Emergency tripping device for tundish nozzle in round billet conticaster and maintenance method of emergency tripping device

A technology of accidental cutting and continuous casting of round billets, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems such as incalculable production accidents, uncontrollable flow, corrosion of stopper rods, etc., and achieve convenient and quick use , Reduce the cost of spare parts, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

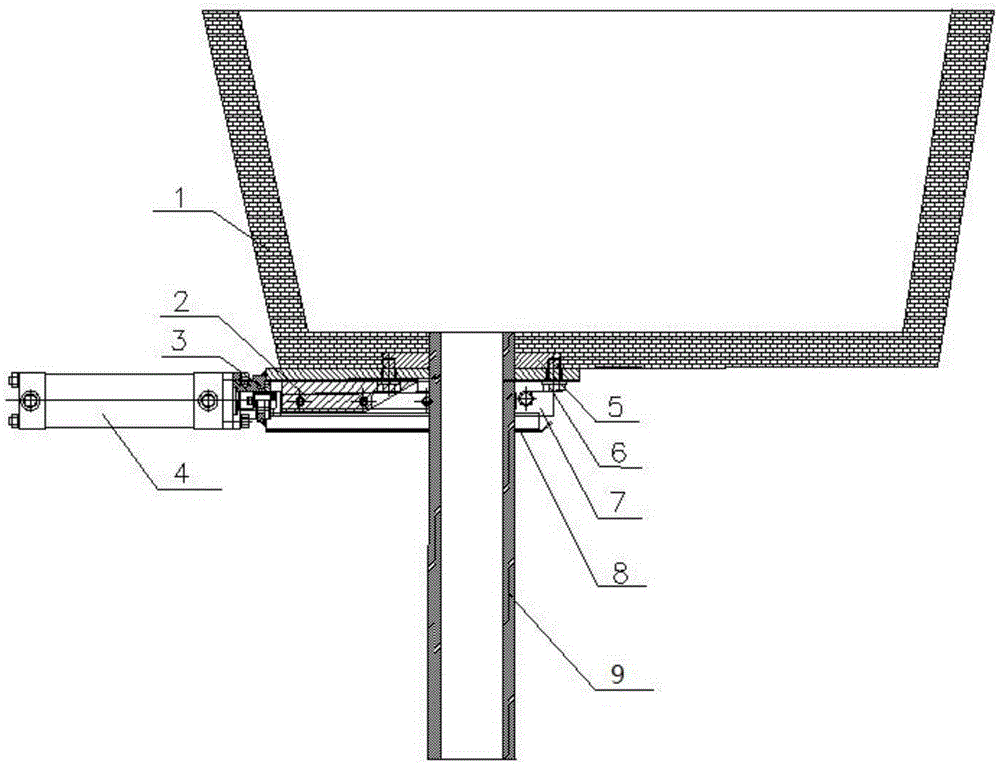

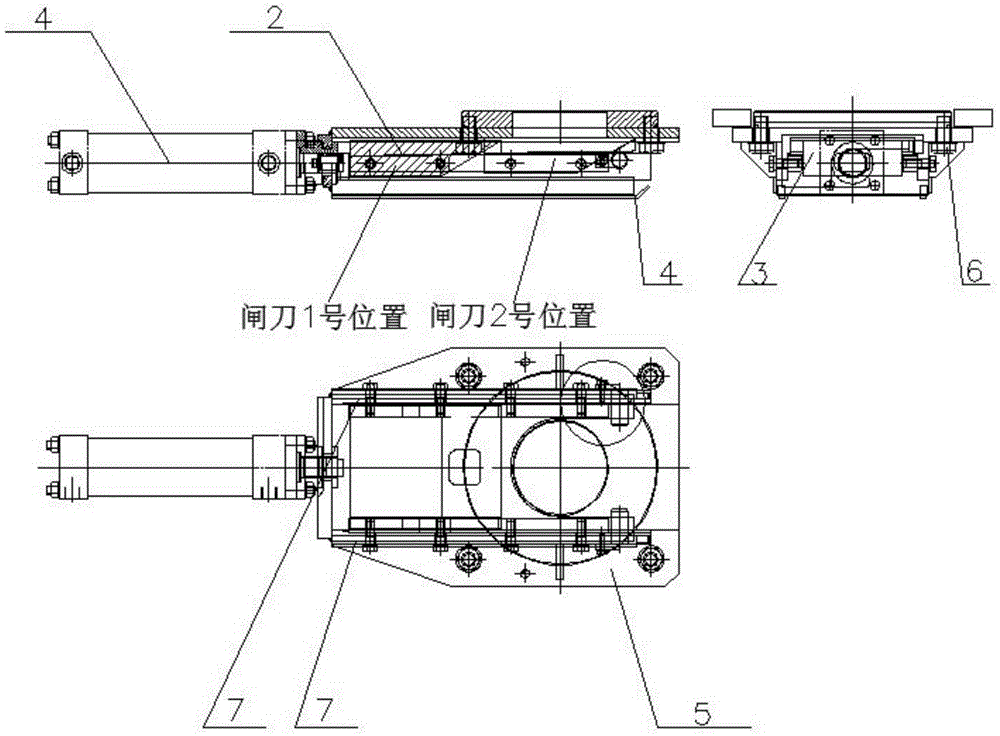

[0018] The structure diagram of an emergency cut-off device for the round billet continuous casting machine is shown in the following figure: figure 1 As shown, the device mainly includes 7 parts: including the cutting knife 2, the oil cylinder mounting plate 3, the cutting oil cylinder 4, the fixed bottom plate 5, the fixing bolt 6, the knife guide groove 7, and the protective plate 8. The whole device is installed on the tundish 1, and the tundish nozzle 9 passes through the center of the cutting device.

[0019] The fixed bottom plate 5 of the cutting device is installed on the lower bottom surface of the tundish 1 at the installation position of the tundish nozzle 9 through the fixing bolt 6, and the piston rod of the driving cylinder 4 is used to push the cutting knife 2 along the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com