Tank body tilting safety control device of iron mixing vehicle

A technology of safety control and mixed iron car, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of low turnover rate of mixed iron car, endangering the personal safety of operators, and out-of-control tank tipping, etc. Achieve the effect of improving the turnover rate of online operation, reducing the cost of maintenance and spare parts, and reducing the loss of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

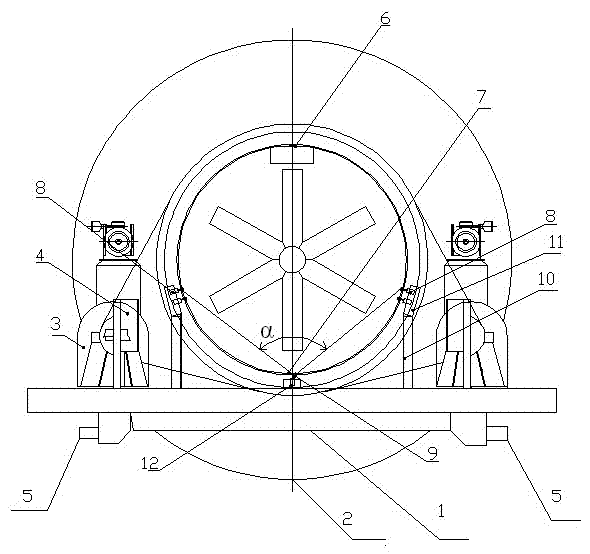

[0011] Depend on figure 1 It can be seen that the mixed iron car is composed of a car body 1 and a molten iron tank body 2, and the tank body is fixed on the car body. A tank body tipping mechanism 3, a terminal junction box 4 and a high-speed socket 5 are arranged on the vehicle body platform. The tipping mechanism with the transmission motor and the output sprocket is linked with the large ring gear of the tank body by a chain. The tilting mechanism drives the tank body to rotate, the motor is electrically connected to the terminal junction box, and the terminal junction box is electrically connected to the high-speed socket. The ground electrical control box is installed on the ground, which is connected with the high-speed socket wire. Depend on figure 1 It can also be seen that the tilting two-way bumper 6 is arranged on the upper center line of the normal position of the tank body, corresponding to the tipping travel switch 8 arranged on the top of the vehicle body pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com