A ball grid array structure chip blanking equipment

A structure chip and ball grid array technology, applied in the field of ball grid array structure chip blanking equipment, can solve the problems of solder ball damage, increased product defect rate, low output, etc., so as to reduce the risk of damage and improve product yield. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

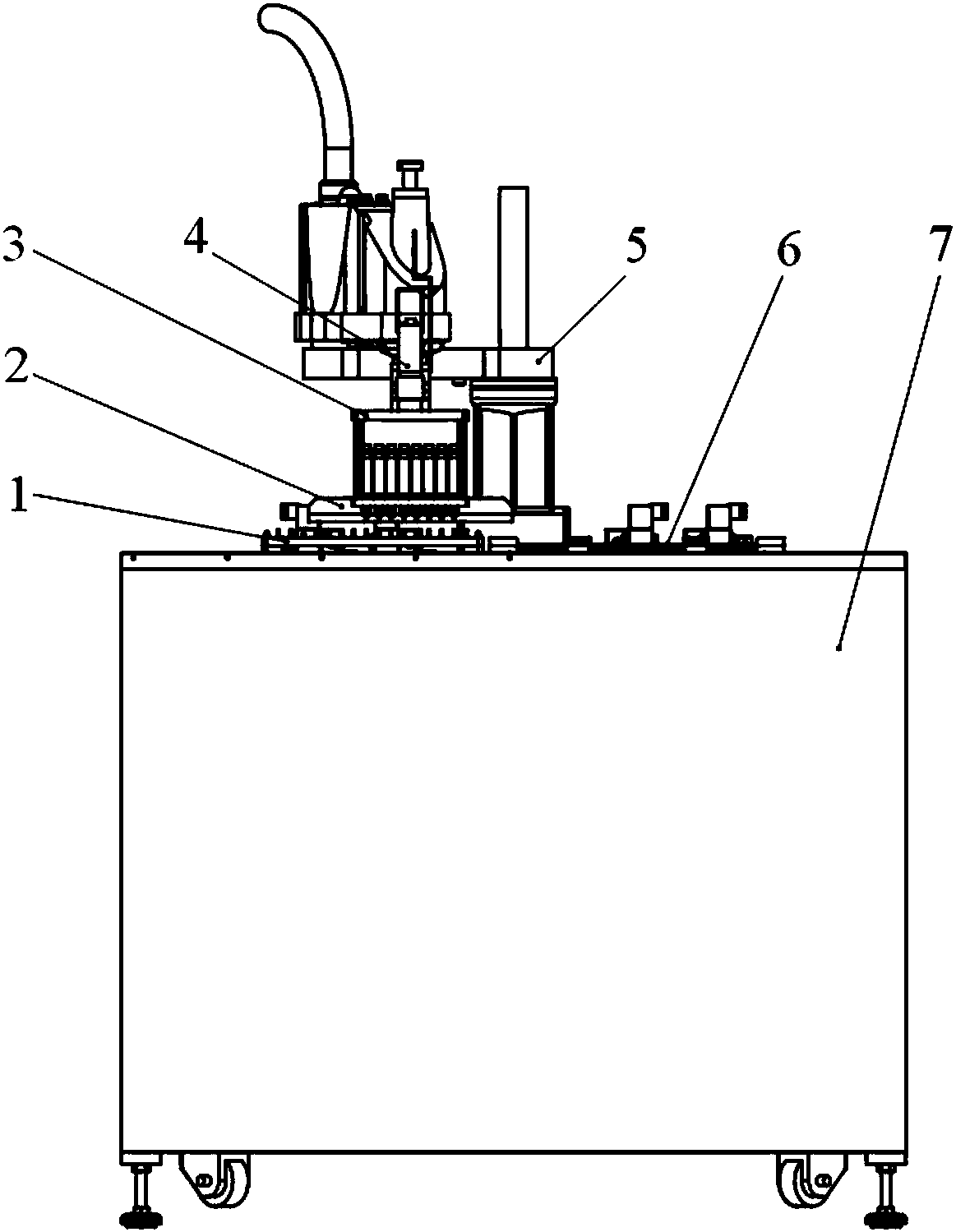

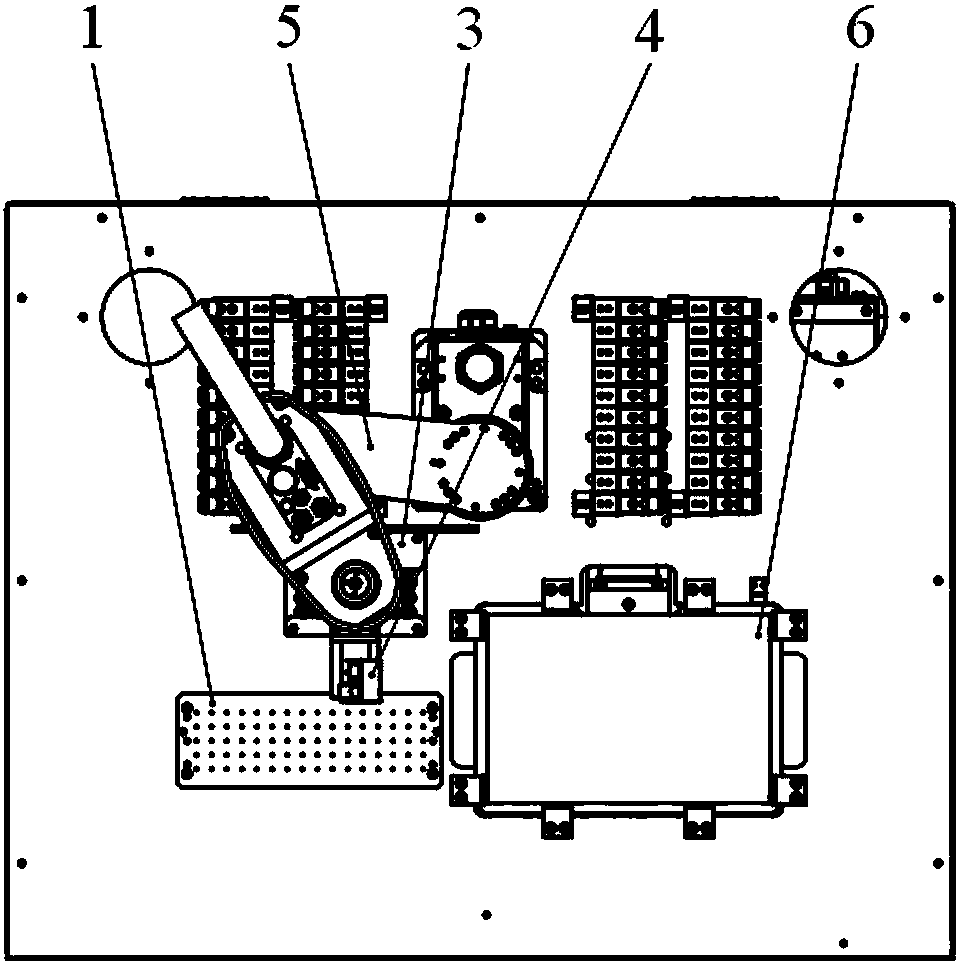

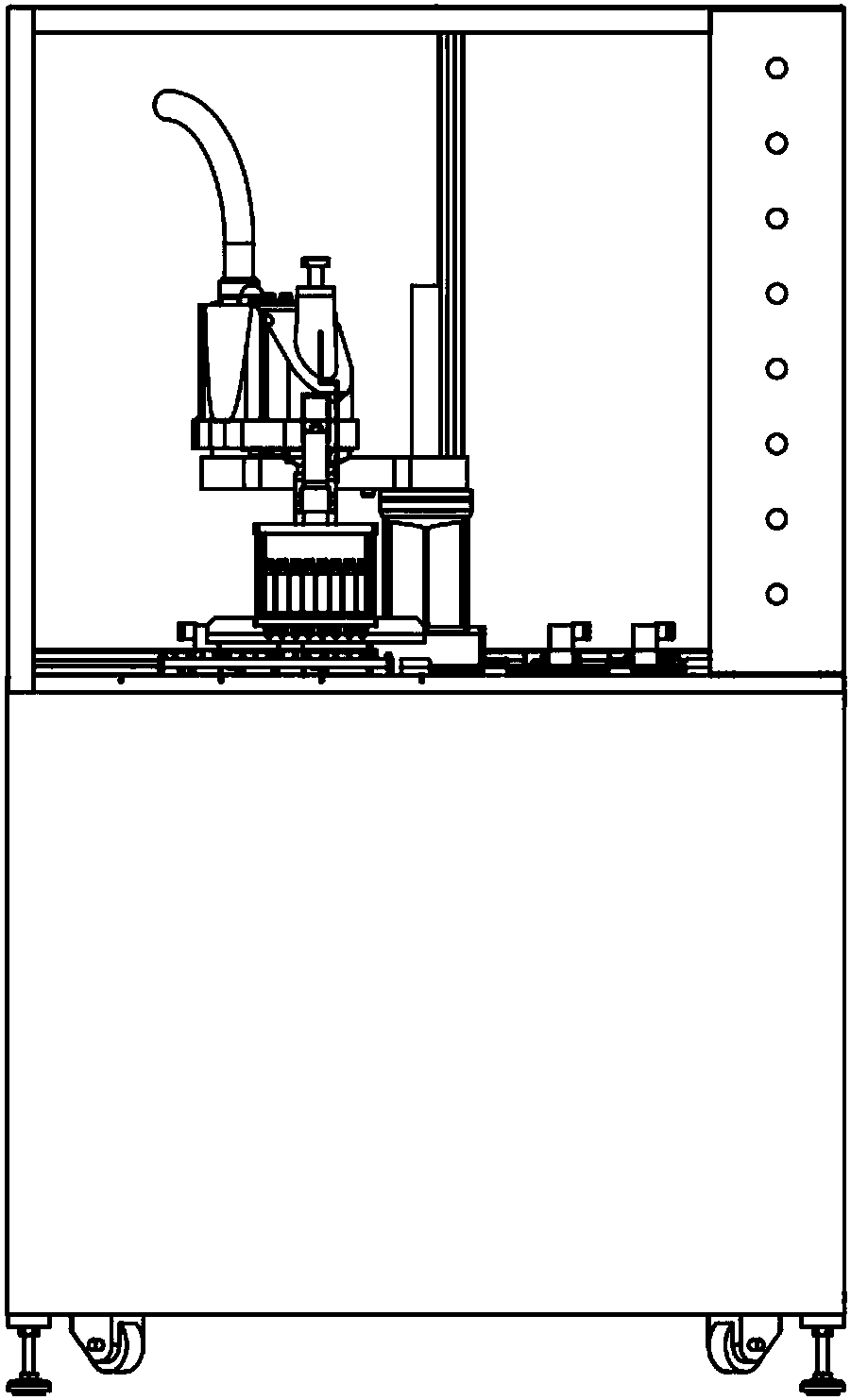

[0032] A ball grid array structure chip blanking equipment, its structure is as follows Figure 1-2 As shown, the equipment consists of a chip tray placement platform 1, an array mechanism 2, a vacuum pick-and-place mechanism 3, a CCD detection mechanism 4, a robot arm 5, and a reflow soldering iron plate conveying mechanism 6, which are erected on the bottom platform and the control system 7. Can also be provided with top safety cover on the bottom platform and control system 7, as image 3 As shown, the chip tray placement platform 1, the array mechanism 2, the vacuum pick-and-place mechanism 3, the CCD detection mechanism 4, the robot arm 5, and the reflow iron plate conveying mechanism 6 are all set in the safety cover.

[0033] The local structure of vacuum pick-and-place mechanism, array mechanism, and CCD detection mechanism is as follows: Figure 4-5 As shown, wherein, the array mechanism 2 is composed of an array plate 21, a pillar 22, a connecting plate 23 and a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com