Ironmaking-steelmaking interface short distance melted iron transportation system

A transportation system and short-distance technology, applied in the field of metallurgy, can solve the problems of increasing the transportation distance and achieve the effects of reducing the temperature drop of molten iron, improving the efficiency of transportation operations, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

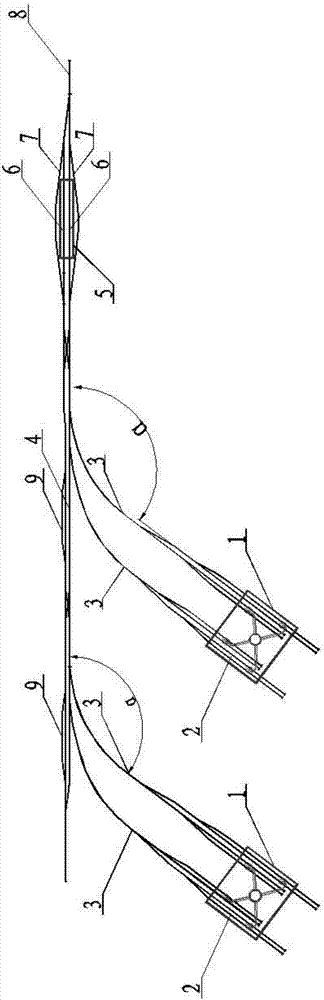

[0023] In this embodiment, four tapholes are arranged under the casthouse 1 of the blast furnace, and two iron receiving lines 2 under each furnace are arranged under each iron outlet, and the iron receiving lines 2 under each furnace are obliquely arranged on the molten iron transport trunk line 4- side. Two molten iron transportation main lines 4 are arranged side by side, and the two molten iron transportation main lines 4 are respectively merged into a pull-out line 8 through a can pouring line 5, and empty can walking lines 7 are correspondingly provided at the side of the two can pouring lines. Empty can parking lines 9 are arranged side by side with the molten iron transportation trunk line 4 along the line direction of the molten iron transportation trunk line 4. There are multiple empty can parking lines, and each empty can parking line 9 is arranged at intervals along the molten iron transportation trunk line. Of course, the number of tapholes under the blast furnace...

Embodiment 2

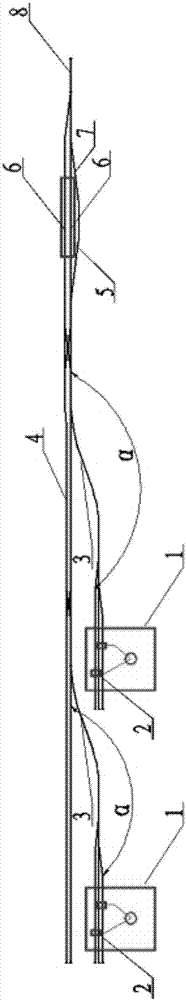

[0028] As another layout form of the transport system, in this embodiment, the iron receiving lines 2 under the blast furnace casthouse 1 are arranged in parallel on one side of the molten iron transport trunk line 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com