Patents

Literature

174results about How to "Reduce spare parts costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

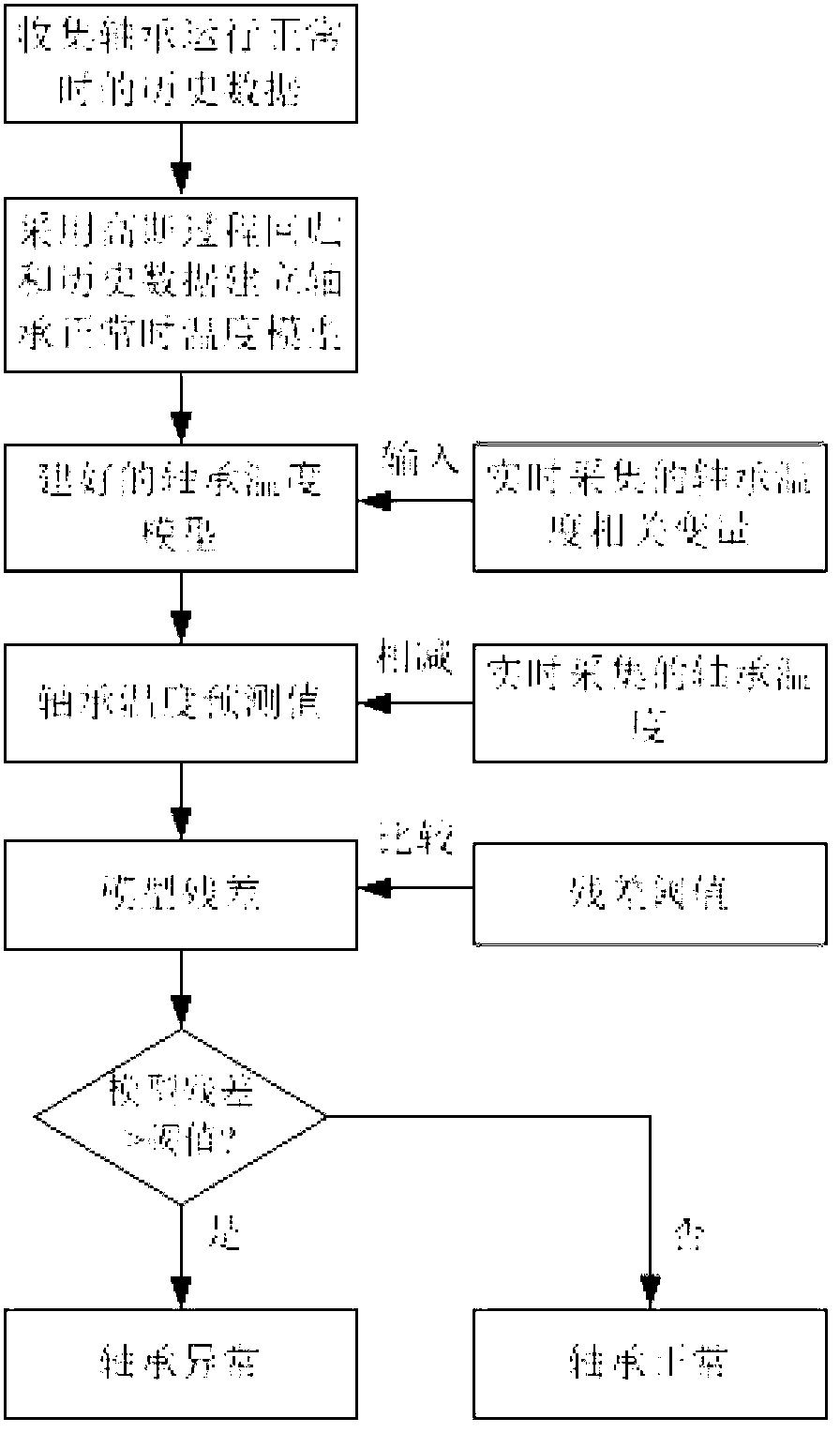

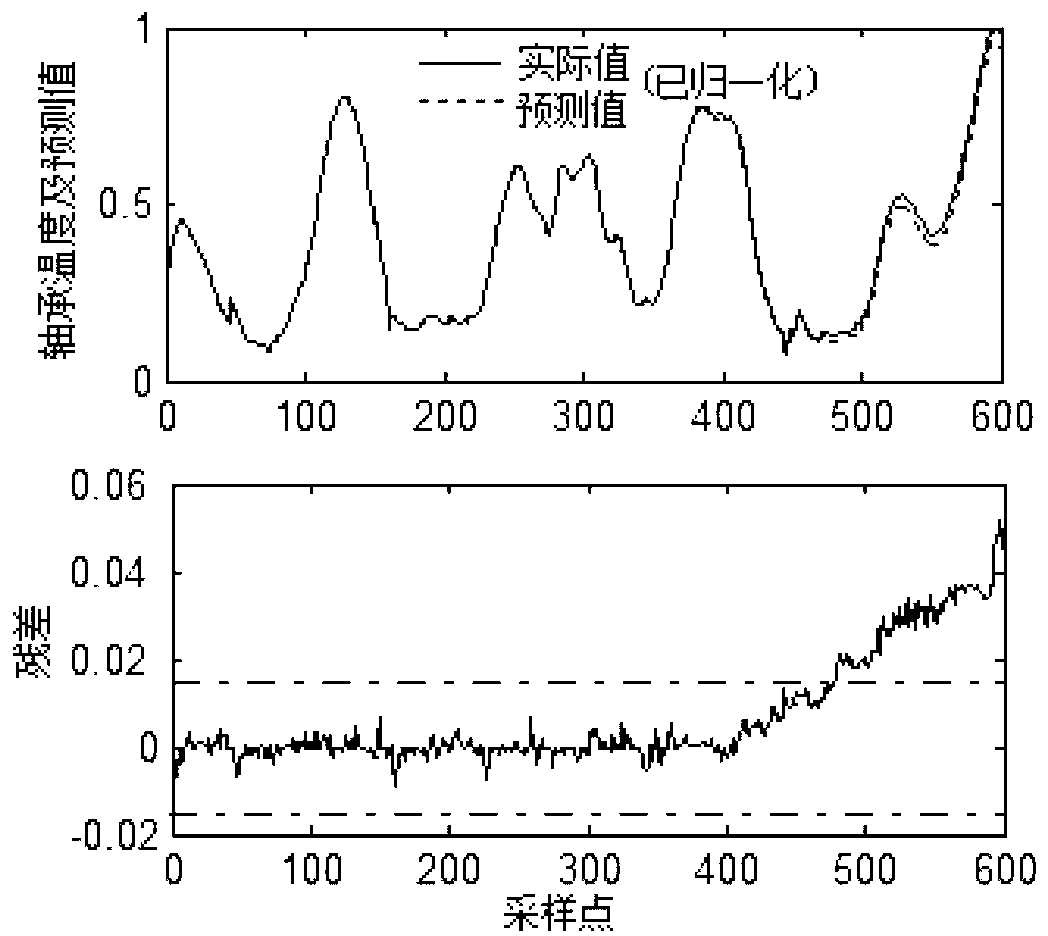

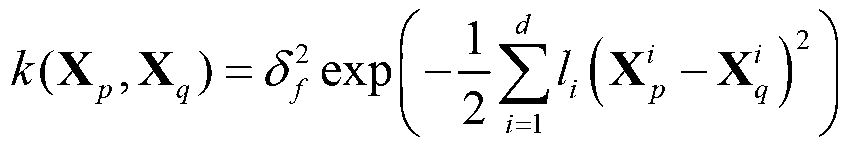

Gaussian process modeling based wind turbine shafting state monitoring method

InactiveCN103234753ADetect early failuresAvoid downtimeMachine bearings testingRenewable energy source integrationElectricitySCADA

The invention discloses a Gaussian process modeling based wind turbine shafting state monitoring method in the field of wind turbine state monitoring. The technical scheme includes: collecting values of normal temperature of a bearing to be monitored and of correlated variables of the bearing temperature from historical data of a wind turbine SCADA system to form a bearing temperature vector set; building a bearing temperature model by the aid of a Gaussian process regression method; using the bearing temperature model for monitoring the bearing in real time, and using difference between the measured bearing temperature and the predicated temperature outputted by the model as predicated model residual; comparing the predicated model residual with a set residual threshold, and when the predicated model residual is larger than the residual threshold, judging the bearing to be abnormal; and otherwise, judging the bearing to be in a normal state. The method has the advantages that under the operation conditions of random changing of wind speed and time varying of rotating speed of a wind turbine shafting, states of bearings on the wind turbine shafting are analyzed and judged accurately, bearing fault alarm is sent timely, and maintenance complexity and cost are lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

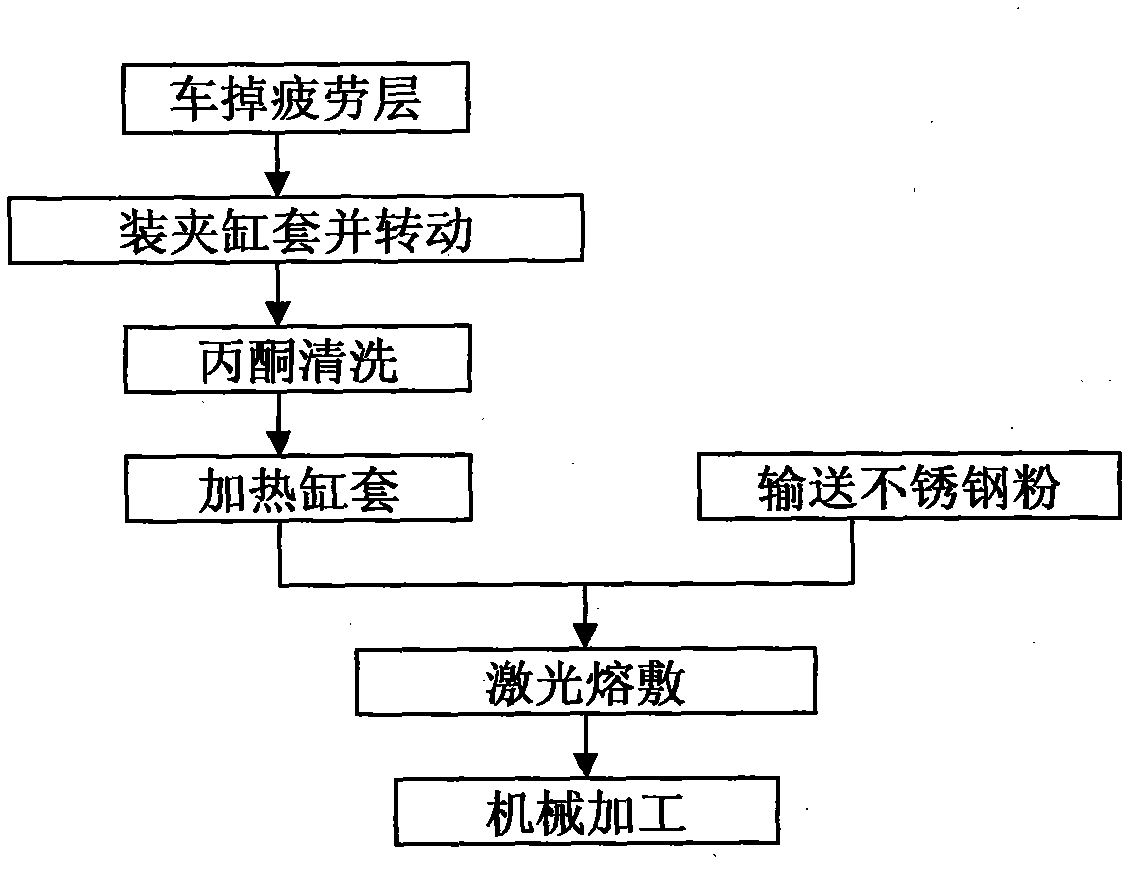

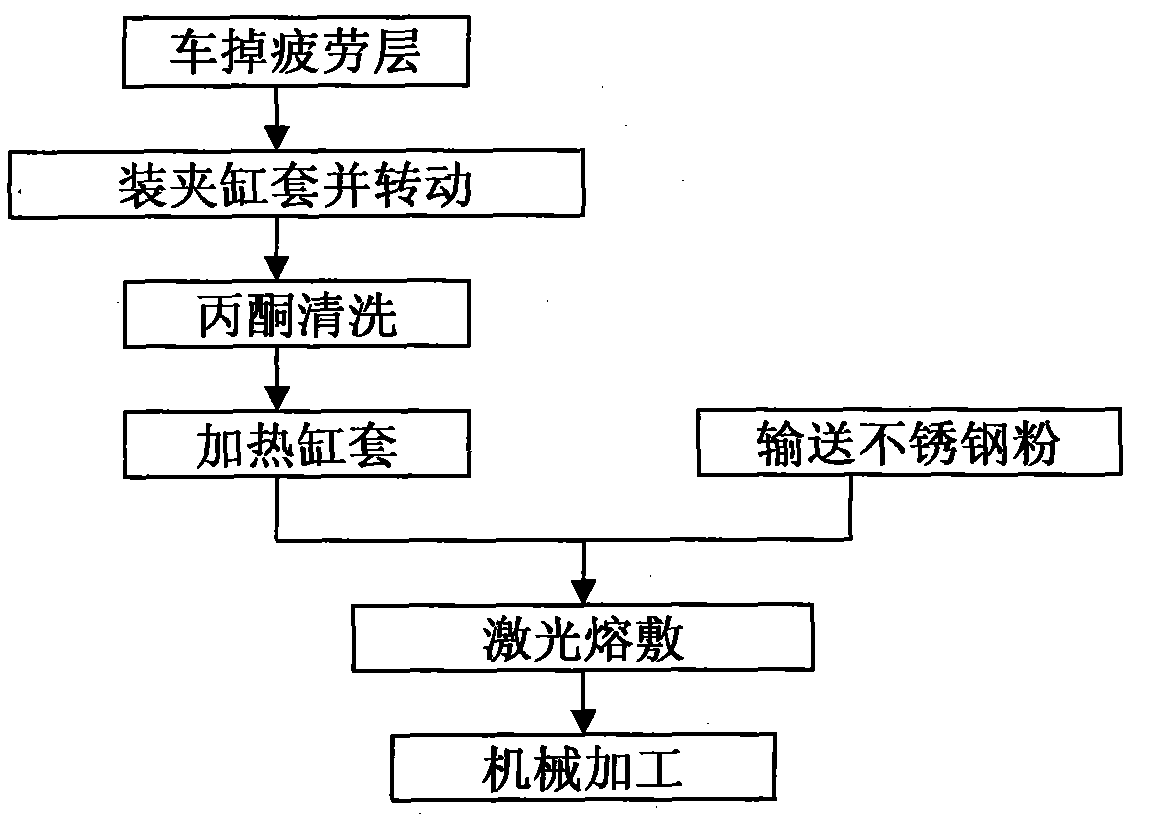

Laser cladding repairing method for cylinder sleeve

InactiveCN102021569AAchieve repair and life extensionReduce spare parts costsMetallic material coating processesForeign matterImpurity

The invention discloses a laser clading repairing process for a cylinder sleeve. The process comprises the following steps: removing a 0.5-2mm body metal fatigue layer from the working surface of a cylinder sleeve through a lathe; after a workpiece is clamped, rotating the workpiece at a linear speed of 400-700mm / min, and washing away surface greasy impurity with acetone; heating the workpiece to 40-100 DEG, and cladding a layer of stainless steel as an antiwear corrosion-resisting surface layer through laser with power being 3.5KW and bandwidth being 3mm; and finally mechanically machining the laser cladding layer to achieve the use size specification of the cylinder sleeve. By the invention, the cylinder sleeve of an old hydraulic cylinder is repaired, the rejection rate of spare parts is reduced, the production cost is saved, and the repaired cylinder sleeve of the hydraulic cylinder has long service life and balanced operating performance. The method solves the use problems that the surface of the cylinder sleeve has burr, hydraulic oil leaks and the like as alternate motion of a piston rod when cooling lubricating oil or foreign matters enter the cylinder from the working surface of the cylinder sleeve.

Owner:KUNMING UNIV OF SCI & TECH

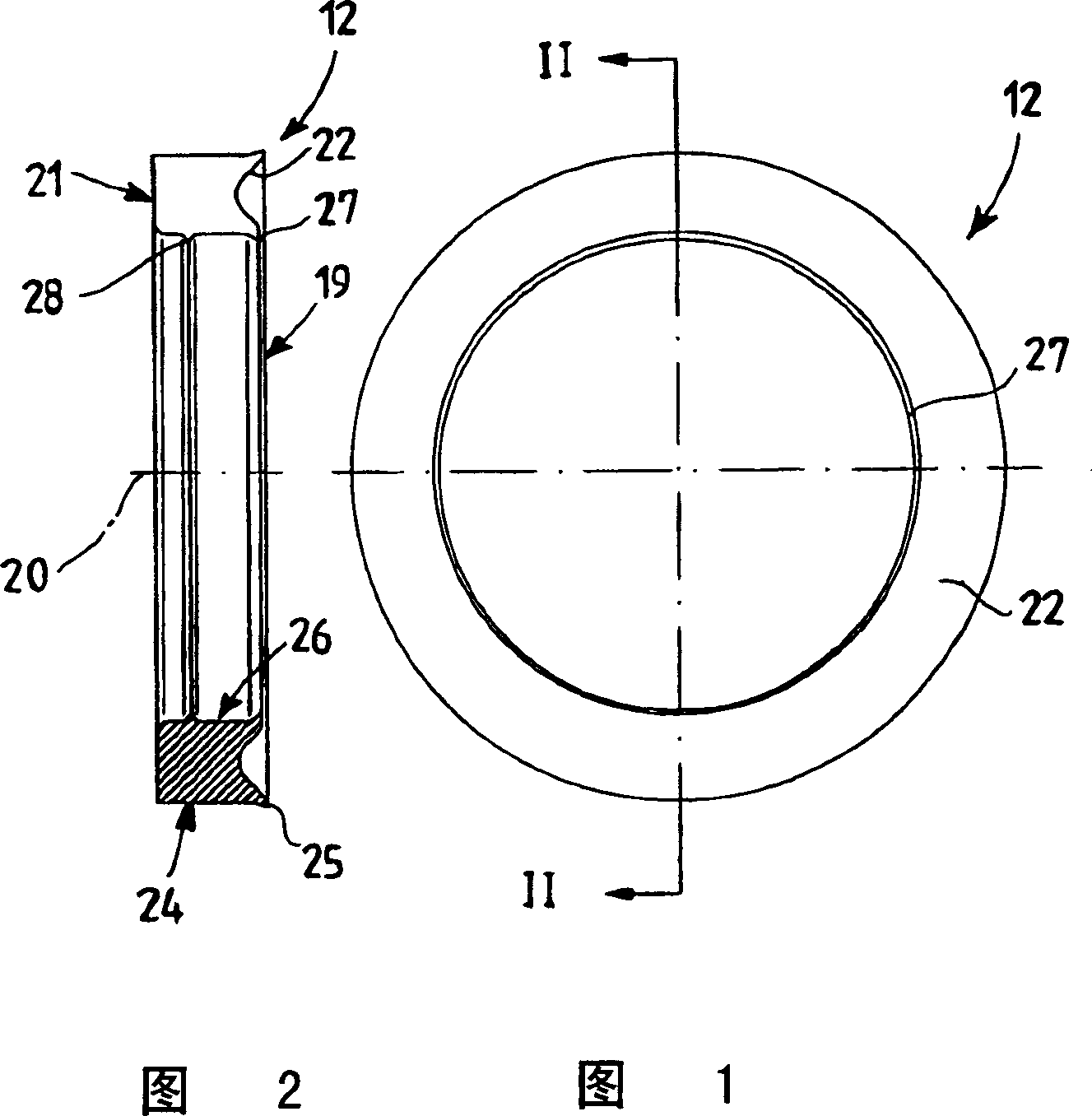

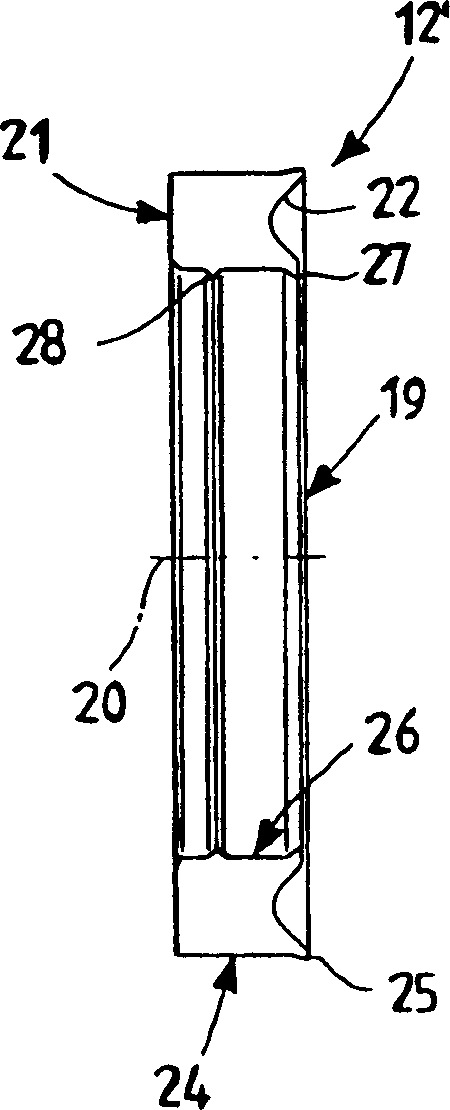

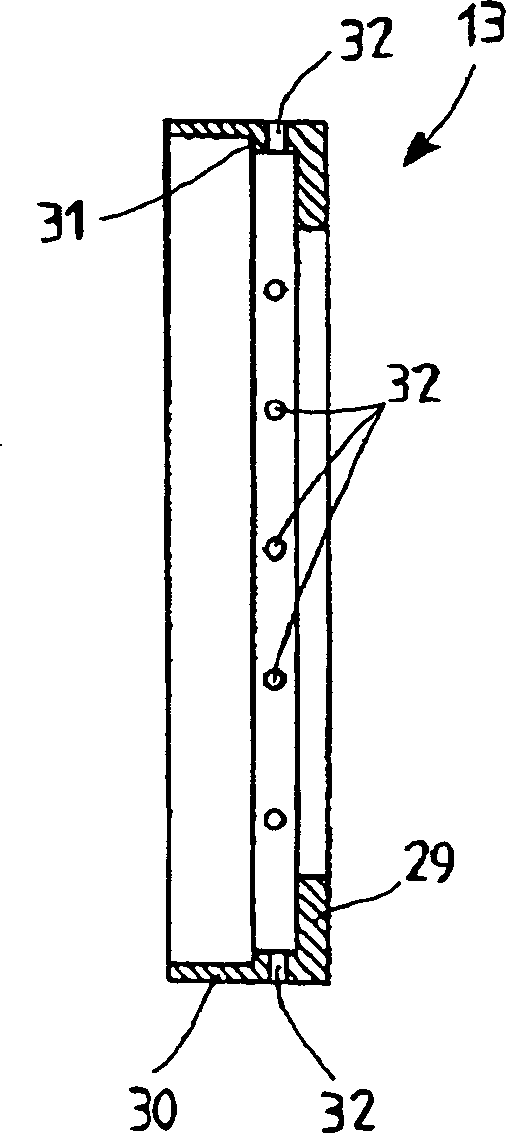

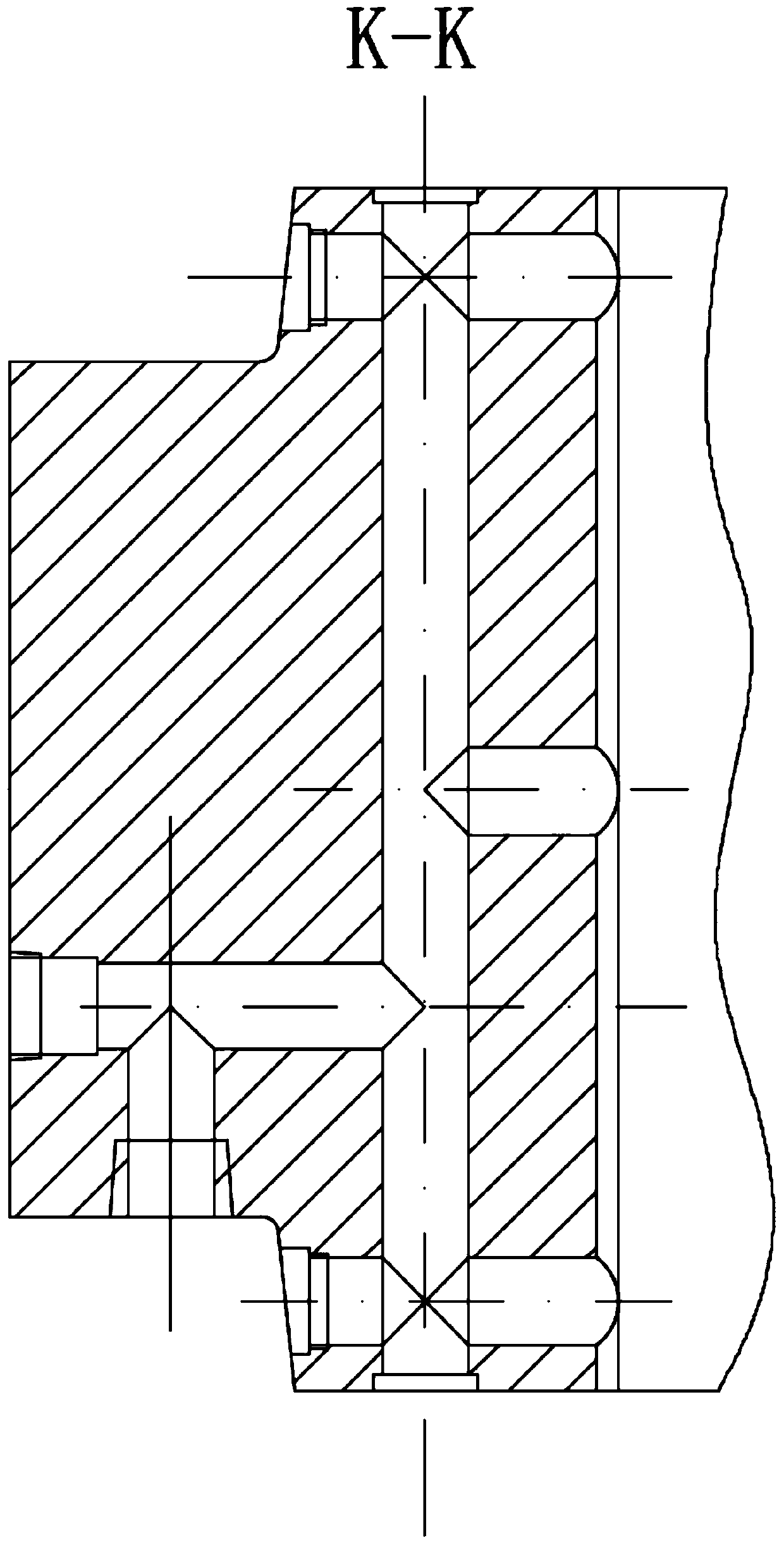

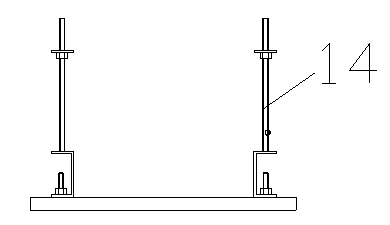

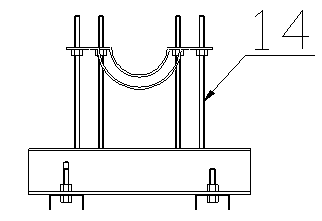

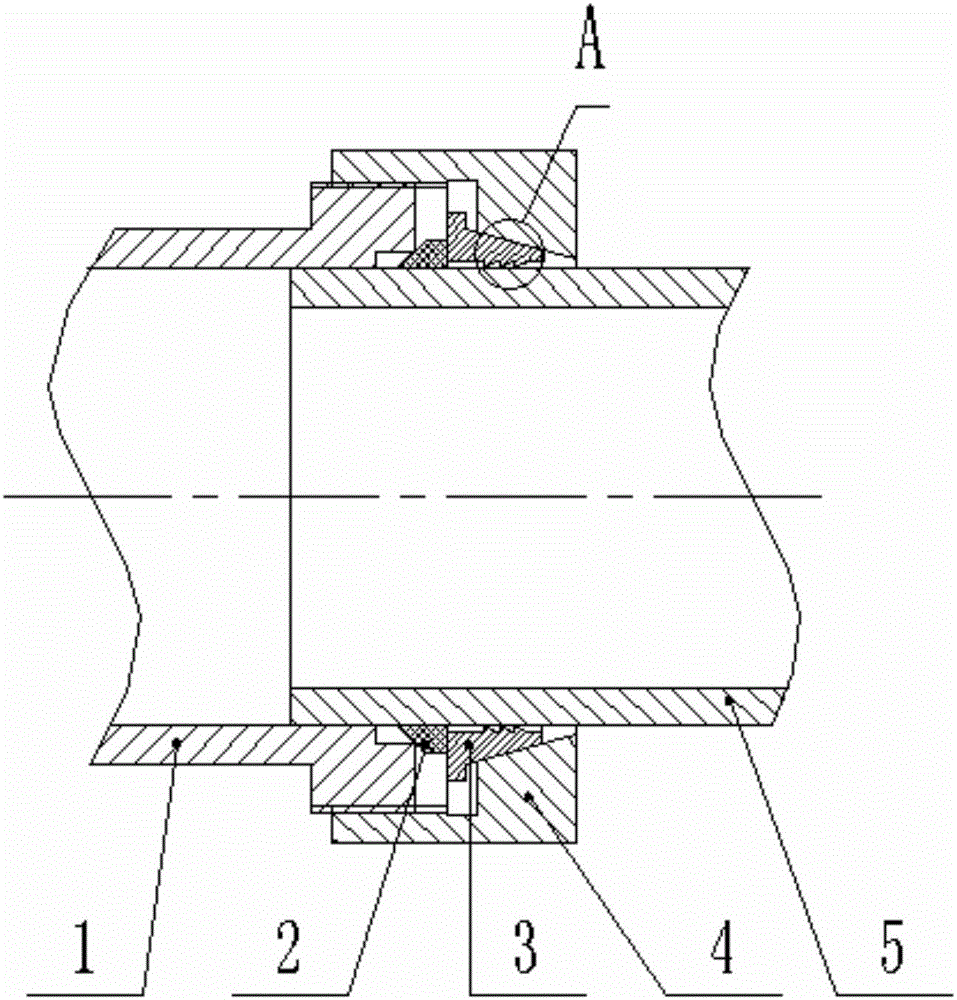

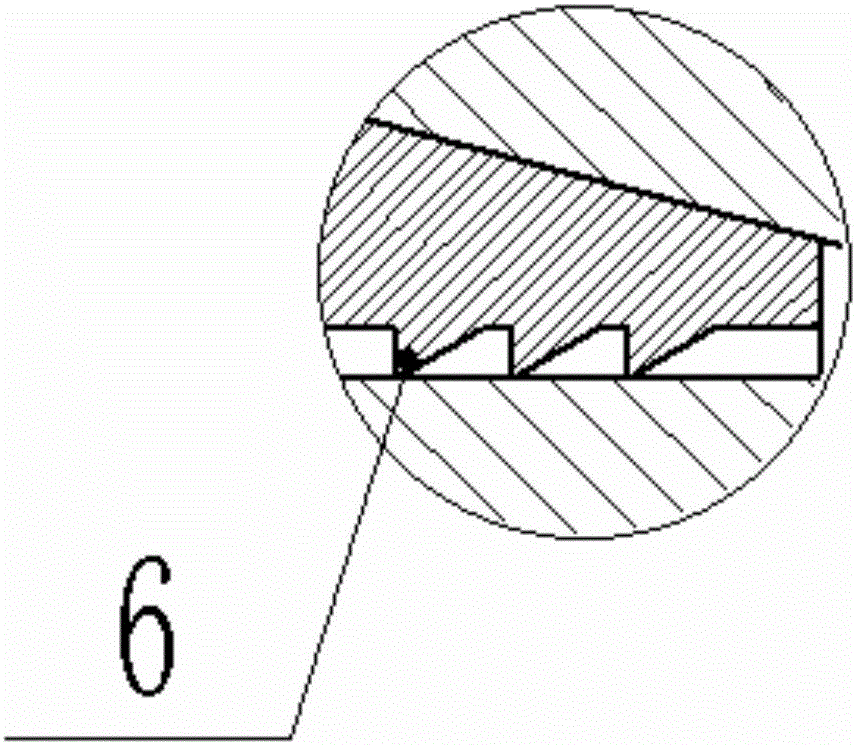

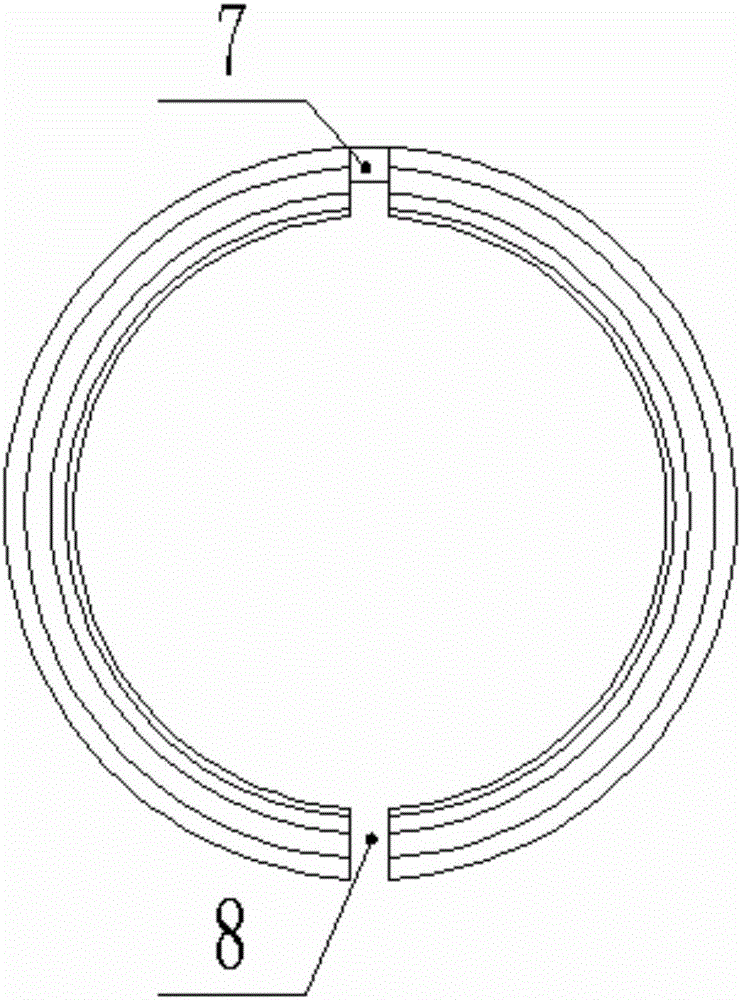

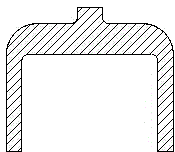

Scraper for piston rod of reciprocating compressor

InactiveCN1417470AReduce downtimeEasy to replaceEngine sealsPositive displacement pump componentsPlastic materialsEngineering

A scraper device (10) for a reciprocating compressor piston rod (11) comprises at least one scraper ring (12), provided with at least one lip which faces the surface of the said rod (11), and a box (13) to contain the scraper ring (12) and for centring on the rod (11), wherein this scraper ring (12) is produced by means of mechanical processing of deformable plastics materials and wherein this container box (13) is accommodated in support elements (14) with radial play (34).

Owner:NUOVO PIGNONE TECH SRL

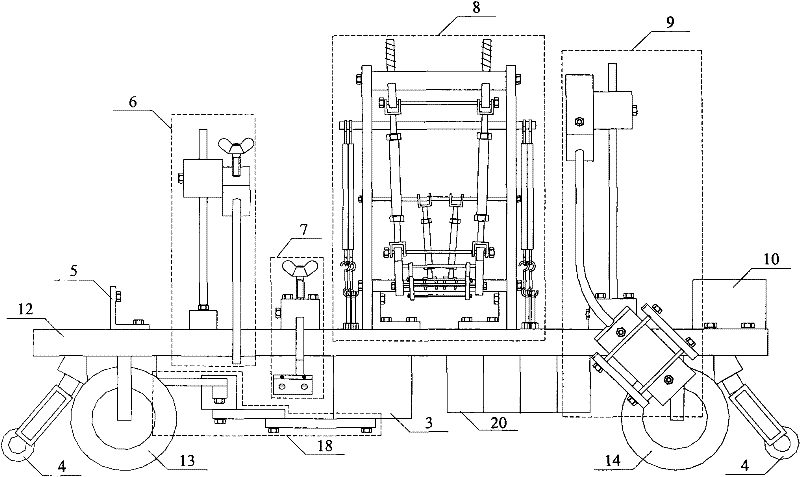

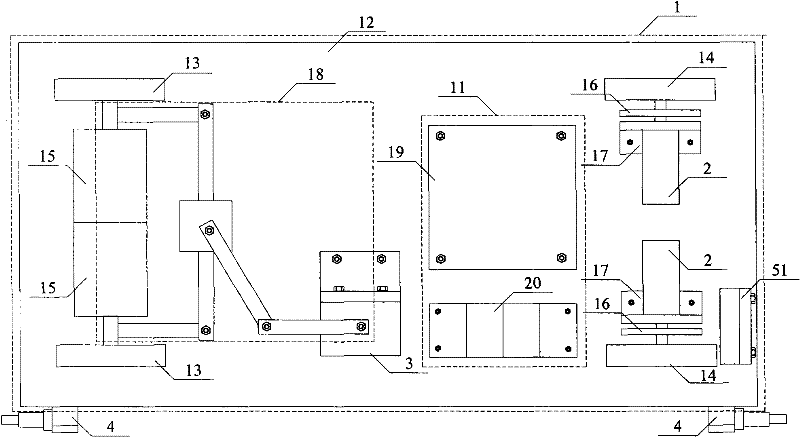

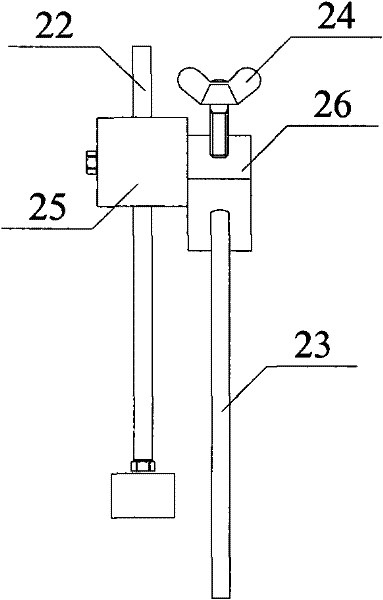

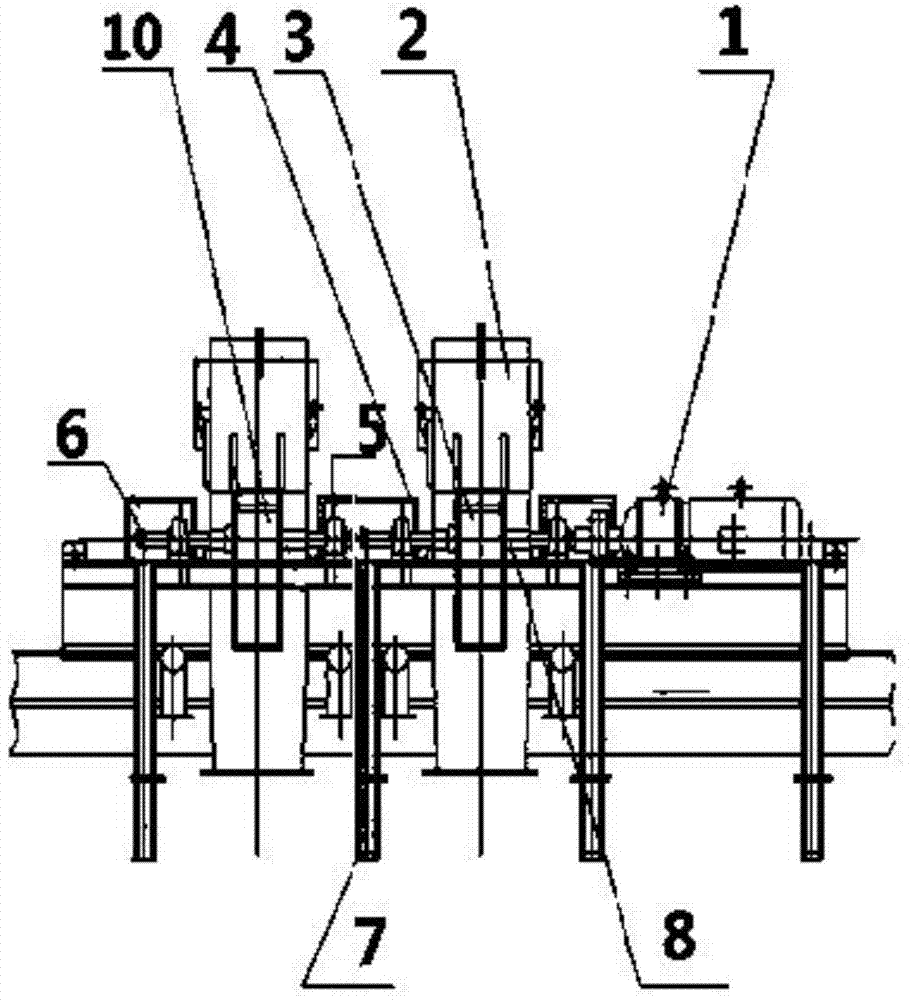

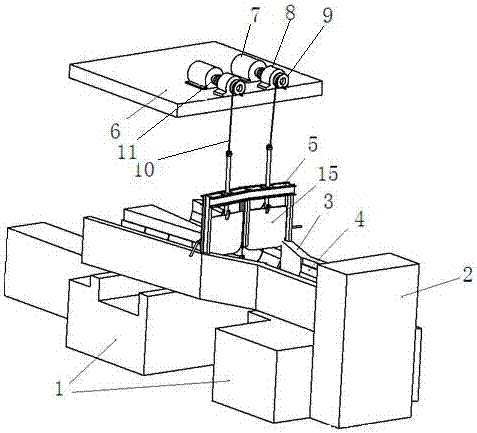

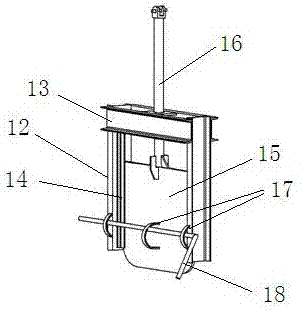

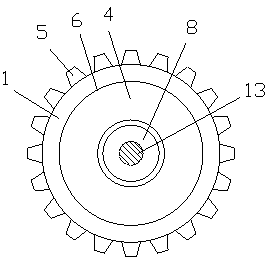

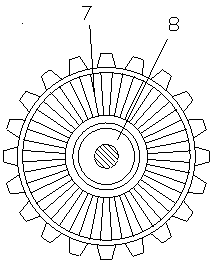

Automatic magnetic particle testing unit for toe cracks at inner wall of straight welded pipe

InactiveCN102346151ARapid Batch DetectionAutomatic detection speed adjustableOptically investigating flaws/contaminationMaterial magnetic variablesDrive wheelTransformer

The invention relates to a testing unit for a straight welded pipe, in particular to an automatic magnetic particle testing unit for toe cracks at inner wall of the straight welded pipe, comprising a car body consisting of a sweep template, a driving wheel, a stop block, a supporting plate, universal wheels and a guide bar which are connected with each other coaxially, and a rotary bearing, a driving motor, a control part, a steering engine, a position switch arranged on the two ends of one end of the car body, and a transformer bearing, a camera bearing, a sprayer bearing, a crossed yoke, an ultraviolet lamp bearing, and a water pump water tank bearing which are successively arranged on the top of the sweep template from left to right, wherein, the upper end of the stop block is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the output end of the steering engine is fixedly connected with the universal wheels through the guide bar, the upper end of the rotary bearing is fixedly connected with the two sides of the rear end of the sweep template bottom in parallel, the lower end of the rotary bearing is fixedly connected with one end of the supporting plate, the other end of the supporting plate is fixed connected with the sweep template bottom, and output shaft of the driving motor is respectively connected with the two driving wheels fixedly. The invention can completely takes the place of manual work to carry out automatic magnetic particle testing, and has the advantages of compact structure and convenient operation.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

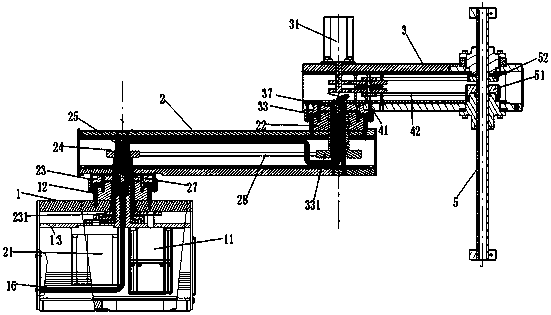

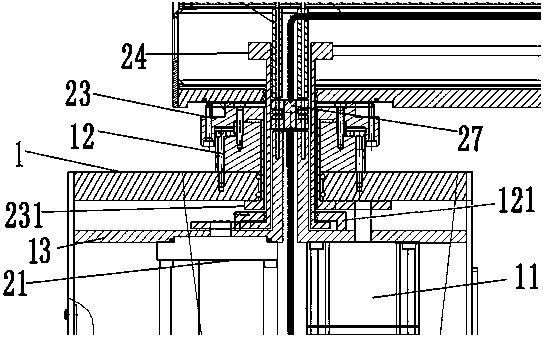

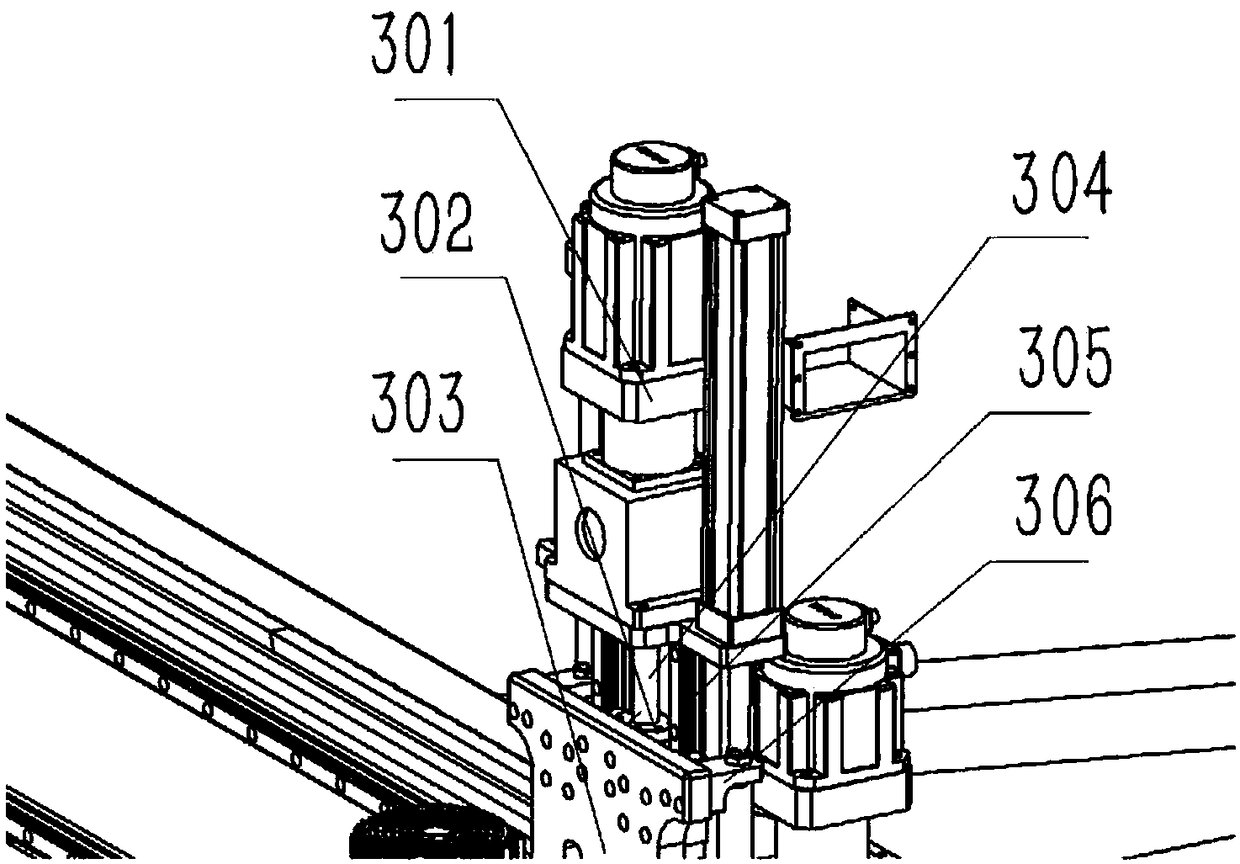

Multi-station SCARA industrial robot

PendingCN107639631ALower acquisition costsReduce weightProgramme-controlled manipulatorWire rodControl engineering

The invention discloses a multi-station SCARA industrial robot. The industrial robot includes a SCARA robot mechanism and a displacement drive mechanism, and the SCARA robot mechanism comprises a base, a first arm, a first arm drive device, a second arm, a second arm drive device, a ball spline wire rod and a power supply cable; a first motor and a second motor on the first and second arm drive devices are arranged inside the base, the rotation and lifting of the ball spline screw rod are driven by a third motor through a third drive component, and the SCARA robot mechanism can move under thedrive of the displacement drive mechanism. When the multi-station SCARA industrial robot is produced, multiple workstations require sharing only one SCARA robot mechanism, and thus the occupied spaceand the acquisition costs of equipment are reduced. Additionally, in the SCARA robot mechanism, the first and second motors are arranged inside the base, only the third motor is arranged on the secondarm, the weight of the load on the second arm can be reduced, the cost of spare parts is reduced, and the motion accuracy is improved.

Owner:GUANGDONG INST OF INTELLIGENT MFG

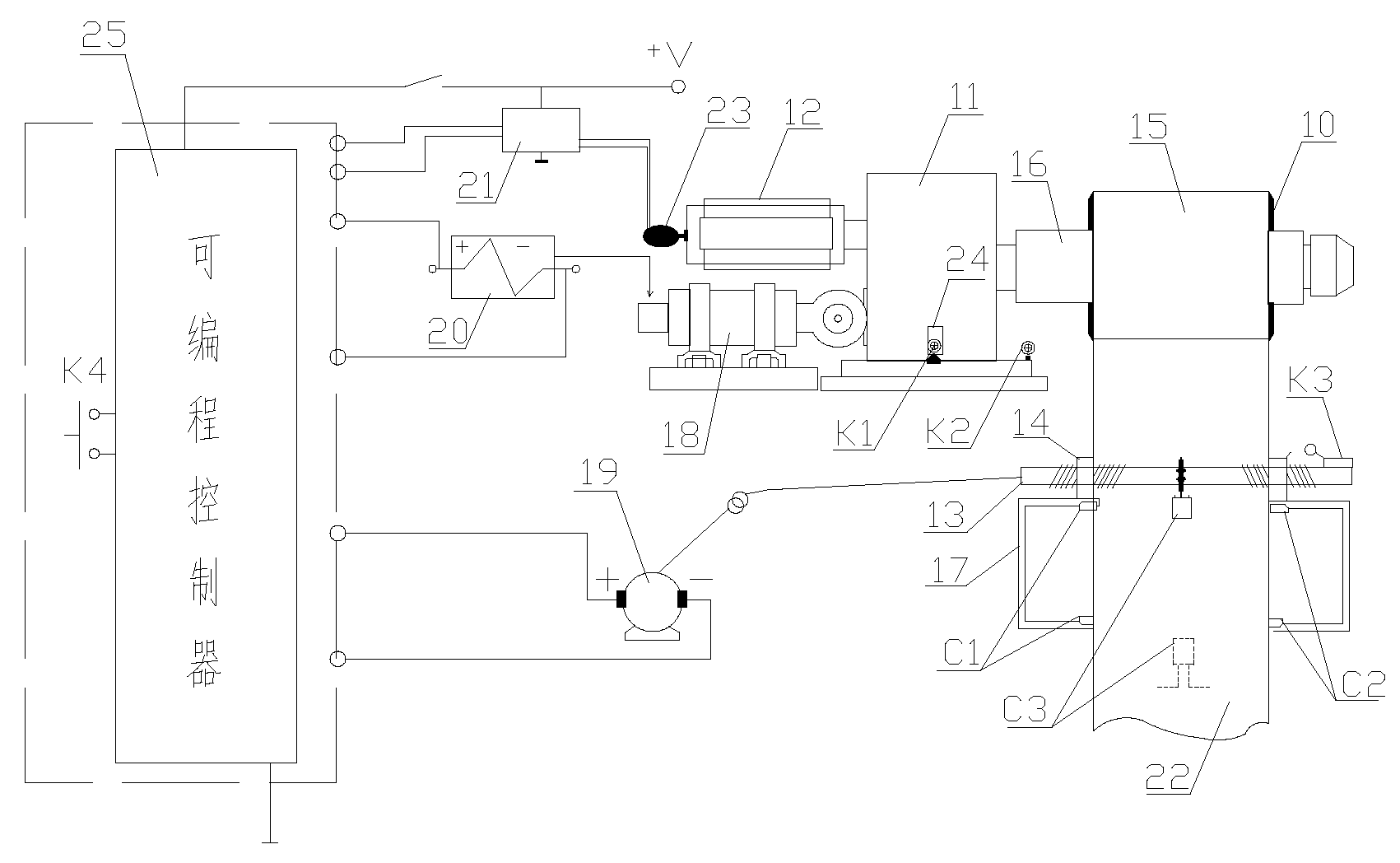

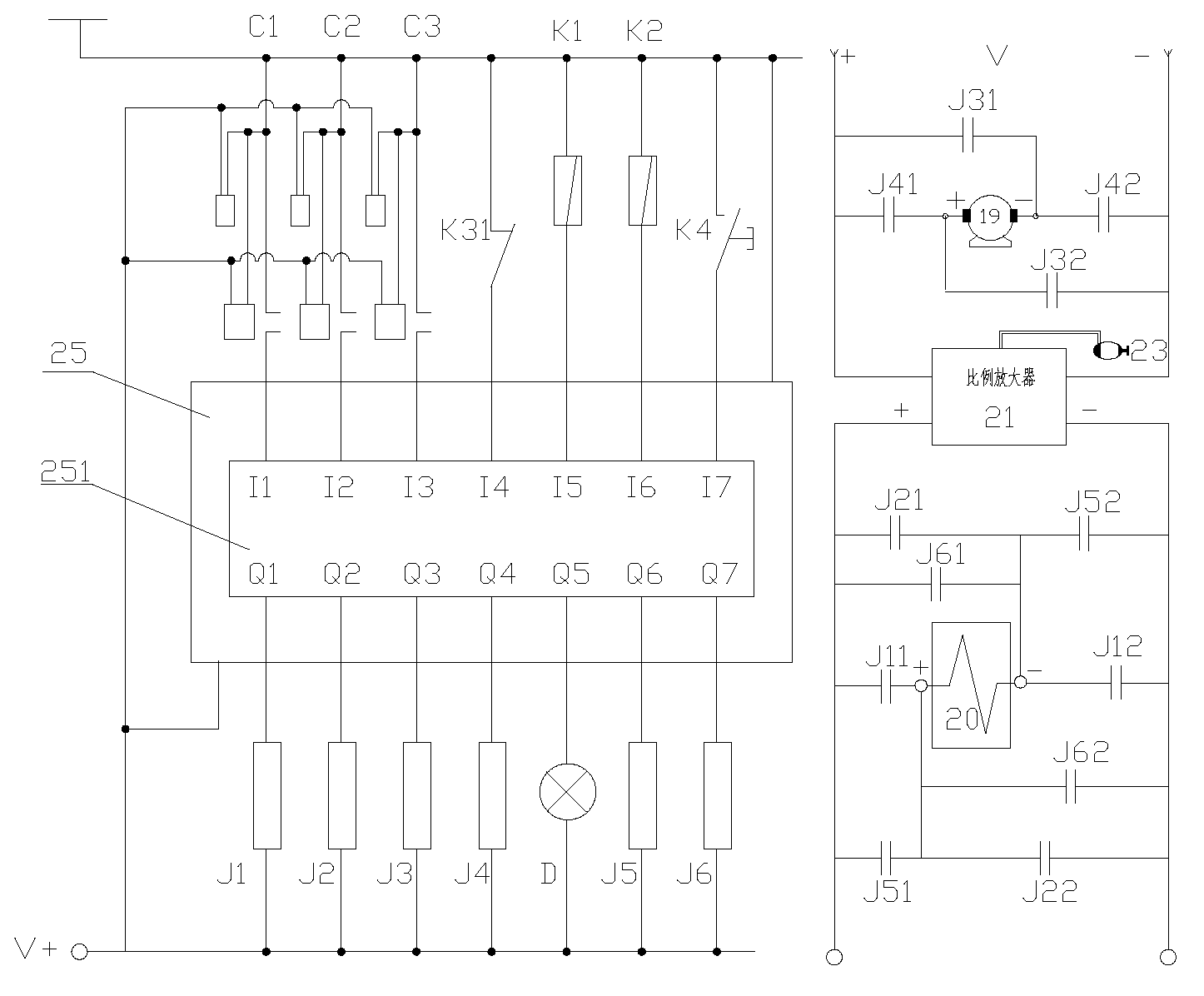

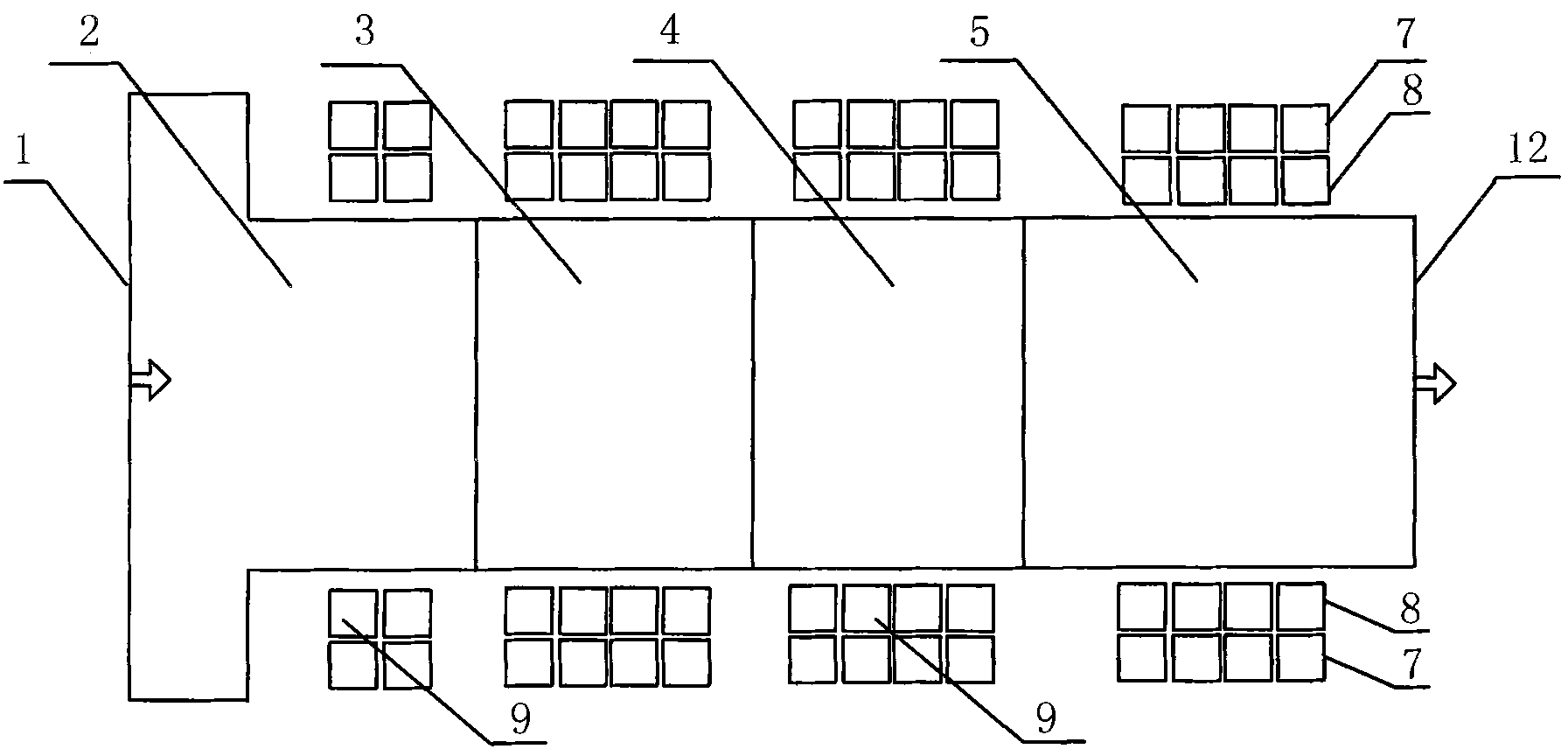

Device for controlling automatic centering of cold-rolling strip steel uncoiler

ActiveCN103008389AGuaranteed uptimeReduce spare parts costsMetal working apparatusProportioning valveElectromagnetic induction

The invention discloses a device for controlling automatic centering of a cold-rolling strip steel uncoiler. The device comprises 1, three infrared photoelectric sensors for detecting strip steel deviation and strip steel uncoiling threading, 2, two electromagnetic induction switches for detecting an uncoiler displacement signal, 3, a limit switch for detecting a displacement limit of a width arrangement block, and 4, a tachogenerator for detecting a rate signal of an uncoiler driving motor, feeding back the rate signal into a proportional amplifier and providing detection signals to a control loop composed of a press-button, six relays and a programmable controller. Through the detection signals, the relays are controlled respectively to act so that a width arrangement motor and a proportional reversing valve are controlled to act according to demands. The proportional amplifier provides signals to the proportional reversing valve and the proportional reversing valve drives a hydraulic cylinder so that an uncoiler moves transversely. The width arrangement motor drives a screw rod so that strip steel width arrangement is realized. The device realizes automatic centering of an uncoiler base, strip steel uncoiling threading detection, automatic edge-search width-arrangement of strip steel, and deflection correction of strip steel, can effectively reduce spare parts and a maintenance cost, and can guarantee normal operation of a cold-rolling unit.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

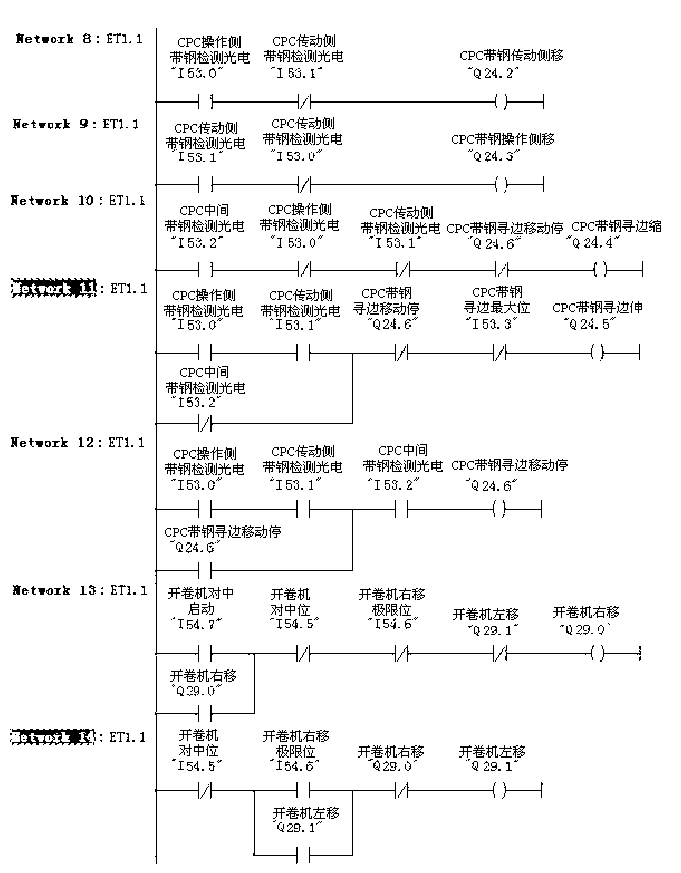

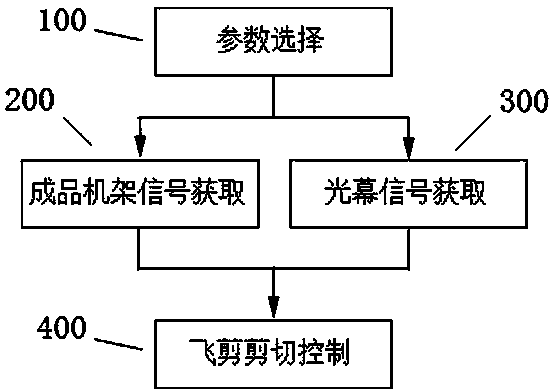

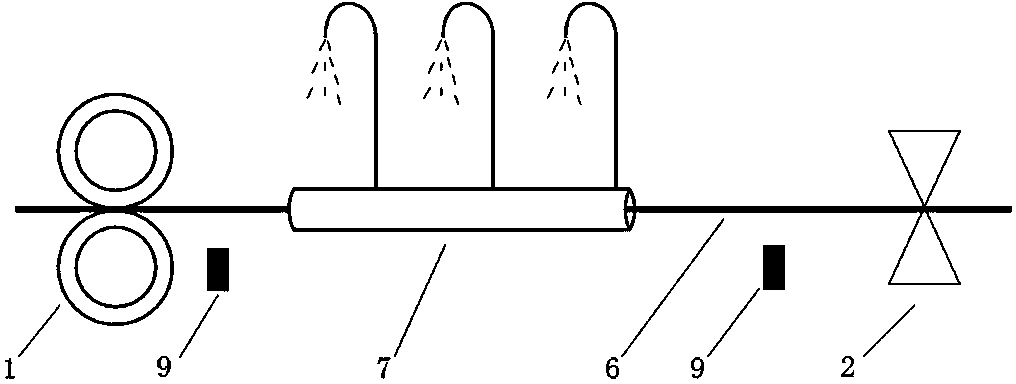

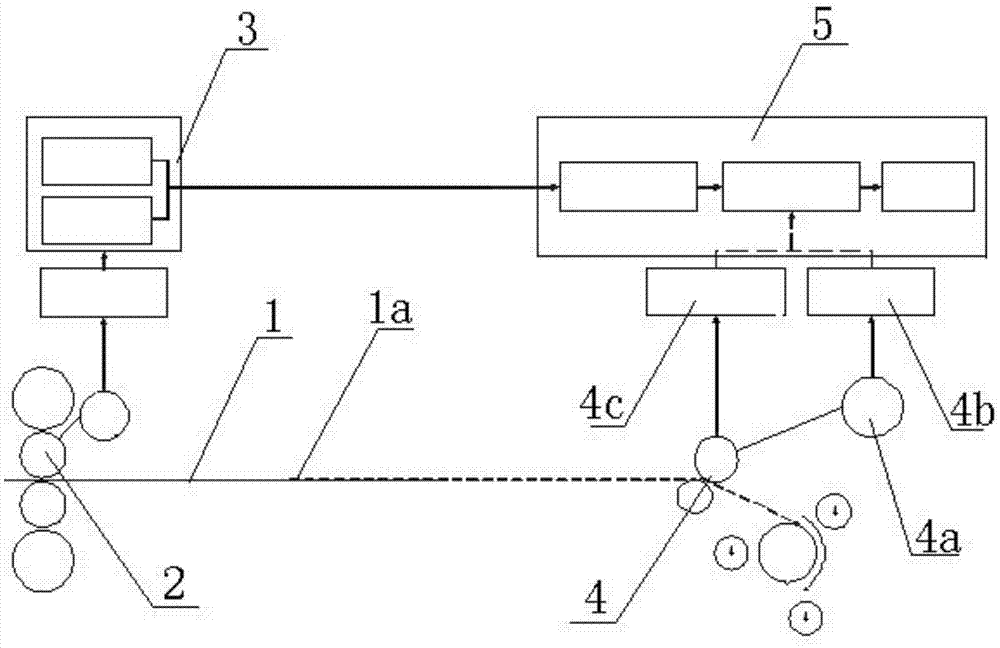

Rod double-length flying shear control method and device

ActiveCN104139210AImprove reliabilityReduce consumptionShearing control devicesFrequency changerStructural engineering

The invention discloses a rod double-length flying shear control method and device. The control method comprises the steps of parameter selection, finished product rack steel content signal acquisition, light curtain signal acquisition and flying shear shearing control. The device comprises a finished product rack, a double-length flying shear, an encoder and a control device, wherein the finished product rack is provided with a frequency converter electrically connected with a main shaft motor, the encoder is coaxially and rotationally connected with a finished product rack main shaft or the main shaft motor, the control device is in signal connection with the frequency converter, the double-length flying shear and the encoder, the rear end of the double-length flying shear is further provided with a light curtain sensor corresponding to a rod path, and the light curtain sensor is in signal connection with the control device. The rod double-length flying shear control method and device have the advantages that since the control device is in signal connection with the frequency converter, the encoder and the light curtain, current values are used for replacing the traditional pre-shearing thermal inspection signals for judging the state of the rod; since a double-length flying shear afterheat metal detector is changed to be the light curtain sensor, the problems of no shearing, shearing negligence and double length error caused by poor double-length flying shear signals are solved.

Owner:WUKUN STEEL

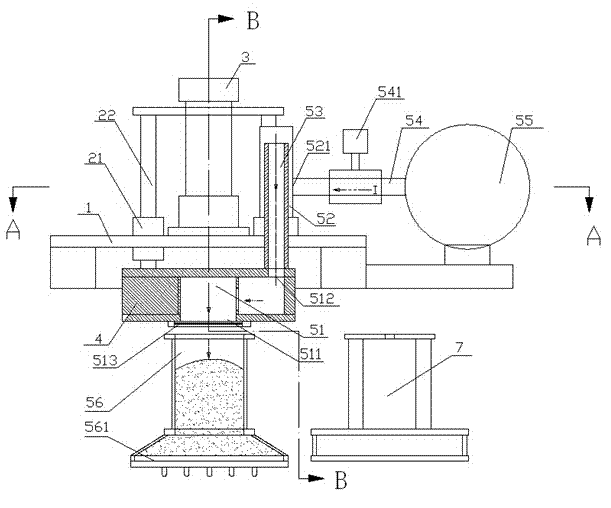

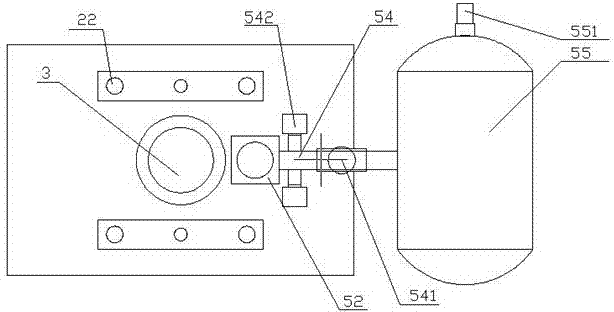

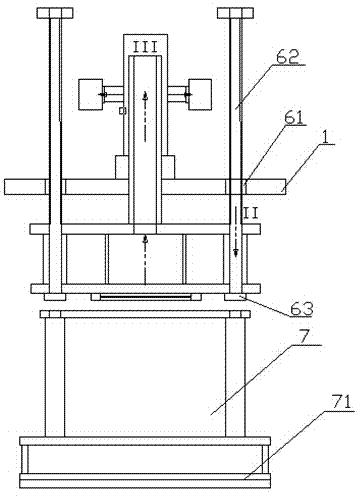

Pressure head device of sand jetting mechanism of upper pressing type core making machine

The invention discloses a sand jetting ventilation mechanism of an upper pressing type core making machine. The sand jetting ventilation mechanism of the upper pressing type core making machine comprises a first ventilation guide sleeve and a first ventilation guide pipe, wherein the first ventilation guide sleeve is fixedly mounted on a bracket plate; the axis of the ventilation guide sleeve is perpendicular to the bracket plate; an upper end opening of the first ventilation guide sleeve is sealed; a first ventilation end opening is formed in the side wall of the first ventilation guide sleeve or the upper end opening of the first ventilation guide sleeve serves as the first ventilation end opening; an upper end opening of the first ventilation guide pipe is communicated with the first ventilation guide sleeve; the outer wall of the upper end opening of the first ventilation guide pipe is connected with the inner wall of a lower end opening of the first ventilation guide sleeve in a sealing and guiding manner; the lower end opening of the first ventilation guide pipe is fixedly communicated with a second runner end opening. By virtue of the sand jetting ventilation mechanism of the upper pressing type core making machine, the reliability of the sand jetting ventilation mechanism and a curing ventilation mechanism is improved, the costs of spare parts are reduced, the length of a sand jetting and curing pipeline is reduced, the sand jetting and curing energy loss is reduced, the sand jetting and curing effect is improved, the gas heat energy loss is reduced, the consumption of catalyst and air is reduced, and the overall reliability of the core making machine is improved.

Owner:SUZHOU MINGZHI TECH

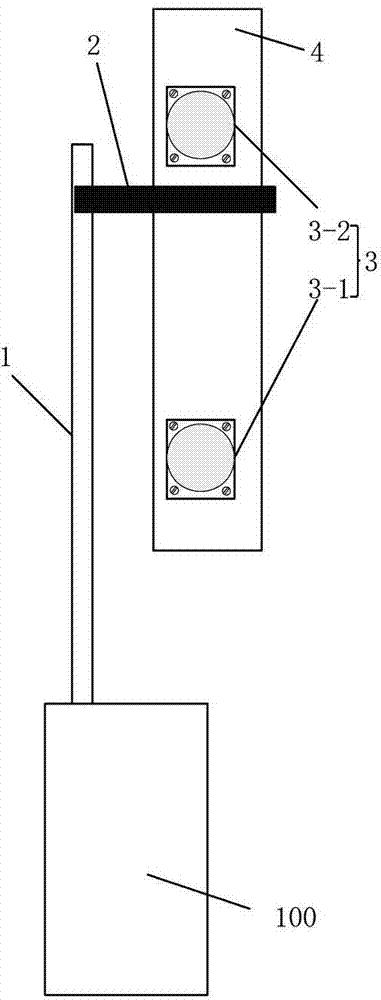

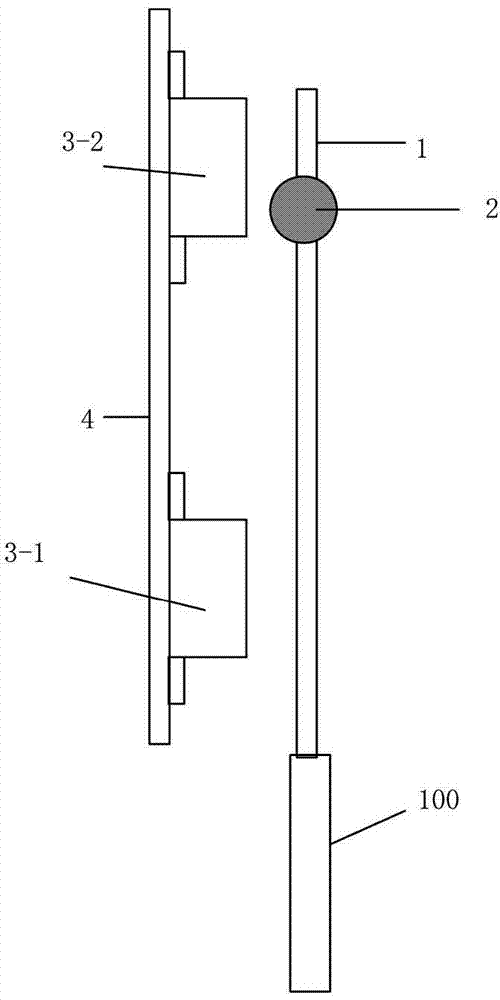

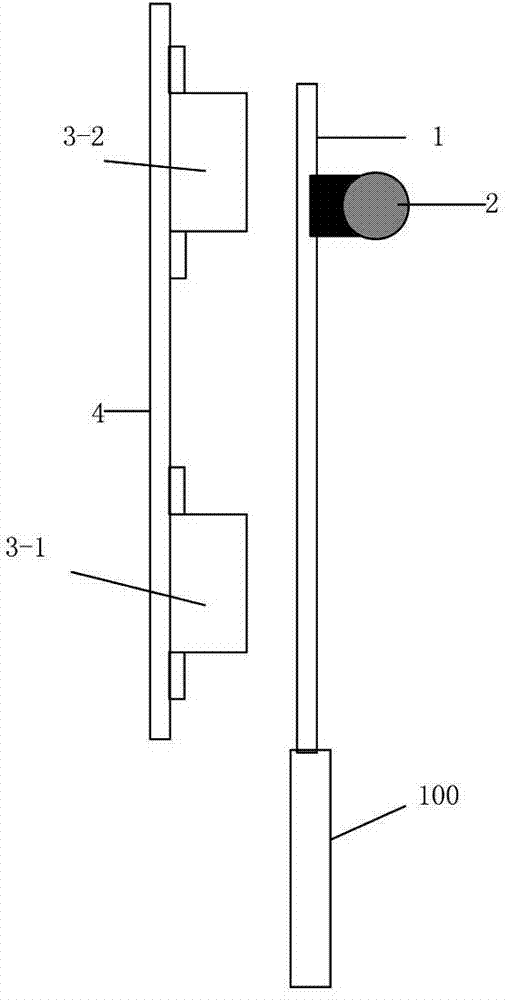

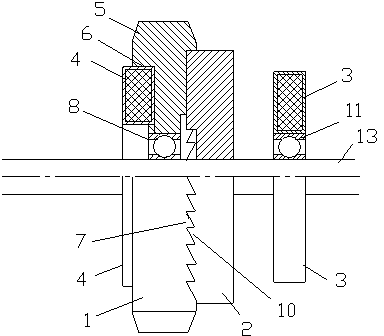

Position detecting device

ActiveCN103499321AImprove stability and reliabilityLow failure rateMeasurement devicesDevice failureFault rate

The invention provides a position detecting device. The position detecting device is used for detecting the position of mobile equipment and comprises an approach switch, an approach body and an auxiliary mechanism, wherein the auxiliary mechanism is used for installing the approach switch and the approach body; the auxiliary mechanism comprises a support, a limiting sliding groove and a connecting component, wherein the limiting sliding groove is arranged on the support; one or more approach switch(es) is / are arranged on the support along the length direction of the limiting sliding groove, and the distance between the limiting sliding groove and the support and the distance between the limiting sliding groove and the sensing surface of the approach switch can be adjusted; the connecting component is used for connecting the approach body onto the mobile equipment; the approach body is positioned in the limiting sliding groove and can move with the movement of the mobile equipment along the length direction of the limiting sliding groove so as to be close to or separated from the sensing surface of the approach switch. The position detecting device provided by the invention can prevent external factors from causing bad detecting signals of the approach switch or faults of the equipment, and has the advantages of stable operation, no environmental influence, low fault rate and the like.

Owner:PANGANG GRP ENG TECH

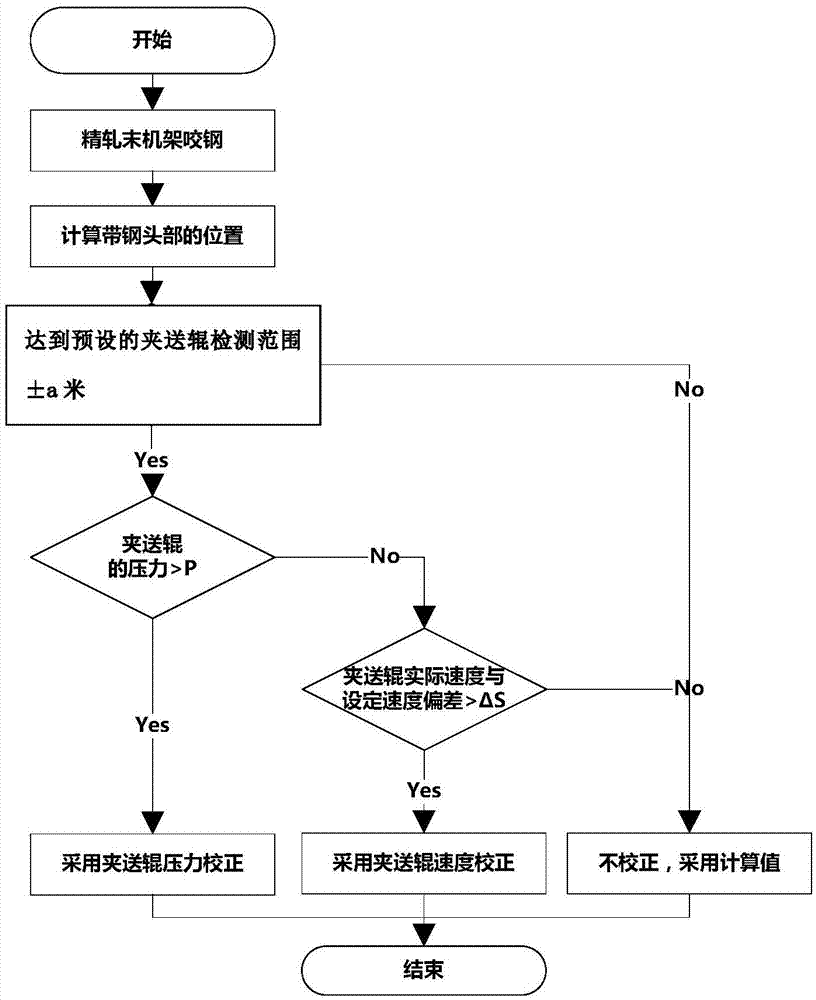

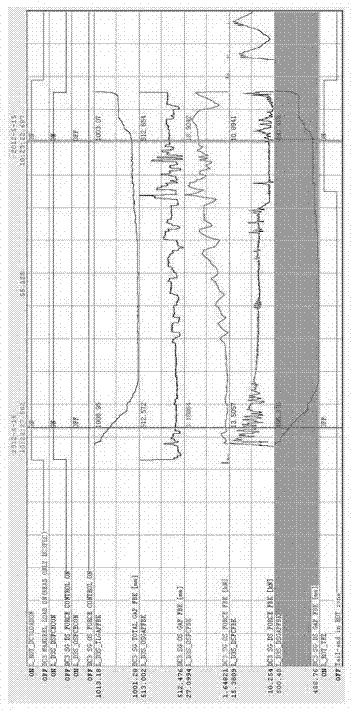

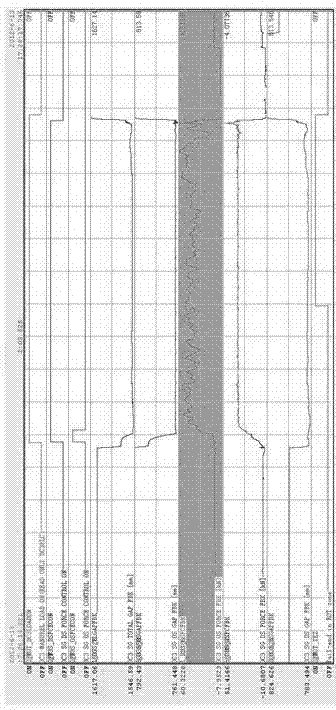

Correction device and correction method capable of improving tracking precision of pinch roller of reeling machine

ActiveCN107020309AImprove tracking accuracySolve the problem of unstable pressure signalStrip steelCorrection method

The invention discloses a correction device and correction method capable of improving tracking precision of a pinch roller of a reeling machine. The device comprises strip steel, a finishing mill group end rack and a finishing mill basic automatic computer, wherein the finishing mill basic automatic computer is in signal communication with the finishing mill basic automatic computer; the finishing mill basic automatic computer is in signal communication with a reeling basic automatic computer arranged at the position of a pinch roller assembly; the pinch roller assembly is provided with a pinch roller rotating speed measuring device at the position of a pinch roller motor, the pinch roller rotating speed measuring device is in signal communication with the reeling basic automatic computer, and obtained pinch roller actual rotating speed is sent to the reeling basic automatic computer to be compared. Through changes of pinch roller pressure and pinch roller speed, the calculated head position of the strip steel is corrected, and the problem that after a pinch roller is worn, pressure signals are not stable is solved; the tracking precision of the reeling machine is improved; the correction device and correction method have the beneficial effects that existing equipment is small in modification, the cost is low, and production and spare part cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Coiler side guide plate control method for preventing steel coils on hot rolling production line from staggering

InactiveCN103203365AAvoid splittingAvoid wear and tearRare end control deviceMetal rolling arrangementsProduction lineControl manner

The invention relates to a coiler side guide plate control method for preventing steel coils on a hot rolling production line from staggering, and belongs to the technical field of metallurgical plate production process. The technical scheme includes that programming is changed in a PLC (programmable logic controller) for controlling a coiler side guide plate, a force control link is added into a side guide plate control logic of a position control side, the side guide plate of the position control side is switched to the force control link and presses strip steel after a coiler mandrel is loaded, and then positions are controlled. The coiler side guide plate control method has the advantages that the problem that a side guide plate of a position control side cannot press strip steel is effectively solved, tail staggering of the steel coils is prevented, compared with an improved side guide plate control mode, the coiler side guide plate control method enables the side guide plate of the position control side to automatically position the edge of the strip steel without manual intervention and is efficient, safe and reliable, owing to double-sided pressure control, the strip steel is more rapidly pressed as compared with traditional one-sided pressure control, scrolling of inner rings can be more effectively controlled, and as the problem of swing after pressing of the side guide plate is solved, the replacement cycle of a transmission mechanism for the side guide plate can be prolonged, the expense of spare parts is saved, and maintenance time is shortened.

Owner:HANGANG GRP HANBAO IRON & STEEL +1

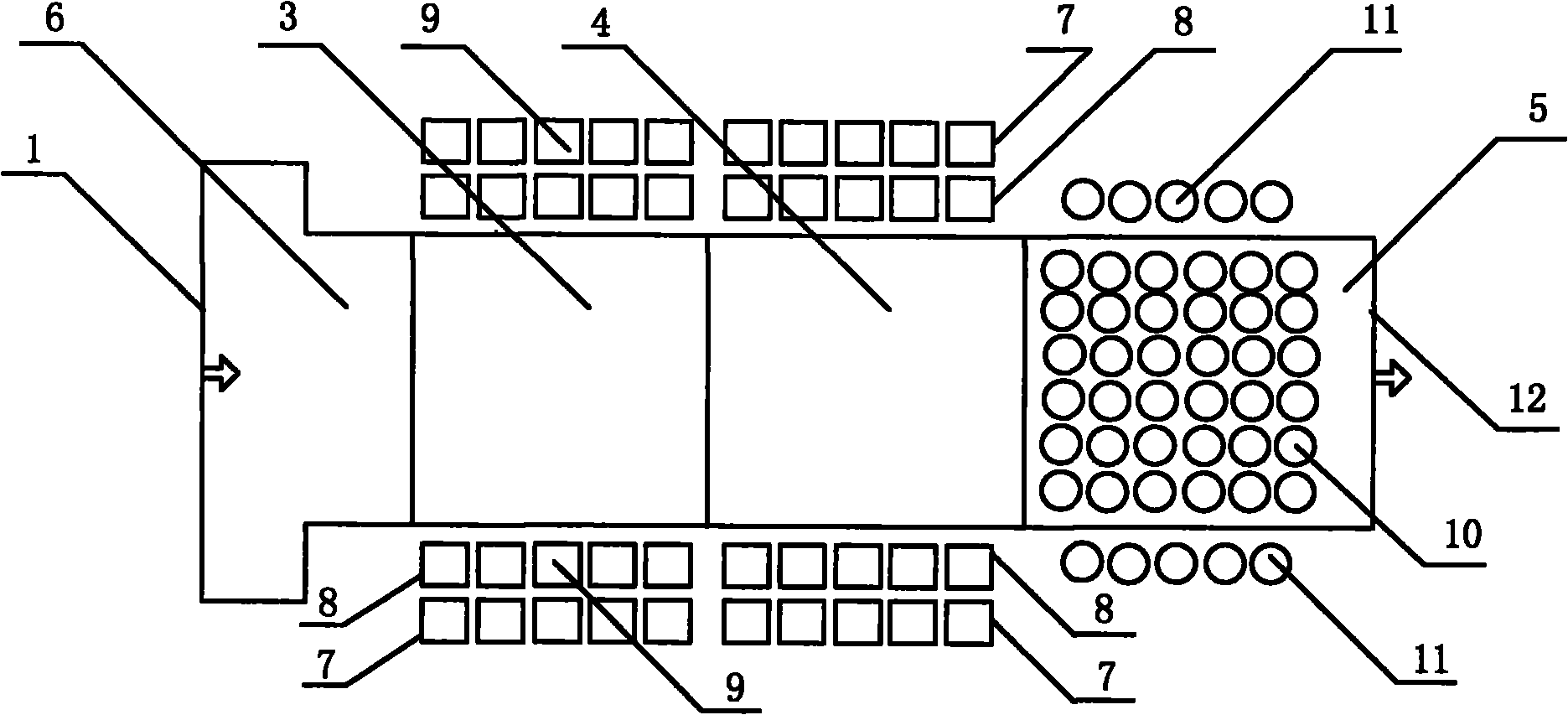

Heating furnace and heating method thereof

The invention relates to a heating furnace and a heating process thereof, in particular to the heating furnace adopting a regenerative burner and a conventional burner to perform combined heating, and the heating process thereof. The heating furnace structurally comprises a furnace body, and a feeding end wall and a discharging end wall which are arranged at the two ends of the furnace body respectively, wherein the furnace body between the feeding end wall and the discharging end wall is sequentially divided into a heat recovery section, a first heating section, a second heating section and a soaking section; partition walls are arranged between every two adjacent sections; and the furnace body is provided with the regenerative burner used for heating the furnace body, a flat flame burner and a flame adjustment burner. The heating process comprises the following steps of: starting igniting the heating furnace from the flame adjustment burner of the soaking section, and igniting the flat flame burner to switch the second heating section and the first heating section into a thermal storage state of the regenerative burner to finish the ignition heating work. The heating furnace of the invention effectively realizes energy saving, emission reduction and improvement in blank heating quality, greatly reduces spare part production and maintenance cost, and reduces the production cost.

Owner:武钢集团有限公司

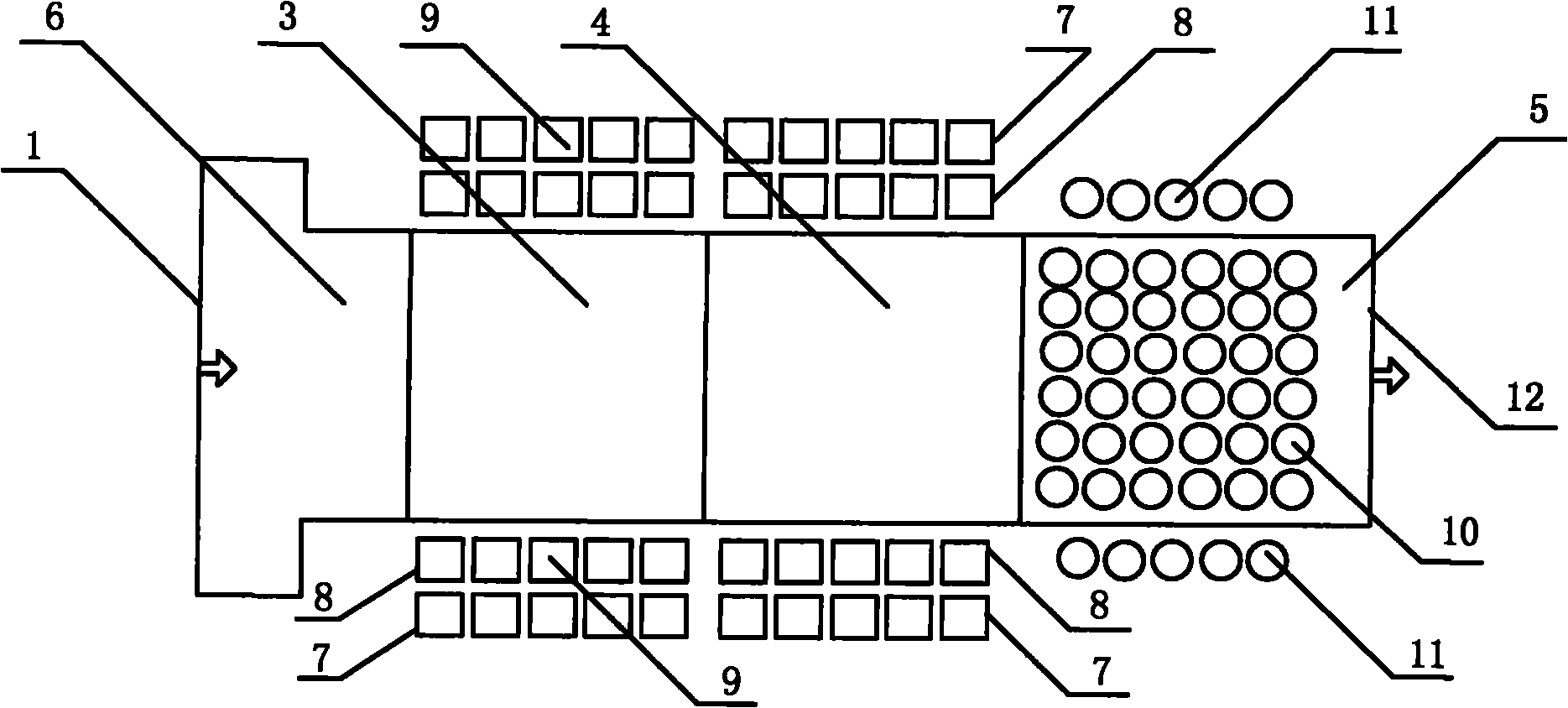

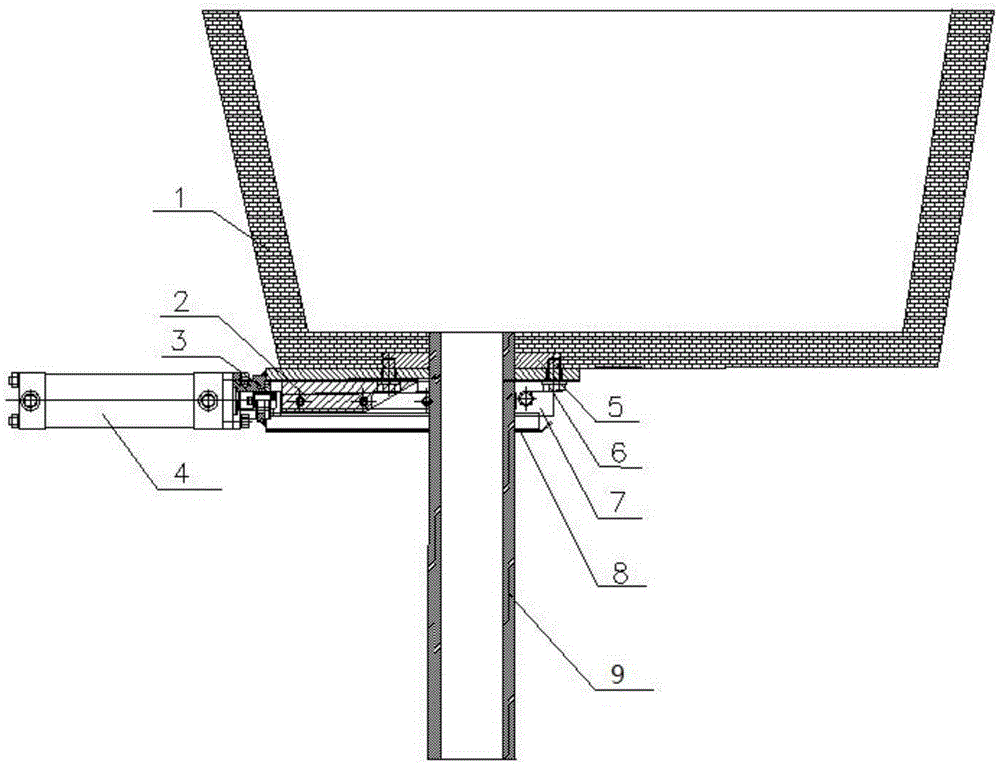

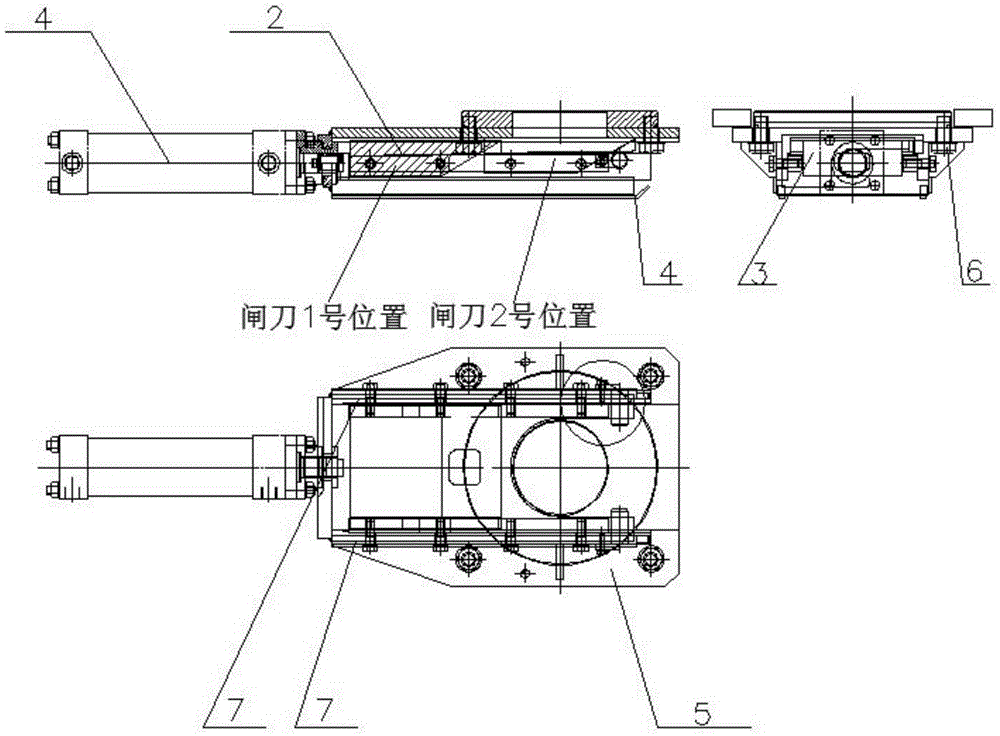

Emergency tripping device for tundish nozzle in round billet conticaster and maintenance method of emergency tripping device

The invention relates to an emergency tripping device for a tundish nozzle in a round billet conticaster and a maintenance method of the emergency tripping device. The emergency tripping device comprises a tripping switch blade, a tripping oil cylinder and a switch blade guide groove, wherein the tripping switch blade is arranged in the switch blade guide groove and rapidly moves to the direction of the tundish nozzle along the switch blade guide groove, and a piston rod of the tripping oil cylinder is connected with the switch blade and can push the switch blade. The emergency tripping device has the advantages of being convenient to install, flexible to disassemble, small in maintenance quantity and long in service life; when offline maintenance is conducted, only a fixed bolt on a fixed base plate needs to be disassembled, and the fixed base plate can be disassembled to conduct offline maintenance; when the device is used online, an operator can conveniently install a driving oil cylinder on an oil cylinder installation plate, and the device is put into use conveniently and rapidly; meanwhile, the emergency tripping device can be repeatedly used if the tripping switch blade is not damaged, and the cost of spare parts is greatly reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

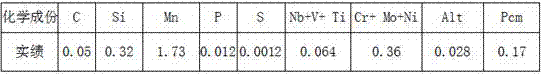

Rolling method for large-wall-thickness pipeline steel

InactiveCN107442568ASave labor costs and spare parts costsLow manufacturing costMetal rolling arrangementsCooling temperatureReduction rate

The invention discloses a method for rolling pipeline steel with large wall thickness, which includes the following process steps: (1) Heating: the continuous casting slab is heated by a walking beam heating furnace, and the preheating section is from room temperature at a rate of 4 to 5 min / cm heating speed, the temperature is controlled at 800~900°C; the heating speed of the heating section is controlled at 6~8min / cm, the temperature is controlled at 1160~1180°C; the temperature of the soaking section is controlled at 1160±20°C, and the holding time is 120~160 minutes; (2) Rolling: rough rolling, finish rolling temperature ≥ 980 ℃, middle billet thickness range 80~90mm, adopt large reduction system at the same time, after widening, there are 2 consecutive passes with reduction rate ≥ 25%; finish rolling, start rolling The temperature is 830°C, the final rolling is 720~740°C, and the rolling is two passes; cooling, the starting cooling temperature is 690~710°C, the cooling speed is 15~18°C / S, and the final cooling is 380~420°C. A pipeline steel with a large wall thickness of 30.8mm, a pipe diameter of 1422mm, and a steel grade of X80 with excellent crack arrest performance was produced by using a billet with a cross-sectional size of 260mm×2280mm. Compared with the TMCP+OLT process, the manufacturing cost is reduced, that is, the online tempering cost is saved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Cross scraper type sampler for coal transporting belt

InactiveCN104713749ARealize redundant automatic error-free interceptionLow costWithdrawing sample devicesCouplingEngineering

The invention relates to a device, in particular a cross scraper type sampler for a coal transporting belt. The cross scraper type sampler comprises an electric motor, a rotary main body connected with the electric motor, a first sampling head driven by the rotary main body, a sampling chute corresponding to the first sampling head, and a support bracket for fixing equipment. The cross scraper type sampler is structurally characterized by comprising a second sampling head, a sampling chute corresponding to the second sampling head, and a shaft coupler for connecting the second sampling head with the rotary main body, wherein rotating shafts of the first sampling head and the second sampling head are respectively fixedly connected with a rotating shaft of the rotary main body. On the basis of the primary equipment, a second set of sampling system is added to redundantly and automatically intercept representative coal samples with zero error.

Owner:电力工业产品质量标准研究所有限公司

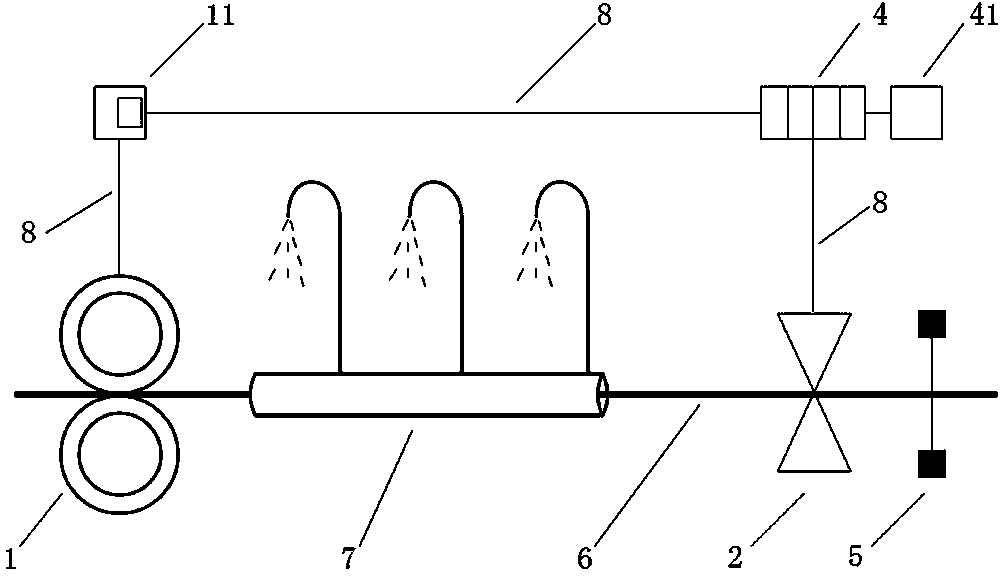

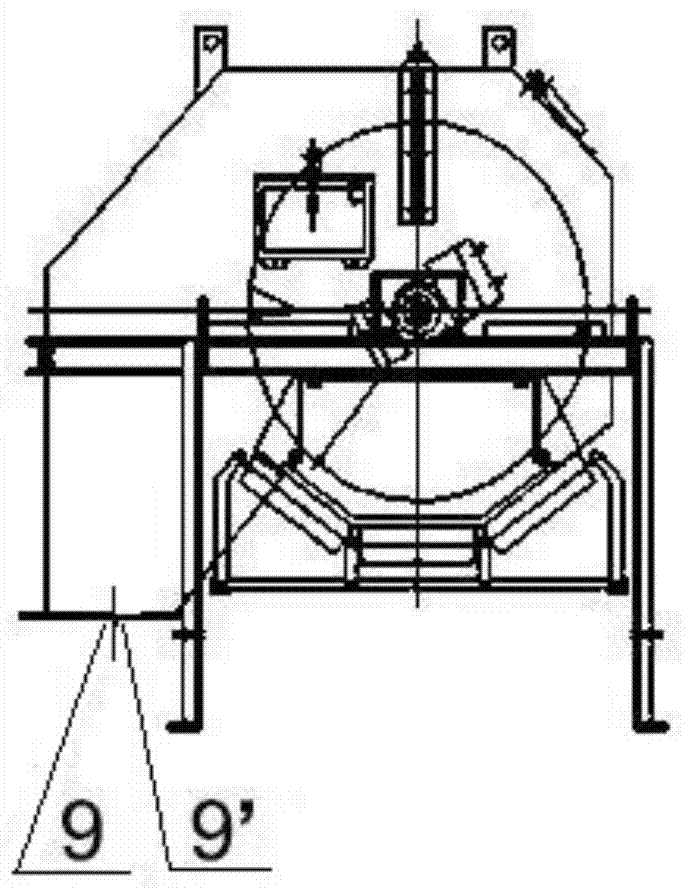

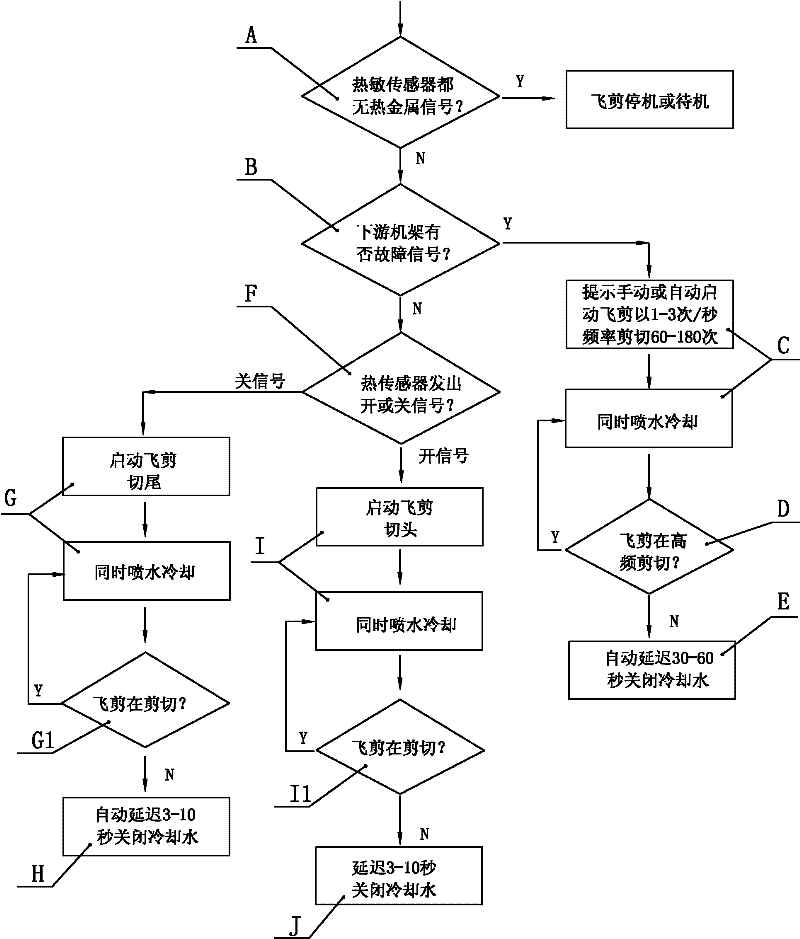

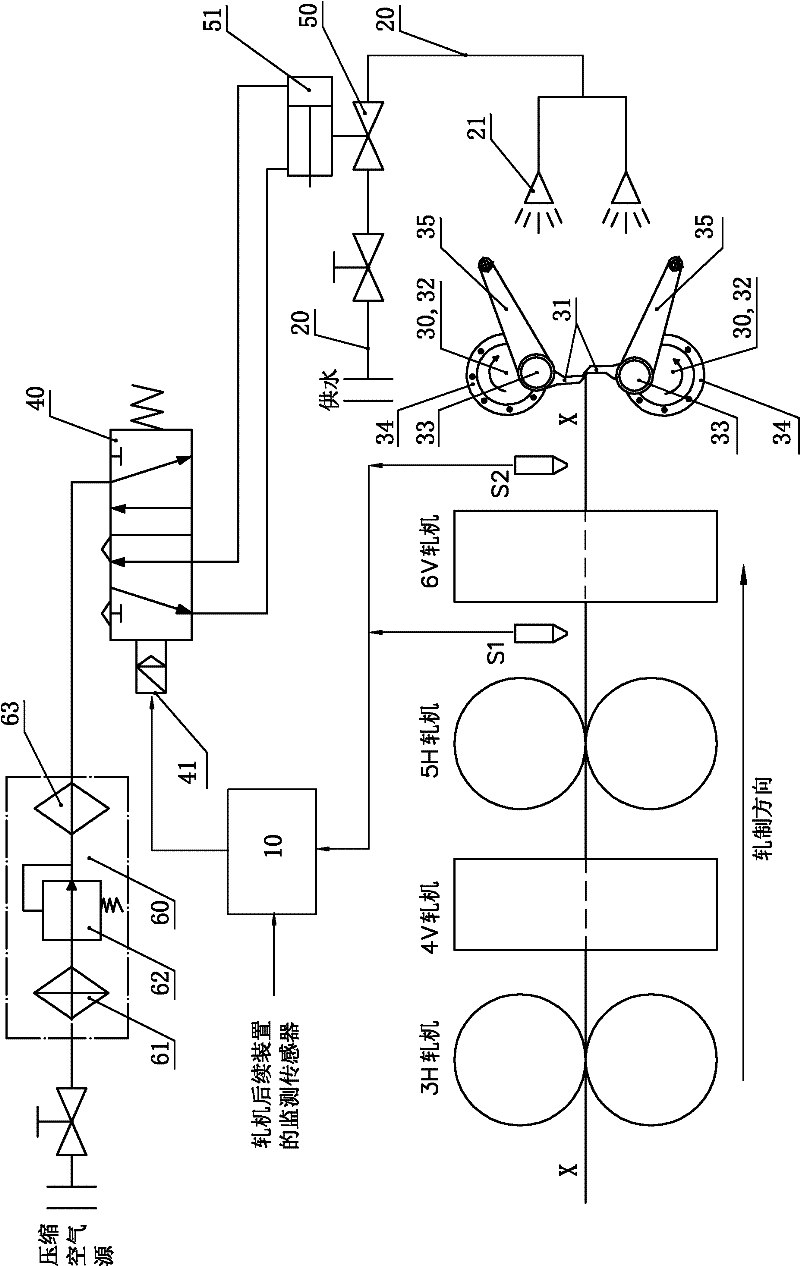

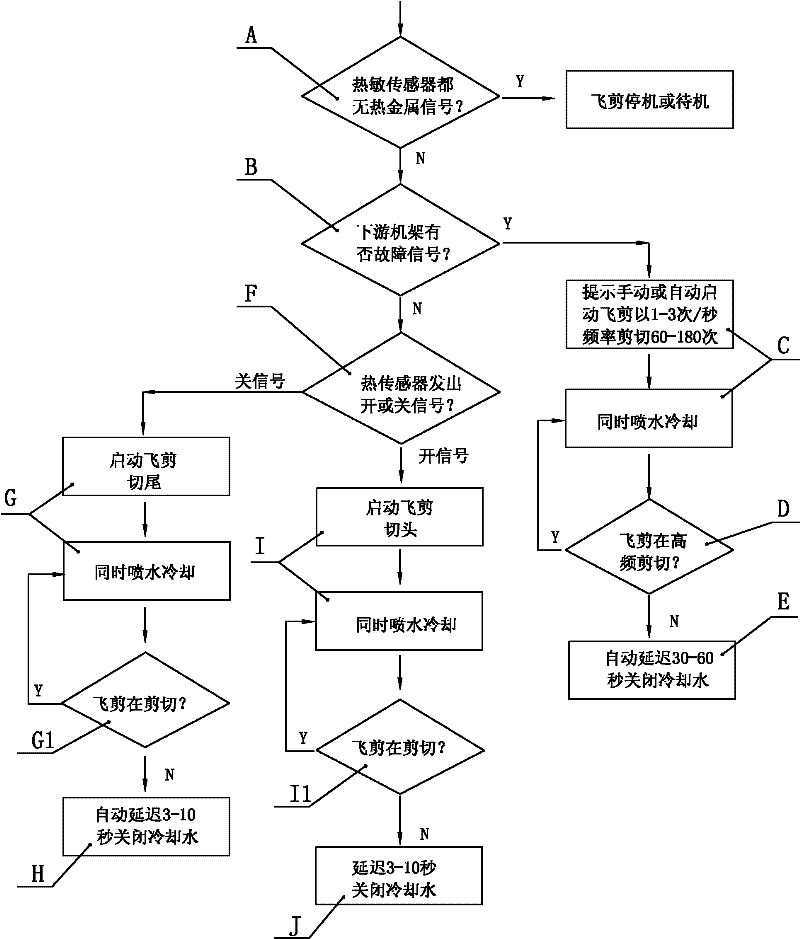

Rolling mill flying scissor blade cooling method and cooling device thereof

ActiveCN102310224AAccurate Status SignalTimely status signalMeasurement/indication equipmentsMaintainance and safety accessoriesFailure rateWire rod

The invention relates to a rolling mill flying scissor blade cooling method and a cooling device thereof. In the cooling method, a heat-sensitive sensor is arranged to detect the movement and the position of wire stocks in the process in which the wire stocks are transported to a flying scissor blade, and a detection signal is transmitted to a control circuit. The method comprises the following steps: sending out a hot metal existence / non-existence detection signal and controlling the flying scissor blade to halt or stand by; or spraying water to cool the flying scissor blade and automatically delaying the close of sprayed cooling water. According to the cooling method and the device thereof disclosed by the invention, on the premise of saving water and preventing water from splashing andinfiltering into a bearing oil seal, a more effective water cooling mode is adopted to cool the flying scissor blade, so the temperatures of the flying scissor blade as well as a cutter shaft and a crankshaft thereof can be greatly reduced, the shearing quality of flying scissors is improved, the overall working life of the blade and the flying scissors is prolonged, and the failure rate of the whole device is reduced.

Owner:SHAOGUAN IRON & STEEL GROUP CORP GUANGDONG PROV +1

Blast furnace slag slurry conveying conversion device not liable to be damaged

ActiveCN107190111ARealize conversion deliveryAvoid unstable factorsRecycling and recovery technologiesSlide valveSlagEconomic benefits

The invention discloses a blast furnace slag slurry conveying conversion device not liable to be damaged and belongs to the technical field of blast furnace iron smelting equipment. The blast furnace slag slurry conveying conversion device is used for conveying blast furnace slag slurry to different filter pools. According to the technical scheme, a concrete-poured foundation platform is located between a slag ditch and the two filter pools. A slag dividing pipeline is located on the foundation platform. A main pipeline is arranged at one end of the slag diving pipeline, and a slag inlet of the main pipeline is connected with the slag ditch. Two branch pipelines are arranged at the other end of the slag diving pipeline. Slag outlets of the two branch pipelines are connected with slag inlets of the two filter pools correspondingly. Gates are mounted at slag inlets of the two branch pipelines correspondingly. A lifting platform is arranged above the gates. Two lifting mechanisms are mounted on the lifting platform and connected with the upper ends of the two gates correspondingly. The structure is simple, mounting is convenient, the using effect is good, the manufacturing cost is low, the spare part cost is saved, the overhaul cost is reduced, the whole device operates stably, normal operation of a blast furnace is guaranteed, and significant economic benefits are achieved.

Owner:TANGSHAN IRON & STEEL GROUP +1

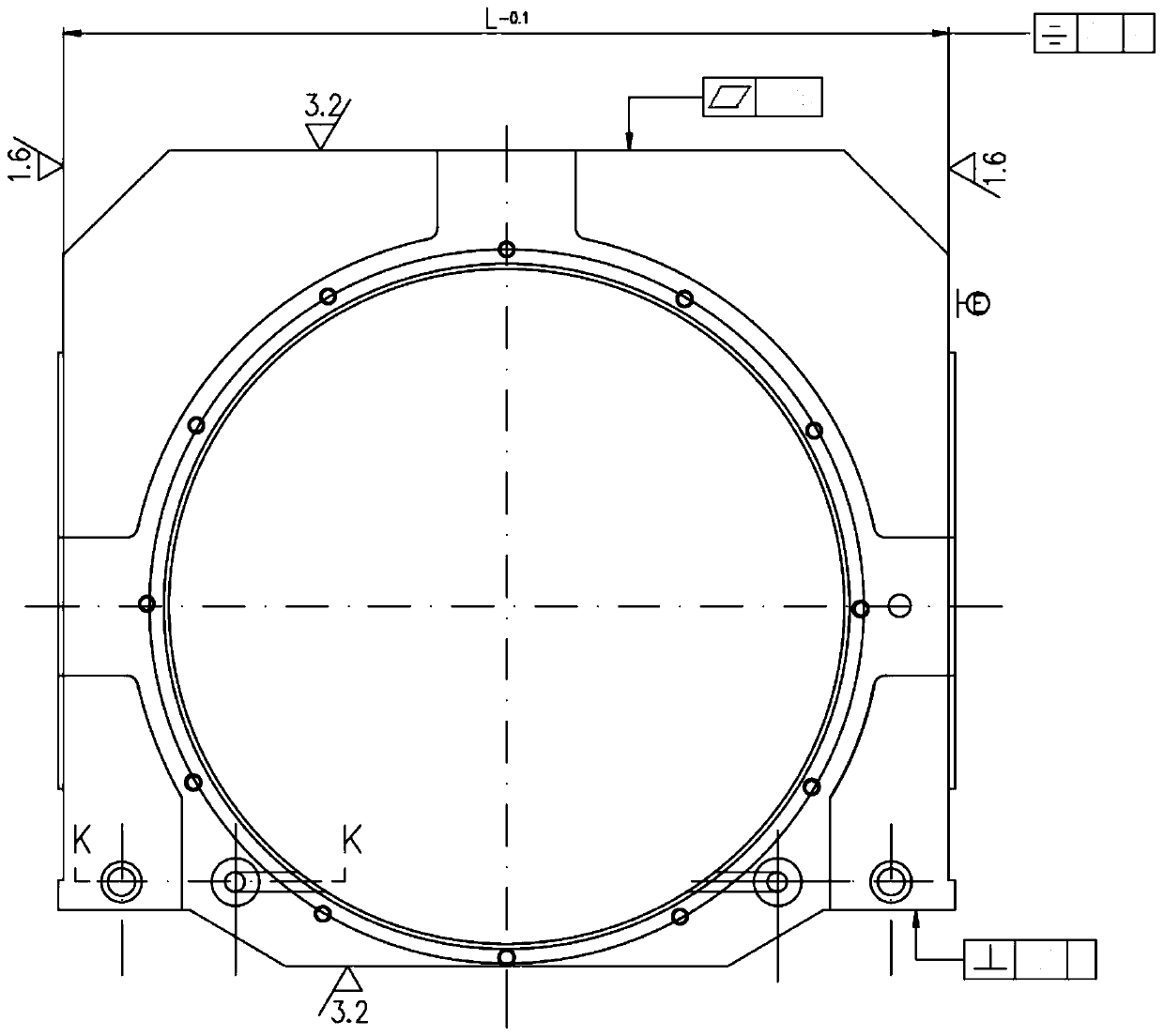

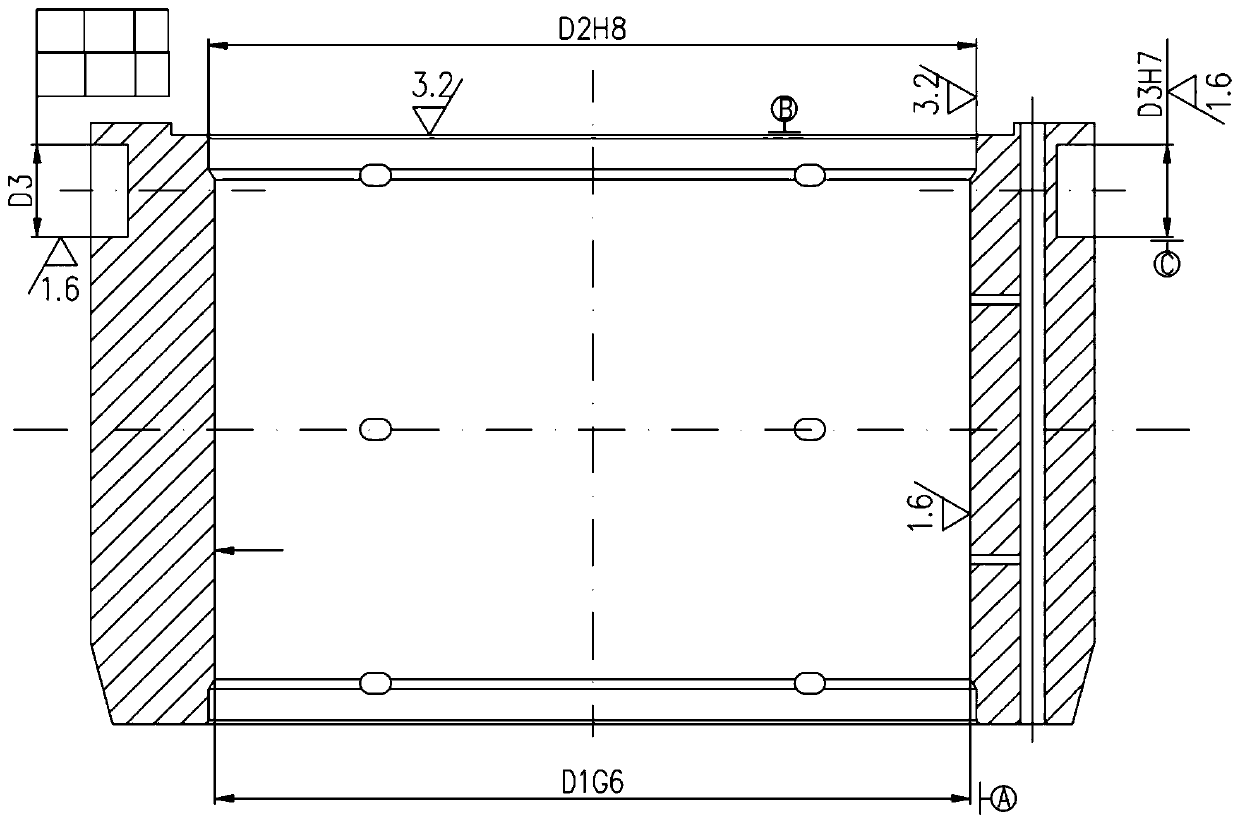

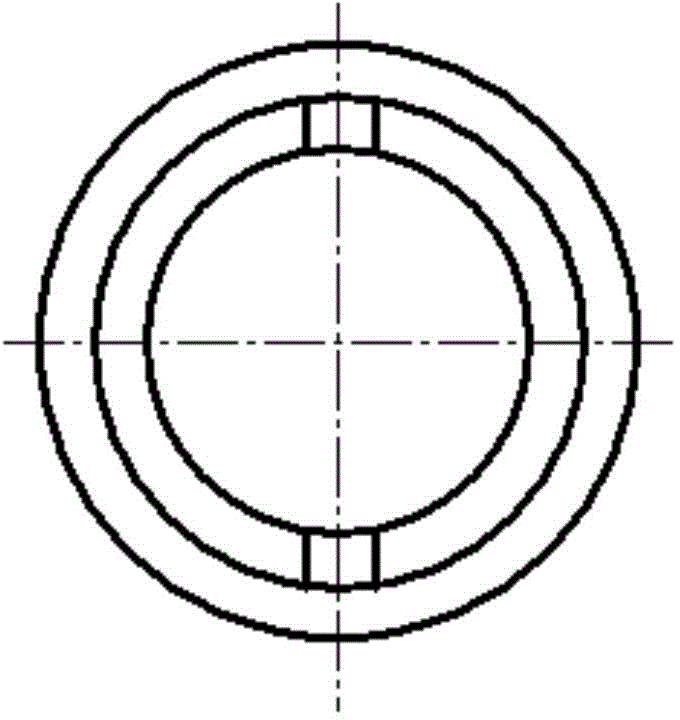

Rolling mill bearing base and manufacturing method thereof

ActiveCN109731916AMeet quick replacement requirementsAxial positioning is accurateMetal rolling stand detailsFurnace typesSurface roughnessSlide plate

The invention discloses a rolling mill bearing base and a manufacturing method thereof. The rolling mill bearing base is forged and processed from high-quality alloy steel, and is mounted at the two ends of a supporting roller of a symmetrical structure on a large rolling mill; the sliding surface which is in contact with a rolling mill memorial gate is equipped with a copper slide plate; precision of a bearing hole is G6, surface roughness of the bearing hole is Ra1.6 and cylindricity of the bearing hole is 0.03mm; precision of a bearing end cover matching hole is H8, surface roughness of thebearing end cover matching hole is Ra3.2, surface roughness of sliding surfaces at the two sides is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, flatness of an upper surface is 0.05mm, perpendicularity, to the sliding surfaces, of a lower surface is 0.2 mm, the two sliding surfaces are symmetrically equipped with dowel pin holes, precision of the dowel pin holes is H7, surface roughness of the dowel pin holes is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, and center perpendicularity to the bearing hole is 0.1 mm. An intensive lubricating system is adopted, and a ratioof hole depth to hole diameter of an oil inlet and outlet is 20 or higher. The rolling mill bearing base can meet the requirements of quickly replacing and interchanging a supporting roller, is accurate in positioning, is good in cooling and lubricating effect, is high in precision, reduces rolling mill faults, and guarantees the processing quality.

Owner:武汉钢铁有限公司

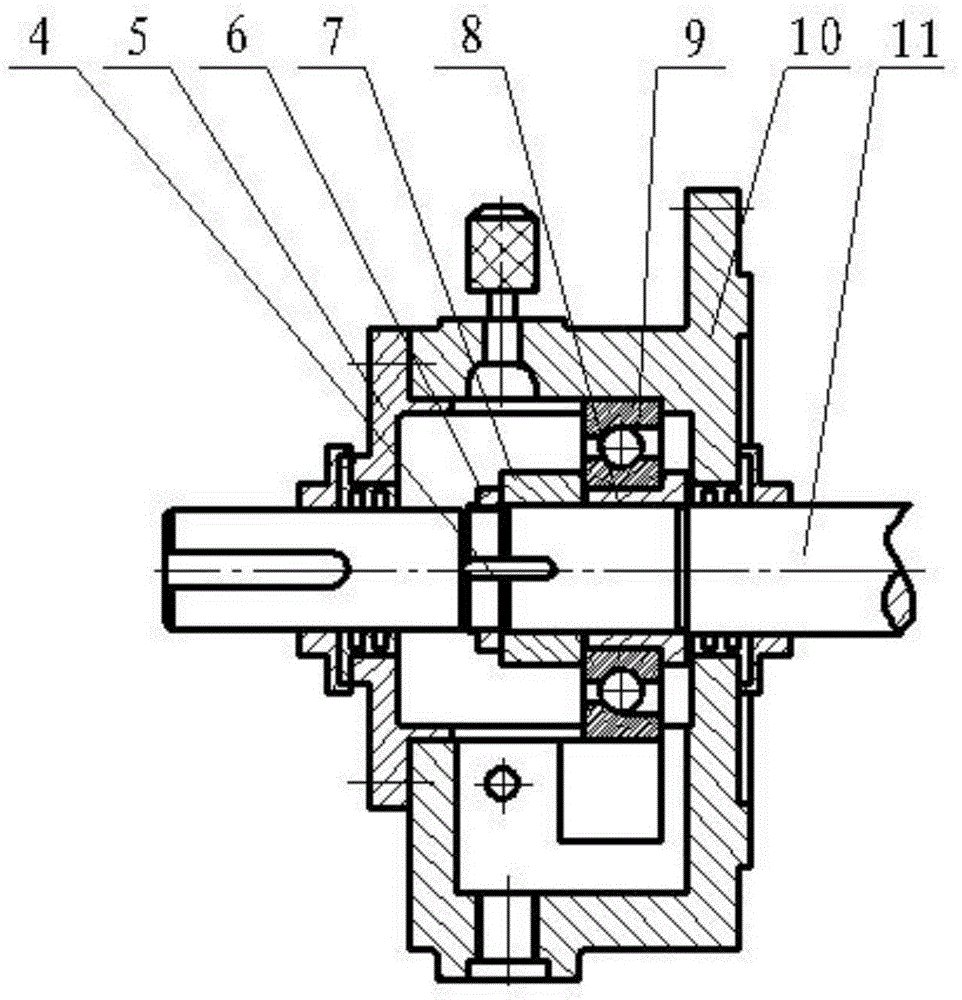

Replacing method for high-speed wire finishing mill roller box bearings

ActiveCN103447750AImprove stabilityImprove assembly efficiencyMetal working apparatusEngineeringUltimate tensile strength

The invention relates to a replacing method for high-speed wire finishing mill roller box bearings including an angular contact bearing and a roller box oil film bearing. The replacing method is characterized by including the steps: firstly, manufacturing a drawing device for the angular contact bearing; secondly, disassembling an eccentric bushing and the angular contact bearing; thirdly, manufacturing a simple press device for disassembling and assembling the oil film bearing; fourthly, disassembling the oil film bearing of the eccentric bushing on a working side; fifthly, disassembling the oil film bearing of the eccentric bushing on a transmission side; sixthly, mounting the oil film bearing; seventhly, assembling a roller shaft; eighthly, assembling the angular contact bearing; ninthly, assembling a press cover of the angular contact bearing. The assembly efficiency of a high-speed wire (preliminary) finishing mill roller box is improved, the probability of damage and scrap of assembly spare parts caused by an assembly method is reduced, the cost of the spare parts is saved, and labor intensity is reduced.

Owner:SHANGHAI BAOYE GRP CORP

Totally-closed maintenance-free threaded fitting

InactiveCN105937677APrevent extractionGuaranteed firmnessJoints with sealing surfacesEngineeringMechanical engineering

The invention belongs to the field of pipeline devices and particularly relates to a totally-closed maintenance-free threaded fitting. The totally-closed maintenance-free threaded fitting comprises a connector and a pipe body. The end of the pipe body is inserted into the connector, a stop opening is formed in the end of the connector, a sealing ring is arranged in the stop opening, the pipe body is sleeved with a locking ring, the sealing ring is sealed in the stop opening through the locking ring, a retreat stopping structure for preventing the pipe body from being pulled out of the connector is arranged on the inner side of the locking ring, the retreat stopping structure is composed of at least two parallel annular protrusions, the locking ring is installed on the connector through a pressing cap, the pressing cap is in threaded connection with the connector, a set of matched conical faces are arranged on the outer side of the locking ring and the inner side of the pressing cap, the locking ring is provided with a notch and an incision, and the notch and the incision are symmetrically formed. Detachable design is adopted, frequent disassembly and assembly can be achieved after connection, the fitting cannot be damaged in the maintenance or redirection process, and therefore the maintenance cost is reduced.

Owner:张超

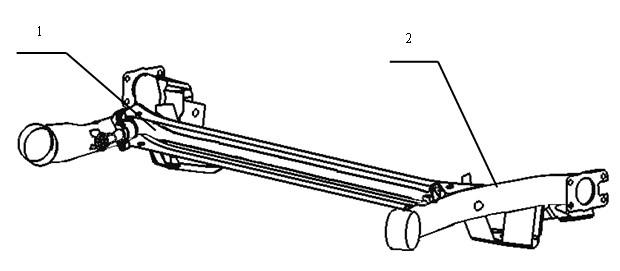

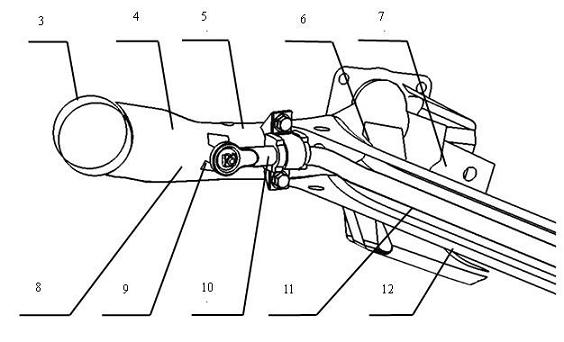

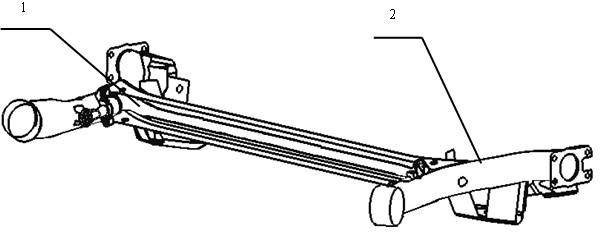

Back torsion beam suspension frame structure

InactiveCN102358136AChange roll stiffnessLight in massInterconnection systemsEconomic benefitsEngineering

The invention discloses a back torsion beam suspension frame structure, which comprises a left longitudinal beam (4), a right longitudinal beam (4), a transverse beam (12), a lining casing (3), a vibration damper installation bracket (6) and a spring installation bracket (7), and is characterized in that: a transverse stabilizer rod (11) is arranged on a hollow part of the transverse beam (12), and is fixed on the left and right longitudinal beams (4) through left and right side brackets. A replaceable stabilizer rod is arranged on a back torsion beam suspension frame, so that the structures of components such as the transverse beam and the like are optimized, the total weight of the suspension frame is reduced, and the economic efficiency of an entire vehicle is realized. The back suspension frame is general, so that spare part cost of the same platform car type on the market is lowered, and better economic benefit is achieved. The entire stabilizer rod is hidden inside the transverse beam, so that the arrangement space of the back suspension frame is not influenced on the whole, the structure is simple and practical, and convenience is brought to implementation.

Owner:CHERY AUTOMOBILE CO LTD

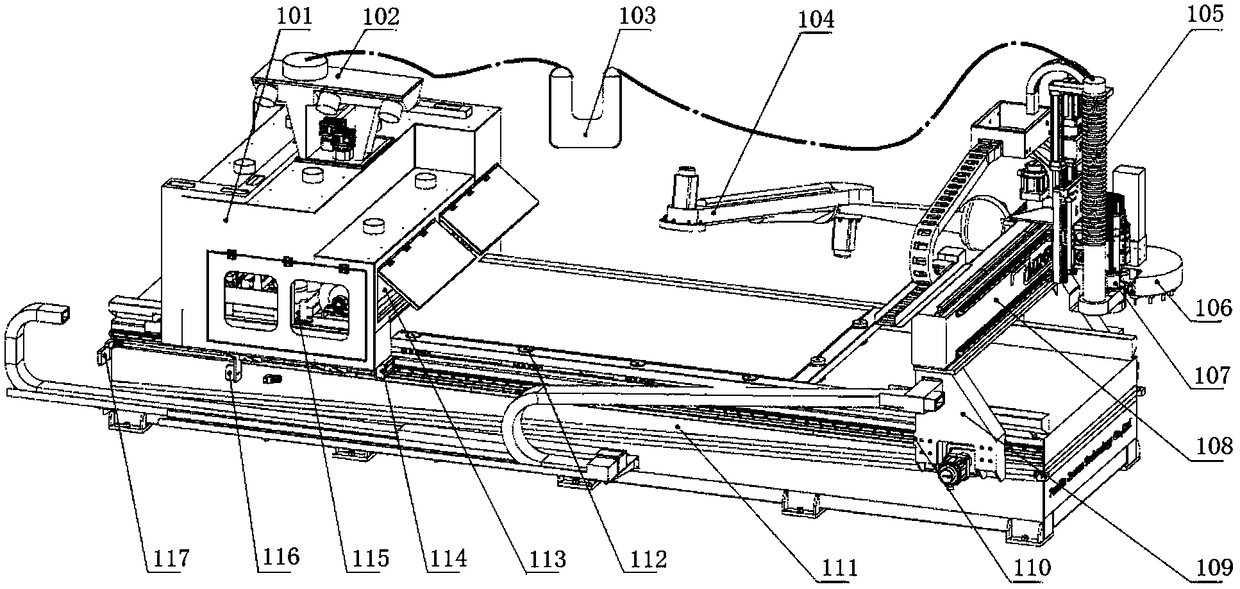

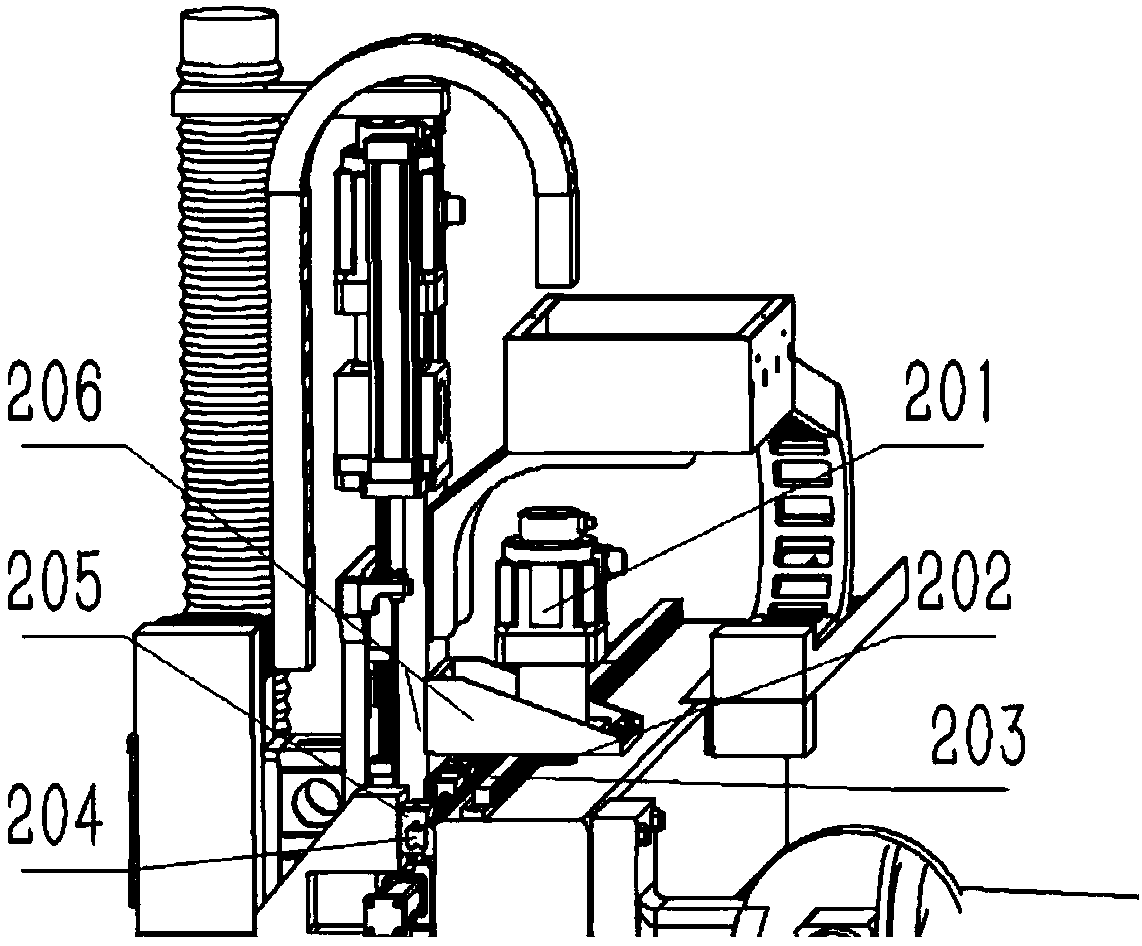

Numerical control engraving sanding composite machining center

PendingCN108481984ASimple processImprove work efficiencyGrinding drivesGrinding machinesNumerical controlWood machining

The invention relates to the technical field of automatic tool changing numerical control machining, in particular to automatic tool changing numerical control machining integrated with carpentry plate cutting, engraving and sanding, and particularly discloses a numerical control engraving sanding composite machining center. The numerical control engraving sanding composite machining center mainlycomprises a sanding machine main device, a dust collector, a mechanical arm feeding and discharging device, a cross beam, a tool changer, a spindle, a side plate, an attraction electromagnet fixing plate, a lathe bed, an attraction electromagnet, a large sand roller, a small sand disc, a sucking disc electromagnet, a suction disc electromagnet fixing plate and the like. The defects that in the prior art, the automatic tool changing numerical control wood machining process is complex in procedure, low in work efficiency, high in equipment purchasing cost and the like are overcome, and the aimsthat one machine has multiple functions, the procedure is simplified, the work efficiency is improved, machining is precise, and equipment purchasing cost is saved are achieved.

Owner:盘锦智人科技有限公司

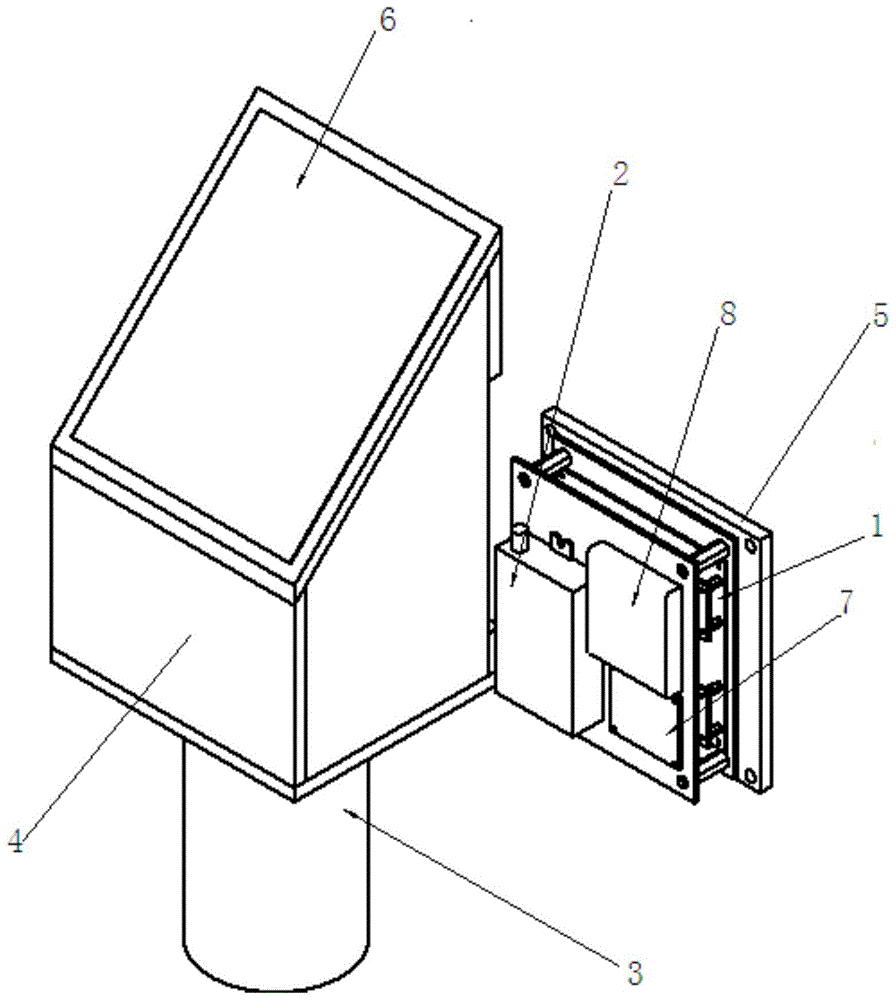

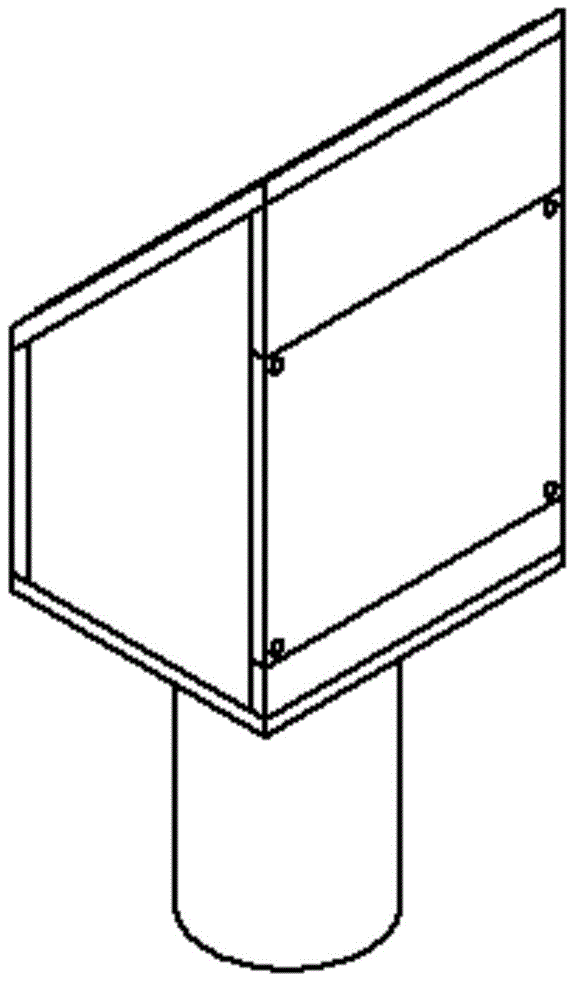

Field monitoring pile for geological disasters of pipeline

ActiveCN105090752AReduce volumeReduce the risk of theftPipeline systemsWireless transmissionData acquisition

The invention discloses a field monitoring pile for geological disasters of a pipeline. A solar panel is directly embedded and fixed on a top plate through an embedding groove; a data acquisition nodule, a solar controller, a storage battery and a wireless transmission module are all distributed on a back plate in a concentrated and upper-down layering manner; the back plate is arranged on a rear plate; the data acquisition module, the solar controller, the storage battery and the wireless transmission module are all positioned in a casing of the monitoring pile and are sealed. The field monitoring pile disclosed by the invention has the advantages of good performance, waterproof and dustproof capabilities, convenience in transportation and maintenance, high flexibility, low energy consumption and low cost; firstly, due to small size and light weight, the transportation cost of the device is reduced; secondly, a bracket needs no special customized processing, so that the cost of accessories is reduced; the solar panel adopts an embedding form, so that the mounting and fixing expenses of the solar panel are reduced.

Owner:北京科力华安地质灾害监测技术有限公司

Brake clutching device used for rear brake of automobile

InactiveCN104228788AImprove braking performanceShorter braking distanceBraking element arrangementsMechanical braking transmissionEngineeringMechanical engineering

The invention provides a brake clutching device used for a rear brake of an automobile, and belongs to the technical field of automobile braking equipment and the brake clutching device is used for improving the braking effect. The technical scheme is as follows: a gear brake disc, a gear brake pad, a releasing electromagnet and a suction electromagnet are mounted on half shafts on two sides of the automobile respectively; the gear brake disc is opposite to one side of the gear brake pad and a disc surface is engaged with a fluted disc on the disc surface; the suction electromagnet is fixedly connected onto the gear brake disc; the releasing electromagnet sleeves the half shaft on the other side of the gear brake pad. In a braking process, the gear brake pad is engaged with the gear brake disc and the power of the half shafts is transmitted to a braking gear through the gear brake disc so that a braking pull rod drives a U-shaped brake plate to brake. The brake clutching device does not generate a slipping phenomenon so that the brake clutching is very tight and reliable and the braking effect of a rear brake device of the automobile is greatly increased. The brake clutching device is simple in structure, convenient to mount, good and reliable in use effect and low in cost, and is particularly suitable for being mounted and used on the rear brake device of the automobile.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

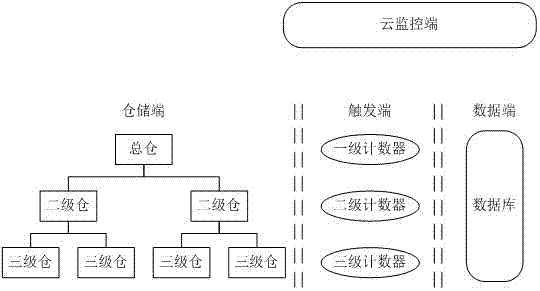

Automatic ratio monitoring-based spare part stock early warning system

InactiveCN107169140ARealize rational managementAccurate early warning effectDatabase queryingLogisticsEarly warning systemLower limit

The invention discloses an automatic ratio monitoring-based spare part stock early warning system. The system comprises a storage end, a triggering end, a data end and a cloud monitoring end; the triggering end sets a corresponding counter for a warehouse of each level, the counter is triggered when a spare part state of each warehouse is changed, and a data change value is sent to the data end; and the cloud monitoring end receives spare part quantity and state of each spare part in the warehouse from the data end, and sends an early warning signal to the storage end when a spare part ratio of any warehouse exceeds an upper limit or a lower limit. Early warning parameters are generated directly according to spare part stock ratios of each warehouse of each level and lower-level warehouses of each warehouse of each level. The use replacement speeds of different warehouses are more accurate and adapted, so that corresponding more standby spare parts can be provided for the warehouse with higher spare part usage rate. The cloud monitoring end not only can monitor the spare part ratios according to the levels but also can monitor the ratio condition of the specific warehouse, and fully considers the conditions of the spare parts of the lower-level warehouses.

Owner:广州智萃电子科技有限公司

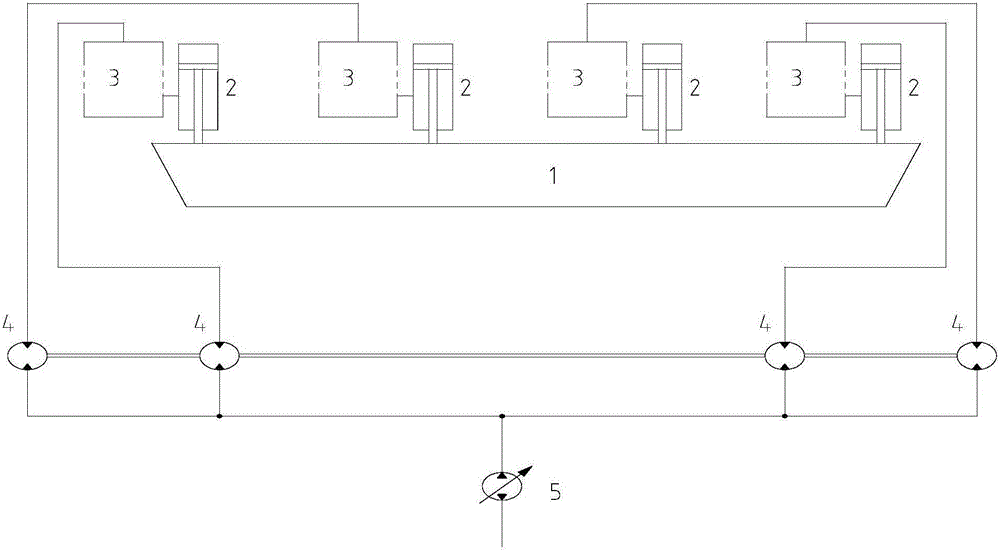

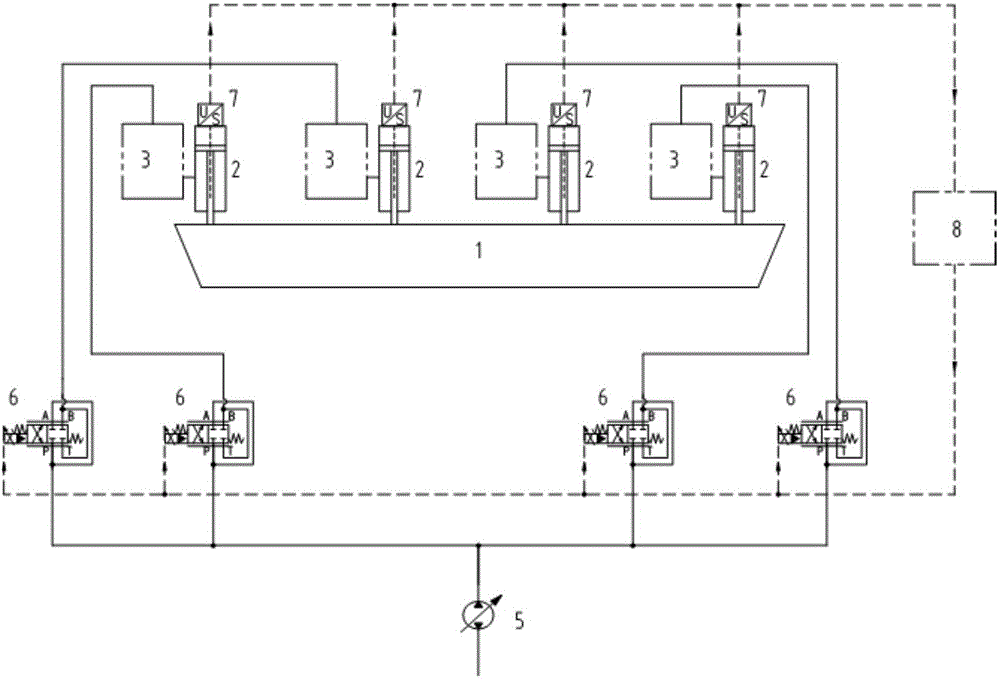

Novel steel ladle lifting synchronous control system

InactiveCN105020192AMeet various control requirements for synchronous operationEasy maintenanceServomotor componentsServomotorsHydraulic cylinderAutomatic control

The invention discloses a novel steel ladle lifting synchronous control system. The novel steel ladle lifting synchronous control system comprises four steel ladle lifting hydraulic cylinders, position locking devices, proportional valves, a hydraulic main pump, position detection devices and synchronous electric control devices, wherein the four steel ladle lifting hydraulic cylinders are arranged on a steel ladle, the position locking devices and the proportional valves are connected with the steel ladle lifting hydraulic cylinders respectively, the hydraulic main pump is connected with the four proportional valves, the position detection devices are mounted on the steel ladle lifting hydraulic cylinders respectively, and the synchronous electric control devices are connected with the position detection devices and the proportional valves. The steel ladle is synchronously lifted through the four steel ladle lifting hydraulic cylinders. The lifting position of the steel ladle is controlled through the proportional valves. The position of the steel ladle is detected in real time through the position detection devices. The synchronous electric control devices can independently control the opening degrees of the corresponding proportional valves in real time according to actual values fed back by the position detection devices and automatically control the flow flowing to the steel ladle lifting hydraulic cylinders from the hydraulic main pump through the proportional valves, and thus it is guaranteed that the steel ladle is lifted synchronously. According to the novel steel ladle lifting synchronous control system, the synchronous lifting control function that four lifting hydraulic cylinders are controlled through existing large-flow synchronous motors connected in parallel is replaced with the function that the lifting hydraulic cylinders are independently controlled through the proportional valves, and accordingly the defects in the prior art are overcome.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

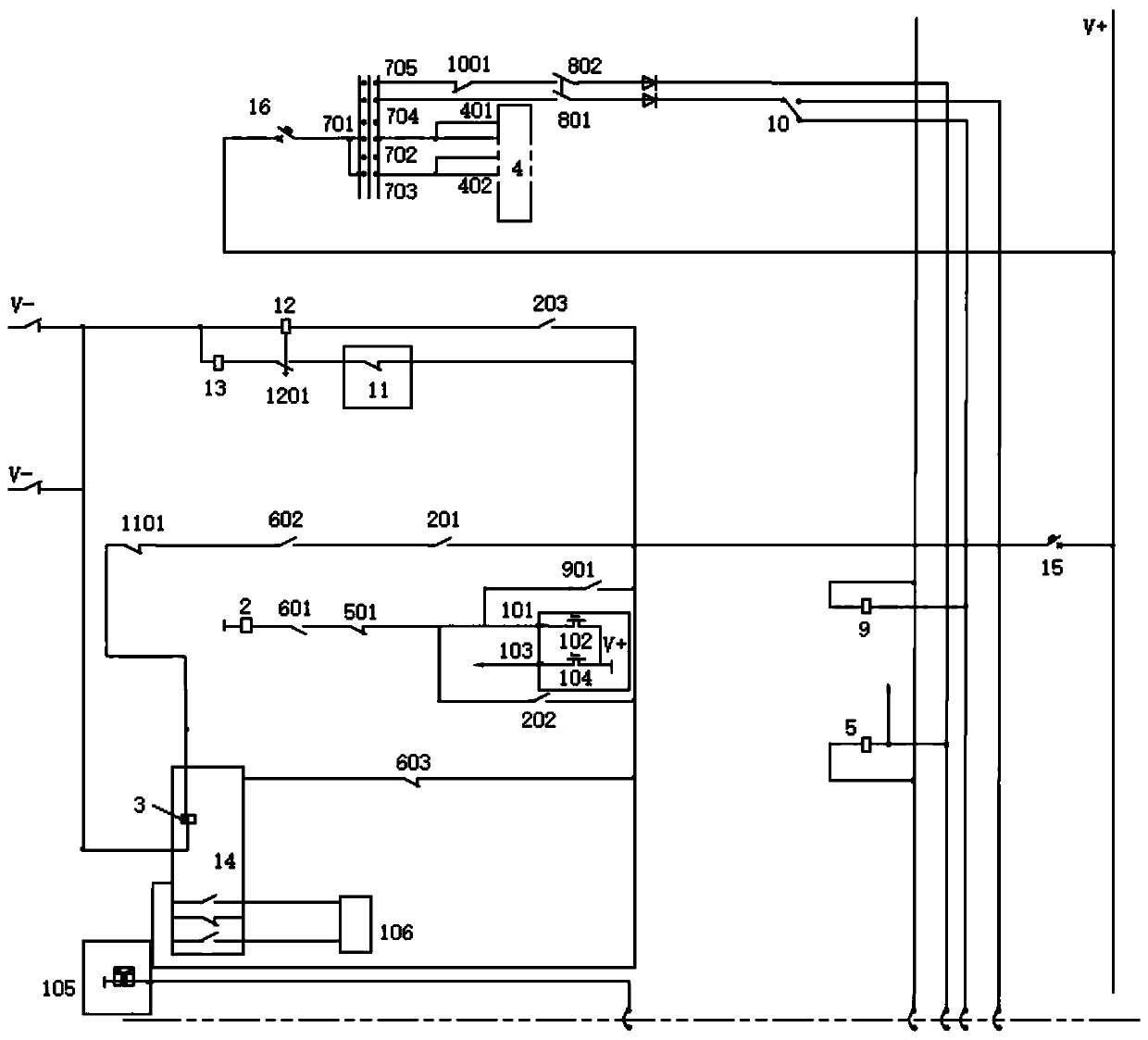

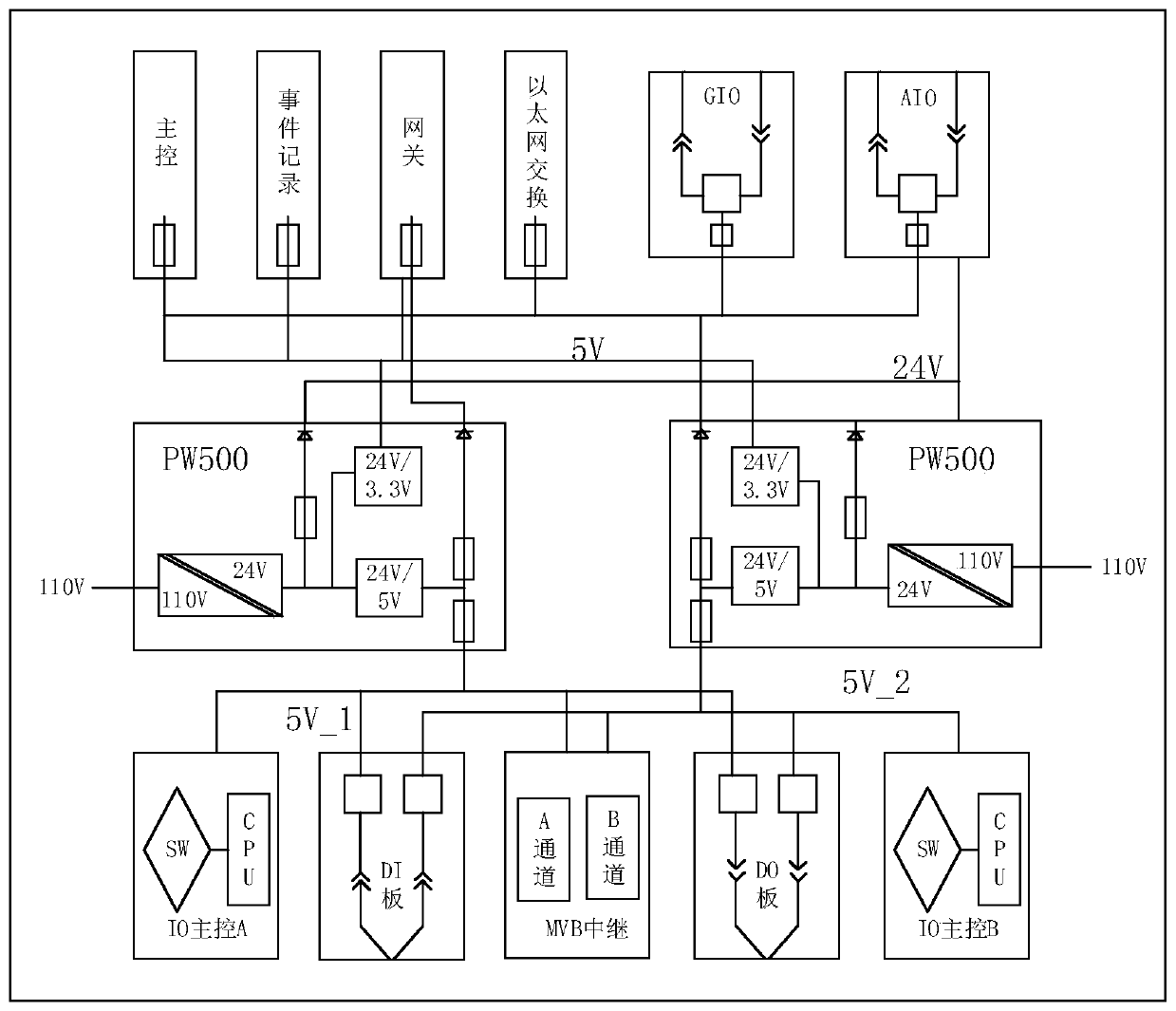

Train pantograph logical intelligent control system based on intelligent control units

ActiveCN110525224ASave the cost of design and operation modificationReduce post-maintenance costsProgramme control in sequence/logic controllersPower current collectorsRelay logicElectronic switch

The invention provides a train pantograph logical intelligent control system based on intelligent control units. The train pantograph logical intelligent control system based on the intelligent control units comprises the intelligent control units, a pantograph rising execution relay, a pantograph rising electromagnetic valve and a train network unit. After the intelligent control units receive apantograph rising instruction sent by the train network unit, the intelligent control units control a first electronic switch to close, the pantograph rising execution relay is electrified, a first contact point of the pantograph rising execution relay is closed, the pantograph rising electromagnetic valve is electrified, and a pantograph rises. The train pantograph logical intelligent control system based on the intelligent control units realizes control for the pantograph by using the intelligent control units of an LCU (logic control unit) and the like as a control core, solves the problemsthat an existing D-series high-speed train set relay logical control circuit is complex, contact points are abnormally adhered together, a circuit board is burnt and the like at present, saves designand use remolding, late maintenance and spare part cost, improves reliability and realizes circuit simplification for the high-speed train set logical control circuit, and improves late maintenance and remolding efficiency.

Owner:CRRC QINGDAO SIFANG CO LTD

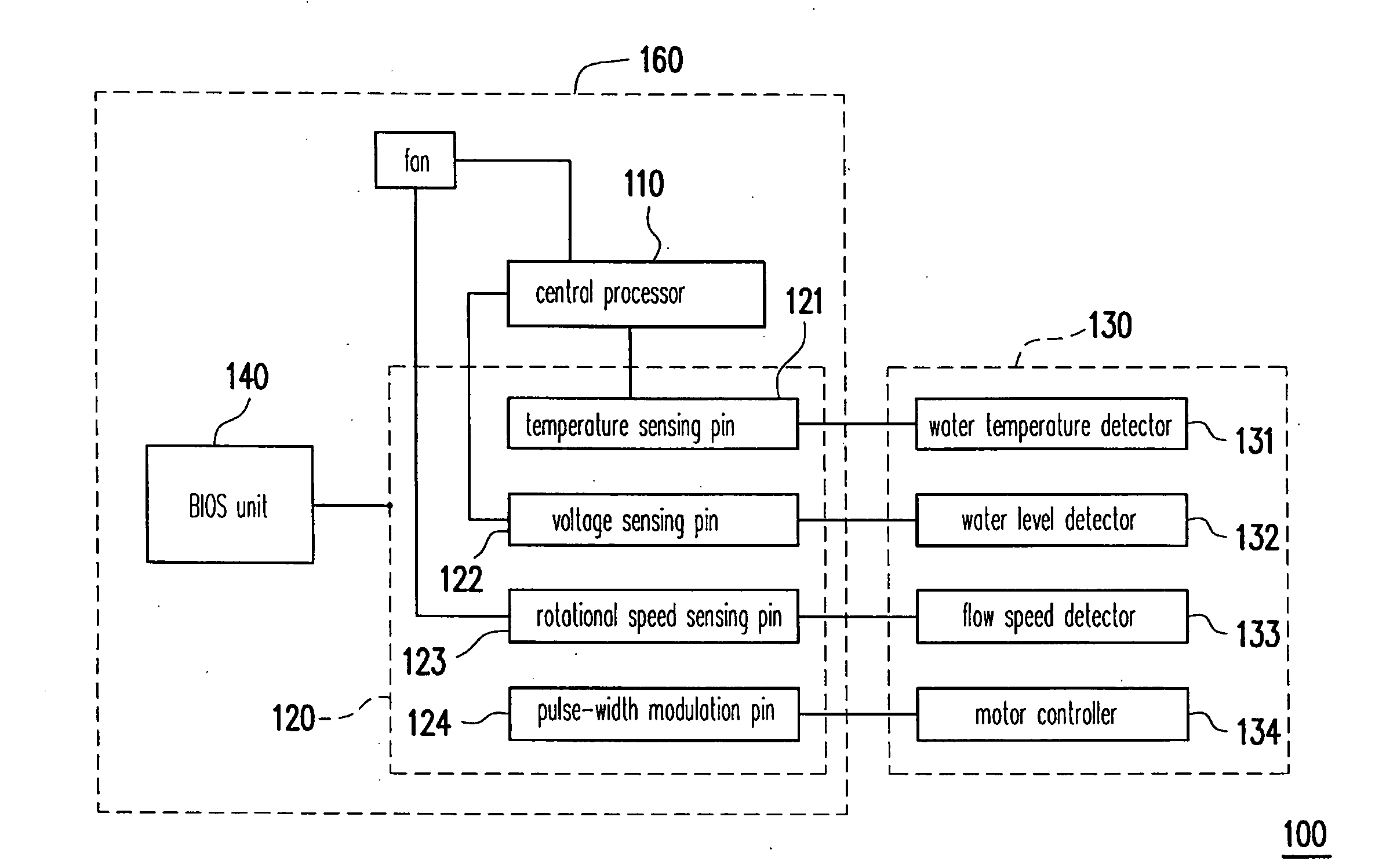

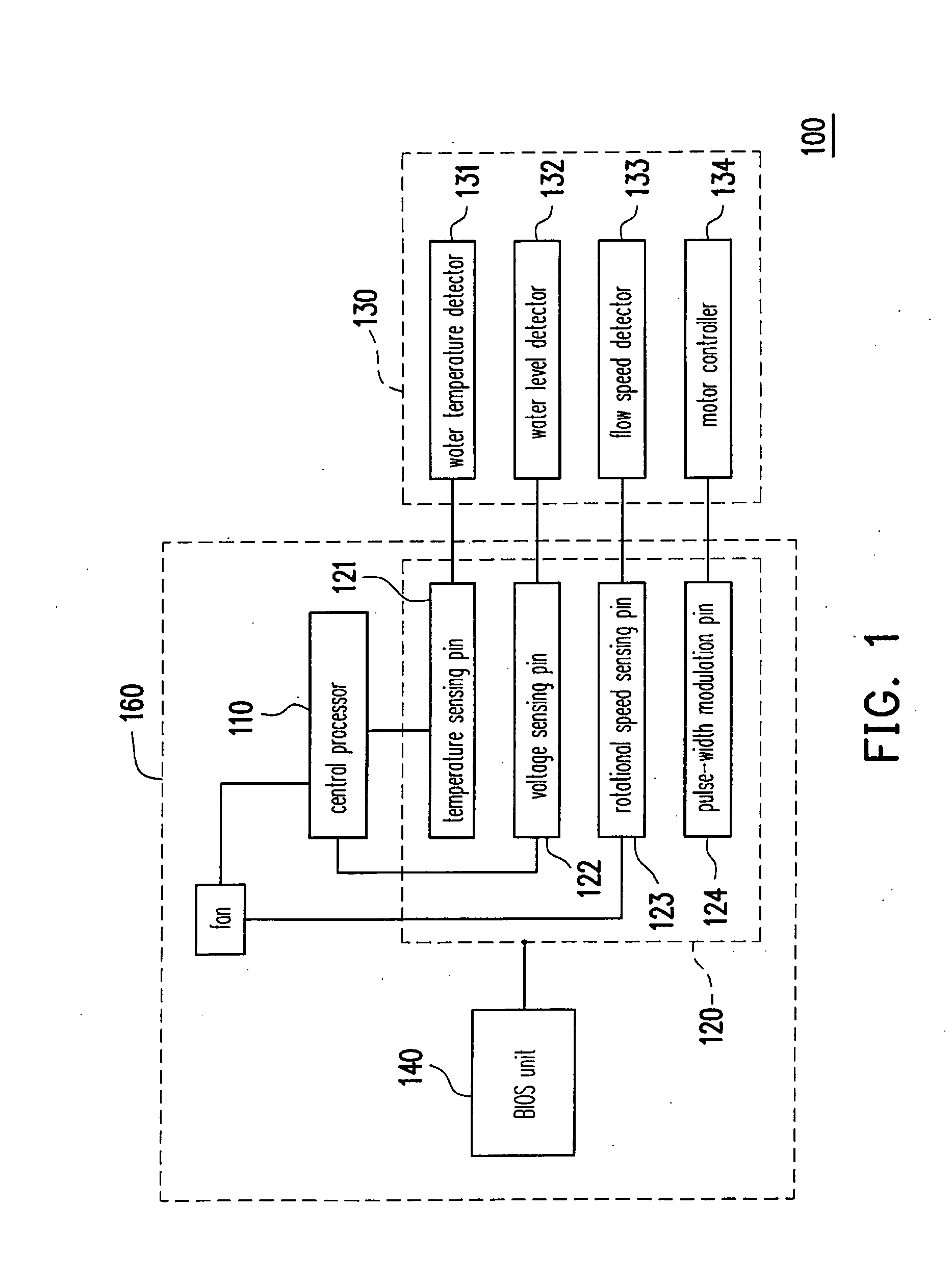

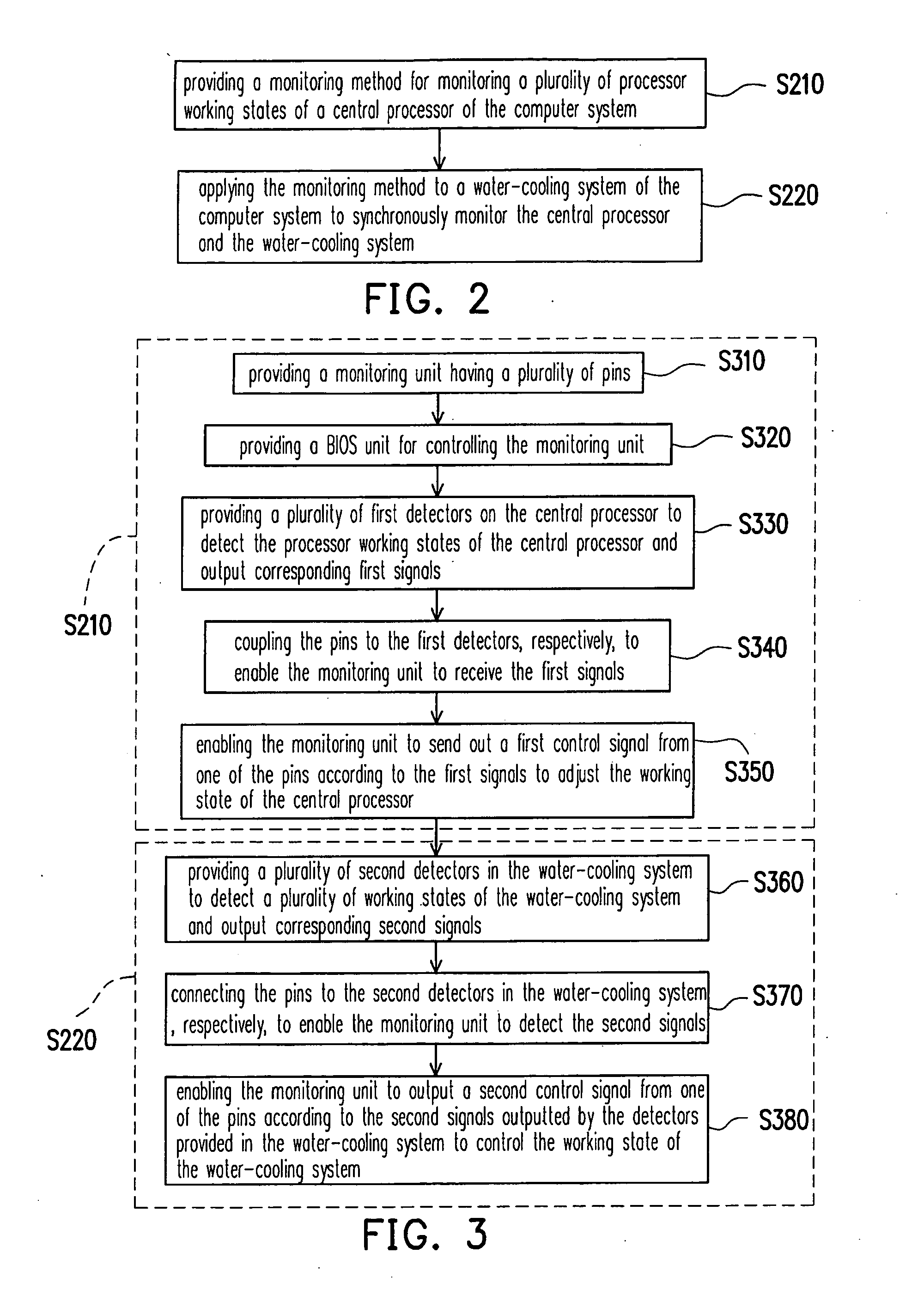

Motherboard, computer system and multi-monitoring method thereof

InactiveUS20090063841A1Inconvenient to useReduce spare parts costsDigital data processing detailsDigital computer detailsComputerized systemEngineering

A computer system includes a center processor, a monitoring unit, a water-cooling system and a basic input output system (BIOS) unit. The monitoring unit is coupled to the central processor, and it is used for monitoring a plurality of processor working states of the central processor and generating a plurality of signals. The water-cooling system is coupled to the monitoring unit, and then the monitoring unit is allowed to monitor a plurality of system working states of the water-cooling, system, wherein each of the system working states is respectively corresponding to one of the processor working states. The BIOS unit is coupled to the monitoring unit, and it is used for outputting a plurality of control commands to adjust the operation of the central processor and the water-cooling system according to the signals and the setting value of a user.

Owner:ASUSTEK COMPUTER INC

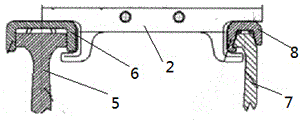

Integrated, heat-insulated and non-deformed sintering pallet device

InactiveCN104896930AReduce the impactReduce spare parts costsFurnace typesThermal insulationEngineering

The invention discloses an integrated, heat-insulated and non-deformed sintering pallet device which comprises a pallet body, a grate device, baffles, side sealing devices, side heat preservation devices and a thermal insulation mat. The grate device is mounted in a middle frame of the pallet body, the baffles are arranged at the two ends of the pallet body, the side sealing devices are mounted on the baffles, the side heat preservation devices are mounted between two pallet bodies, and the thermal insulation mat is arranged between the grate device and a pallet cross beam. The integrated, heat-insulated and non-deformed sintering pallet device can improve the burn through rate of sintering materials, reduce the manufacturing cost of grate spare parts, improve labor intensity and reduce pallet body deformation phenomena.

Owner:马春强

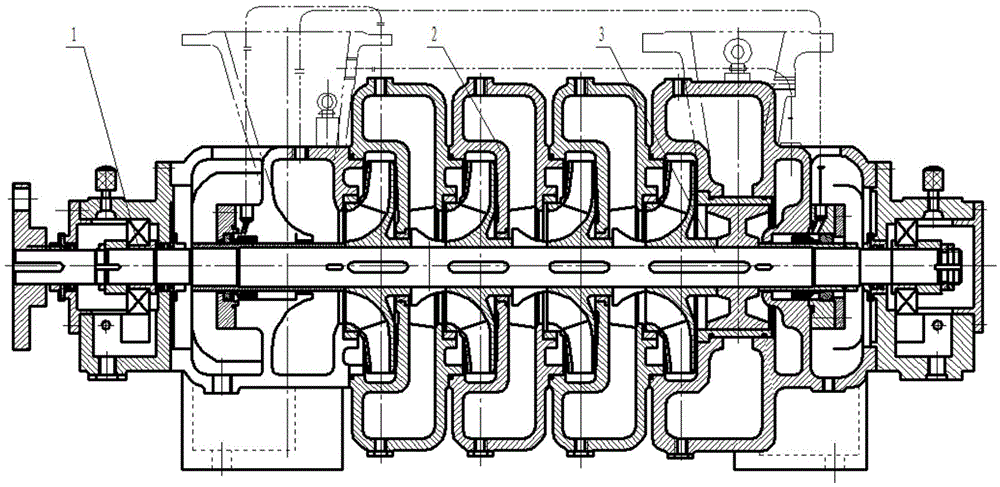

Centrifugal pump convenient to dismantle

InactiveCN103557187AExtended service lifeSo as not to damagePump componentsPumpsUser needsAgricultural engineering

The invention provides a centrifugal pump convenient to dismantle. The centrifugal pump comprises a bearing component, a pump casing and a rotor component, wherein the bearing component is connected with the rotor component; the pump casing is connected with the bearing component and the rotor component; the bearing component comprises a bearing gland, a bearing ring, a bearing sleeve, a bearing, a bearing body, a shaft and a bearing nut; the bearing is in interference connection with the bearing sleeve; the bearing sleeve is in clearance connection with the shaft; the bearing is connected with the bearing body; the bearing ring is connected with the bearing sleeve; the bearing gland is connected with the bearing body; the bearing is connected with the inner ring of the bearing body after being connected with the bearing sleeve; the bearing ring is connected with the shaft; the bearing nut is connected with the shaft and the bearing ring. According the invention, the problems that when the bearing is replaced, a user need to demount the bearing body, and after the bearing and the shaft are burnt, the user needs to dismantle the whole centrifugal pump to replace the bearing are solved; the bearing is convenient and fast to replace; the phenomenon that the shaft is scratched when the bearing is replaced is reduced, and thus the service life of the shaft is prolonged.

Owner:重庆星格泵业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com