Handling device for elements of tapping runners

A technology for processing devices and tapping troughs, which is applied to discharge devices, blast furnace parts, furnace components, etc., and can solve problems such as difficult parking positions and bulky structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

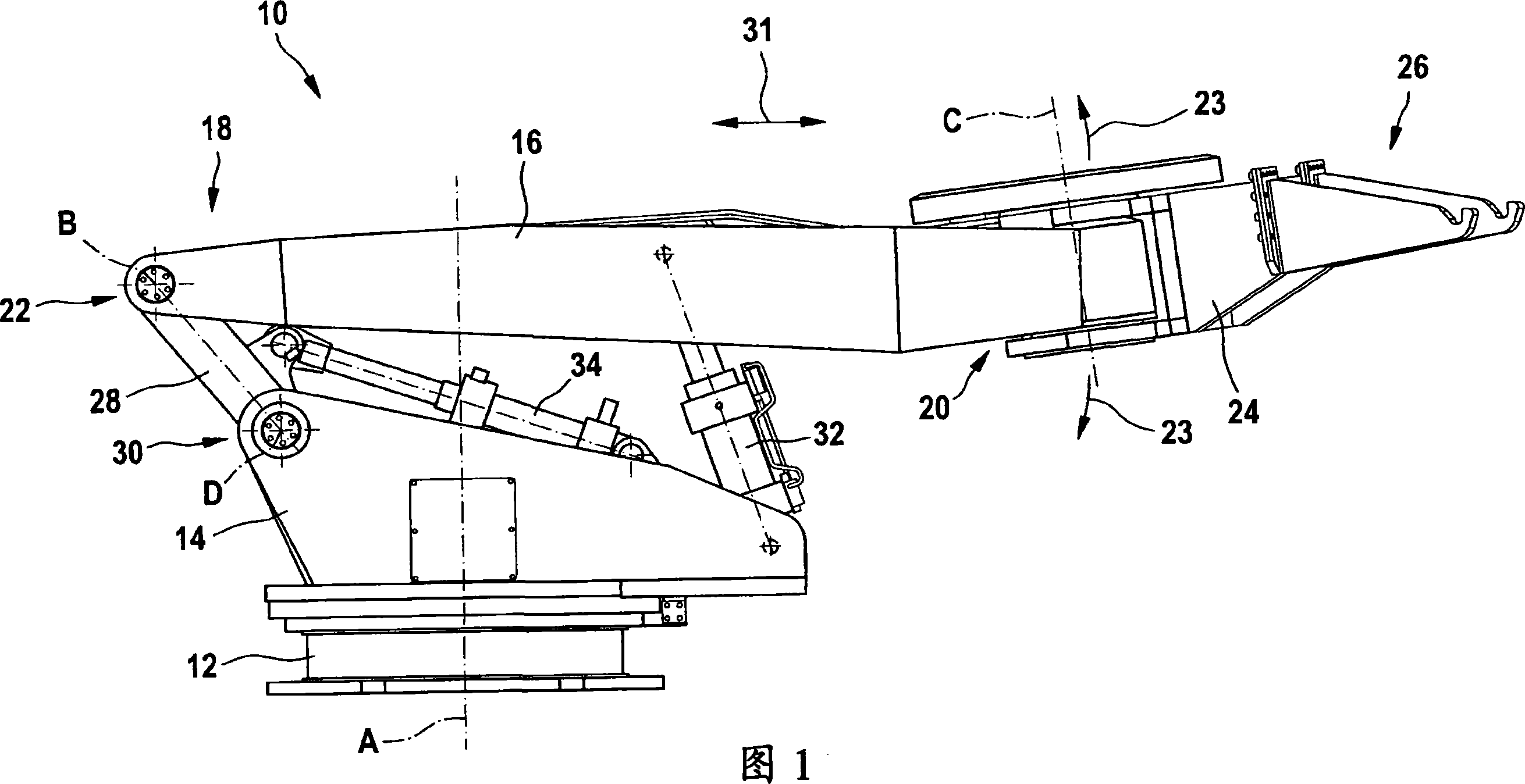

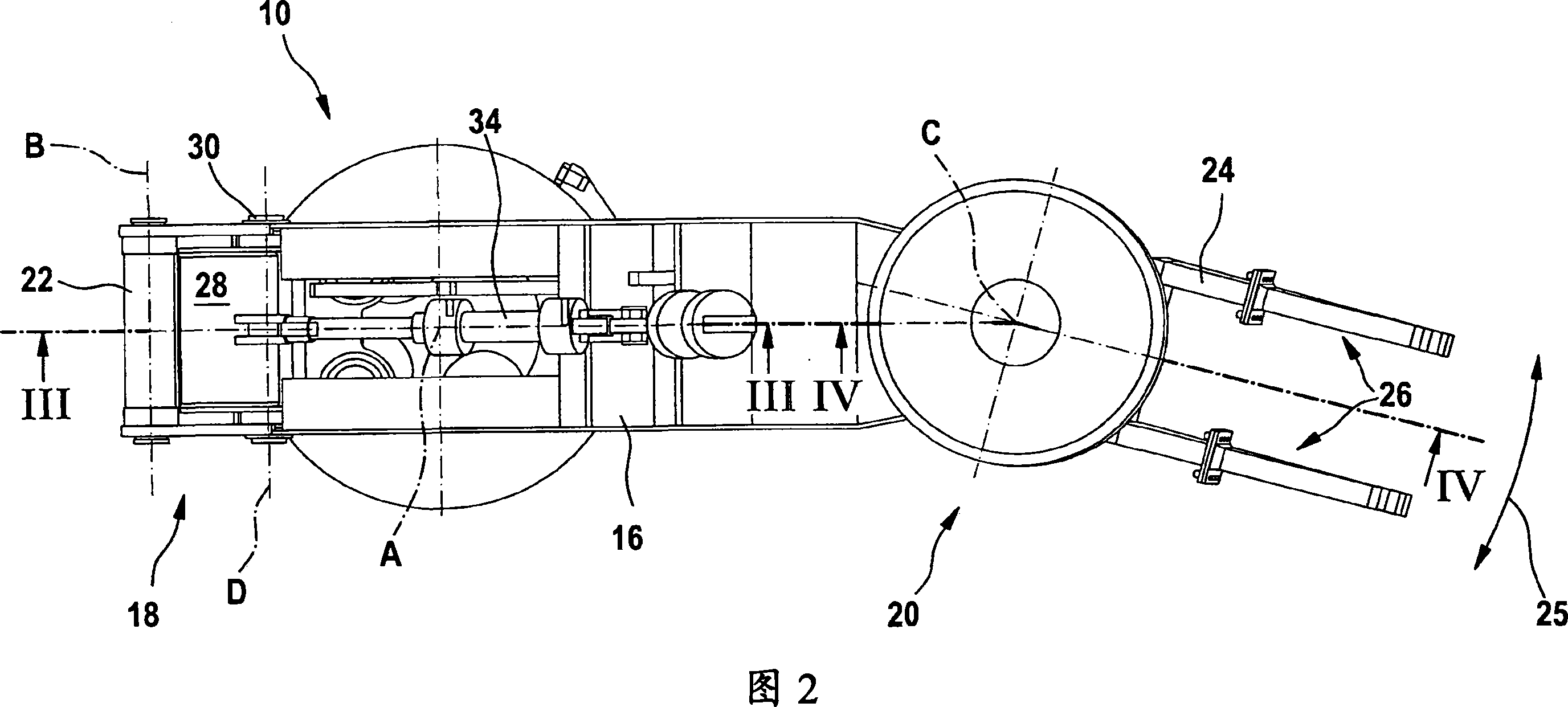

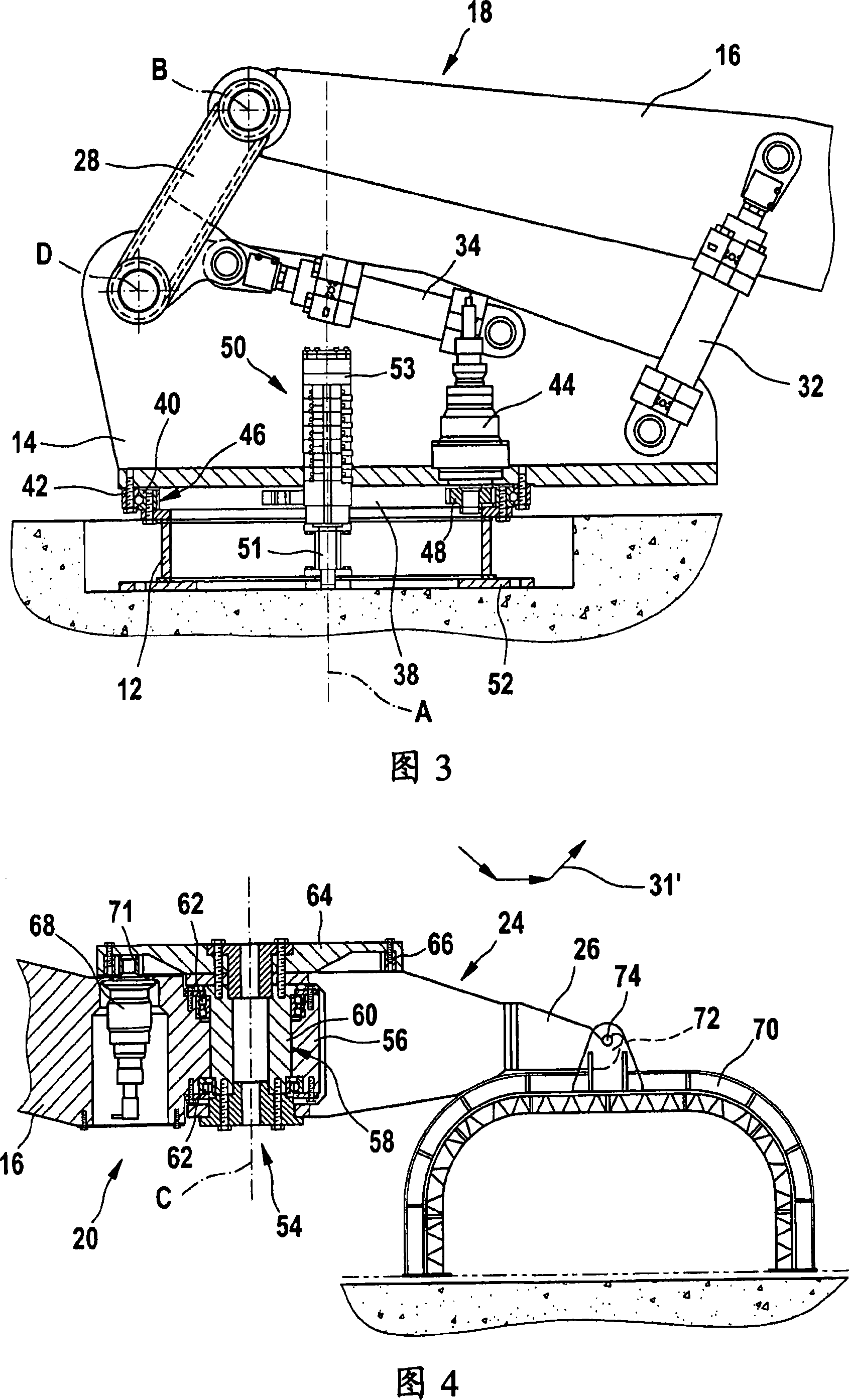

[0031]1 and 2 show a processing device generally indicated by reference numeral 10 . The handling device 10 includes a support base 12 and a frame 14 . The supporting base 12 is secured by suitable means to the casthouse floor and provides a stable support for the handling device 10 . The frame 14 is connected to the support base 12 by bearings (described in detail below) providing a first axis of rotation A, which is substantially vertical. Thus, the frame 14 is supported by the support base 12 and is rotatable about the axis A relative to the support base. It will be appreciated that the support base 12 and frame 14 may be configured to allow substantially 360° rotation. However, the range of rotation can be limited according to structural requirements, for example to prevent collisions with fixed structures. The handling device 10 further includes a lift arm 16 having a first end 18 and an opposite second end 20 . The first end 18 of the lift arm 16 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com