Patents

Literature

48 results about "Iron transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron transport. the process whereby iron is carried from the intestinal mucosa to sites of use and storage. Iron binds with transferrin and shuttles to storage and utilization sites. Transferrin becomes attached to exogenous iron that enters through the intestinal villi or that reenters the plasma from the sinusoids of the spleen.

Ferroportin1 nucleic acids and proteins

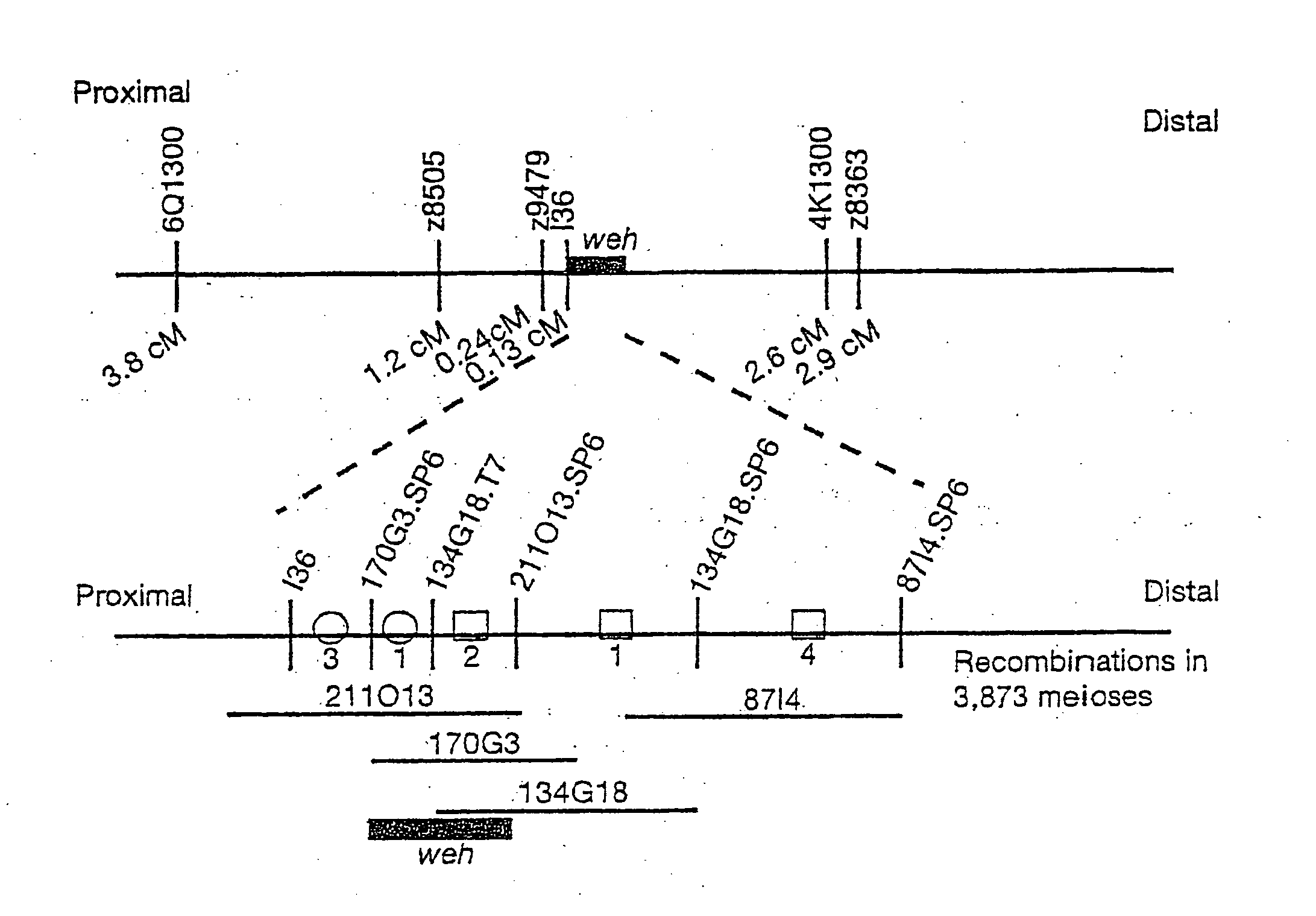

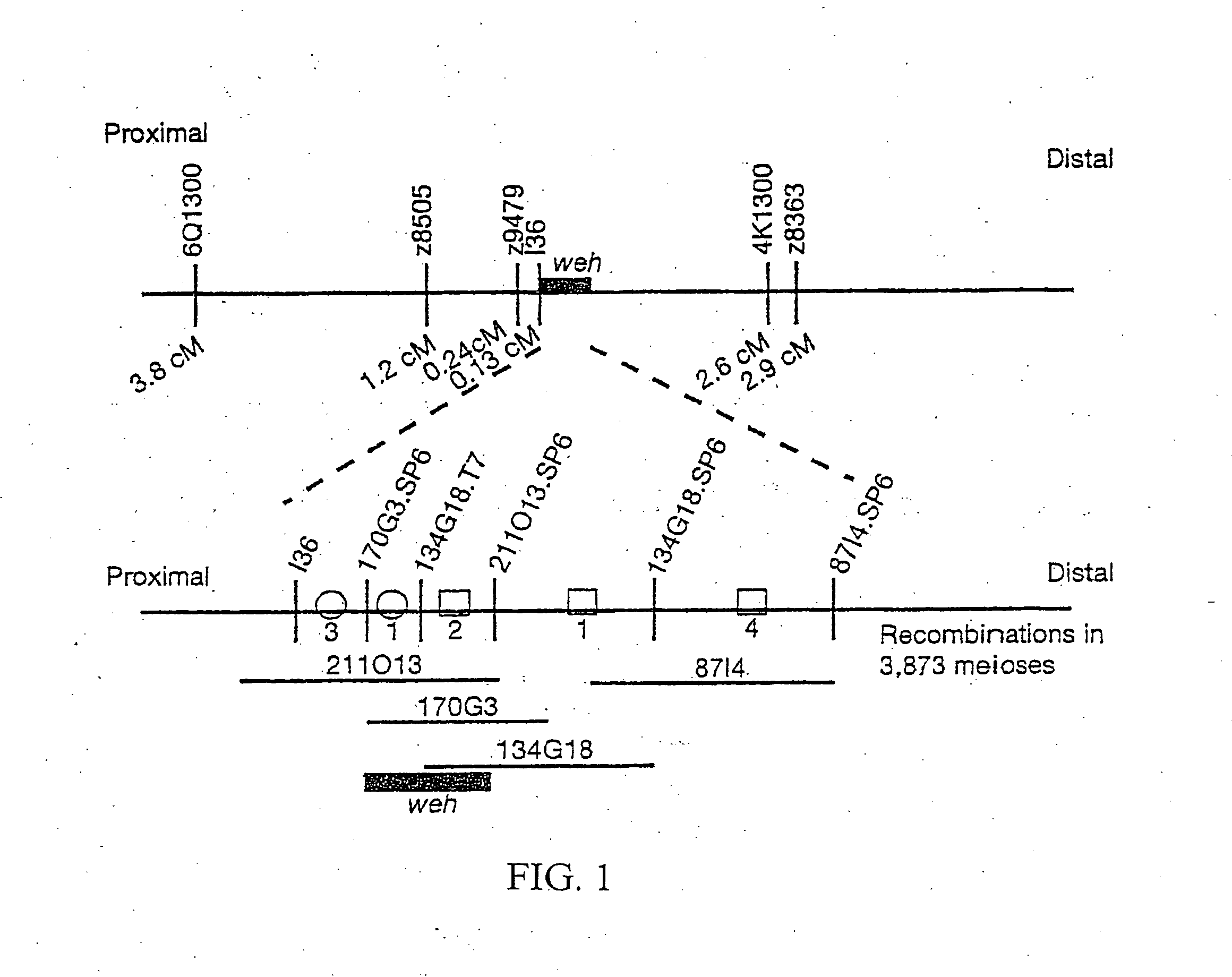

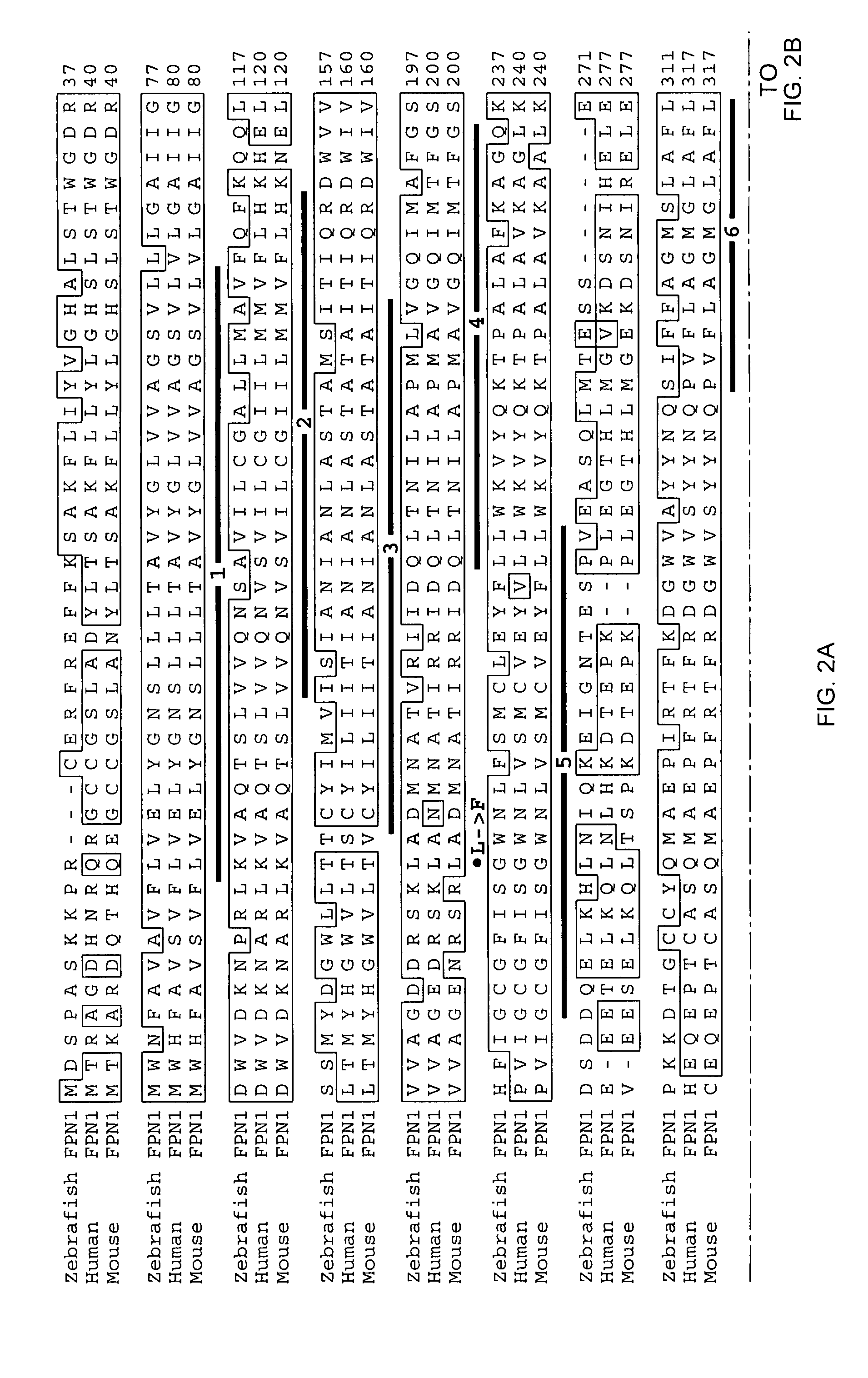

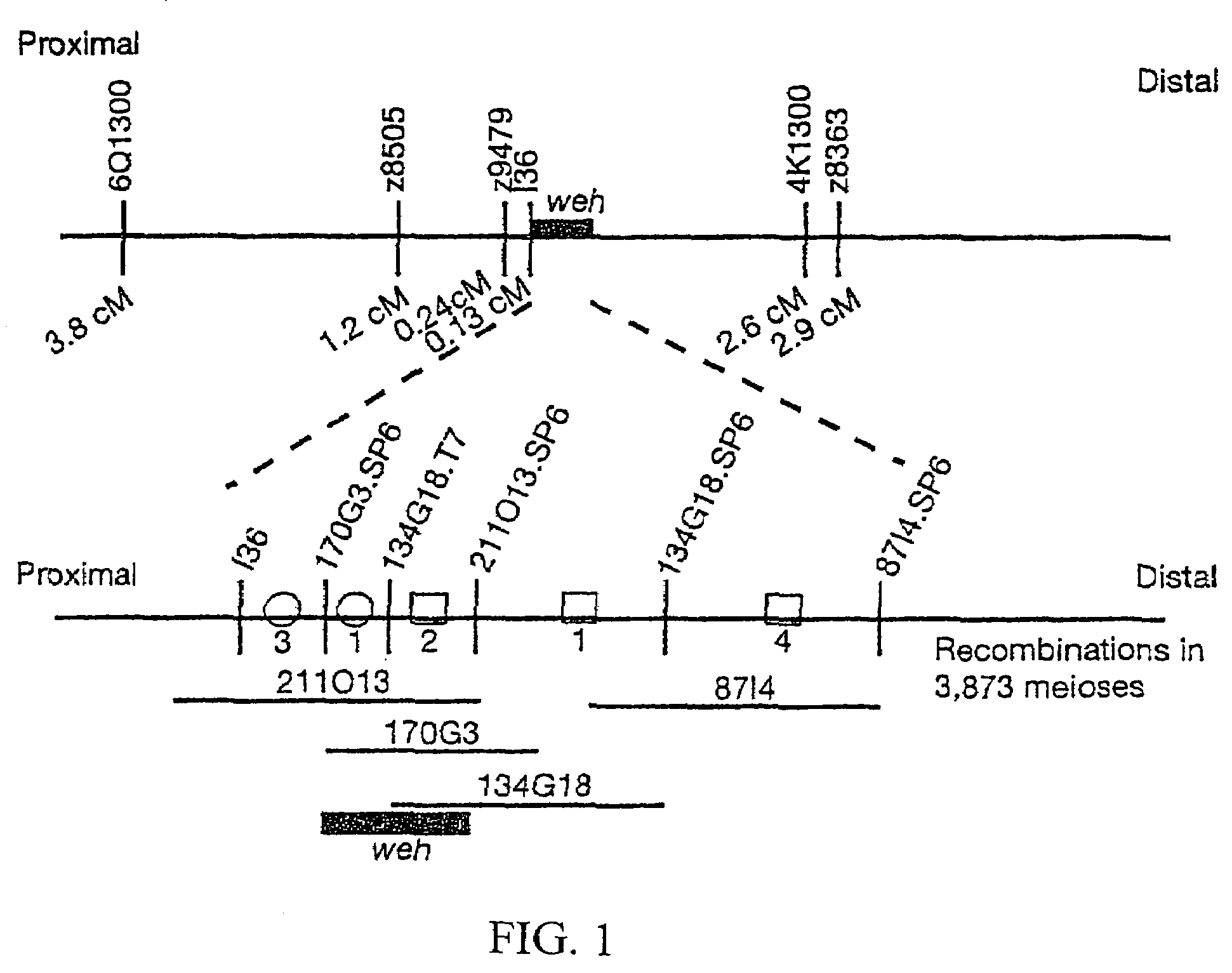

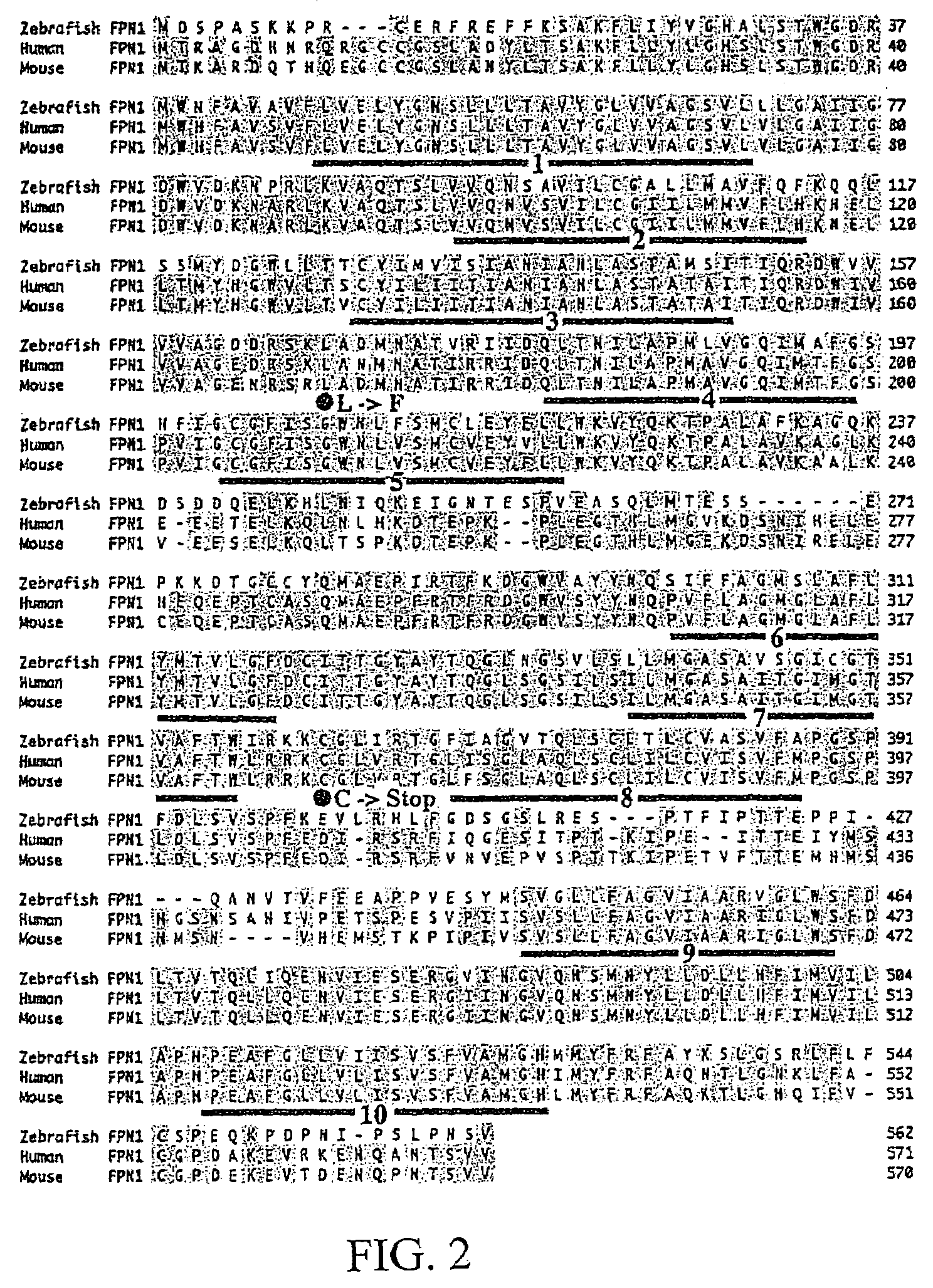

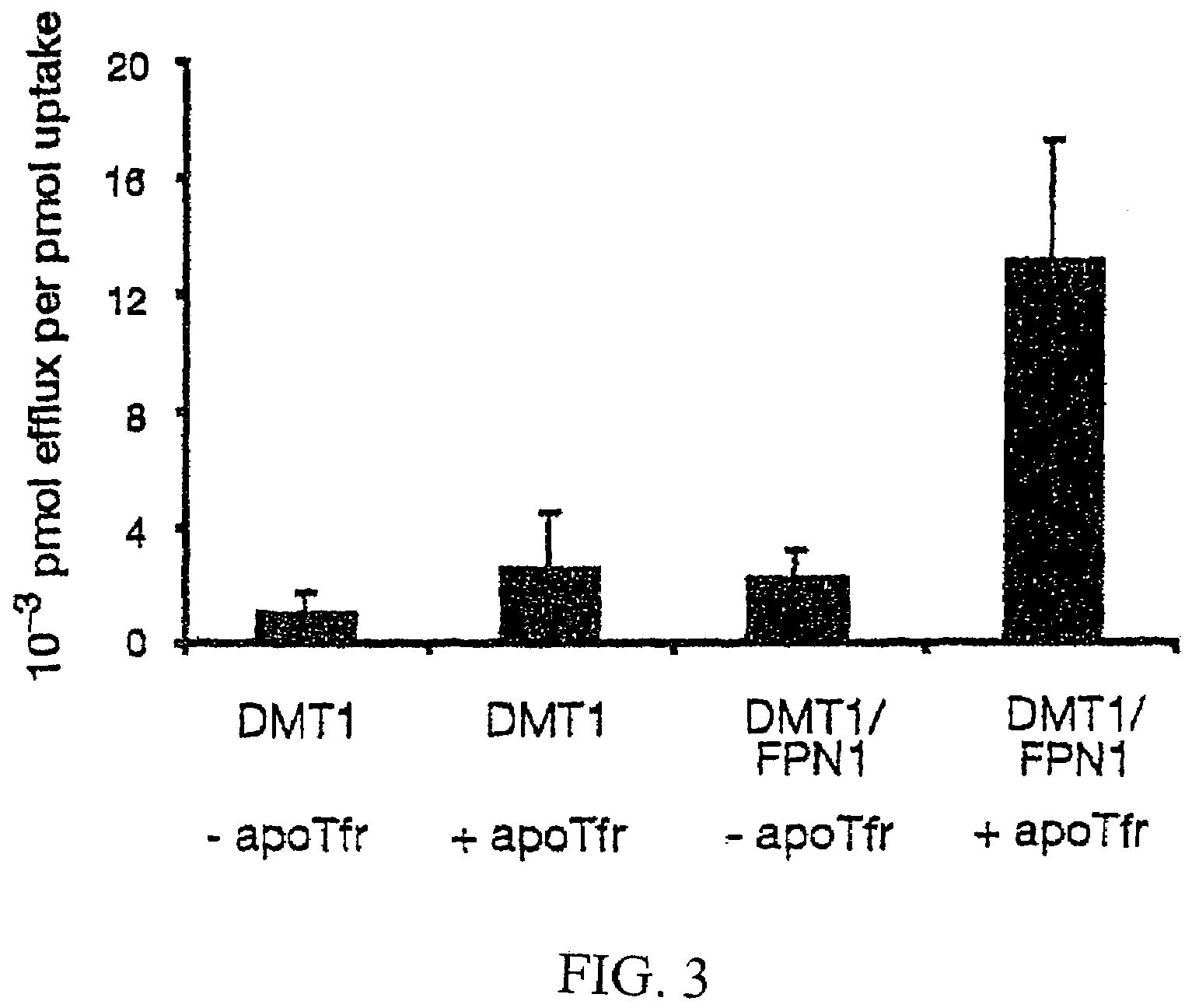

Positional cloning has been carried out to identify the gene responsible for the hypochromic anemia of the zebrafish mutant weissherbst. The gene, ferroportin1, encodes a novel multiple-transmembrane domain protein, expressed in the yolk sac. Zebrafish ferroportin1 is required for the transport of iron from maternally-derived yolk stores to the circulation, and functions as an iron exporter when expressed in Xenopus oocytes. Human and mouse homologs of the ferroportin1 gene have been identified. The invention includes isolated polynucleotides, vectors and host cells comprising nucleotide sequences encoding Ferroportin1 proteins and variants thereof, including those having iron transport function. The invention also includes polypeptides encoded by ferroportin1 genes and variants of such polypeptides, and fusion polypeptides comprising a Ferroportin1 or a portion thereof. Methods to produce a Ferroportin1, methods to produce antibodies to a Ferroportin1 and methods to identify agents binding to a Ferroportin1, which can be inhibitors or enhancers of Ferroportin1 iron transport activity, are also described. Inhibitors of Ferroportin1 activity can be used in a therapy for hemochromatosis.

Owner:CHILDRENS MEDICAL CENT CORP

Ferroportin1 nucleic acids and proteins

Positional cloning has been carried out to identify the gene responsible for the hypochromic anemia of the zebrafish mutant weissherbst. The gene, ferroportin1, encodes a novel multiple-transmembrane domain protein, expressed in the yolk sac. Zebrafish ferroportin1 is required for the transport of iron from maternally-derived yolk stores to the circulation, and functions as an iron exporter when expressed in Xenopus oocytes. Human and mouse homologs of the ferroportin1 gene have been identified. The invention includes isolated polynucleotides, vectors and host cells comprising nucleotide sequences encoding Ferroportin1 proteins and variants thereof, including those having iron transport function. The invention also includes polypeptides encoded by ferroportin1 genes and variants of such polypeptides, and fusion polypeptides comprising a Ferroportin1 or a portion thereof. Methods to produce a Ferroportin1, methods to produce antibodies to a Ferroportin1 and methods to identify agents binding to a Ferroportin1, which can be inhibitors or enhancers of Ferroportin1 iron transport activity, are also described. Inhibitors of Ferroportin1 activity can be used in a therapy for hemochromatosis.

Owner:CHILDRENS MEDICAL CENT CORP

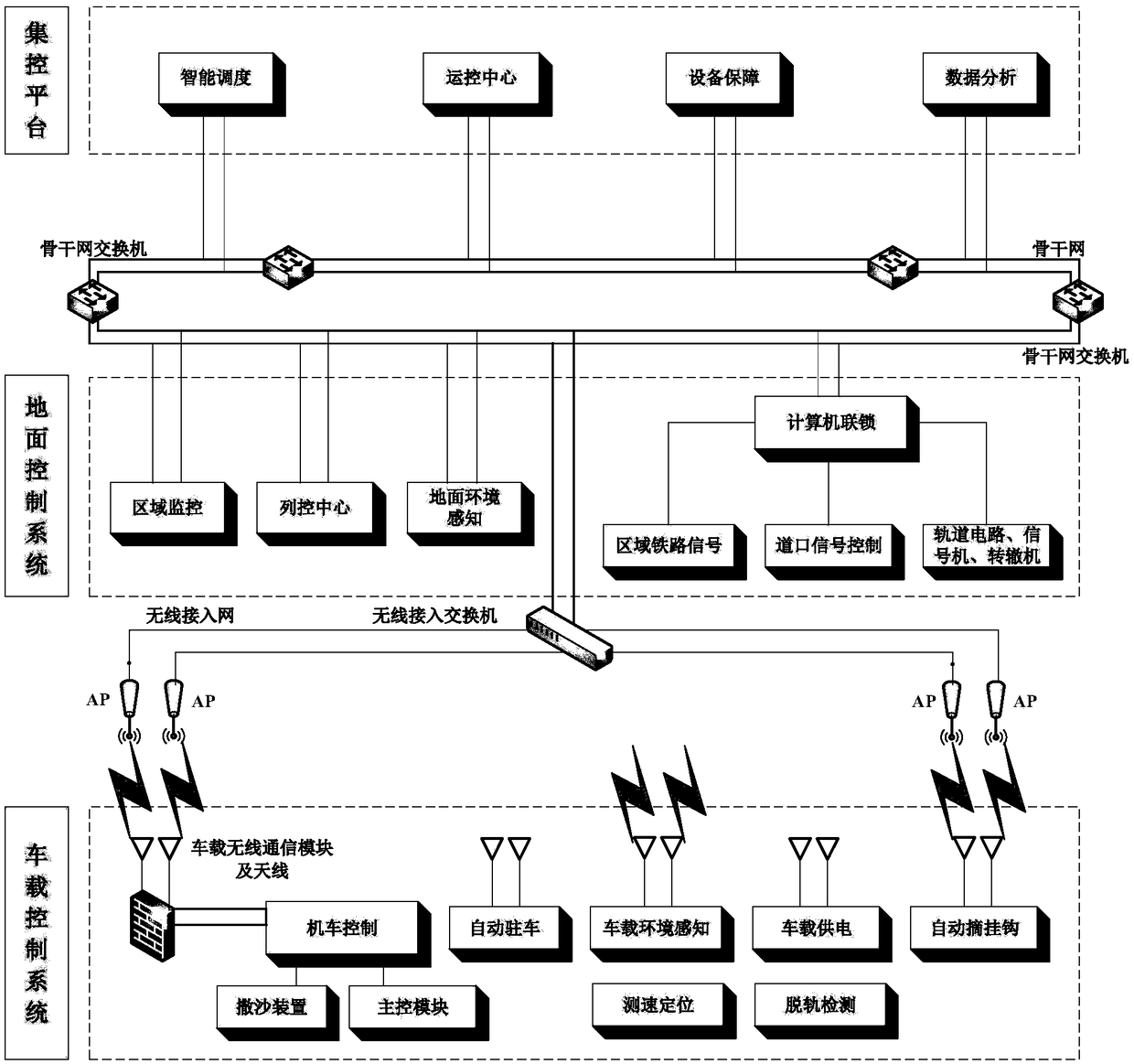

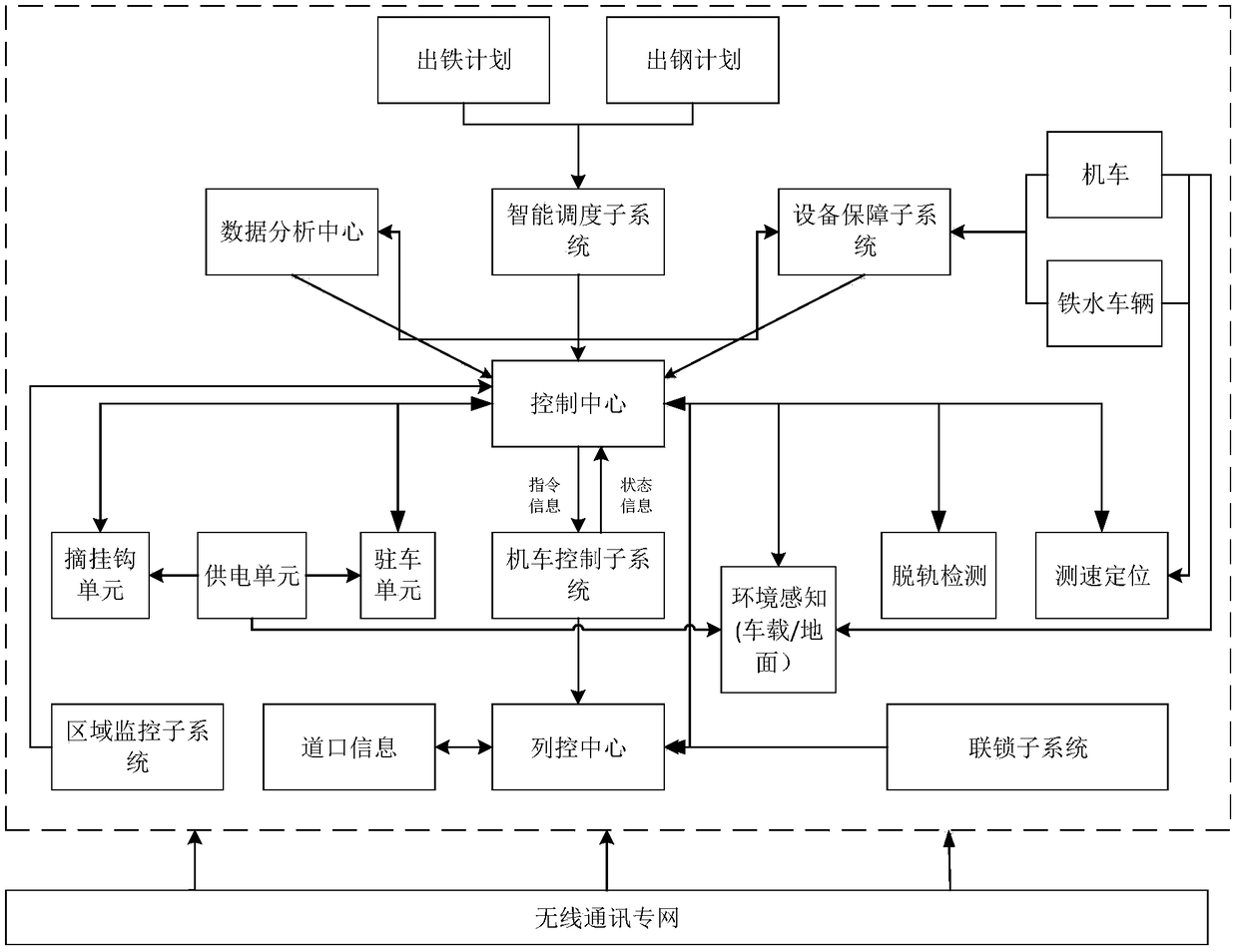

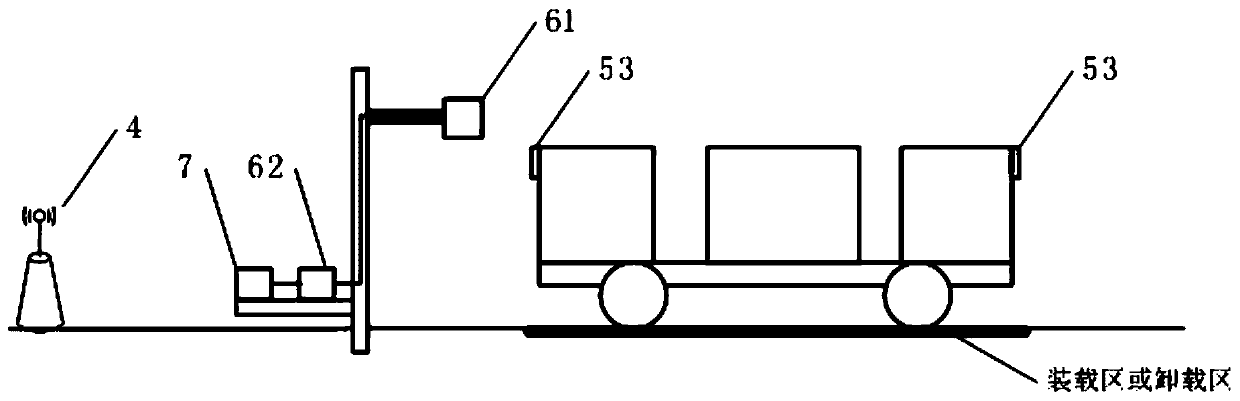

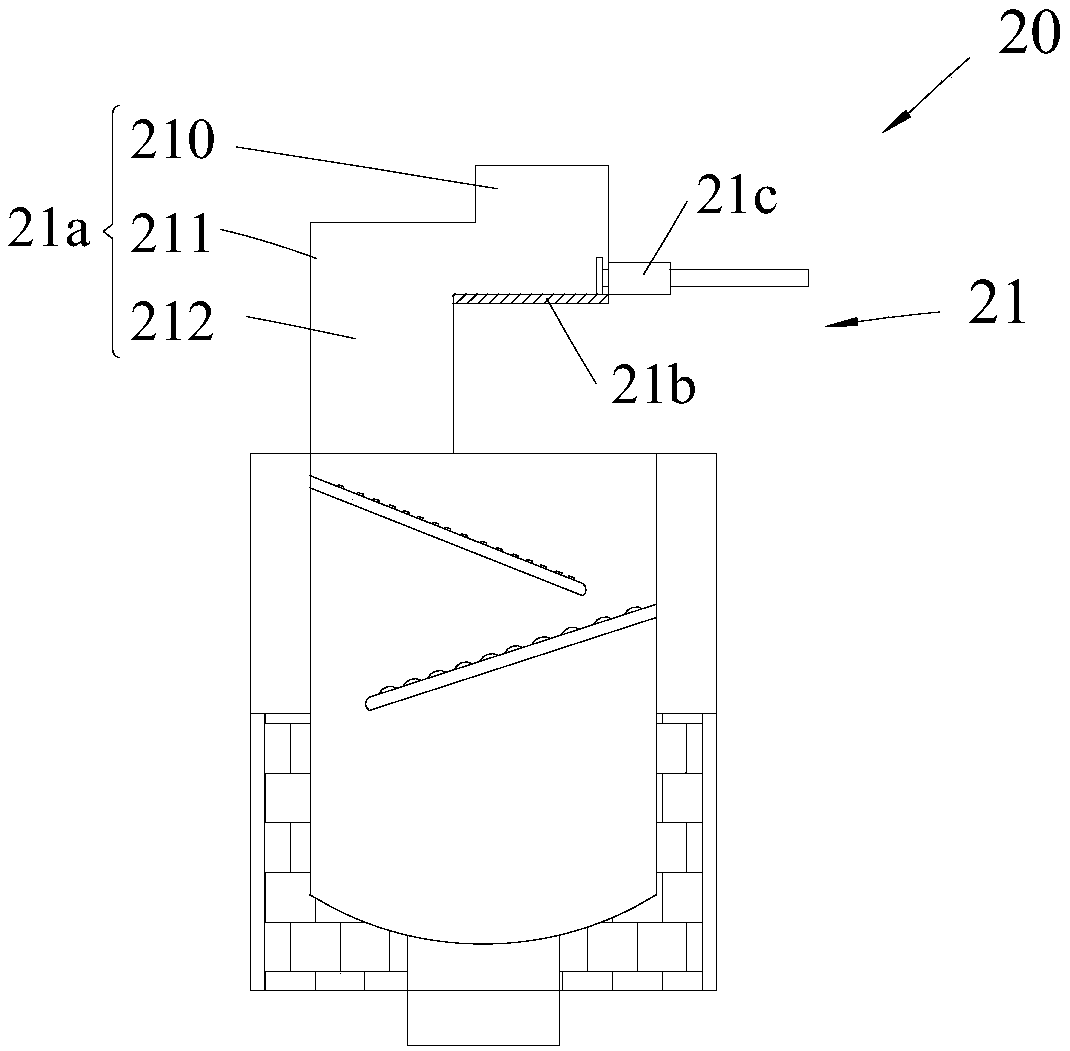

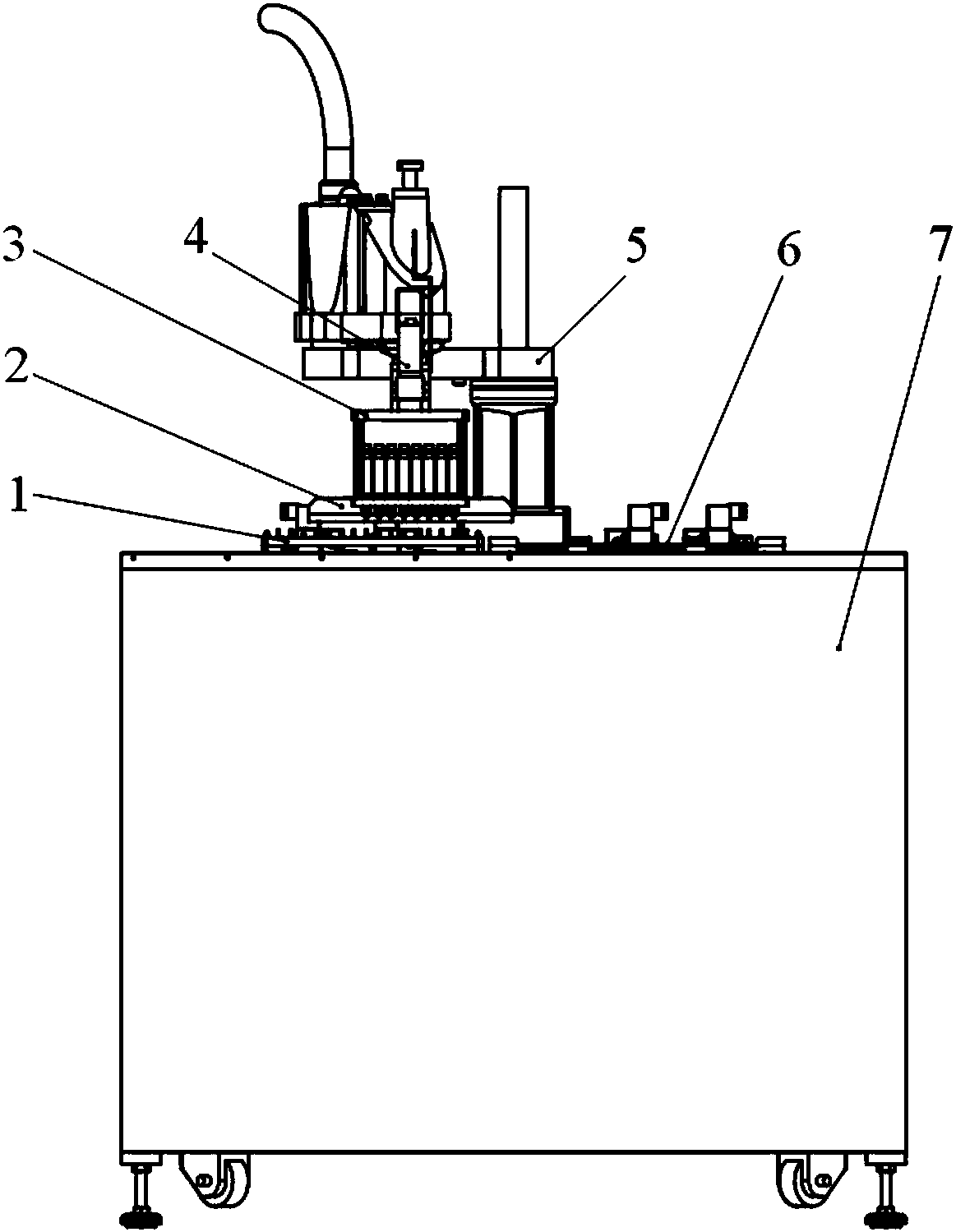

Intelligent molten iron conveying system

PendingCN109353359AReduce temperature dropAvoid temperature dropAutomatic systemsWagons/vansControl systemIron transport

The invention provides an intelligent molten iron conveying system. The system comprises a haulage motor body, a molten iron conveying vehicle body, a vehicle-mounted control system and a ground control system, wherein the vehicle-mounted control system is used for controlling motions of the haulage motor body and the molten iron conveying vehicle body according to a control instruction, the ground control system is used for collecting external environment information and controlling a ground advancing line of the haulage motor body and the molten iron conveying vehicle body according to the control instruction, and a centralized control platform is used for sending the control instruction to the vehicle-mounted control system and the ground control system. Automatic interaction of information and the control instruction is performed through the centralized control platform, a molten iron transporting vehicle achieves unmanned and organization scheduling intelligence in the whole molten iron transporting working process from a blast furnace casting field to a steel making transit station, the haulage motor operation efficiency is improved, the iron molten temperature drop is lowered, the road and haulage motor operation safety is improved, equipment damage and accidents caused by faults such as worker operation and judgment are completely eradicated, the operation risk is lowered, and personal safety of workers is ensured.

Owner:CISDI ENG CO LTD

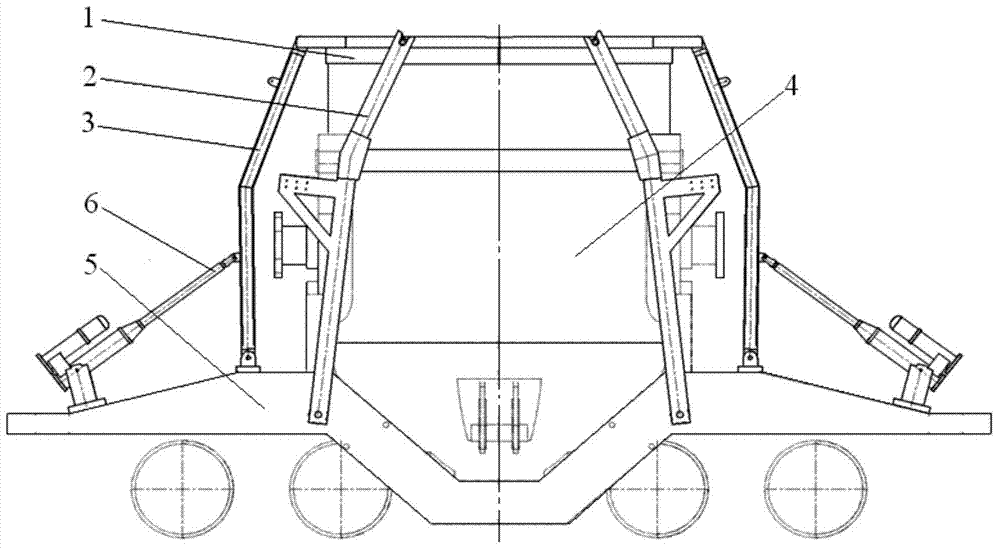

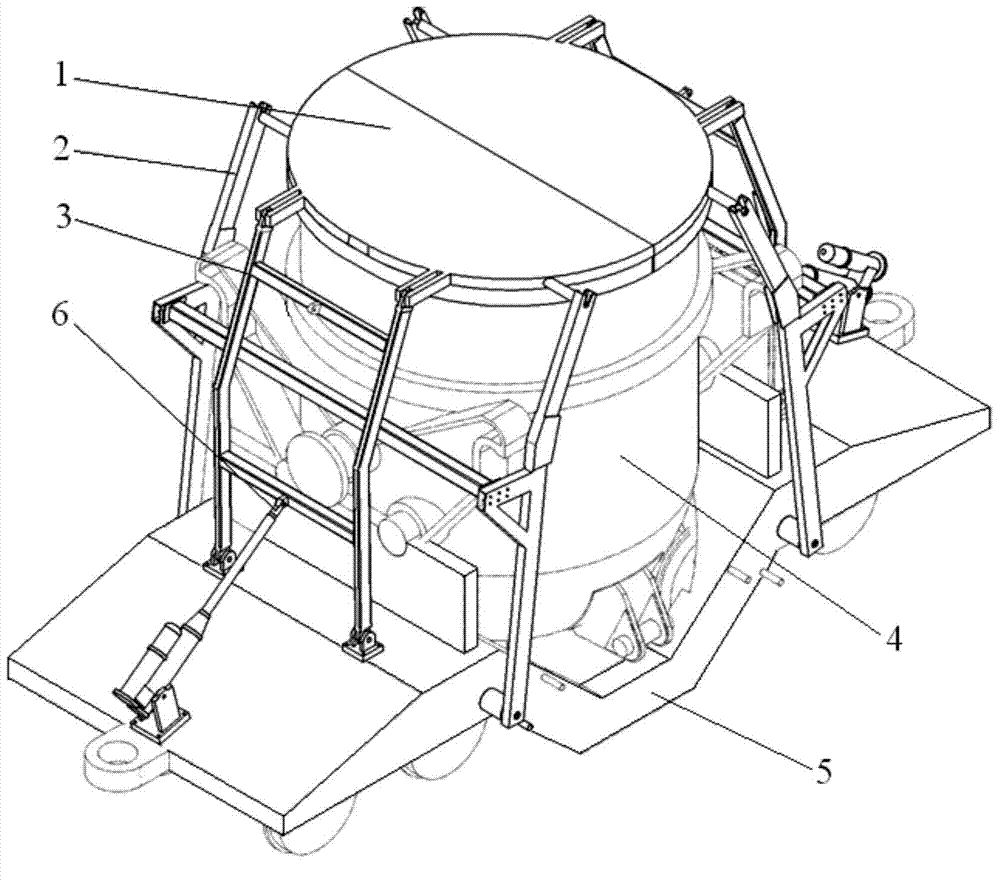

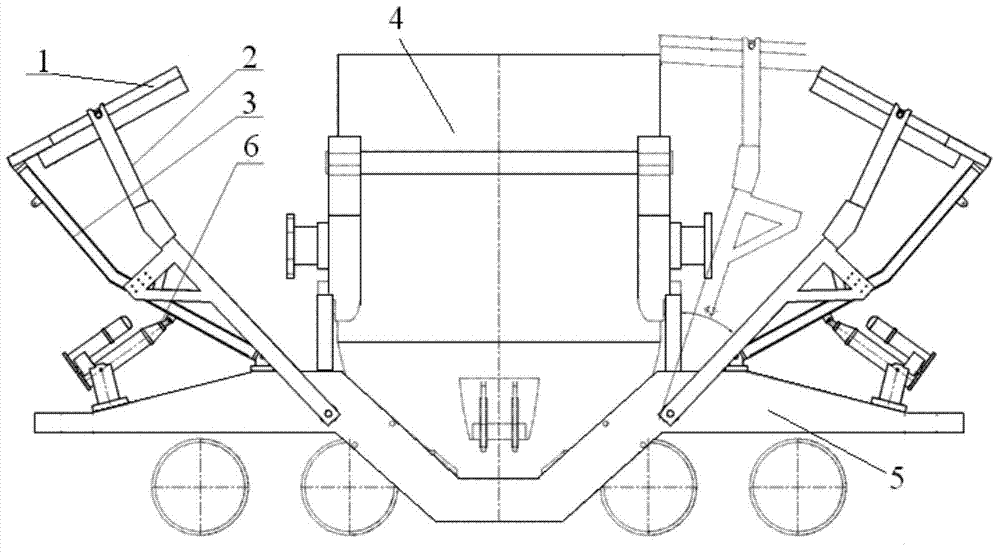

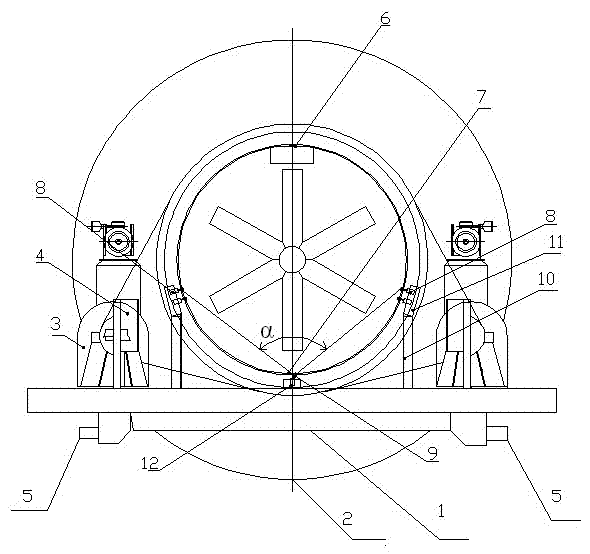

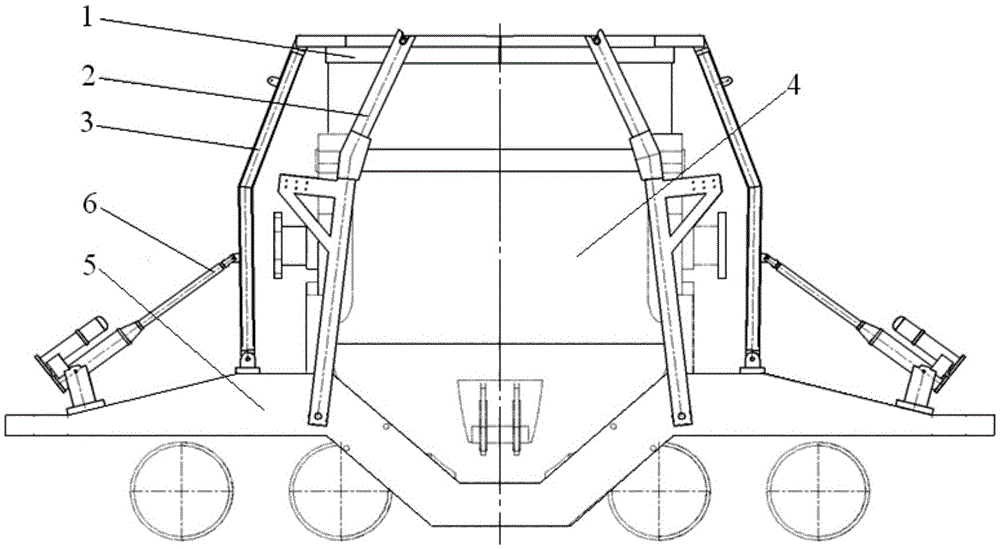

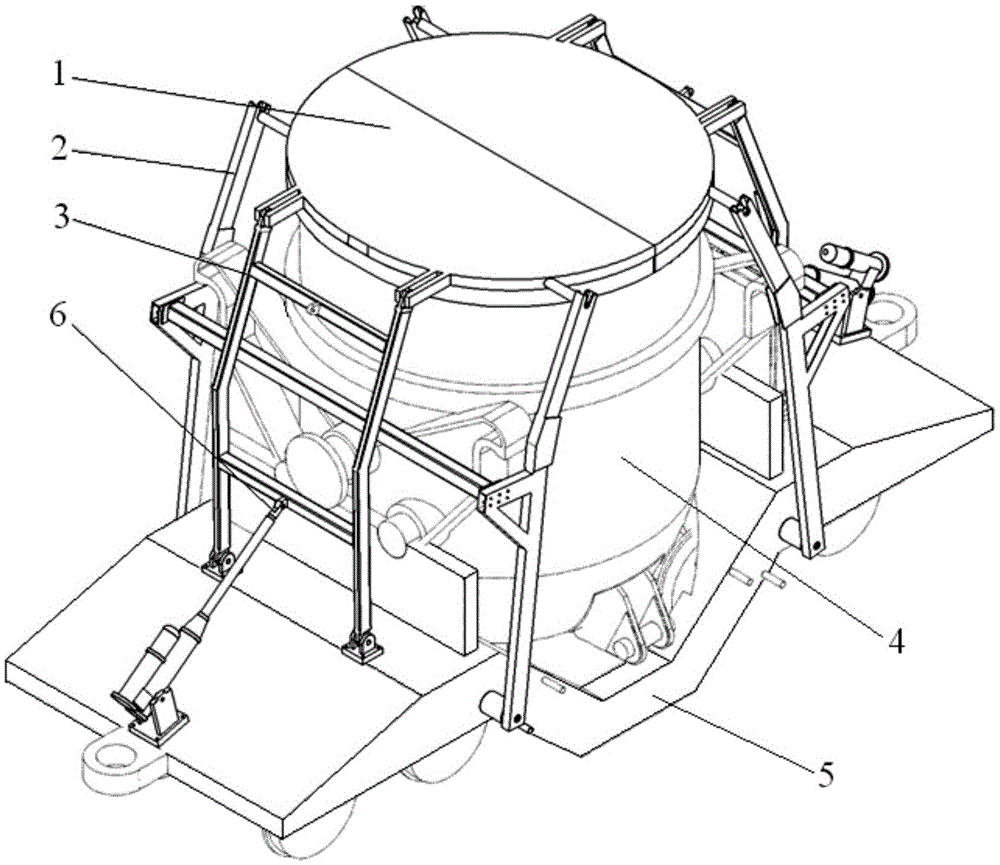

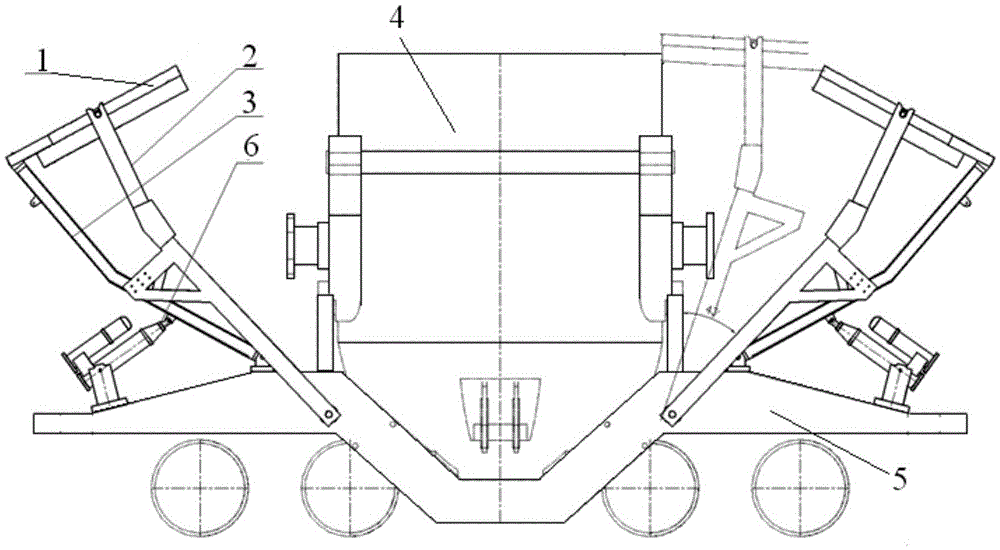

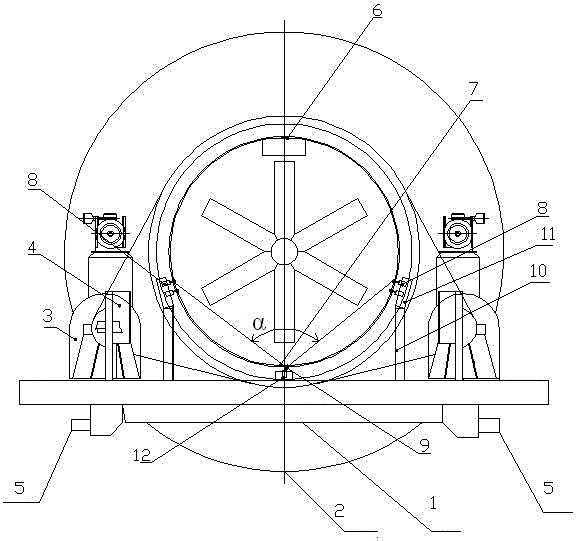

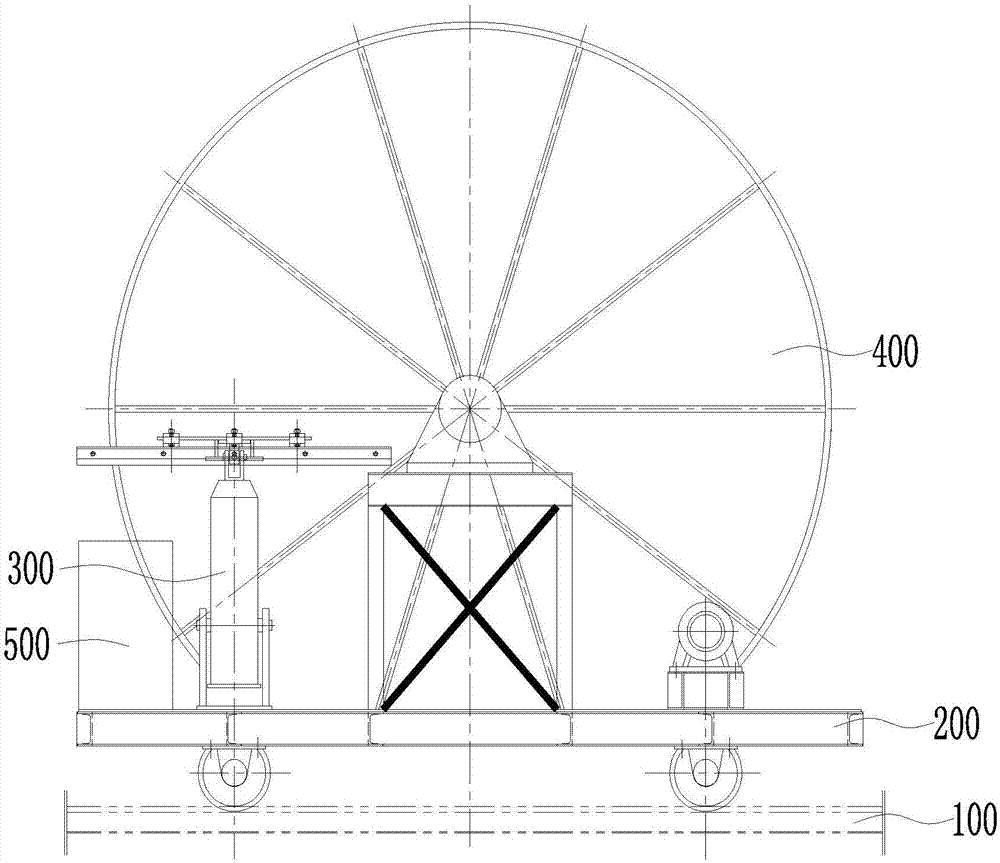

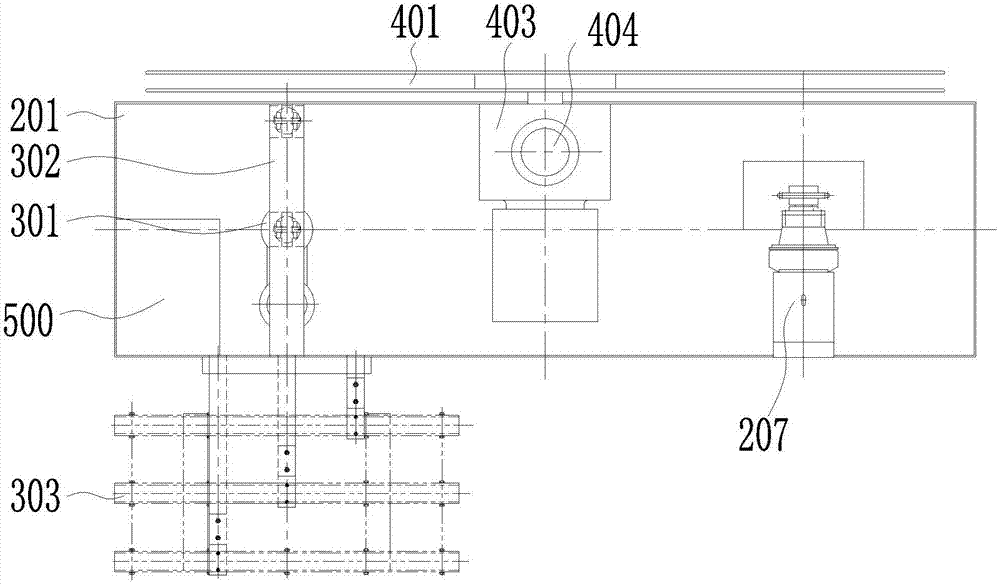

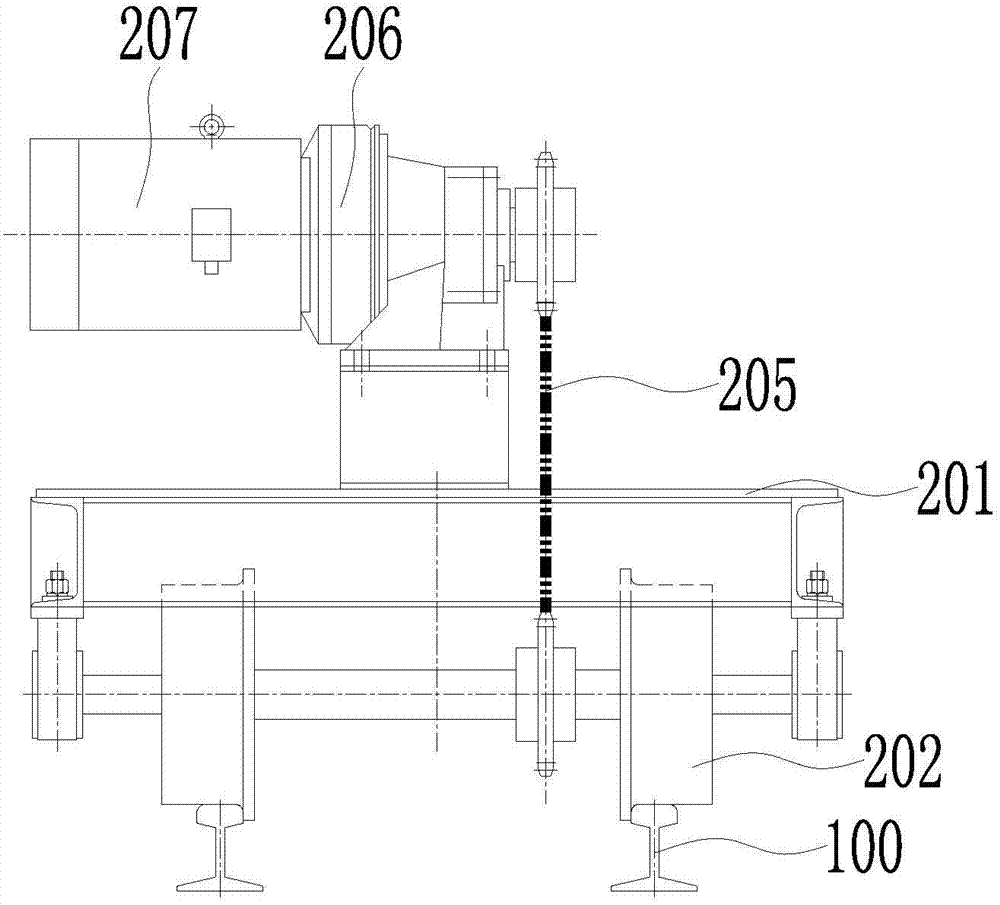

Molten iron transportation online molten iron tank heat preservation device and covering and uncovering method thereof

ActiveCN103934444AReduce energy lossDoes not affect normal operationMelt-holding vesselsMetallurgyIron transport

The invention discloses a molten iron transportation online molten iron tank heat preservation device. Two ladle covering and uncovering mechanisms are arranged on molten iron transport carts (5) and symmetrically distributed at the two sides of a molten iron tank (4) with the axis of the molten iron tank (4) serving as the center. By the adoption of the technical scheme, the molten iron tank is transported in a covered mode in the whole molten iron transport cart operation process, the molten iron tank is covered for heat preservation, and therefore energy loss caused by molten iron temperature drop is reduced; a four-bar mechanism is adopted, covering and uncovering operation conducted on a molten iron pouring station with narrow space is achieved; normal operation of the two carts is not affected; each molten iron tank heat preservation device is only provided with one power execution device and a point of action is near the center of symmetry of the mechanisms, so that overall stable operation of covering and uncovering operation of the mechanisms is guaranteed; the structure is compact, operation is simple, use is convenient, and the device is safe, reliable and long in service life.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

Iron melt transfer system

InactiveCN101249560AReduce temperature dropStrong transfer continuityMelt-holding vesselsCasting plantsTransfer systemIron transport

The invention discloses a molten iron transport system, which comprises a first transport path of molten iron in a blast furnace, a second transport path of molten iron between adjacent blast furnaces, and a third transport path for transporting molten iron to a steel-making plant, wherein the first transport path is linearly arranged between the blast furnace and the second transport path ; the second transport path is linearly arranged between two adjacent blast furnaces; the third transport path is linearly arranged between the second transport path and the steel-making shop; a first transport vehicle is arranged at the transition position of the first transport path and the second transport path; a second transport vehicle is arranged at the transition position of the second transport path and the third transport path; a desulfurizing station is also arranged at the transition position of the second transport path and the third transport path ; a first ground molten iron tank car, a second ground molten iron tank car and a third ground molten iron tank car are respectively arranged on the first transport path, the second transport path and the transport path third. The molten iron transport system has high transport continuity, and can maximally shorten the transport cycle and eliminate the influence of centrifugal force on the production safety in the transport process, thus improving the transport speed and reducing temperature drop of the molten iron.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

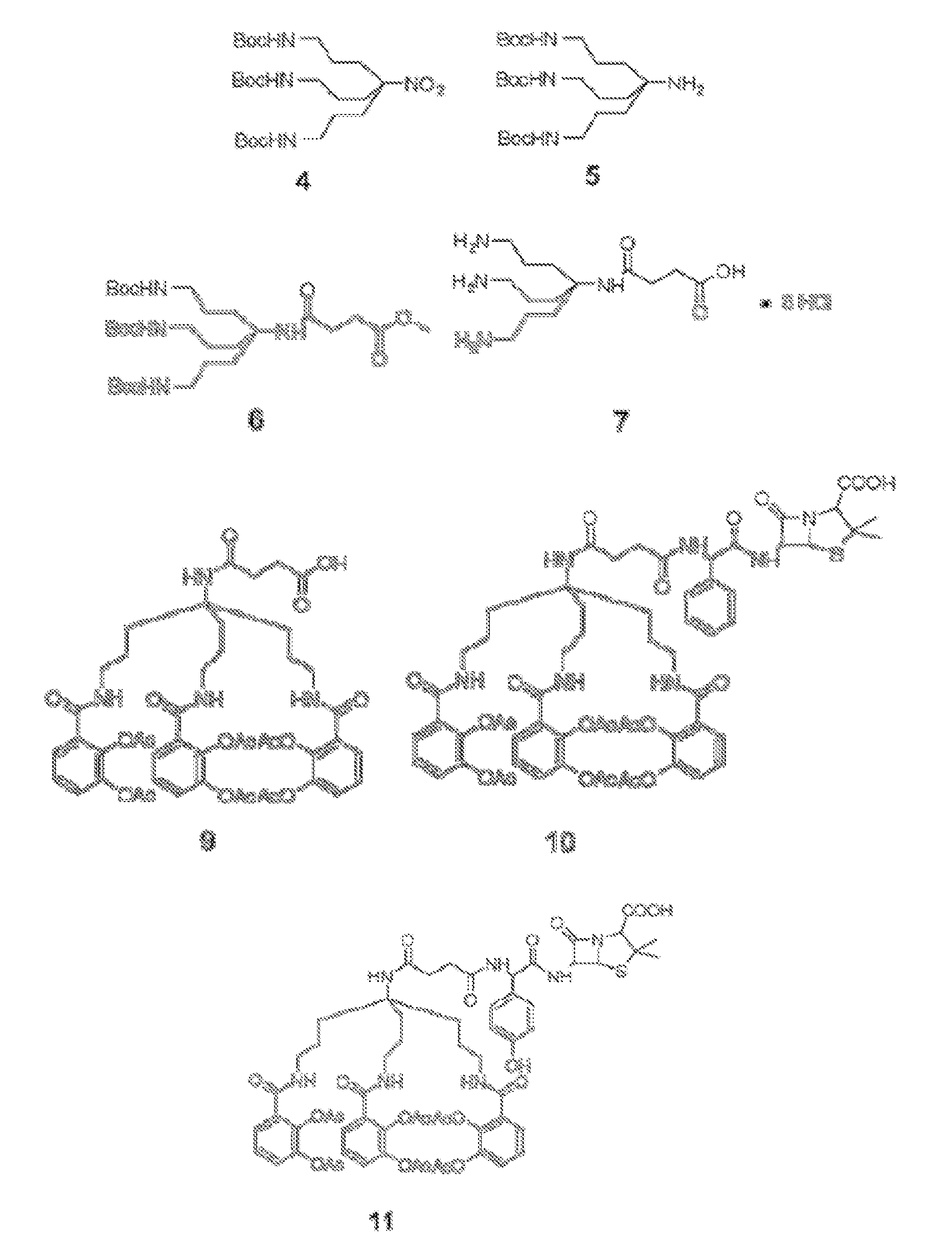

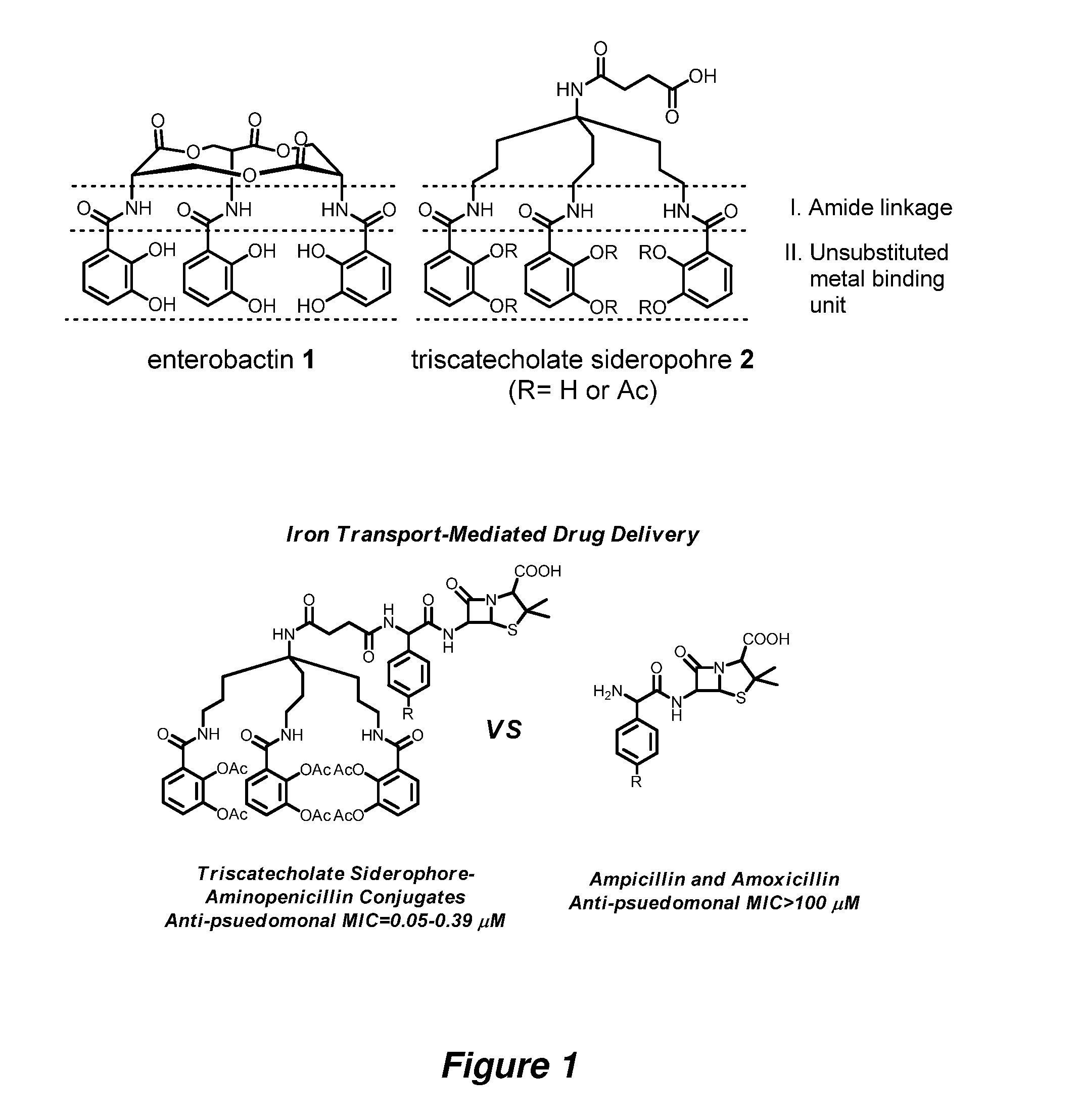

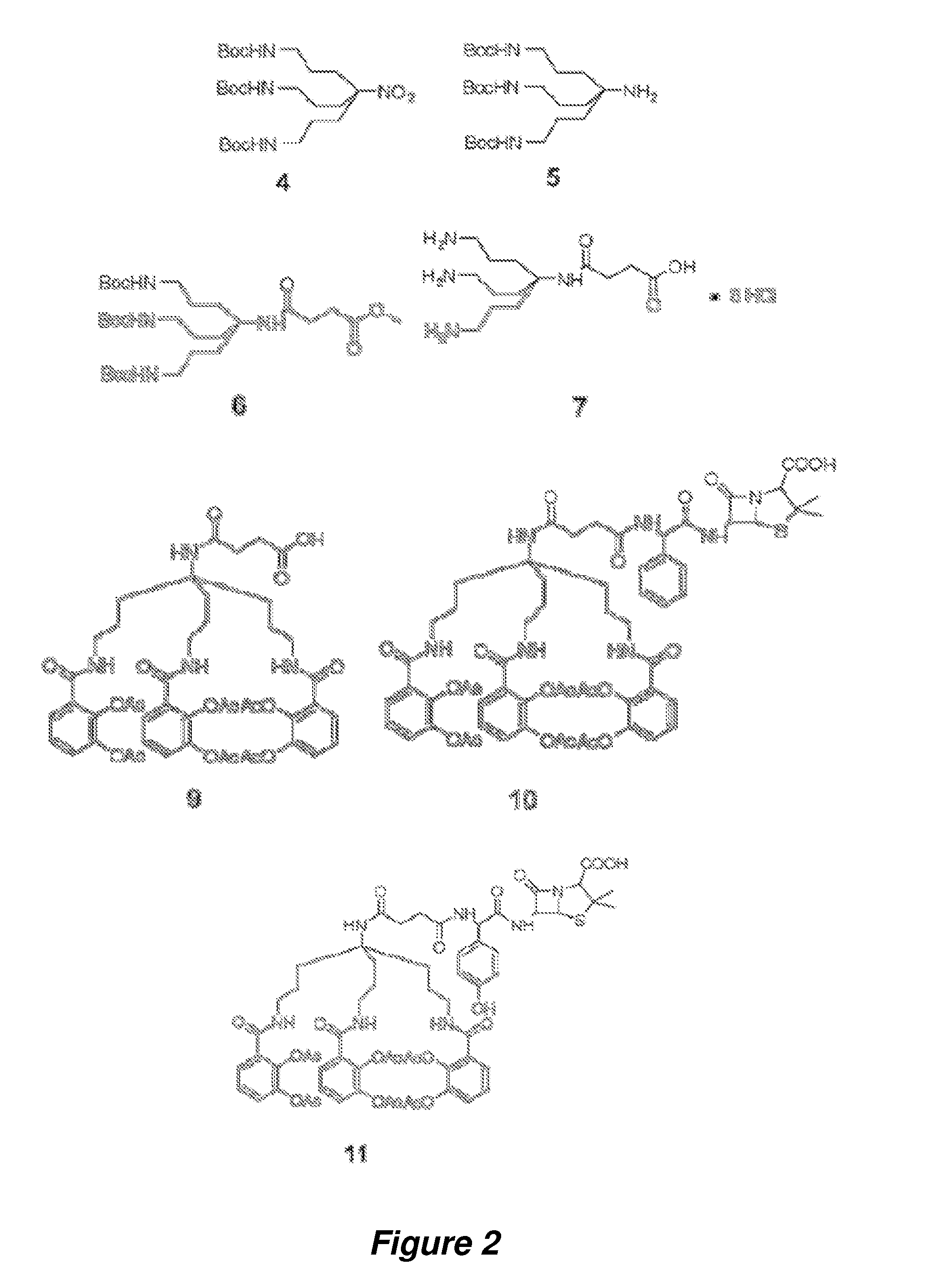

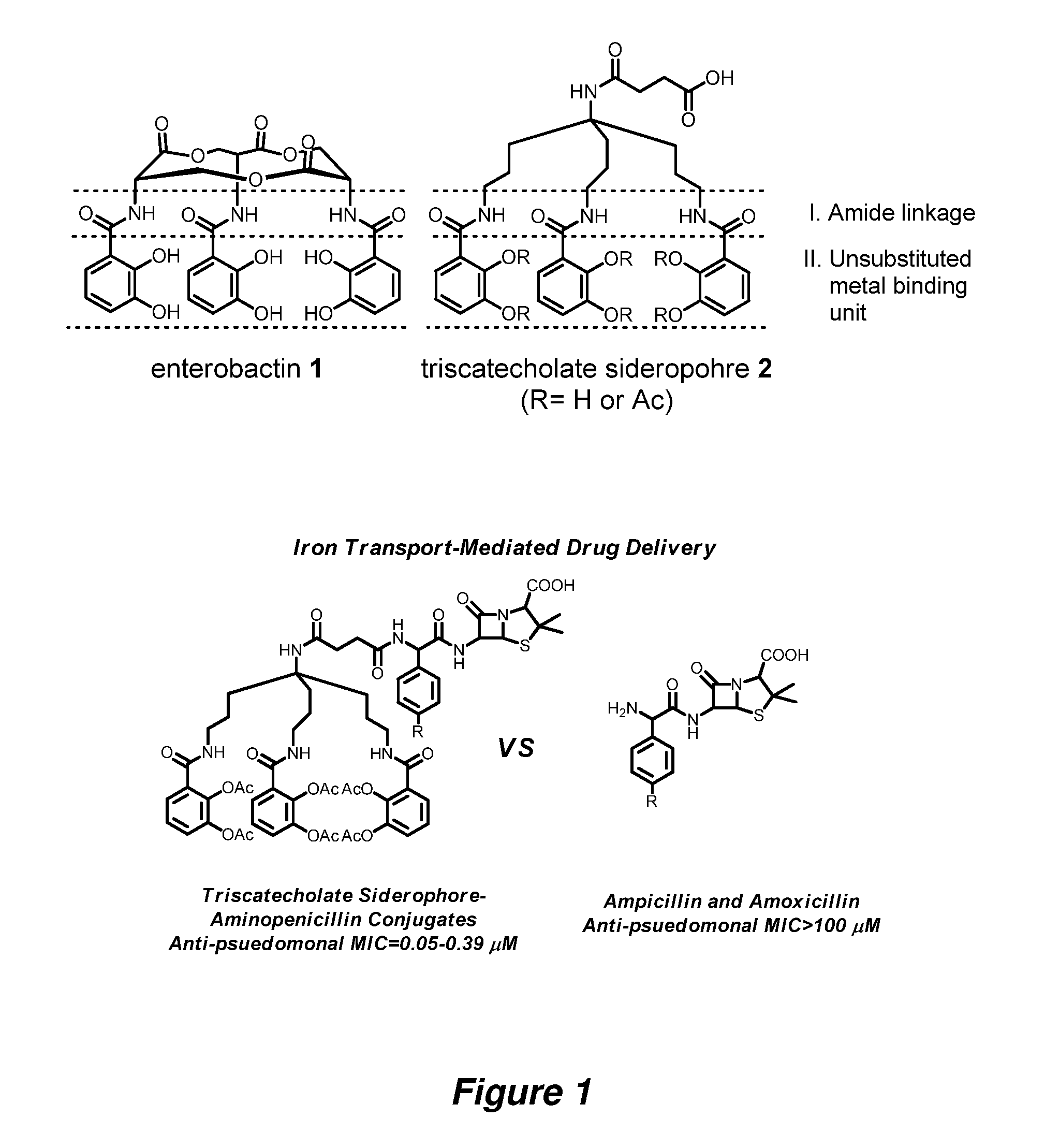

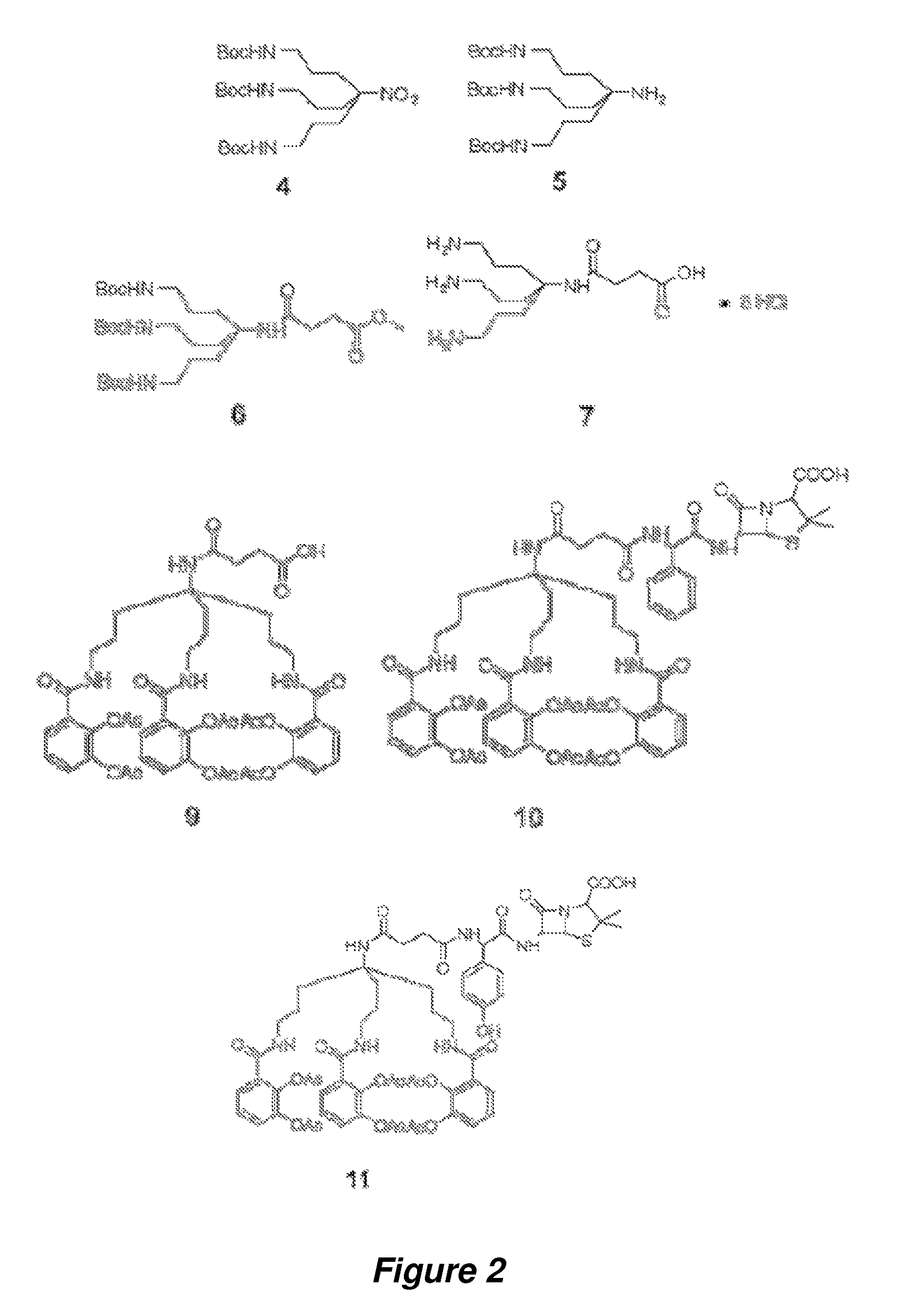

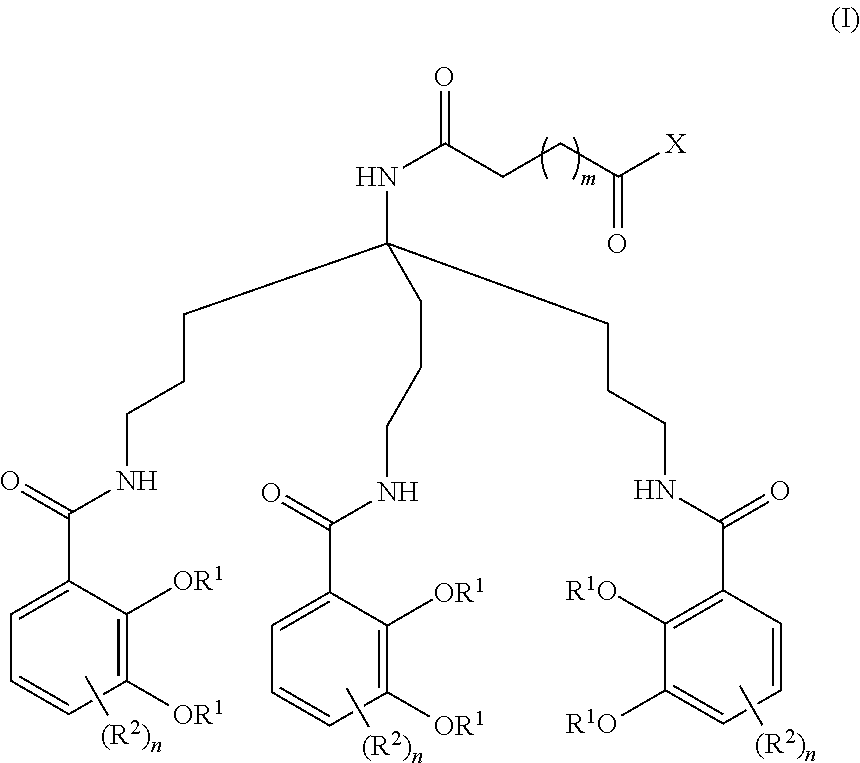

Anti-bacterial siderophore-aminopenicillin conjugates

ActiveUS20130281424A1Improve breathabilityAntibacterial agentsOrganic chemistryBacteroidesIron transport

An artificial tris-catecolate siderophore with a tripodal backbone and its conjugates with ampicillin and amoxicillin were synthesized. Both conjugates exhibited significantly enhanced in vitro antibacterial activities against Gram-negative species compared to the parent drugs, especially against P. aeruginosa. The conjugates appear to be assimilated by an induced bacterial iron transport process as their activities were inversely related to iron concentration. The easily synthesized tris-catecolate siderophores can be used with a variety of drugs as conjugates to target antibiotic-resistant Gram-negative bacteria.

Owner:UNIV OF NOTRE DAME DU LAC

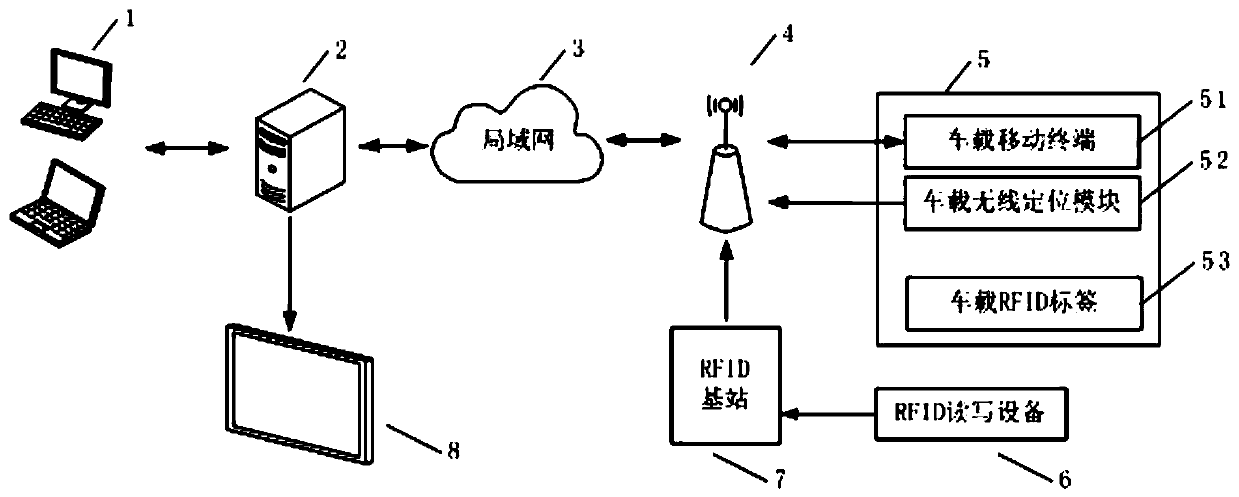

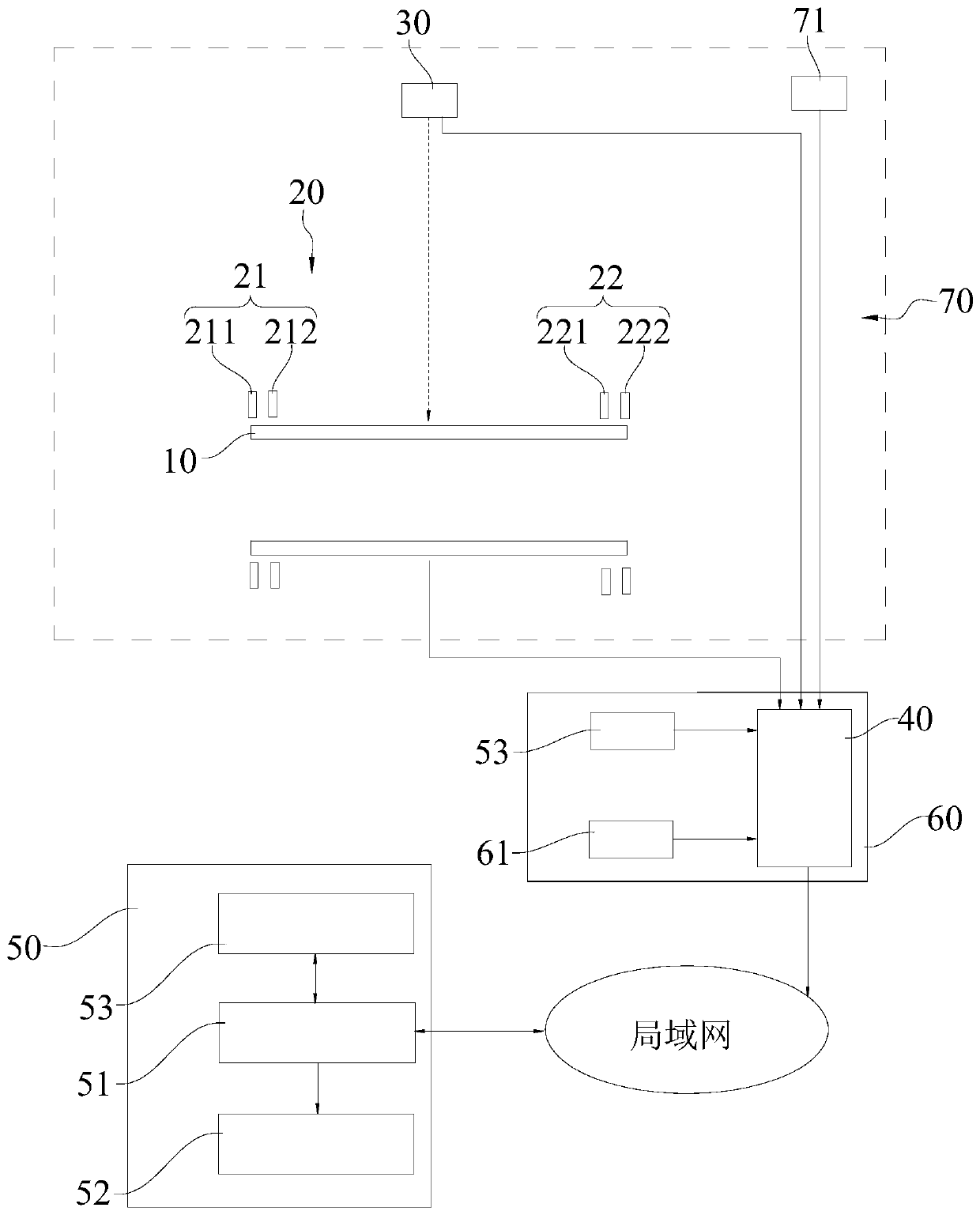

Molten iron vehicle scheduling system and scheduling method

ActiveCN109919271AResolve dependenciesResolve locationData processing applicationsCo-operative working arrangementsDual modeLarge screen

The invention discloses a molten iron vehicle scheduling system and scheduling method, and the method comprises the steps: enabling a vehicle-mounted mobile terminal to be connected with a local areanetwork through a factory WIFI base station, and enabling the vehicle-mounted mobile terminal to keep communication with a command monitoring device through a server; connecting avehicle-mounted wireless positioning module with the local area network through the factory area WIFI base station, and enabling the vehicle-mounted wireless positioning module to transmit information to a command monitoring device through the server; arranging a vehicle-mounted RFID tag on the molten iron transport vehicle, wherein an RFID read-write device is connected with the local area network through the RFID base station and the factory WIFI base station, the RFID read-write device transmits information to the command monitoring device through the server, and the RFID read-write device reads the vehicle-mounted RFID tag and obtains molten iron transport vehicle information; and connecting the command monitoring equipment to a monitoring large screen through the server. According to the invention, the technology of combining Beidou / GPS dual-mode positioning and stop point RFID identification is adopted, so that accurate positioning of the stop point can be realized even if the stop point is shielded,and the problems that the traditional molten iron vehicle scheduling depends on manpower, the position information feedback is not timely, the positioning is inaccurate and the like are well solved.

Owner:江苏睿孜星智控科技有限公司

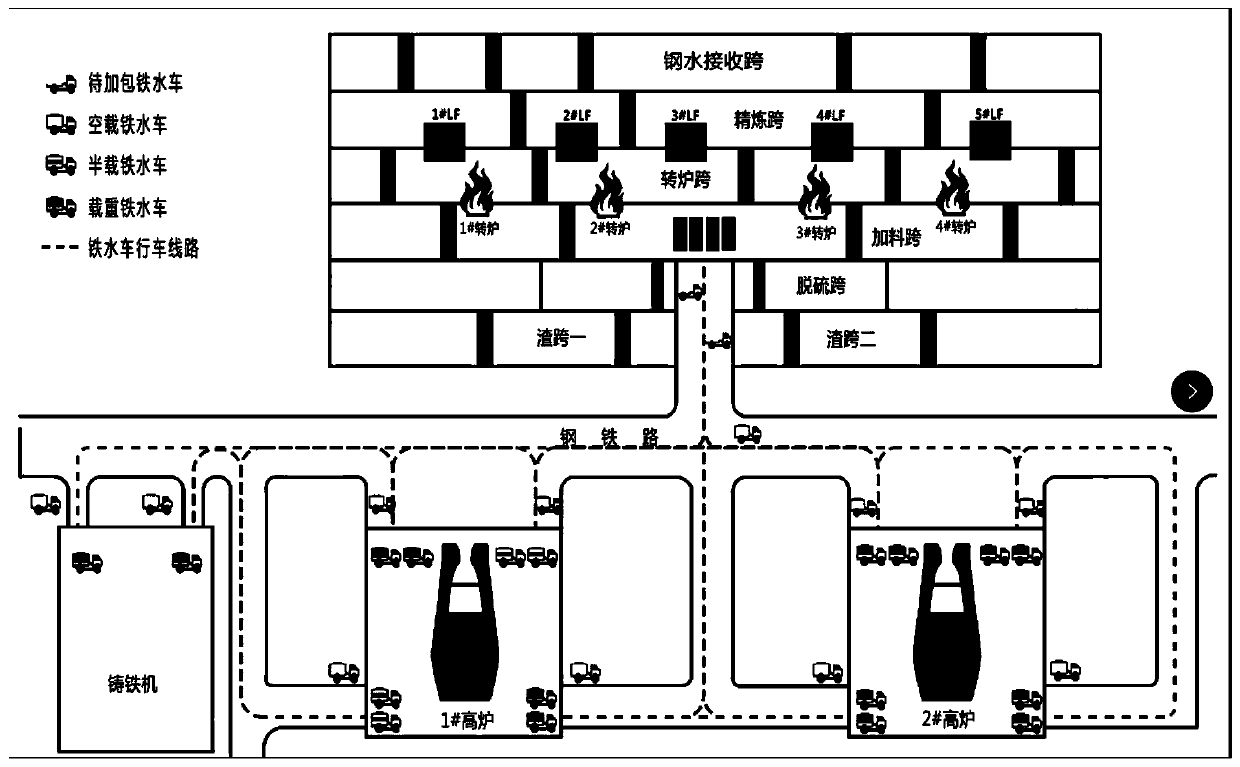

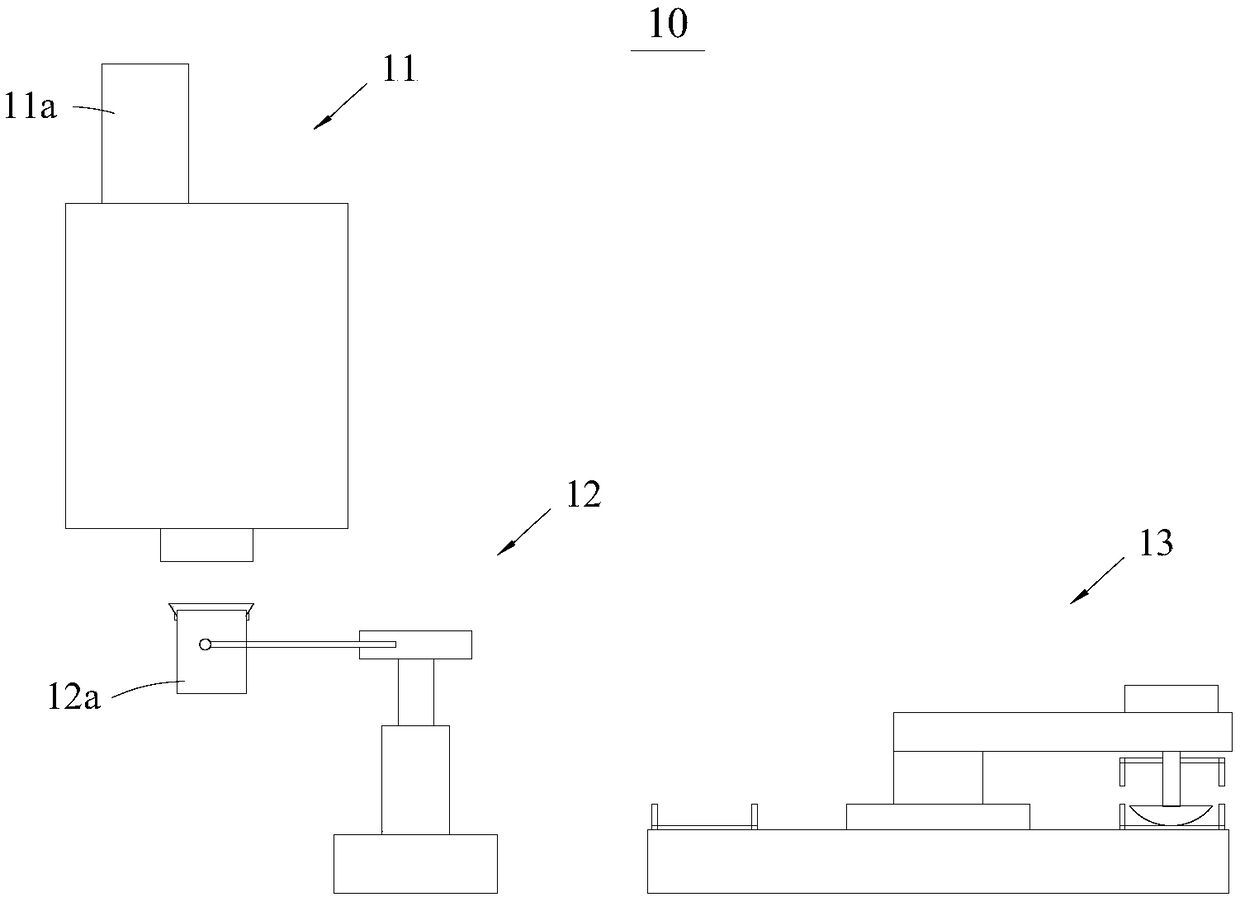

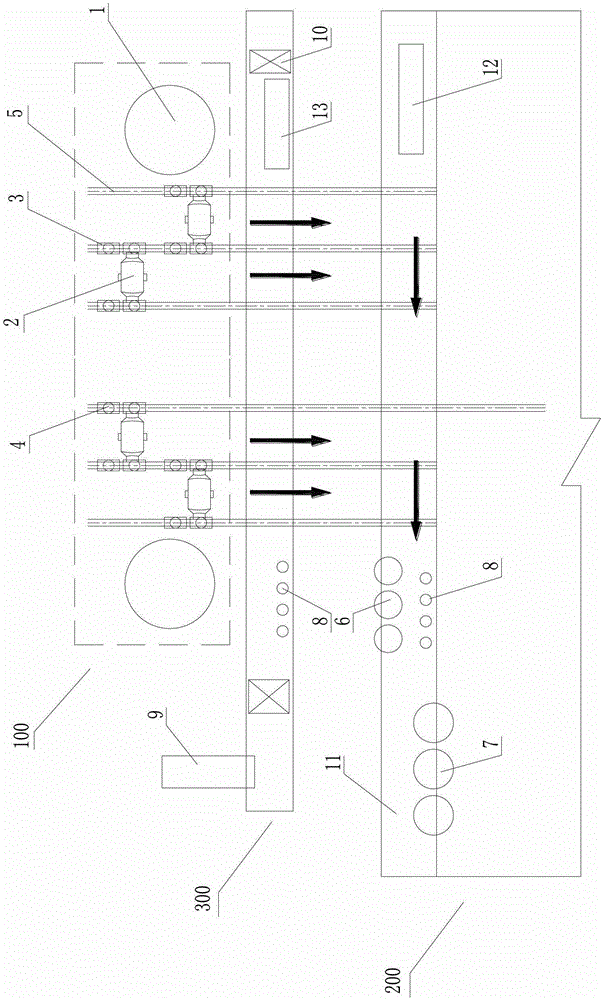

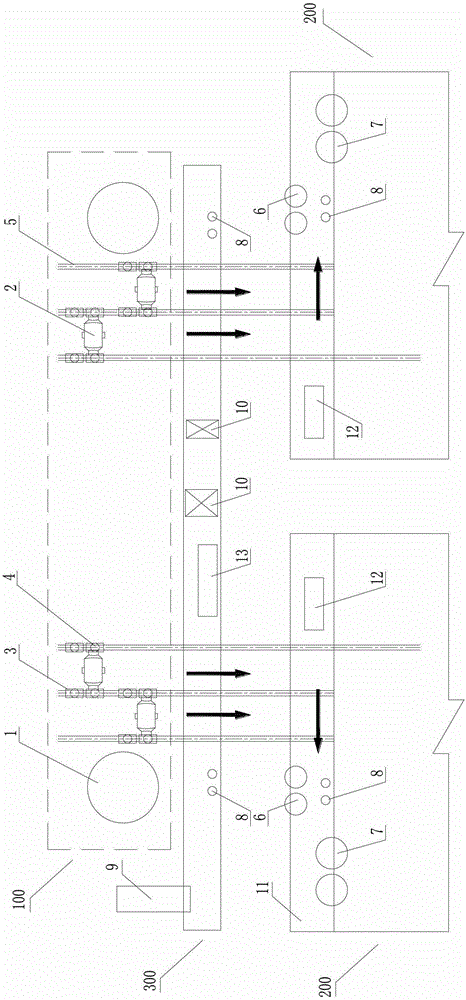

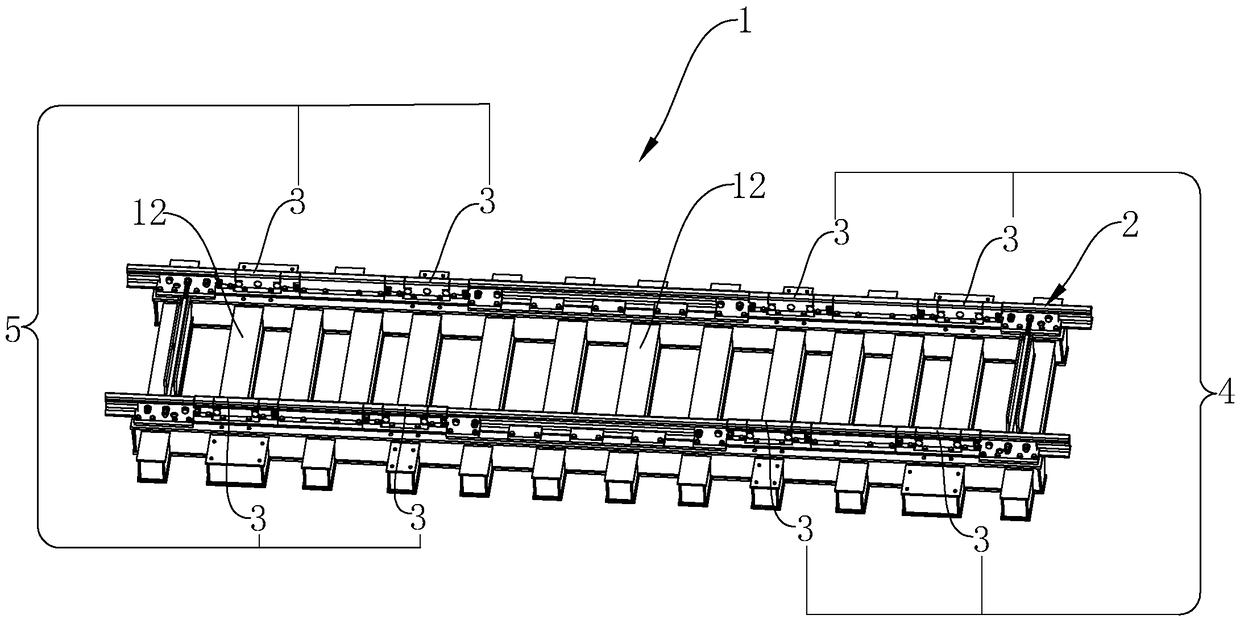

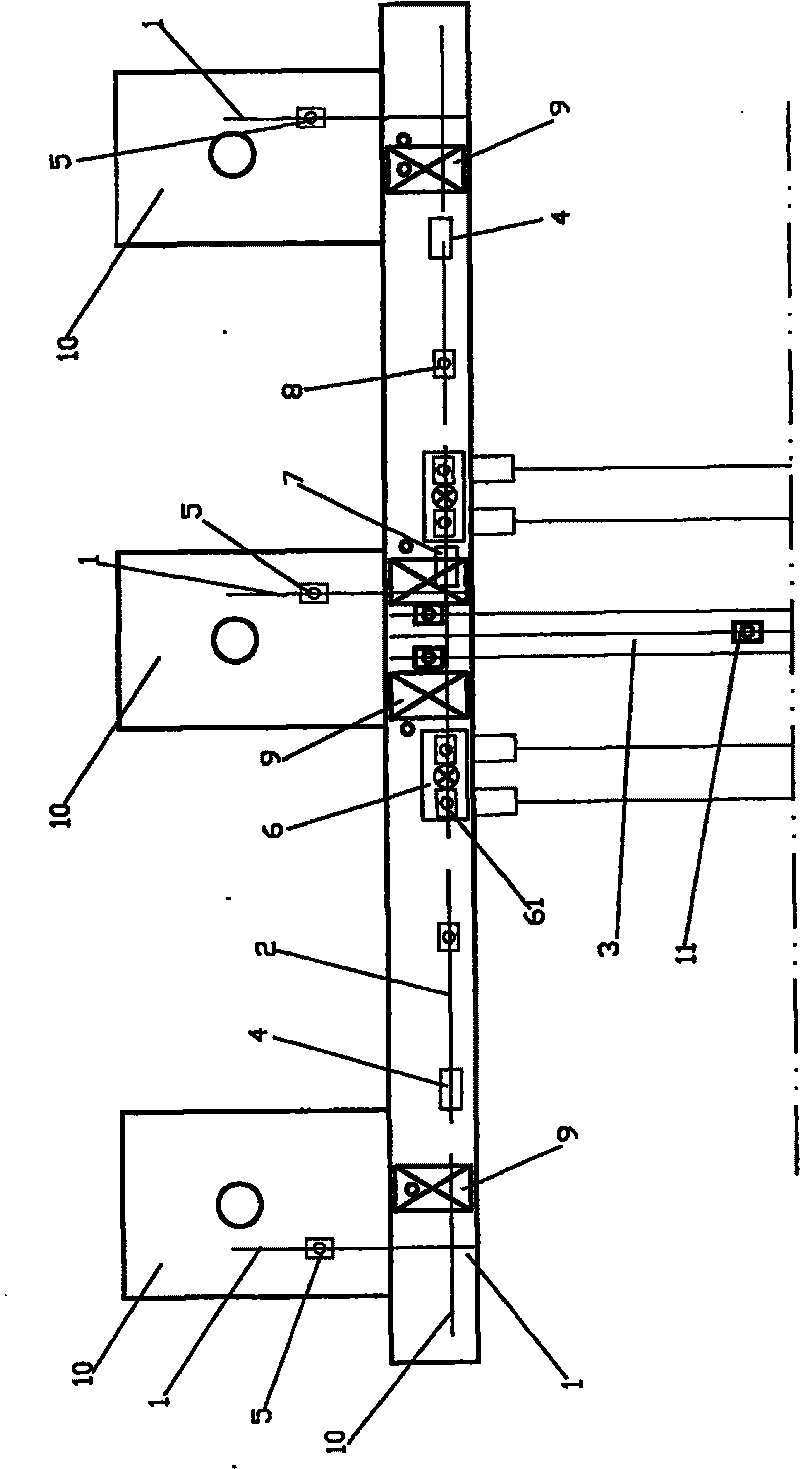

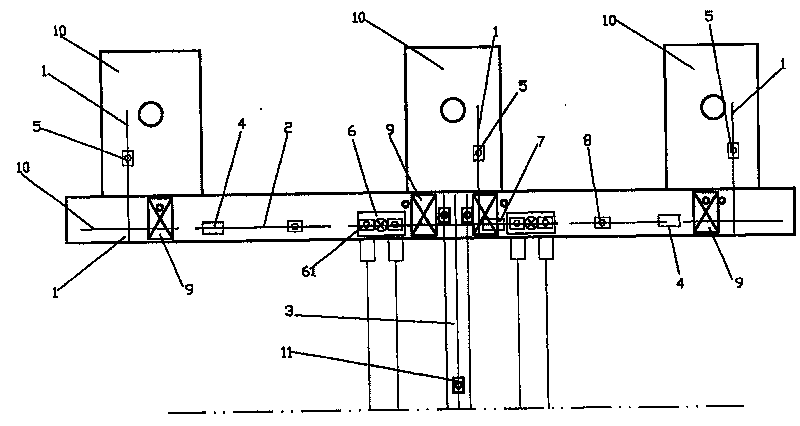

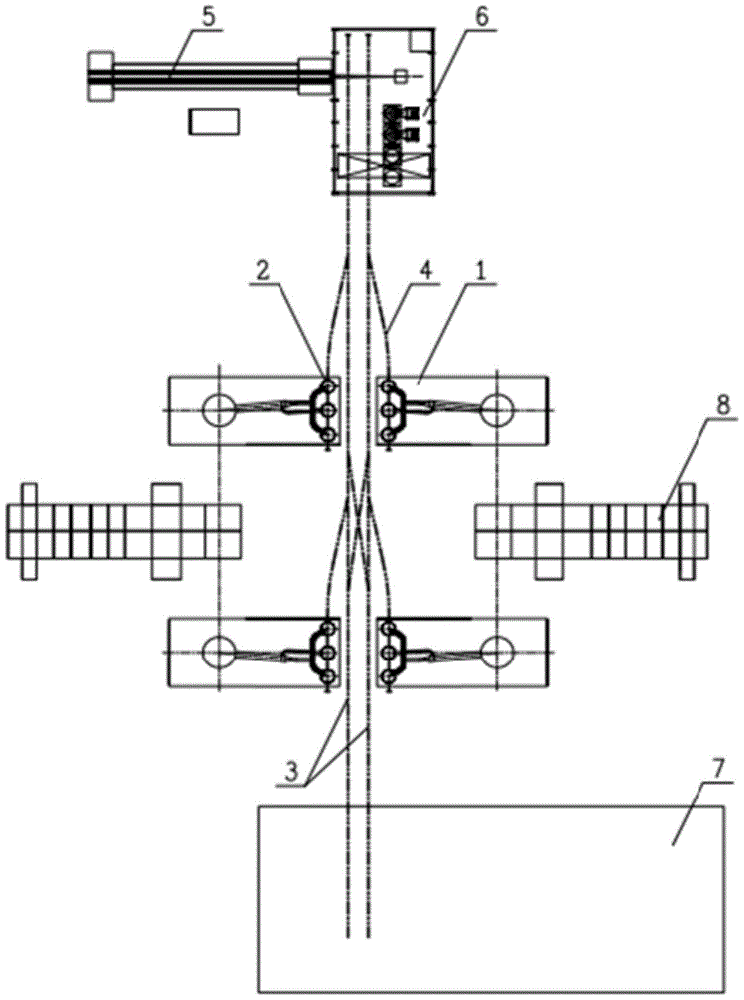

Molten iron transport system

ActiveCN105170965ACompact layoutSmall footprintMelt-holding vesselsRailway tracksIron transportMaterials science

The invention discloses a molten iron transport system. The molten iron transport system comprises casting houses (1) of ironmaking blast furnaces and a steel-making workshop (7), parallel track lines (3) are arranged between the casting houses (1) of the ironmaking blast furnaces and the steel-making workshops (7), the casting houses (1) of a plurality of ironmaking blast furnaces are symmetrically and compactly arranged at two sides of the parallel track lines (3), each casting houses (1) of each ironmaking blast furnace is connected to adjacent track line (3) via a molten iron pot storing line (4) of each casting houses, and a molten iron pot (2) of each casting houses (1) of each ironmaking blast furnace can be transported to the track lines (3) along each molten iron pot storing line (4). The steel-making workshop (7) is arranged at one end of the parallel track lines (3), the molten iron pots (2) can be transported to the steel-making workshop (7) along the track lines (3). The molten iron transport system is compact in arrangement, less in land occupation without a transition across workshop and a crane, so the investment can be saved.

Owner:BERIS ENG & RES CORP

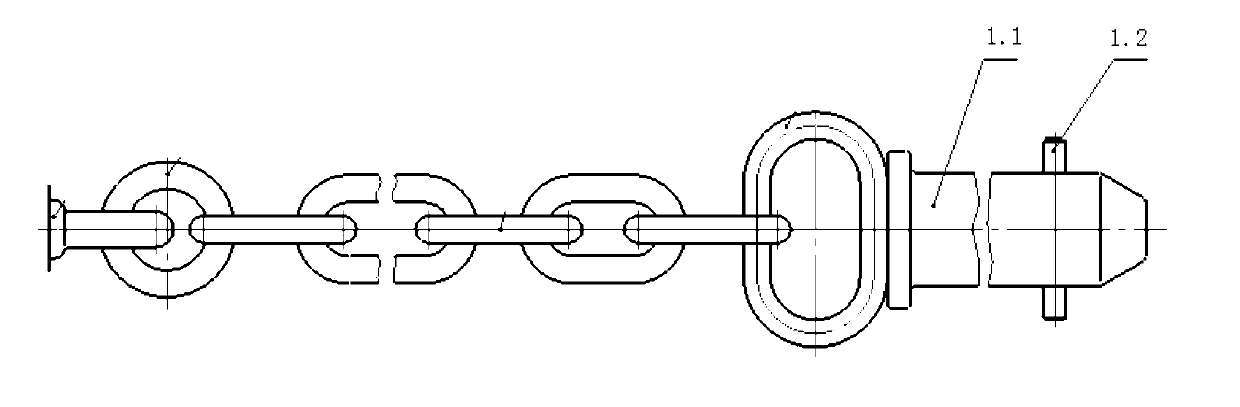

Method for transporting road rail iron in mine and road rail iron transport vehicle

ActiveCN102991512ASolve the problem of transporting long materialsReduce labor intensityRailway couplingsWagons/vansVehicle frameEngineering

The invention relates to the technical field of transport equipment for a mine, and discloses a method for transporting road rail iron in a mine and a road rail iron transport vehicle. The road rail iron transport vehicle comprises a vehicle A and a vehicle B, wherein the front vehicle A is flexibly connected with the vehicle B through a steel wire rope; the steel wire rope is used for adjusting the space between the two vehicles through ratchet wheel tensioning devices on frames of the vehicle A and the vehicle B, and the spacing is adjusted within the range from 6mm to 10mm; slewing devices for slewing are arranged on the frames of the vehicle A and the vehicle B; vehicle bodies for transporting the road rail iron are arranged on the slewing devices; bolt falling preventing chains are arranged at two ends of the frames; and buffering devices are arranged at the outer ends of the bolt falling preventing chains. The road rail iron transport vehicle can be widely applied to the transportation of long materials in the mine; the vehicles can flexibly turn a corner according to the condition in a well, so that the problem due to the transportation of the long materials in the mine can be solved, the working efficiency can be greatly improved, the working intensity of workers can be reduced; and the vehicles can be widely applied to the transportation of the long materials.

Owner:河南中车重型装备有限公司

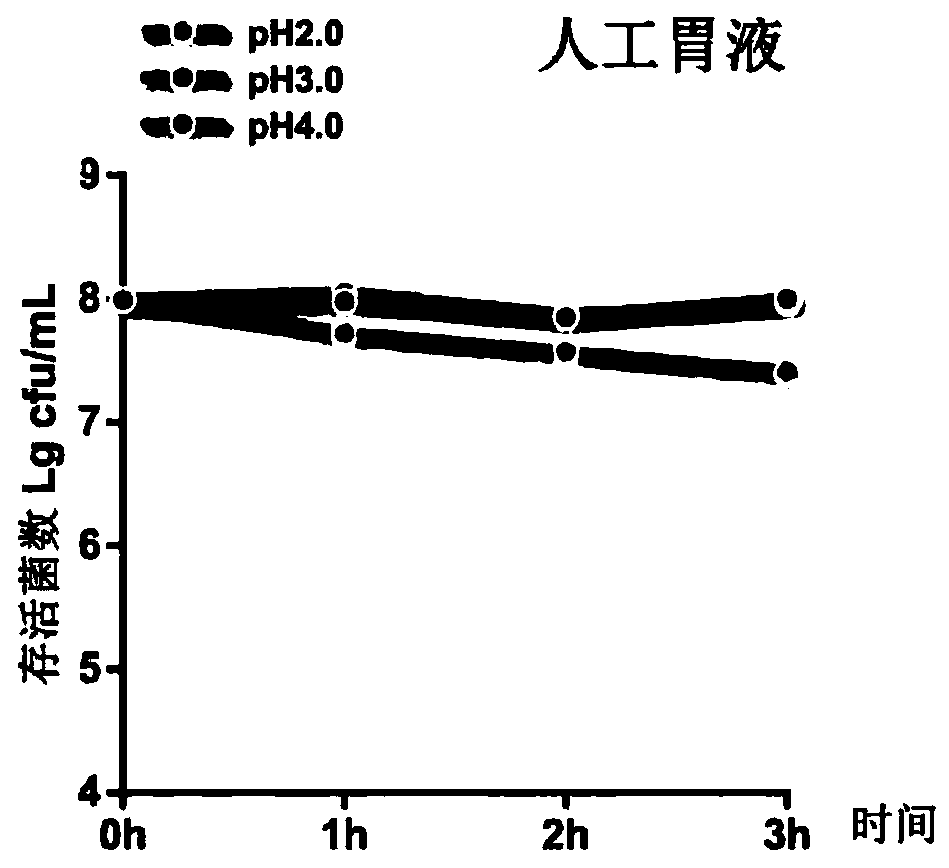

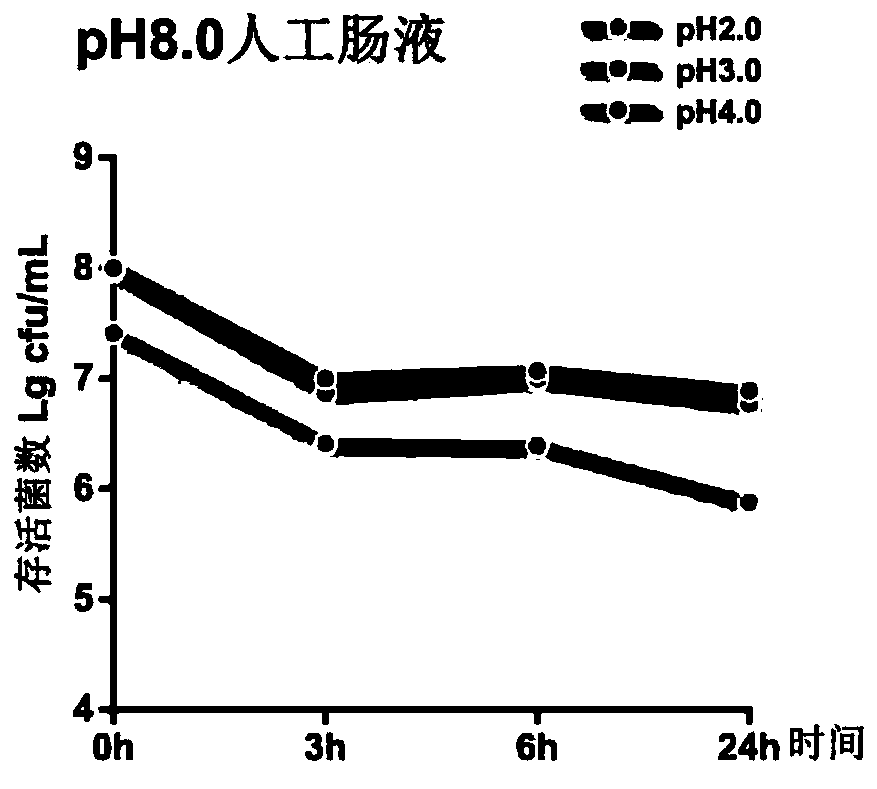

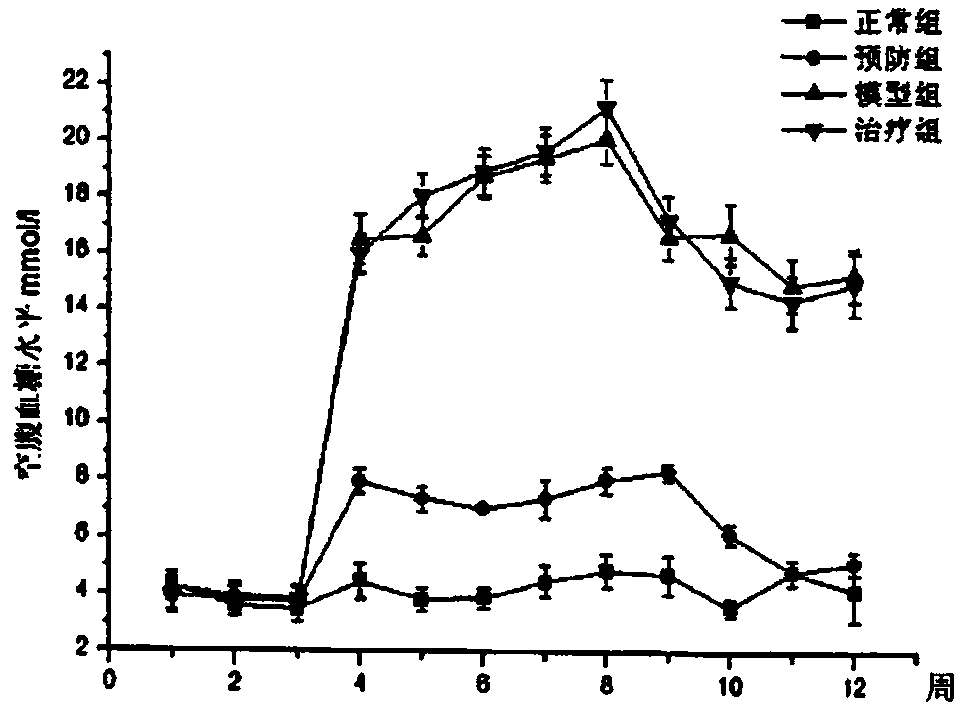

Lactobacillus casei for prevention and auxiliary treatment of type II diabetes and application of lactobacillus casei

InactiveCN111575202AGrowth inhibitionImprove immunityBacteriaMetabolism disorderBiotechnologyTransferrin iron

The invention discloses lactobacillus casei for prevention and auxiliary treatment of type II diabetes and application of the lactobacillus casei. The lactobacillus casei LCZ has a remarkable functionof preventing type II diabetes and the process of the type II diabetes can be well prevented after the lactobacillus casei intervenes for two weeks; the weight increase of a high-fat diet mice can beintervened and delayed, and the oral glucose tolerance increase induced by high-fat diet is prevented; expression of intestinal tract iron-related protein (transferrin and iron transport carrier protein) can be improved, chronic inflammation caused by endotoxin entering tissue is reduced, and then the effect of lowering the hyperglycemia level is achieved. Due to the remarkable functional characteristics of the lactobacillus casei, the lactobacillus casei has wide application value in various forms of probiotic foods, such as probiotic tabletting candies and probiotic solid beverages.

Owner:BEIJING SCITOP BIO TECH CO LTD

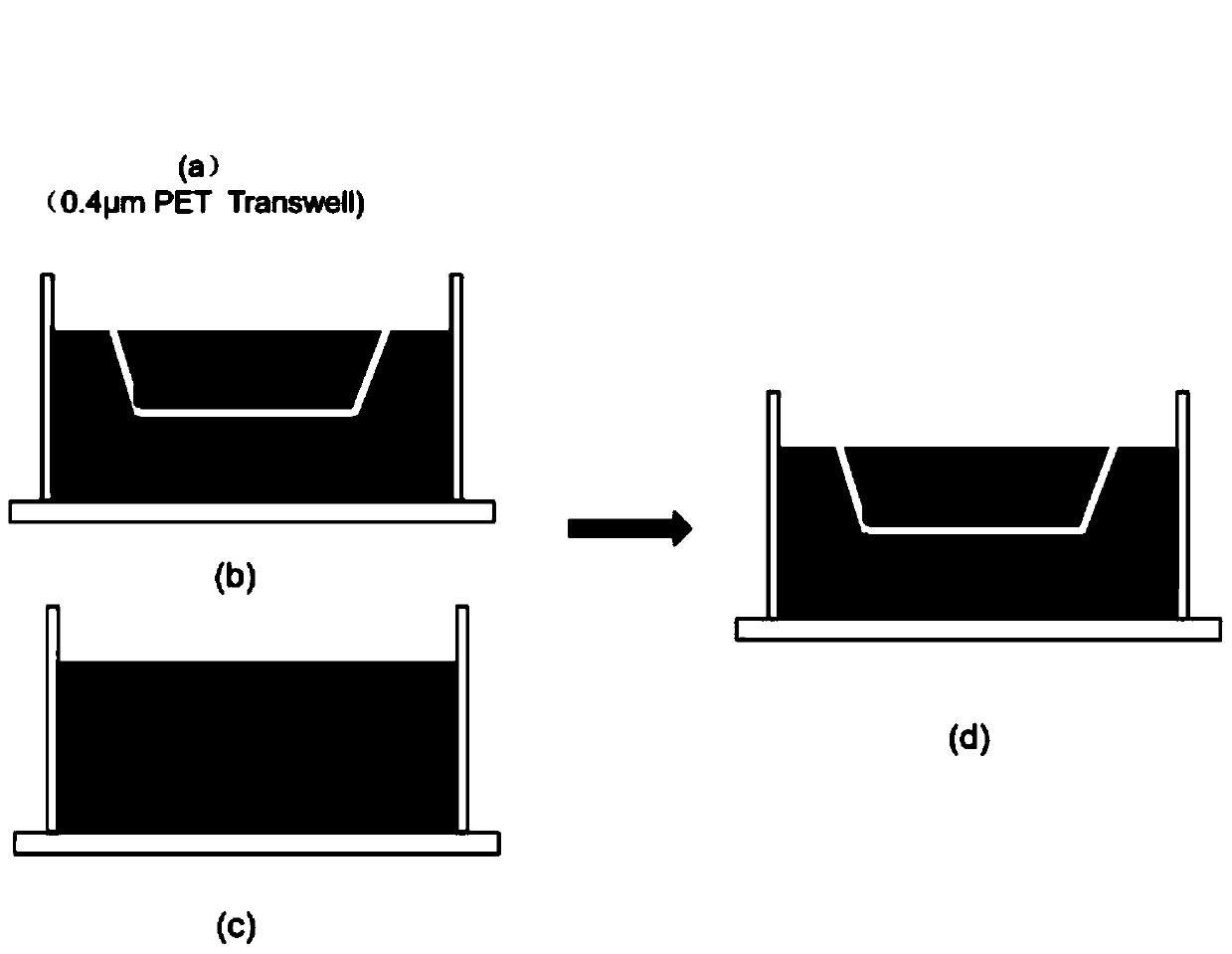

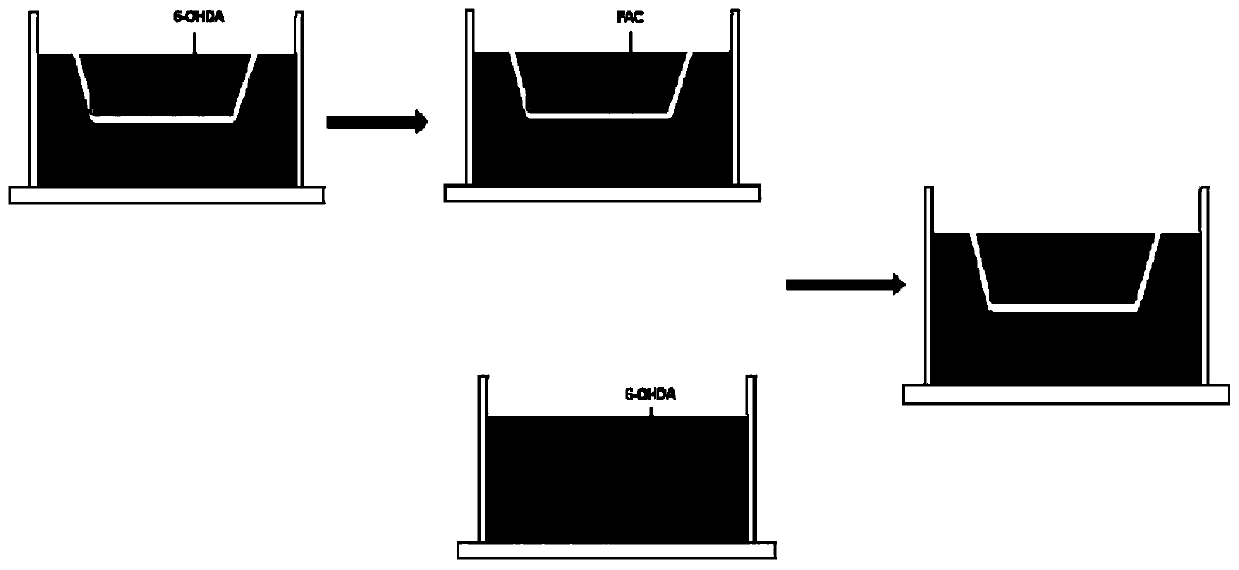

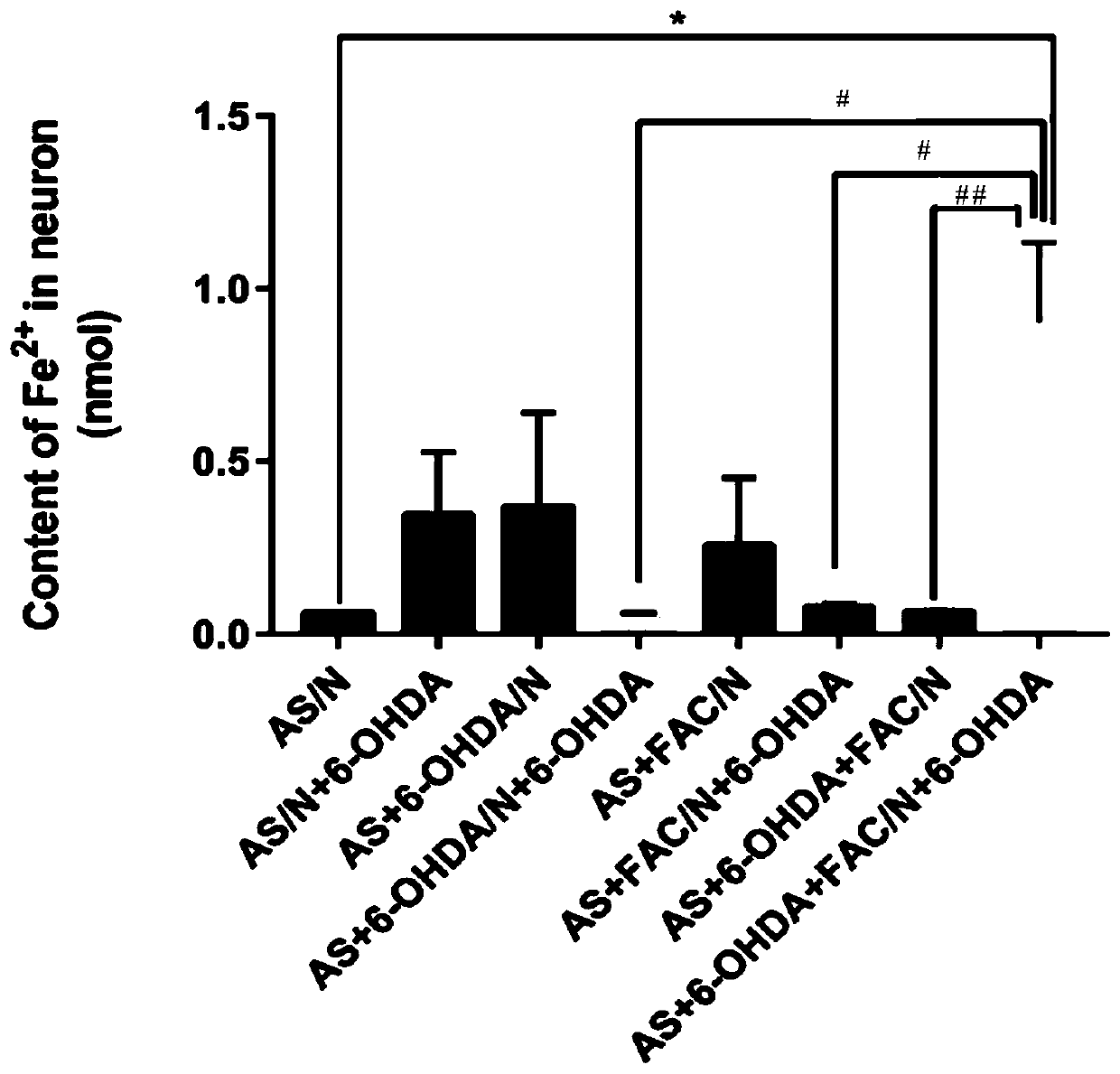

Applications of primary astrocyte/primary midbrain ventral neuron co-culture system in iron metabolism

ActiveCN110205294ADetermine co-cultivation timeDefine the experimental designCell dissociation methodsNervous disorderDiseaseMidbrain

The invention provides applications of a primary astrocyte / primary midbrain ventral neuron co-culture system in iron metabolism, especially in iron transport, and belongs to the field of cytobiology.The technical schemes detect a co-culture system by designing test methods, the sources of iron in neurons, the mutual influence between interstellar astrocyte and the directionality problems of irontransport can be cleared at the cellular level. The established primary astrocyte and primary midbrain ventral neuron co-culture system is a novel cell model for studying Parkinson diseases, and can be used for studying the related research of high iron in the brain of neurodegenerative diseases such as the Parkinson diseases.

Owner:QINGDAO UNIV

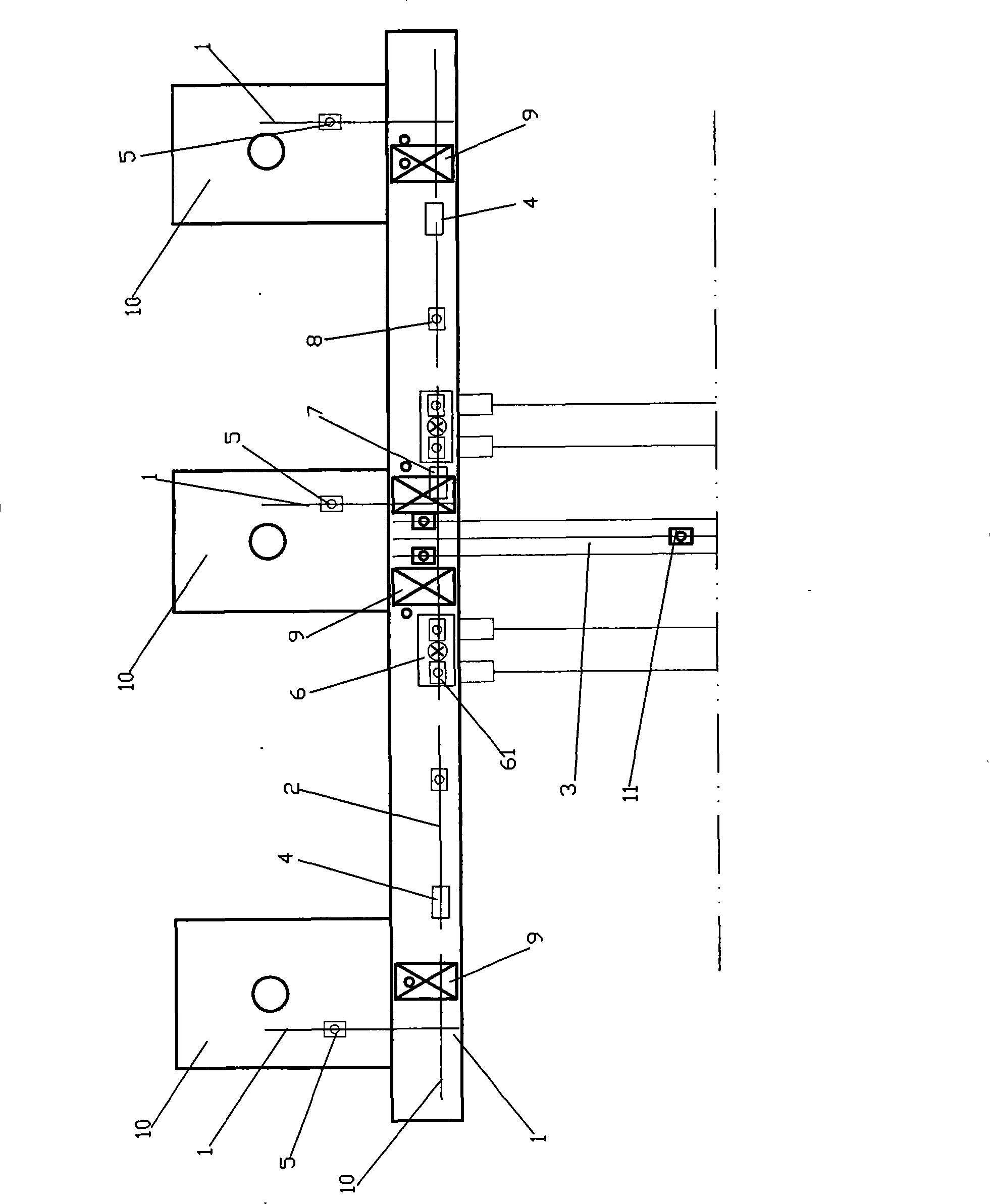

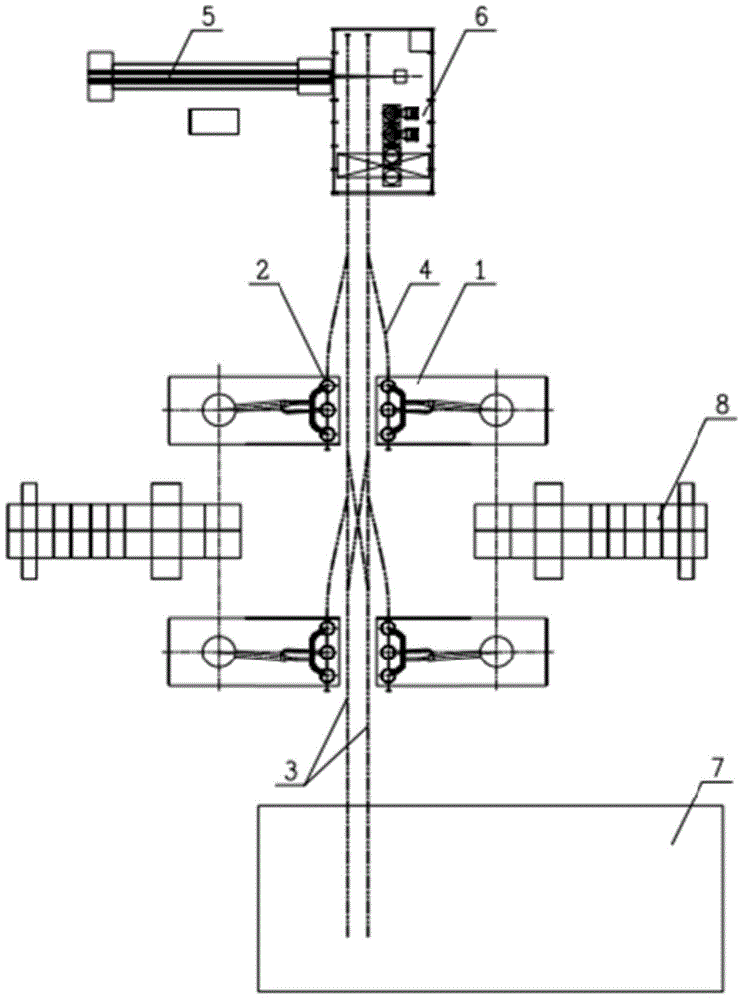

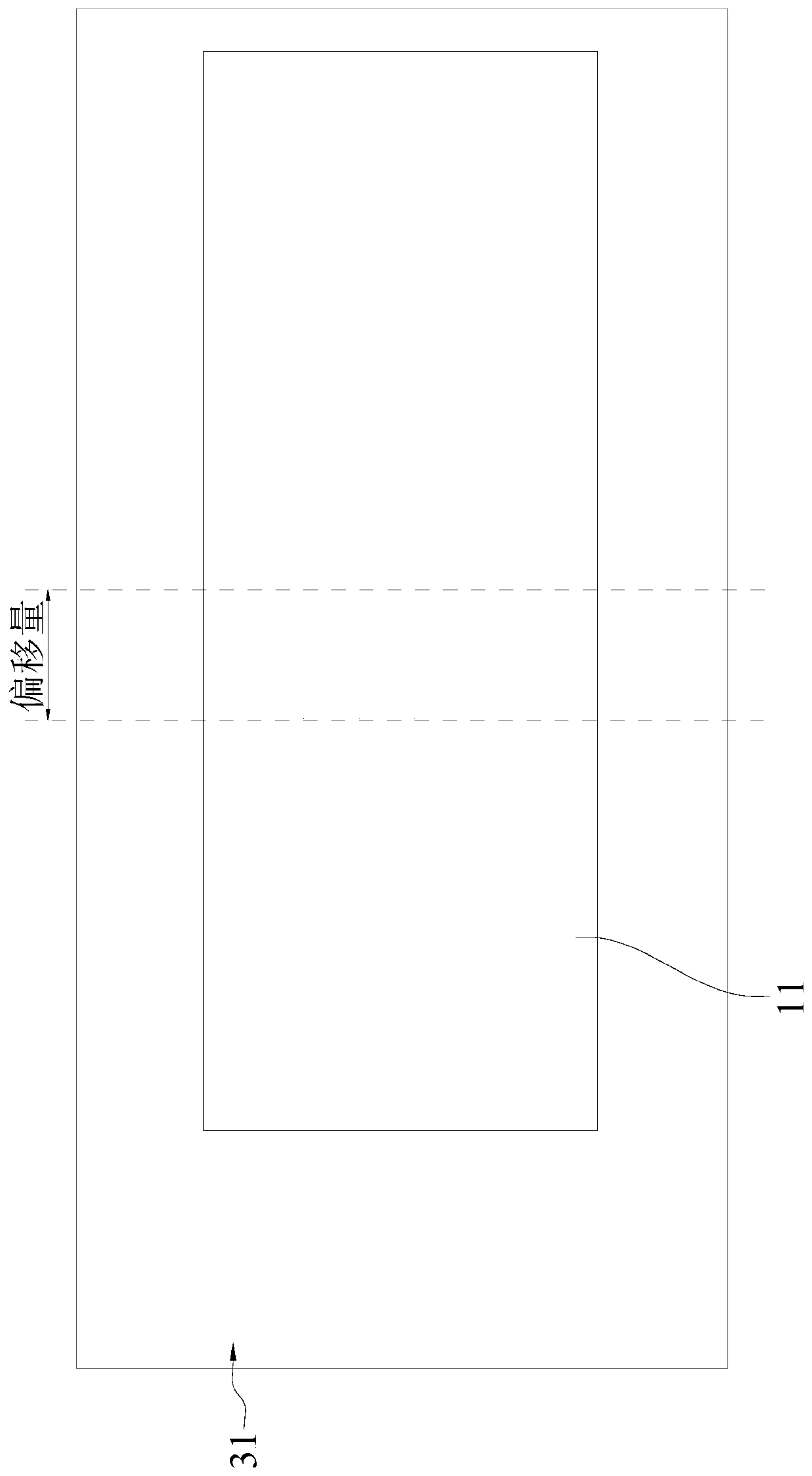

Metering and positioning system for molten iron tank, and molten iron transport production line

InactiveCN109751954AAchieve precisionReduce mistakesClosed circuit television systemsUsing optical meansData informationEngineering

The invention belongs to the technical field of metering systems, in particular to a metering and positioning system for a molten iron tank, and a molten iron transport production line. The metering and positioning system of the molten iron tank comprises a railway scale, a positioning module, a visual imaging module and a control module, wherein the positioning module corresponds to the railway scale, the visual imaging module corresponds to the calibration position of the railway scale, the control module controls the visual imaging module to start running according to a return signal of thepositioning module and calculates the offset of a molten iron tank car relative to the calibration position of the railway scale according to the return image information of the visual imaging module, the positioning module monitors the molten iron tank car and sends data information, the visual imaging module acquires a label image on the molten iron tank car, and the control module compares thelabel image with the marked position of the railway scale to calculate the offset of the center position of the label image relative to the marked position. The operator adjusts the positional relationship of the molten iron tank car relative to the railway scale according to the offset, which realizes the precise low-error positioning of the molten iron tank car.

Owner:LIANYUAN IRON & STEEL GROUP CO LTD +2

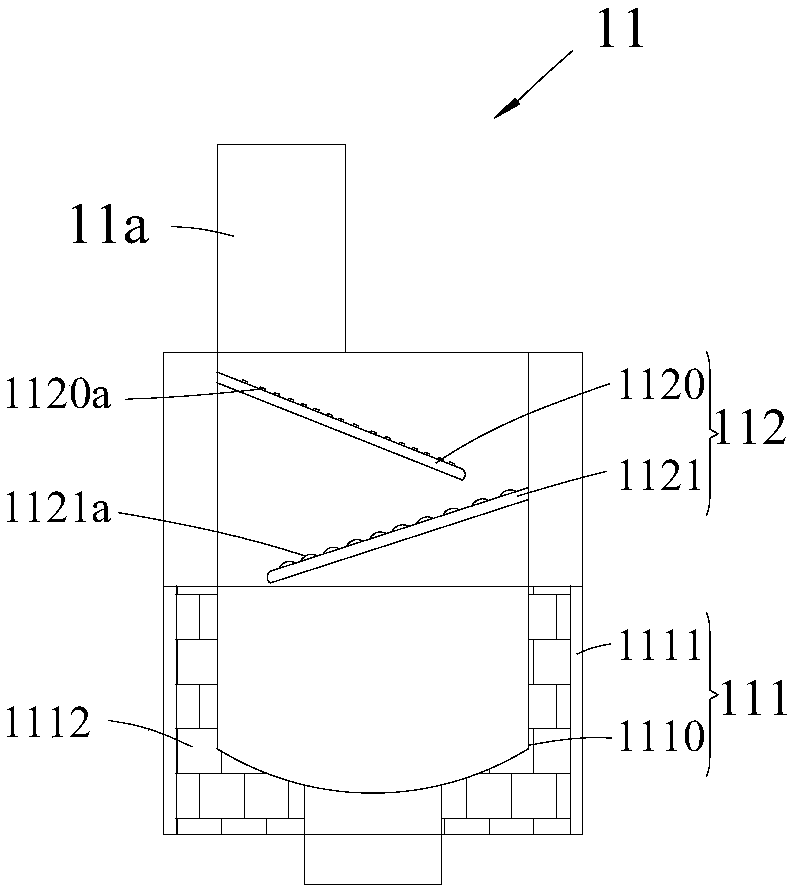

Pressure die-casting production line for iron pans

The invention discloses a pressure die-casting production line for iron pans and relates to the field of mechanical manufacturing. The pressure die-casting production line for iron pans comprises a molten iron melting device, a molten iron transfer device and a pressure die-casting device, wherein the molten iron transfer device is provided with a receiving container for receiving molten iron transported from a molten iron outlet; the pressure die-casting device comprises a rotary table, a plurality of lower pressure die-casting dies arranged on the rotary table and an upper pressure die-casting die arranged on the rotary table; the multiple lower pressure die-casting dies are arranged to rotate around the axis of the rotary table; and the molten iron transfer device is arranged to drive the receiving container to move back and forth between the pressure die-casting device and the molten iron outlet, so that molten iron in the receiving container is transported to the lower pressure die-casting dies. The pressure die-casting production line for iron pans can manufacture iron pans efficiently.

Owner:武汉安博力厨具有限公司

Compact hot metal transport system

ActiveCN103343632BSmall footprintReduce investmentBlast furnace detailsIndustrial buildingsSteelmakingIron transport

Owner:BERIS ENG & RES CORP

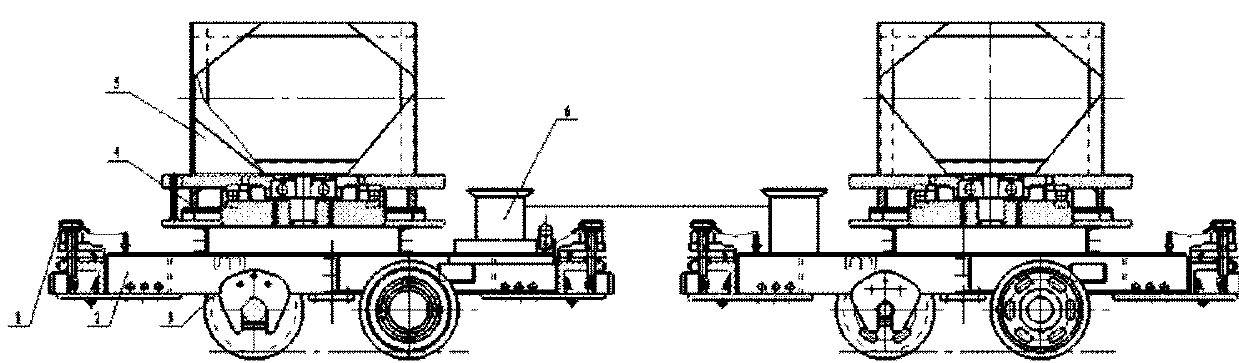

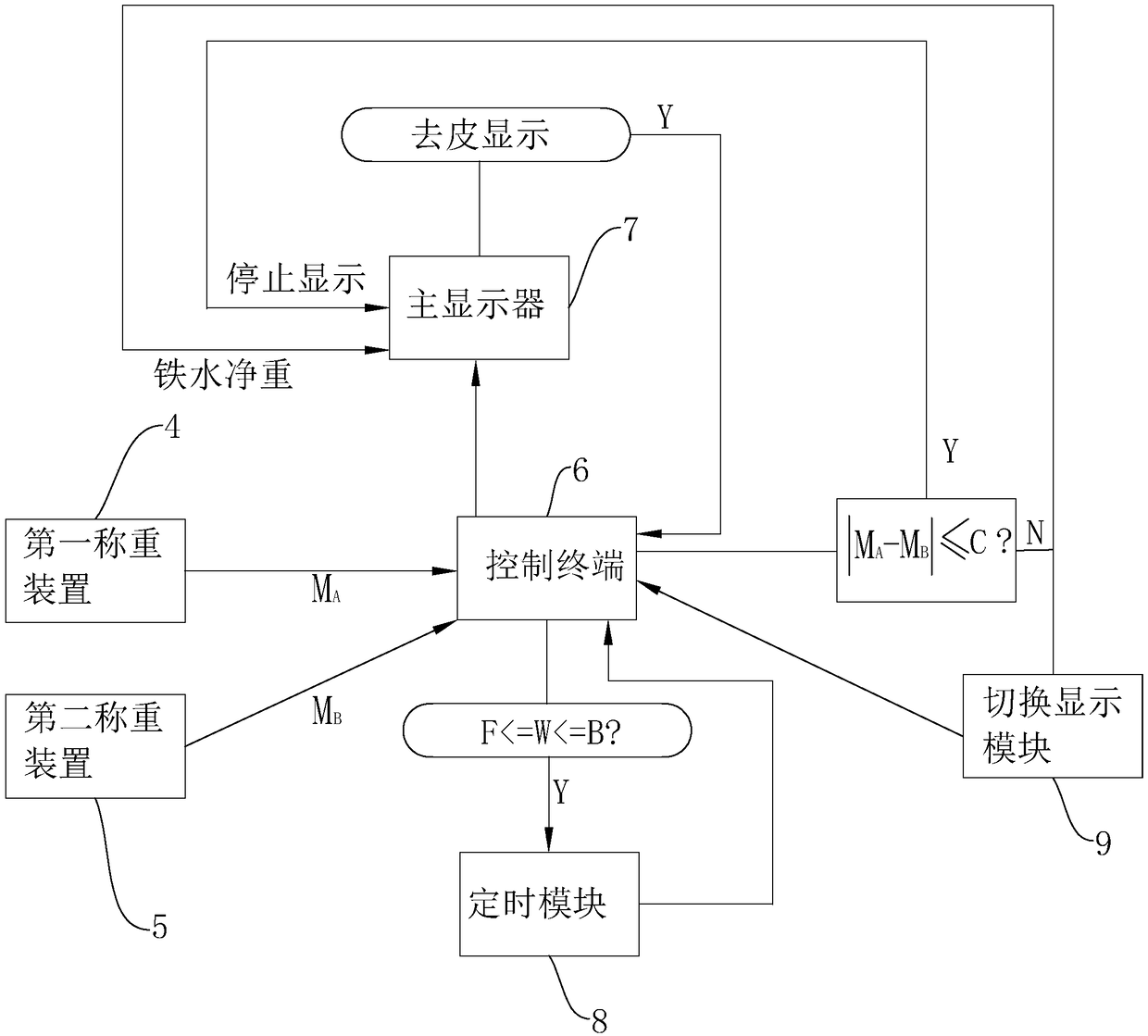

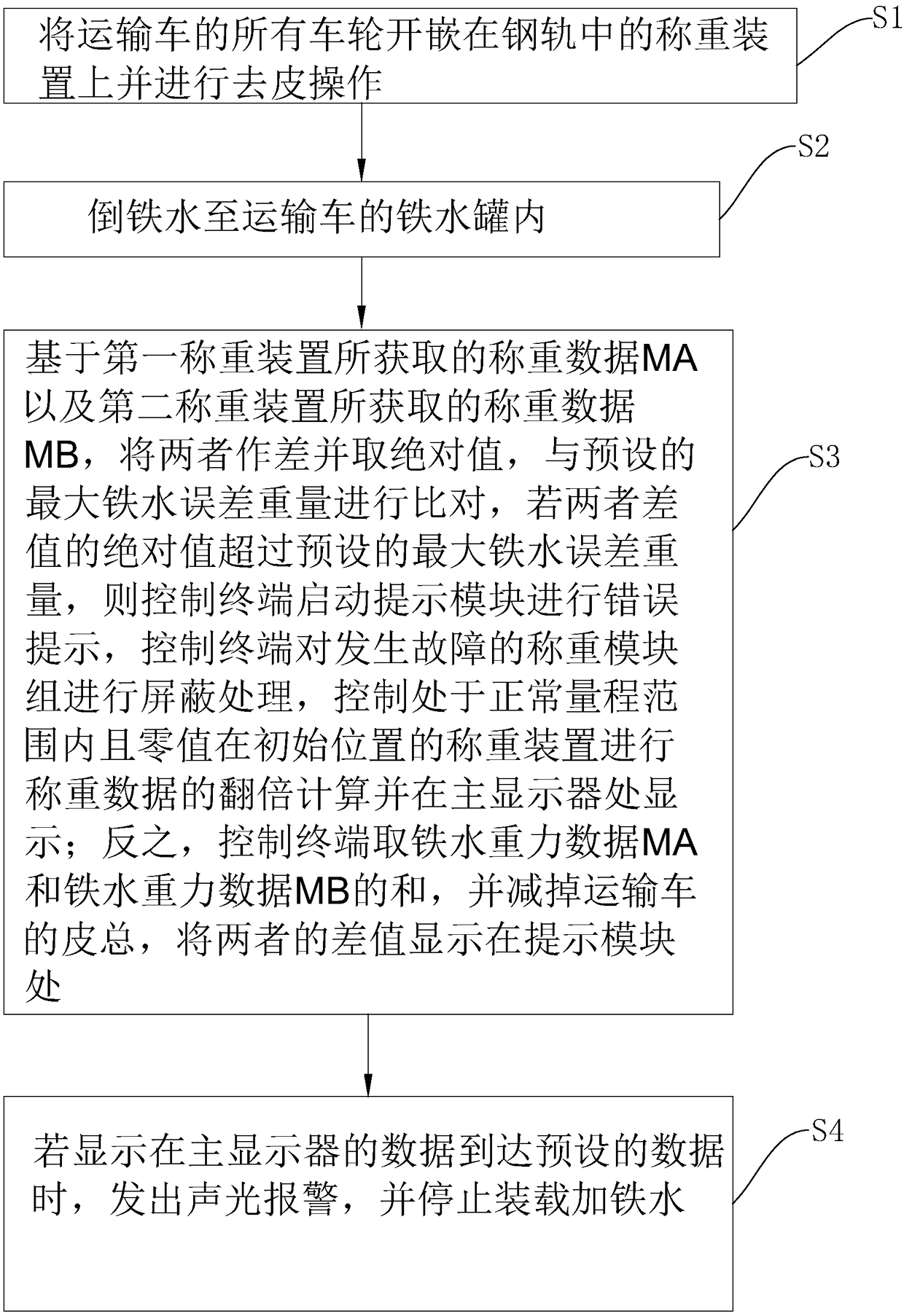

Molten iron quantitative loading system and molten iron quantitative loading method

InactiveCN109084874AAvoid misleadingPrevent overflow accidentsWeighing apparatus testing/calibrationWeighing apparatus for materials with special property/formMaximum errorComputer module

The invention discloses a molten iron quantitative loading system and a molten iron quantitative loading method, and relates to a weighing device. Since the existing molten iron transport vehicle is composed of two groups of wheels in front and back, a molten iron tank for holding the molten iron is arranged between two groups of wheels, a group weighing modules arranged below the transport wheelsare used for weighing the transport vehicle so as to judge whether the molten iron is in quantitative loading, and the weighing module has a use condition for guaranteeing the normal use thereof, sothat the weighing module is prone to failure once the condition dissatisfies a use environment range of the weighing module in normal use (such as the molten iron overflows to the weighing module); and the problem that the weighing module is prone to failure is solved through the molten iron quantitative loading system disclosed by the invention. The technical scheme key point is that a control terminal computes the difference between weighing data MA of a first weighing device and weighing data MB of a second weighing device, and takes an absolute value of the difference, the absolute value is compared with the preset maximum error data, so that a worker can timely acquire whether the weighing of the molten iron is exactly correct; and the system is in favor of accurately and quantitatively loading the molten iron.

Owner:宁波中和衡器有限公司

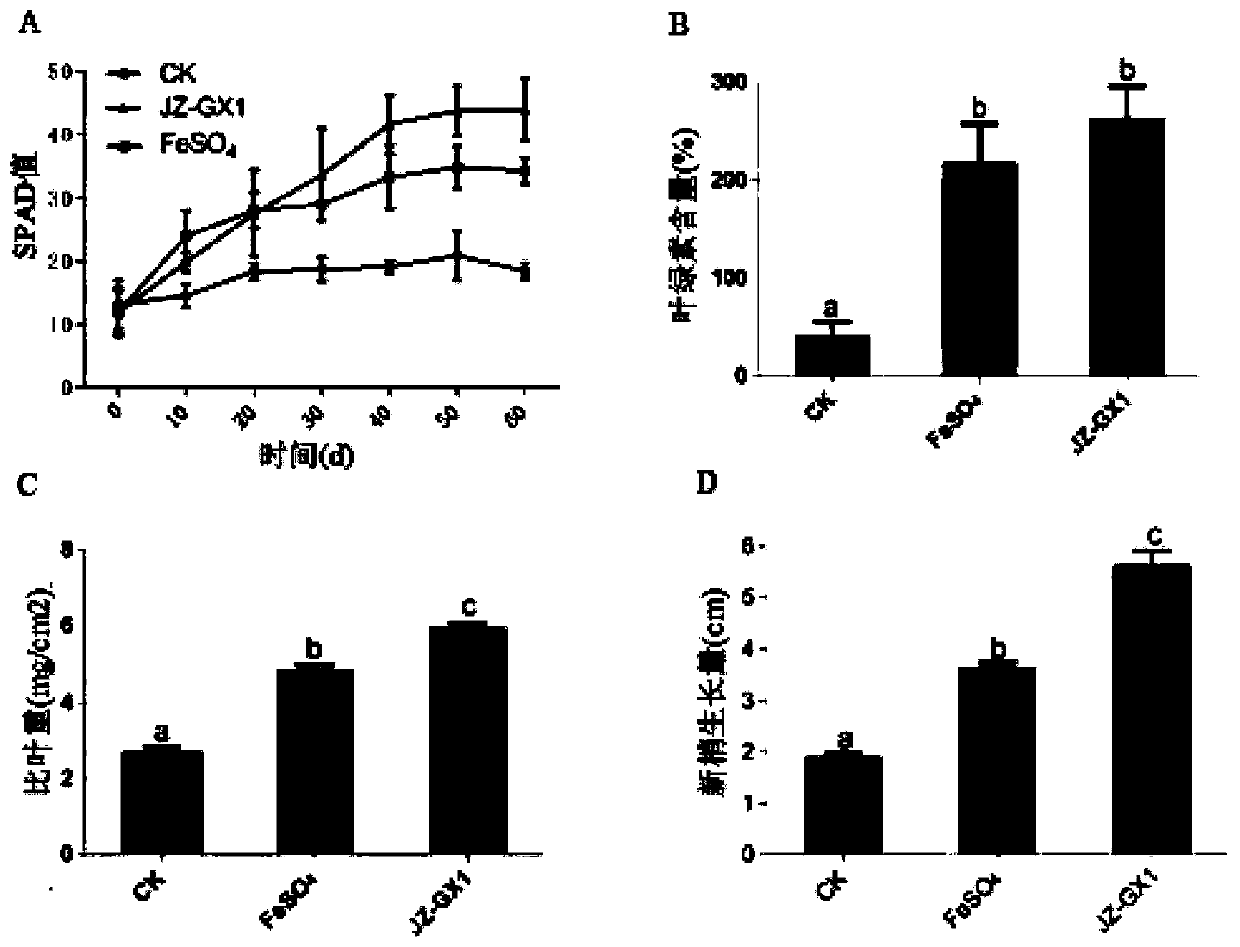

Method for using microorganisms to control iron deficiency yellowing of cinnamomum camphora

InactiveCN110199765AFacilitates iron transportBoost Iron NutritionMicroorganism based processesCultivating equipmentsBacteroidesDisease

The invention discloses a method for using microorganisms to control iron deficiency yellowing of cinnamomum camphora and belongs to the technical field of controlling iron deficiency yellowing diseases in trees. The method includes applying plant growth promoting rhizobacteria (PGPR), rahnella aquatilis JZ-G 1 ferritin fermentation broth into the root of a cinnamomum camphora tree to improve irondeficiency yellowing of the cinnamomum camphora. The PGPR, rahnella aquatilis JZ-GX1 ferrtin fermentation broth is applied to the control of iron deficiency yellowing of the cinnamomum camphora to promote iron transport, and multiple roles are played in improving plant iron nutrition; the PGPR, rahnella aquatilis JZ-GX1 ferrtin fermentation broth applied to alkaline or nutrient-poor soil as an important improvement measure to alleviate the symptoms of iron deficiency and chlorosis, and a broad application prospect is achieved.

Owner:NANJING FORESTRY UNIV

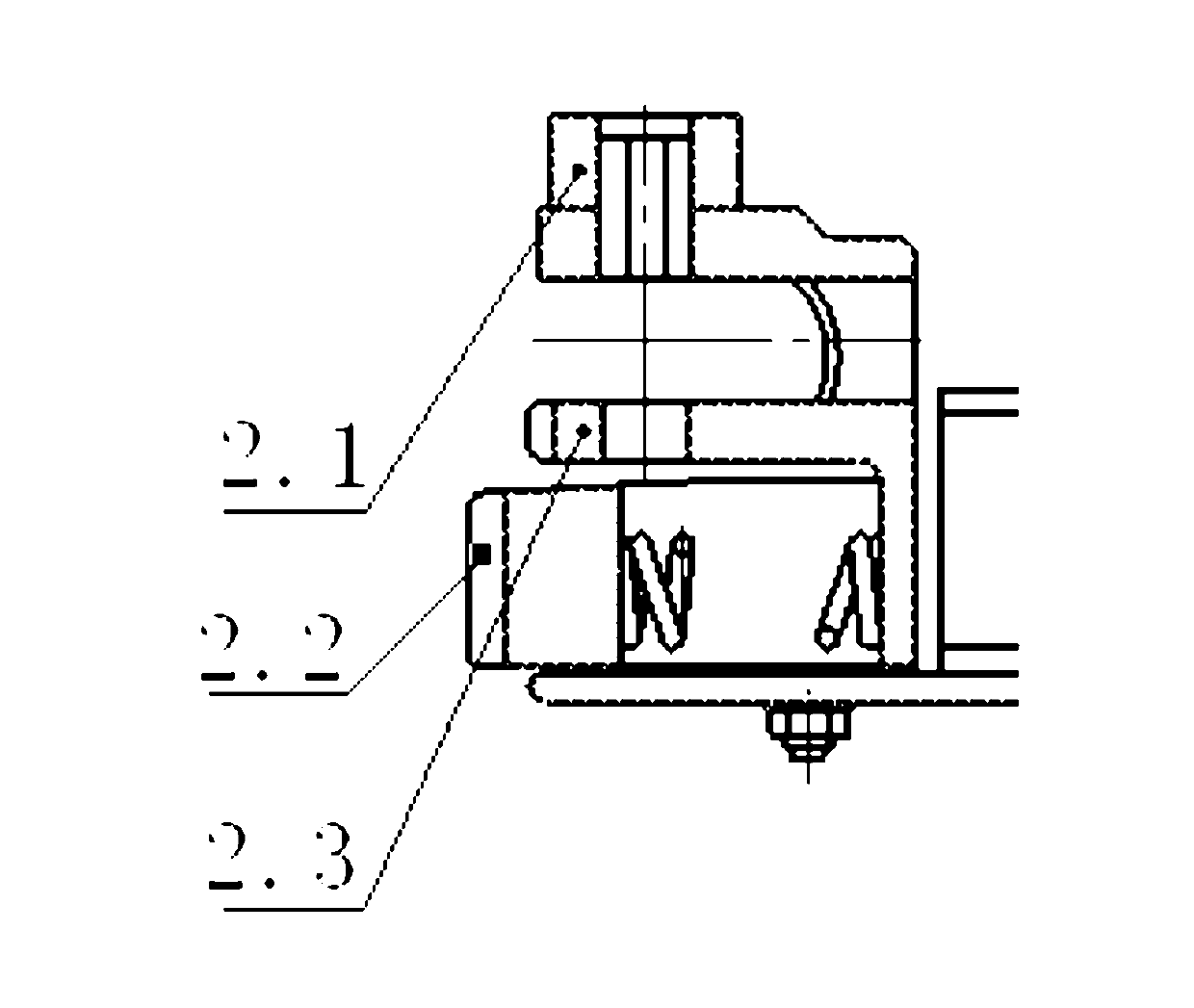

Tank body tilting safety control device of iron mixing vehicle

InactiveCN102847927AReduce lossImprove the turnover rate of online operationMelt-holding vesselsLarge toothSafety control

The invention relates to a tank body tilting safety control device of an iron mixing vehicle, which belongs to blast furnace iron making and relates to a blast furnace molten iron transport device. The tank body tilting safety control device comprises a vehicle body, a tank body, a tilting mechanism, a high speed receptacle and a junction box, wherein the tank body, the tilting mechanism, the high speed receptacle and the junction box are arranged on the vehicle body, the tilting mechanism is connected with a large gear of the tank body through a chain, and an electrical control box is arranged on the ground and electrically connected with the high speed receptacle. The tank body tilting safety control device is characterized in that a tilting two-way contact is arranged on the center line of the tank body, a zero position contact is arranged under the center line, the tilting two-way contact and the zero position contact respectively correspond to a tilting travel switch and a zero position travel switch which are arranged on a platform, and the tilting travel switch and the zero position travel switch are electrically connected with the junction box. The tank body tilting safety control device has the advantages of novel concept, simple structure, easiness in operation and low manufacturing cost. The position of the tilting travel switch can be adjusted so as to adapt to different tilting angles of the tank body, the tilting process is safe and reliable, an accident that molten iron falls on the ground because the tank body is tilted and out of control due to mechanical, electrical and operational causes is effectively avoided, waste of the molten iron is reduced, the cost for maintenance and spare parts is reduced, the online operation turnover rate of the iron mixing vehicle is increased, and smooth production is guaranteed.

Owner:ANHUI MASTEEL ENG & TECH GRP

Iron melt transfer system

InactiveCN101249560BReduce temperature dropStrong transfer continuityMelt-holding vesselsCasting plantsTransfer systemIron transport

The invention discloses a molten iron transport system, which comprises a first transport path of molten iron in a blast furnace, a second transport path of molten iron between adjacent blast furnaces, and a third transport path for transporting molten iron to a steel-making plant, wherein the first transport path is linearly arranged between the blast furnace and the second transport path ; the second transport path is linearly arranged between two adjacent blast furnaces; the third transport path is linearly arranged between the second transport path and the steel-making shop; a first transport vehicle is arranged at the transition position of the first transport path and the second transport path; a second transport vehicle is arranged at the transition position of the second transportpath and the third transport path; a desulfurizing station is also arranged at the transition position of the second transport path and the third transport path ; a first ground molten iron tank car,a second ground molten iron tank car and a third ground molten iron tank car are respectively arranged on the first transport path, the second transport path and the transport path third. The molten iron transport system has high transport continuity, and can maximally shorten the transport cycle and eliminate the influence of centrifugal force on the production safety in the transport process, thus improving the transport speed and reducing temperature drop of the molten iron.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Fusion protein, production method thereof, and production method of transgenic rice

ActiveCN106519038AHigh expressionFunction as a terminatorHybrid peptidesVector-based foreign material introductionGenetically modified riceIron transport

The invention relates to a fusion protein, a production method thereof, and a production method of transgenic rice. The fusion protein is a plant seed endosperm expressed Ex-TF fusion protein. The gene sequence of the fusion protein comprises a plant endosperm specific expression promoter (pGluB-5); a plant endosperm storage protein signal peptide (sp), an exenatide polypeptide (Exendin-4), a connection polypeptide (GGGGS)x3linker that connects Exendin-4 and human iron transport protein (hTF), a human iron transport protein (hTF), a histone label (6xHis) for the purification of proteins, and a transcription terminator (GluB-5-3'-UTR) of a plant gene (GluB-5). By utilizing the GluB-5 promoter, the fusion protein can be massively expressed in the whole endosperm. At the same time, the advantages of paddy rice such as high yield, easy plantation and management, and the like, and the advantages of paddy rice seed such as long shelf life, easy extraction, and the like, are utilized to realize the continuous production of Ex4-TF fusion protein drugs; the waste and shortage are avoided, and the production cost is reduced at the same time.

Owner:SHENZHEN RES INST THE CHINESE UNIV OF HONG KONG

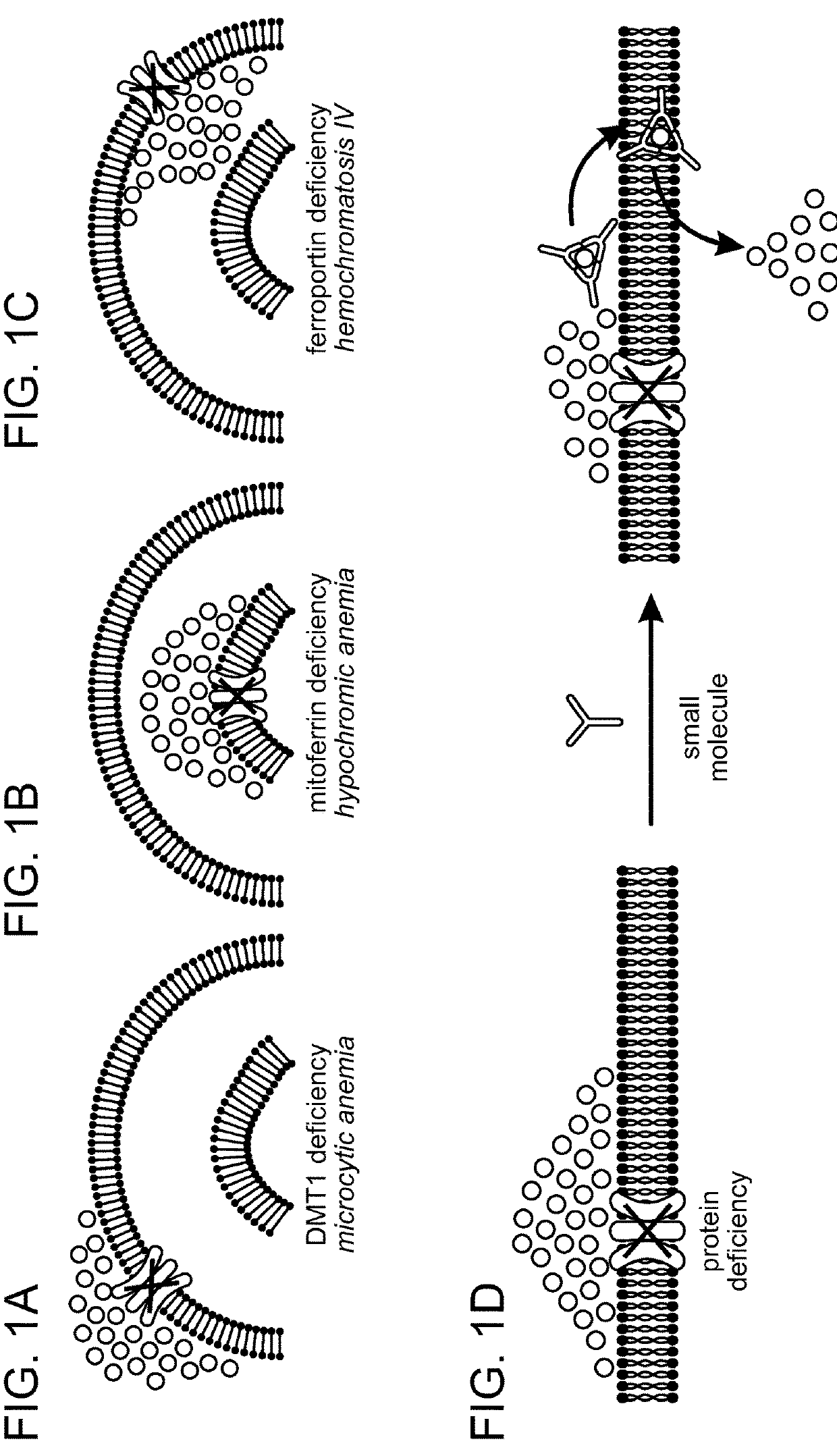

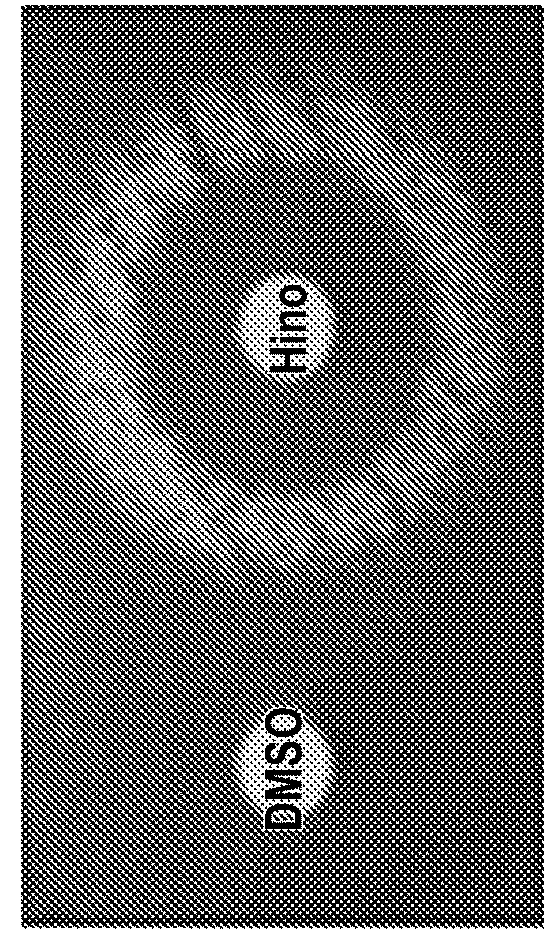

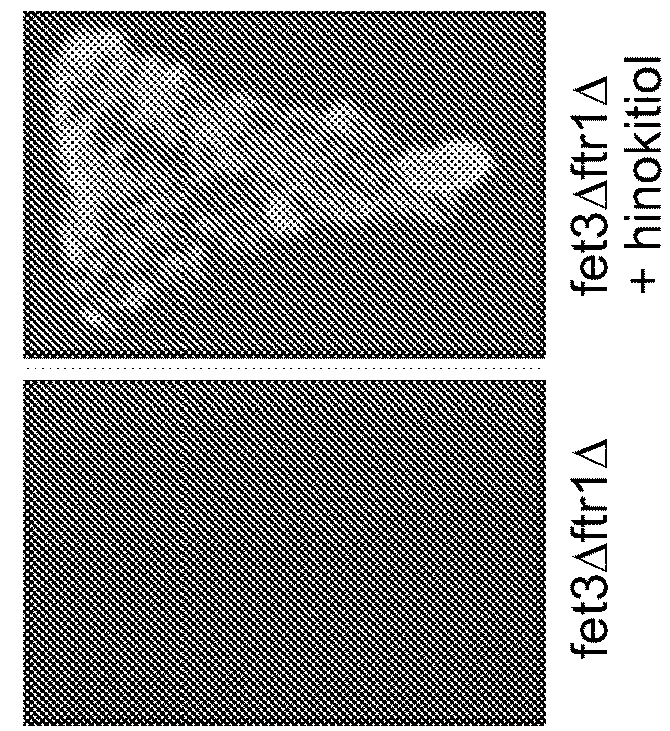

Restoring Physiology in Iron-Deficient Organisms Using Small Molecules

Provided are methods of treating a disease or condition characterized by a deficiency of or a defect in an iron transporter using a small molecule. For example, the method may increase transepithelial iron transport, or it may increase iron release. Additionally, the small molecule may be hinokitiol, or it may be selected from the group consisting of amphotericin B, calcimycin, nonactin, deferiprone, purpurogallin, and maltol. Also provided is a method of identifying a compound capable of treating a disease or condition characterized by a deficiency of or a defect in an iron transporter.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

A molten iron transportation system

ActiveCN105170965BCompact layoutSmall footprintMelt-holding vesselsRailway tracksIron transportMaterials science

The invention discloses a molten iron transport system. The molten iron transport system comprises casting houses (1) of ironmaking blast furnaces and a steel-making workshop (7), parallel track lines (3) are arranged between the casting houses (1) of the ironmaking blast furnaces and the steel-making workshops (7), the casting houses (1) of a plurality of ironmaking blast furnaces are symmetrically and compactly arranged at two sides of the parallel track lines (3), each casting houses (1) of each ironmaking blast furnace is connected to adjacent track line (3) via a molten iron pot storing line (4) of each casting houses, and a molten iron pot (2) of each casting houses (1) of each ironmaking blast furnace can be transported to the track lines (3) along each molten iron pot storing line (4). The steel-making workshop (7) is arranged at one end of the parallel track lines (3), the molten iron pots (2) can be transported to the steel-making workshop (7) along the track lines (3). The molten iron transport system is compact in arrangement, less in land occupation without a transition across workshop and a crane, so the investment can be saved.

Owner:BERIS ENG & RES CORP

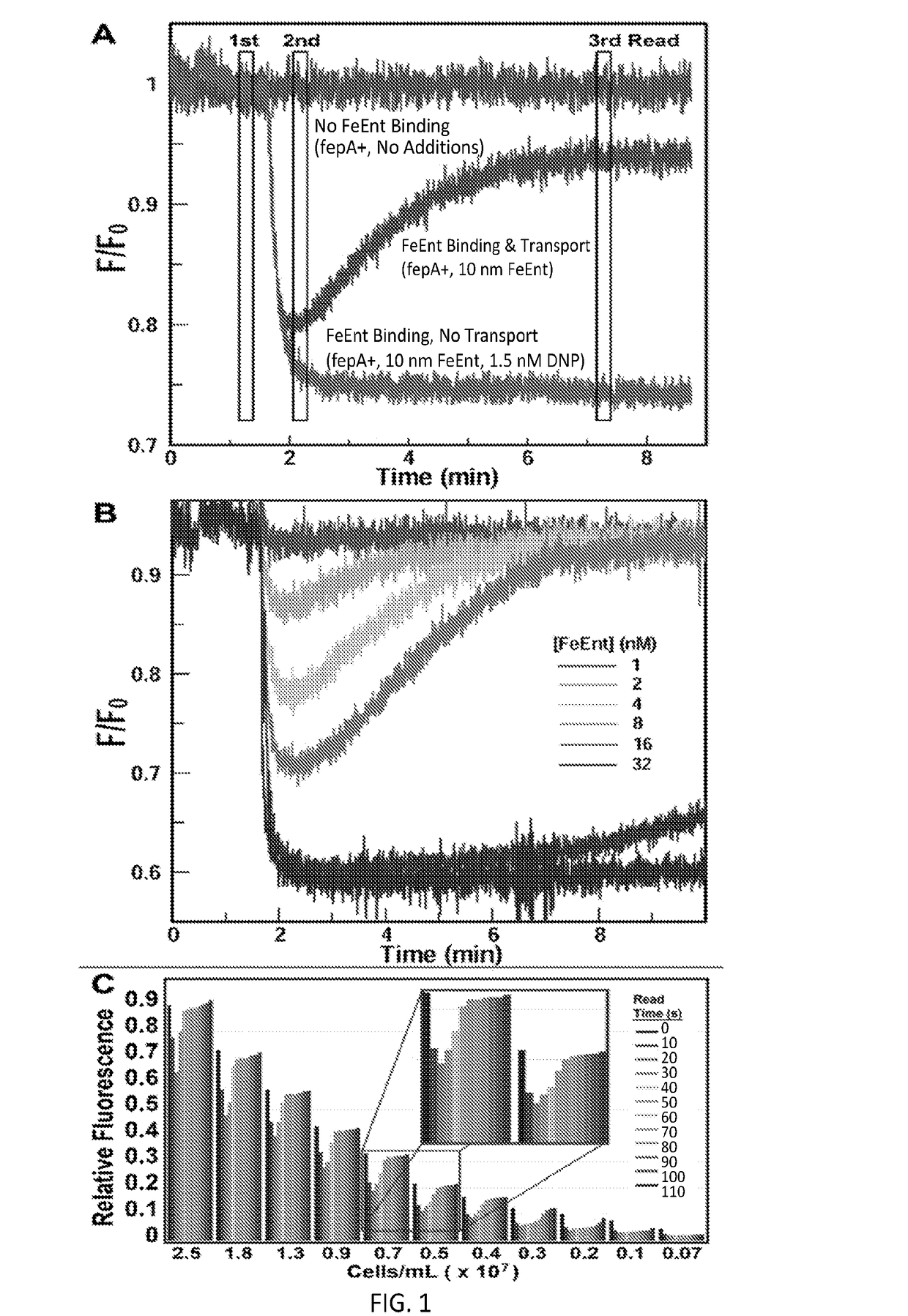

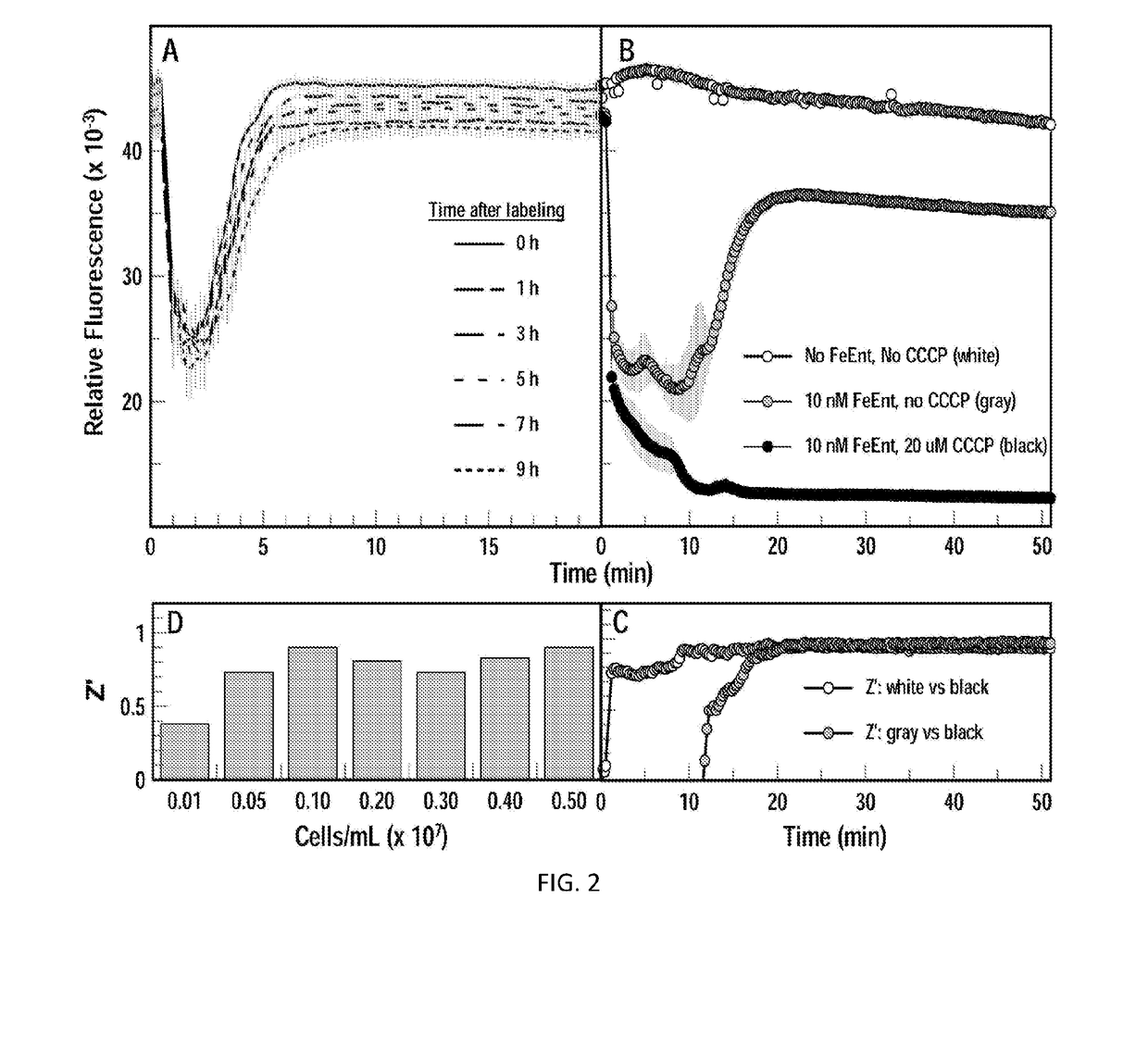

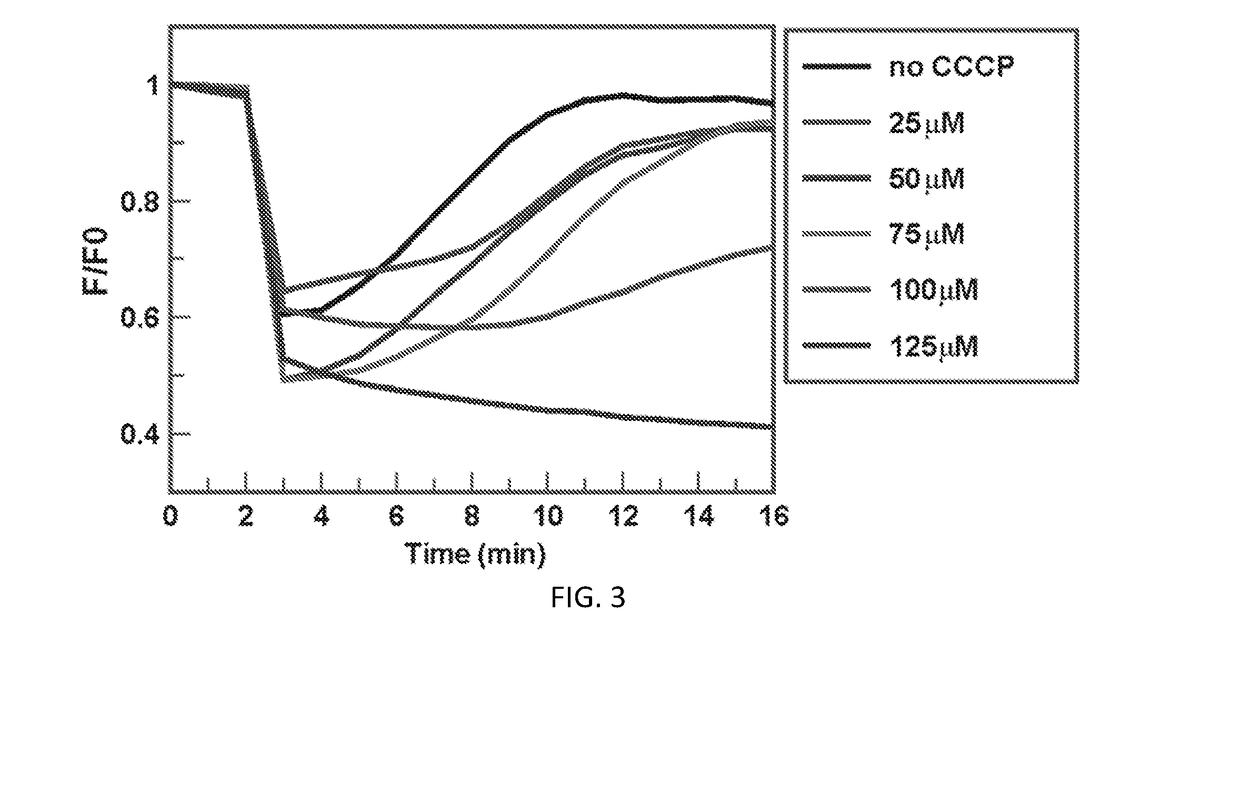

High-throughput fluorescent screening assay for inhibitors of gram-negative bacterial iron uptake

ActiveUS20180187236A1Easy to detectHigh Z-factorsBacteriaMicrobiological testing/measurementFluorescenceIron transport

A cell-based assay for identifying a compound that inhibits iron transport in Gram-negative bacteria, engineered bacterial cells, and kits for conducting the same. The assay involves contacting a candidate compound with an engineered Gram-negative bacteria in the presence of iron for a sufficient period of time, exposing the reaction solution to an energy source to generate the detectable signal, and detecting changes in the detectable signal in the reaction solution over time. The engineered Gram-negative bacteria comprises an iron transport protein on its outer membrane that comprises an amino acid residue that has been engineered with a detectable label that generates a detectable signal. The changes in the detectable signal in the assay system over time correspond to the effect of the candidate compound on iron transport in the Gram-negative bacteria.

Owner:KANSAS STATE UNIV RES FOUND

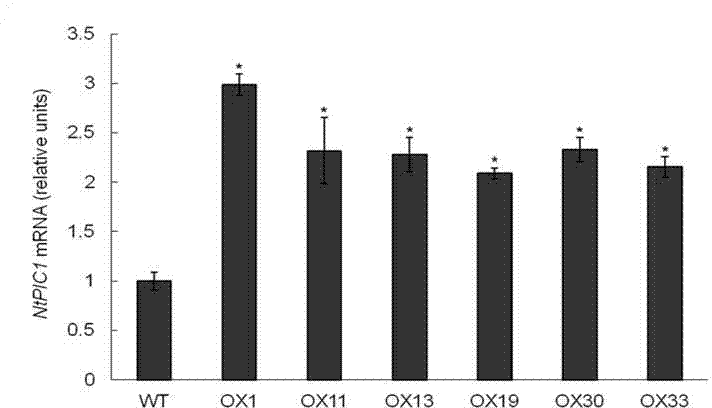

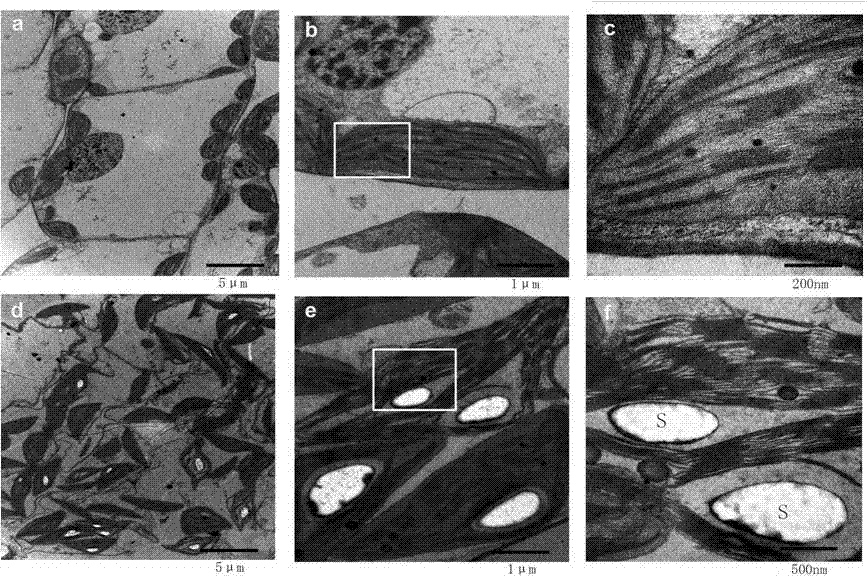

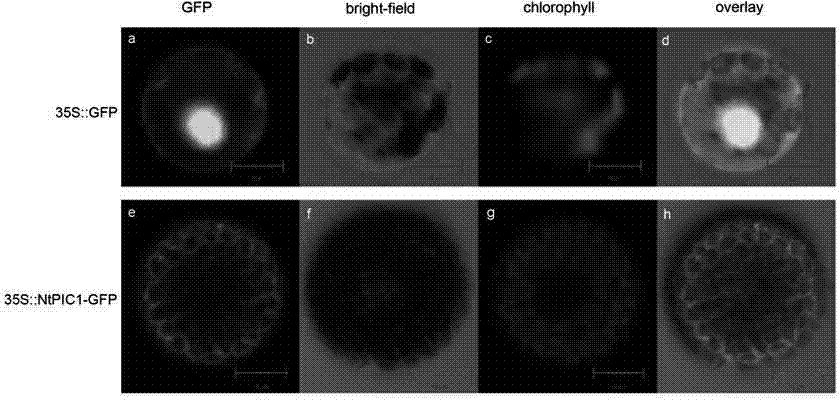

Chloroplast iron transporter gene NtPIC1 and application thereof

The invention discloses a tobacco (Nicotianatabacumcv.SR-1) chloroplast iron transporter gene NtPIC1 and application of encoding protein of the tobacco (Nicotianatabacumcv.SR-1) chloroplast iron transporter gene NtPIC1 in chloroplast iron transport. A nucleotide sequence of the gene is shown in a sequence table SEQIDNO: 1; a corresponding amino acid sequence is shown in a sequence table SEQIDNO: 2; the gene comprises 849bp of open reading frames; 282 amino acids are encoded; the predicted molecular weight is 29.7kDa. The accession number of the nucleotide sequence of the open reading frames on GeneBank is KF640606. By virtue of positioning analysis of GFP fusion protein cells, NtPIC1 protein is positioned on a chloroplast membrane. Proven by a yeast function complementary experiment, expression of the gene in a yeast can be used for effectively transporting iron ions. According to the tobacco (Nicotianatabacumcv.SR-1) chloroplast iron transporter gene NtPIC1 disclosed by the invention, the gene NtPIC1 is introduced into tobaccos so as to obtain transgenic tobaccos with high iron content in the chloroplast; a research result shows that the NtPIC1 gene is involved in the chloroplast iron transport and the chloroplast development process.

Owner:HARBIN NORMAL UNIVERSITY

Insulation device for molten iron tank on-line transportation of molten iron and method for removing and covering it

ActiveCN103934444BReduce energy lossDoes not affect normal operationMelt-holding vesselsIron transportEnergy loss

The invention discloses a molten iron transportation online molten iron tank heat preservation device. Two ladle covering and uncovering mechanisms are arranged on molten iron transport carts (5) and symmetrically distributed at the two sides of a molten iron tank (4) with the axis of the molten iron tank (4) serving as the center. By the adoption of the technical scheme, the molten iron tank is transported in a covered mode in the whole molten iron transport cart operation process, the molten iron tank is covered for heat preservation, and therefore energy loss caused by molten iron temperature drop is reduced; a four-bar mechanism is adopted, covering and uncovering operation conducted on a molten iron pouring station with narrow space is achieved; normal operation of the two carts is not affected; each molten iron tank heat preservation device is only provided with one power execution device and a point of action is near the center of symmetry of the mechanisms, so that overall stable operation of covering and uncovering operation of the mechanisms is guaranteed; the structure is compact, operation is simple, use is convenient, and the device is safe, reliable and long in service life.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

Safety control device for dumping tank body of mixed iron car

InactiveCN102847927BReduce lossImprove the turnover rate of online operationMelt-holding vesselsLarge toothElectrical control

The invention relates to a tank body tilting safety control device of an iron mixing vehicle, which belongs to blast furnace iron making and relates to a blast furnace molten iron transport device. The tank body tilting safety control device comprises a vehicle body, a tank body, a tilting mechanism, a high speed receptacle and a junction box, wherein the tank body, the tilting mechanism, the high speed receptacle and the junction box are arranged on the vehicle body, the tilting mechanism is connected with a large gear of the tank body through a chain, and an electrical control box is arranged on the ground and electrically connected with the high speed receptacle. The tank body tilting safety control device is characterized in that a tilting two-way contact is arranged on the center line of the tank body, a zero position contact is arranged under the center line, the tilting two-way contact and the zero position contact respectively correspond to a tilting travel switch and a zero position travel switch which are arranged on a platform, and the tilting travel switch and the zero position travel switch are electrically connected with the junction box. The tank body tilting safety control device has the advantages of novel concept, simple structure, easiness in operation and low manufacturing cost. The position of the tilting travel switch can be adjusted so as to adapt to different tilting angles of the tank body, the tilting process is safe and reliable, an accident that molten iron falls on the ground because the tank body is tilted and out of control due to mechanical, electrical and operational causes is effectively avoided, waste of the molten iron is reduced, the cost for maintenance and spare parts is reduced, the online operation turnover rate of the iron mixing vehicle is increased, and smooth production is guaranteed.

Owner:ANHUI MASTEEL ENG & TECH GRP

Anti-bacterial siderophore-aminopenicillin conjugates

ActiveUS9302012B2Improve breathabilityAntibacterial agentsOrganic chemistryBacteroidesIron transport

An artificial tris-catecolate siderophore with a tripodal backbone and its conjugates with ampicillin and amoxicillin were synthesized. Both conjugates exhibited significantly enhanced in vitro antibacterial activities against Gram-negative species compared to the parent drugs, especially against P. aeruginosa. The conjugates appear to be assimilated by an induced bacterial iron transport process as their activities were inversely related to iron concentration. The easily synthesized tris-catecolate siderophores can be used with a variety of drugs as conjugates to target antibiotic-resistant Gram-negative bacteria.

Owner:UNIV OF NOTRE DAME DU LAC

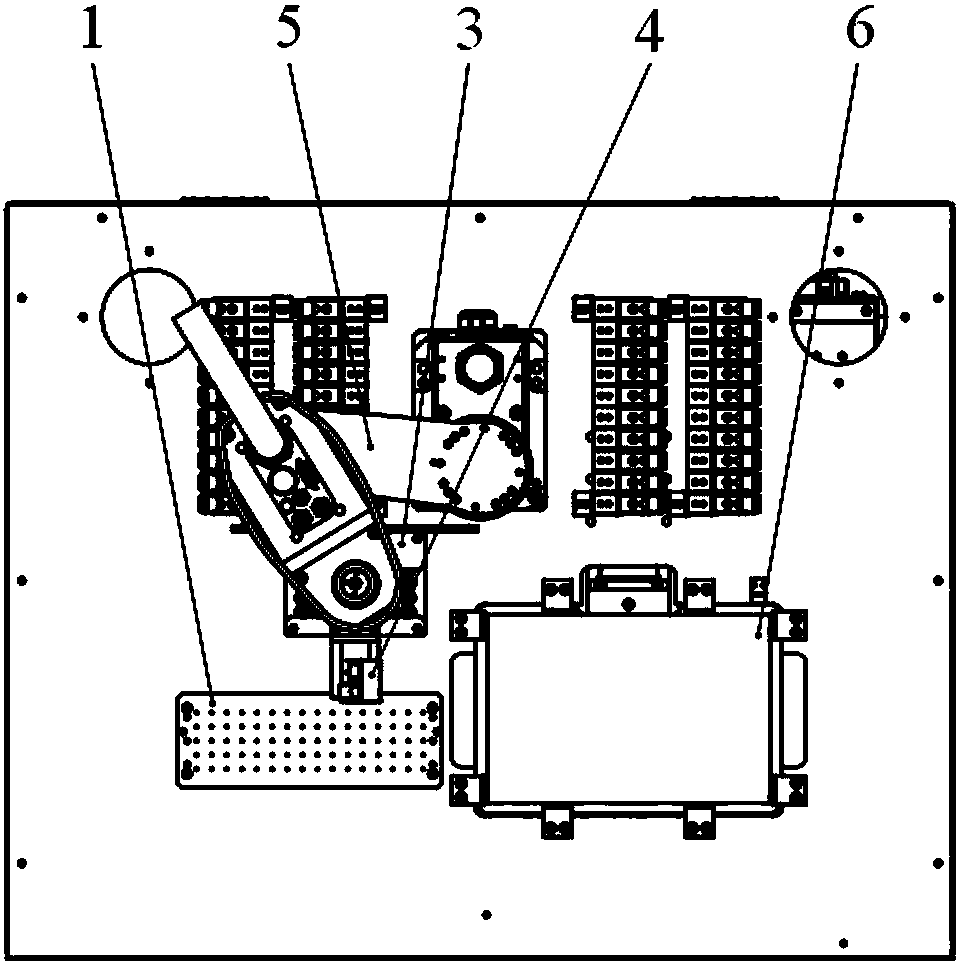

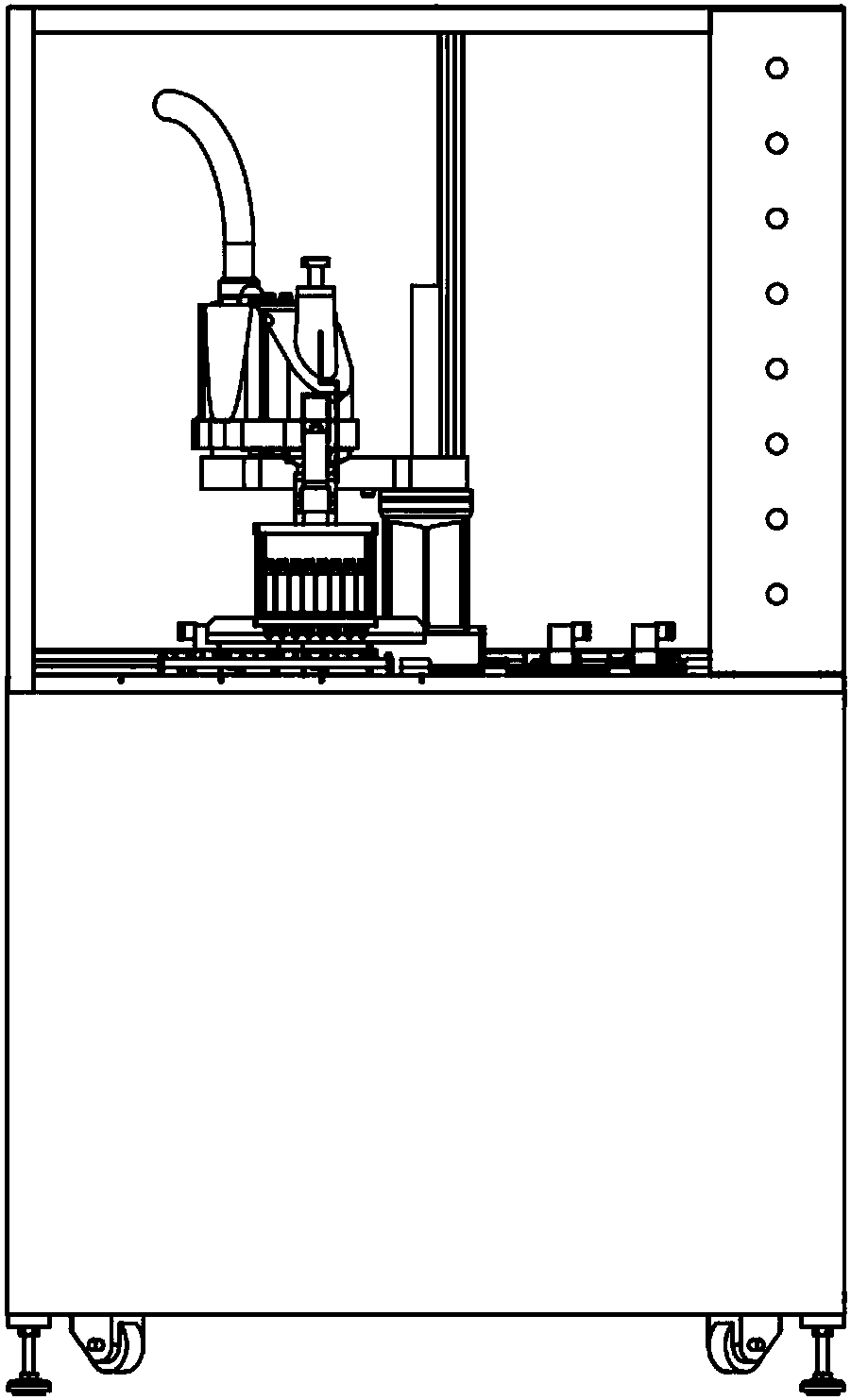

A ball grid array structure chip blanking equipment

The invention relates to a ball grid array structure chip blanking device, which consists of a chip tray placement platform (1), an array mechanism (2), a vacuum pick-and-place mechanism (3), a CCD set up on a bottom platform and a control system (7). Composed of detection mechanism (4), robot arm (5), and reflow soldering iron plate conveying mechanism (6), chip tray placement platform (1) and reflow soldering iron plate conveying mechanism (6) respectively place trays and iron plates with chips , the array mechanism (2), the vacuum pick-and-place mechanism (3), and the CCD detection mechanism (4) are mounted on the robot arm (5). Compared with the prior art, the invention can automatically complete quality screening, improve production efficiency, and is simple to operate and easy to use.

Owner:江苏弘琪工业自动化有限公司

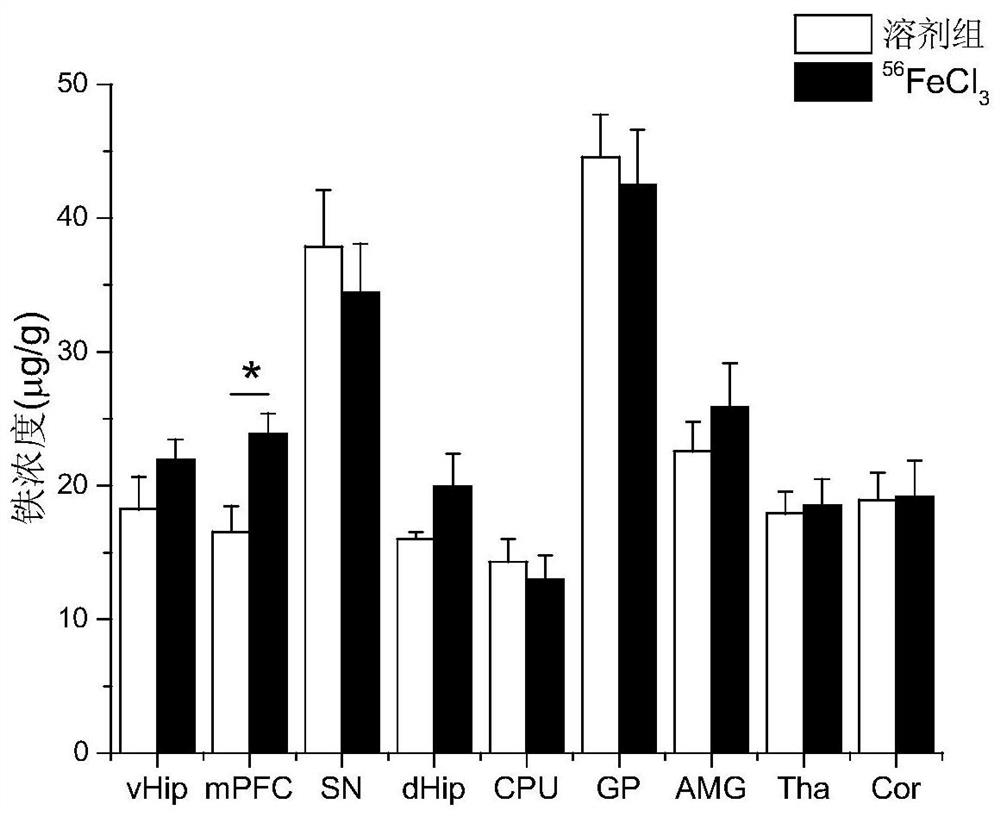

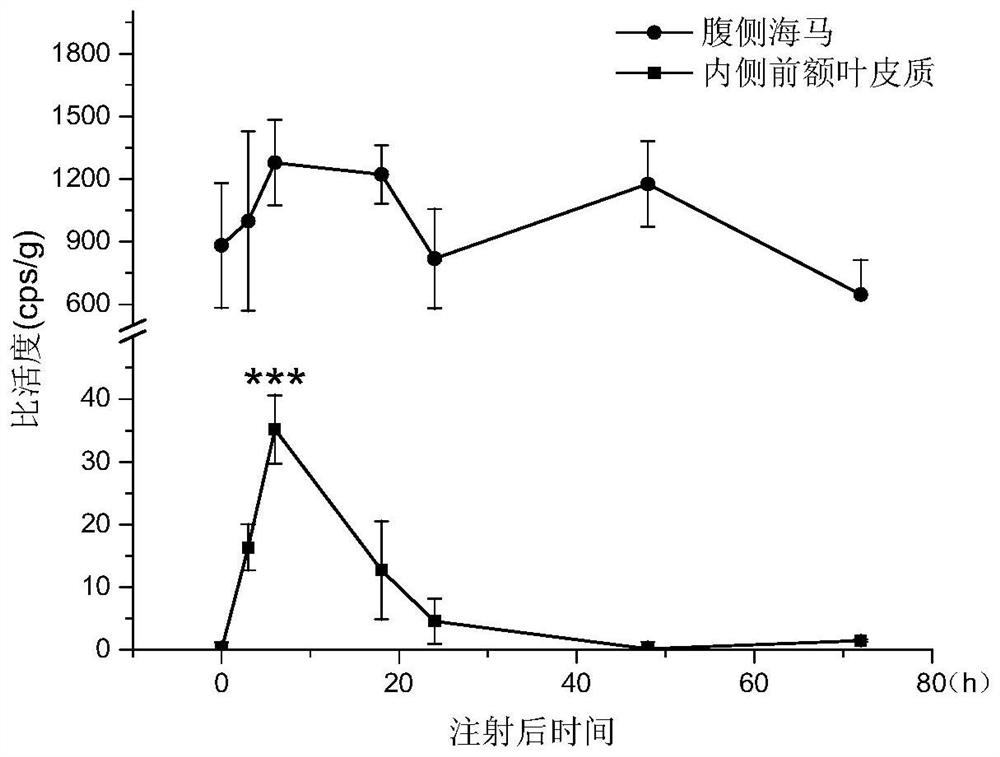

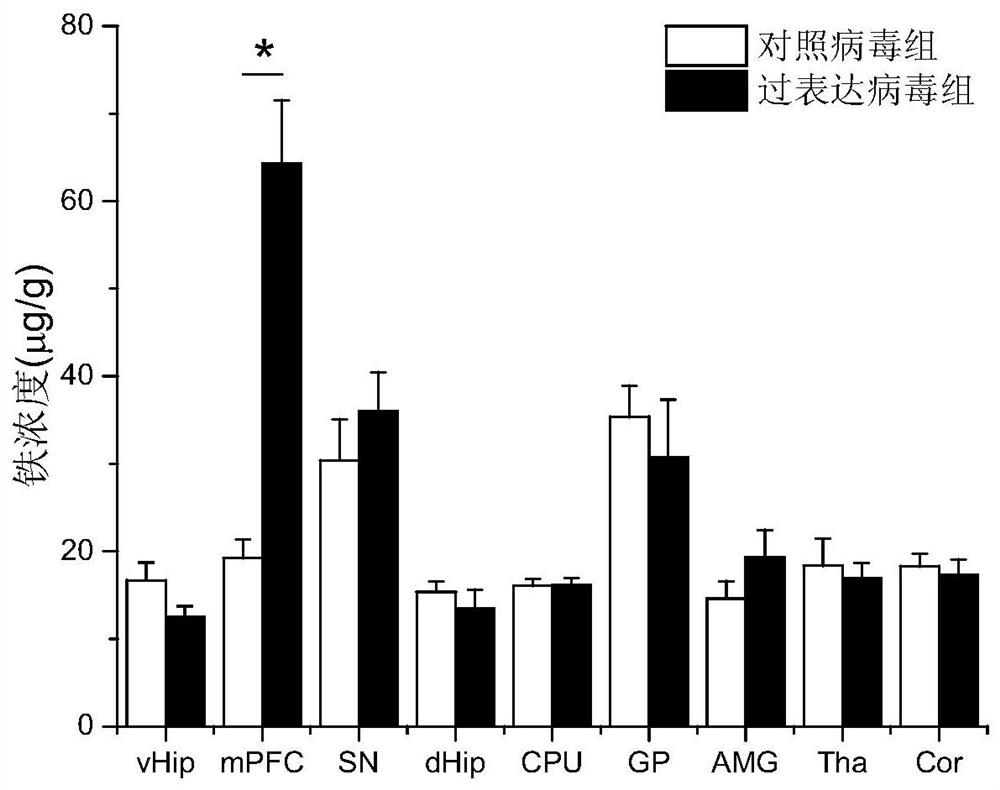

Application of drugs that increase iron transport from the ventral hippocampus to the medial prefrontal cortex in the preparation of drugs for the treatment of neuropsychiatric diseases

ActiveCN110179984BEffective treatmentNervous disorderPharmaceutical active ingredientsDiseaseNeurophysins

The invention discloses the application of the medicine for increasing the iron transport from the ventral hippocampus to the medial prefrontal cortex layer in the preparation of the medicine for treating neuropsychiatric diseases. The inventors overexpressed human ferroportin in neurons in the ventral hippocampus projecting to the medial prefrontal cortex layer. It was found that after 14 days of overexpression virus expression, the iron concentration in the medial prefrontal cortex layer was significantly increased, demonstrating that this method can increase iron transport from the ventral hippocampus → medial prefrontal cortex layer. Compared with the control mice, the overexpression mice showed an increased total movement distance, an increased intermediate time in the open field, a decreased time in the black box, and an increased time in the elevated open arm, showing anxiolytic-like behavior. After successful modeling, compared with normal controls, mice with increased iron transport after injection of deferiprone increased the time of elevated open arms, increased the number of times of entering open arms, and exhibited anxiolytic-like behaviors. In summary, increasing iron transport from the ventral hippocampus to the medial prefrontal cortex has preventive and therapeutic effects on anxiety.

Owner:SOUTHERN MEDICAL UNIVERSITY

A power supply system for mobile iron ladle and uncovering equipment

ActiveCN106410734BAdapt to the status quoCompact structureArrangements using take-up reel/drumElectricityFoundry

The invention discloses a mobile foundry ladle covering and uncovering equipment power supply system. The system comprises an auxiliary light rail in parallel arranged with a foundry ladle vehicle heavy rail; an electric dolly which is arranged on the auxiliary light rail and is provided with a body and two walking rollers installed below the body, wherein the body is provided with a pendulum seat and an upright column, and the walking rollers drive the electric dolly to run linearly on the auxiliary light rail; and a power delivery mechanism which is connected with a low-voltage power supply through a cable and is provided with a force application part, a swing arm and a conductive rack arranged at the head portion of the swing arm, wherein the force application part is hinged to the pendulum seat, the swing arm is hinged to the upright column, the force application part is hinged to the middle rear portion of the swing arm, under the effect of the force application part, the conductive rack is driven to swing, and power is sent to foundry ladle covering and uncovering equipment through a gap bridge effect. The system is compact in structure and long in power receiving distance and can be adapted to present situations of the vast majority of steel factory molten iron transport lines; and during work, the system is convenient, safe and reliable in power receiving, realizes whole-course PLC control, realizes automatic work and is time-saving and labor-saving.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

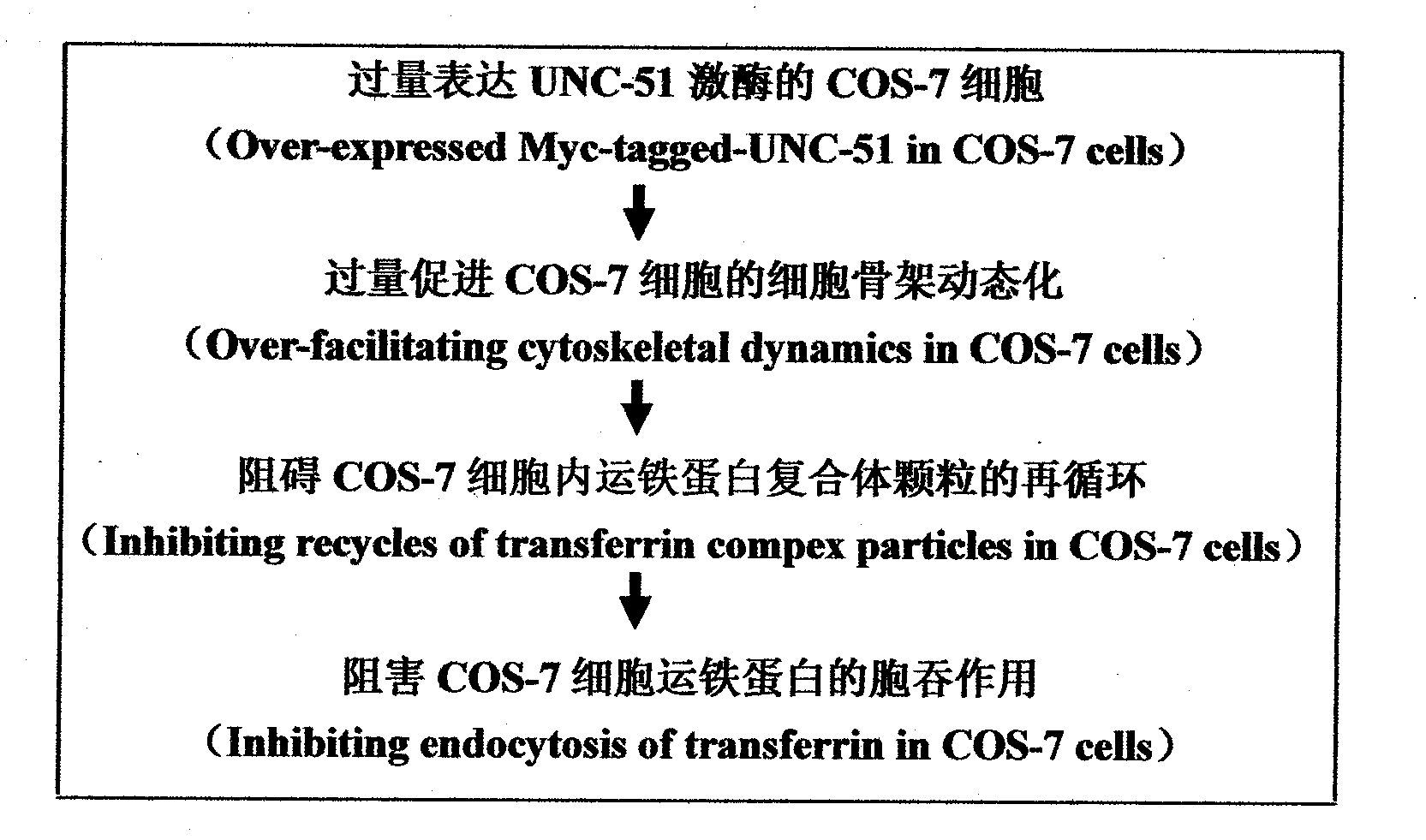

Research for influence on endocytosis of cell transferrins of UNC-51 kinase

InactiveCN103160565APromote dynamic changeHinder recyclingMicrobiological testing/measurementDiseaseIron transport

The invention discloses research for the influence on the endocytosis of cell transferrins of UNC-51 kinase, wherein maintenance for the stable level of iron elements in cells and body is necessary to the health of life; cell absorption and iron transport are mainly performed via the endocytosis of cell transferrins; the molecular mechanism and the cell mechanism of the endocytosis of cell transferrins are not clear yet; and interpretation for the molecular mechanism and the cell mechanism of the endocytosis of cell transferrins has important significance for prevention and treatment for neurological diseases. The research shows that the COS-7 cells for over-expressing Myc-tagged UNC-51 kinase inhibit the endocytosis of cell transferrins due to that the over-expressed UNC-51 kinase in the COS-7 cells have the function of promoting the dynamic changes of cytoskeletons, thus blocking the recirculation of the complex particles of transferrins, and achieving the effect of preventing the endocytosis of cell transferrins. The research shows the first mode of participating in the endocytosis of cell transferrins of UNC-51 kinase.

Owner:彩虹天健康科技研究(北京)有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com