Molten iron quantitative loading system and molten iron quantitative loading method

A loading system and molten iron technology, applied in the direction of measuring devices, weighing, instruments, etc., can solve problems affecting the accuracy of weighing data, failure of weighing modules, misleading operators of weighing data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

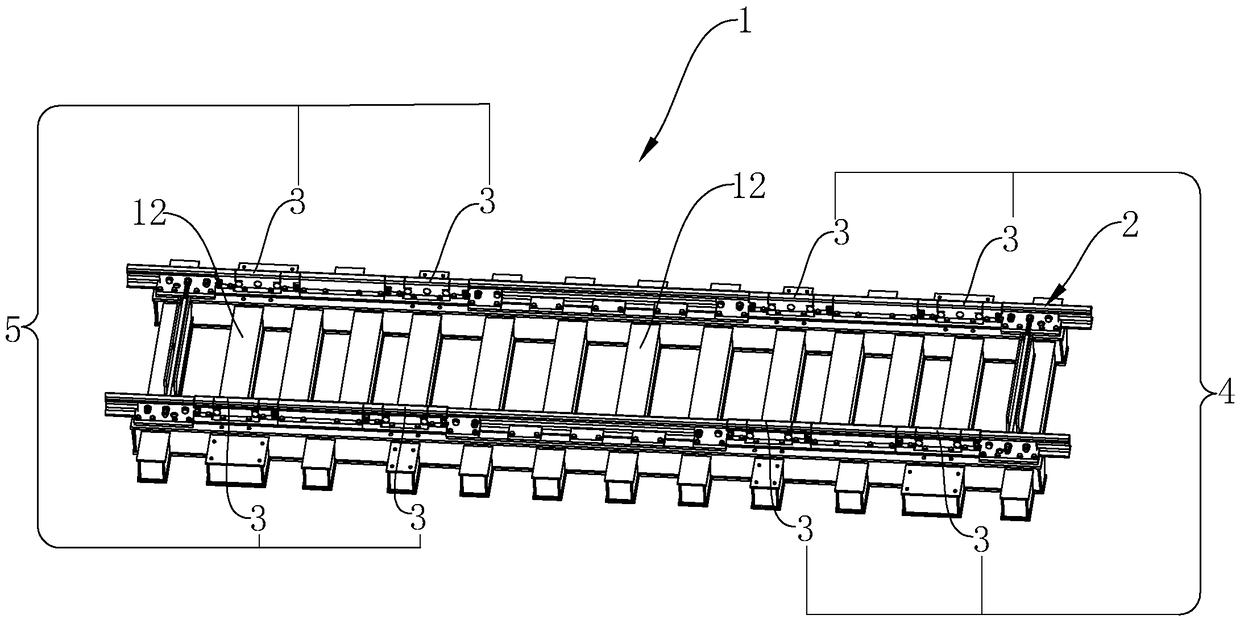

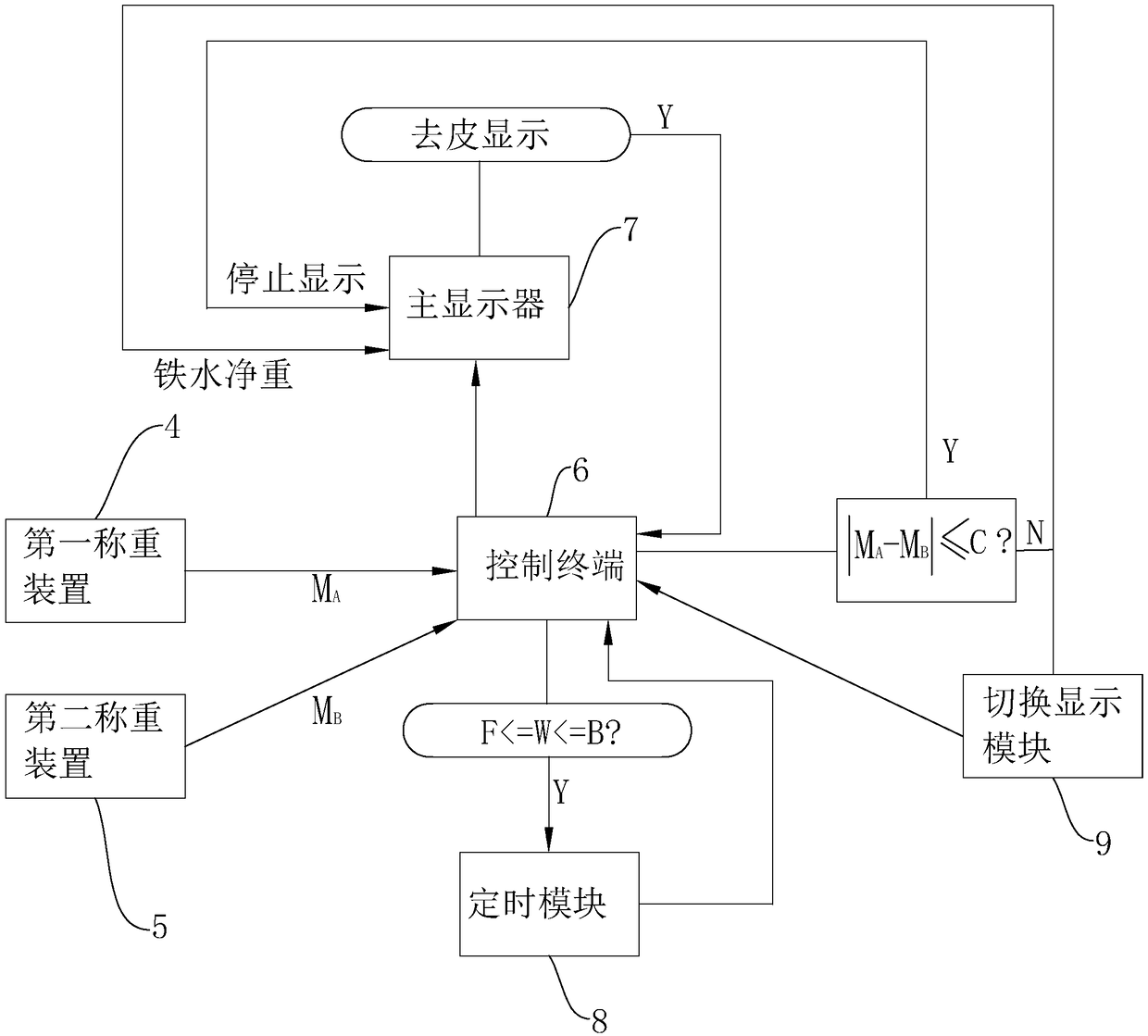

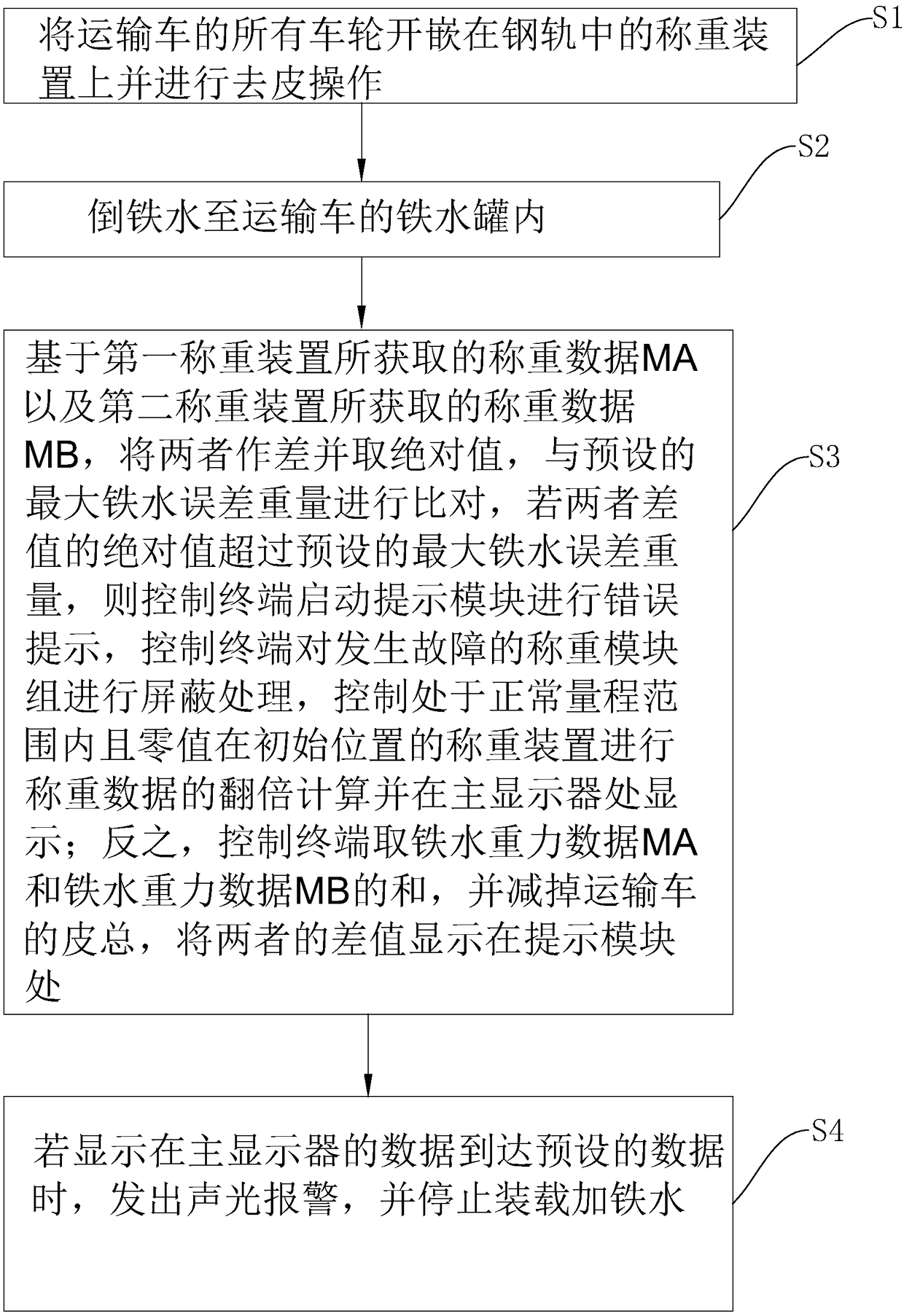

[0044] Such as figure 1 , 2 As shown, a quantitative loading system for molten iron disclosed in this embodiment includes a rail scale body 1, and the rail scale body 1 includes steel rails 2 that are arranged on both sides of the long side and are parallel to each other for the wheels of the transport vehicle 10' to run on. 2 is set without foundation pit, which can avoid the impact of a small amount of molten iron overflowing into the foundation pit and affecting the quantitative loading system of molten iron. Both sides of the two rails 2 are embedded with a number of weighing modules 3 for detecting the gravity of the wheels. Module 3 constitutes the first weighing device 4, and some weighing modules 3 on the other side of the two rails 2 constitute the second weighing device 5, and the weighing data of the first weighing device 4 is defined as M A , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com