Patents

Literature

240results about How to "Not easy to burst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex Tang-dynasty jun glaze with blue spots in white and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in white and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in white for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in white adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in white. According to the Tang-dynasty jun glaze with blue spots in white and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, milky white glaze is presented in the process of firing by adding zircon into a formula of the glaze in white; and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Iron-runner quick-drying casting material combined with silica sol

The invention relates to a fireproof material used in an iron runner of a blast furnace cast house, in particular to an iron-runner quick-drying casting material combined with silica sol, which comprises the following raw materials in percentage by weight: 67 percent of Al2O3, 24.8 percent of SiC, 3 percent of carbon element material, 0.2 percent of dispersant, 2 percent of antioxidant and 3 percent of expanding agent. The raw materials are prepared into bone powder and fine powder which are evenly stirred to obtain a finished product. When the iron-runner quick-drying casting material is used, the silica sol in 6-10 percent of the total casting material is added, stirred and cast in an iron-runner die to form a product, and the product is demoulded and roasted under a large fire for 3-4h to yield iron. The invention has the advantages of short trenching time, burst resistance, high construction quality, short roasting time, long service life of the casting material, lightened labor intensity of workers, castoff and waste utilization, energy saving, emission reduction, no environment pollution and environmental protection.

Owner:通化耐博耐火材料有限责任公司

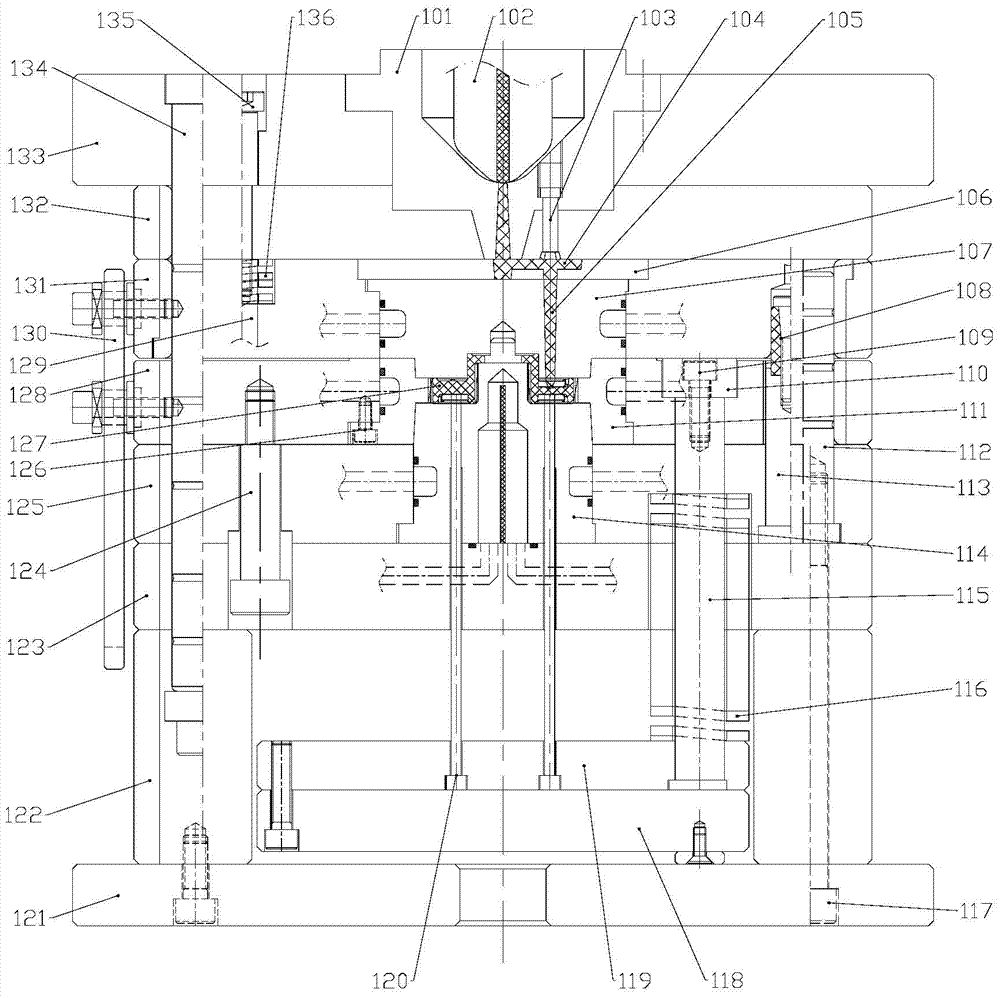

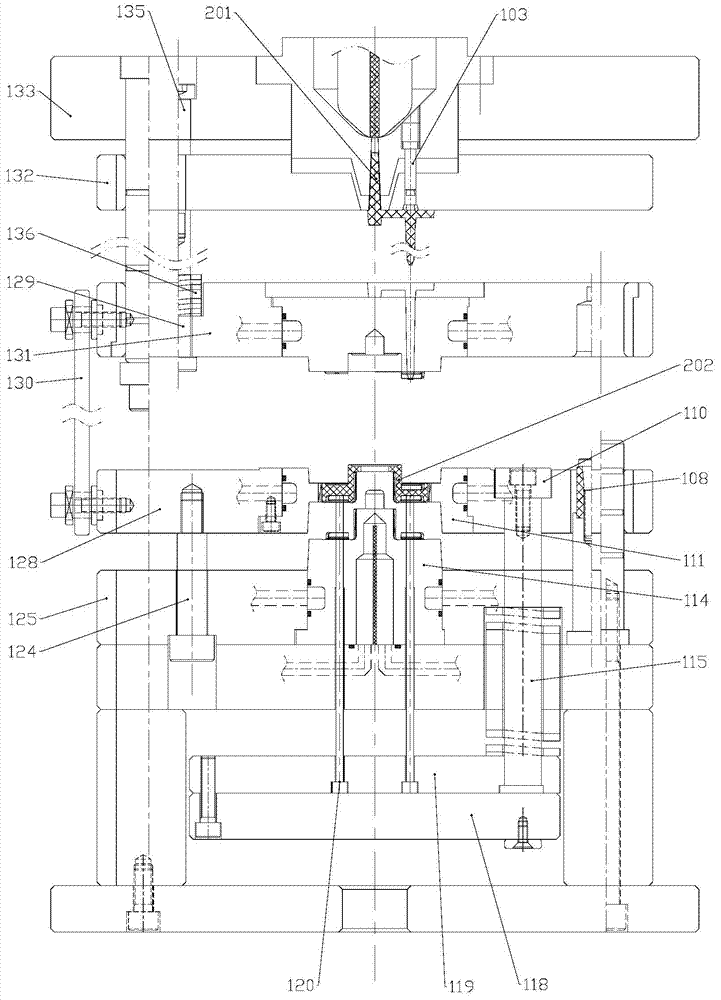

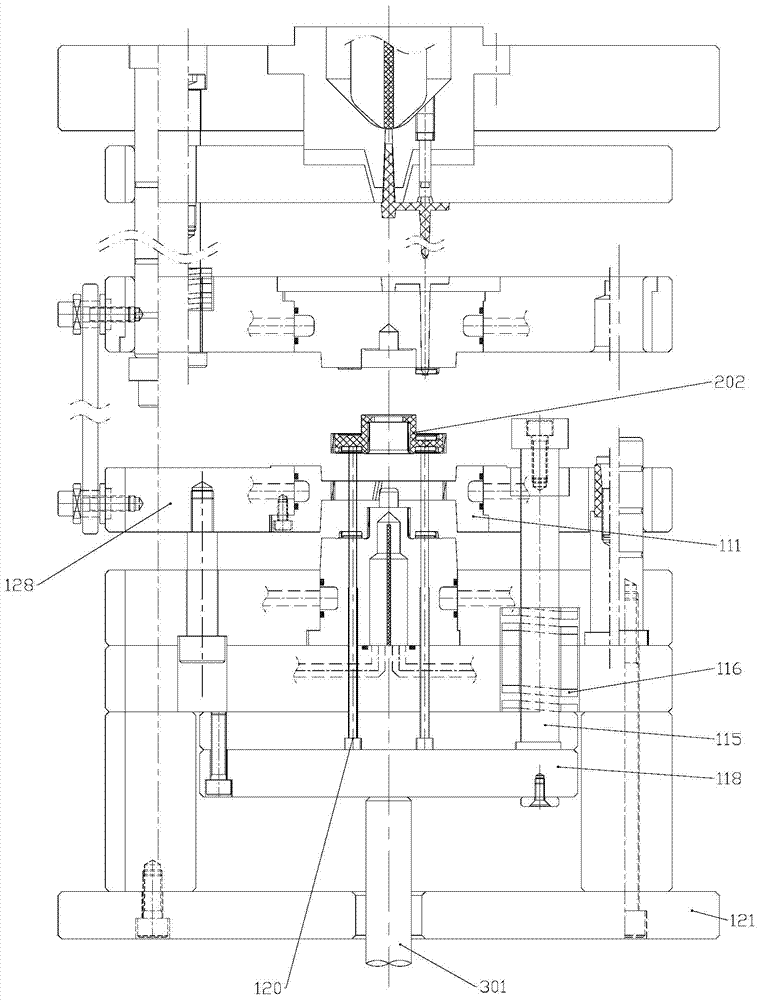

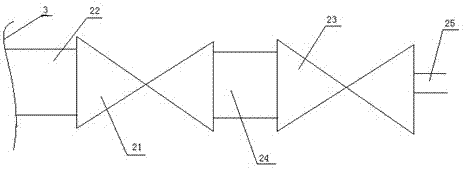

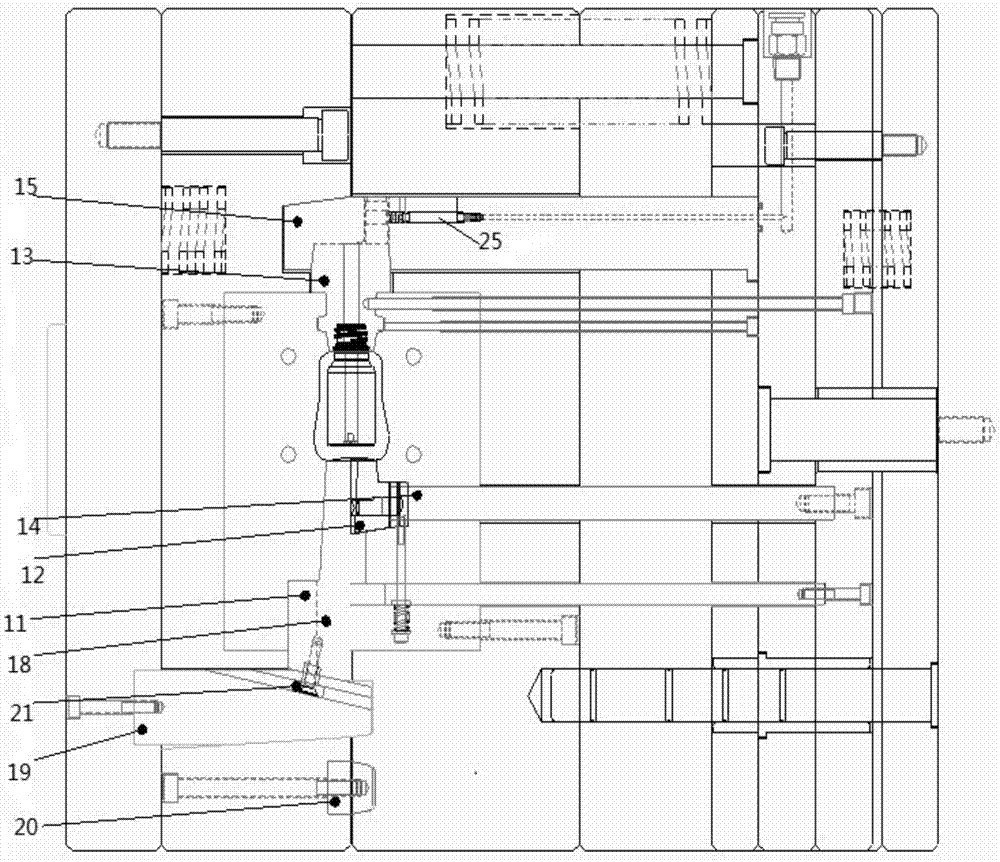

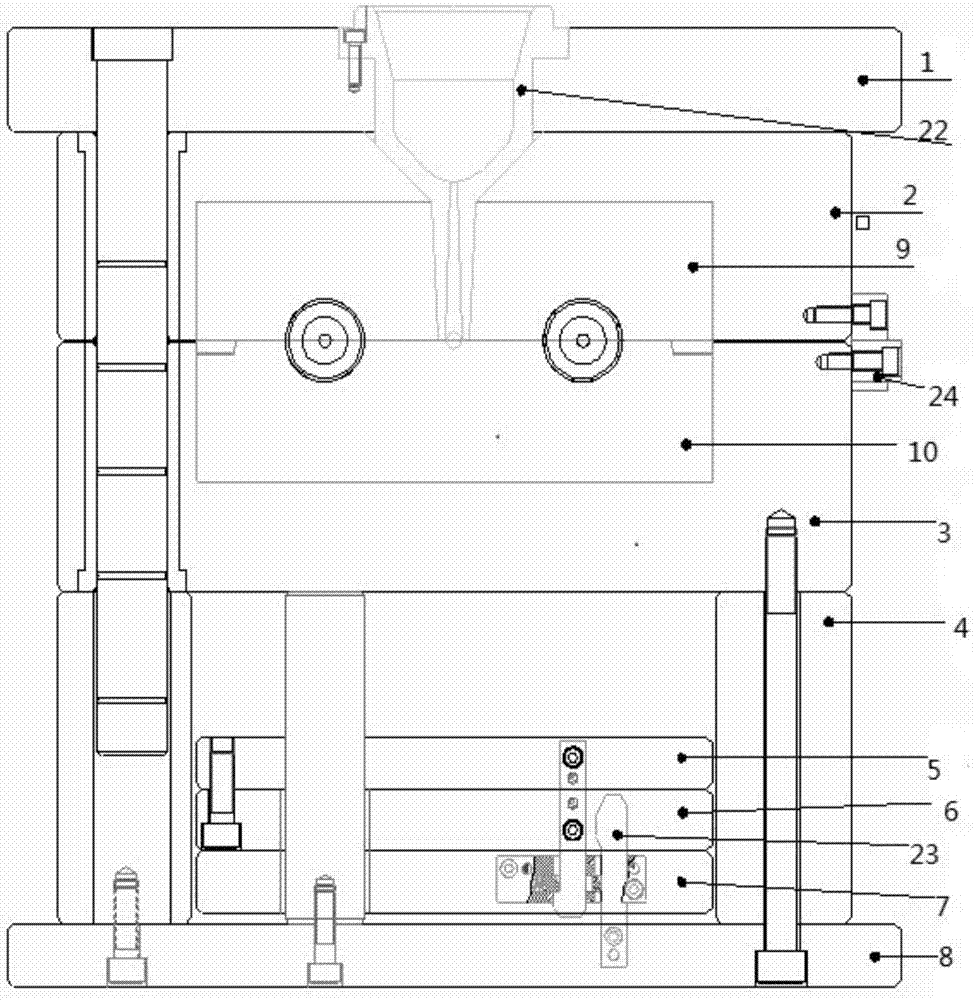

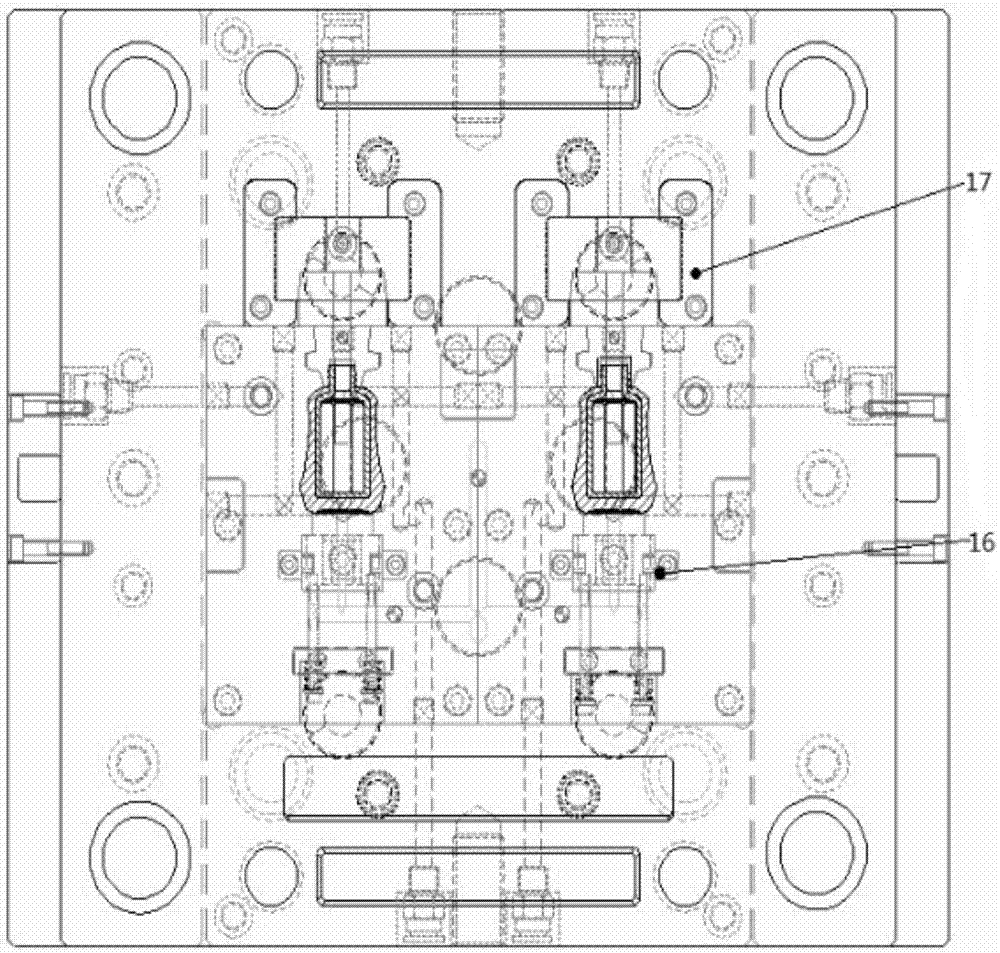

Demoulding structure for plastic helical gear injection molding

The invention relates to the field of mould making, in particular to a demoulding structure for plastic helical gear injection molding. The plastic helical gear mould comprises a fixing mould part, a moving mould part, and a demoulding component comprising a pulling plate fixed on a fixing mould cavity plate and a gear cavity plate, and an ejection structure arranged on the moving mould part, wherein a fixing mould cavity positioned in the fixing mould cavity plate, a gear cavity positioned in the gear cavity plate, and a moving mould cavity in the moving cavity plate mutually form step shapes, and sequentially and tightly connected in a sleeving manner to form a helical gear cavity. During the demoulding process, under the effect of the demoulding component, the injection molded plastic helical gear rotationally moves forwards in a spiral manner along the inner surface of the gear cavity to realize mold stripping, so that the finished plastic helical gear is obtained. The structure has the advantages that the mould is simple in structure, high in product accuracy and stable in production, and overcomes difficulties of easiness in deformation of the spiral plastic helical gear during the injection process, gear ring cooling, gear ring resetting performed to satisfy the requirements for gear position.

Owner:SHENZHEN HISYM IND

White-ground red-spot composite tangjun glaze and process of preparing jun porcelain with same

The invention discloses white-ground red-spot composite tang jun glaze and a process of preparing jun porcelain with the same. The preparing process comprises the steps that a porcelain body material is smashed and molded firstly, plain porcelain body firing is conducted, then a plain porcelain body is dipped in white-ground glaze slurry for glazing, local spot application of red-spot glaze slurry is conducted on the surface of the plain porcelain body after the white-ground glaze slurry attached to the surface of the plain porcelain body is dried in the air, the plain porcelain body is placed in a kiln to be fired after the red-spot glaze slurry is dried in the air, and then the white-ground red-spot composite tang jun glaze jun porcelain is obtained. According to the white-ground red-spot composite tang jun glaze and the process of preparing the jun porcelain with the same, by adding a certain proportion of zirconite to white-ground glaze and adopting secondary glazing, the position of red-spot glaze is fixed, and a glaze layer is cracked evenly and not prone to rupture; the coloring technology of overglaze or underglaze adopted for general piebald porcelain is replaced, the economic value of the jun porcelain is increased through innovation in glazing color and coatings, the jun porcelain represents the advanced manufacturing technology of China, and the social value of the jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Porcelain pot for electromagnetic range and production method thereof

The invention discloses a porcelain pot for an electromagnetic range and a production method thereof. The porcelain pot for the electromagnetic range comprises a pot body which is a lithium and cordierite compound porcelain pot body produced by combining lithium and cordierite ceramic; and a ferrous film layer is arranged at the bottom of an inner surface of the pot body. The production method of the porcelain pot for the electromagnetic range comprises the steps of firing the lithium and cordierite compound porcelain pot body, coating a film containing a ferrous element at the bottom of the inner surface of the pot body, firing under protective gas and finally obtaining the porcelain pot containing the ferrous film layer for the electromagnetic range. The ferrous film layer is coated at the bottom of the inner surface of the porcelain pot, so that the porcelain pot with the ferrous film layer can generate an electric magnetic field when applied to the electromagnetic range; the heat generated by the ferrous film layer under the action of the electromagnetic field is directly used for heating food, so that the ferrous film layer has the advantages of high heating speed and energy source saving; and the porcelain pot body can also effectively avoid the dissipation of the heat. The production method has the advantages of simple process, convenient operation, strong controllability and the like and is beneficial to being popularized and applied.

Owner:宜兴市致力科技开发有限公司

Blue background and mottled spot composite Tang jun glaze and technology for preparing jun porcelain through same

The invention provides a blue background and mottled spot composite Tang jun glaze and a technology for preparing jun porcelain through the same. Firstly, casing body raw materials are smashed and molded, and a prime casing is fired; then, the prime casing is soaked into blue background glaze slurry to be subjected to glazed, and after the blue background glaze slurry attached to the surface of the prime casing is dried, mottled spot glaze slurry is applied to local points on the surface of the prime casing; after the mottled spot glaze slurry attached to the surface of the prime casing is dried, the prime casing is placed in a kiln to be fired, and then the blue background and mottled spot composite Tang jun glaze jun porcelain is obtained. According to the blue background and mottled spot composite Tang jun glaze and the technology for preparing the jun porcelain through the same, due to the fact that iron elements, copper elements and cobalt elements are added in the blue background glaze according to specific proportions and a secondary glazing mode is used, glaze layer hacking is uniform and is not prone to bursting. The technology breaks through the overglaze color or underglaze color coloring technology adopted by a common mottled spot porcelain, the economic value of the jun porcelain is creatively increased on the aspects of glaze colors and a coating, the technology represents the advanced level of the manufacturing technology in China, and the social value of the jun porcelain is improved.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Producing technology of silver-liner double-deck glass cup

ActiveCN107114978ASimple production processNon-deformable when heatedGlass shaping apparatusDrinking vesselsHeat resistanceWork in process

The invention relates to a producing technology of a glass cup, in particular to a producing technology of a silver-liner double-deck glass cup. The producing technology comprises the following steps of choosing a proper glass tube and a silver tube, heating the silver tube from the middle part of the silver tube, and conducting undercutting on the silver tube to form a liner which is closed at one end and opened at the other end; rotating the glass tube while conducting local heating on the middle of the glass tube till glass is softened, using a blade to conduct cutting to form two external cup bodies which have cup bottoms, covering the liner with the external cup bodies, conducting rotary heating on the liner and the external cup bodies so that the cup bottom is formed through firing, using a fire sprayer to conduct preheating on a cup rim of the glass cup, and then using a die to conduct compression moulding after the cup rim is burned and fused, conducting annealing treatment on the formed cup body to obtain a semi-finished product, and graving, grinding, polishing, cleaning the semi-finished product to obtain the silver-liner double-deck glass cup. The producing technology of the glass cup has the advantages of being outstanding in low energy consumption, simple in technology, and the produced glass cup has good impact resistance, weather fastness, heat resistance, and airtightness.

Owner:安徽晶晶玻璃制品有限公司

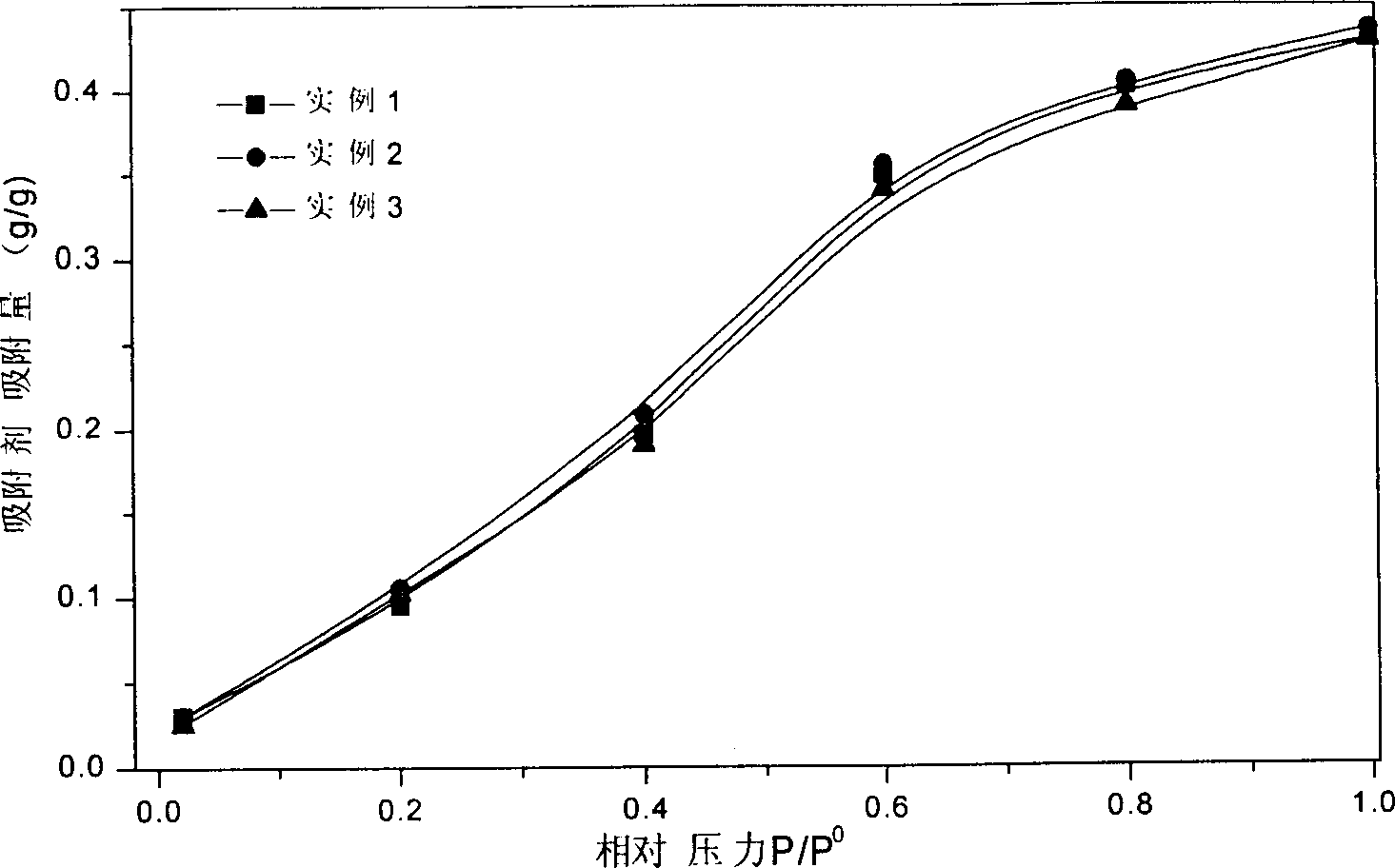

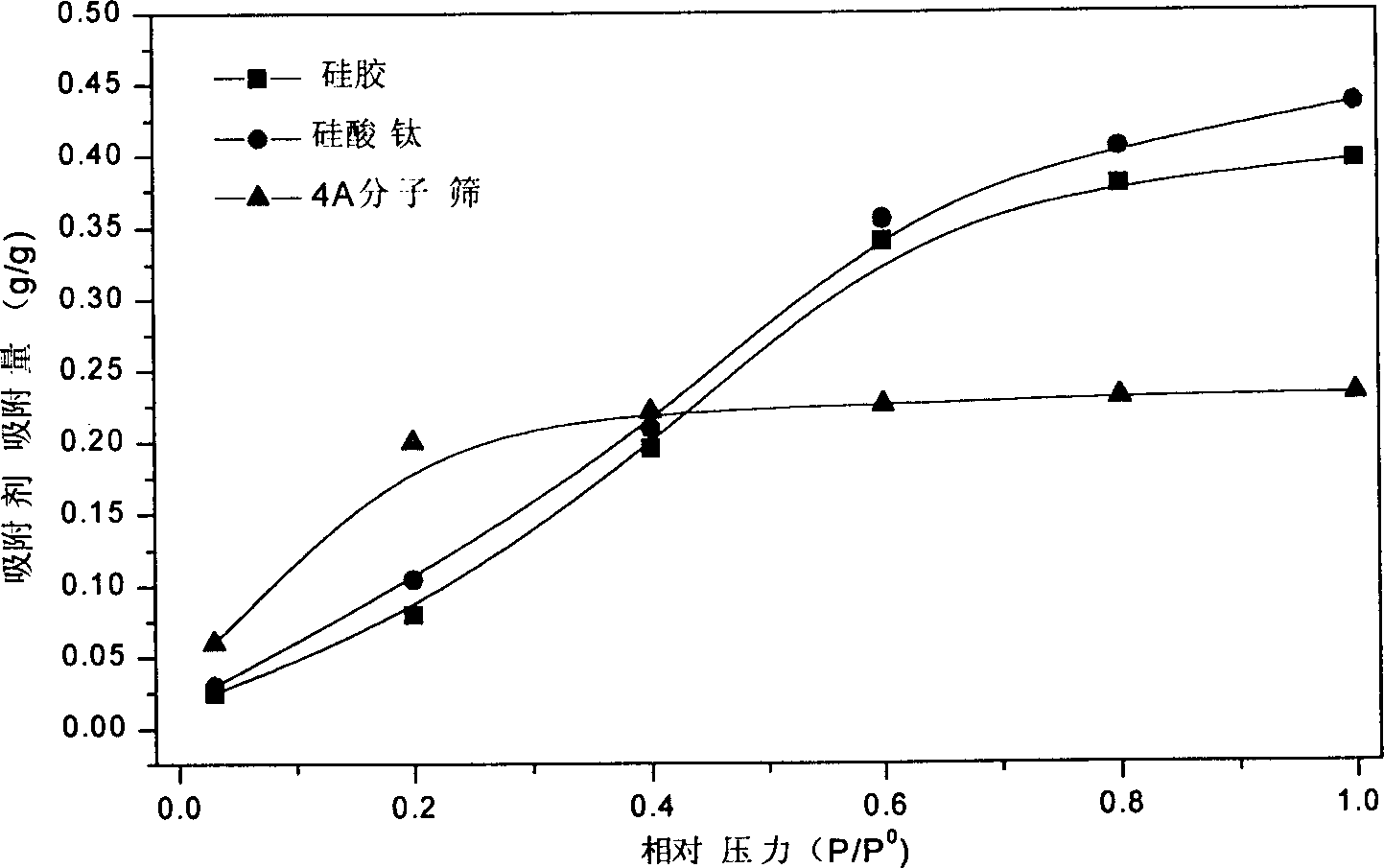

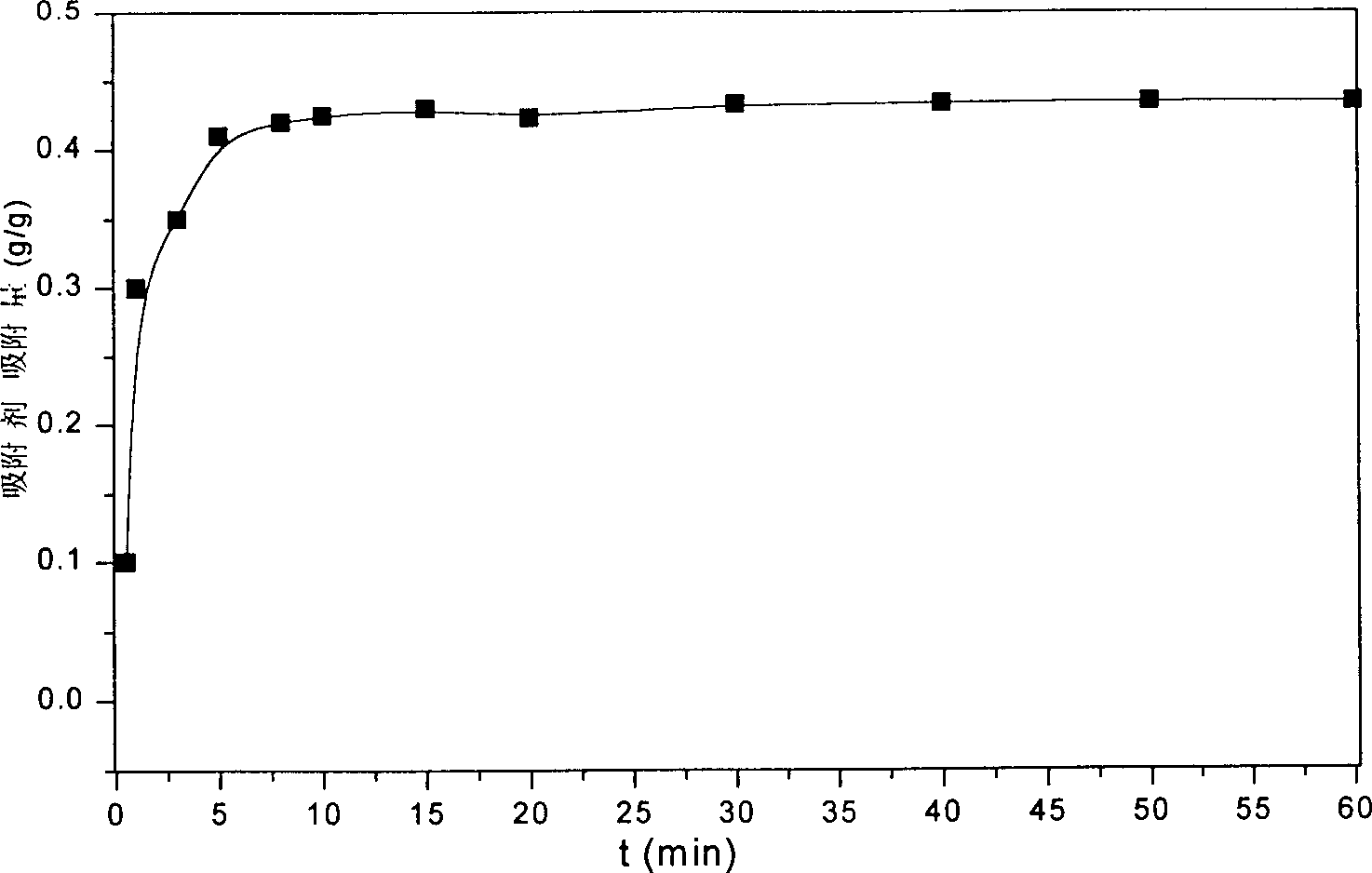

Prepn and application of titanium silicate adsorbent with high adsorption performance

InactiveCN1387942AImprove toughnessHigh rotational speed, corresponding energy requirements for turning the dehumidification wheelOther chemical processesSilicon compoundsPartial hydrolysisSorbent

The material for preparing titanium silicate adsorbent has molar ratio between Si and Ti of 8-20,and the proportion among alkoxide, water and polyethylene glycol of 1 to 5-15 to 0.002-0.005. The preparation includes the steps of sol preparation and titanium silicate preparation. The sol preparation includes partial hydrolysis of ethanol solution of silanolate, adding ethanol solution of titanic alkoxide while heating for complete hydrolysis; and adding polyethylene glycol for condensation to form sol. In the titanium silicate preparation, the sol is prepared into hydrogel through oil-free formation process and the hydrogel is then prepared into nano spherical titanium silicate via washing, drying and sieving. The titanium silicate product has high adsorption performance and is used in producing core of dehumidifying wheel.

Owner:SOUTH CHINA UNIV OF TECH

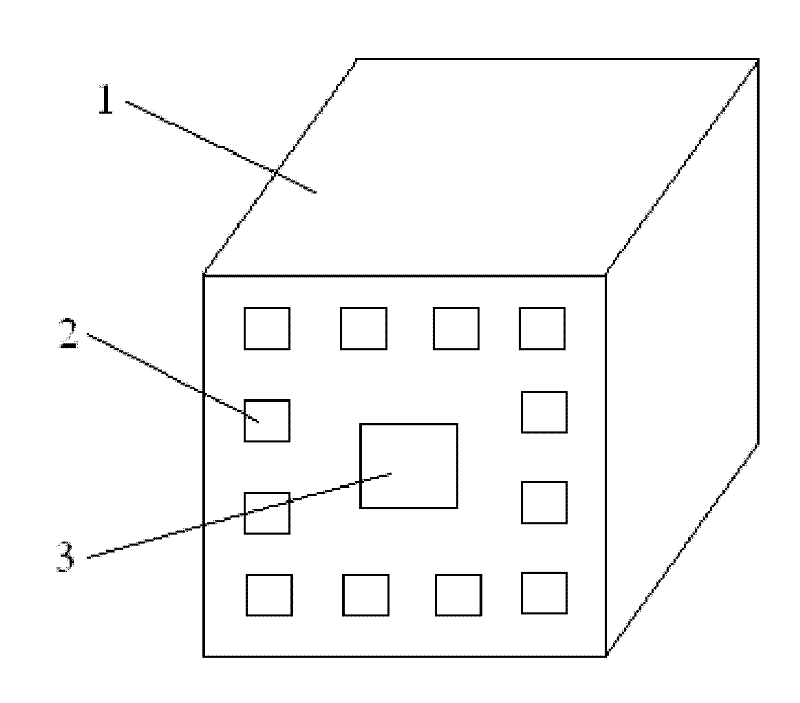

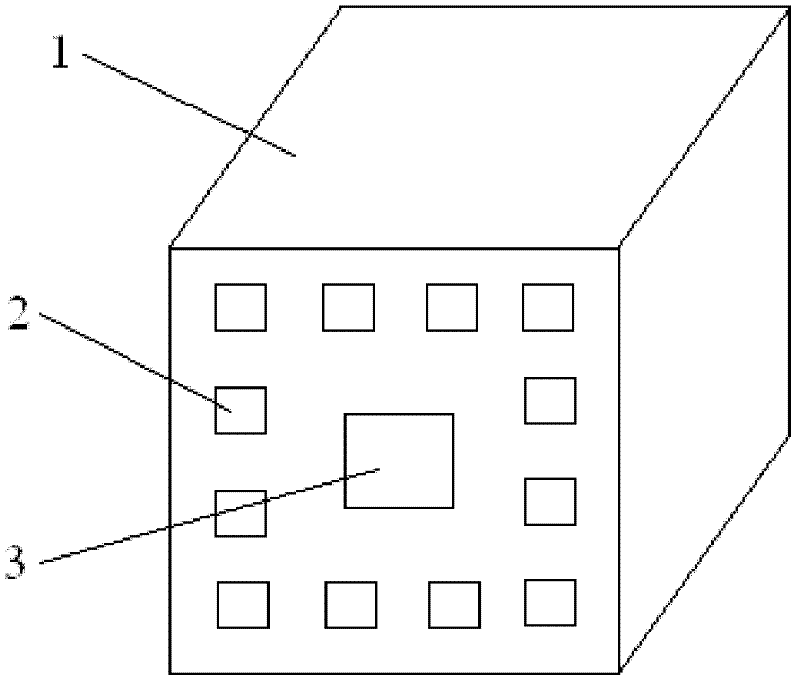

Porous ceramic and manufacturing process thereof

The invention discloses porous ceramic with good drainage performance and a manufacturing process. The porous ceramic employs silicon carbide, pottery clay, mullite, and iolite as aggregates; wollastonite and spodumene are used as auxiliary materials, and low temperature ceramic glaze powder is used as a fluxing agent; bamboo charcoal and wood chip are used as pore forming agents; the raw materials are prepared according to a certain proportion, paraffin is used as a binder for preparing a slurry, a hot pressure casting and forming machine is used for preparing green compacts, and one-time wax discharging and sintering are carried out by a kiln in order to obtain finished products. Compared with prior art, the product has the functions of common porous ceramics, such as filtering, heat insulation, noise abatement and the like, and the product is characterized in that the product has liquid drainage, penetration, adsorption and fine filtering and other excellent functions, and at the same time, the product has high temperature resistance, quenching and quick heating resistance, and good thermal conductivity; in addition, the common ceramic raw materials are selected, and the porous ceramic has the advantages of low energy consumption, environmental protection without secondary pollution, low cost, and simple technology, and the ceramic is suitable for large scale production. The porous ceramic has wide applications and extremely good development prospects.

Owner:李安成

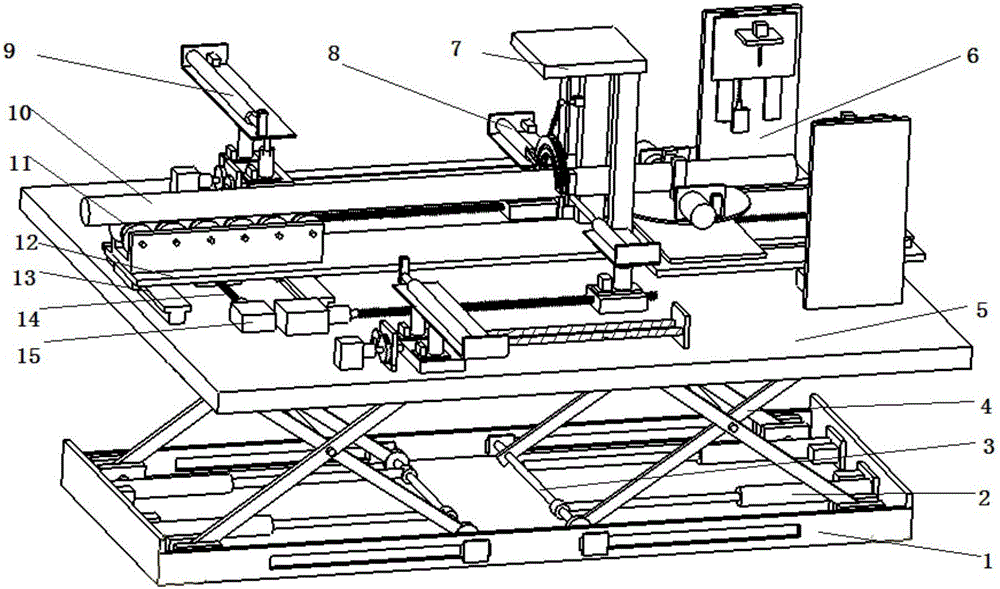

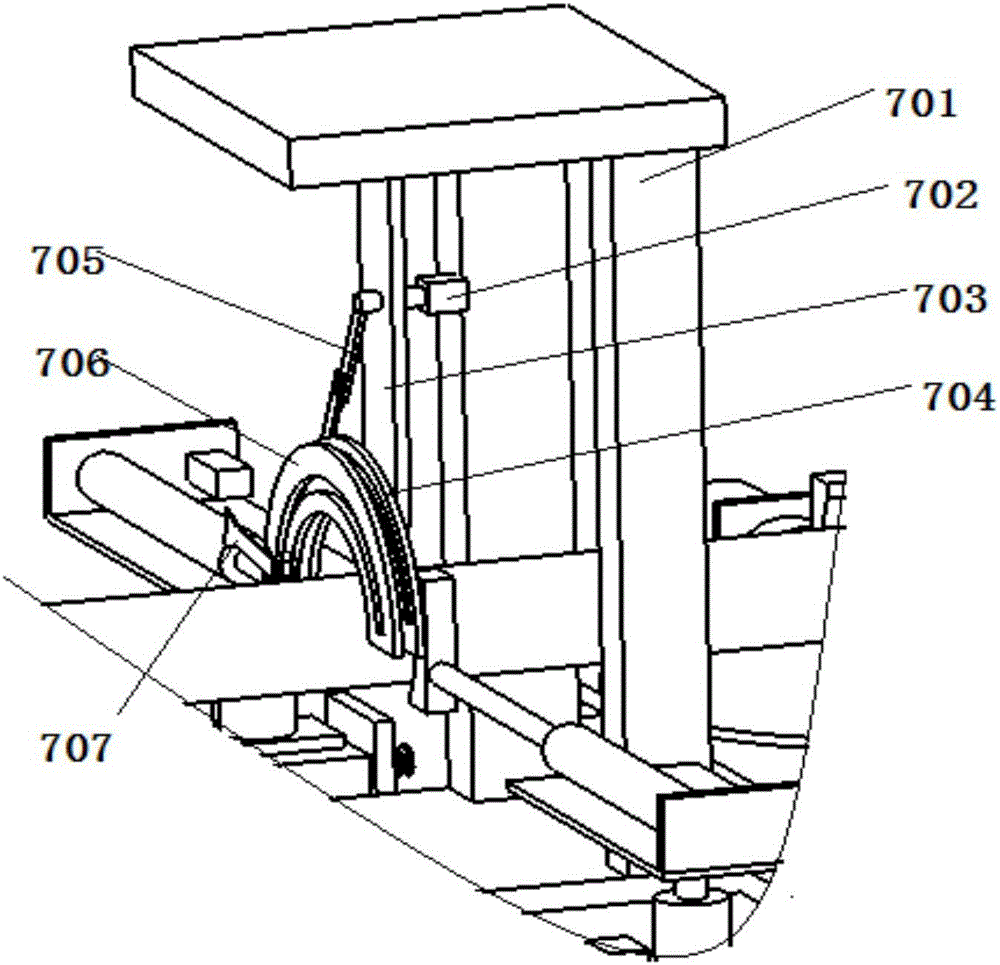

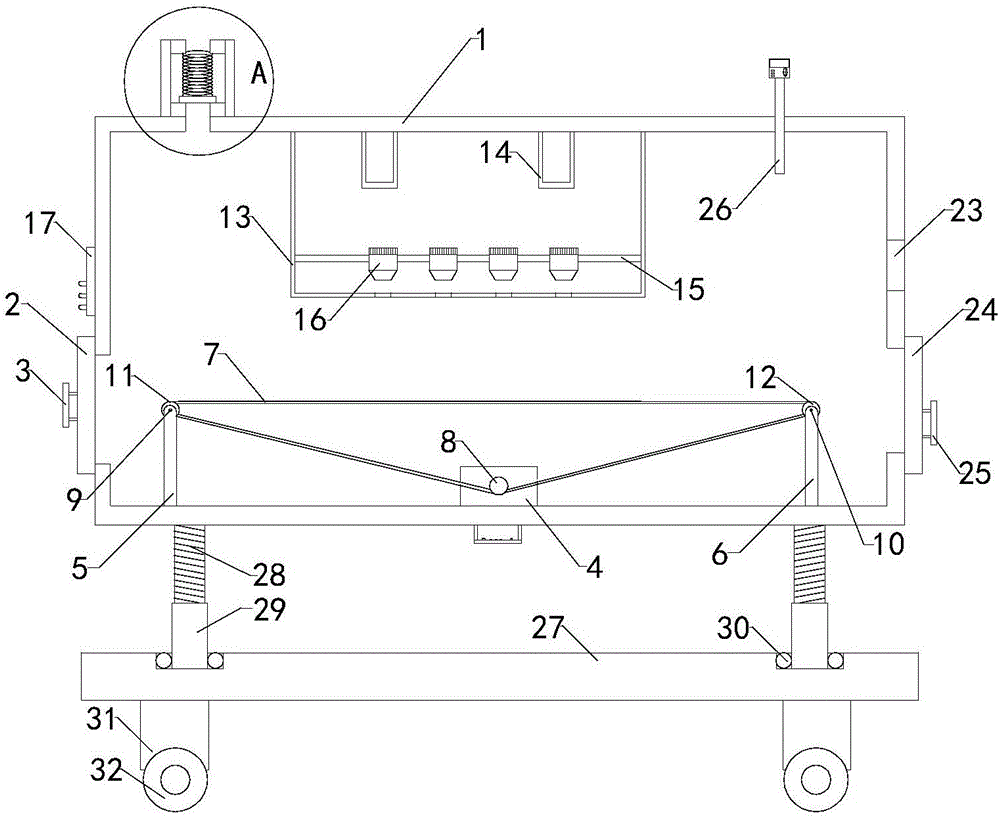

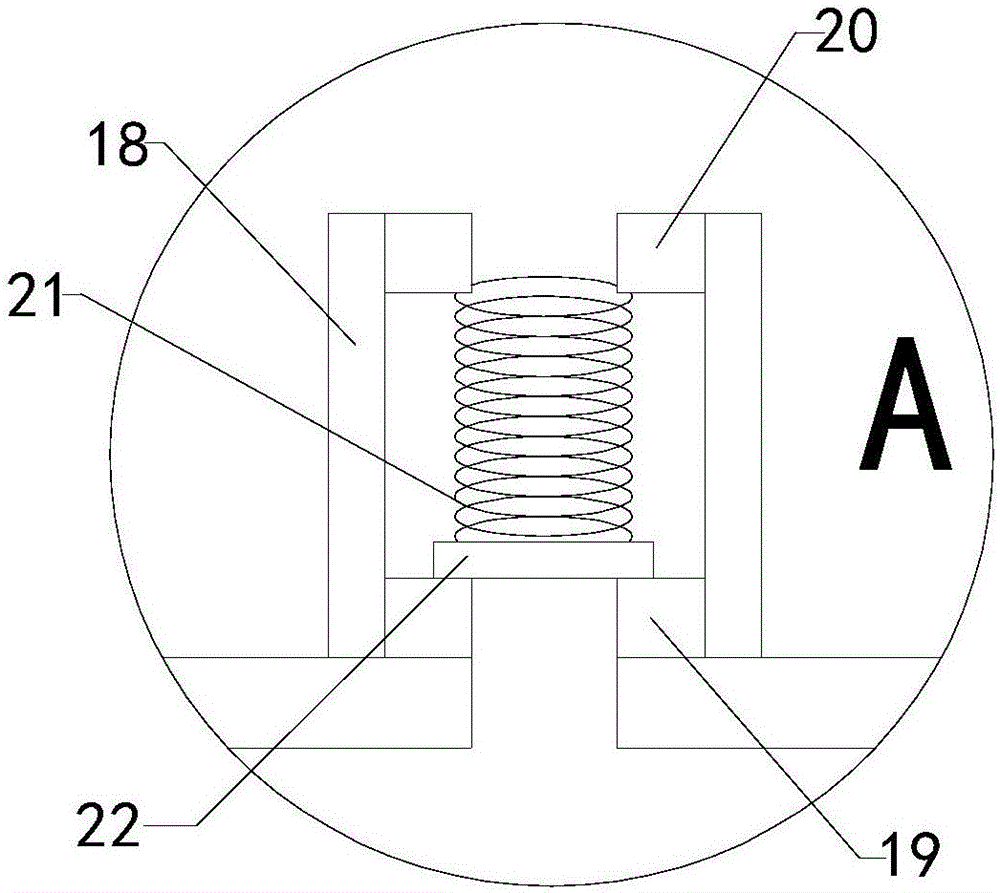

Equal-length glass tube batch production cutting device

InactiveCN106495457AReduce workloadReduce time for step-by-step processingEdge grinding machinesGlass severing apparatusBatch productionEngineering

The invention provides an equal-length glass tube batch production cutting device which comprises a base and a lift plate. A pad plate is slidably connected to the lift plate, rollers are arranged on the pad plate, a clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism, the first clamping mechanism comprises a first motor and a first transmission rod, the cutting mechanism comprises a support and a cutter arranged on the support, a first arc connection plate and a second arc connection plate are arranged on the support, the milling mechanism comprises a side wall and a milling cutter slidably connected with the side wall, and a sliding plate is slidably connected to the pad plate. By using the equal-length glass tube batch production cutting device, cutting and milling of equal-length glass tubes can be completely efficiently, staff's manual operation during the entire process is omitted, potential safety hazards of staff are reduced, production efficiency is improved, and machining cost is reduced.

Owner:天津南玻节能玻璃有限公司

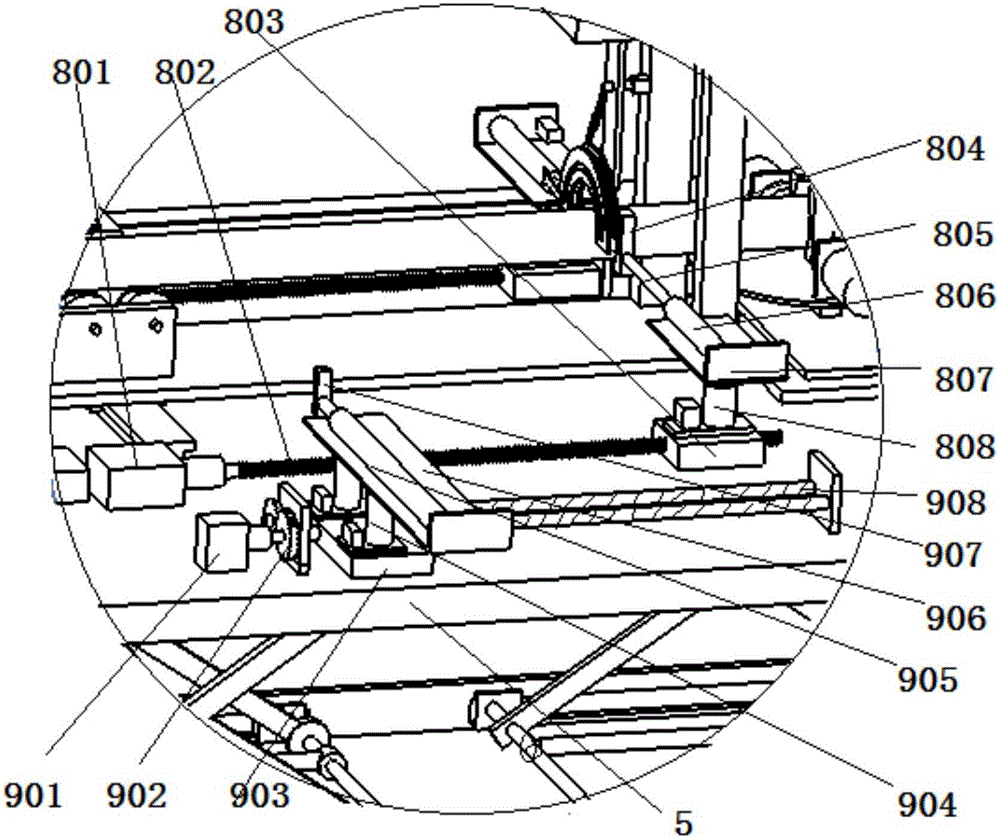

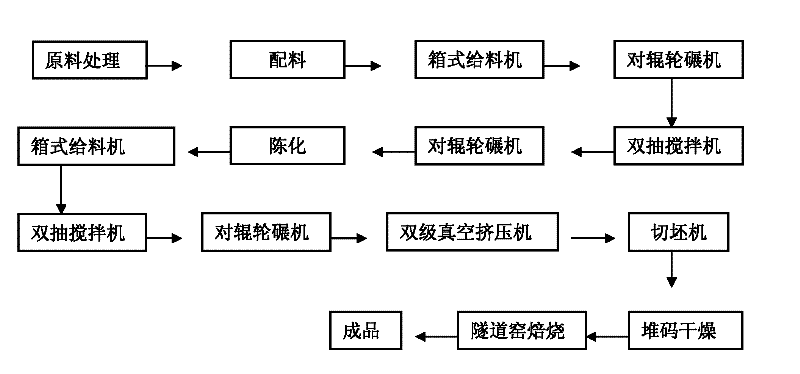

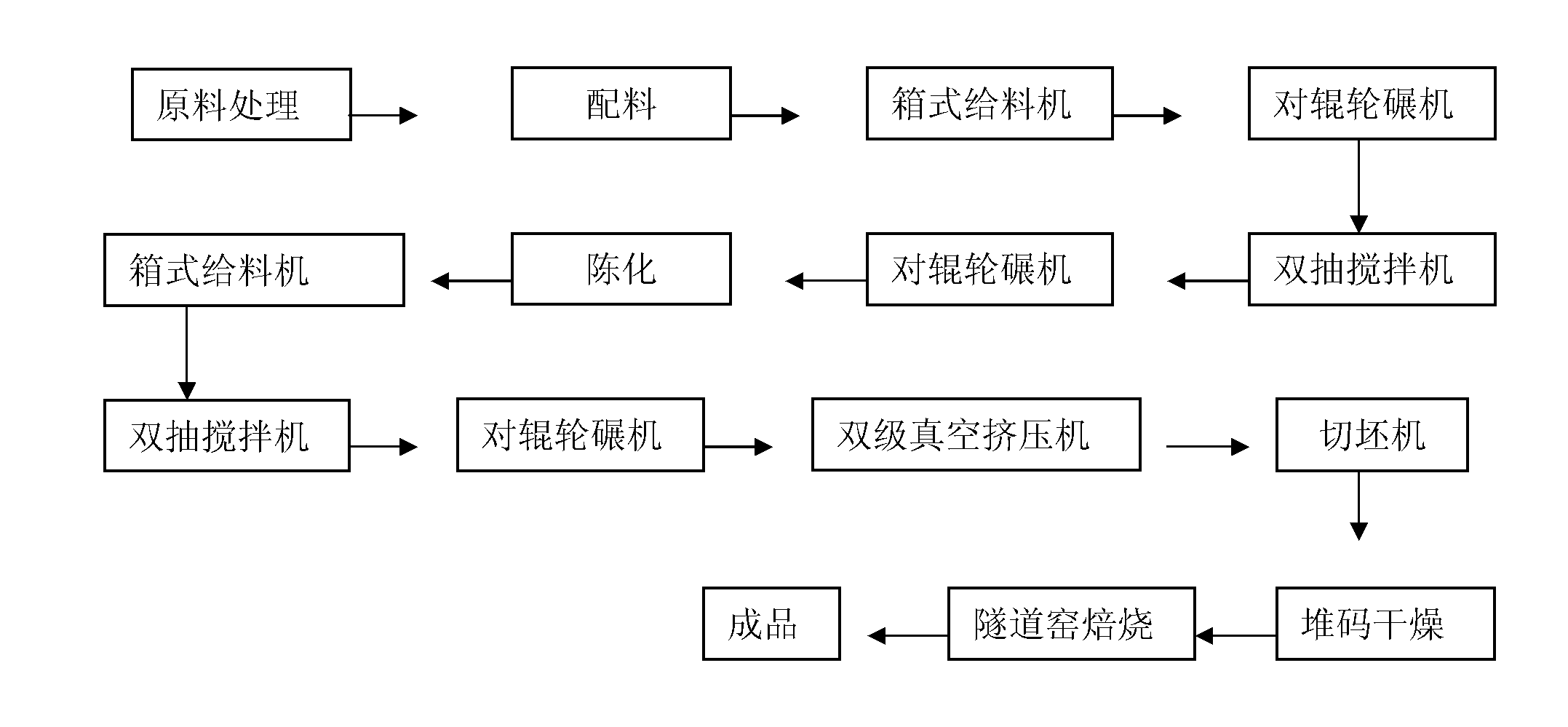

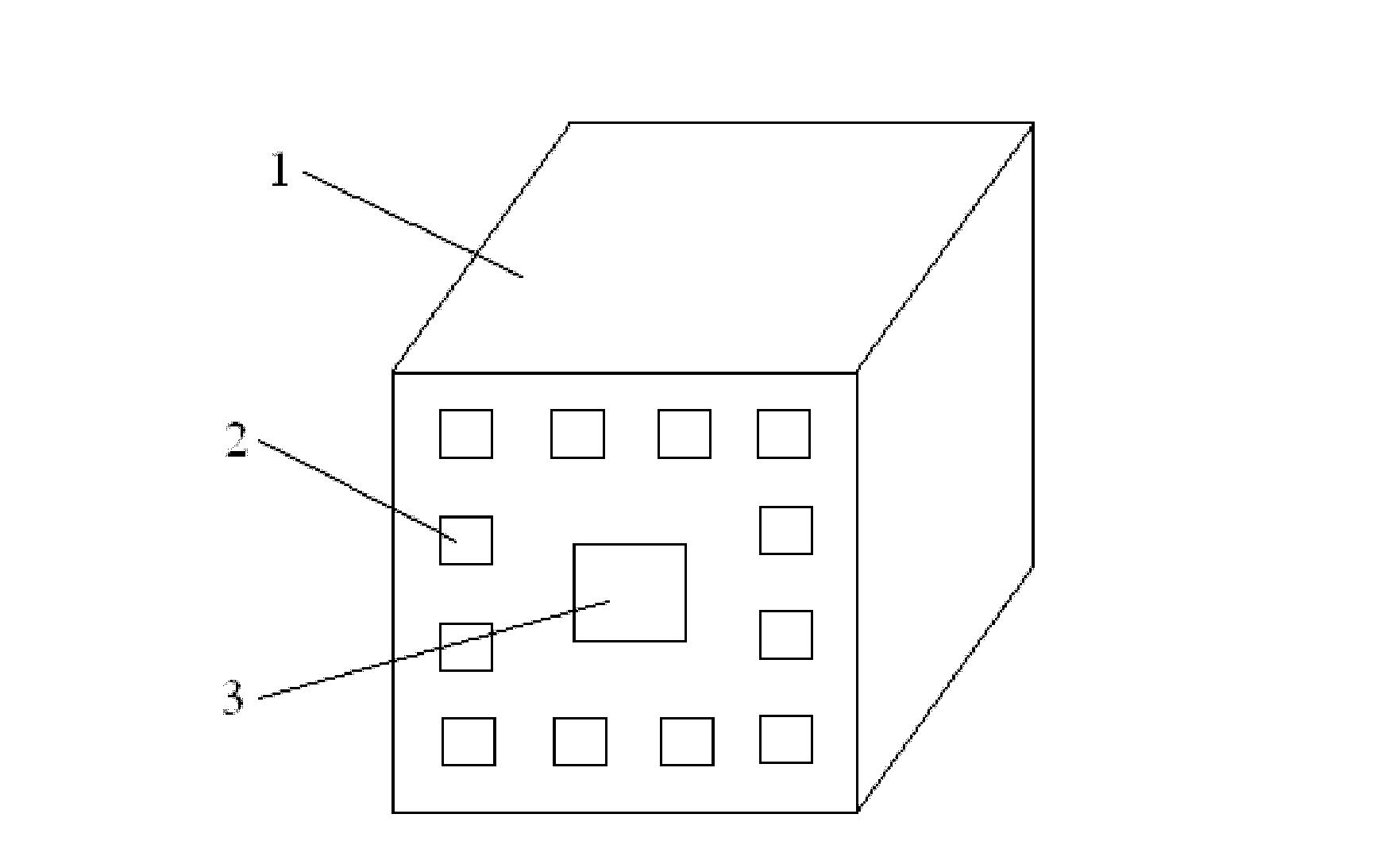

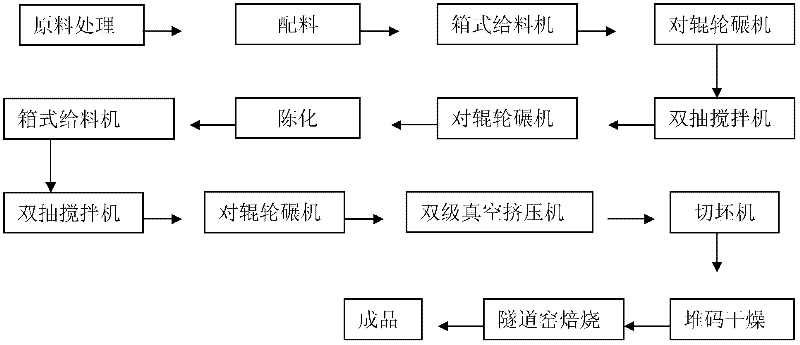

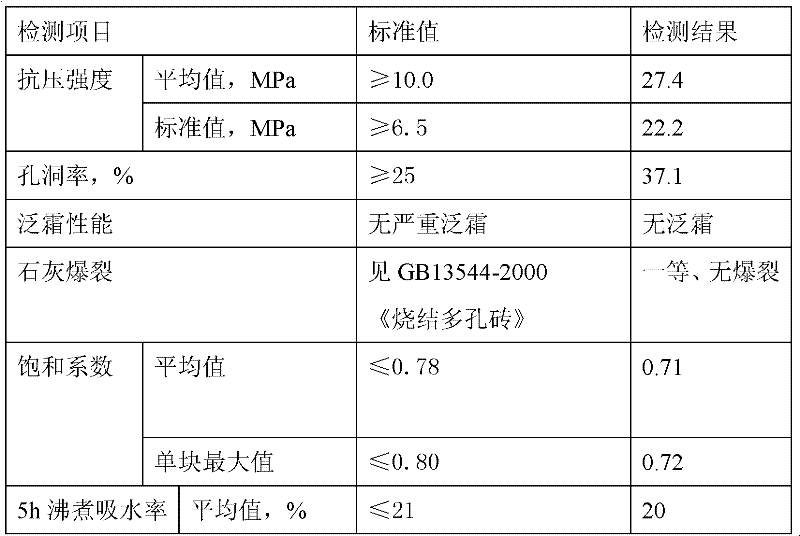

Slickens baked brick and production method thereof

The invention relates to a braked brick, specifically a braked brick prepared from slickens and a preparation process thereof. The sintering material of the slickens baked brisk, in terms of oven dry weight, comprises the following components in part by weight: 35 to 45 parts of slickens by weight, 30 to 45 parts of coal gangue or coal cinder by weight, 10 to 25 parts of engineering dregs or shale by weight, 5 to 10 parts of clinker by weight and 3 to 8 parts of fine sawdust or rice husks by weight. The material source of slickens baked brisk is extensive, so that the waste slickens is recycled to save the land resources and protect the cultivated land, thus the large-surface yield slickens waste which easily generates raise dust is sufficiently used for changing waste into valuable and purifying the environment. The acquired slickens baked brisk is thermally insulated and heat-insulated, shock and pressure resistant, free of decrustation and distortion, and difficult to break and burst; the yield can be more than 99%, thus the slickens baked brick is suitable for the large-scale industrial production.

Owner:上海鑫晶山建材开发有限公司 +1

Complex Tang-dynasty jun glaze with blue spots in black and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in black and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in black for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in black adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in black. According to the Tang-dynasty jun glaze with blue spots in black and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into glaze in black, are fired at a high temperature to form black glaze which is stable in color generation, uniform in color and luster and full of a jade texture, and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Phosphogypsum sintered brick and production process thereof

ActiveCN102503517AWide variety of sourcesSave land resourcesSolid waste disposalCeramicwareDistortionCoal gangue

The invention relates to a sintered brick, and concretely relates to a sintered brick prepared by using phosphogypsum and a preparation process thereof. The phosphogypsum sintered brick comprises the following sintering raw materials, by oven dry weight, 17-29.75 parts of phosphogypsum, 27.6-41.4 parts of coal gangue or 25.5-38.25 parts of coal slag, 22.5-30 parts of river silt, and 5-15 parts ofa dry powder additive. The phosphogypsum sintered brick of the invention has the advantages of wide raw material source, realization of the resource recovery of the waste phosphogypsum, land resourcesaving, cultivated land protection, full utilization of the phosphogypsum waste which is extensive and easily generates pollution, and environment purification through changing wastes into valuables The obtained phosphogypsum sintered brick which has the advantages of thermal insulation, earthquake resistance and stress resistance, no peeling or distortion, non-frangibility, non-explosion, and high yield of above 99%, is suitable for the industrial production.

Owner:上海鑫晶山建材开发有限公司 +1

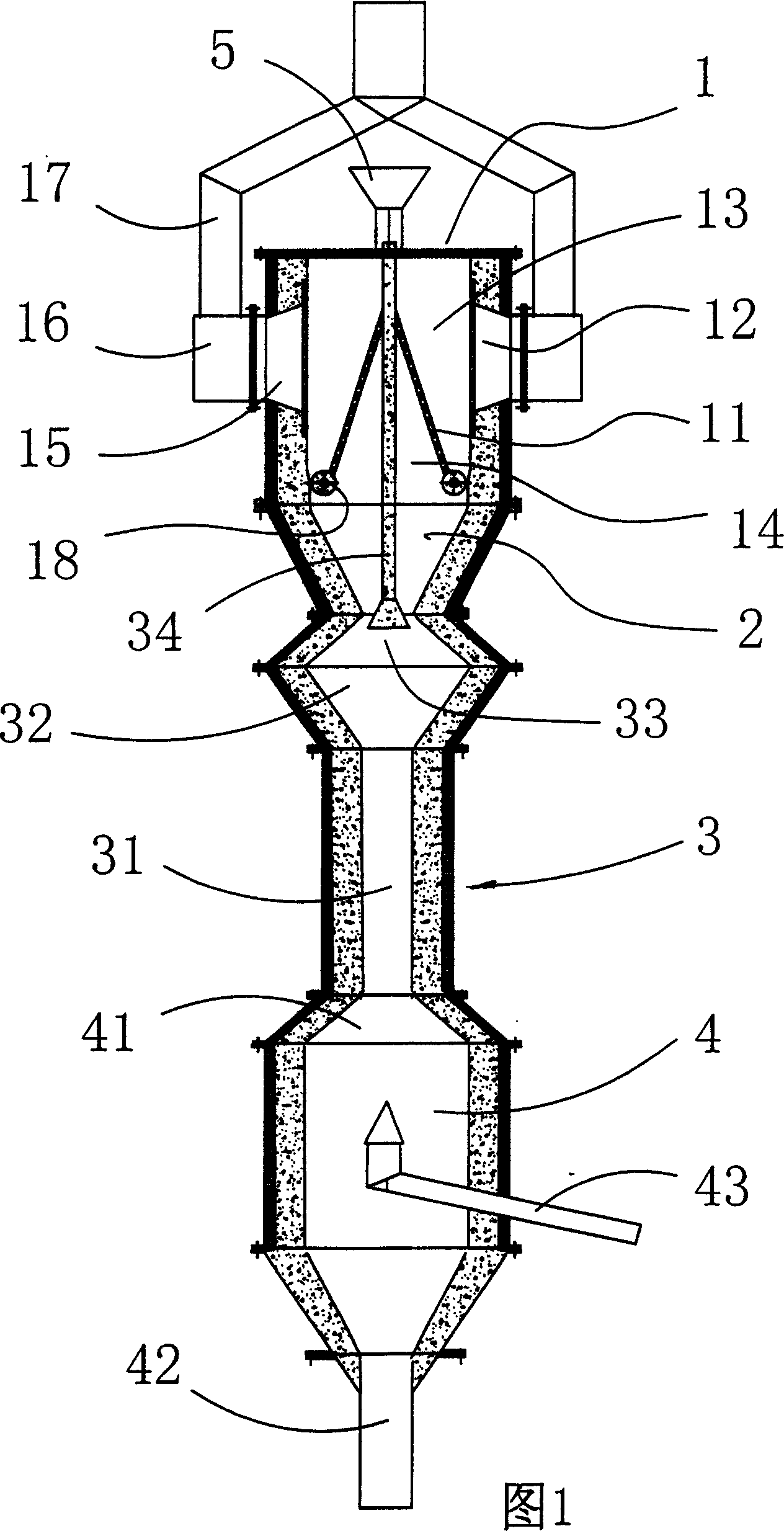

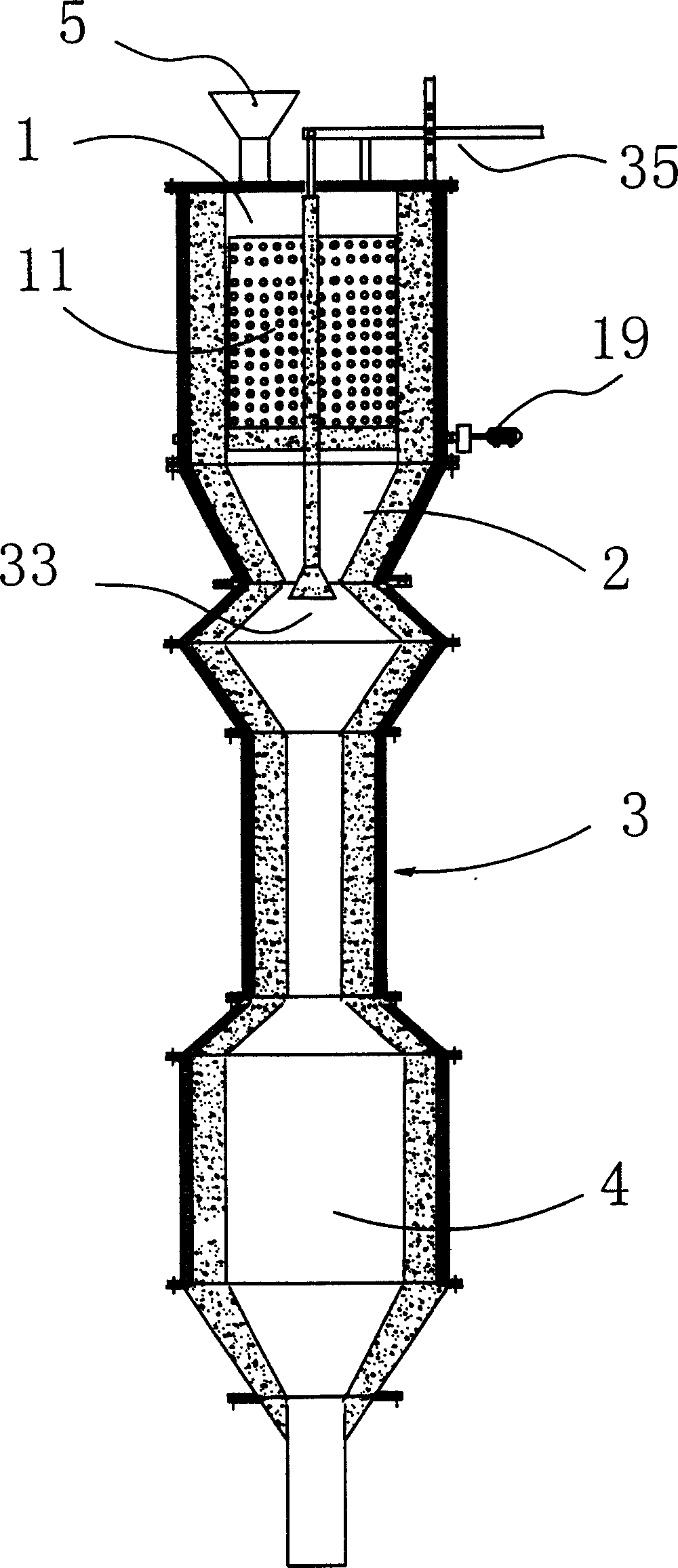

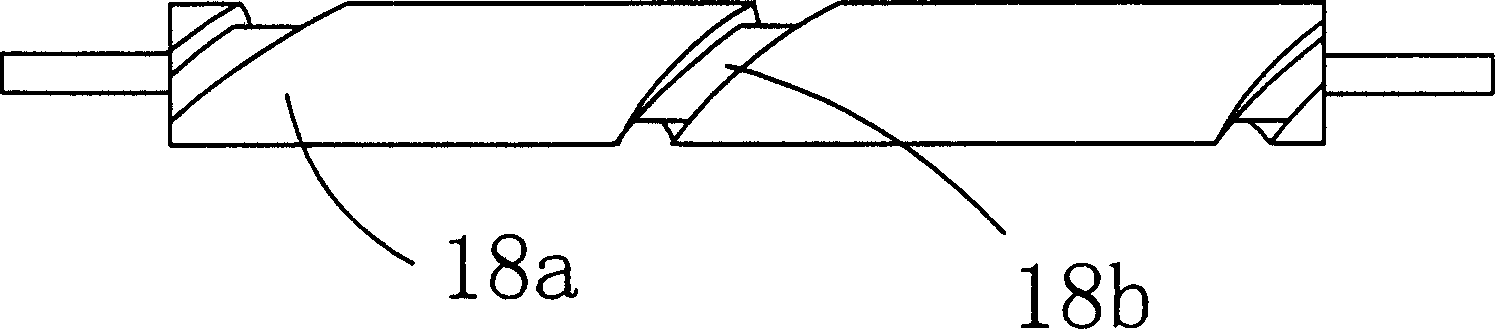

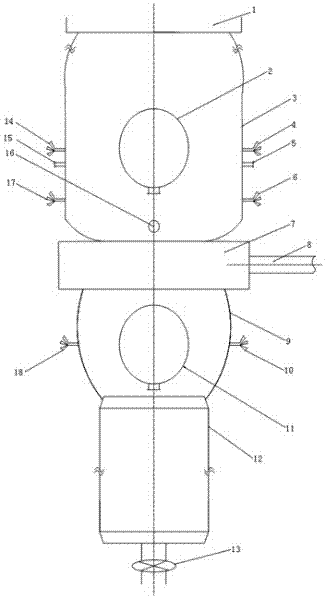

Equipment for calcinating cement clinker in large granule and fluidiazation

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

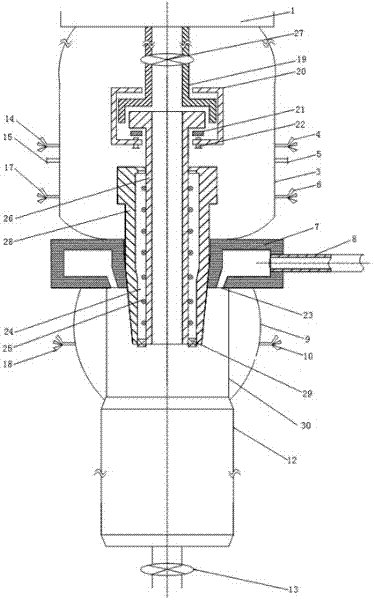

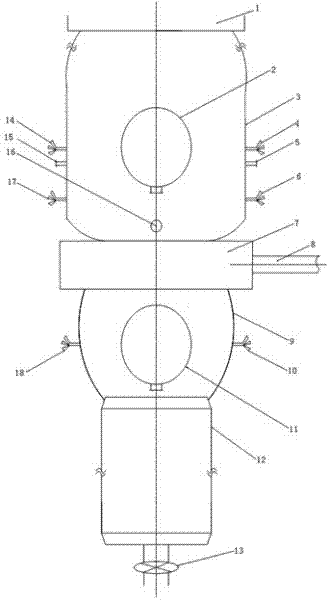

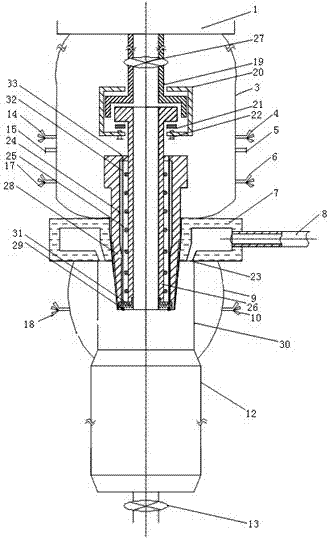

Totally closed gas atomization pulverization device

The invention discloses a totally closed gas atomization pulverization device. The device comprises a heat insulation crucible, an atomizer, an atomization tower, a telescopic plastic pipe A, a telescopic plastic pipe B and the like, wherein the atomizer is arranged in the telescopic plastic pipe A; the telescopic plastic pipe A is respectively connected with the heat insulation crucible and the upper surface of a nozzle of the atomizer in a sealed mode; the atomization tower is connected with the lower surface of the nozzle through the telescopic plastic pipe B in the sealed mode; and two half metal cylindrical barrels are arranged in inner and outer metal grooves on the lower surface of the nozzle and on the atomization tower, so that a totally closed system structure is formed. The structure can prevent oxide and nitride from being formed on the atomizer and blocking the atomizer. The totally closed gas atomization pulverization device has the advantages that: the device has a simple structure and is convenient to install, blocking is effectively prevented, the quality of powder is improved, and the like.

Owner:SHANGHAI INST OF TECH

Complex Tang-dynasty jun glaze with white spots in blue and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with white spots in blue and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in blue for glazing; applying slurry of the glaze with white spots in surface points of the plain carcass after the slurry of the glaze in blue adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with white spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with white spots in blue. According to the Tang-dynasty jun glaze with white spots in blue and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into a glaze material of glaze in blue, and the position of the glaze with white spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

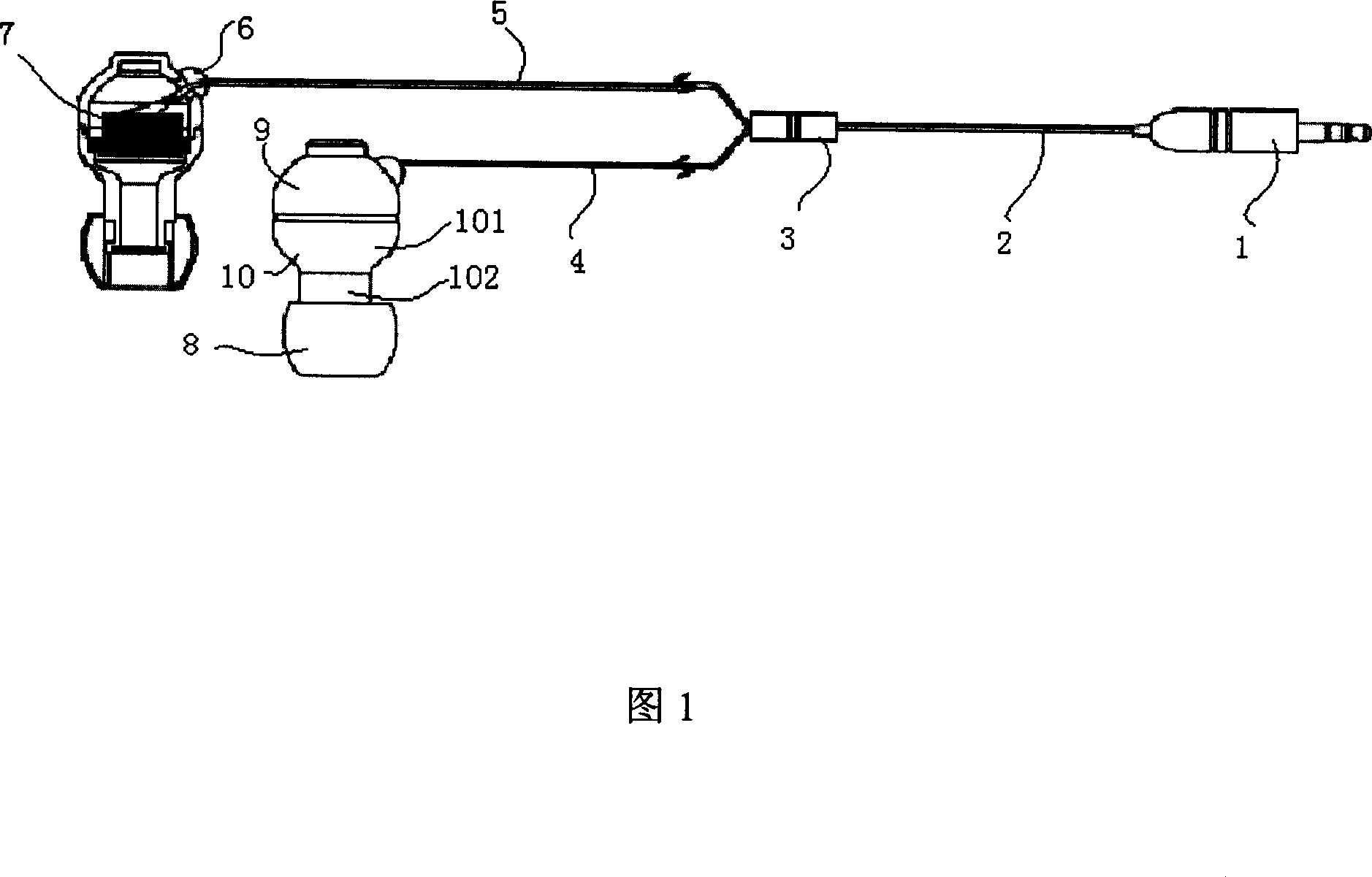

Built-in earphone

InactiveCN1929692AOvercoming technical biasUniform textureEarpiece/earphone attachmentsEngineeringSound quality

This invention discloses one ear small phone to process ear phone front and back shells, wherein, the materials is of good resistance property to absorb redundant vibration besides trumpet to make the sound quality more pure, clear; the materials quality is of good spring and tightness to absorb trumpet.

Owner:张耀国

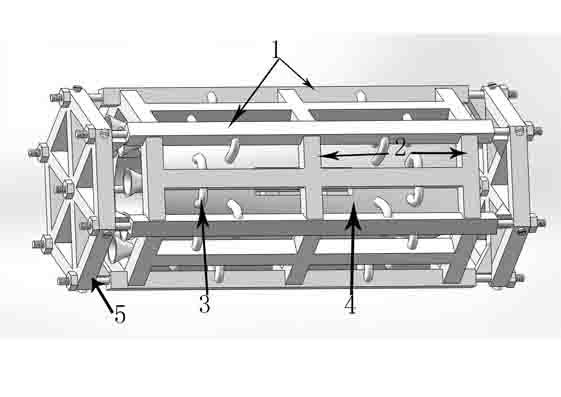

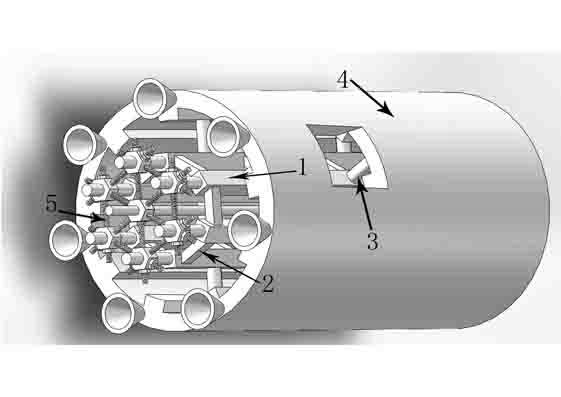

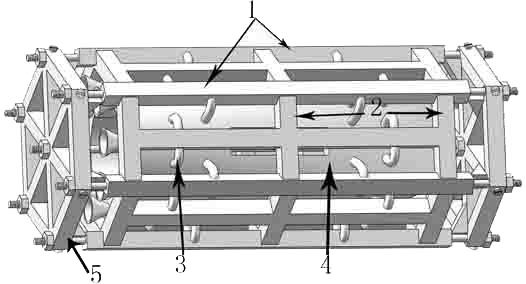

Squirrel-cage shell load bearing structure integrated with runner film tire

ActiveCN102658355ANo deformationGuaranteed structural strengthFoundry mouldsFoundry coresMechanical engineeringPrecision casting

The invention discloses a squirrel-cage load bearing structure integrated with a runner film tire in a fusible pattern precision cast shell manufacturing process. The squirrel-cage load bearing structure comprises an embedded primary-secondary runner film tire 1, a transverse runner film tire 2, an inner runner film tire 3 and a bracket 5, wherein the primary-secondary runner film tire is a main shell load bearing member, passes through the bottom of a runner, is connected with the transverse runner film tire in a wax welding way, and is tightly fixed on the bracket, so that a squirrel-cage structure is formed; and the primary-secondary runner film tire, the transverse runner film tire and a wax pattern 4 are connected together by using the inner runner film tire (inner water port shape) in a wax welding way. Due to the adoption of the structure, load bearing in the shell manufacturing process of ultra-conventional large-sized and super large-sized shells is realized, the size is up to 600mm*600mm*1800mm or even larger, the weight is up to hundreds of kilograms or even certain tons, the structural strength and stiffness can be ensured effectively, a pouring system and the wax pattern are prevented from being broken and deformed and are convenient to move, rotate and place, and convenience is brought to shell manufacturing operation of workers.

Owner:SUS LAB FOR IND SCI & TECH

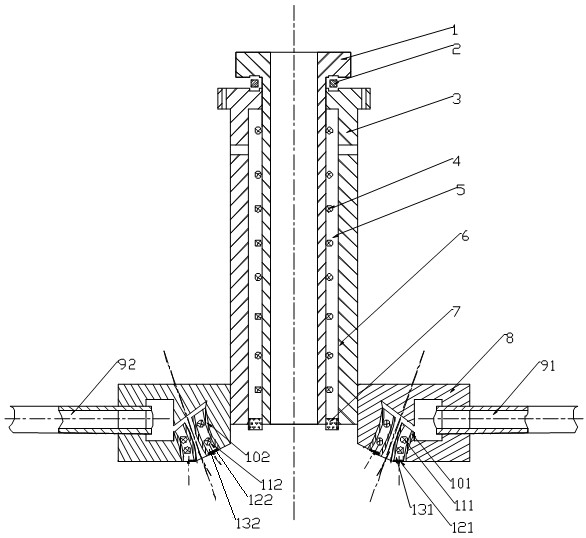

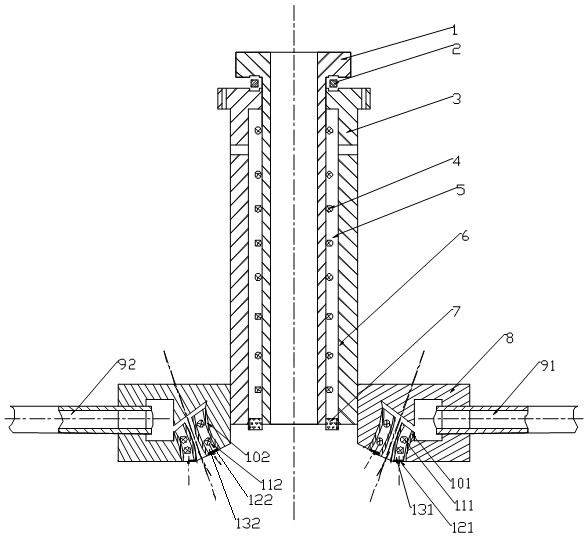

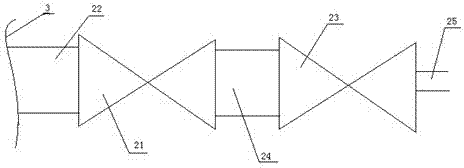

Atomizer capable with nozzle and flow guide tube prevented from blockage

The invention discloses an atomizer with a nozzle and a flow guide tube prevented from blockage. The atomizer is composed of a flow guide tube, a metal jacket, a nozzle, a heating body A, a ceramic sealing ring, a metal sealing ring, a gasket and the like, wherein a gap between the flow guide tube and the metal jacket is provided with the heating body A; a heating body B is arrange each of gaps of the two Laval-structure air outlet tubes of the nozzle; the inner surface of the metal jacket is provided with a metal reflection film or a sprayed white reflection coating; the lower end part of the metal jacket and the lower end part of the flow guide tube are level; the end part of a gap between the lower end part of the metal jacket and the lower end part of the flow guide tube is sealed by the ceramic sealing ring; and the end parts of the gaps between the two Laval-structure air outlet tubes of the nozzle are in threaded connection and sealed by the metal sealing ring. The atomizer has the functions of effectively preventing metal and alloy from being blocked and solving the blockage problem, is suitable for melt flow guidance for metal or alloy atomization, has the advantages of simple structure and the like, and is convenient to install, and the production efficiency can be improved.

Owner:SHANGHAI LUOKE CENT CONTROLLED ENERGY SAVING TECH CO LTD

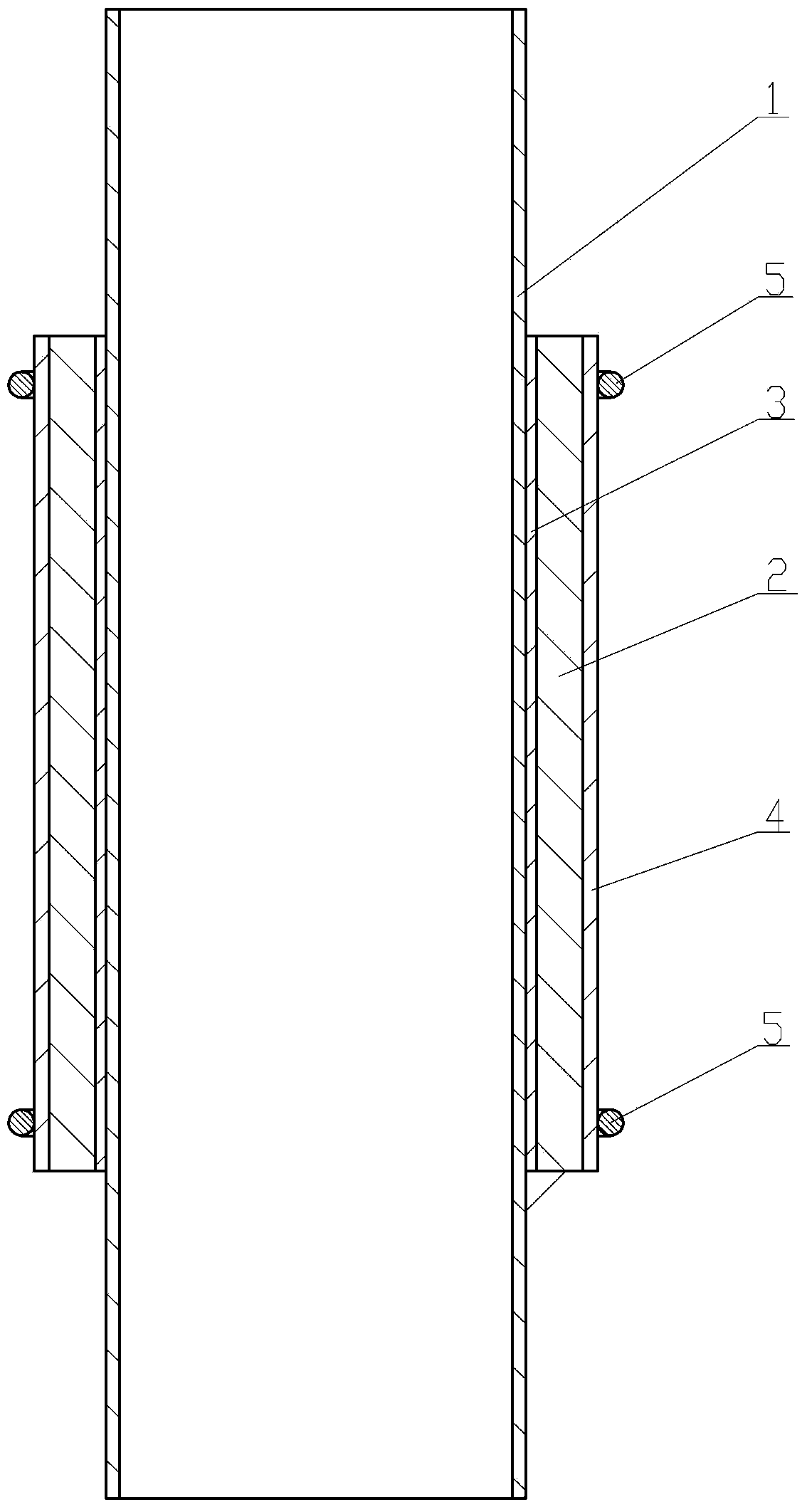

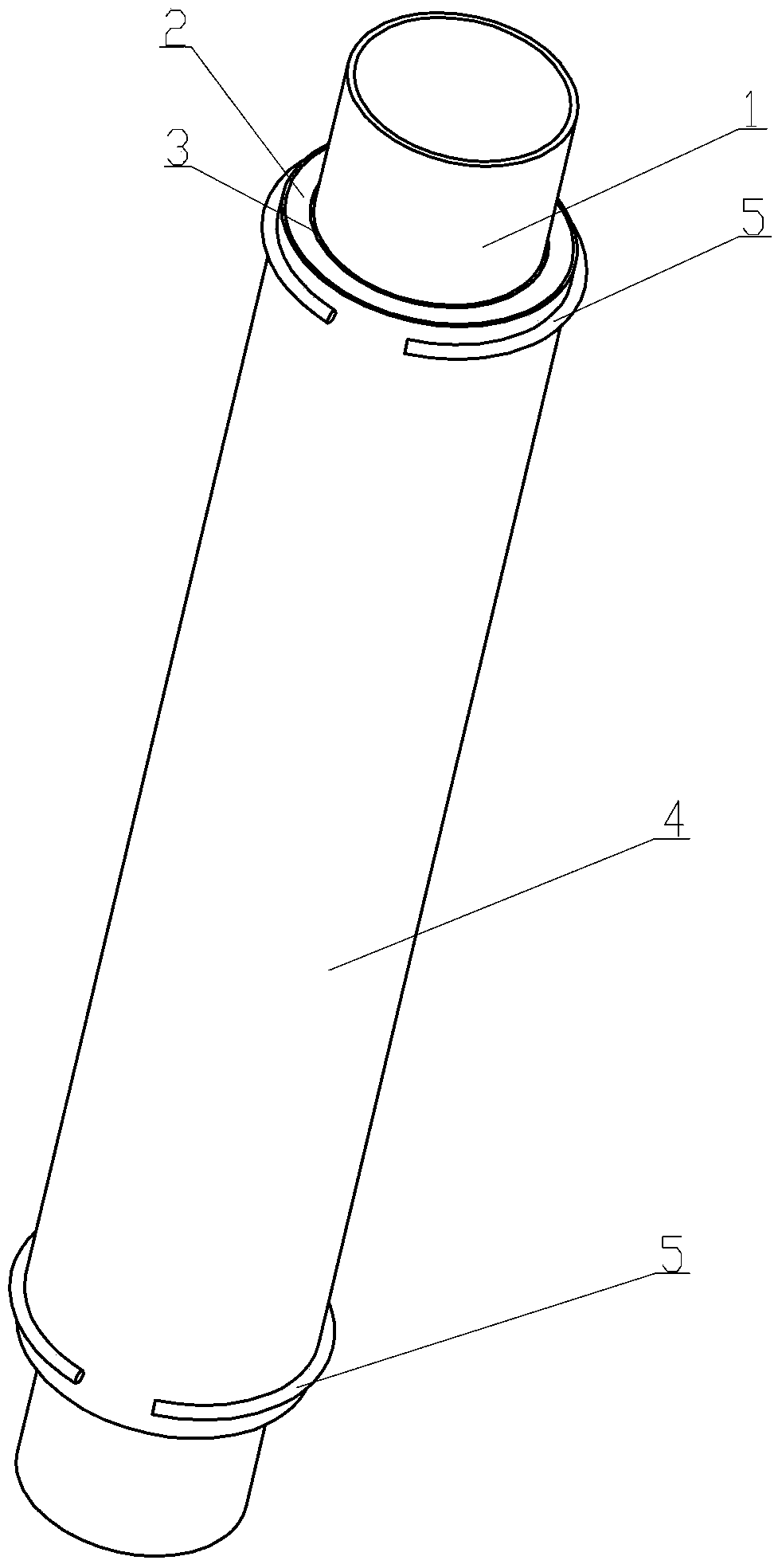

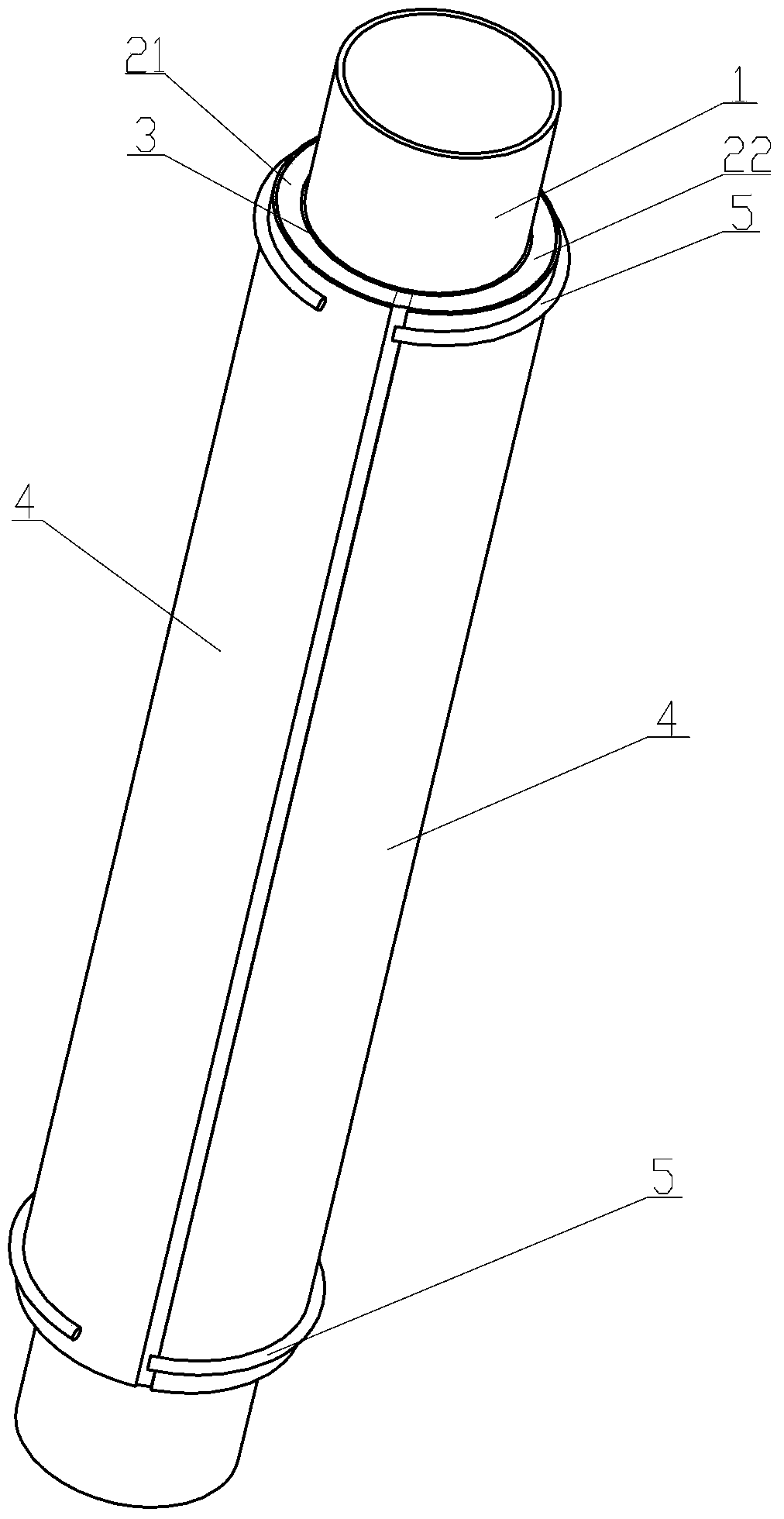

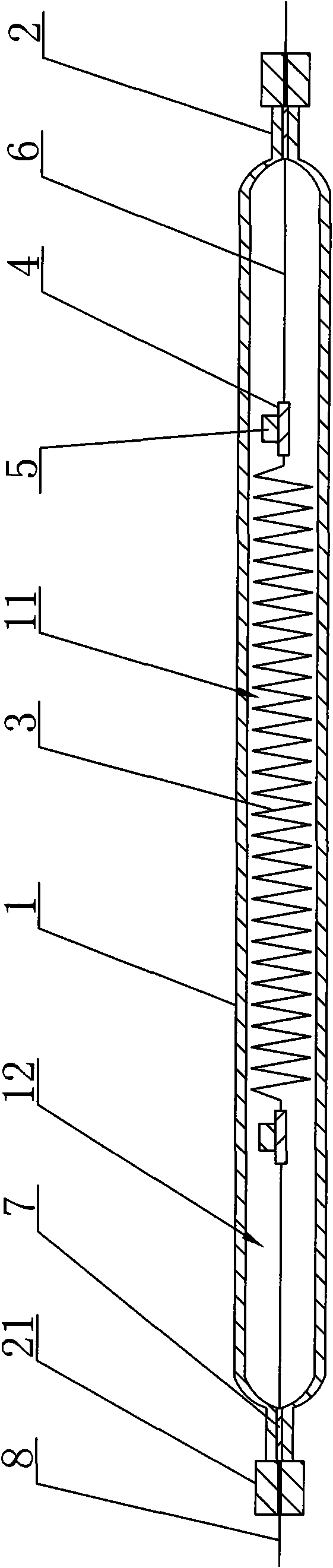

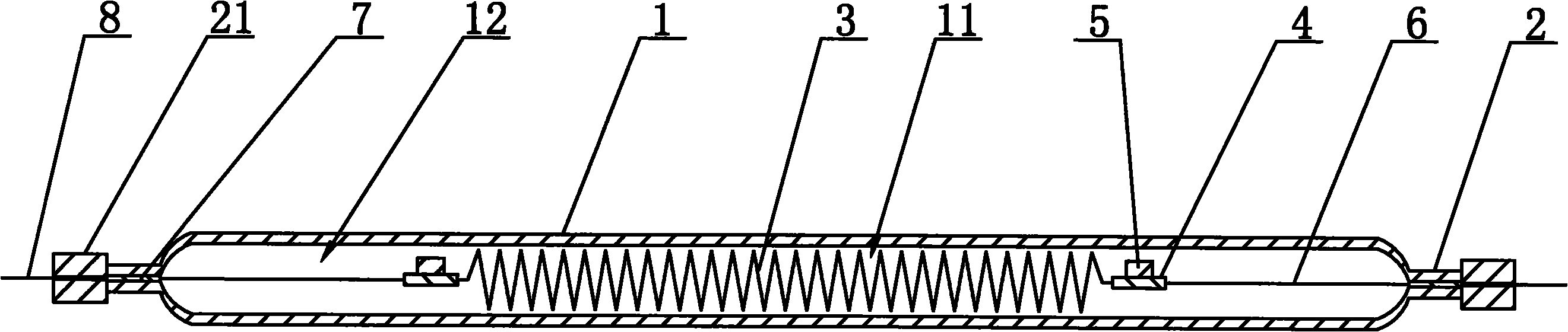

Electric heating pipe for heating liquid

ActiveCN103369748ANot easy to burstPrevent burstHeating element shapesHeating element materialsInsulation layerHeat conducting

The invention relates to an electric heating pipe for heating liquid. The technical points are as follows: the electric heating pipe comprises a metal pipe, an insulation layer is arranged outside the metal pipe, a heat conducting layer is arranged between the metal pipe and the insulation layer, a heating membrane is arranged outside the insulation layer, and electrodes for leading current to the heating membrane are arranged on the heating membrane. The electric heating pipe has a simple structure and high heat transfer performance and safety performance, and the whole device can be effectively prevented from explosion.

Owner:LITTLE STONE CERAMIC BLADE ZHONGSHAN CO LTD

Production method of stainless steel band used for internal round diamond blade

The invention discloses a production method of a stainless steel band used for an internal round diamond blade. The production method comprises the following steps: rolling a stainless steel cold-rolled intermediate blank with thickness of 0.6-1.2mm at least once by adopting a 12-roller cold rolling mill unit, thus obtaining a rolled semi-finished stainless steel band with thickness of 0.2-0.6mm, and carrying out solution treatment every time after the rolling; then rolling the semi-finished stainless steel band with thickness of 0.2-0.6mm by using the 12-roller cold rolling mill unit to obtain a finished stainless steel band with thickness of 0.1-0.12mm; and finally, cleaning and continuously relieving stress. By using the production method disclosed by the invention, the stainless steel band can be made after steps such as semi-finished product rolling, solution treatment, finished product rolling, cleaning, stretching, bending, straightening treatment and stress relieving treatment. The produced internal round diamond blade utilizing the stainless steel band has the characteristics that the hardness is easier to control, and the hardness scope can be controlled within Vickers hardness HV+ / -15. Therefore, in the process of manufacturing the internal round diamond blade, deformation and crack are not easy to occur, the blade service life is long. the blade can be used for about 1500 times, and the production cost is also reduced.

Owner:冶科金属有限公司 +2

Silk-screen UV glaze printing ink and preparation method thereof

The invention discloses silk-screen UV glaze printing ink and a preparation method thereof, and belongs to the technical field of printing ink and preparation thereof. The printing ink is prepared from 28-32% of epoxy modified acrylate, 18-22% of urethane acrylate, 8-12% of tri(propylene glycol)diacrylate, 18-22% of 1,6-hexamethylene diacrylate, 6-10% of a 184 macroinitiator, 3-7% of an active-amine auxiliary photoinitiator, 0.8-3% of an organosilicone flatting agent, 0.8-3% of an organosilicone antifoaming agent and 3-7% of fumed silica, and is prepared by processes of mixing, stirring at a high speed, grinding, and the like. The preparation method is simple. The printing ink prepared by the method has a transparency effect and a matte effect, thus satisfying a conceive of applying the technical quality of blue and white porcelain and other famous porcelain in history to packaging and printing, and simulating the glaze quality, of the porcelain, that is mild and humid like jade. The printing ink provided by the invention has high environmental protection property. The VOCs smell residue totally reaches requirements of the national standards.

Owner:ZHEJIANG MINONG CENTURY GRP +1

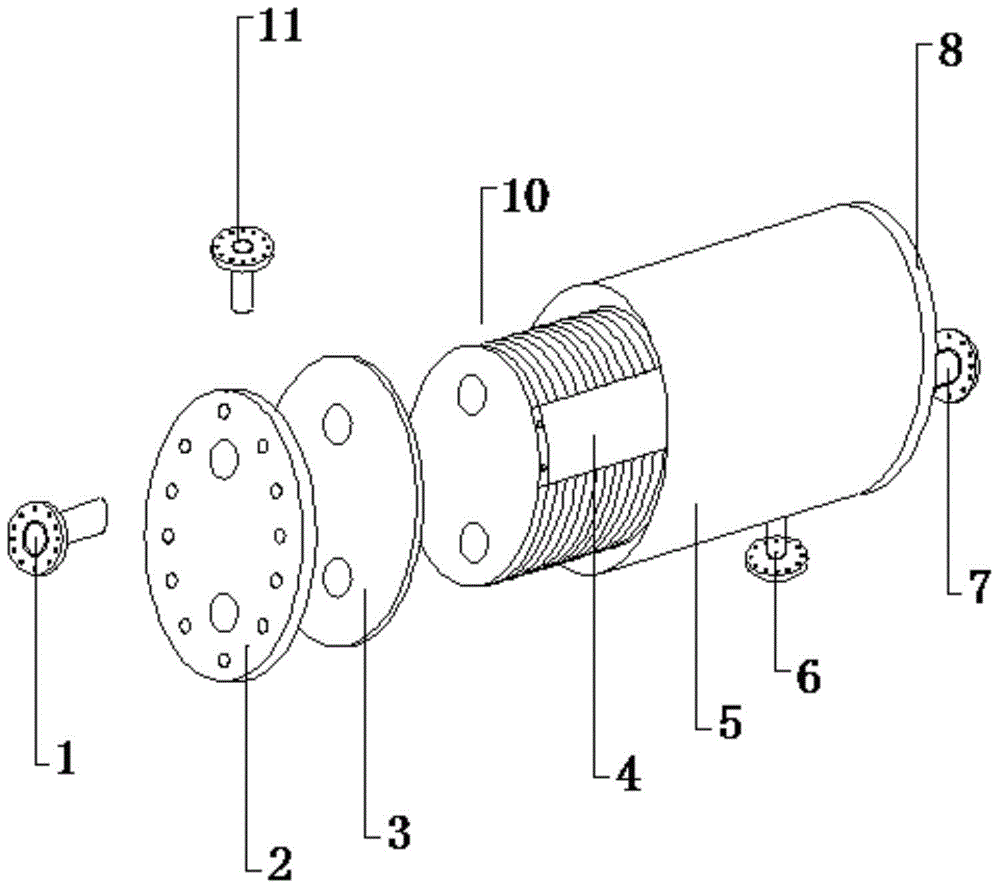

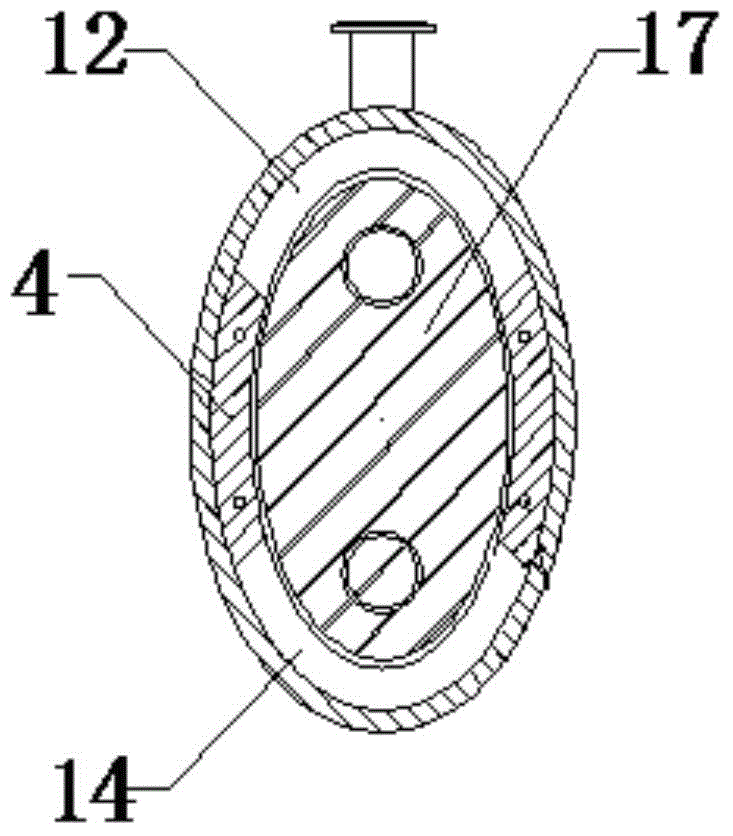

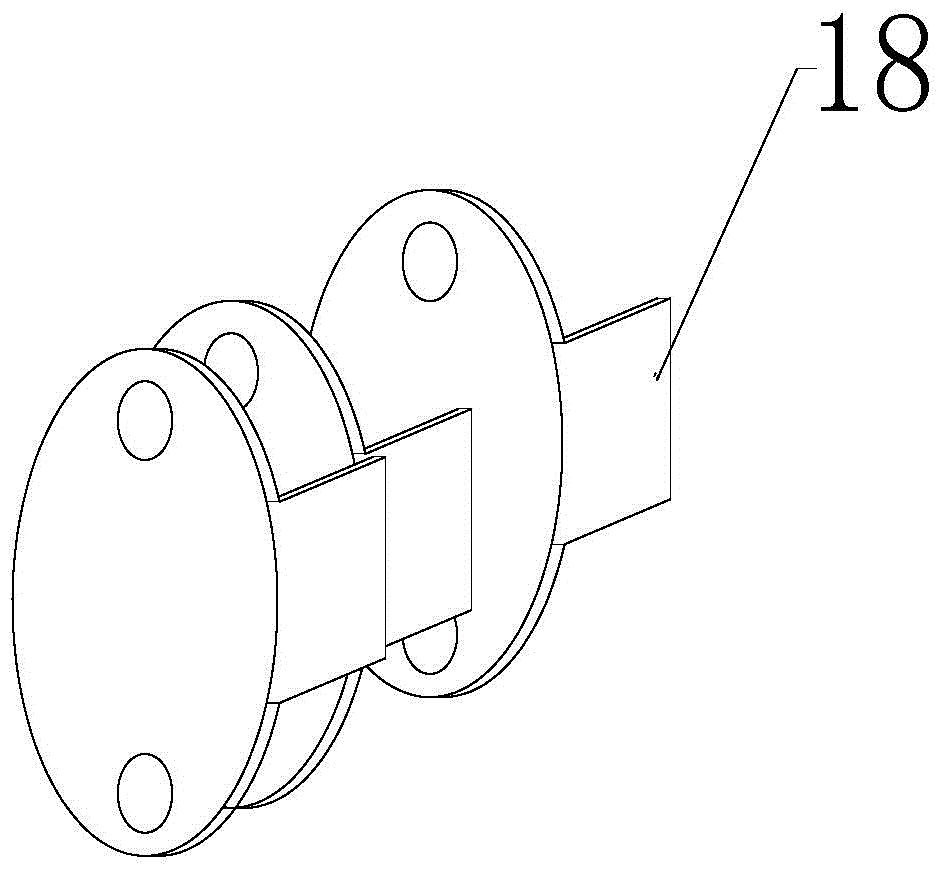

Plate-shell heat exchanger with oval corrugated plates

InactiveCN104089503AImprove heat transfer efficiencyReduce leakageLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention relates to a plate-shell heat exchanger with oval corrugated plates. The multiple oval corrugated plates form a corrugated plate bundle, each corrugated plate is provided with two corner holes correspondingly, the corrugated plate bundle is arranged in a shell, the shell is provided with a plate pass inlet and a plate pass outlet, and the plate pass inlet and the plate pass outlet are communicated through the corner holes in the corrugated plates; a guide block is formed between the corrugated plate bundle and the shell and divides the annular area between the corrugated plate bundle and the shell into a shell pass inlet cavity and a shell pass outlet cavity; the shell is provided with a shell pass inlet and a shell pass outlet correspondingly. The plate-shell heat exchanger is characterized in that the corrugated plates are oval, and the two corner holes of each corrugated plate are formed in the upper portion and the lower portion of the corrugated plate respectively.

Owner:HARBIN ENG UNIV

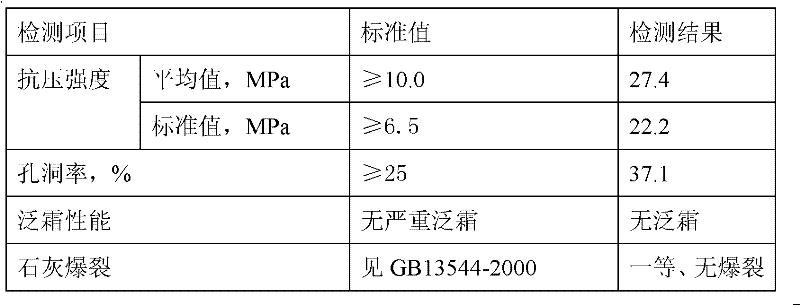

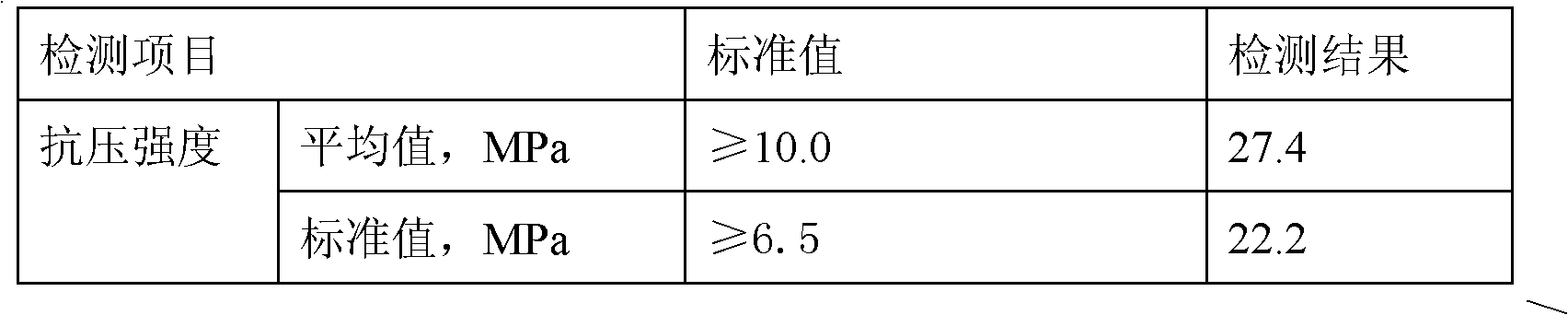

White-mud baked brick and production method thereof

The invention relates to a baked brick, in particular to a baked brick prepared from white mud of a paper plant and a preparation process thereof. Baking raw materials of the white-mud baked brick provided by the invention comprise the following components in parts by weight according to absolute dry weight: 28-36 parts of the white mud, 27.6-41.4 parts of coal gangue, 12-20 parts of project dregs or 13.5-22.5 parts of shale, and 5-15 parts of clinker. The white-mud baked brick provided by the invention has the advantages of wide resource of the raw materials and reutilization of the waste pollutant white mud, so that the land resource is saved, the cultivated land is protected, the white mud of the paper plant which has a wide range and great amount and is easy to cause secondary pollution is sufficiently utilized, wastes are changed into valuable things and the environment is purified. The white-mud baked brick provided by the invention has the advantages of heat preservation and heat insulation, seismic resistance and pressure resistance, no peeling or hoarseness, and uneasiness of being crushed and burst, and the yield can reach to be more than 99 percent, so that the white-mud baked brick is applicable to industrial production in a large scale.

Owner:上海鑫晶山建材开发有限公司 +1

Carbon fiber quartz heating tube

InactiveCN101909372AIncrease temperatureNot easy to burstOhmic-resistance heating detailsHeating element shapesFiberVolatile substance

Owner:苏州中龙光电科技有限公司

Archaistic ceramic art ware made by utilizing magnetite tailing and manufacturing process thereof

ActiveCN107200558AImprove heat resistanceImprove breathabilityCeramic materials productionClaywaresHeat resistanceLaterite

The invention belongs to the field of daily ceramic products, and particularly speaking, relates to archaistic ceramic art ware made by utilizing magnetite tailing and a manufacturing process thereof. According to the archaistic ceramic art ware made by utilizing the magnetite tailing, the magnetite tailing, laterite, spodumene and vesuvianite are used as raw materials for a green body. According to the archaistic ceramic art ware made by utilizing the magnetite tailing, the plasticity of a ceramic green body is improved; the production cost is decreased; the rate of finished products is improved; a ceramic product with the water absorption of 8 percent can be made. A product of the archaistic ceramic art ware is maroon; black granular spots are distributed in a ceramic body, so taht a sand inclusion texture is formed; the archaistic ceramic art ware is good in heat resistance and air permeability, is difficultly ruptured and is improved in practicability; The archaistic ceramic art ware utilizes the waste magnetite tailing, is low in the costs of the raw materials, is energy-saving and environment-friendly, and is suitable to make a flowerpot, a water pot, a retro ornament and the like; an archaistic ceramic made by utilizing the magnetite tailing can be subjected to underglaze colored drawing decoration through a colored drawing glaze; the product is exquisite.

Owner:福建省德化同鑫陶瓷有限公司

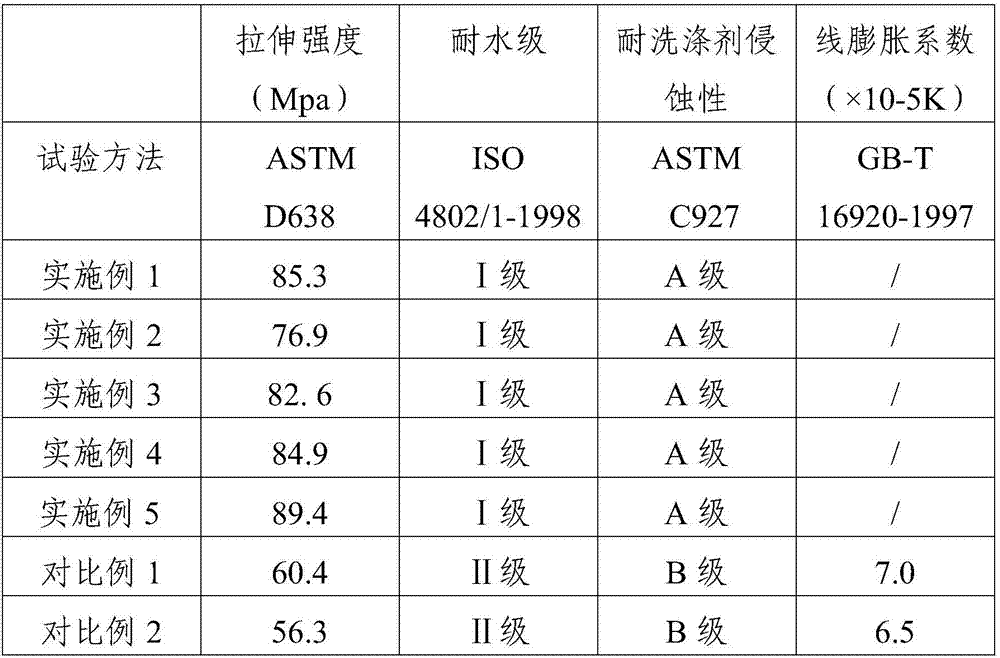

Technology of injection moulding with surface of glass bottle body fully coated with plastic and mould thereof

The invention discloses a technology of injection moulding with the surface of a glass bottle body fully coated with plastic. The technology comprises the following steps: preparing a mould and an injection molding machine matched with the mould, and preparing a plastic raw material and a glass bottle; placing the glass bottle between the front mould insert and the rear mould insert of the mould, and fixing the glass bottle with a plastic sleeve; and setting the technological parameters of injection moulding of the injection molding machine after mould assembly, and performing edge-gate plastic injection upwards from the bottom of the glass bottle to finish injection moulding. The invention further discloses the mould used in the technology of injection moulding. According to the invention, full plastic coating of the surface of the glass bottle body is realized through once injection moulding, the glass bottle body is prevented from explosion in the production process, the product quality is guaranteed, the percentage of breakage of the glass bottle body is almost zero, the production safety is greatly guaranteed, the production efficiency is improved, the finished product has high quality and a good appearance, the surface of the product feels good and soft, and the product has a wide market prospect.

Owner:滁州文特仪器科技有限公司

Totally-enclosed gas atomizing powder making device for preventing high-melting-point substance from being blocked

The invention discloses a totally-enclosed gas atomizing powder making device for preventing a high-melting-point substance from being blocked. The device comprises a heat-preserving crucible, an atomizer, an atomizing tower, a telescopic plastic pipe A, a telescopic plastic pipe B and the like, wherein the atomizer is arranged in the telescopic plastic pipe A; the telescopic plastic pipe A is hermetically connected with the heat-preserving crucible and the upper surface of a nozzle of the atomizer respectively; and the atomizing tower is hermetically connected with the lower surface of the nozzle through the telescopic plastic pipe B, so that a totally-enclosed system structure is formed, and the formation of a high-melting-point substance on the atomizer and caused blockage of the atomizer can be prevented. A heating body is arranged in a gap between a honeycomb duct of the atomizer and a metal jacket, so that nozzle blockage caused by a metal or an alloy can be solved by electrifying. When the atomizer is blocked, the problem of blockage can be solved by replacing a ceramic circular ring. The totally-enclosed gas atomizing powder making device for preventing the high-melting-point substance from being blocked disclosed has the advantages of simple structure, convenience for installing, effective prevention and solving of blockage, improvement on the powder quality, and the like.

Owner:SHANGHAI INST OF TECH

Textile drying machine

InactiveCN107525387ATimely exclusionImprove work efficiencyDrying gas arrangementsDrying chambers/containersExhaust valvePulp and paper industry

The invention relates to the technical field of textile processing and in particular relates to a textile drying machine. The textile drying machine dries a textile repeatedly, so that the work efficiency is relatively high; the textile drying machine is not closed inside during work, so that residual gas in a working cavity can be immediately removed and is unlikely to burst, and therefore, the service life of the textile drying machine is guaranteed, and the using reliability of the textile drying machine is improved; the textile drying machine comprises a box body, a placing plate and a fan. The working cavity is formed in the box body, an opening is formed in the left side wall of the box body, a door plate is arranged on the opening, and a handle is arranged on the door plate; the textile drying machine also comprises a servo motor, a left supporting rack, a right supporting rack and a conveyor belt; the textile drying machine also comprises a heating box, two silicon carbide rods, a fan supporting rack, a plurality of fans and a temperature controller. A heating cavity is formed in the heating box. The textile drying machine also comprise a one-way exhaust valve, an exhaust cavity is formed in the one-way exhaust valve, and a lower exhaust baffle plate, an upper exhaust baffle plate, an exhaust spring and an exhaust baffle plate are arranged in the exhaust cavity.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com