Patents

Literature

89 results about "Cast house" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

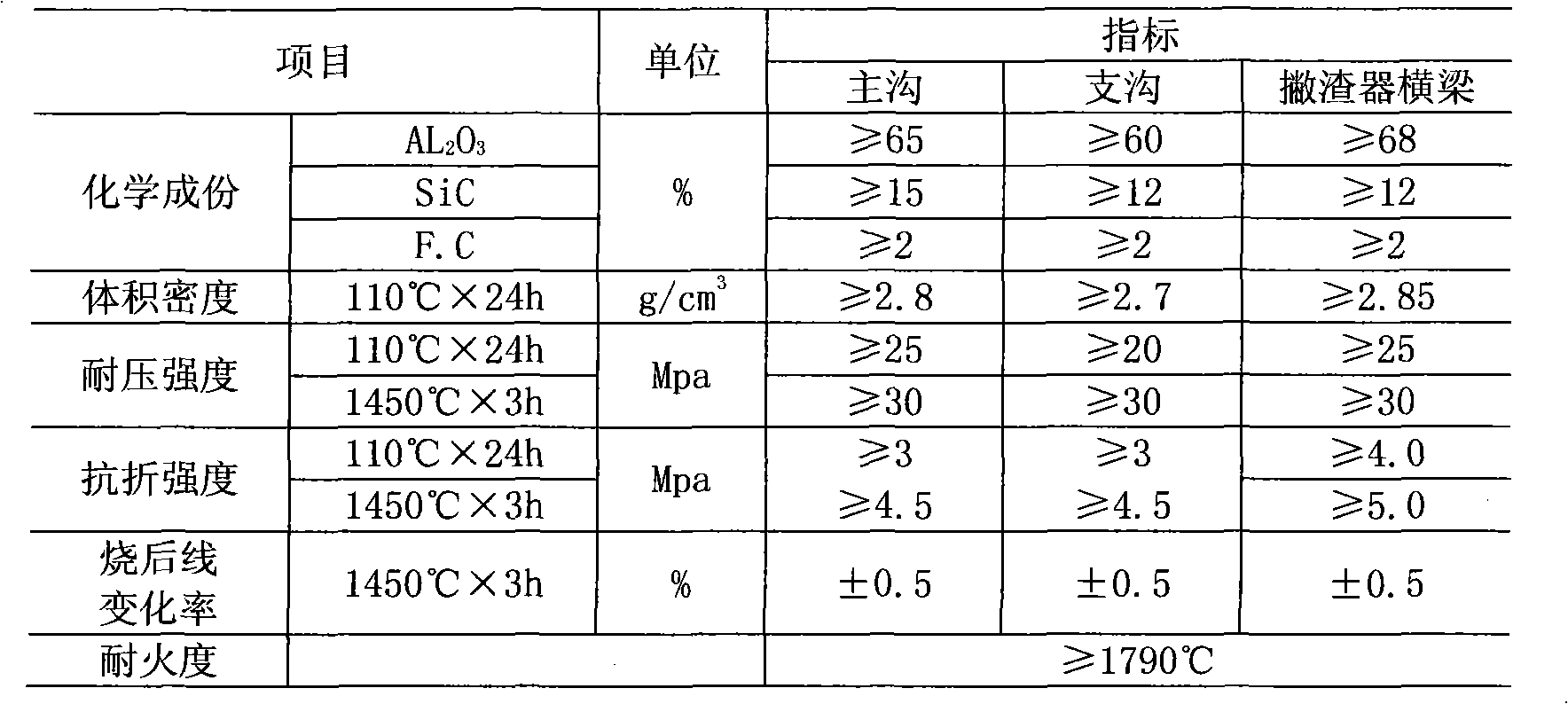

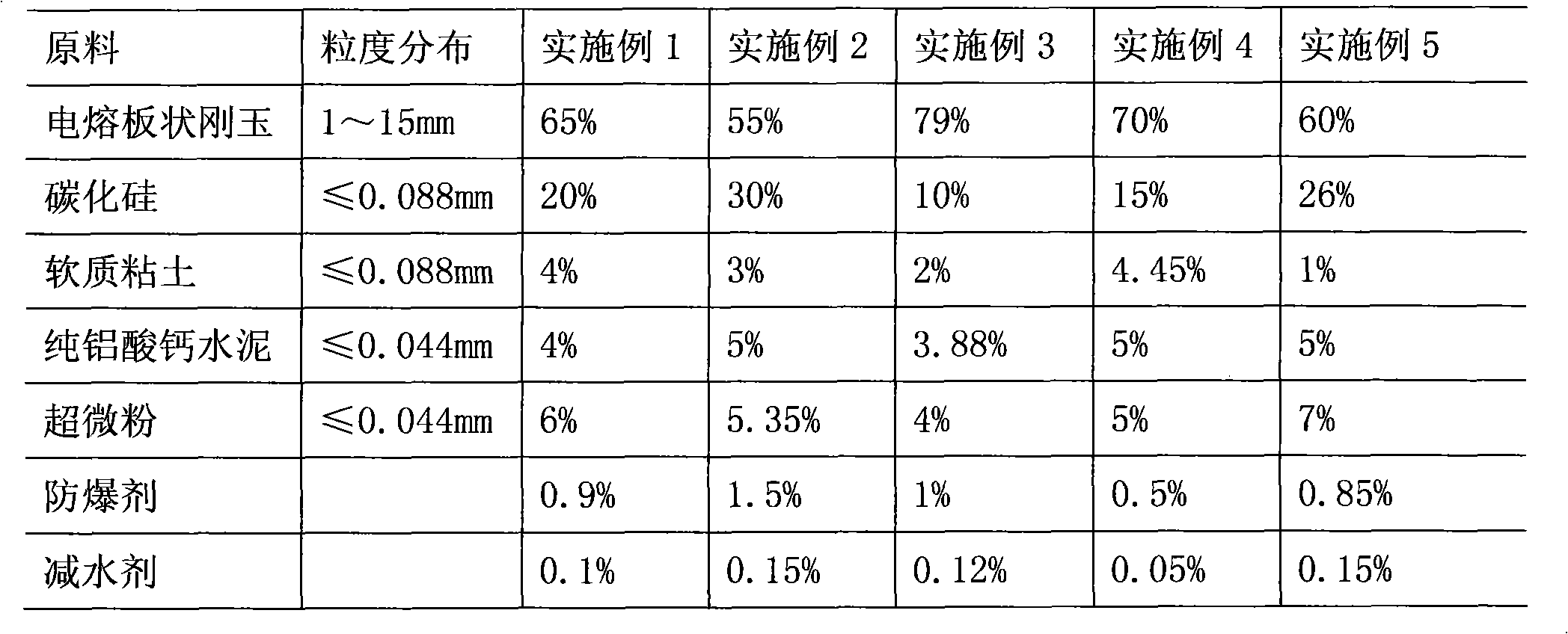

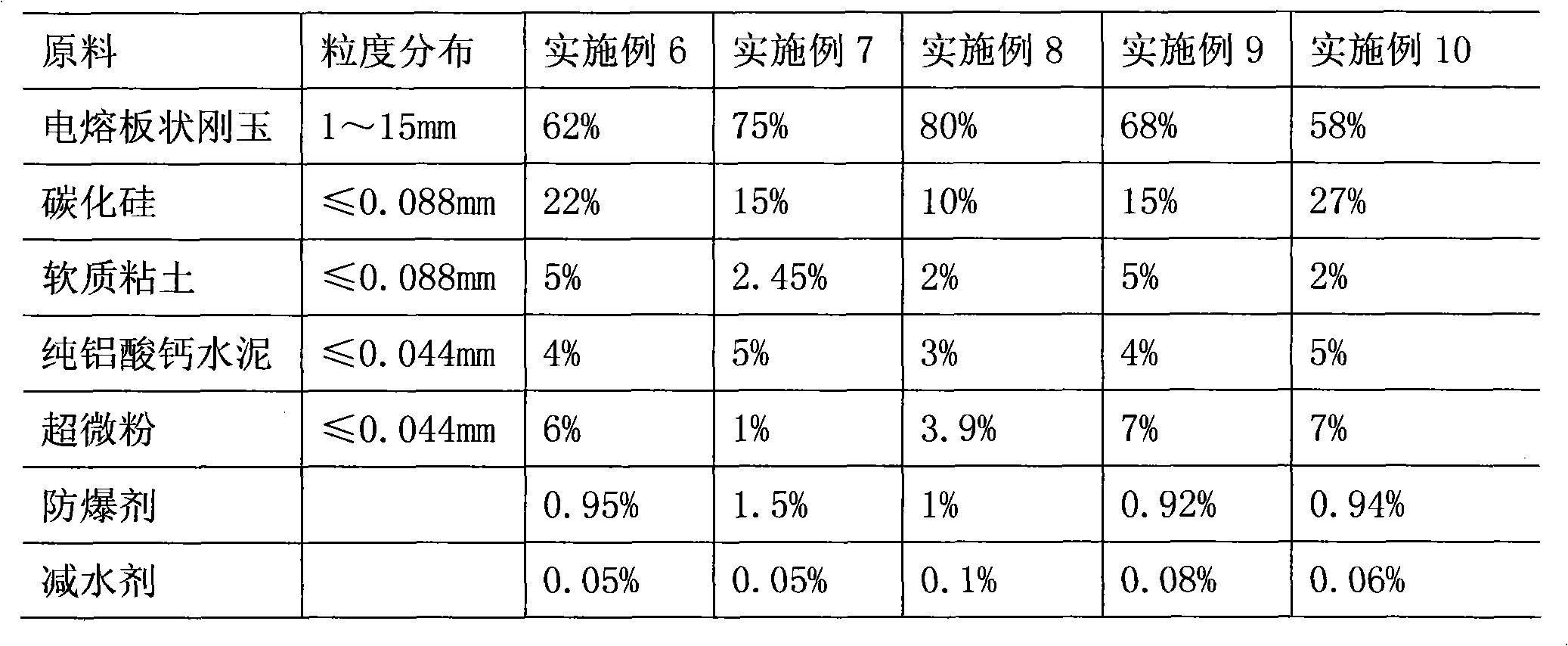

Explosion-proof iron runner castable

The invention relates to an explosion-proof iron runner castable which comprises the following raw materials in percentage by weight: 55-80 percent of fusion tabular corundum, 10-30 percent of silicon carbide, 1-5 percent of soft clay, 2-5 percent of pure calcium aluminate cement, 1-7 percent of submicron powder, 0.5-1.5 percent of explosion-proof agent and 0.05-0.15 percent of water reducing agent, wherein the explosion-proof agent is a mixture of aluminum powder, aluminum lactate, explosion-proof fiber and boron carbide powder with the weight ratio of 1-2:2.5-4:1-2.5:2-4. The castable of the invention has no cracks after demoulding and drying and no spalling during baking, has the safe explosion-proof temperature of 800 DEG C increased from 500 DEG C, can be subjected to construction under heat state and rapid temperature rise without spalling and can meet the operating requirements of rapid construction of middle and small size blast furnace iron runner. The castable has long service life, can improve the environment of a casting house, greatly reduces the labor intensity of the workers, improves the quality of molten iron and enhances the application safety factor of the iron runner.

Owner:HENAN HUAXI FURNACE REFRACTORY

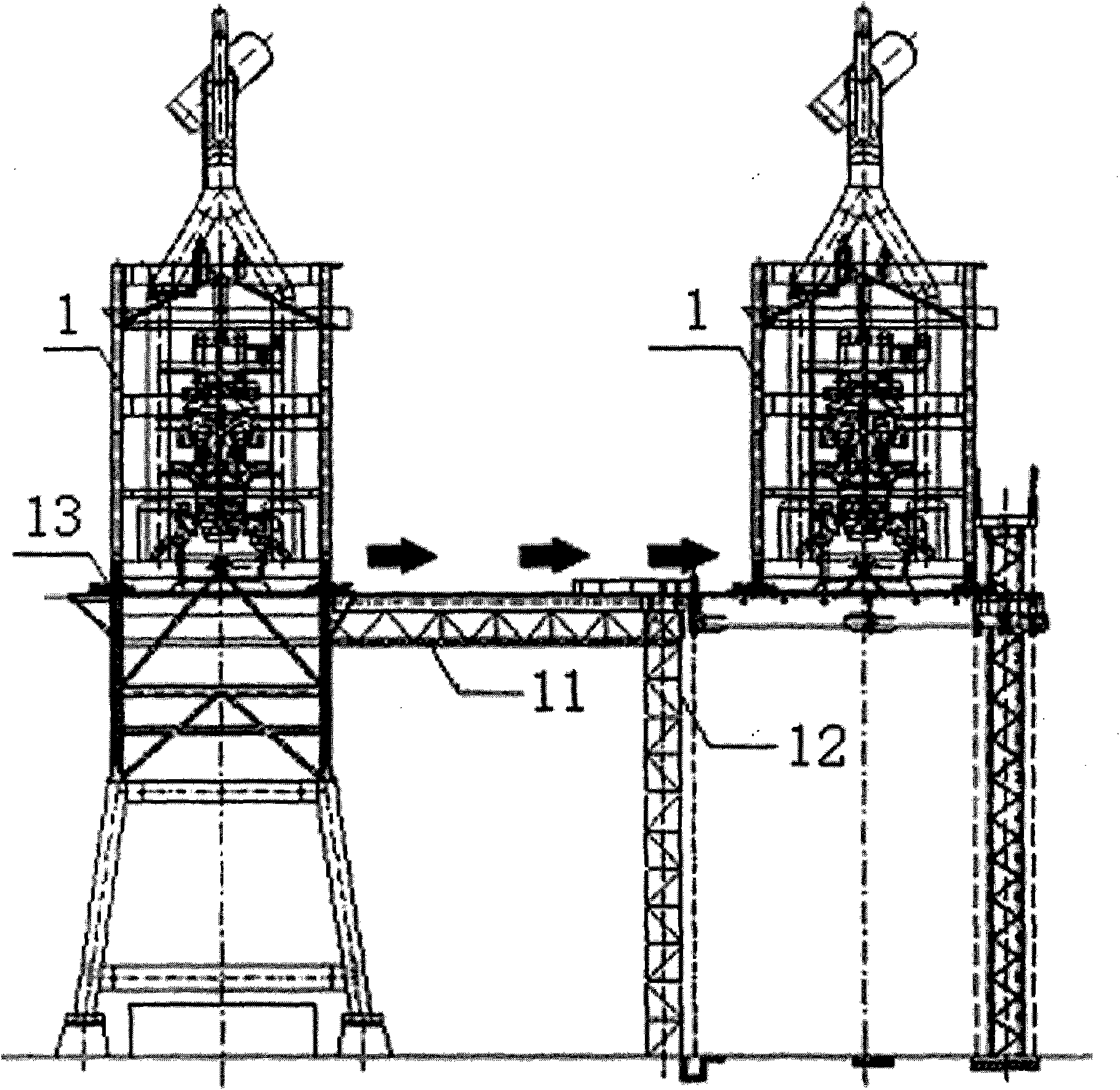

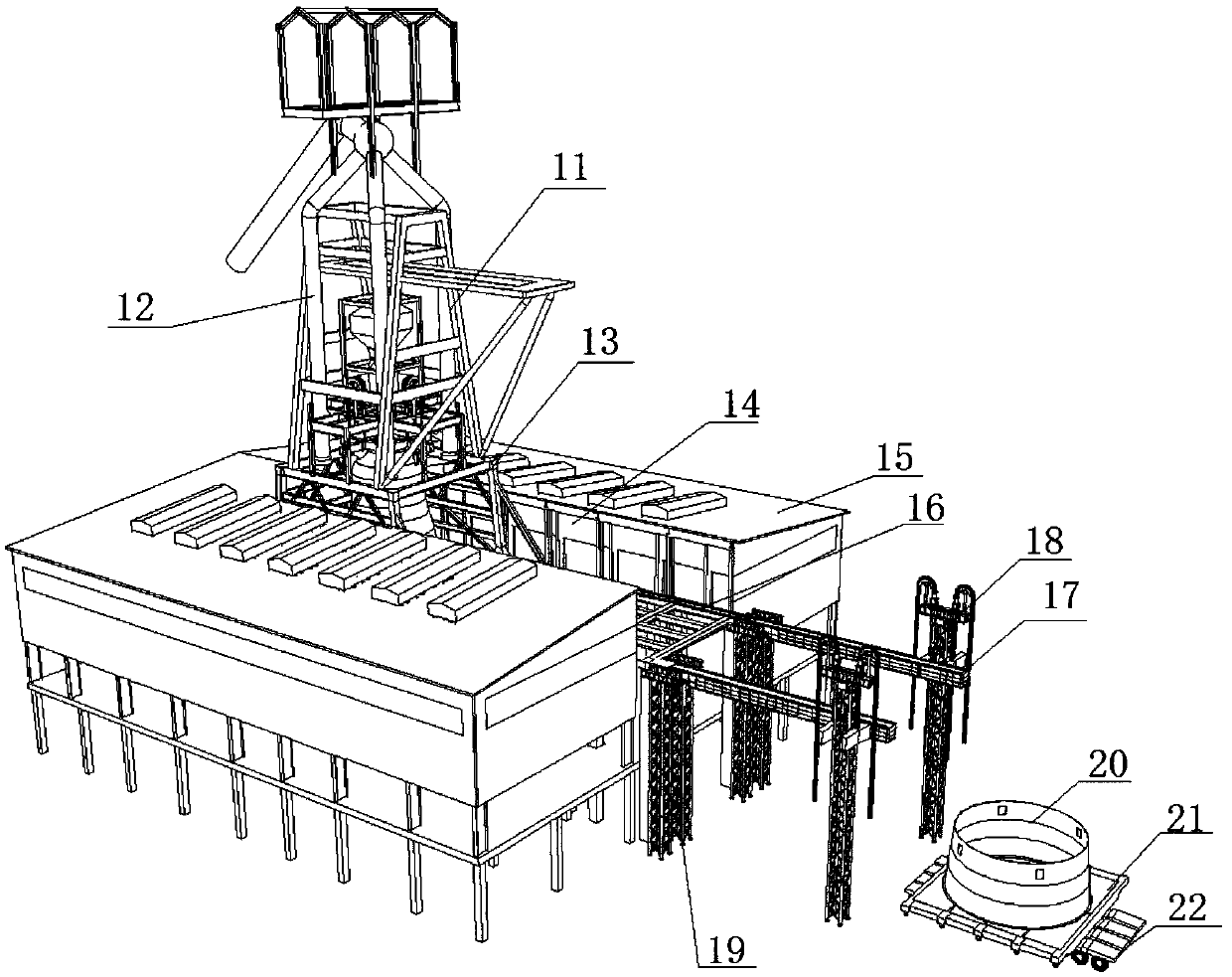

Modularized and integrative disassembling and installing methods for blast furnace

InactiveCN102146488ASatisfy construction safetyMeet construction requirementsBlast furnace componentsBlast furnace detailsCast houseBuilding construction

The invention relates to the installation method field of smelting equipment of iron, in particular relates to modularized and integrative disassembling and installing methods for a blast furnace. The modularized and integrative disassembling method for the blast furnace comprises: disassembling a furnace top system, disassembling a hot wind surrounding pipe, disassembling a layer beam and casting house platform and disassembling a furnace body. The modularized and integrative disassembling method is characterized in that when the furnace top system, the hot wind surrounding pipe, the layer beam and casting house platform and the furnace body are dissembled, the modularized and integrative disassembling method is adopted. The modularized and integrative insulating method for the blast furnace comprises: installing the furnace top system, installing the hot wind surrounding pipe, carrying out furnace body construction, carrying out layer beam and casting house platform construction and carrying out finished product groove construction and is characterized in that when the furnace top system, the hot wind surrounding pipe, the furnace body, the layer beam and casting house platform and the finished product groove are installed, the modularized and integrative installing method is adopted. According to the invention, construction efficiency is high, safety is high, and production cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

Iron-runner quick-drying casting material combined with silica sol

The invention relates to a fireproof material used in an iron runner of a blast furnace cast house, in particular to an iron-runner quick-drying casting material combined with silica sol, which comprises the following raw materials in percentage by weight: 67 percent of Al2O3, 24.8 percent of SiC, 3 percent of carbon element material, 0.2 percent of dispersant, 2 percent of antioxidant and 3 percent of expanding agent. The raw materials are prepared into bone powder and fine powder which are evenly stirred to obtain a finished product. When the iron-runner quick-drying casting material is used, the silica sol in 6-10 percent of the total casting material is added, stirred and cast in an iron-runner die to form a product, and the product is demoulded and roasted under a large fire for 3-4h to yield iron. The invention has the advantages of short trenching time, burst resistance, high construction quality, short roasting time, long service life of the casting material, lightened labor intensity of workers, castoff and waste utilization, energy saving, emission reduction, no environment pollution and environmental protection.

Owner:通化耐博耐火材料有限责任公司

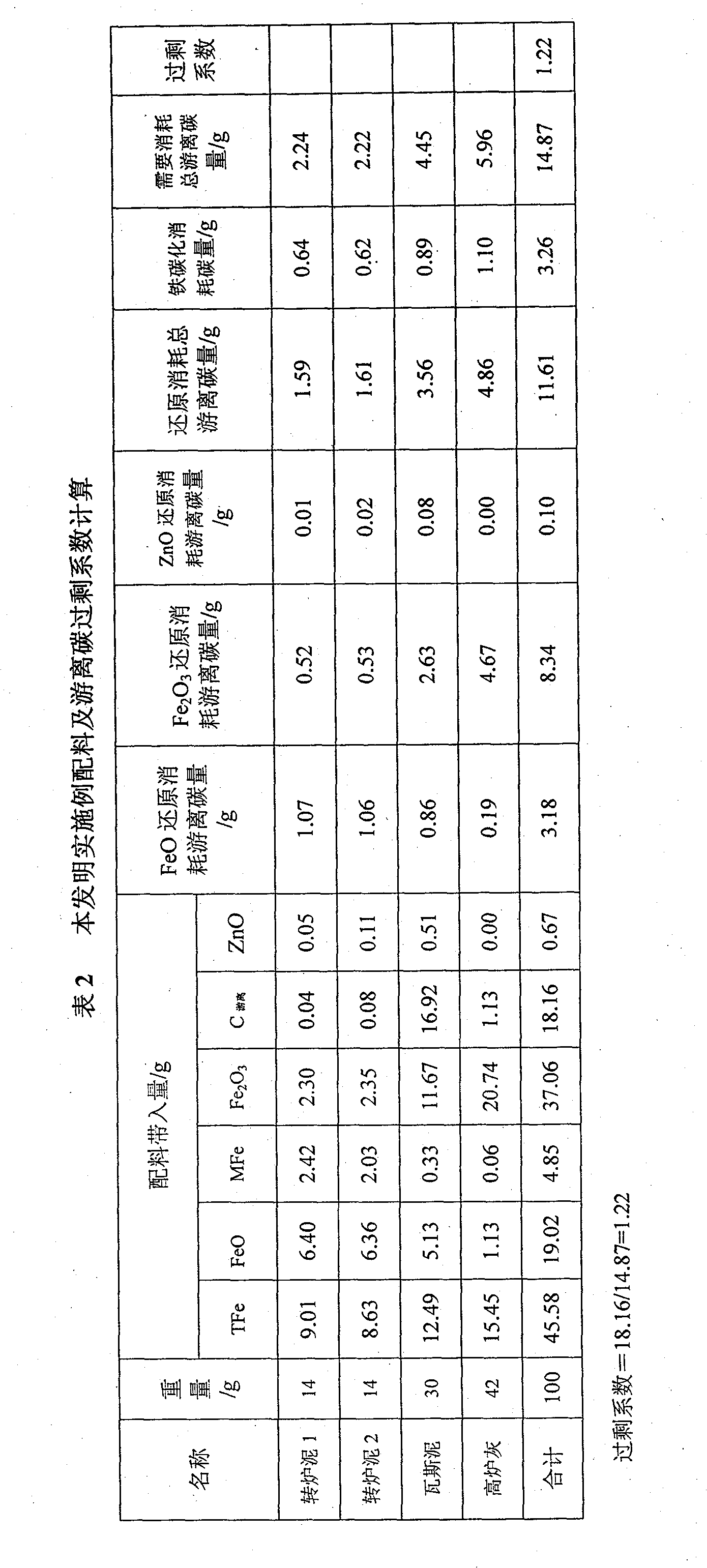

Method for reclaiming zinc-iron-containing dust and sludge

ActiveCN101818263AGood contact reaction conditionsLow costBlast furnace detailsProcess efficiency improvementMaterials preparationSludge

The invention provides a method for reclaiming zinc-iron-containing dust and sludge. The method comprises the following steps of: (1) material preparation, namely performing calculation according to components of different dusts and sludge to ensure that the excess coefficient of free carbon in the materials reaches 1.0 to 1.4; (2) material mixing, namely uniformly mixing and drying the materials to be sent to a storage bin for later use; (3) material feeding, namely continuously and uniformly adding dust and sludge from the storage bin into molten iron flow from a main molten iron trough and other positions through feed equipment according to determined weight by calculation, and reducing ferric oxide and zinc oxide in the dust and sludge by using heat of high-temperature molten iron; and (4) zinc and iron separation, namely recovering zinc-containing smoke by using dust-collection equipment of a casting house to obtain a zinc oxide product or zinc oxide enriched dust so as to realize zinc and iron separation. The zinc-iron-containing dust and sludge can be recovered by using conventional equipment without adding a reducing agent or a catalyst, or needing any special equipment, and has the advantages of convenience and operability, short process, low cost and good effect; and the recovery rate of iron reaches over 90 percent, and the recovery rate of zinc is more than 95 percent.

Owner:ANGANG STEEL CO LTD

Blast furnace-converter interface 'compact one tank mode' process

InactiveCN101280347AThe effect of reducing temperature dropReduce the number of turnover unitsBlast furnace componentsBlast furnace detailsSteelmakingEnergy consumption

The invention belongs to the technical field of the metallurgical industry, which discloses a compacted- type canning process of the blast furnace-converter interface, and a method for adjusting the production un-equilibrium between the blast furnace and the converter. In a steelmaking plant and an operating area where at least one blast furnace is comprised, the blast furnace is composed of at least a main ditch and an iron ditch thereof, a tilting trough, two running lines mixed of cross-train and the railway, a railway running line, two iron receiving tanks and two cross-trains, and the material charging bay of the steel making plant is laid out next to the cast house on one side of the blast furnace cast house; the cross-train adopts an electronic cross-train, and a weighing device is arranged on the cross-train. The method has advantages that hot metal temperature drop is better reduced, the energy consumption is further reduced, and the requred quantity of the iron receiving tank is also reduced; the measuring accuracy of the iron receiving tank is enhanced, thus the controlling for steel making process is stable; the areas of factory is reduced, the project investment is saved, and the method is suitable for an optimization design of the steel making and the steel making interface process engineering and the optimization of the general layout.

Owner:CISDI ENG CO LTD

Construction method for replacement of blast furnace shell in blast furnace overhaul project

InactiveCN109097516ABlast furnace componentsBlast furnace detailsAccessory structureSequential method

The invention discloses a construction method for replacement of a blast furnace shell in a blast furnace overhaul project. The construction method comprises the following steps: a new blast furnace shell is divided into sectional combining structures, and a lifting support frame and a pushing trolley are erected on the pushing side of a new blast furnace outside a cast house; a lifting device iserected on a blast furnace top rigid frame, a plurality of furnace body frame platforms on the upper surface of the pushing side of an old furnace shell and the wall surface and roof of the cast houseon the pushing side are dismounted, a pushing channel for the new furnace shell is erected, and the old blast furnace shell and accessory structures to be replaced are dismounted; the lower half of the new blast furnace shell is hoisted with a sequential method; the upper half of the new blast furnace shell is hoisted with a reverse loading method, and the upper half and the lower half of the newblast furnace shell are connected. According to the construction method for replacement of the blast furnace shell in the blast furnace overhaul project, influence on overall stability and bearing capacity of the furnace body frame can be reduced, and the problem of incapability of large crawler cranes to enter for operation is solved.

Owner:CHINA FIRST METALLURGICAL GROUP

Rapid molten iron conveying method and device combination between interfaces of molten iron and molten steel

The invention relates to a rapid molten iron conveying method and a device combination between interfaces of molten iron and molten steel and belongs to the technical field of metallurgical industry. A molten iron conveying line is configured between a blast furnace or a blast furnace group center line and a converter or a converter group center line, and the molten iron conveying line is configured on one side of a blast furnace casting house; from the blast furnace casting house down into a converter charging aisle, the molten iron conveying line is provided with at least one interruption to divide the molten iron conveying line into a blast furnace side molten iron conveying line and a converter side molten iron conveying line which are connected with each other through a transition device, a molten iron conveying unit consists of a molten iron conveying carrier vehicle and a molten iron jar located on the molten iron conveying carrier vehicle, and the molten iron conveying unit is operated on the molten iron conveying line from the blast furnace casting house down into a converter workshop. According to the rapid molten iron conveying method and the device combination between the interfaces of molten iron and molten steel, a molten iron conveying mode from the blast furnace to a converter is changed, layout of conveying lines is changed, and purposes of saving investment and reducing energy consumption are achieved.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

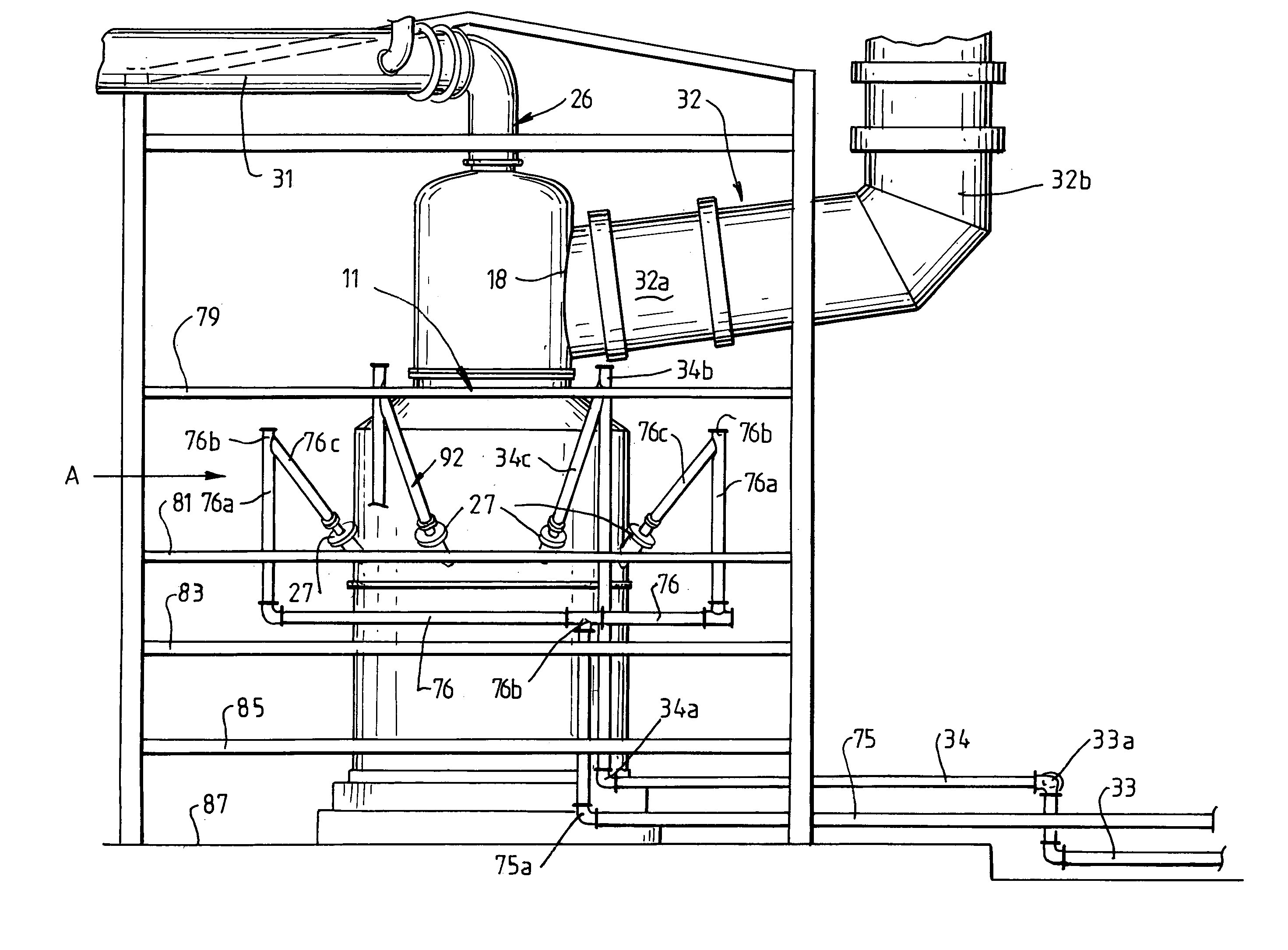

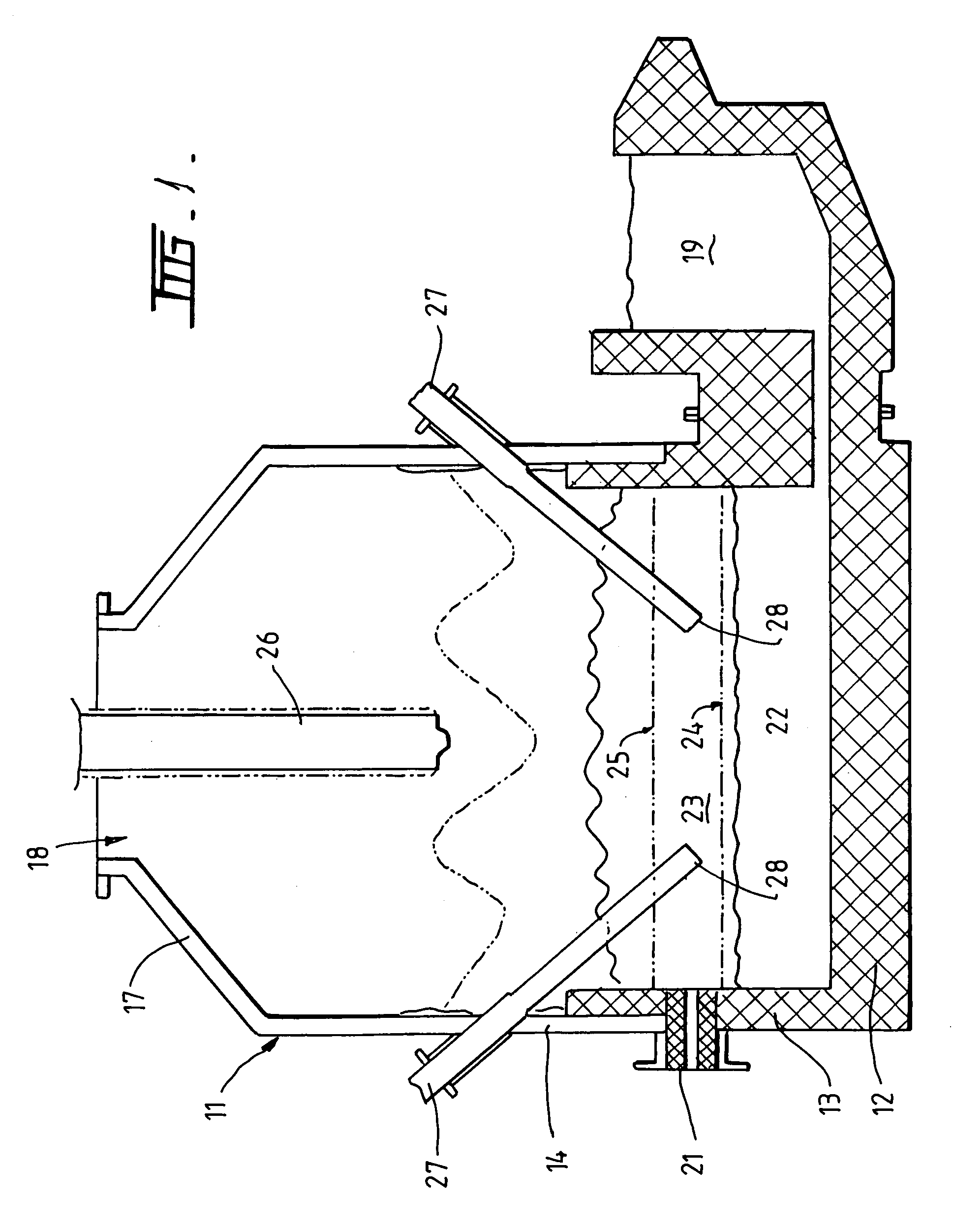

Direct smelting plant

A direct smelting plant for producing molten metal from a metalliferous feed material is disclosed. The plant includes a fixed smelting vessel to hold a molten bath of metal and slag and a gas space above the bath. The plant also includes means for supplying solids and gas feed materials to the vessel and for tapping molten material from the vessel. The plant also includes at least two platforms for supporting plant operators at different heights of the vessel. The metal tapping means and the slag tapping means are located so as to be accessible by plant operators on a cast house platform and the end metal tapping means and the end slag tapping means are located to be accessible by plant operators on an end tap platform that is at a lower height than the cast house platform.

Owner:TECH RESOURCES PTY LTD

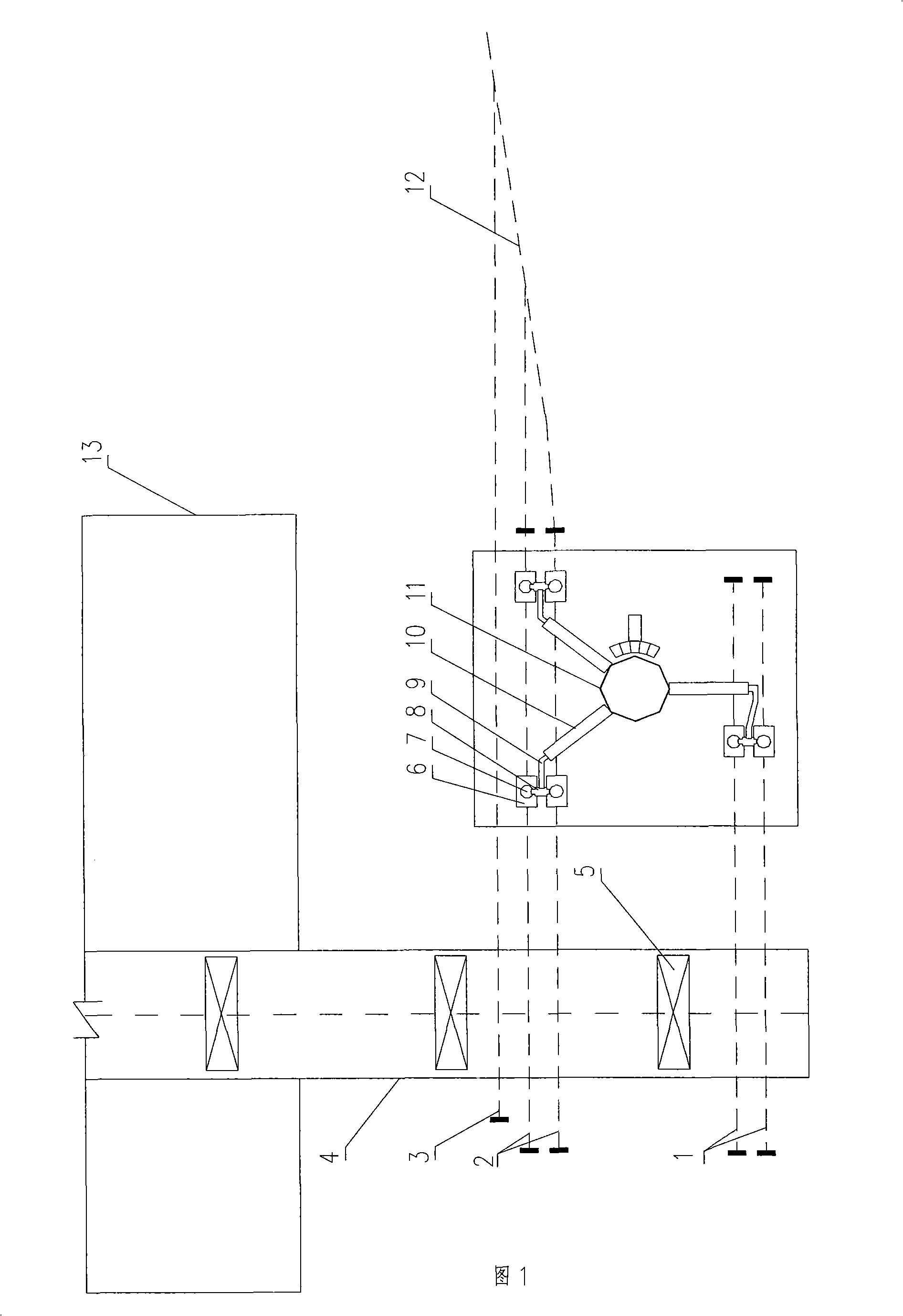

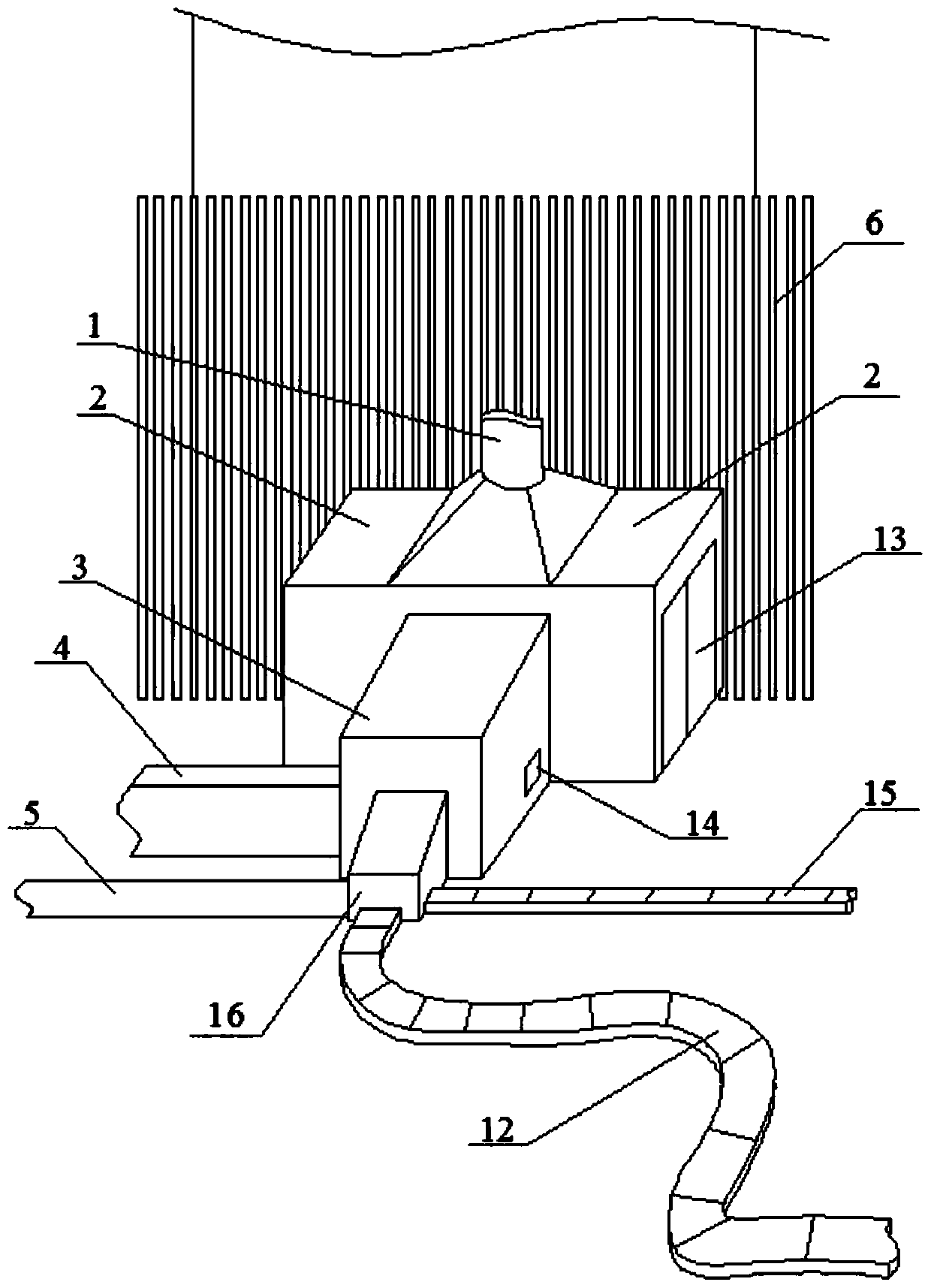

Hot-metal bottle combined cover and method thereof for adding and lifting cover

The invention relates to a hot-metal bottle combined cover and a cover adding and uncovering method thereof, and belongs to the technical field of hot metal transportation. The hot-metal bottle combined cover consists of a positioning ring (1), a hot-metal bottle cover (2), a suspension ring (3), a hinge (4), a hot metal receiving opening cover (5) and a swinging shifting ring (6), wherein the hot-metal bottle cover (2) is connected with the hot metal receiving opening cover (5) through the hinge (4); and the whole combined cover is positioned on a fixed pin shaft on a hot-metal bottle through the positioning ring (1). The adding and uncovering method for the hot metal receiving opening cover (5) of a casting house is to arrange a special mechanism in a hot metal outlet opening position of the casting house to complete cover adding and uncovering operations; and the adding and uncovering method for the hot-metal bottle cover (2) of the casting house is to realize cover adding and uncovering operations by a special hanger and a gantry trolley (15). The cover adding and uncovering method has the advantages that a hot-metal bottle is provided with the cover for shielding during transmission and shelving, so that the cover adding and uncovering method greatly saves energy resources, reduces consumption of resistant materials and a heat-insulated covering agent and environmental pollution, prolongs the service life of the resistant materials of the hot-metal bottle, and obviously reduces the turnover number of the hot-metal bottle.

Owner:北京北科中钢工程技术有限公司

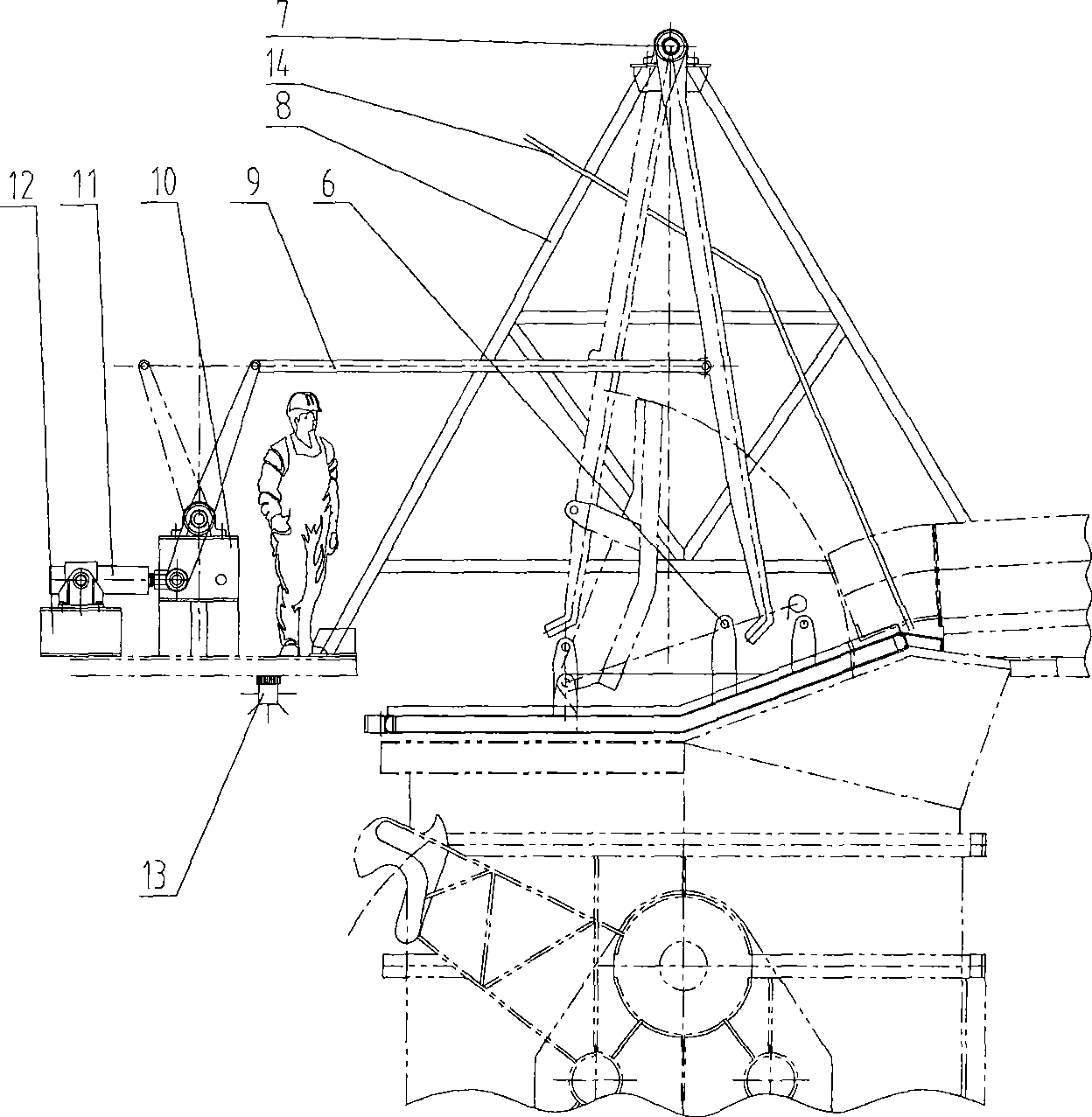

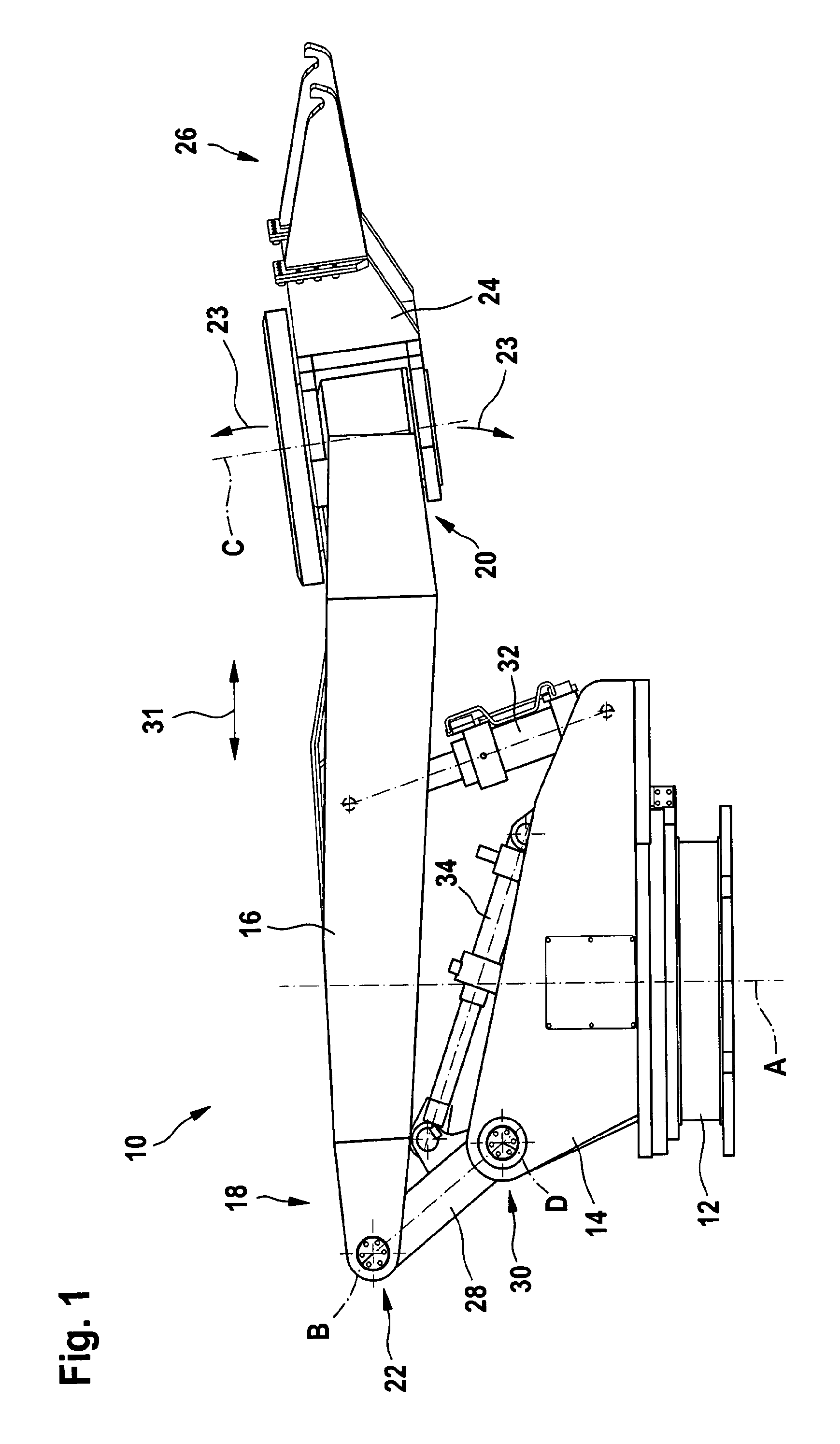

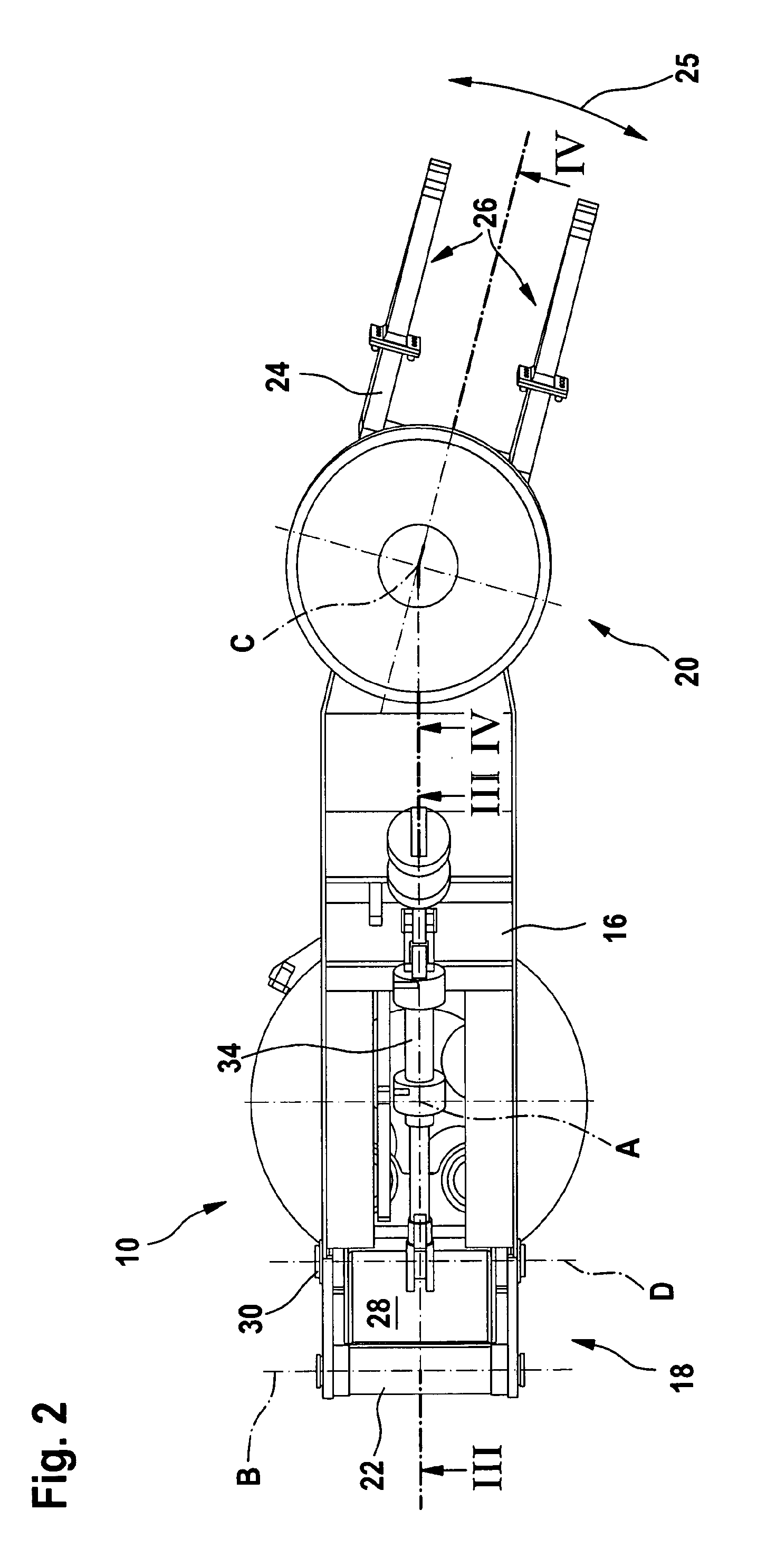

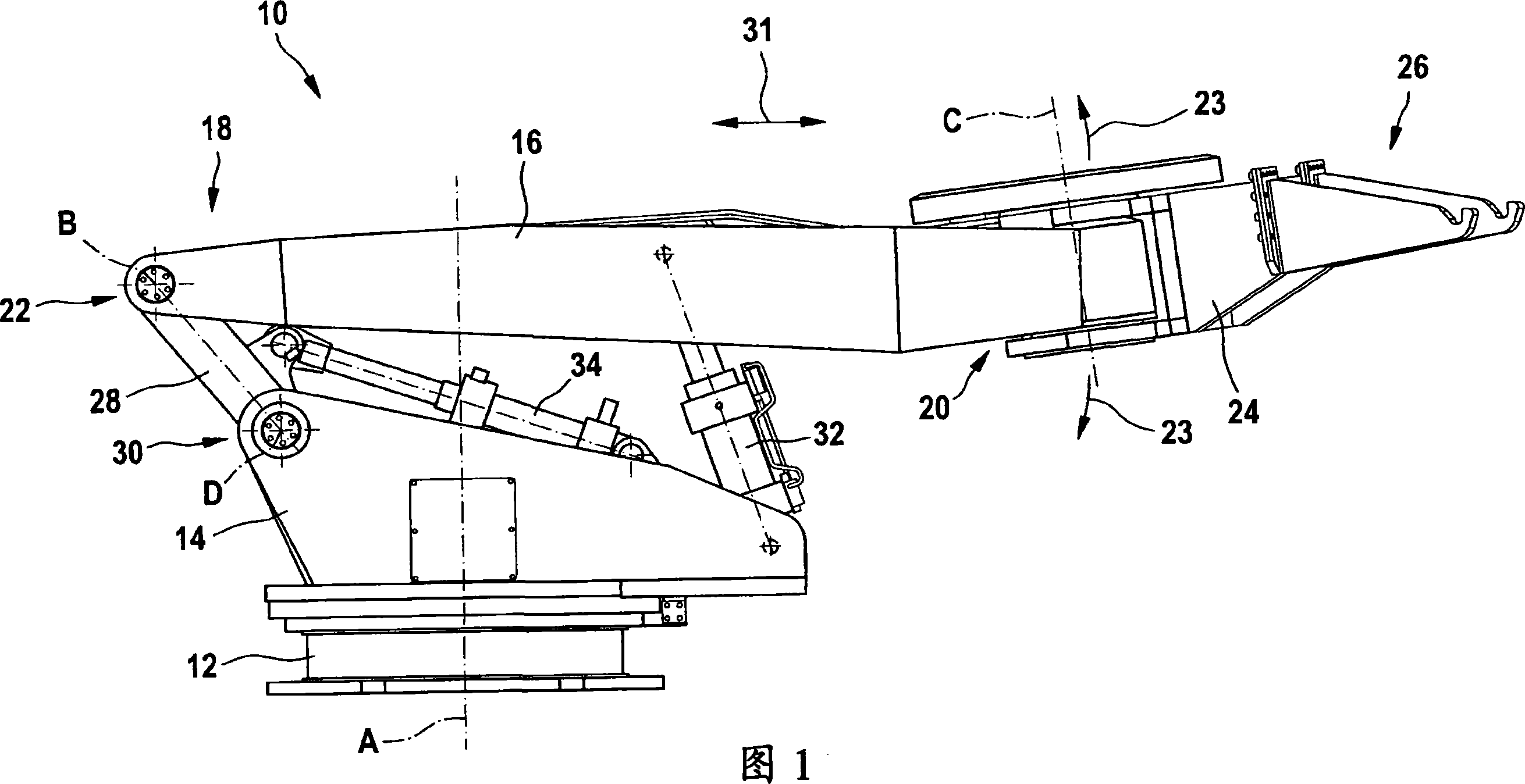

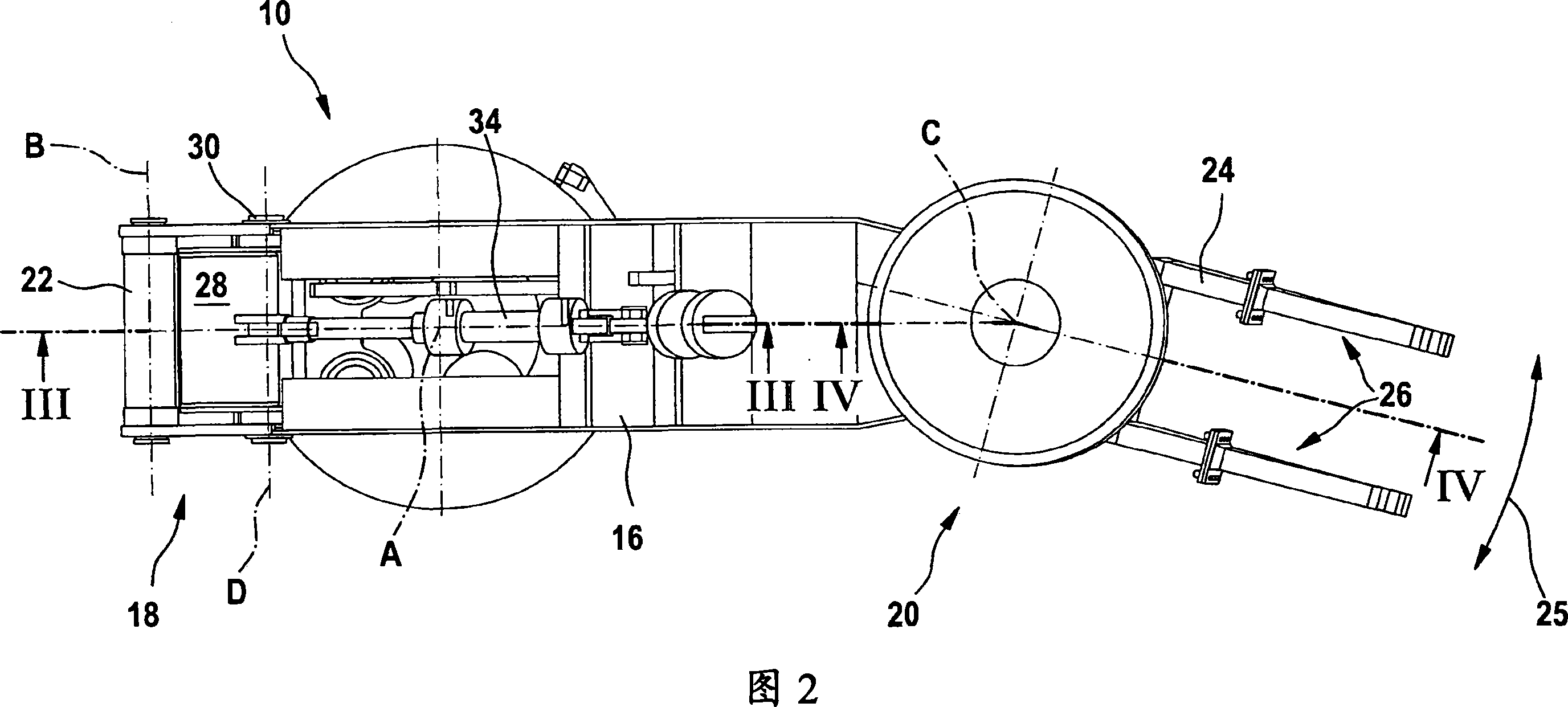

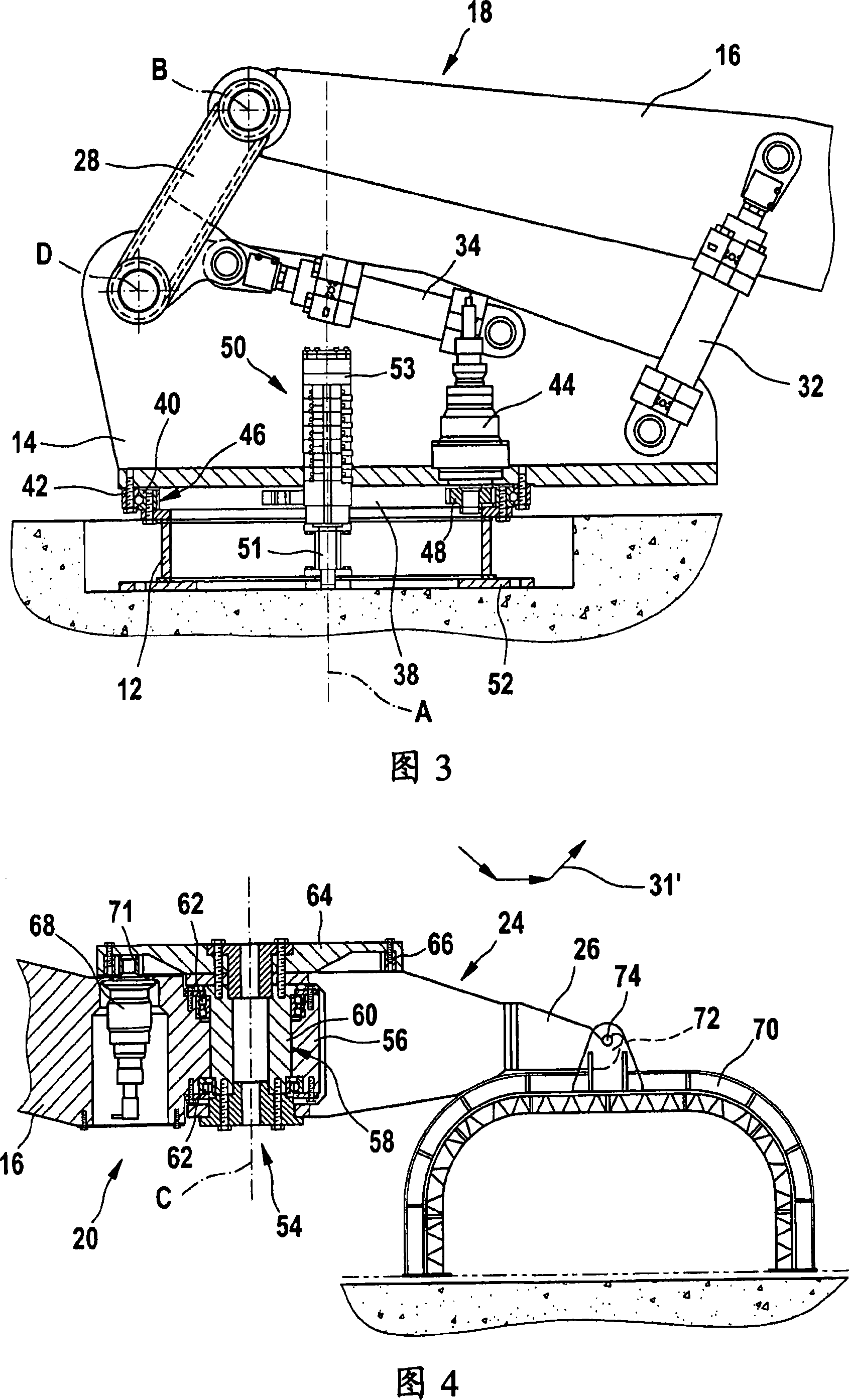

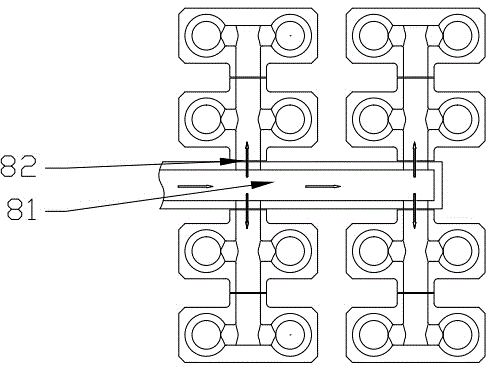

Handling Device For Elements of Tapping Runners

InactiveUS20080230965A1Increase flexibilityCompact structureCharge manipulationBlast furnace detailsEngineeringShaft furnace

A handling device for elements of tapping runners on a shaft furnace, in particular for runner covers, the device including a support base arranged on the cast house floor of a blast furnace, laterally of the tapping runner and a frame (14) which is supported by the support base and connected thereto by means of a bearing defining a first axis of rotation, which is essentially vertical and about which the frame can rotate relative to the support base. The device further includes a lifting arm having a first end portion and a second end portion, the first end portion being connected to the frame by means of at least a first rotational joint defining a second axis of rotation, which is essentially horizontal, about which the lifting arm can pivot in order to lower or lift its second end portion. A handling member is connected to the second end portion of the lifting arm by means of a second rotational joint defining a third axis of rotation, which lies in a plane essentially perpendicular to the second axis of rotation, about which the handling member can pivot with respect to the lifting arm. Furthermore, the handling device includes a fork-type grab connected to the handling member and arranged so as to allow picking up; transferring and putting down such elements.

Owner:TMT TAPPING MEASURING TECH

Overturn type top dust cover

InactiveCN101418357AReduce work intensityEasy to operateDust arrestersEngineeringMechanical engineering

The invention relates to a flip-flop top dust hood, which comprises a hood body, wherein the hood body is arranged above a main iron tap channel of a casting house; the rear side of the hood body is pivoted on the edge of a blast tuyere platform; the front side of the hood body is provided with a suspension rope which pulls the hood body and can make the hood body overturned around a pivoted shaft on the rear side of the hood body; and the side face of the hood body is provided with an outlet which can be communicated with a dust removal pipeline. The flip-flop top dust hood sucks dust of an iron notch and the main iron tap channel and improves the stokehole environment, simultaneously can perform mechanized operation by utilization of a disassembly machine and a crane, greatly reduces the working strength of stokehole operators, and improves the working conditions of the operators, thereby having great significance in environmental protection of a blast furnace and improvement of the operating level of the blast furnace.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

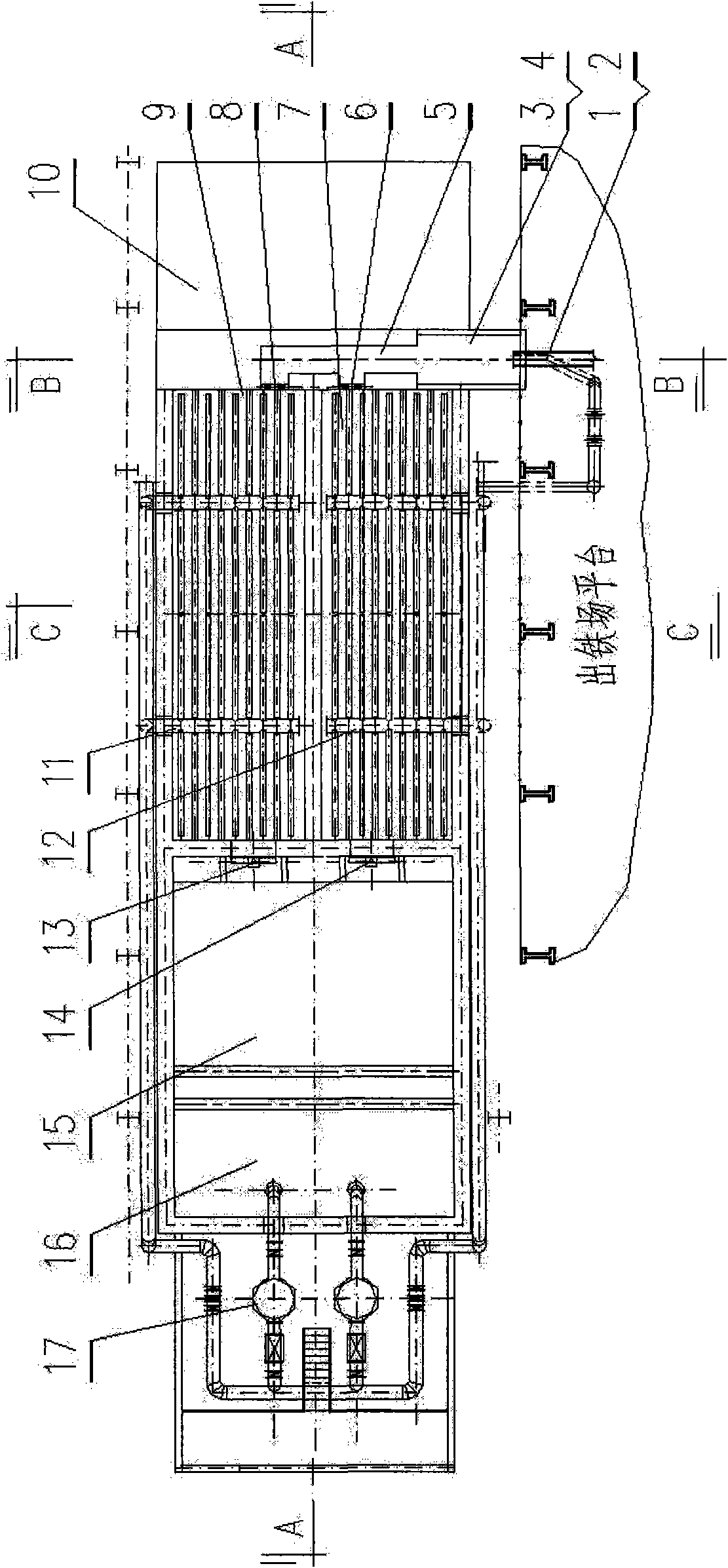

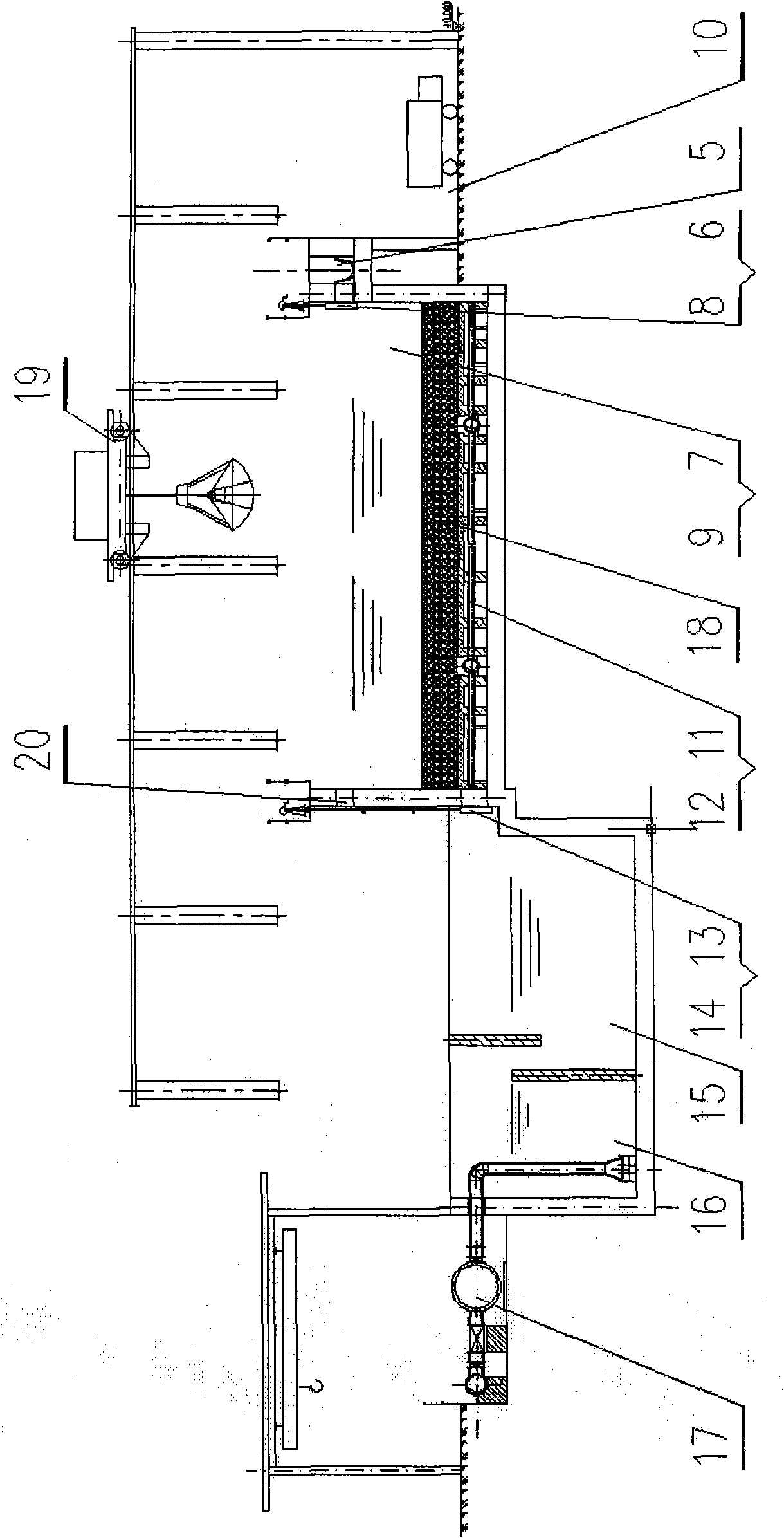

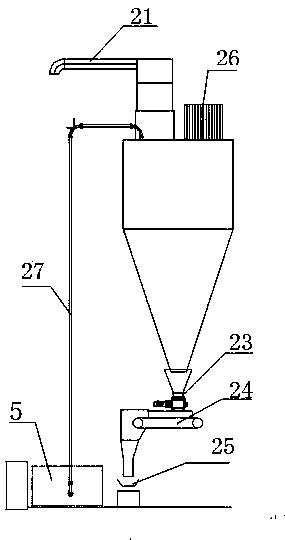

Blast-furnace slag processing system

ActiveCN101781691ASmall footprintSimple structureRecycling and recovery technologiesVertical planeSlag

The invention belongs to the technical field of metallurgical iron-making devices, and specifically relates to a blast-furnace slag processing system. The blast-furnace slag processing system mainly comprises a bottom filter chamber group, a horizontal flow chamber and a circulating water chamber, wherein the bottom filter chamber group is arranged closely adjacent to a casting house in the long and narrow spare space at the casting house side and is positioned above the ground level, the horizontal flow chamber and the circulating water chamber connected in series are arranged behind the bottom filter chamber group, and the horizontal flow chamber and the circulating water chamber are positioned under the ground level. The invention is characterized in that the overall system is arranged closely adjacent to the casting house side, thereby avoiding the long distance conveyance of the slag-water slurry; and the bottom filter chamber is positioned above the ground level, thereby fully making use of the space in the horizontal plane and the vertical plane at the casting house side. The invention has the advantages of small occupied area, simple equipment and facility, low construction investment, low operating cost, convenient operation and maintenance and environmental friendliness, and achieves the effects of environmental protection, high efficiency and energy saving. The invention can be widely used in the blast-furnace slag processing system, and can also be used in other slag-flushing processing systems.

Owner:CISDI ENG CO LTD

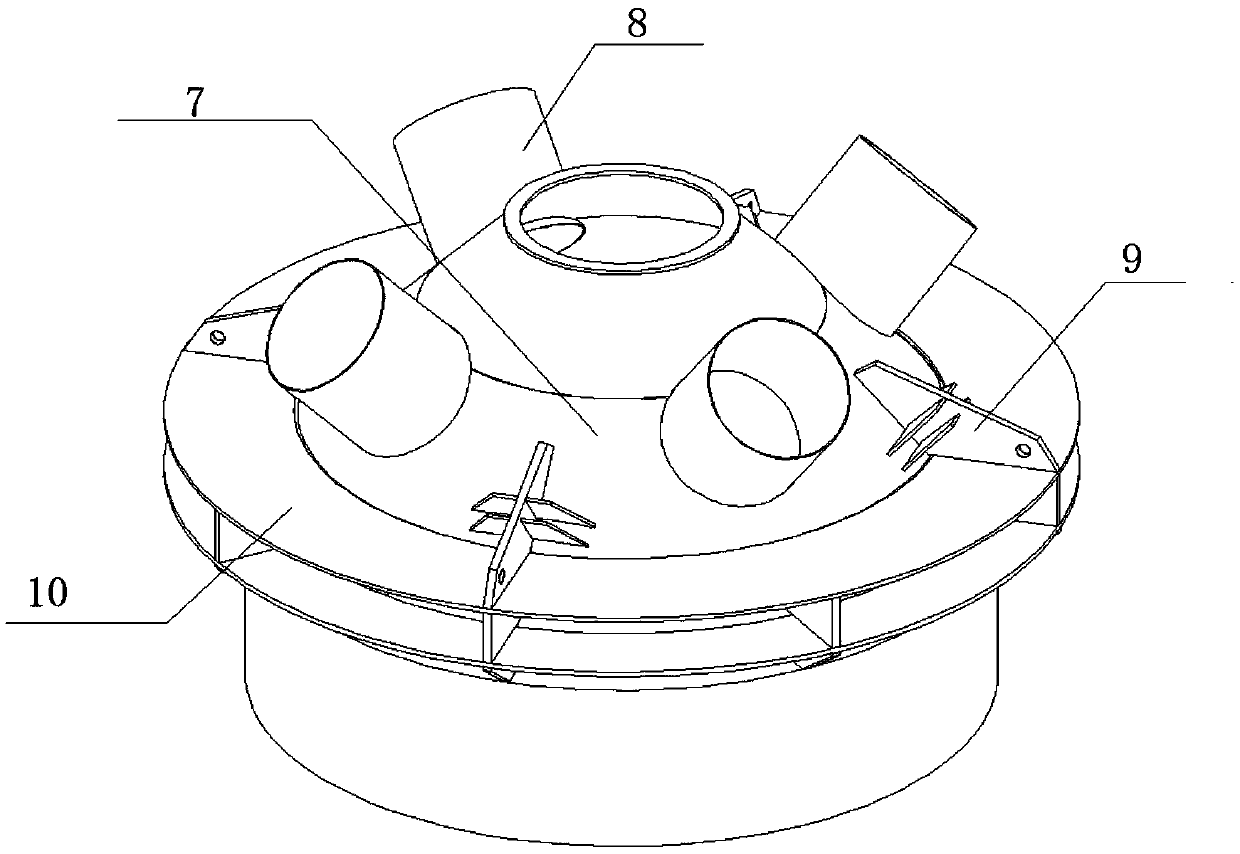

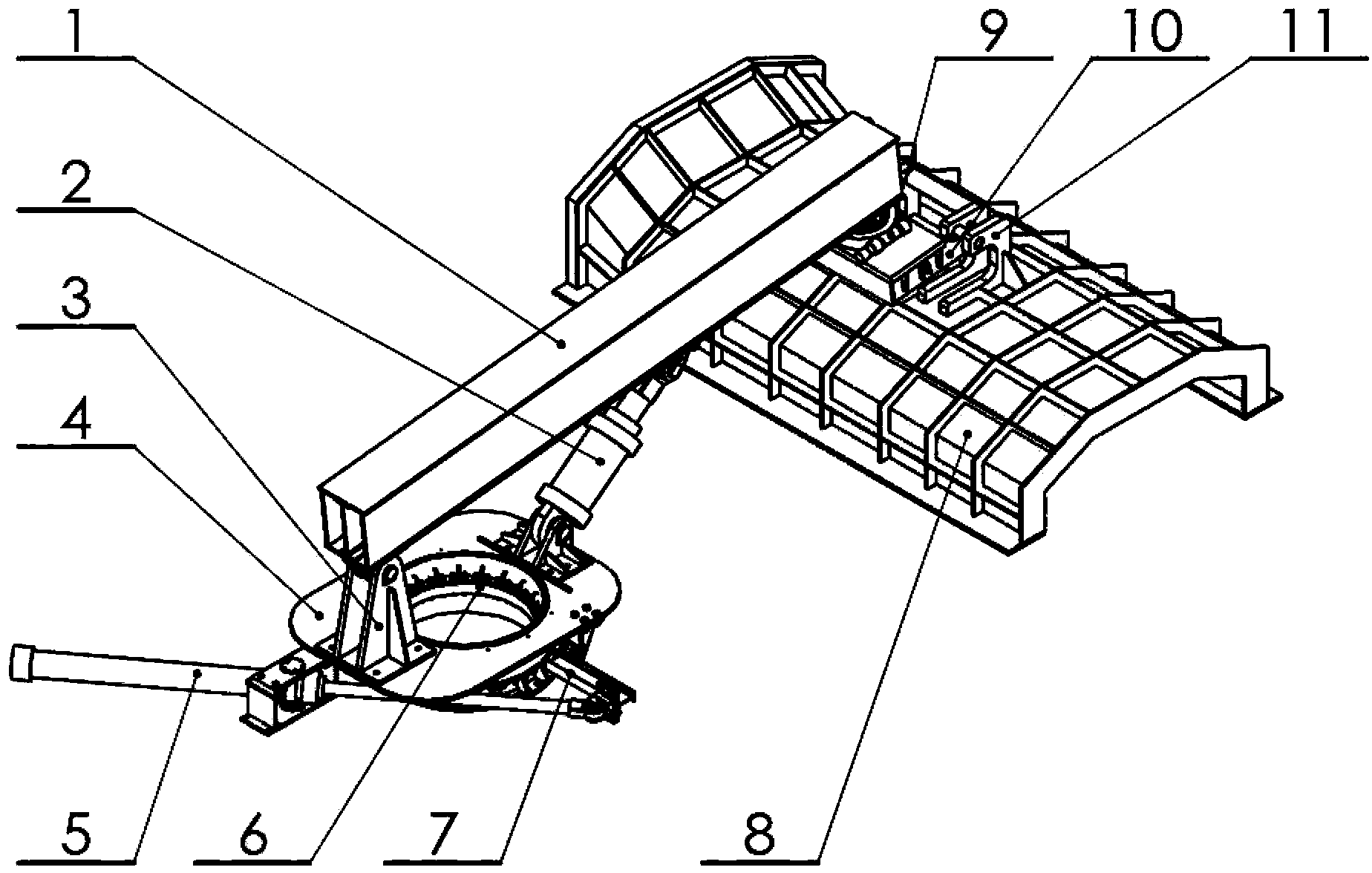

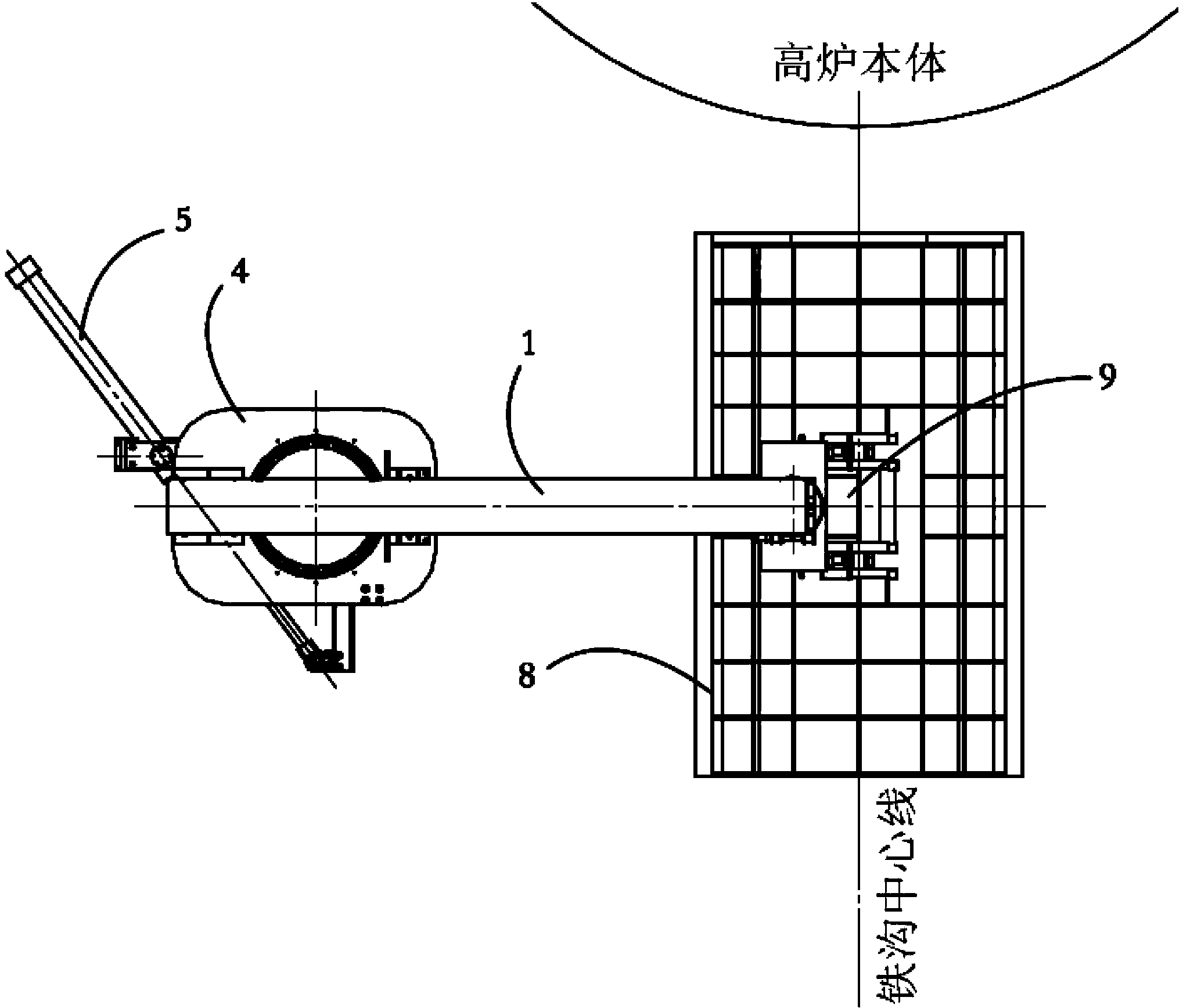

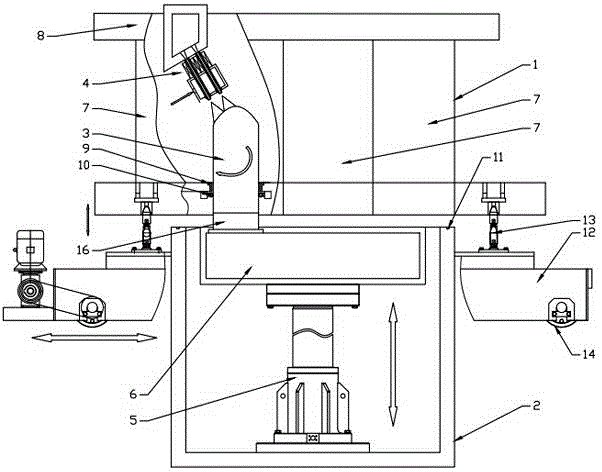

Rotary type uncovering machine and rotary type uncovering method for blast furnace iron runner

ActiveCN103352094ASimple structureSafe and reliable workBlast furnace componentsBlast furnace detailsSlewing bearingMechanical engineering

The invention provides a rotary type uncovering machine and a rotary type uncovering method for a blast furnace iron runner. The rotary type uncovering machine and the rotary type uncovering method are used for uncovering and sealing a runner cover on the blast furnace iron runner. The uncovering machine comprises a rotating mechanism, a lifting mechanism, a runner cover swing mechanism and a lifting socket, wherein a slewing bearing is arranged on the rotating mechanism; the slewing bearing comprises a revolving platform; the lifting mechanism is fixed on the revolving platform; a supporting seat, a lifting arm and a lifting driving device are arranged on the lifting mechanism; a swing driving device is arranged on the runner cover swing mechanism; a hoisting hook is fixed below the swing driving device; a transverse pole of the lifting socket is attached to the hoisting hook. The rotary type uncovering machine provided by the invention can effectively lower the total height of the uncovering machine and is preferably suitable for complex environments of a casting house; the rotating mechanism has the advantages that the structure is simple, the installation is easy, the working is safe, and the maintenance is convenient.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

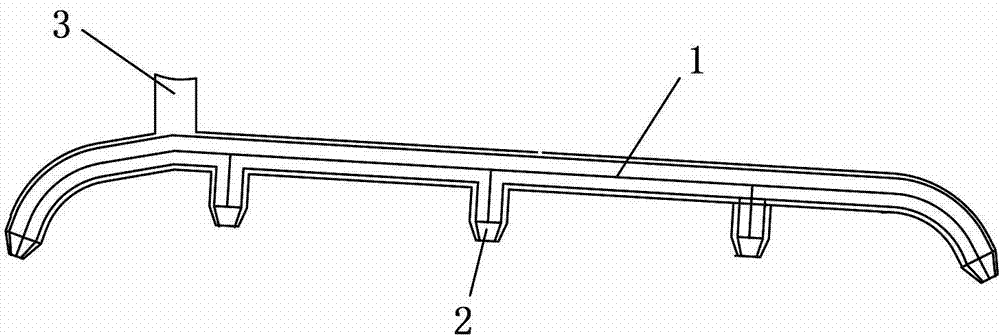

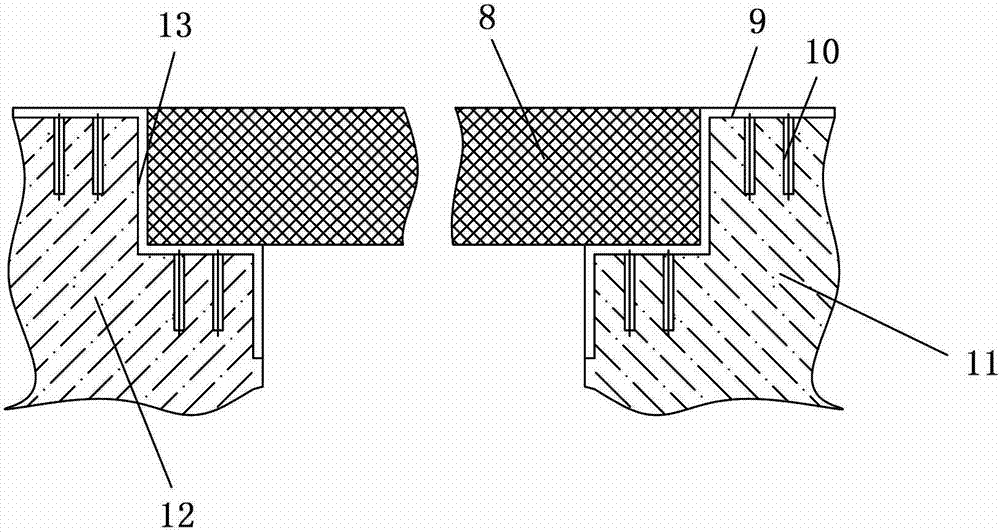

Iron tap channel swing spout prefabricated piece and manufacturing method thereof

InactiveCN106702056AReduce maintenance costsImprove erosion resistanceDischarge devicesParticulatesFiber

The invention discloses an iron tap channel swing spout prefabricated piece. The iron tap channel swing spout prefabricated piece comprises different particulate finesses of dense corundum, different particulate finesses of tabular corundum, silicon carbide, tabular corundum powder, silicon carbide powder, active alumina powder, graphite powder, ferro-silicon nitride, asphalt powder, boron carbide, borosilicate glass powder, calcium aluminate cement, silicon powder, anti-explosion fiber and sodium hexametaphosphate. A production method of the iron tap channel swing spout prefabricated piece comprises the steps that the various raw materials are mixed, water is added, the mixture is stirred and then poured into a mold for pouring forming, demolding is conducted after forming, and then maintenance is conducted; the maintained product is placed in a firing furnace, the temperature is raised and then kept, the temperature is then lowered at a constant speed and then kept; the temperature is raised at the temperature rising speed, and then the temperature is kept; and natural cooling is conducted. The iron tap channel swing spout prefabricated piece and the production method of the iron tap channel swing spout prefabricated piece have the advantages that the prepared iron tap channel swing spout prefabricated piece has good anti-scouring performance, high-temperature strength and oxidation resistance and can keep high iron flux, and the iron tap channel swing spout prefabricated piece has the important functions on shortening the length of an iron tap channel, reducing the area of a cast house, improving the flushing and casting conditions, reducing the maintenance expense of the iron tap channel and reducing the energy consumption of per ton of iron.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

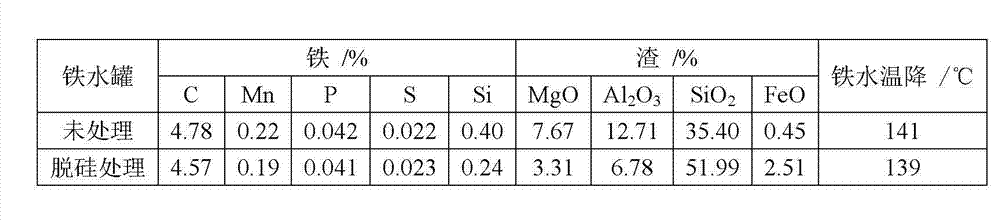

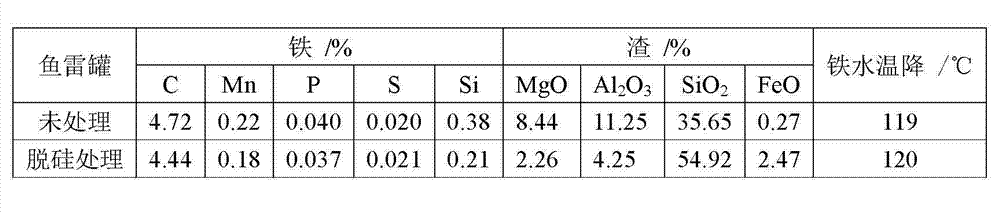

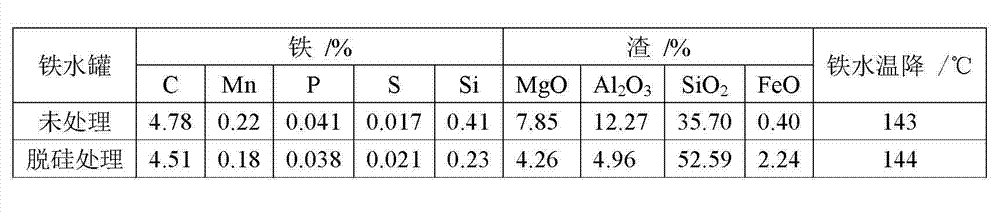

Desiliconization agent for molten iron and preparation and using methods for desiliconization agent

InactiveCN102925624ANo additional processing time requiredLittle influence of temperatureOxygenIron oxide

The invention discloses a desiliconization agent for molten iron and preparation and using methods for the desiliconization agent. The desiliconization agent comprises the following components in percentage by mass: 4 to 10 percent of fluorite powder, 0 to 10 percent of binder and the balance of two or more of blast furnace gas ash, blast furnace dedusting ash, dry quenching dedusting ash, converter ash, scale and allite red solid waste resources, wherein the molar ratio of fixed carbon in the total components to oxygen atoms in an iron oxide (C / O) is 1.1 to 1.2. The preparation method comprises the following steps of: preparing chemical components of raw materials; putting solid materials into a mixing machine for stirring and mixing uniformly; filling water or liquid binder for secondary stirring and mixing uniformly; conveying the final mixture into a ball pressing machine and pressing to form blocks; and drying the blocks. During use, the desiliconization agent which is 1 to 3 percent of the mass of iron in a molten iron ladle can is charged into an empty molten iron ladle, the molten iron ladle which is filled with the desiliconization agent is allocated to a blast furnace casting house, the molten iron is filled during blast furnace casting, and the molten iron ladle can be conveyed to the position where iron is folded during steelmaking so as to finish desiliconization.

Owner:ANGANG STEEL CO LTD

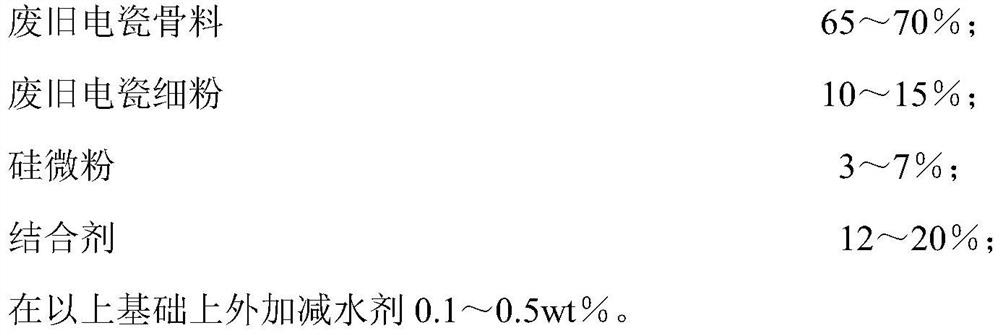

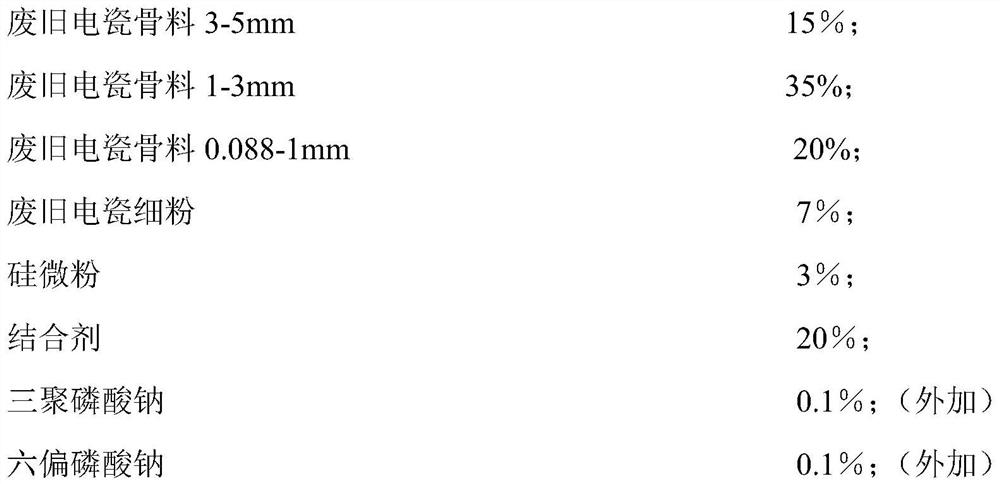

Self-flowing heat-resistant concrete utilizing waste electric porcelain

InactiveCN112079608ALow impurity contentUniform particle distributionEnvironmental engineeringElectroceramics

The invention discloses self-flowing heat-resistant concrete utilizing waste electric porcelain. The self-flowing heat-resistant concrete contains the following components in percentage by weight: 65-70% of waste electric porcelain aggregate; 10%-15% of waste electric porcelain fine powder; 3-7% of silica powder; 12-20% of a binding agent; and 0.1-0.5 wt% of a water reducing agent is added on thebasis. The invention provides the self-flowing heat-resistant concrete for the high-temperature parts of the blast furnace foundation and the casting house platform; meanwhile, the waste electroceramics can be recycled, the content of the waste electroceramics in the obtained self-flowing heat-resistant concrete is 70wt% or above, and the use temperature can reach 1,300 DEG C or above. The high strength and good sintering stability of the waste high-voltage electric porcelain are fully utilized, secondary utilization of solid waste resources is achieved, and the cost is reduced. By adopting the zirconium-removed silica powder, impurities are few, the fluidity is good, the water consumption is greatly reduced, the material can be pumped for construction, and the construction efficiency is greatly improved.

Owner:中冶武汉冶金建筑研究院有限公司

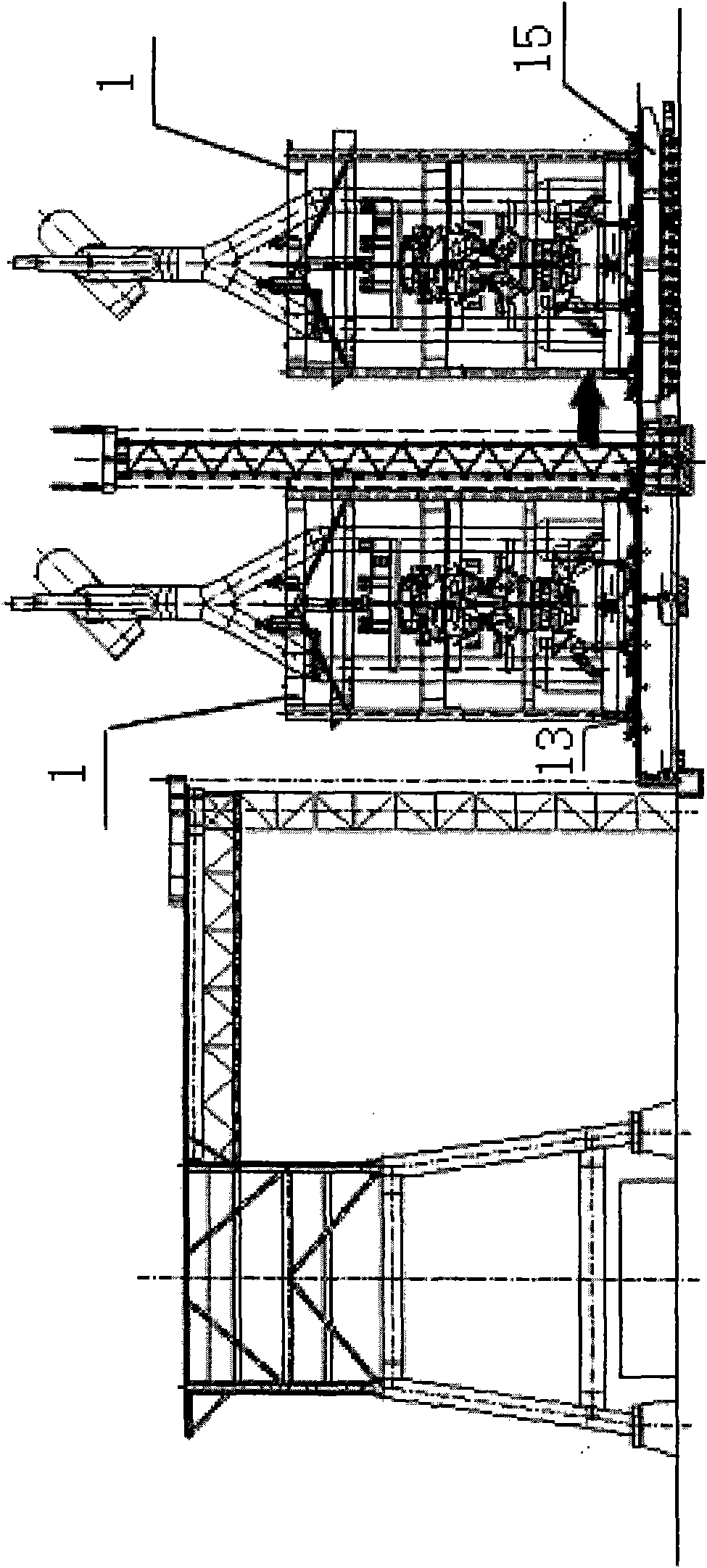

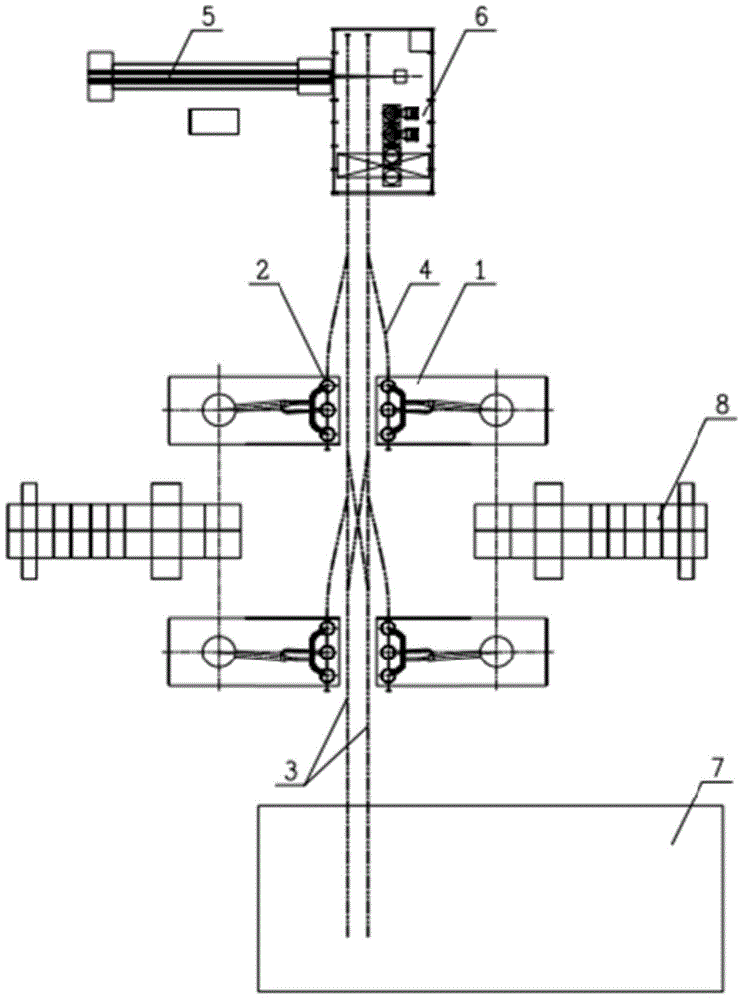

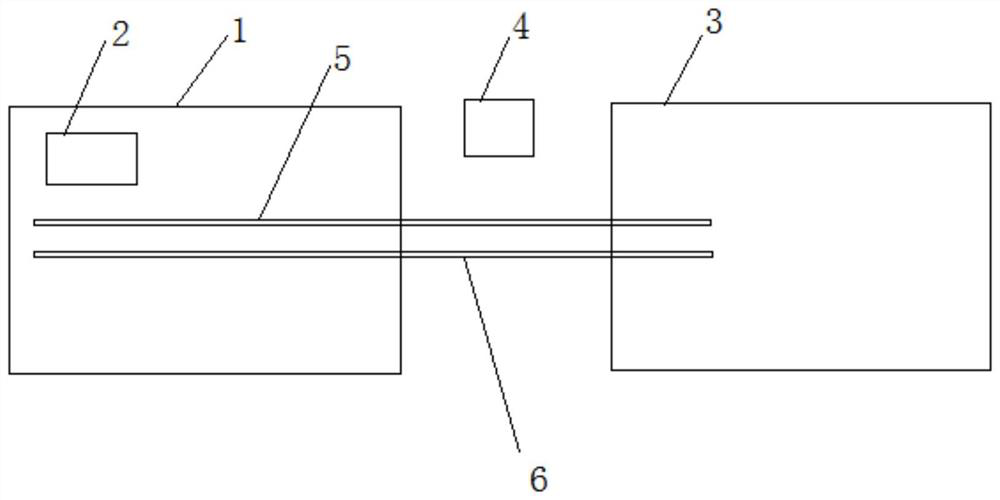

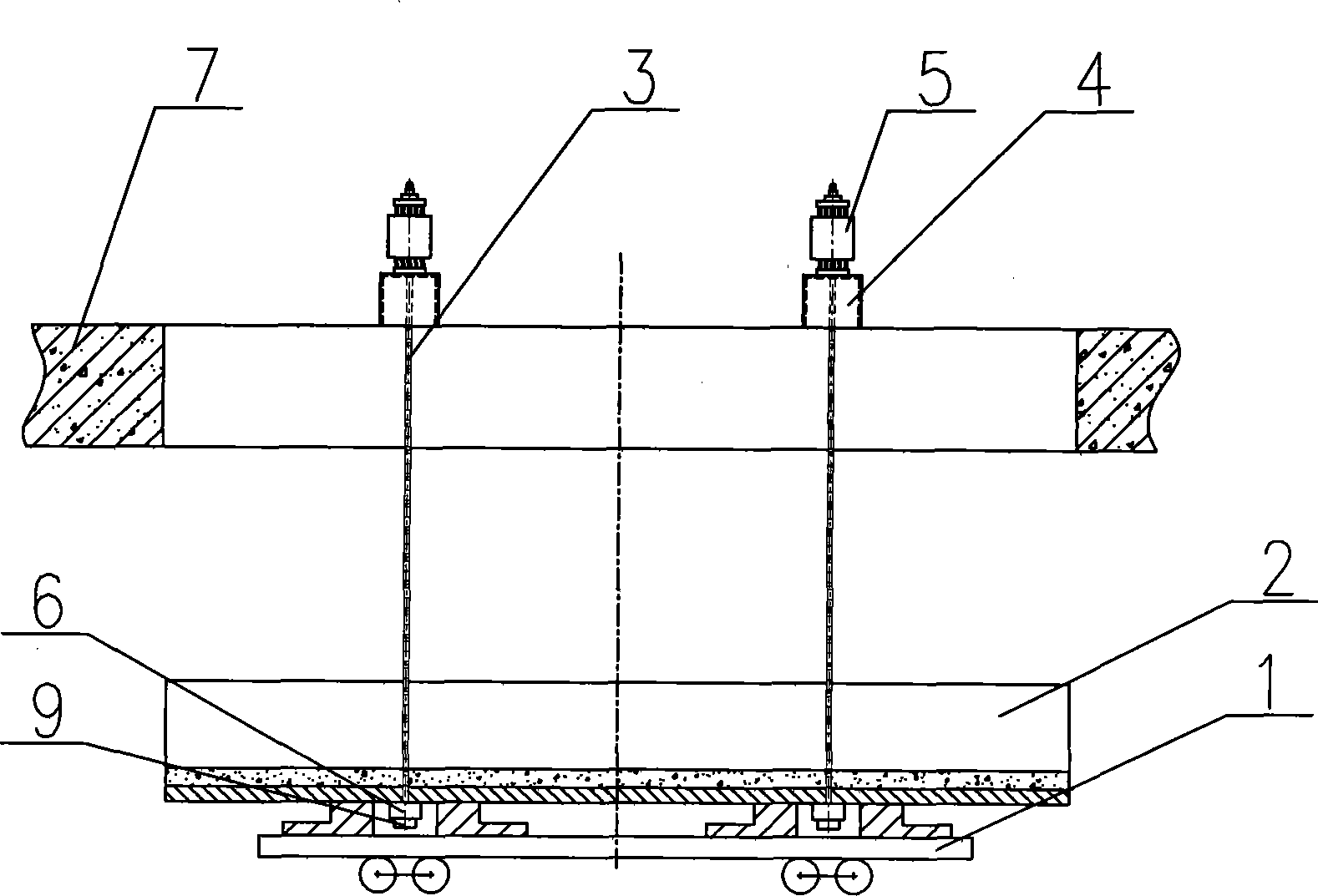

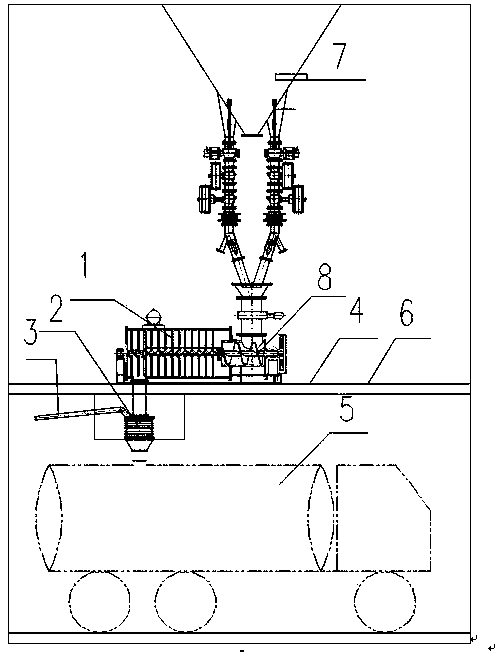

Molten iron transport system

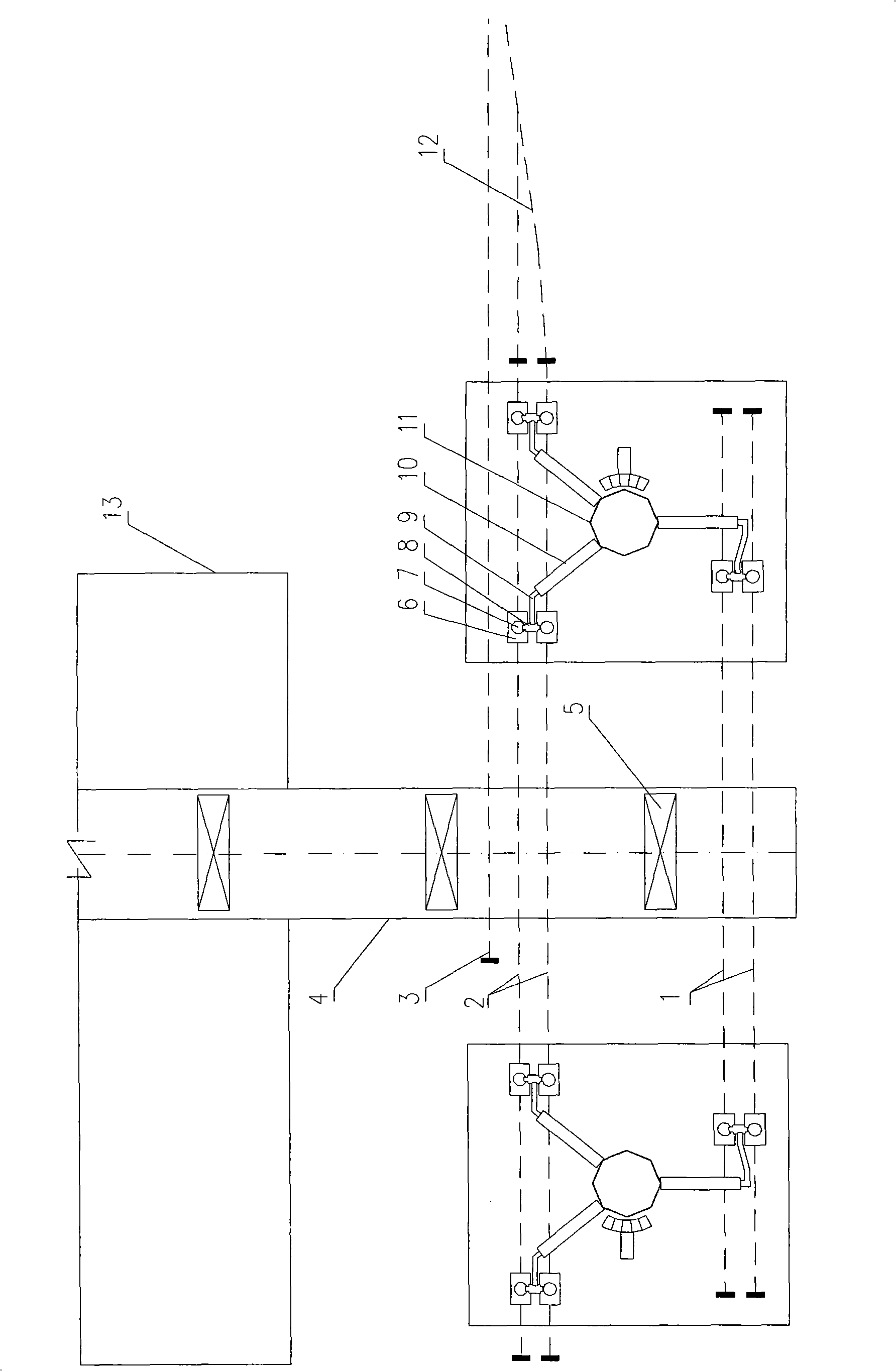

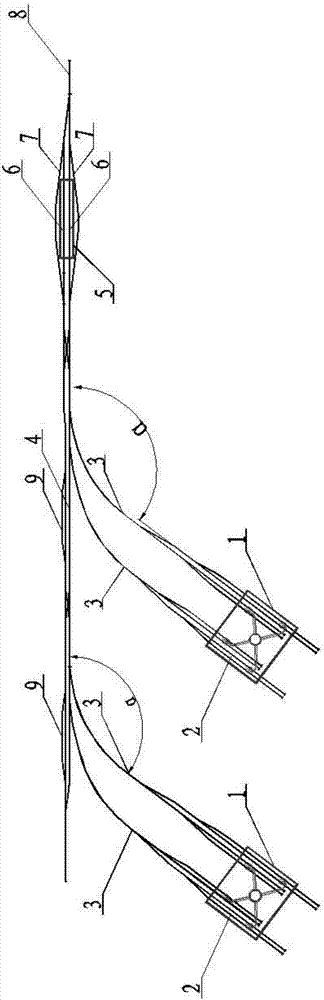

ActiveCN105170965ACompact layoutSmall footprintMelt-holding vesselsRailway tracksIron transportMaterials science

The invention discloses a molten iron transport system. The molten iron transport system comprises casting houses (1) of ironmaking blast furnaces and a steel-making workshop (7), parallel track lines (3) are arranged between the casting houses (1) of the ironmaking blast furnaces and the steel-making workshops (7), the casting houses (1) of a plurality of ironmaking blast furnaces are symmetrically and compactly arranged at two sides of the parallel track lines (3), each casting houses (1) of each ironmaking blast furnace is connected to adjacent track line (3) via a molten iron pot storing line (4) of each casting houses, and a molten iron pot (2) of each casting houses (1) of each ironmaking blast furnace can be transported to the track lines (3) along each molten iron pot storing line (4). The steel-making workshop (7) is arranged at one end of the parallel track lines (3), the molten iron pots (2) can be transported to the steel-making workshop (7) along the track lines (3). The molten iron transport system is compact in arrangement, less in land occupation without a transition across workshop and a crane, so the investment can be saved.

Owner:BERIS ENG & RES CORP

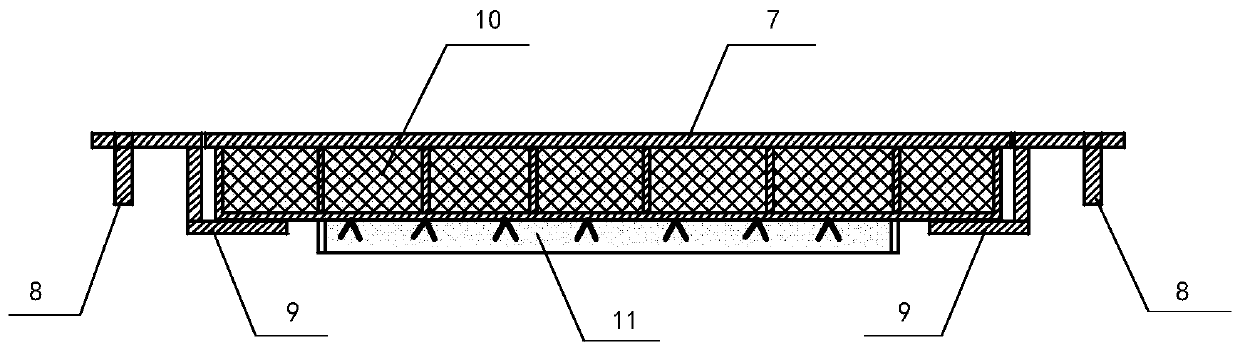

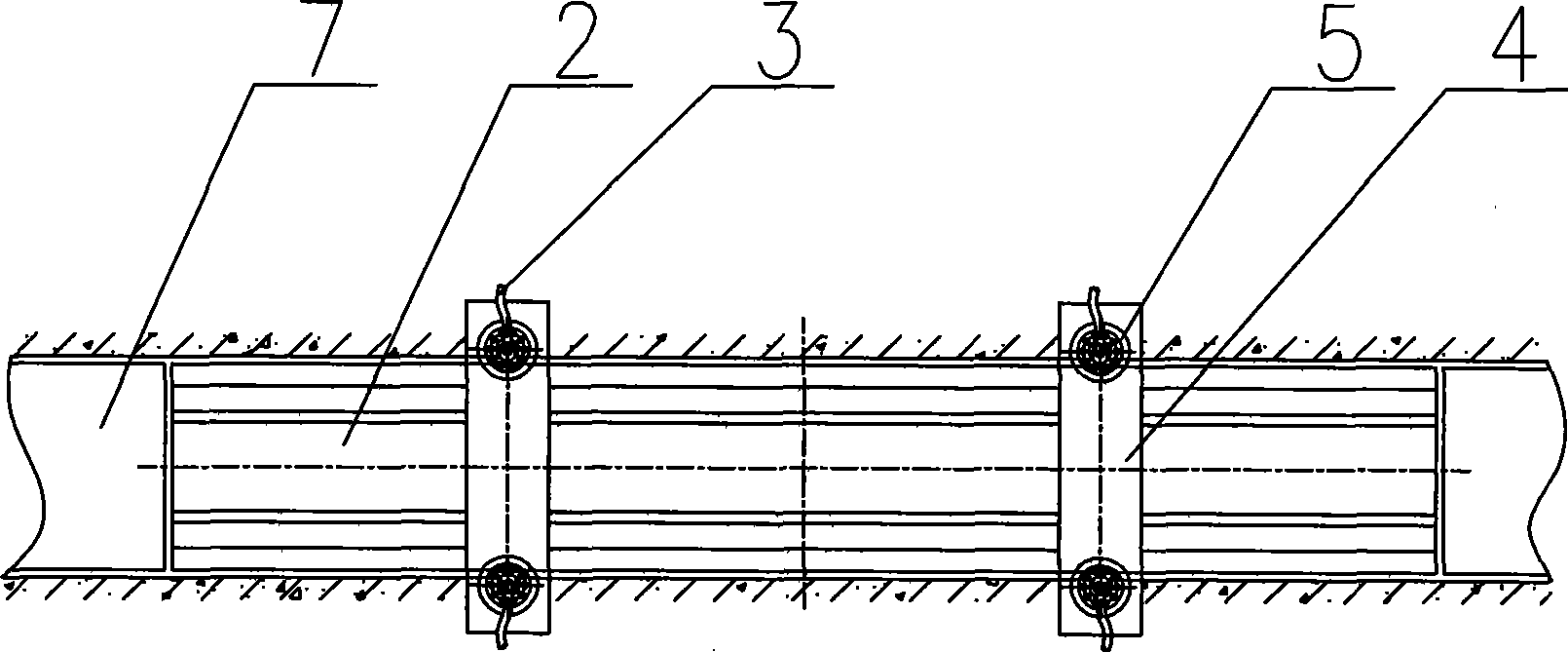

Dust removing device for blast furnace casting house

The invention discloses a dust removing device for a blast furnace casting house, which comprises a plurality of side suction hoods arranged on one side of a casting runner, wherein the casting runner is formed by oppositely and vertically arranged support devices; the top ends of the support devices are flush; cover plate components sealing the casting runner are arranged at the top ends of the support devices; and a casting runner smoke trapping channel communicated with an upper part space of the casting runner is arranged between every two adjacent side suction hoods. As smoke produced above the casting runner is confined to a sealing space formed by the cover plate components and the support devices all the time, the dust removing device can efficiently trap and treat the smoke through the side suction hoods and the casting runner smoke trapping channels.

Owner:LAIWU IRON & STEEL GRP

Totally-closed dust removal cover for casting house in front of blast furnace

PendingCN110306003AReasonable designSimple structureDischarge devicesProcess efficiency improvementSlagMaterials science

The invention discloses a totally-closed dust removal cover for a casting house in front of a blast furnace. The totally-closed dust removal cover comprises a general dust removal cover which covers the position above a main ditch in the casting house and is used for sealing the main ditch and preventing smoke diffusion, and cover plate assemblies which cover an iron ditch, a slag ditch and an emergency molten iron circulation channel in the casting house to seal and prevent smoke diffusion; the general dust removal cover and each cover plate assembly are detachably connected in a sealed manner; the general dust removal cover comprises a main ditch dust removal cover, a middle dust removal cover and a skimmer dust removal cover which are in sequential communication; the position, located above the main ditch, of the top of the ditch dust removal cover is detachably connected with a first dust removal pipeline, and the side face of the middle dust removal cover is connected with a second dust removal pipeline. Through usage of the detachable dust removal cover, the smoke in the casting house in front of the furnace can be effectively collected, and the environment of the casting house can be greatly improved.

Owner:SHAANXI LONGMEN IRON & STEEL

Blowing-type furnace protection charge for blast furnace and using method of blowing-type furnace protection charge

ActiveCN108504802AIncreased [Ti] contentIncrease Ti] contentBlast furnace componentsBlast furnace detailsManganeseNitrogen

The invention relates to blowing-type furnace protection charge for a blast furnace. The blowing-type furnace protection charge for the blast furnace comprises, by weight, 20%-40% of titanium-containing materials and 60%-80% of nitrogen-containing materials, wherein the content of TiO2 in titanium-containing material powder is equal to or higher than 40%, and the nitrogen-containing materials comprise one or two of manganese and silicon nitride and ferro-silicon nitride. The titanium-containing materials comprise one or more of titanium concentrate, high-titanium slag and rutile. A using method of the blowing-type furnace protection charge for the blast furnace comprises the steps that the blowing-type furnace protection charge for the blast furnace is placed into a furnace protection charge blowing tank on a casting house platform, and every time blast-furnace casting work is completed, the blowing-type furnace protection charge for the blast furnace is blown into the blast furnace from a tuyere above a hearth repair position. According to the blowing-type furnace protection charge for the blast furnace, the content of [Ti] in molten iron can be improved, the content of [N] in themolten iron in a hearth can also be remarkably improved, so that the quantity of separated-out TiN is improved, the utilization rate of TiO2 is increased, the furnace protection effect is enhanced, and the furnace protection time is shortened.

Owner:ANGANG STEEL CO LTD

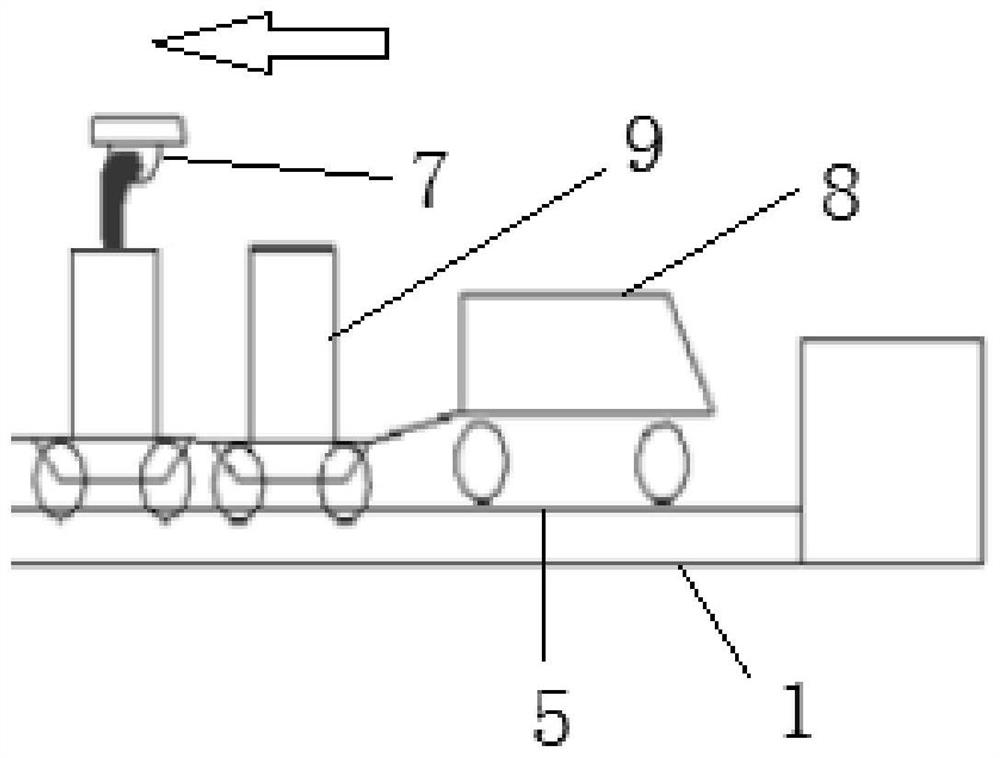

Blast furnace molten iron transportation system and blast furnace molten iron transportation method

PendingCN113736935AIncrease profitReduce in quantityMelt-holding vesselsBlast furnace componentsSteelmakingTransit system

The invention belongs to the technical field of blast furnace molten iron transportation, and particularly relates to a blast furnace molten iron transportation system and a blast furnace molten iron transportation method. The system comprises a blast furnace with a swing flow nozzle, a casting house, a molten iron transportation line unit and a steelmaking area, wherein the molten iron transportation line unit is composed of a first line and a second line. The system further comprises an iron receiving unit, an optional coordination tank and a plurality of tractors, wherein the iron receiving unit is composed of three molten iron tanks, one of the three molten iron tanks is arranged on any one of the first line and the second line, and the other two of the three molten iron tanks are arranged on the spare one of the first line and the second line. According to the system, the molten iron tanks are designed into the iron receiving unit in a 1+2 alignment mode, the molten iron is subjected to iron receiving in multiple batches, the operation efficiency of the molten iron tanks can be improved, the number of the required online molten iron tanks is remarkably reduced, and the number of the generated tail tanks is remarkably reduced.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

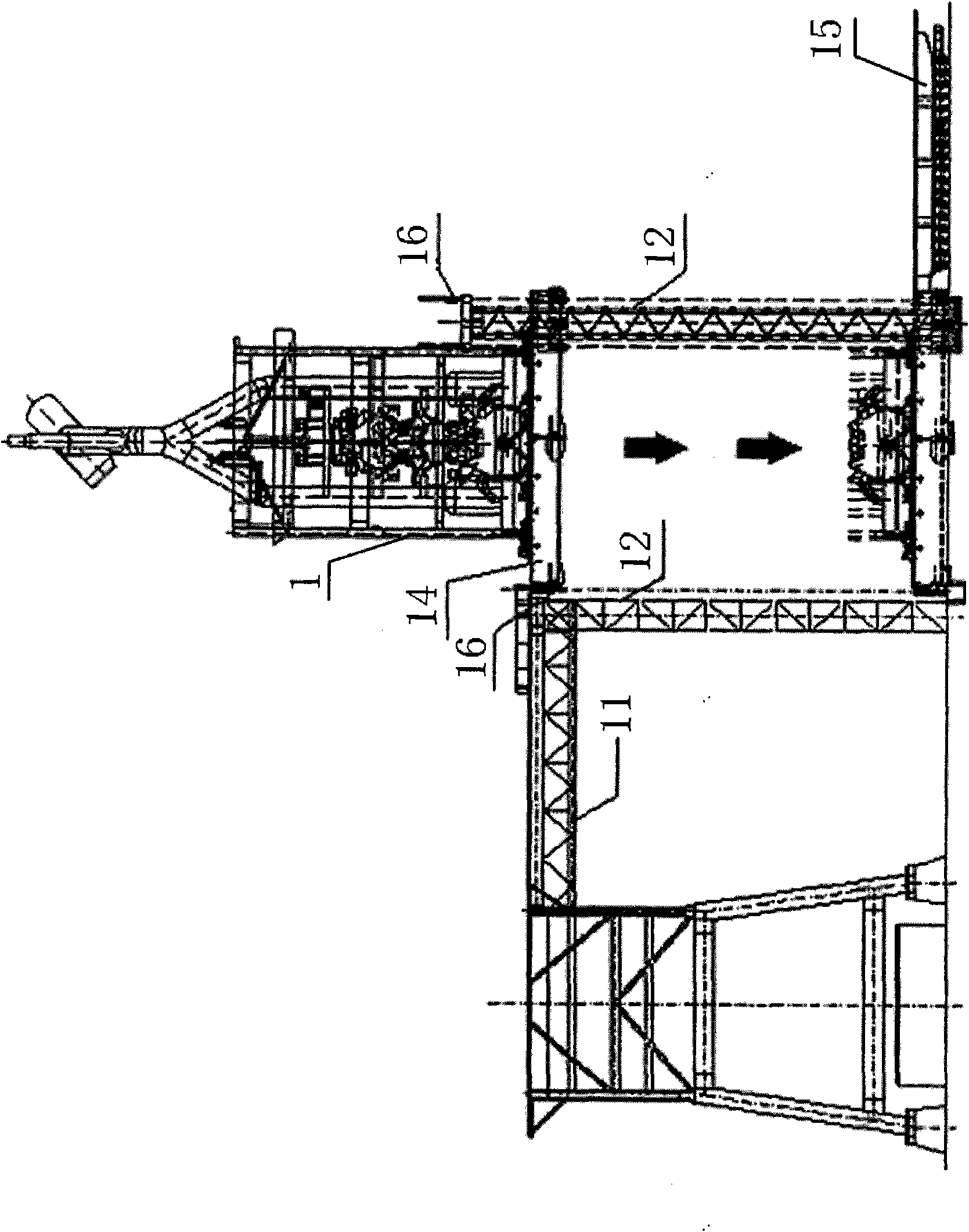

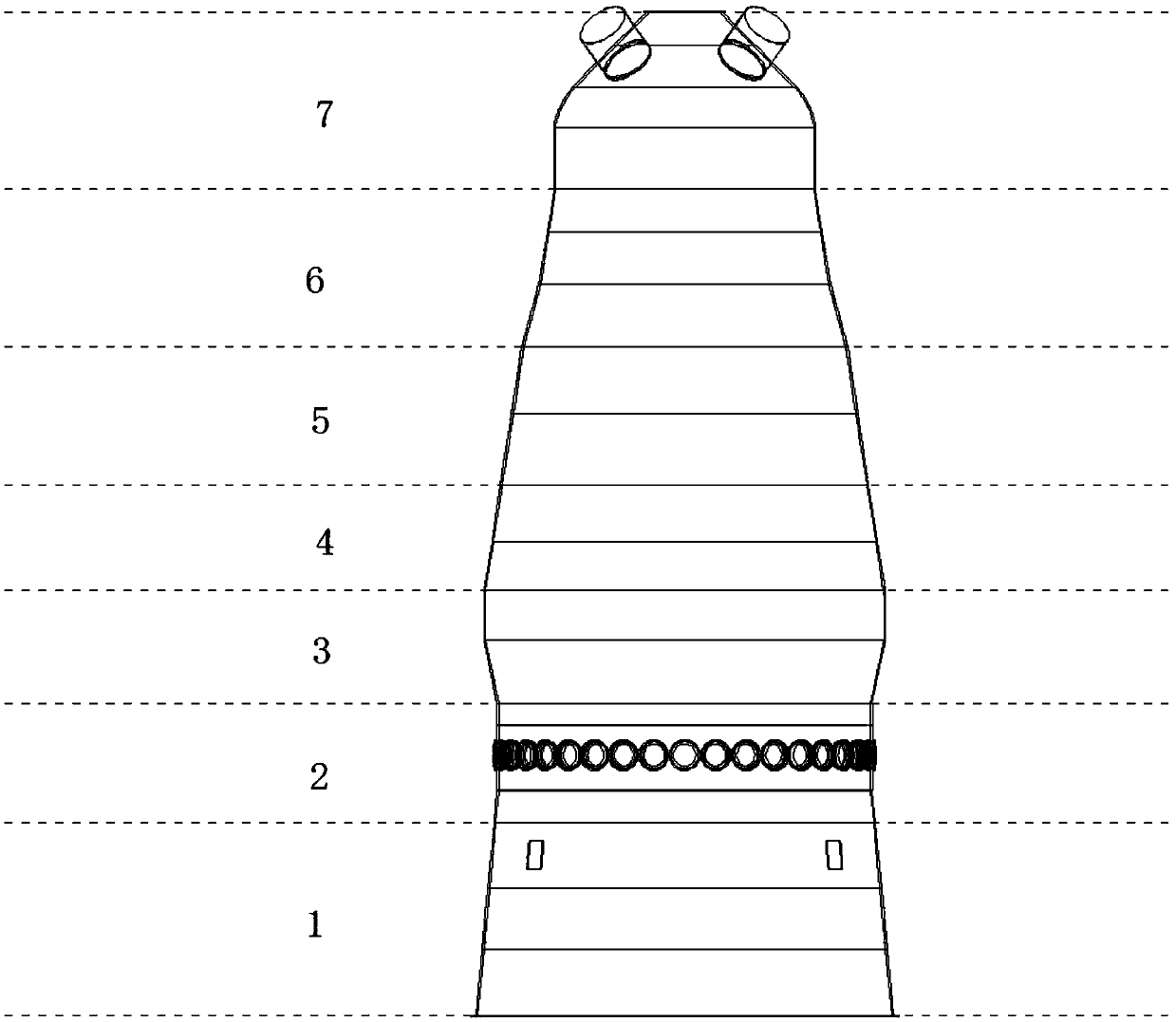

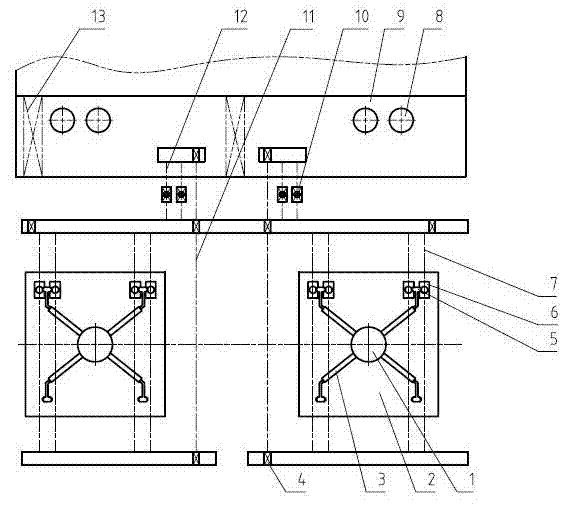

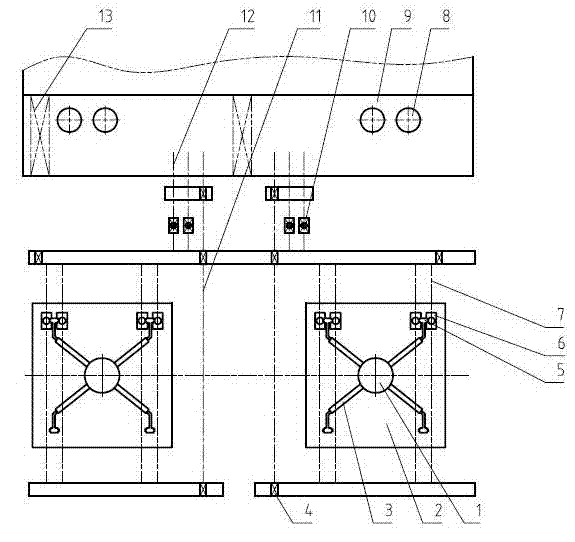

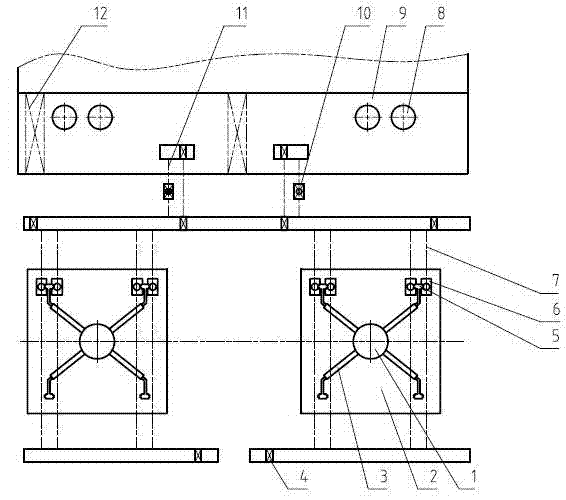

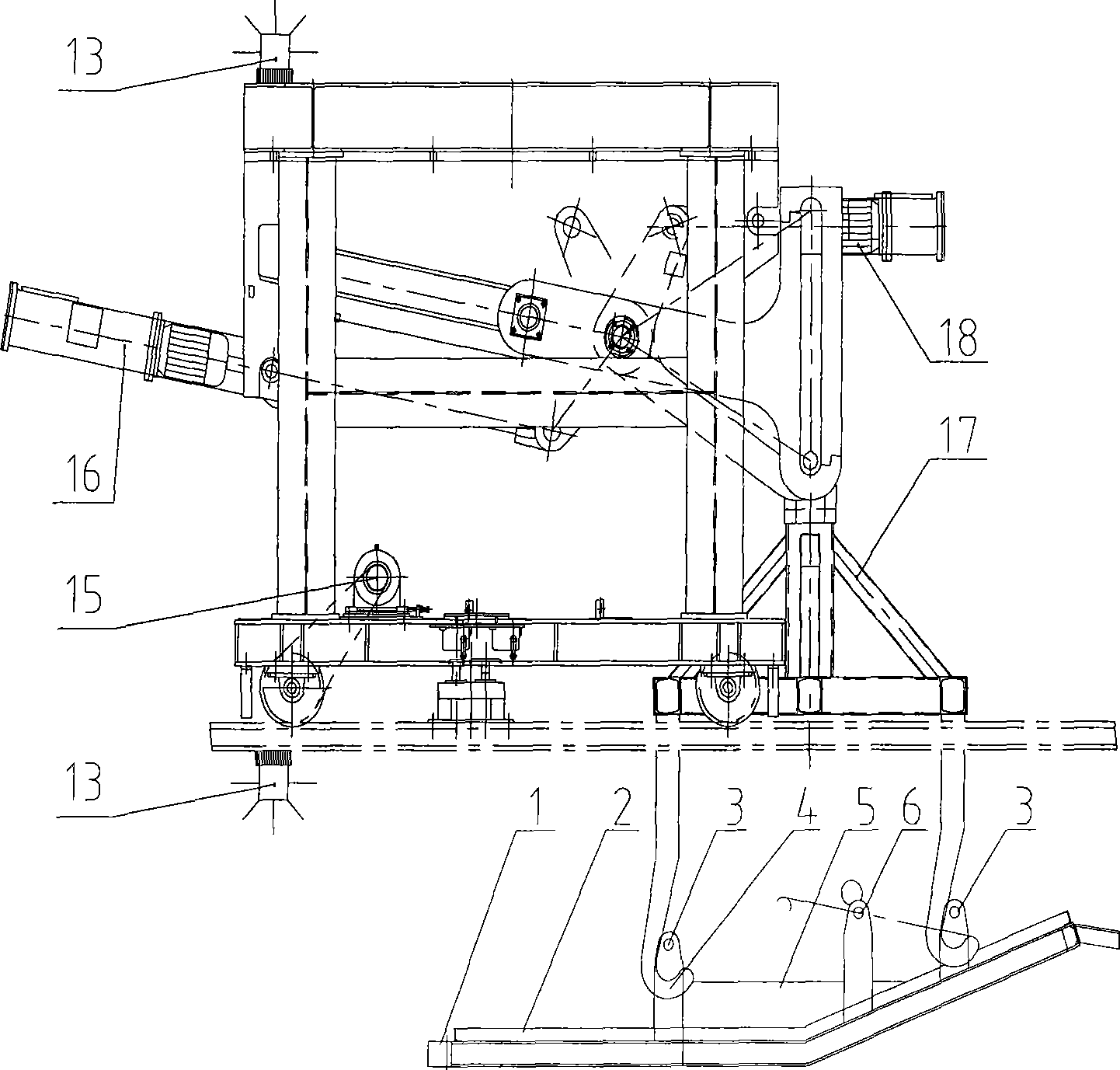

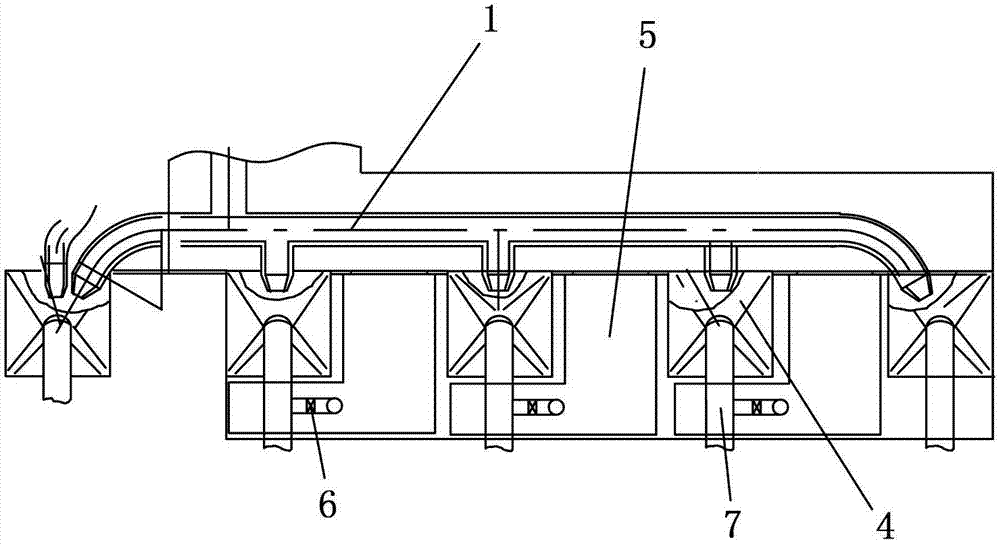

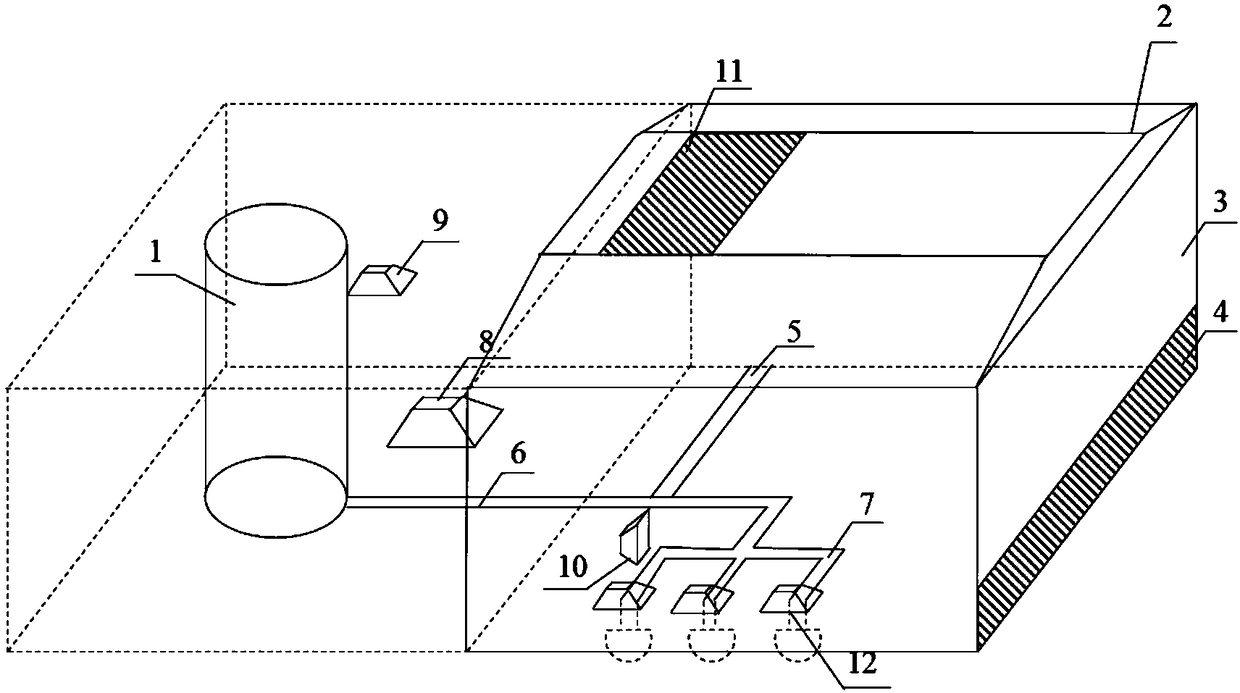

Small-middle blast-furnace casting house mill building construction system

ActiveCN108504809ASolve heat transferSolve the smoke organization in the factory buildingBlast furnace detailsExhaust gas handlingFlue gasArchitectural engineering

The invention relates to a small-middle blast-furnace casting house mill building construction system which comprises a mill building construction, a ventilation and dust-removal system and a small-middle blast-furnace casting house structure; the mill building construction comprises a mill building top (2) and a plurality of fences (3); the mill building construction is of a closed type; the ventilation and dust-removal system comprises a through long strip air inlet (4); the small-middle blast-furnace casting house structure comprises a blast furnace (1); the blast furnace (1) is arranged onone side of the mill building construction; the through long strip air inlet (4) is formed in the bottom of fence on the other side, facing a tap hole, of the blast furnace (1); outside fresh air ishorizontally sent in along the bottom of the mill building construction from the through long strip air inlet, and dust-containing high-temperature flue gas generated by the small-middle blast-furnacecasting house structure is pushed into the ventilation and dust-removal system so as to be trapped and discharged out. The system can effectively improve an air flow structure in a mill building, optimize the ventilation blast capacity, improve the smoke dust collection efficiency and prevent the smoke dust from escaping outside.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

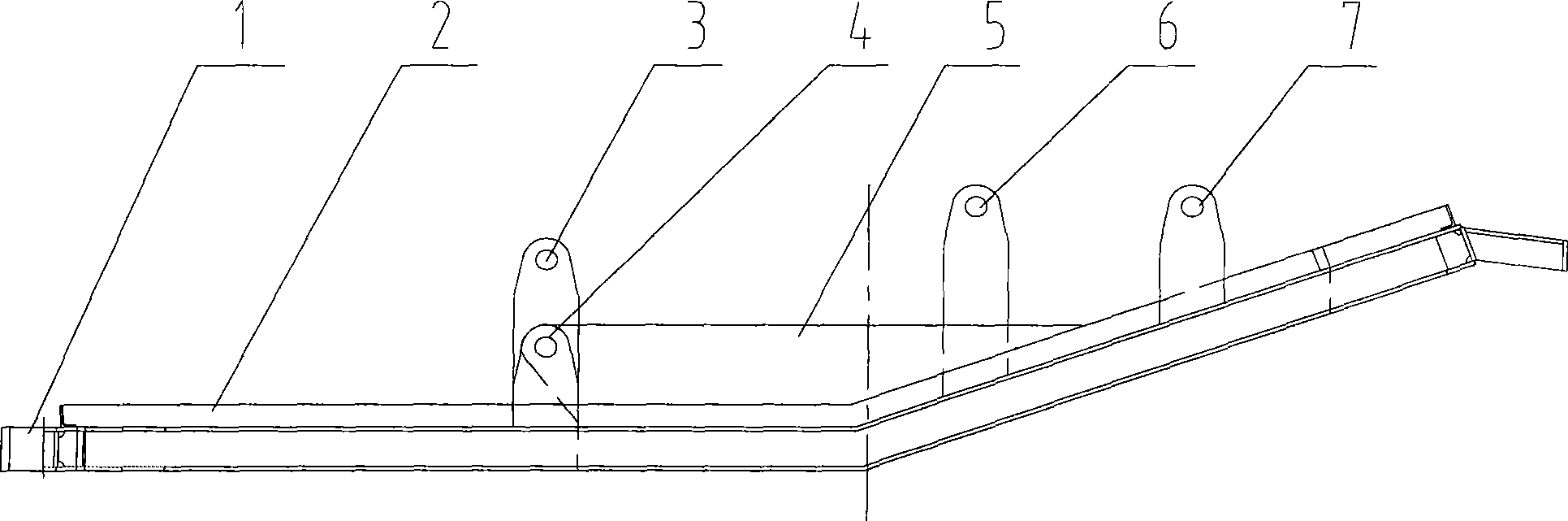

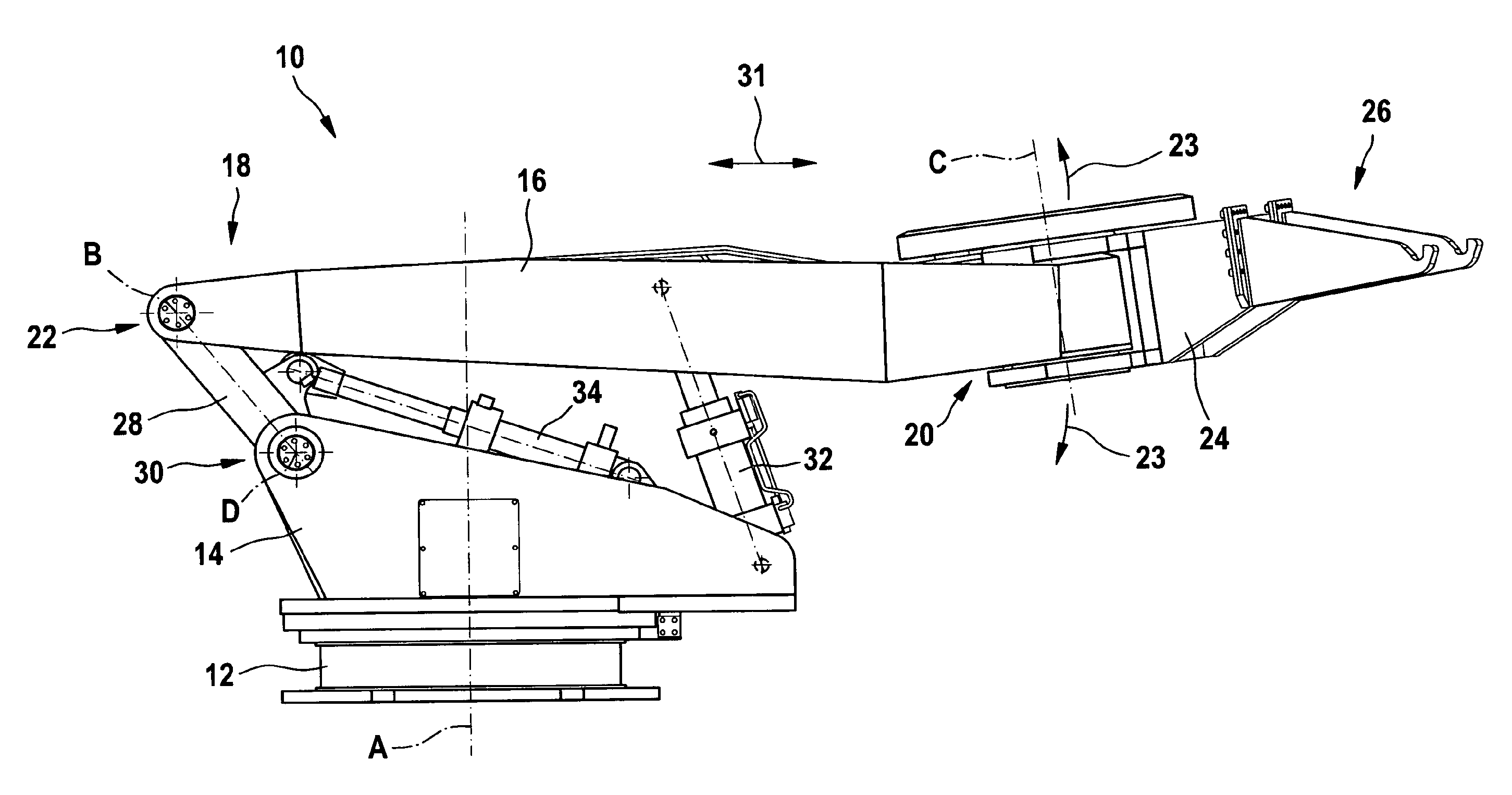

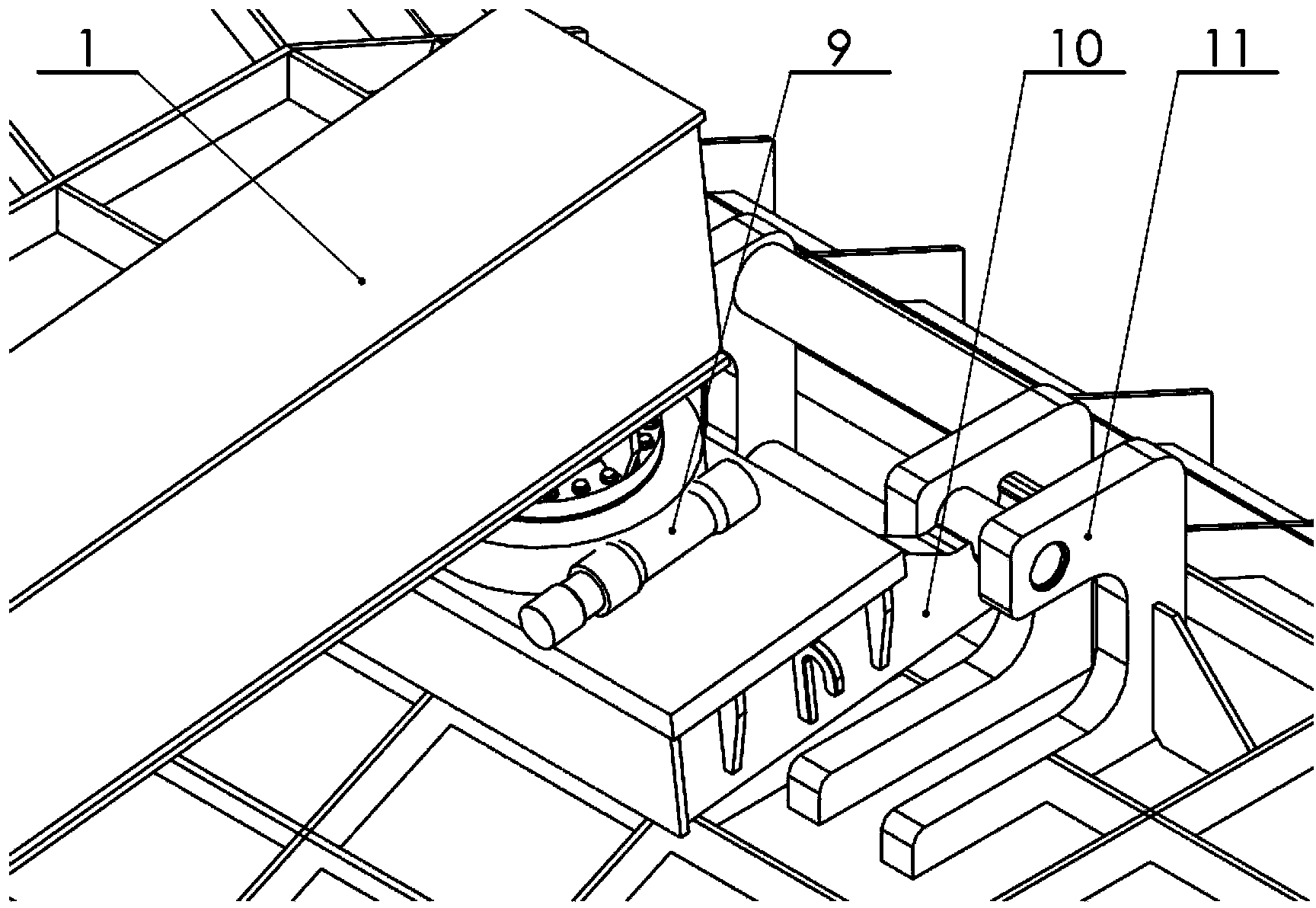

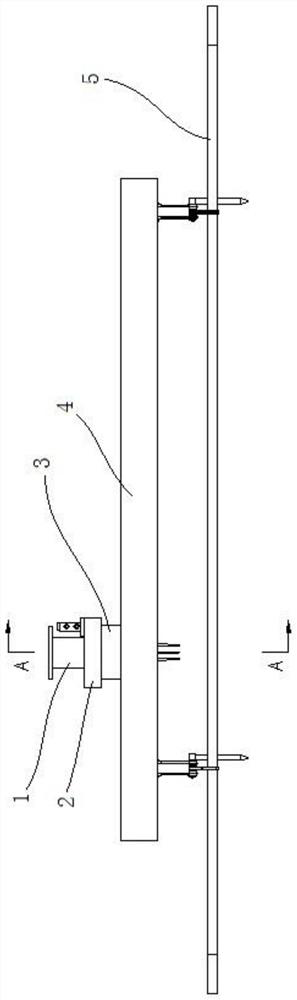

Handling device for elements of tapping runners

InactiveCN101248325AIncrease flexibilityCompact structureBlast furnace detailsCharge manipulationShaft furnaceMechanical engineering

A handling device for elements of tapping runners on a shaft furnace, in particular for runner covers, the device including a support base arranged on the cast house floor of a blast furnace, laterally of the tapping runner and a frame ( 14 ) which is supported by the support base and connected thereto by means of a bearing defining a first axis of rotation, which is essentially vertical and about which the frame can rotate relative to the support base. The device further includes a lifting arm having a first end portion and a second end portion, the first end portion being connected to the frame by means of at least a first rotational joint defining a second axis of rotation, which is essentially horizontal, about which the lifting arm can pivot in order to lower or lift its second end portion. A handling member is connected to the second end portion of the lifting arm by means of a second rotational joint defining a third axis of rotation, which lies in a plane essentially perpendicular to the second axis of rotation, about which the handling member can pivot with respect to the lifting arm. Furthermore, the handling device includes a fork-type grab connected to the handling member and arranged so as to allow picking up; transferring and putting down such elements.

Owner:TMT TAPPING MEASURING TECH

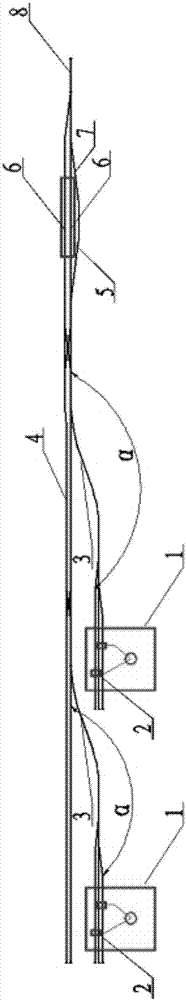

Ironmaking-steelmaking interface short distance melted iron transportation system

ActiveCN106985832AReduce temperature dropReduce start-stop operationsMelt-holding vesselsRailway componentsSteelmakingTransit system

The invention discloses an ironmaking-steelmaking interface short distance melted iron transportation system. The system comprises a blast furnace tapping yard, an under furnace iron bearing wire, a melted iron transport artery, a reladling station, a reladling line and a lead track, wherein the melted iron transport artery, the reladling track and the lead track are connected in sequence, the under furnace iron bearing wire below the blast furnace tapping yard passes through a casting house connecting line and is merged into the melted iron transport artery, an alpha included angle is formed between a casting house connecting line and the melted iron transport artery towards one side of the reladling station, and the alpha is larger than or equal to 90 degrees and smaller than or equal to 180 degrees; according to the system, the whole traction transport of a melted iron transport heavy vehicle from the blast furnace tapping yard to the steelmaking reladling station is achieved, the transport distance between the blast furnace tapping yard and a steelmaking workshop is shortened in a maximum degree, and the temperature drop of the melted water is reduced; the operation steps and the operation time of engine start-stop can be effectively reduced, the transport operation efficiency is improved, and the system has good economic and social benefits.

Owner:CISDI ENG CO LTD

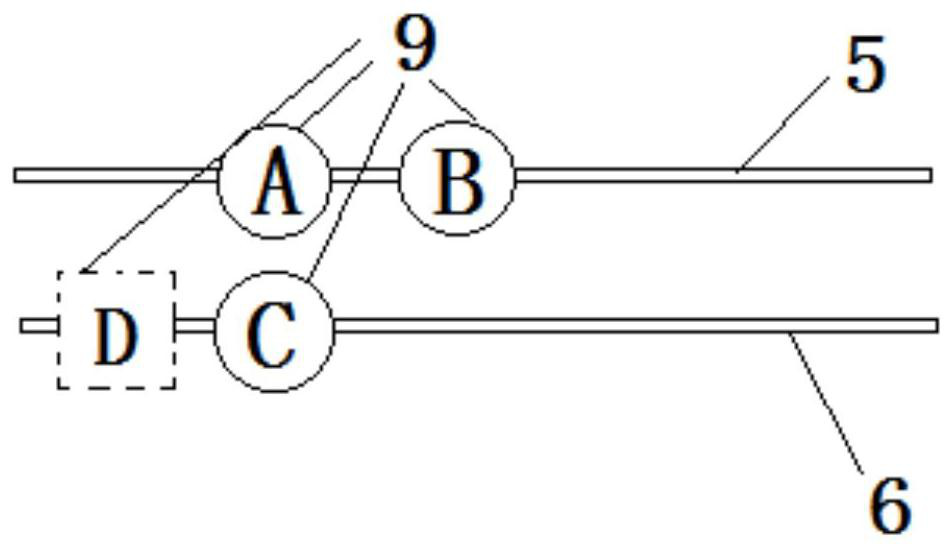

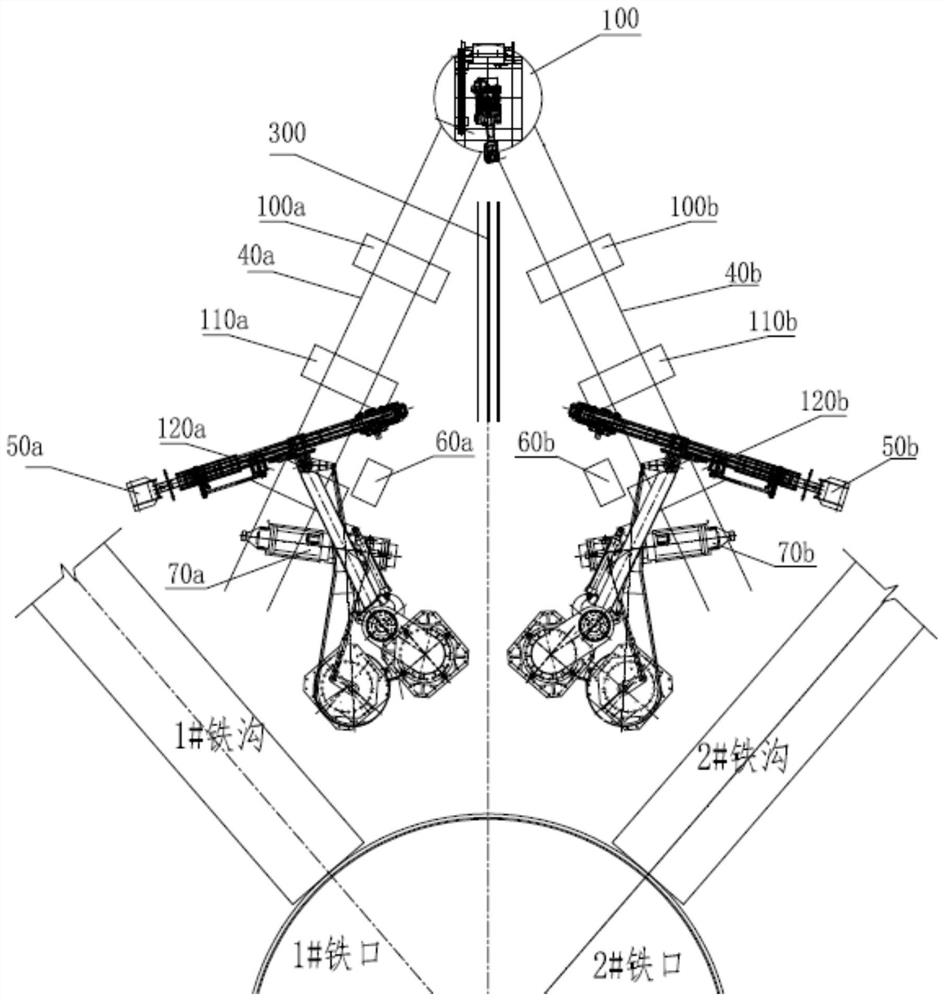

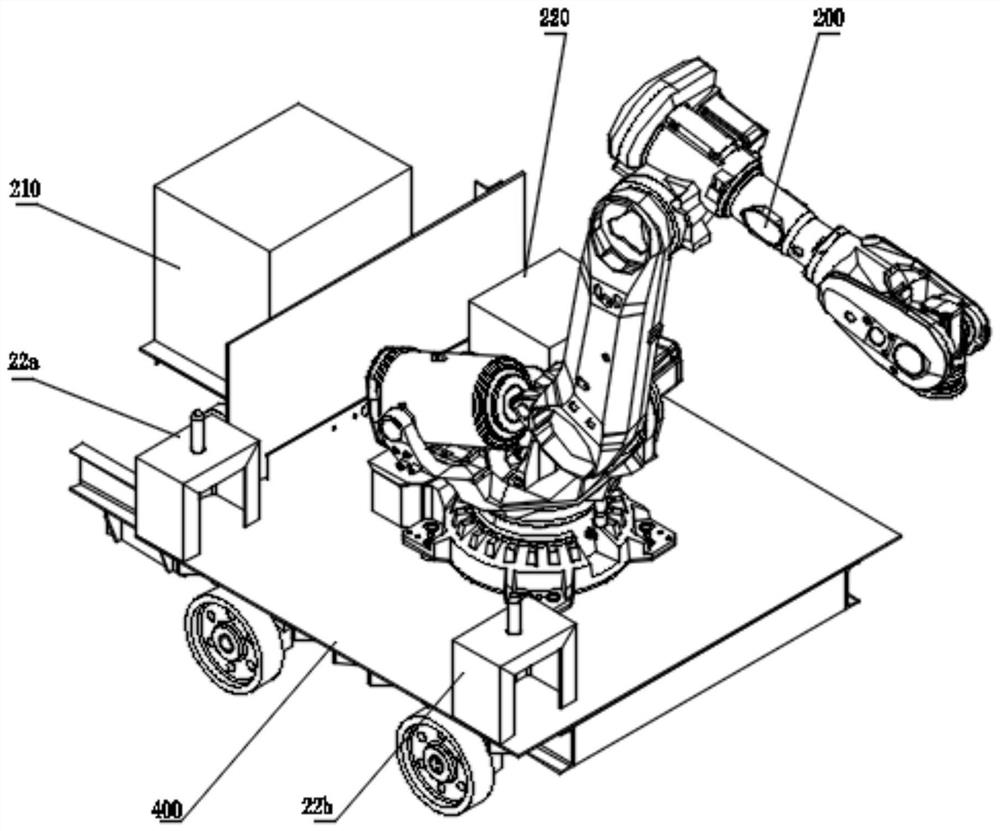

System for adding stemming and replacing crooked chisel to multiple iron notches and working method

PendingCN112458220AReduce the number of fixture changesSolve the problems of large space occupation and high production and maintenance costsBlast furnace componentsBlast furnace detailsChiselControl engineering

The invention belongs to the technical field of blast furnace front casting house equipment, and particularly provides a system for adding stemming and replacing a crooked chisel to multiple iron notches and a working method. The system comprises a mechanical arm, and further comprises a positioning module and iron notch rails corresponding to the iron notches one to one, wherein a flat trolley isarranged on the iron notch rails, and the mechanical arm is arranged on the flat trolley; when the flat trolley receives an operation instruction, the mechanical arm is driven to move to the corresponding operation position along the iron notch rails according to positioning information of the positioning module; and the mechanical arm controls a stemming clamp at the tail end to grab the stemming to fill a clay gun or is connected with a crooked chisel clamp to replace the crooked chisel. According to the positioning information, the flat trolley drives the mechanical arm to move to the corresponding operation position along the iron notch rails, when the crooked chisel is not replaced, the crooked chisel clamp and the stemming clamp are separated, and when the crooked chisel is replaced, the crooked chisel clamp is combined to the stemming clamp, so that cost is saved, efficiency is improved, and meanwhile the frequency of replacing the clamp through the mechanical arm is reduced.

Owner:WISDRI ENG & RES INC LTD

Transferring and furnace-entering device for refractory material and transferring and furnace-entering method for refractory material

ActiveCN106005936AEffective protectionIntegrity guaranteedLoading/unloadingMechanical conveyorsRefractoryMaterials science

The invention relates to a transferring and furnace-entering device for refractory material and a transferring and furnace-entering method for the refractory material. According to the device, a casting house platform and a tuyere platform are arranged on the outer side of a furnace body, and a first tuyere and a second tuyere are formed in the part, located above the tuyere platform, of the furnace body; a scaffold is erected on the casting house platform, a working platform is laid at the top of the scaffold and is provided with a track platform, the track platform penetrates through the second tuyere for entering the furnace body, and a transportation track is laid on the track platform and is provided with a track car; the tuyere platform is provided with a winching mechanism, and the winching mechanism is provided with a steel wire rope; a first fixed pulley is arranged on the inner side wall of the part, corresponding to the first tuyere, of the furnace body, a second fixed pulley is arranged at the top of the furnace body, a third fixed pulley is arranged on the inner side wall of the part, corresponding to the second tuyere, of the furnace body, and the steel wire is connected to the track car after sequentially winding around the three fixed pulleys. According to the device and the method, the transferring efficiency can be greatly improved, and the integrity of the refractory material can be guaranteed.

Owner:河北二十冶建设有限公司

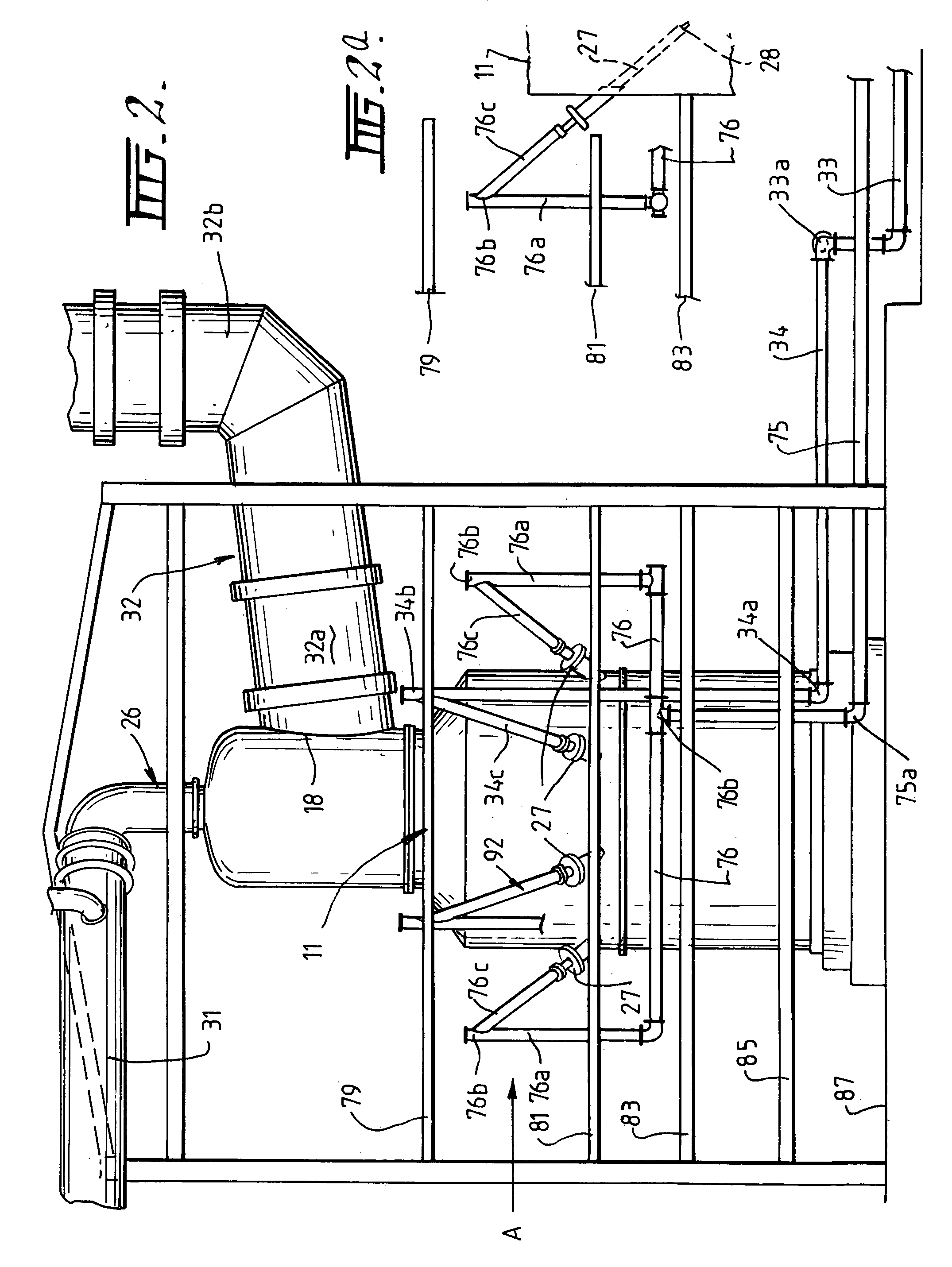

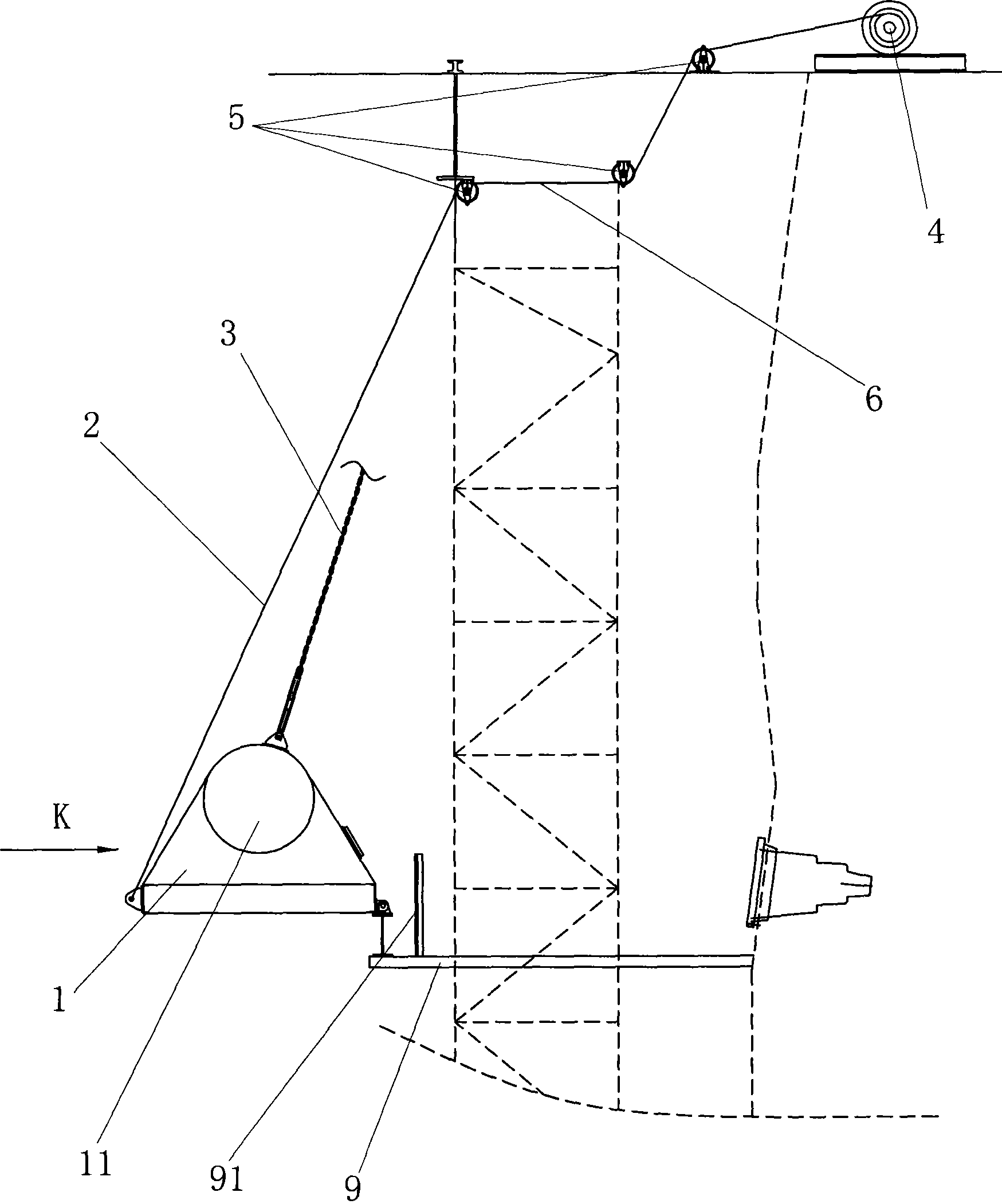

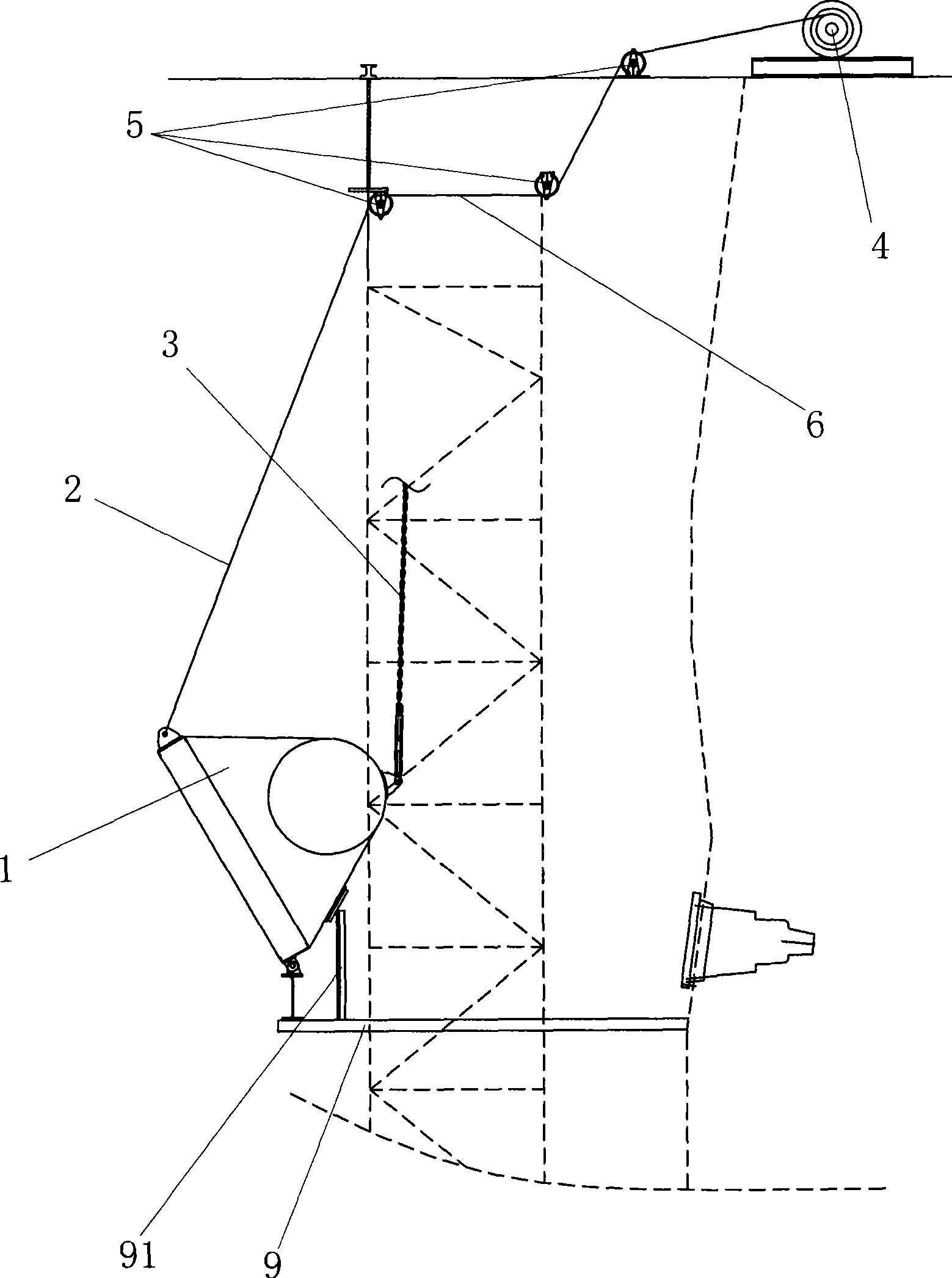

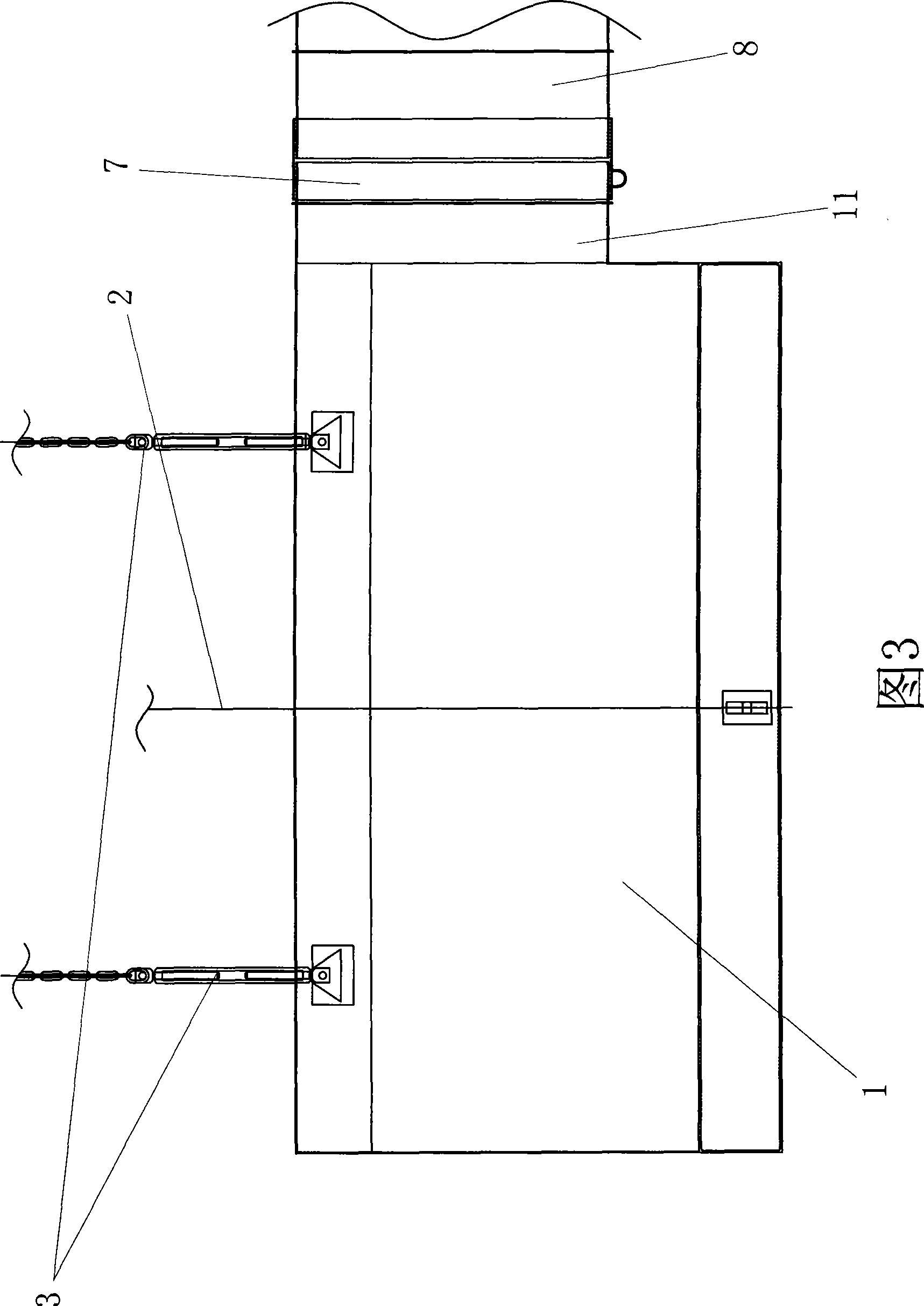

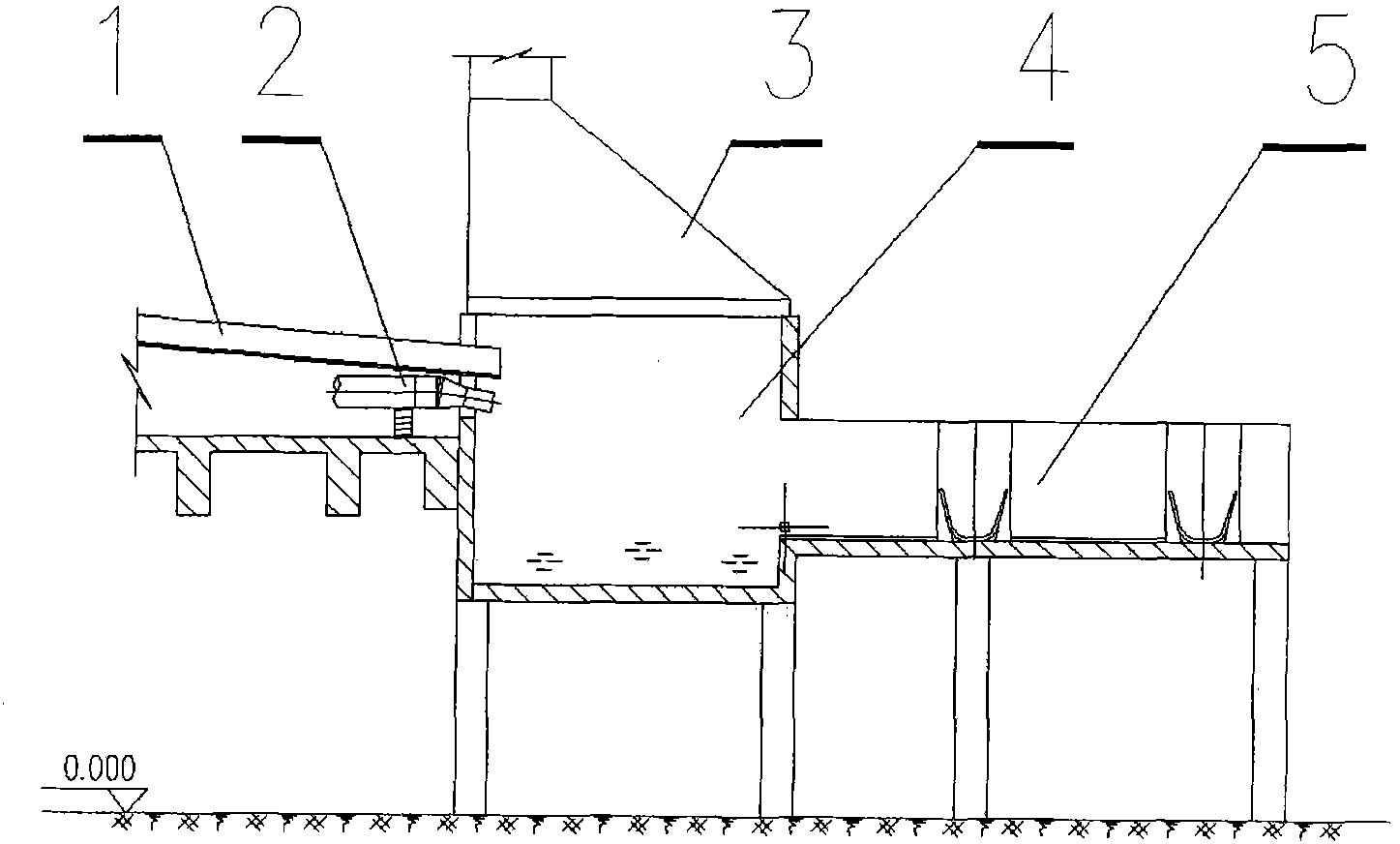

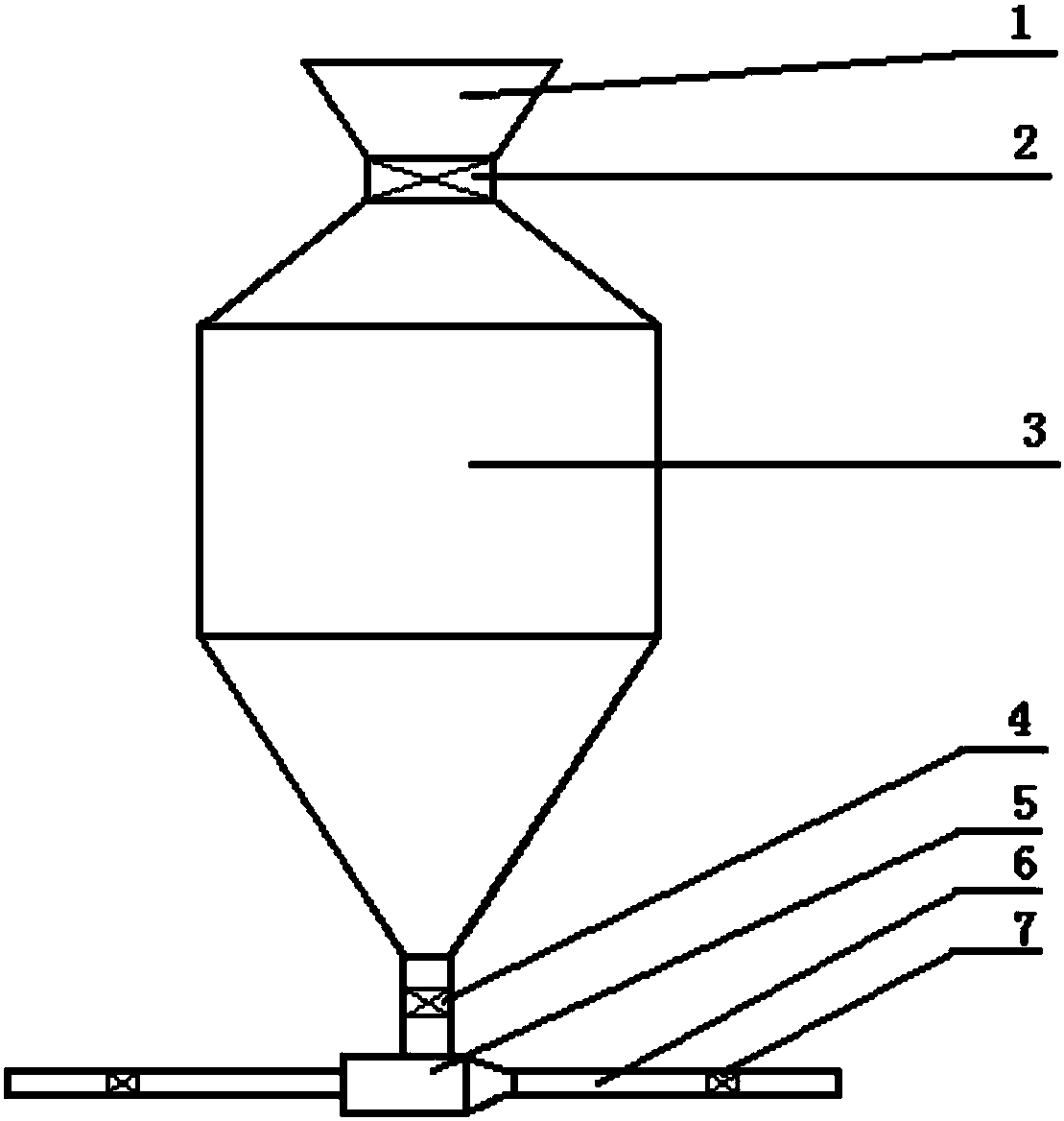

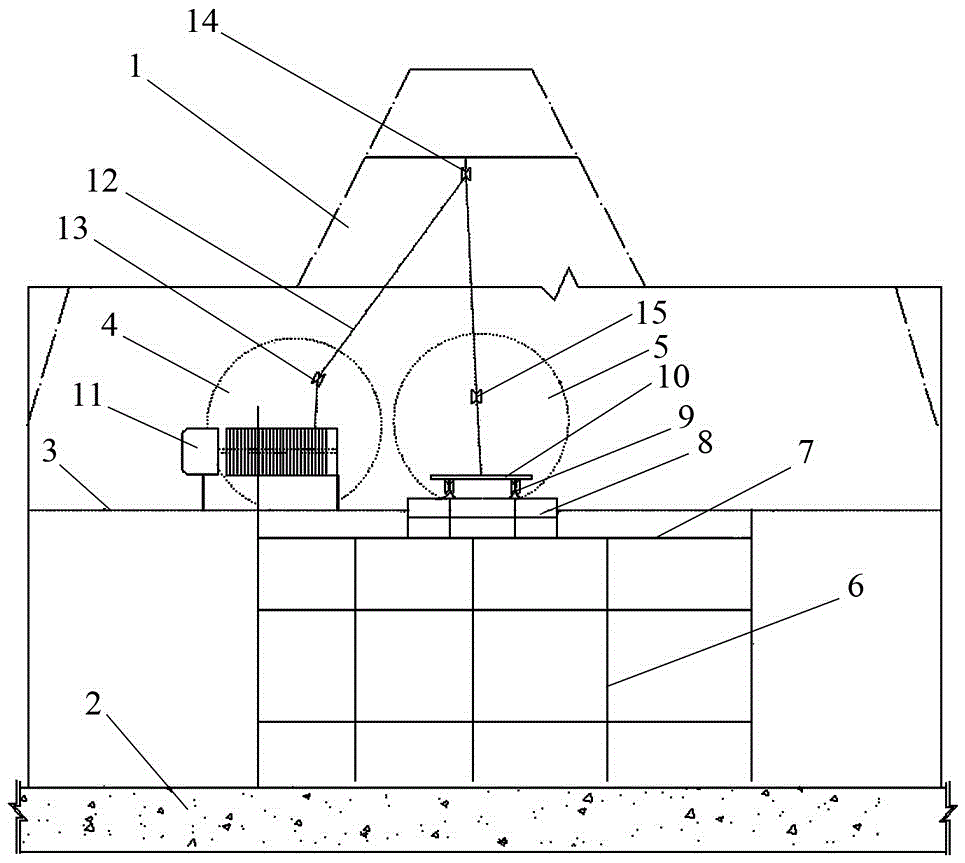

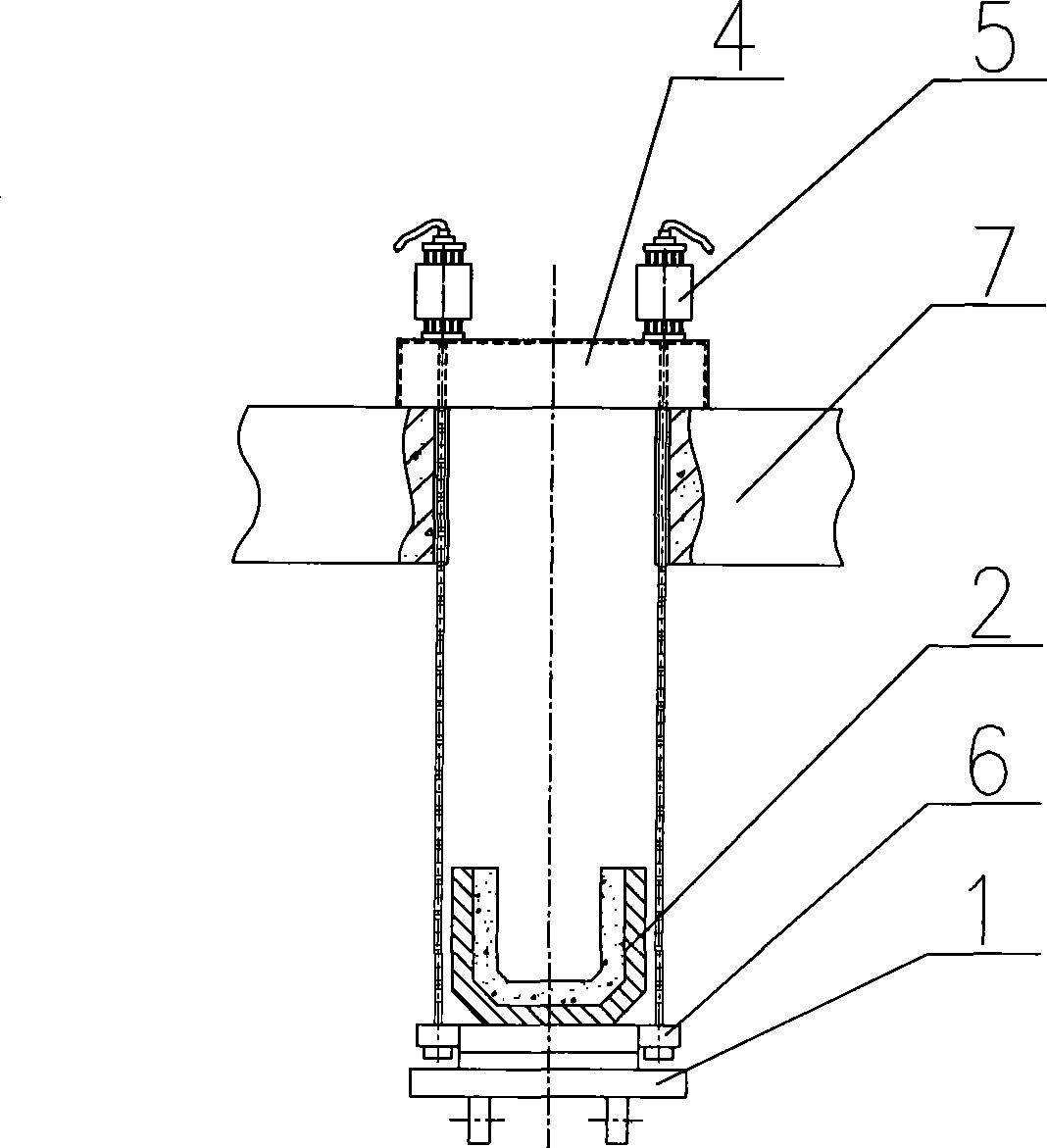

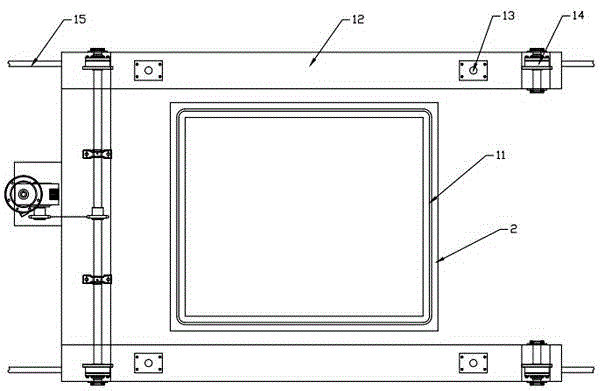

System for replacing blast furnace activity main trough and replacement method therefor

The invention relates to a system for replacing a blast furnace activity main trough, which is characterized in that the system comprises a cast house platform (7), a support beam (4) arranged on the cast house platform (7), a raiser arranged on the support beam (4), a lift cable (3) with the head end tightly clamped in the raiser (5), and a platform lorry (1) used for transporting the main trough. At the same time, the invention relates to a method for replacing the blast furnace activity main trough. The replacement system and the replacement method have the advantages of higher working performance, safety and reliability; the occupied space of the cast housing platform is small; and no extra investment is needed.

Owner:CISDI ENG CO LTD

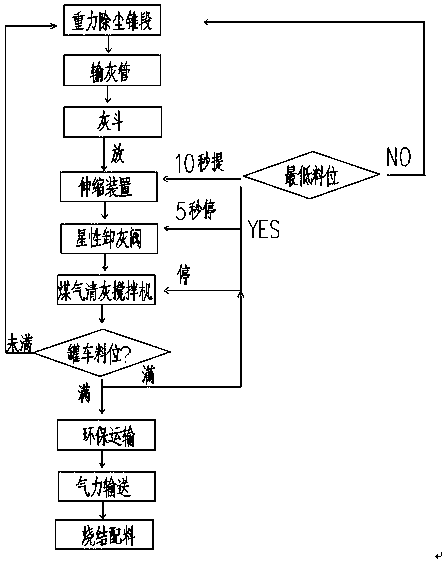

Blast furnace gravitational dust and ash removal device

InactiveCN109897926ARealize sealed dust dischargeUnloading guaranteeDust arrestersFly ashMaterials science

The invention relates to a blast furnace gravitational dust and ash removal device. The blast furnace gravitational dust and ash removal device is characterized by comprising a gas ash removal stirrer, an electric telescopic device, a blast furnace casting house dust removal system pipeline, an electric telescopic device left-and-right sliding rail, a tank car, a steel structure platform, cone section tuning fork material level switches and a star type ash discharge valve; and the gas ash removal stirrer and the left-and-right sliding rail are arranged on the steel structure platform, the startype ash discharge valve is arranged below the cone section tuning fork material level switches, the blast furnace casting house dust removal system pipeline is arranged on the electric telescopic device, and the electric telescopic device is located below the steel structure platform. According to the scheme, the problem that environmental pollution is easily generated by gravitational dust removal and ash discharge and the problem about use of fly ash are solved, and energy saving and environmental protection are achieved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Horizontally-moving multi-die casting house with jetting work rooms

The invention discloses a horizontally-moving multi-die casting house with jetting work rooms. The horizontally-moving multi-die casting house comprises a casting plate and a casting well. A high-speed ejector component is arranged in the casting plate. A lifting oil cylinder and a dummy ingot platform moving up and down along with the lifting oil cylinder are arranged in the casting well. Multiple independent dummy ingot annular seats capable of rotating by 360 degrees in the horizontal direction are arranged on the dummy ingot platform. The casting plate is located on the horizontal ground, the casting well is located under the horizontal ground, and a sealing piece is arranged between the casting plate and the casting well. Casting die rings and locating devices used in cooperation with the casting die rings are arranged at the bottom of the casting plate. The casting plate is divided into multiple work rooms, and the casting die rings and the locating devices are arranged in all work rooms. The horizontally-moving multi-die casting house with the jetting work rooms has the advantages that the purpose of synchronous jet molding of multiple bars is achieved, and the lengths of the cast bars are greatly enlarged; the casting plate and the casting well are dynamically sealed, so that the purpose that the multiple ultralong aluminum alloy bars which are synchronously produced can be conveniently lifted out is achieved, and it is ensured that the whole casting house carries out jet molding under the sealed oxygen-free condition.

Owner:金培力

Method for improving quality stability of mixed iron material for sintering

The invention provides a method for improving the quality stability of a mixed iron material for sintering. The method comprises the following steps: (1) conveying blast furnace gas ash, blast furnace casting house fly ash, steel-making fly ash and oxide scale which are subjected to batching to a powerful mixing granulator for premixing and pre-granulating to obtain a uniformly mixed material; (2) placing the uniformly mixed material in a middle bin position of an ore blending and stacking stock bin by using a bucket type material taking machine; and (3) carrying out secondary stacking on the uniformly mixed material and the mineral powder which are subjected to batching. According to the method, the mixed use effect of the iron-containing fly ash and the mineral powder can be improved, the comprehensive quality stability of the mineral powder for sintering is improved, the sintering mineralization atmosphere is stabilized, and the quality of sintered ore is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com