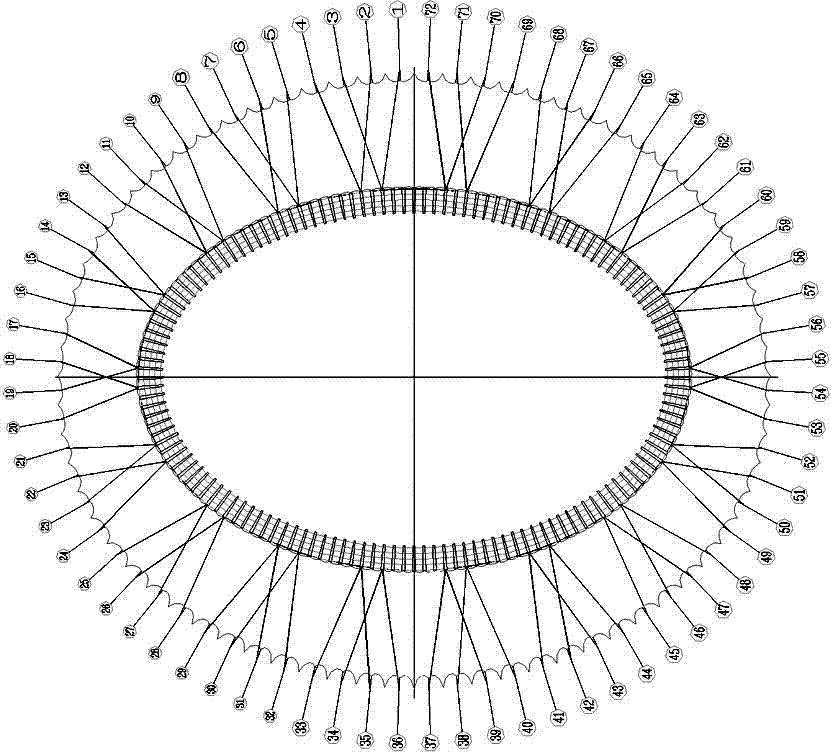

[0057] Examples see figure 1 As shown, it is a structural schematic diagram of the super-large-span saddle-shaped flexible cable net of the present invention, including a main structure 8 and a cable net stretched over the middle of the main structure 8. 5 and notochord 6.

[0058] The specific steps of the super-large-span saddle-shaped flexible cable net tensioning and forming construction method of the present invention are as follows:

[0059] Step 1, using finite element analysis software to establish the overall calculation model of the structure, carry out the simulation analysis of each construction stage, and give the configuration and stress of the structure at each construction stage. The finite element analysis software is ANSYSY or Midas.

[0060] Step 2: After the construction of the surrounding main structure 8 is completed, and before the installation of the slings, measure the hole centers of all sling lugs 3 for 5 times with a total station. During the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com