Cross scraper type sampler for coal transporting belt

A scraper type, sampler technology, applied in the field of mechanical devices, can solve the problems of complex coal sampling, high moisture content, variable moisture content, etc., and achieve the effects of reducing equipment spare parts costs, improving efficiency and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

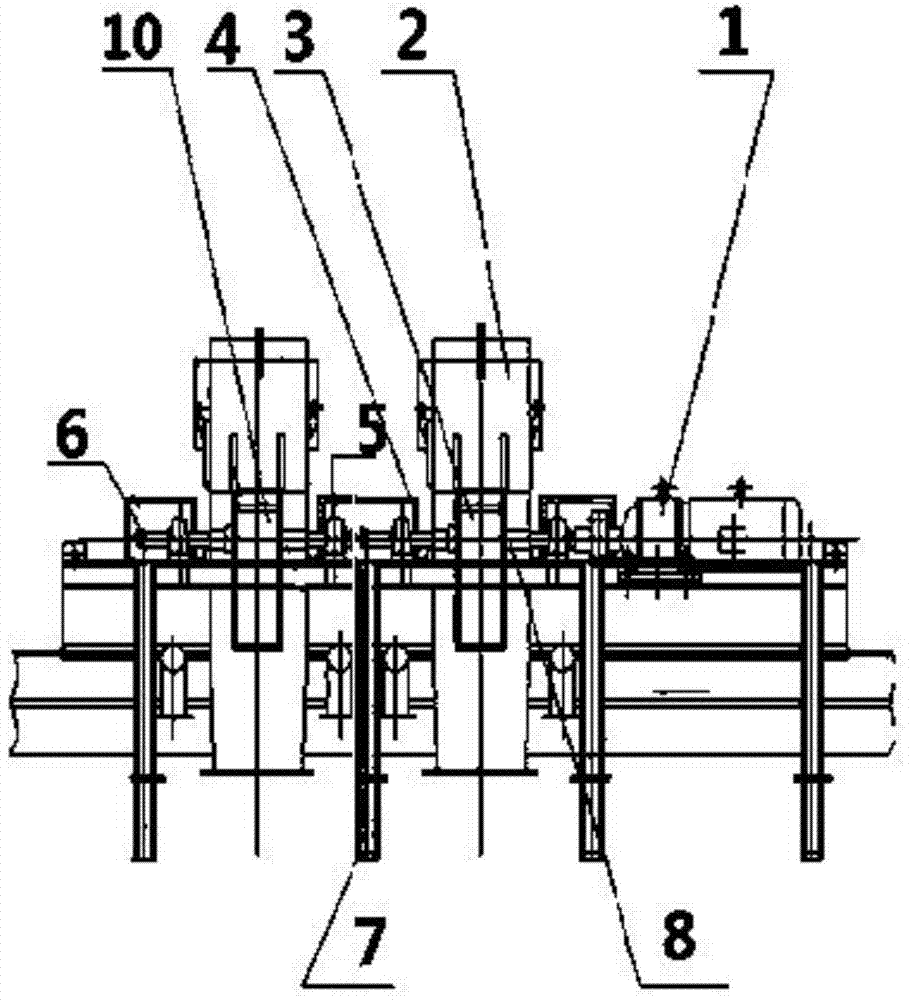

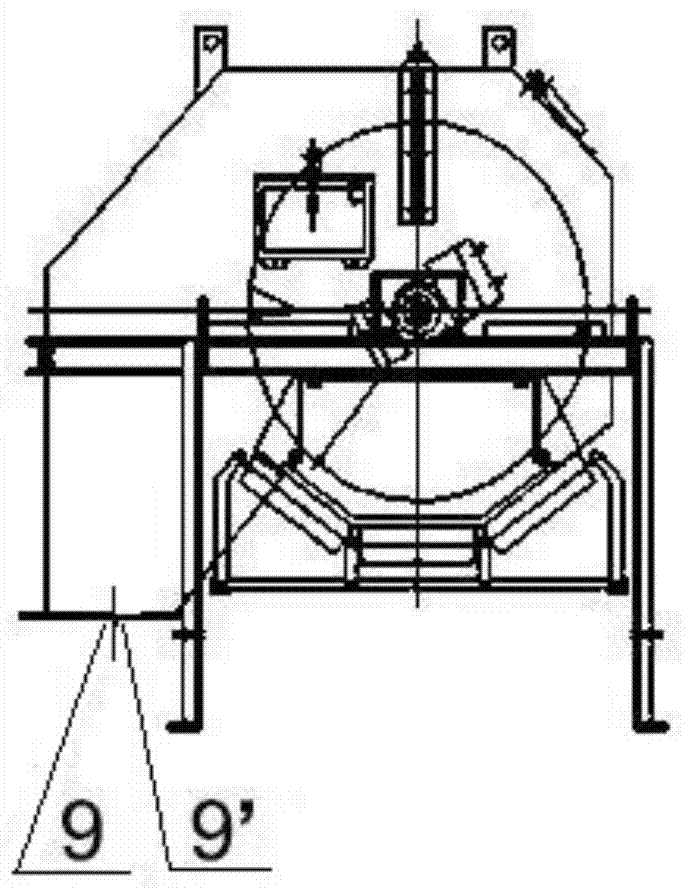

[0029] Example: such as figure 1 and 2 As shown, in this embodiment, a coal conveying belt traverses a scraper type sampler, including a geared motor 1, a rotating body 8 connected to the geared motor 1, a first sampling head 3 and a second sampling head 10 driven by the rotating body 8 , the sampling chute 9 and the sampling chute 9' corresponding to the first sampling head 3 and the second sampling head 10 respectively, the support bracket 7 for fixing all the above-mentioned equipment; wherein the support bracket 7 is provided with a proximity switch 4, the The reduction motor 1 is provided with an electromagnetic brake; the first sampling head 3 and the second sampling head 10 are connected by a plane coupling 5 with a horizontal distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com