Integral forming method of weldless axle housing of heavy truck

An integrally formed, heavy-duty truck technology, applied in the field of automobile manufacturing, can solve the problems of the inner size of the rear oil cover not meeting the requirements of installing bearings, low material utilization, inconvenient blank processing, etc. Reasonable, high shape precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

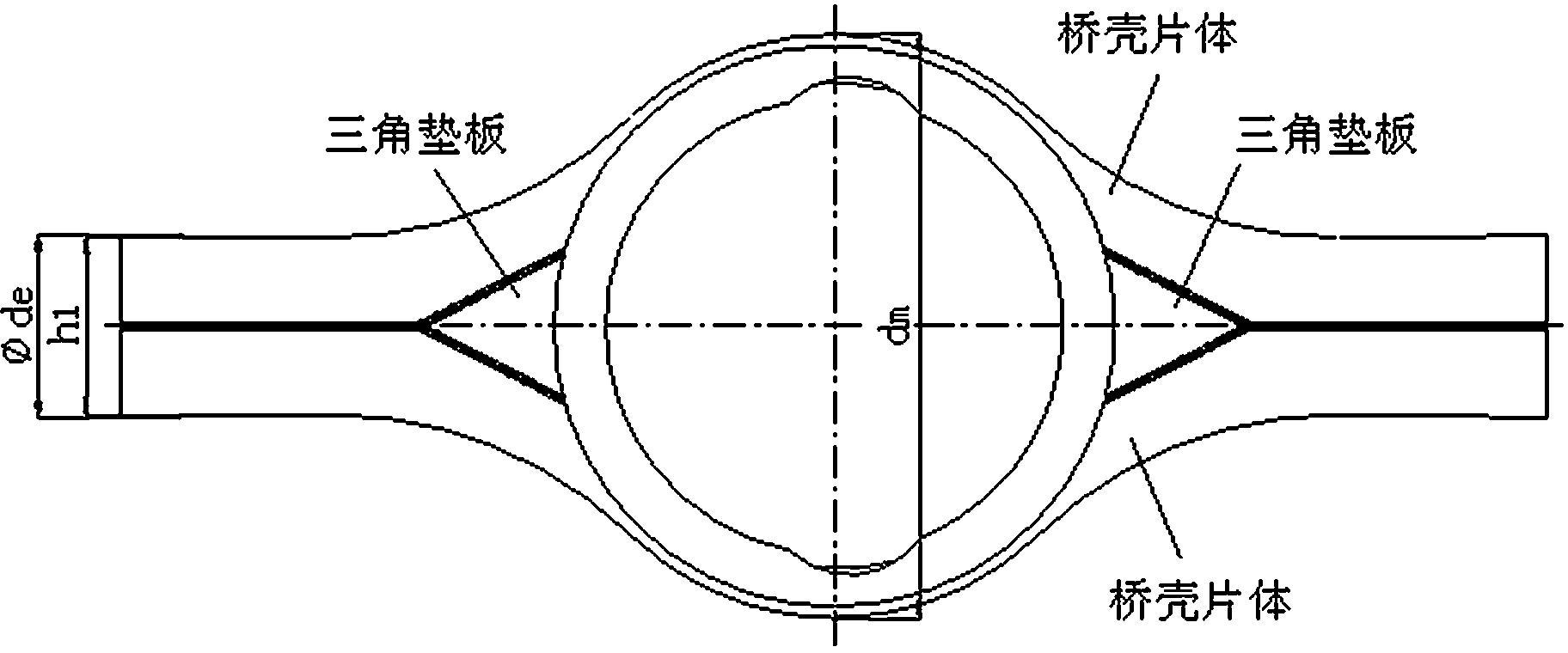

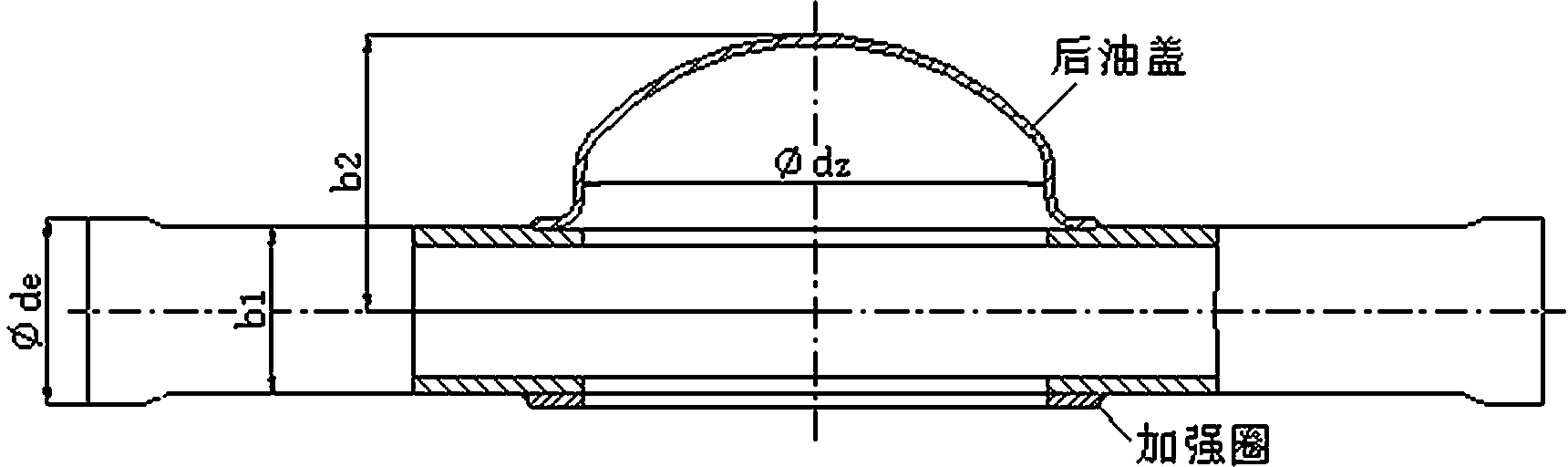

[0033] Such as figure 1 , figure 2 Shown is a heavy-duty truck rear drive axle (without wheel side reducer) stamped and welded axle housing, the main parameters include: the middle section height of the bridge package part d m 540mm, the height of the rectangular straight arms on both sides of the bridge bag is 164mm, the width is 152 mm, and the outer diameter of the two ends of the bridge housing is d e Φ170mm, the inner diameter of the cylindrical hole of the rear oil cap d z It is φ241mm. The process steps of the method for integrally forming a heavy truck axle housing of the embodiment of the present invention are as follows:

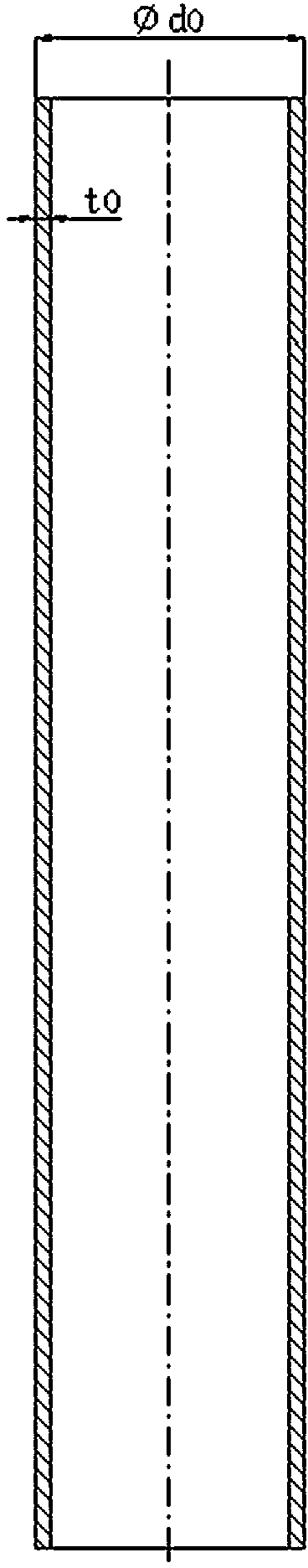

[0034] (1) Choose Q345B seamless steel pipe with outer diameter of 273mm and wall thickness of 16mm, such as image 3 Shown.

[0035] (2) The diameter of the tube blank is compressed by the opposite mandrel on both sides. Reduce the diameter on a three-way hydraulic press, clamp the middle of the tube blank with the upper and lower modules of the mold,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com