Posterior stabilized knee prosthesis

A technology of knee joint prosthesis and main body, applied in the direction of knee joint, prosthesis, elbow joint, etc., can solve the problem of increasing the total mechanical failure of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

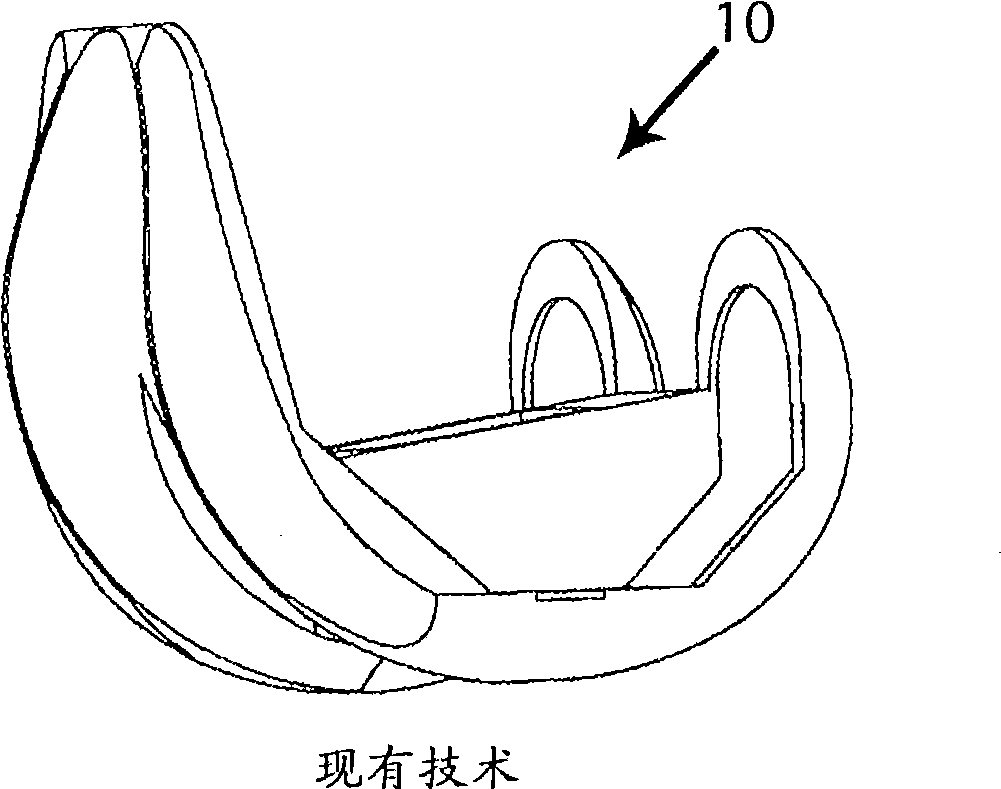

Problems solved by technology

Method used

Image

Examples

Embodiment approach

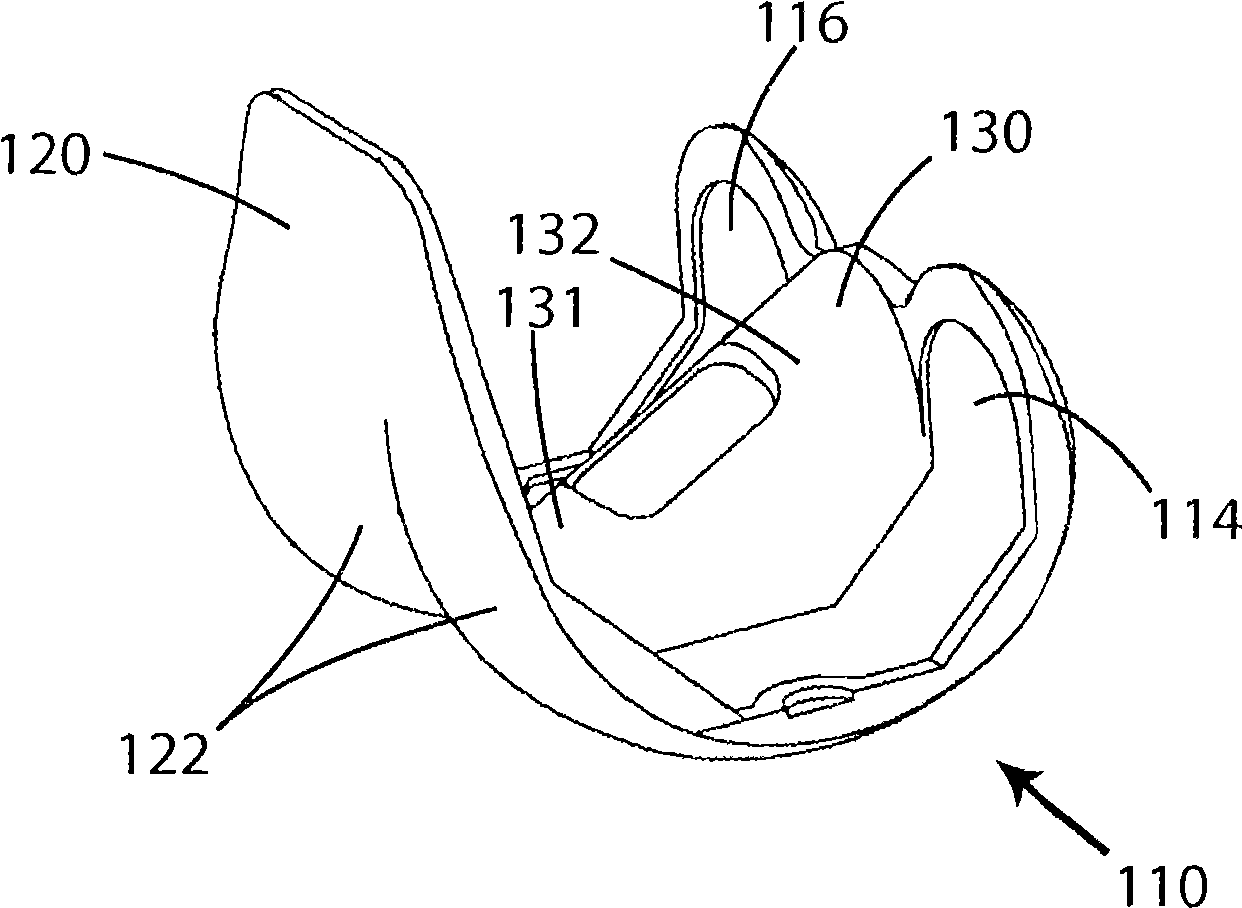

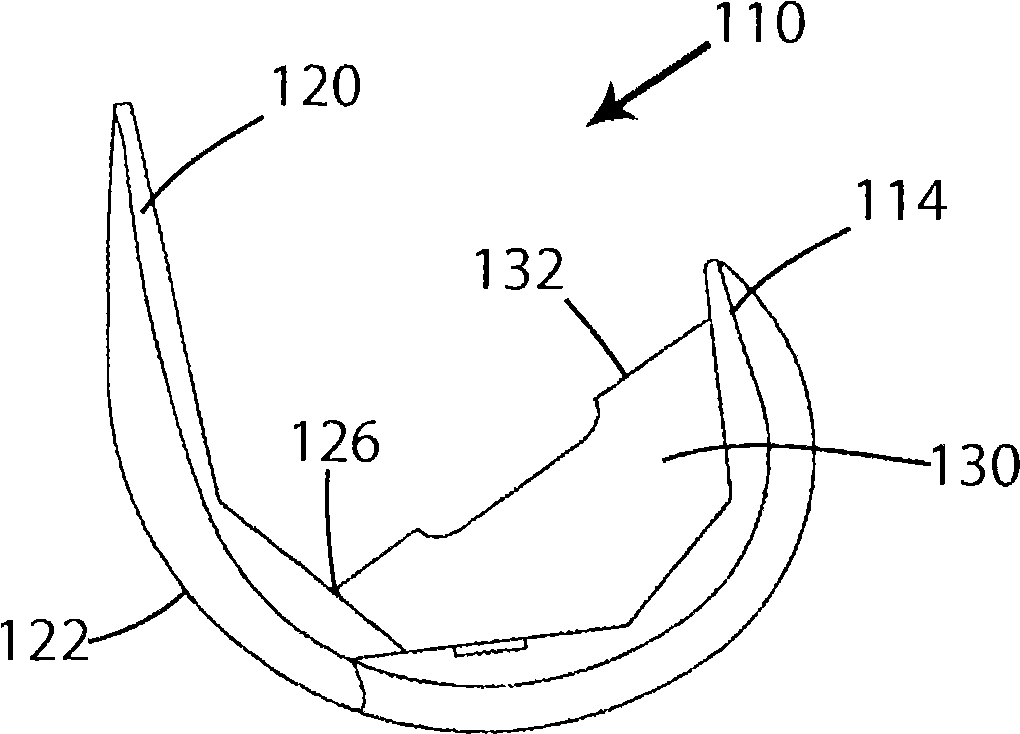

[0038] According to an exemplary embodiment, modification of the geometry of the cassette according to the invention resulted in an average reduction of the volume of bone removed from the intercondylar portion of the femur by approximately 37%. The reduction in bone removal was accomplished by two measures. First, if Figure 6 As shown, the angle of the intercondylar portion 130 of the femoral component 110 is increased to minimize the anteriorly removed bone. For example, the angle of the box measured from the highest point of the top 132 is significantly increased relative to the angle of the box of the traditional intercondylar portion, and at Figure 2-6 In the embodiment shown, the angle of the cassette is increased from 8.3° (traditional design) to approximately 28°. However, it should be understood that the above values are non-limiting and merely exemplary in nature, therefore, the angle of the cassette may be from about 20 degrees to about 35 degrees, such as fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com