Monolithic molding method of light duty truck weldless axle case

An overall forming, light and medium-sized technology, which is applied in the field of automobile manufacturing, can solve the problems of large wall thickness reduction, difficult feeding, large size difference, etc., and achieve the reduction of tonnage of forming equipment, reasonable distribution of wall thickness, and reduction of liquid pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The integral forming method of the non-welded axle housing of light and medium-duty trucks of the present invention will be further described in detail through specific examples below.

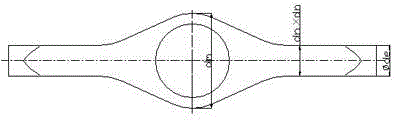

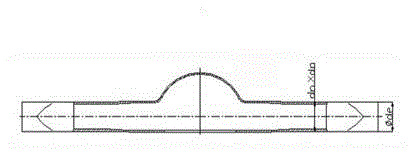

[0042]like figure 1 , figure 2 Shown is the light and medium truck axle housing of the embodiment of the present invention, the main parameters include: the height d of the middle section of the axle package part m 350mm, the square cross-section size on both sides of the bridge package is 112×112mm, and the outer diameter of the circular cross-section at both ends of the axle housing is d e It is φ110mm. The process steps of the light and medium truck axle housing integral forming method in the embodiment of the present invention are as follows:

[0043] (1) Choose outer diameter d 0 Q345B seamless steel round pipe equal to 180mm, such as image 3 shown.

[0044] (2) Both sides of the tube blank are simultaneously reduced in diameter for the first time. The middle part of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com