Semi-sliding hydraulic bulging technology of automobile axle housing part and die thereof

A hydraulic bulging and semi-sliding technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of small single bulging amount of tube blank, large reduction of tube wall thickness, and large equipment tonnage. , to achieve the effect of small wall thickness reduction, reasonable wall thickness distribution and quality reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

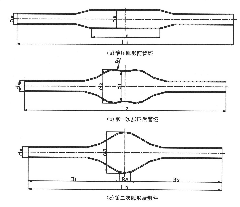

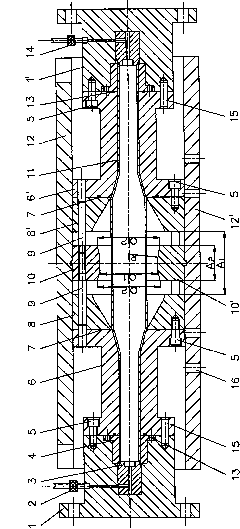

[0015] figure 1 It is a schematic diagram of the semi-sliding hydraulic bulging process for automobile axle housing parts disclosed by the present invention, image 3 , Figure 4 It is a schematic diagram of the mold structure used for the first hydraulic bulging and the second hydraulic bulging of automobile axle housing parts. In the present invention, the semi-sliding hydraulic bulging mold for automobile axle housings includes middle upper and lower fixed modules (10.10'), left and right sliding modules (6, 6'), upper mold guide plate 12, lower mold guide plate 12', high-pressure pipe Joint 2, high pressure gauge 14 and oil discharge hole 16, wherein, the middle fixed module is divided into upper fixed module 10 and lower fixed module 10 ', and upper fixed module 10 and lower fixed module 10 ' are connected with upper mold guide plate 12 and lower mold guide plate respectively 12' connected together. The coaxiality is guaranteed by guide pins 9 between the middle fixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com