Gaussian process modeling based wind turbine shafting state monitoring method

A wind turbine, Gaussian process technology, applied in mechanical bearing testing, sustainable buildings, climate sustainability, etc., can solve the problem of poor condition monitoring effect, inability to adapt to random changes in wind speed of wind turbines, and time-varying shaft speed and load, etc. problems, to achieve the effect of avoiding the expansion of bearing damage, avoiding damage and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

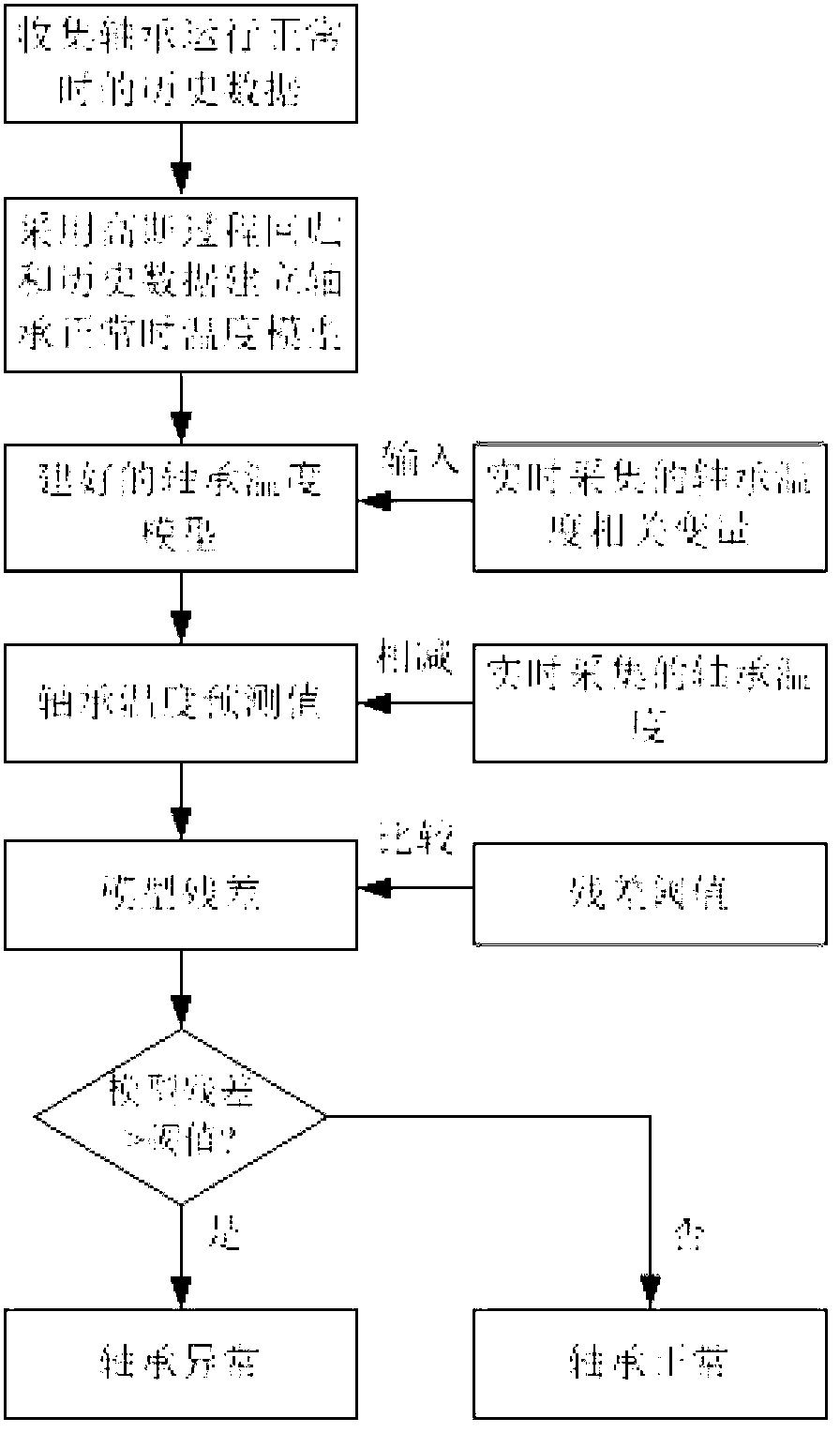

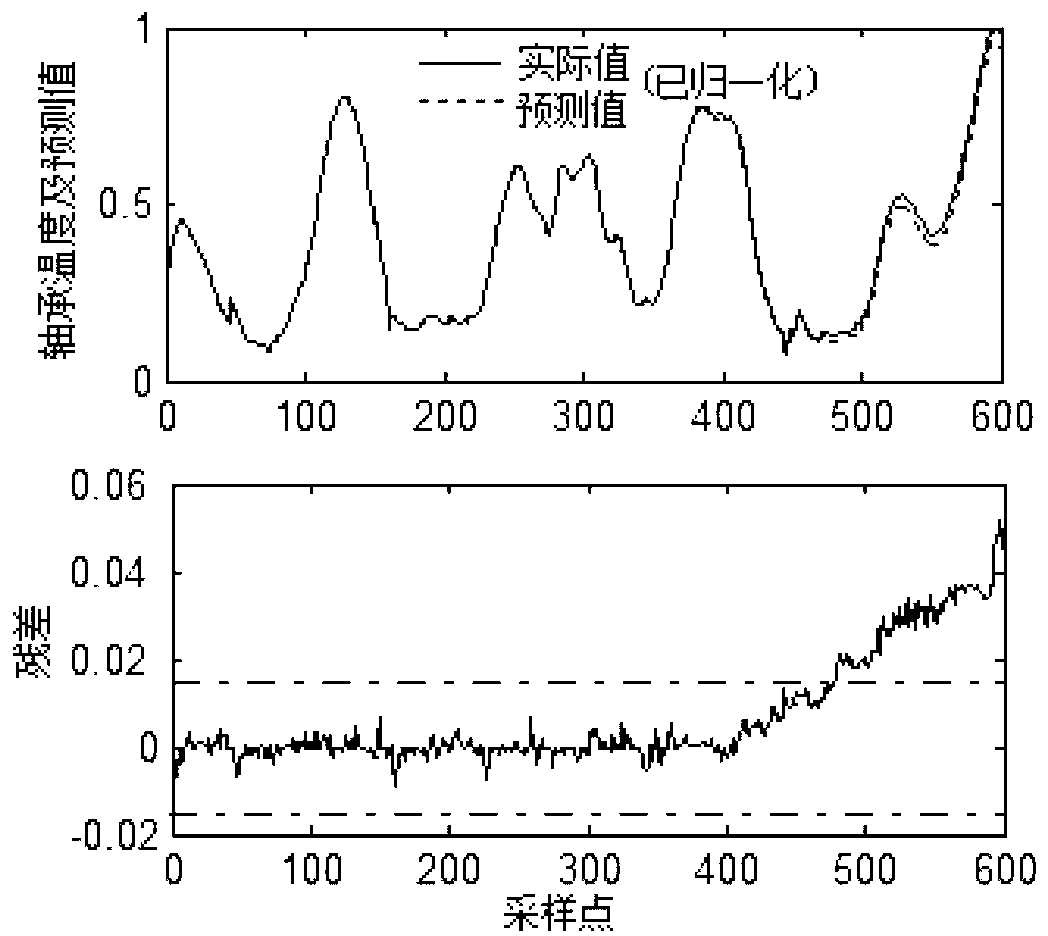

[0046] The specific implementation of the present invention is described by taking the generator bearing in the shafting as an example, which specifically includes:

[0047] (1) Collect historical data of generator bearings during normal operation to form a historical data set (X,Y)={X t ,y t |t=1,2,...,n}. Among them, the input vector X is a four-dimensional vector, It is composed of four variables: wind speed, power, ambient temperature, and the temperature of the generator bearing at the moment; the output is the generator temperature y. There are n input and output data pairs in the historical data set, that is, training samples.

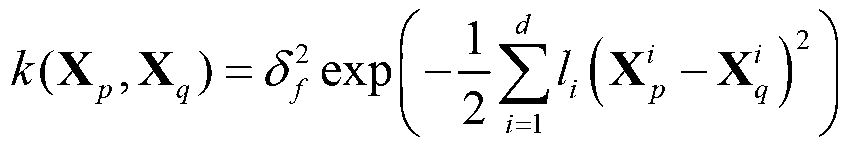

[0048] (2) Using the Gaussian process regression method and the generator bearing temperature historical data set (X,Y)={X i ,y i |i=1,2,…,n} to establish the generator bearing temperature model. First determine the covariance function as:

[0049] k ( X p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com