Patents

Literature

75results about How to "Axial positioning is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

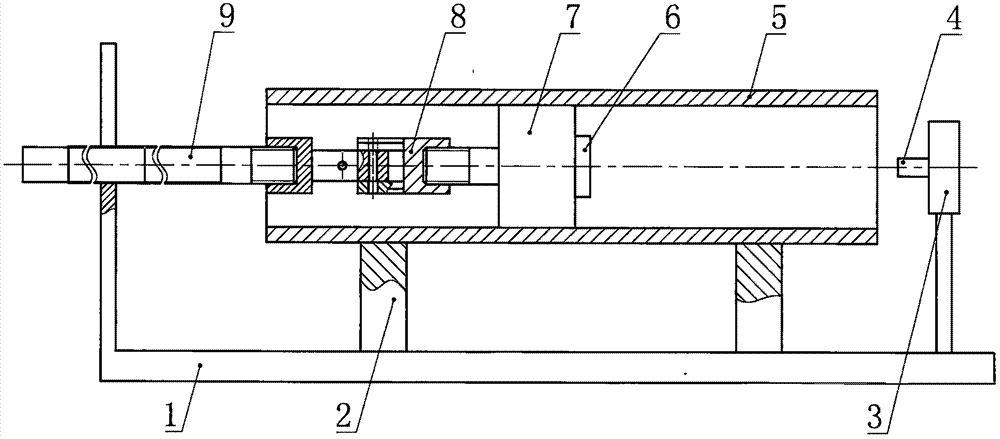

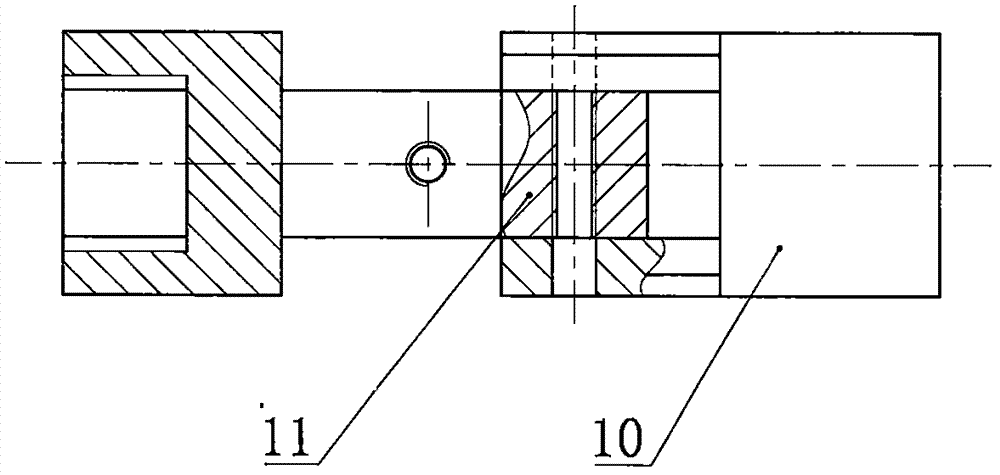

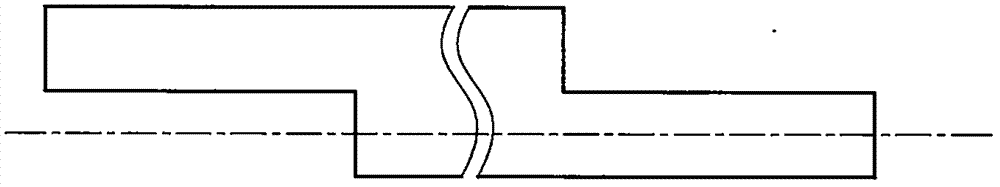

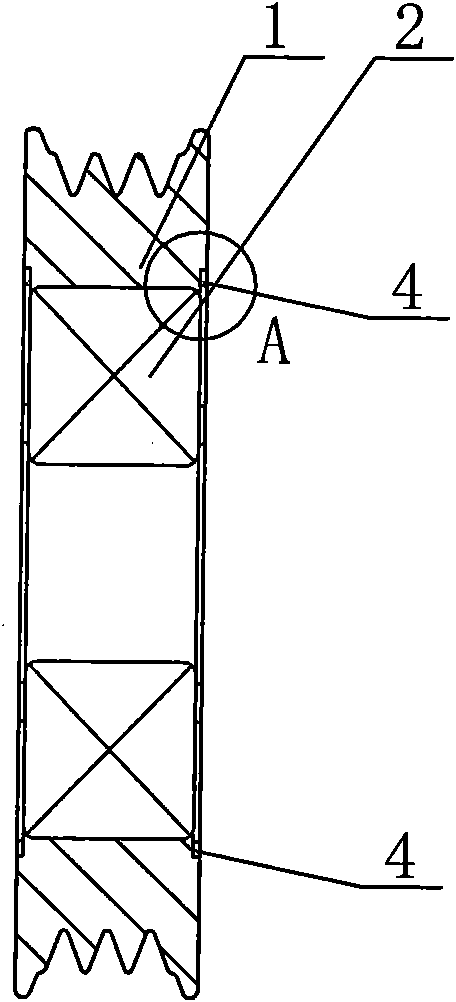

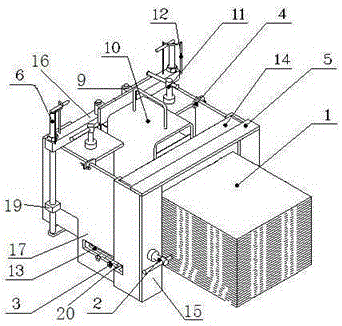

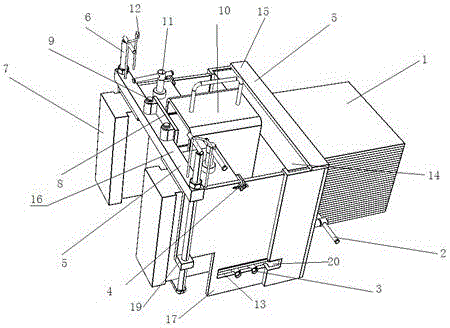

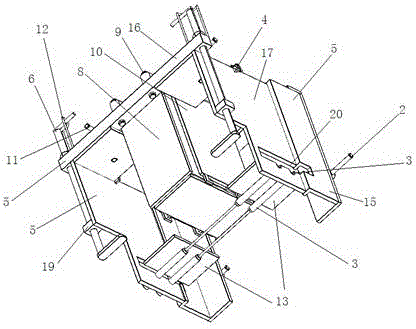

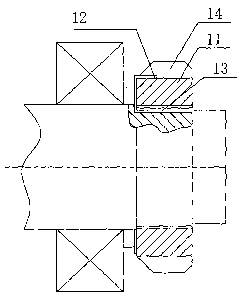

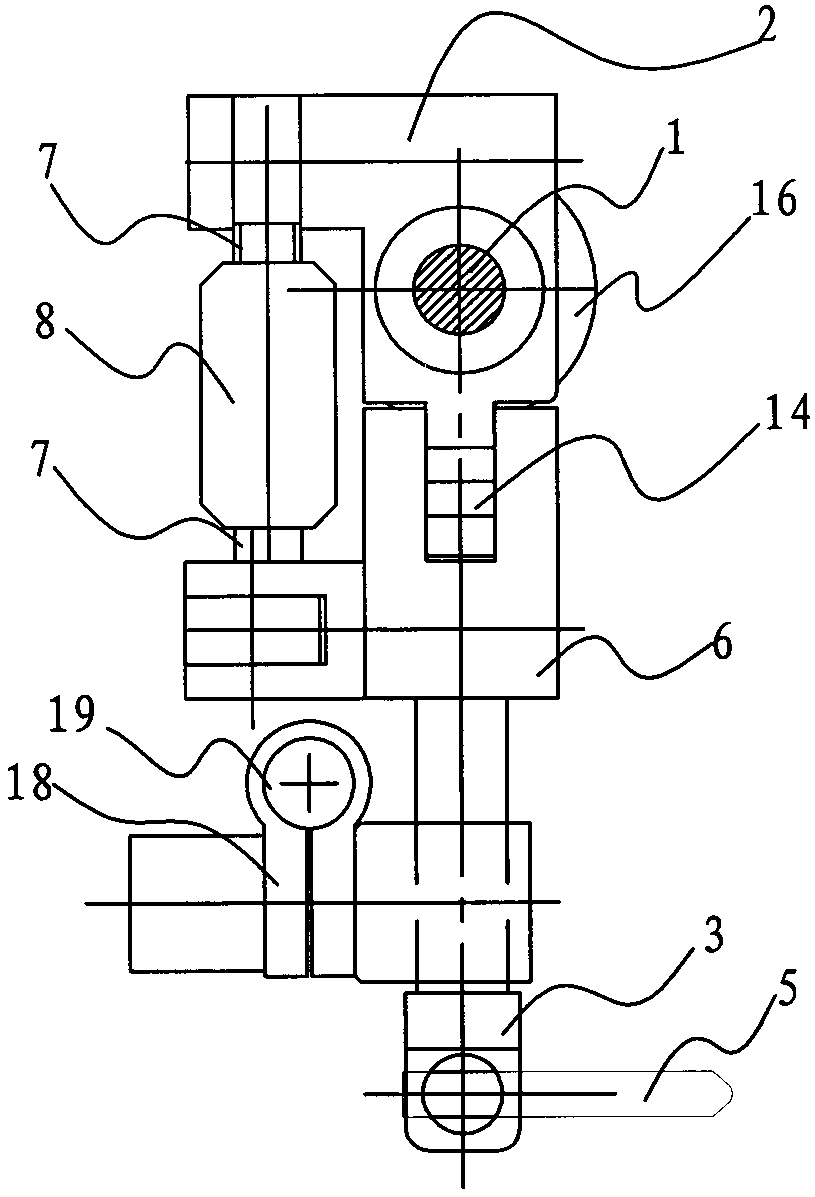

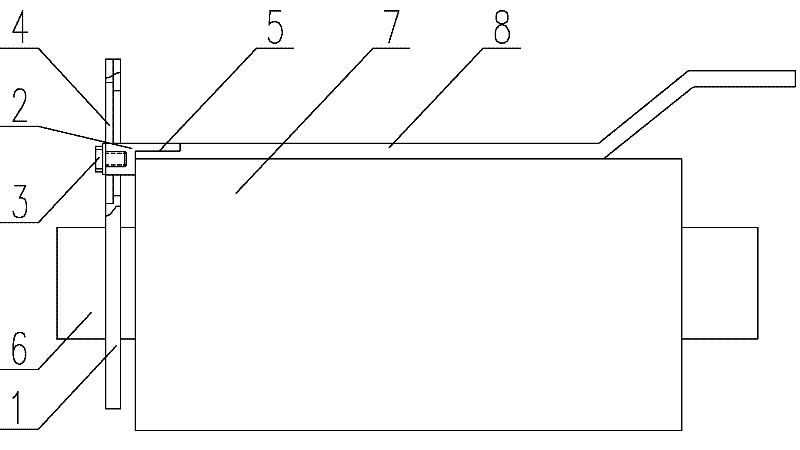

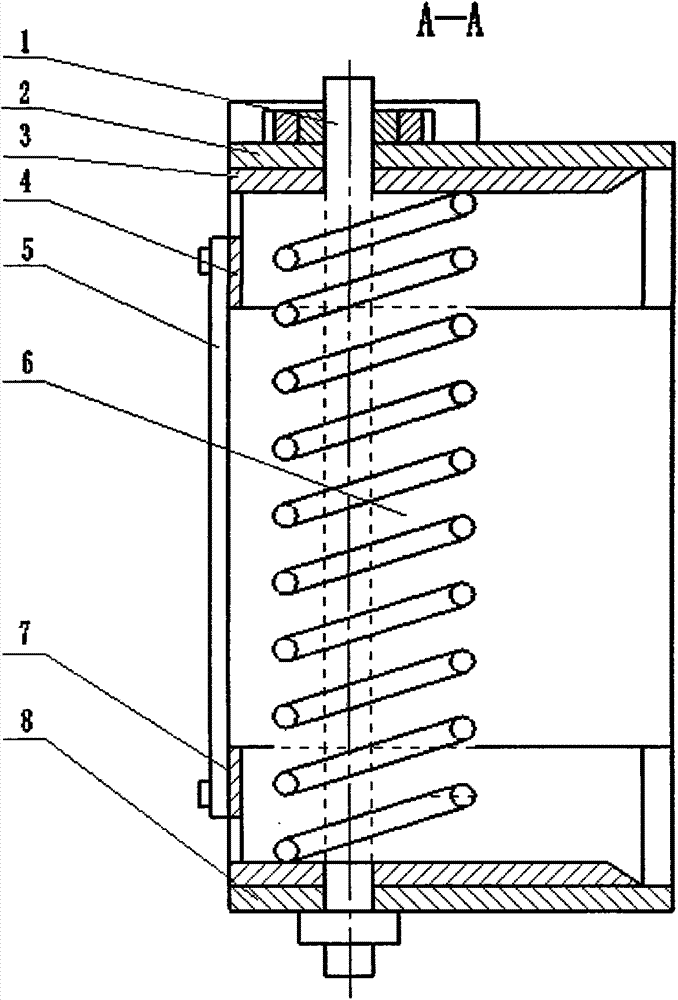

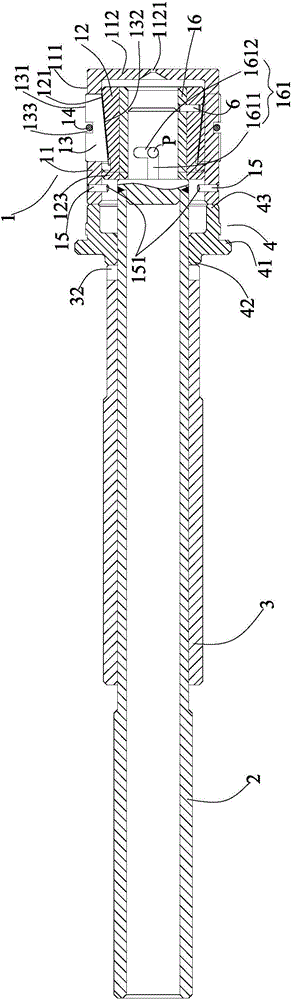

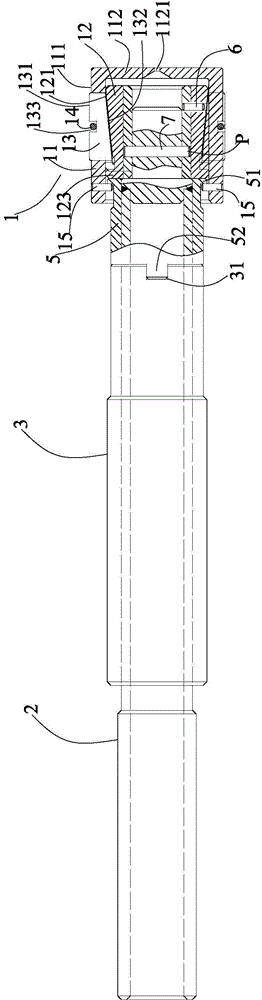

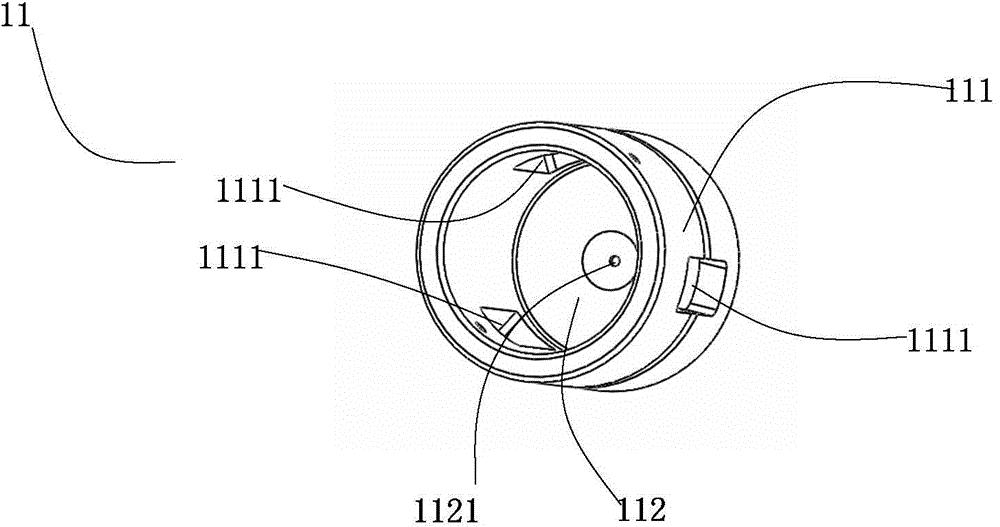

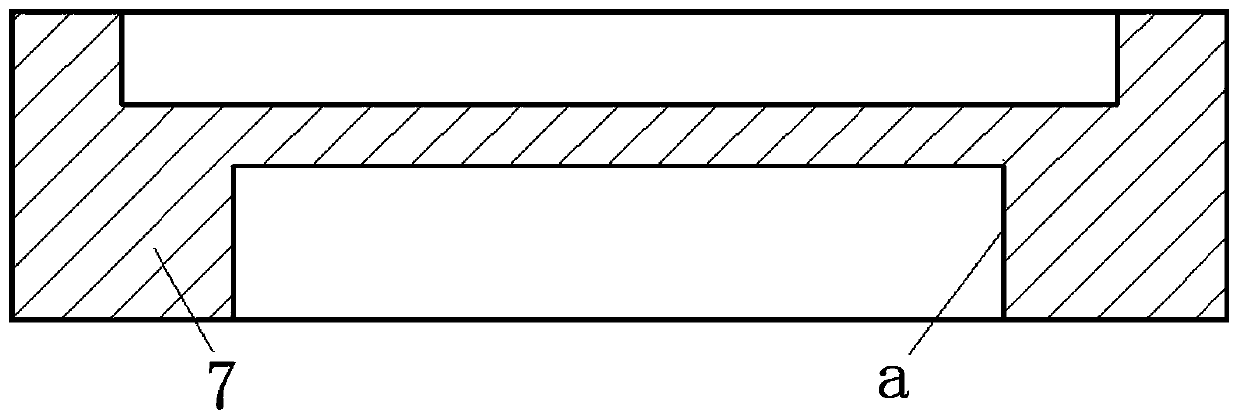

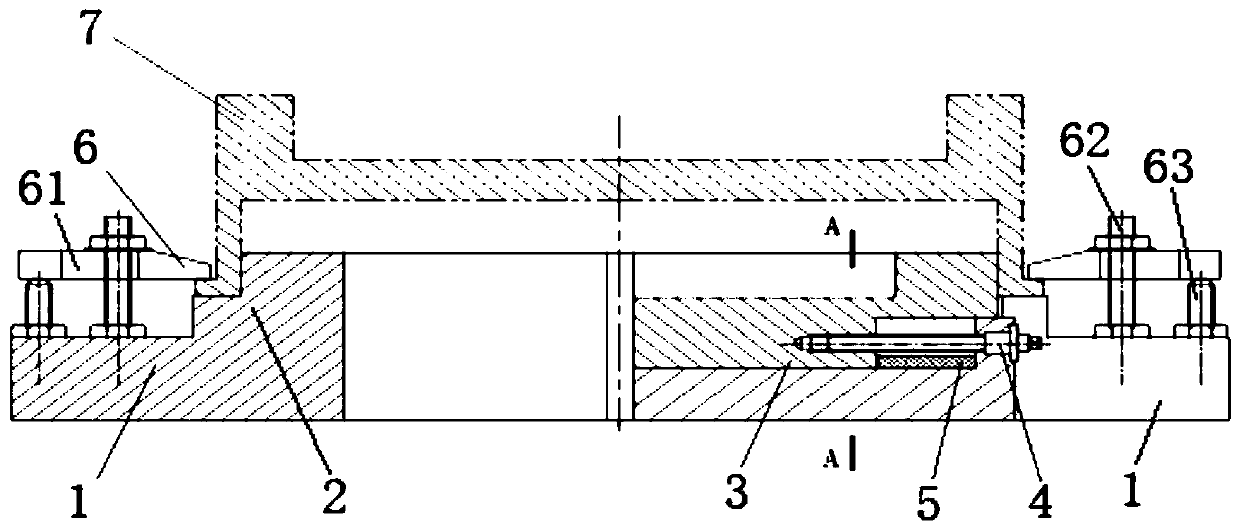

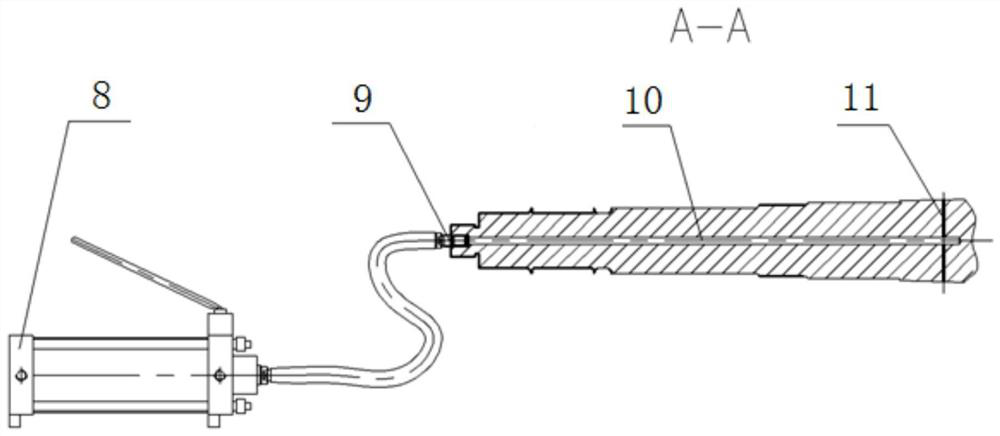

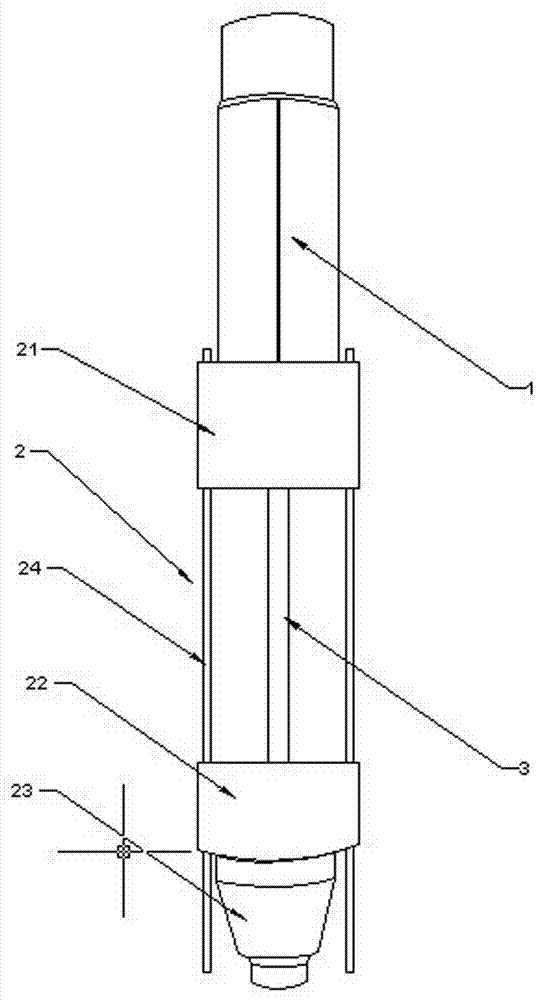

Deep laser hole linearity detecting device having rotation preventing mechanism

InactiveCN107228639AAxial positioning is accurateHigh strengthUsing optical meansRotational degrees of freedomLinearity error

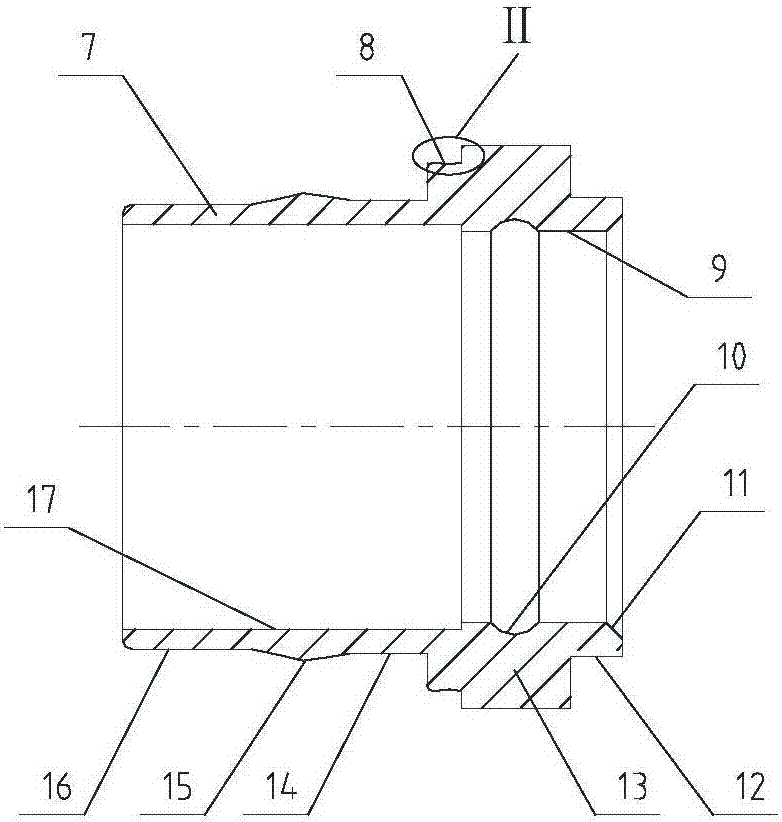

The invention relates to a deep laser hole linearity detecting device having a rotation preventing mechanism. On the basis of the laser alignment principle, a linearity error of an axis of a workpiece hole of a deep hole is measured by using a PSD sensor. A measured workpiece is placed at V-shaped blocks fixed at a detection rack. The PSD sensor is fixed at a measuring head; the measuring head is pulled by a measuring rod to move the PSD sensor from one end of the deep hole to the other end of the deep hole. The measuring rod is a rigid part and multiple segments of the measuring rod are connected to connect the measuring head. In order to prevent rotation of the measuring head around the axis of the deep hole, the measuring rod has a non-circular cross section to realize cooperation with a hole or groove of the detection rack. The measuring rod is connected with the measuring head by a cardan joint to have three translation freedom degrees and have no rotation freedom degree. Detection information is transmitted to the outside of the deep hole by an antenna and the transmitted information is received by a computer. The detecting device has small occupation space; a detection error caused by rotation of the measuring head is eliminated; the antenna extends out of the hole to avoid signal shielding; and the detection precision is high.

Owner:ZHONGBEI UNIV

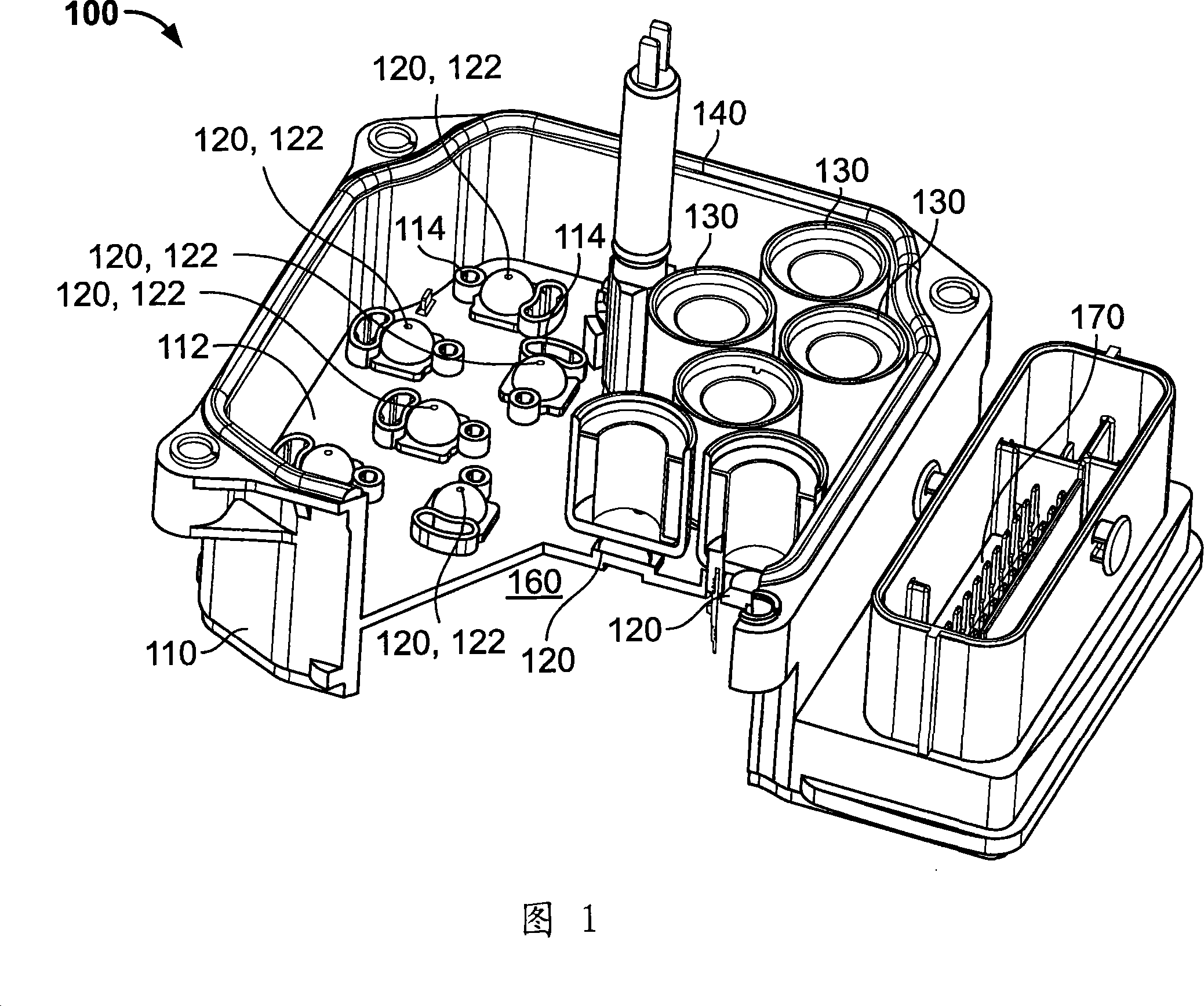

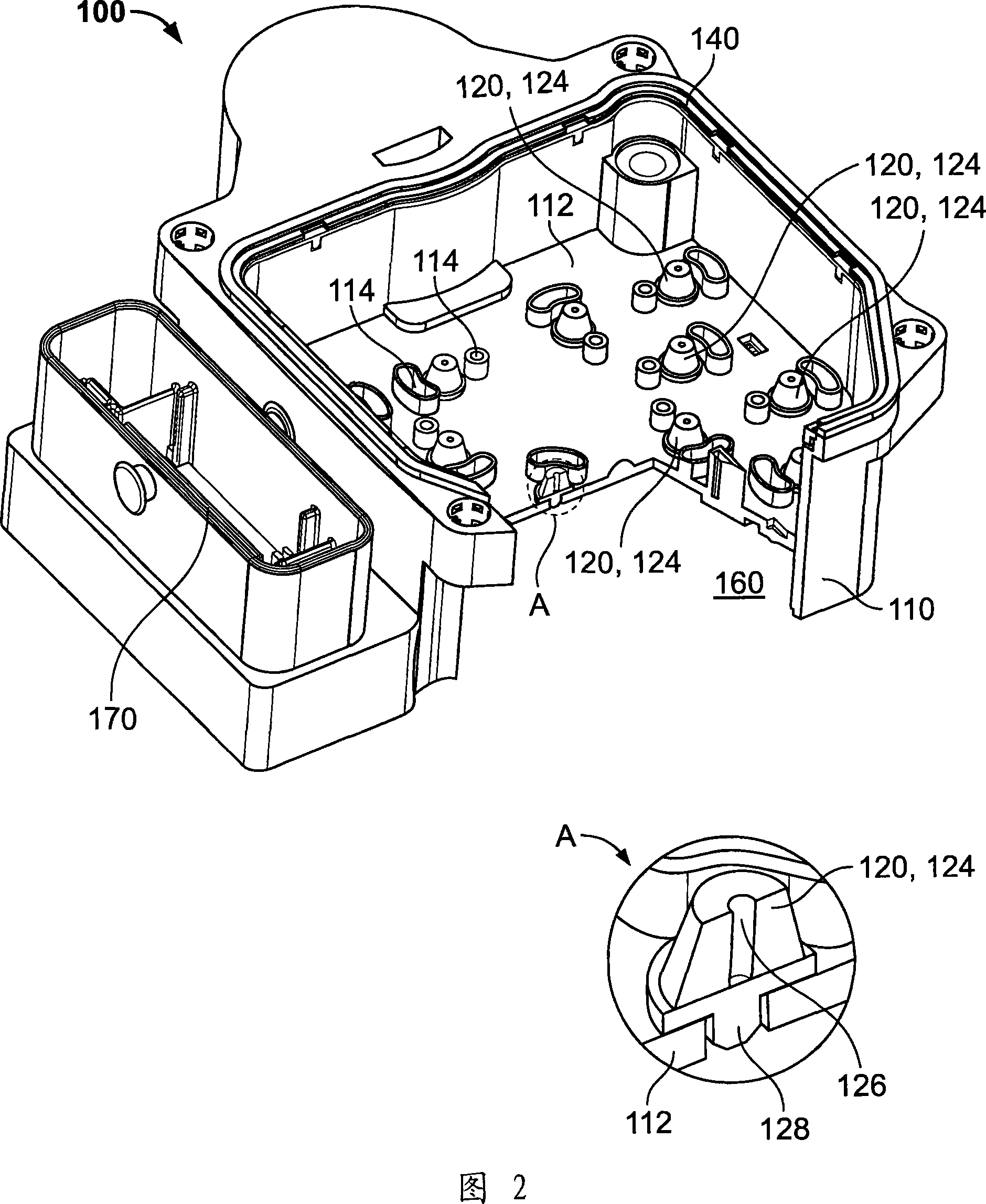

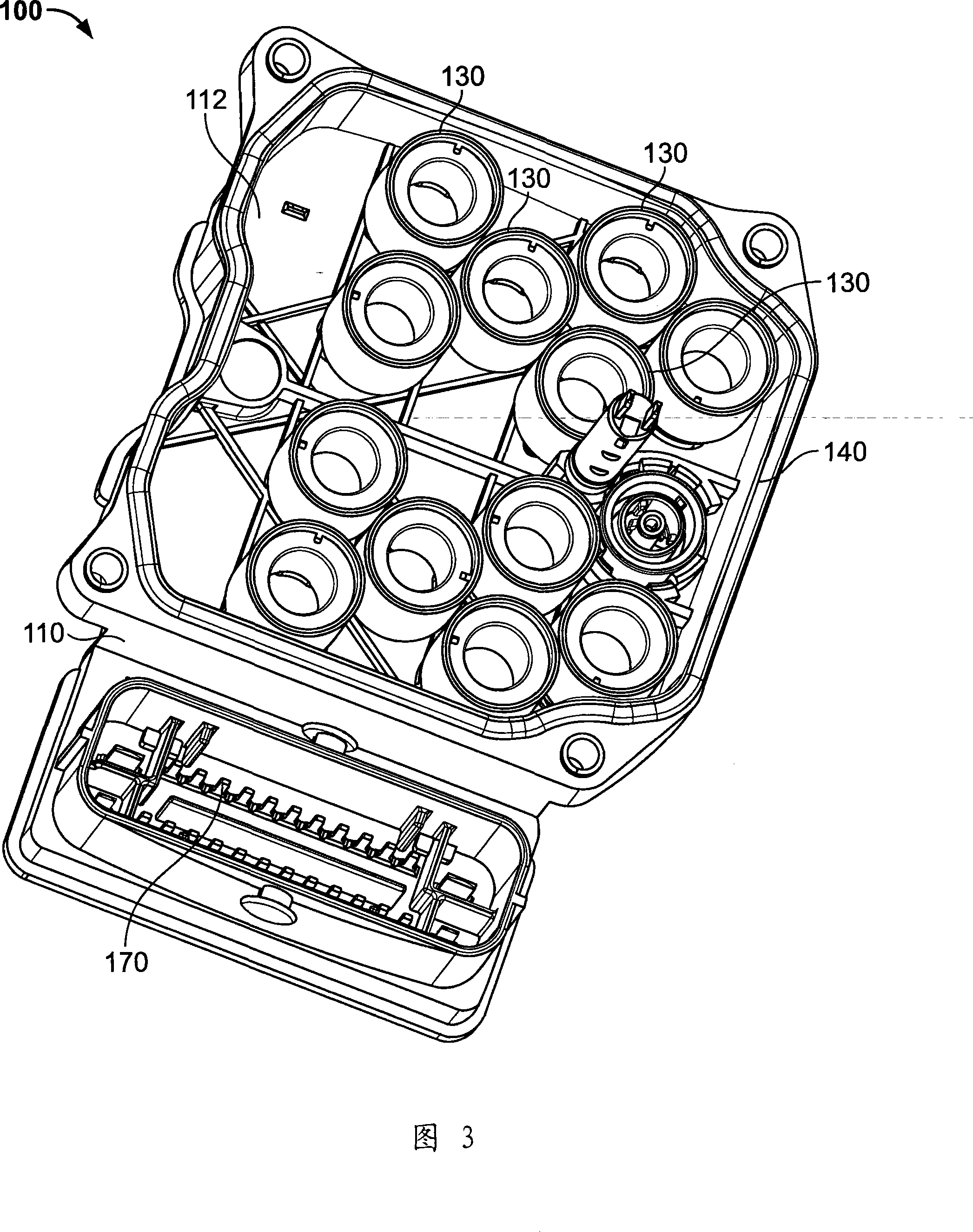

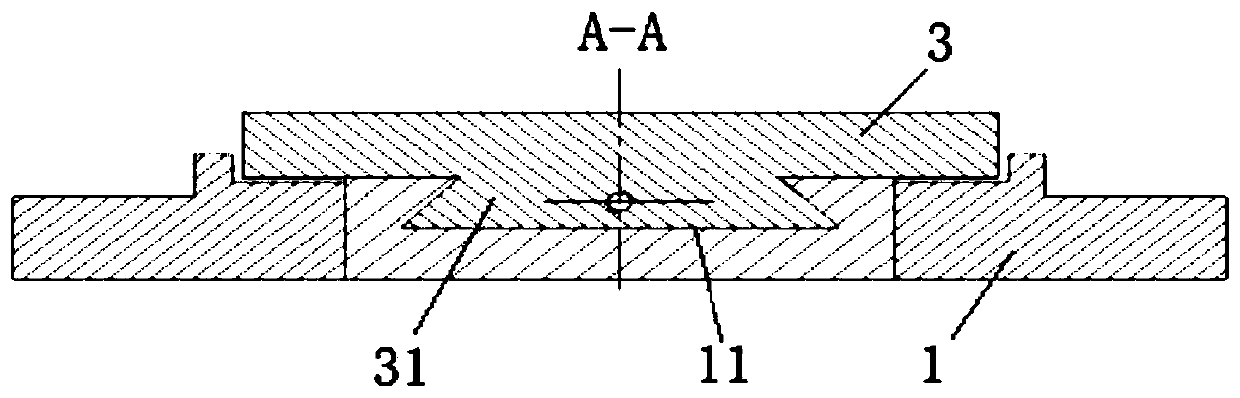

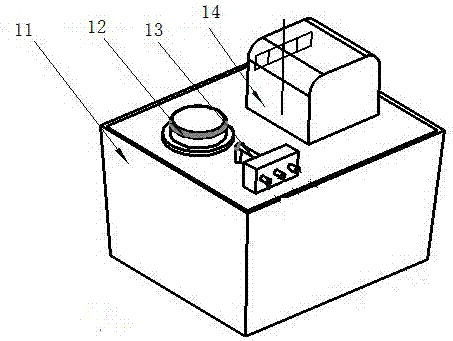

Solenoid valve controller

ActiveCN101253085ARealize free installationPrecise positioningBraking systemsElastomerSolenoid valve

A solenoid valve controller (100) for an ABS / ESP of a motor vehicle is rigidly connected to a hydraulic device (200) by an elastomer element arranged on a base (112) of a control housing (110) of the solenoid valve controller (100). A magnet coil yoke (130) is provided on the elastomer element (120) so that the magnet coil yoke (130) is pushed directly onto an outer side of the hydraulic device (200) by the elastomer element (120) with the control housing (110) and in so doing receives a solenoid valve unit (230) of the hydraulic device (200) . The elastomer element (120) serves as a bearing and an outer side of the hydraulic device (200) serves as an abutment for the magnet coil yoke (130) . As a result, the magnet coil yoke (130) can be fixed without play in the control housing.

Owner:TYCO ELECTRONICS BELGIUM EC +1

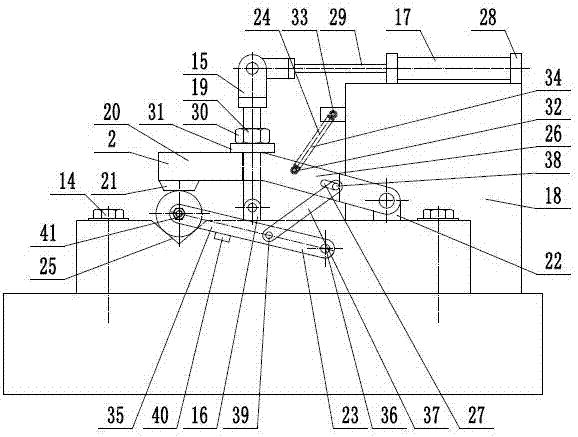

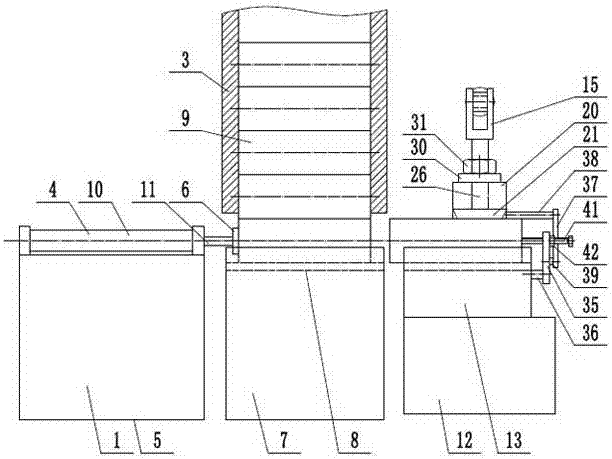

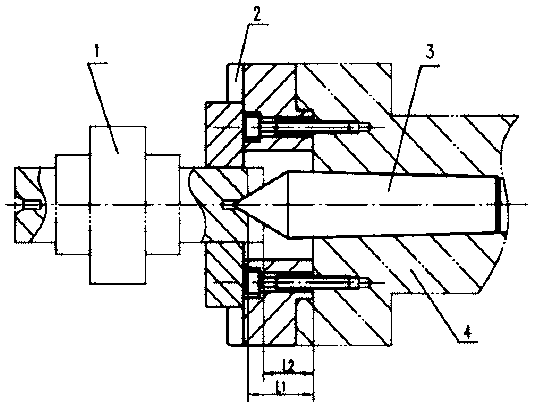

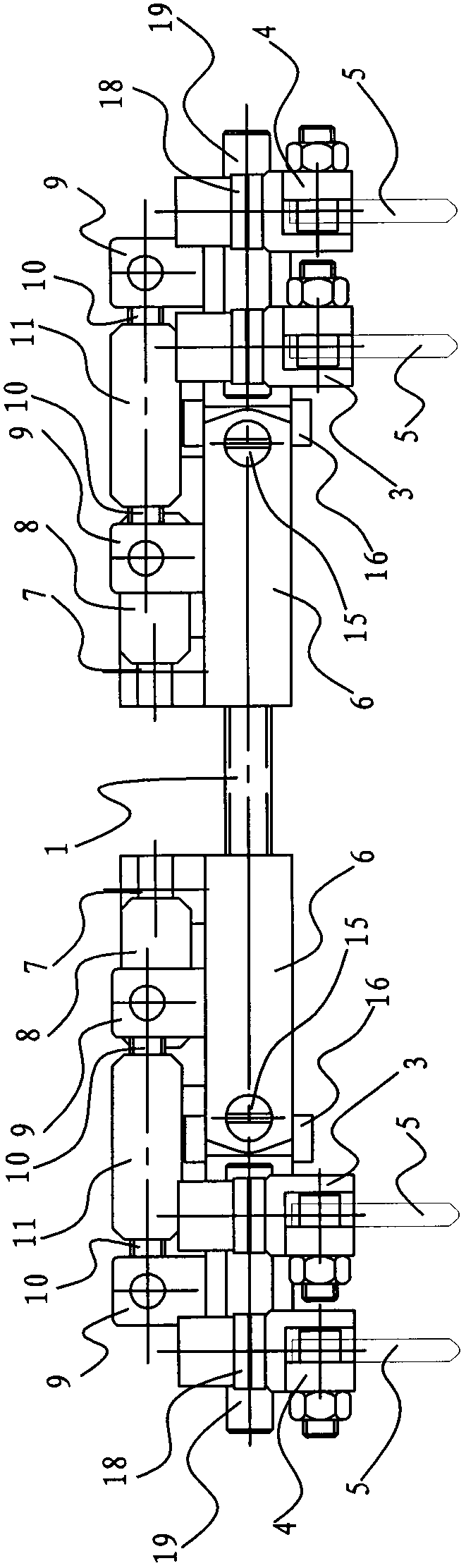

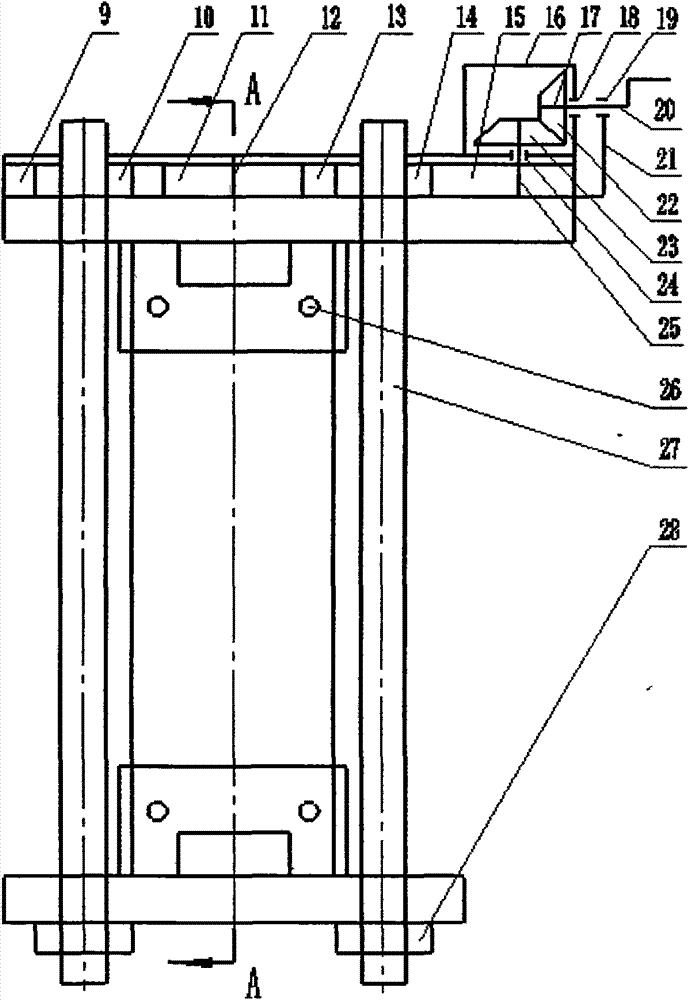

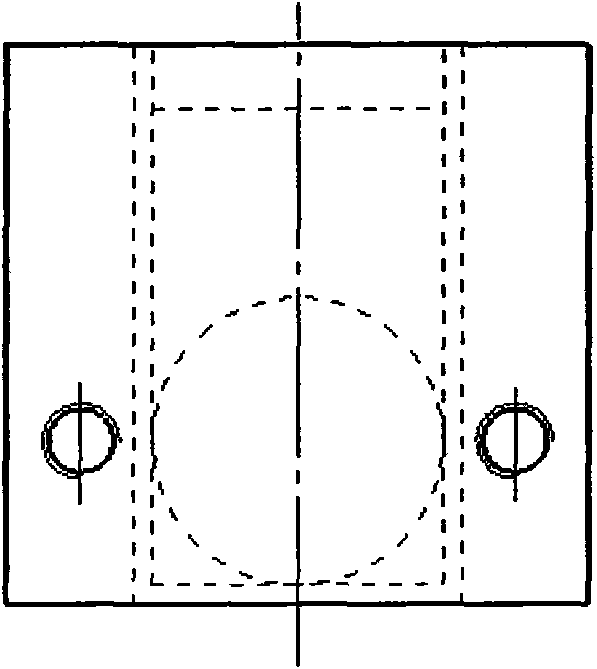

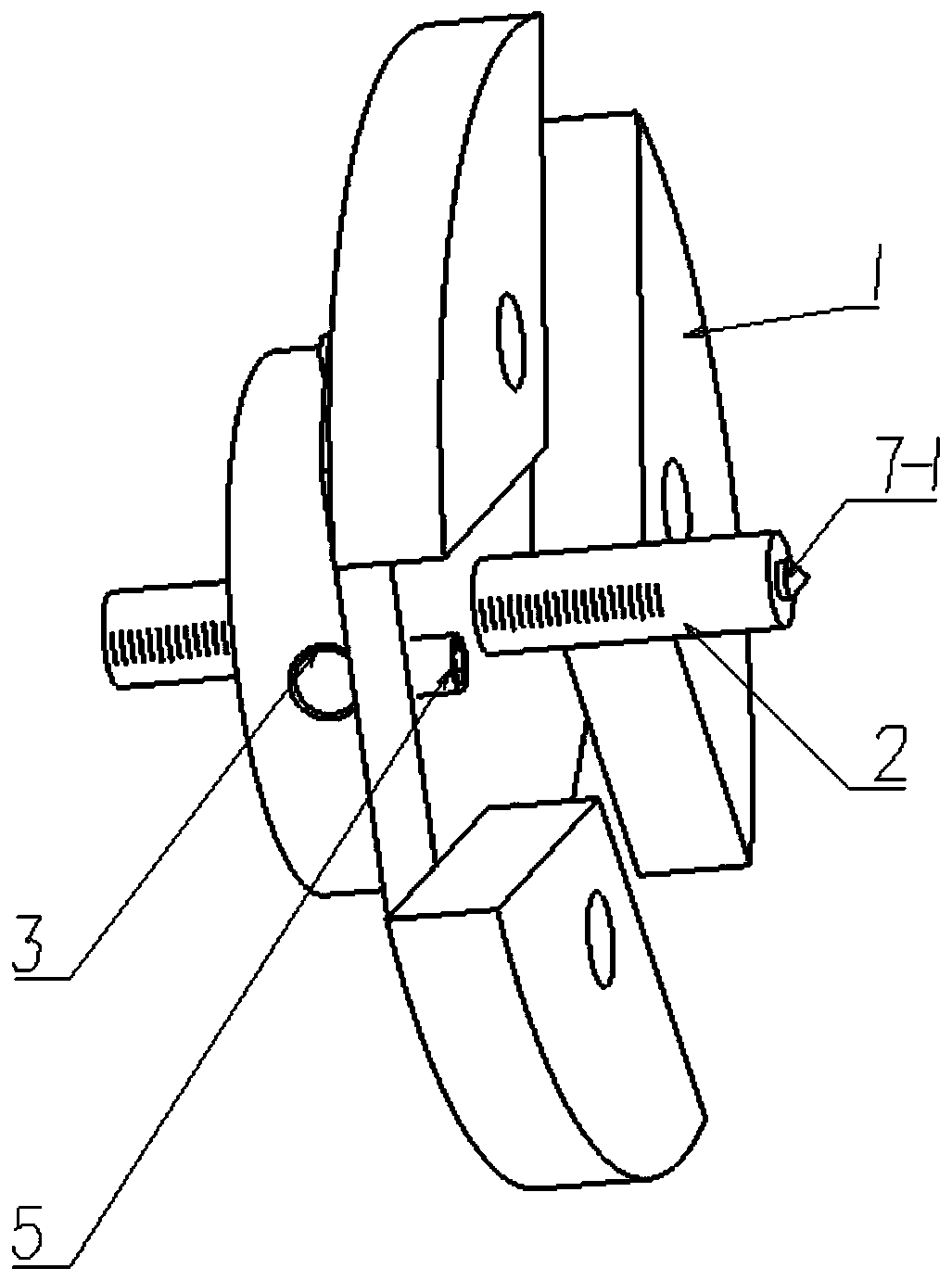

Feeding clamping device for short shaft

InactiveCN107116391AAchieve clampingAchieve releaseWork clamping meansMetal working apparatusEngineeringMachining

The invention provides a feeding and clamping device for a short shaft, which belongs to the technical field of mechanical processing. It includes a feeding mechanism and a limit clamping mechanism. One end of the feeding piston rod of the feeding mechanism is connected to the feeding push plate. The limit clamping mechanism is arranged on the front side of the feeding mechanism. One end of the pressure plate of the limit clamping mechanism is hinged on the support On the seat, the lower end of the rocker is hinged on the rocker support seat, the rocker passes through the U-shaped groove of the pressure plate, one end of the clamping piston rod is hinged to the upper end of the rocker, and the adjusting nut of the compression assembly is connected with the rocker thread , the two ends of the return tension spring of the return assembly are respectively connected to the first tension spring support and the second tension spring support, and the right end of the limit swing lever of the limit component is hinged on the clamping support seat through the swing lever pin , the limit screw is threaded on the left side of the limit swing rod. The invention automatically realizes feeding and clamping of the short shaft, has accurate axial positioning, reasonable structure and good reliability.

Owner:赵凯

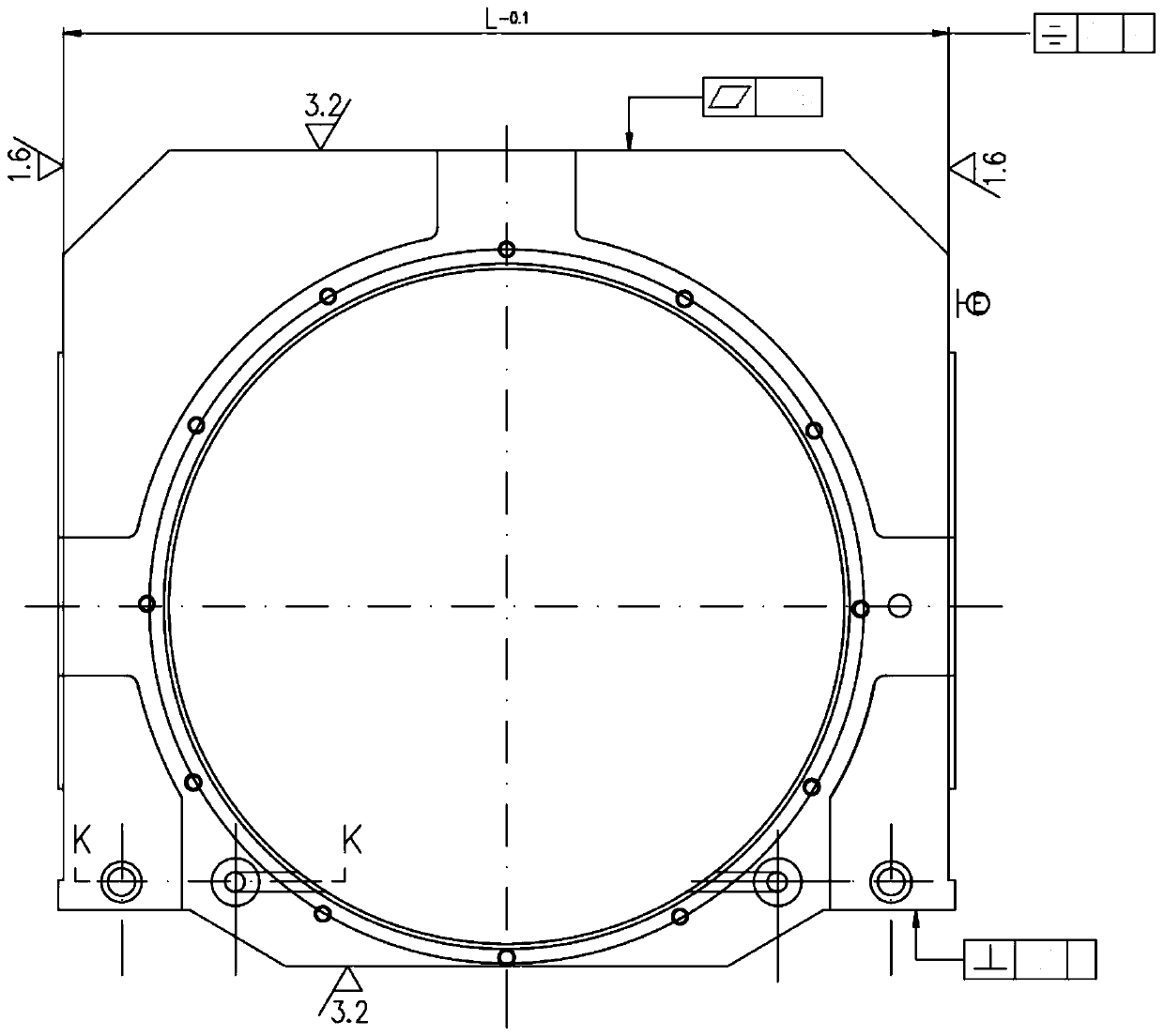

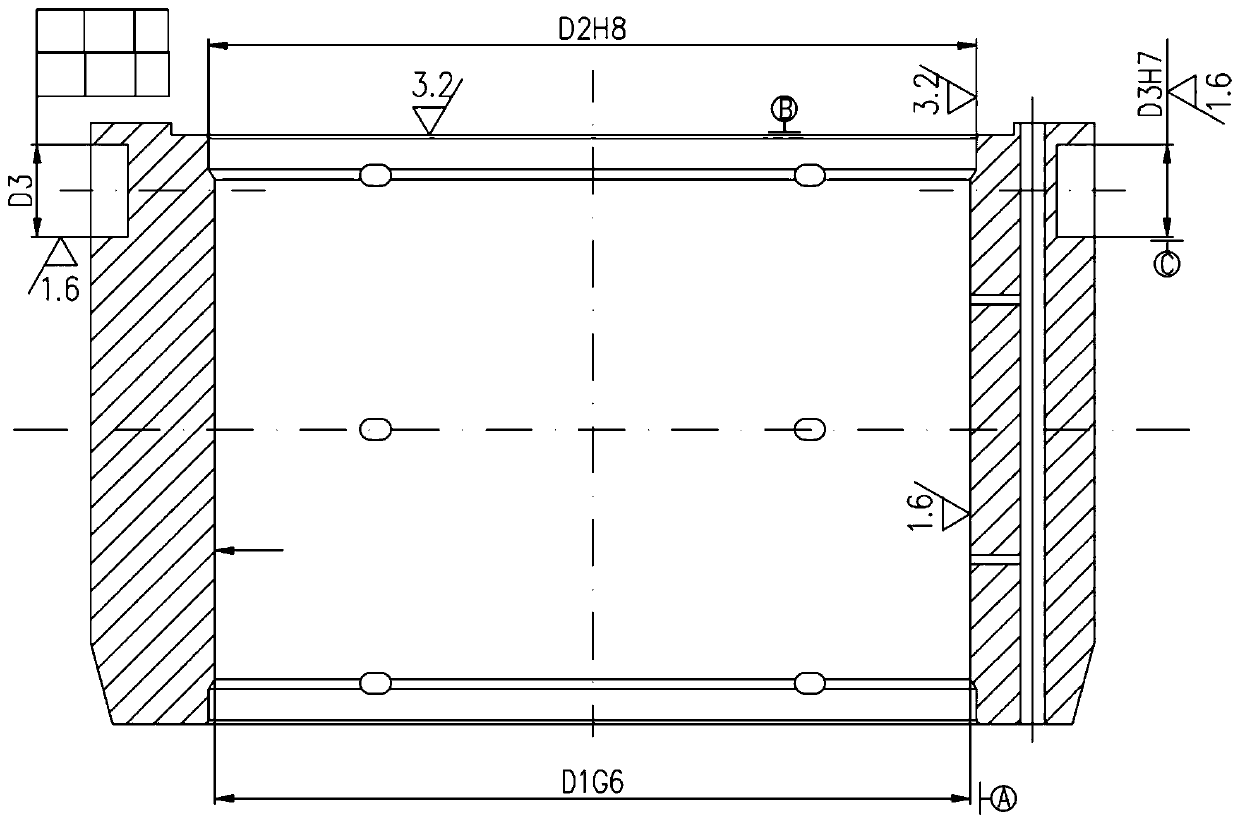

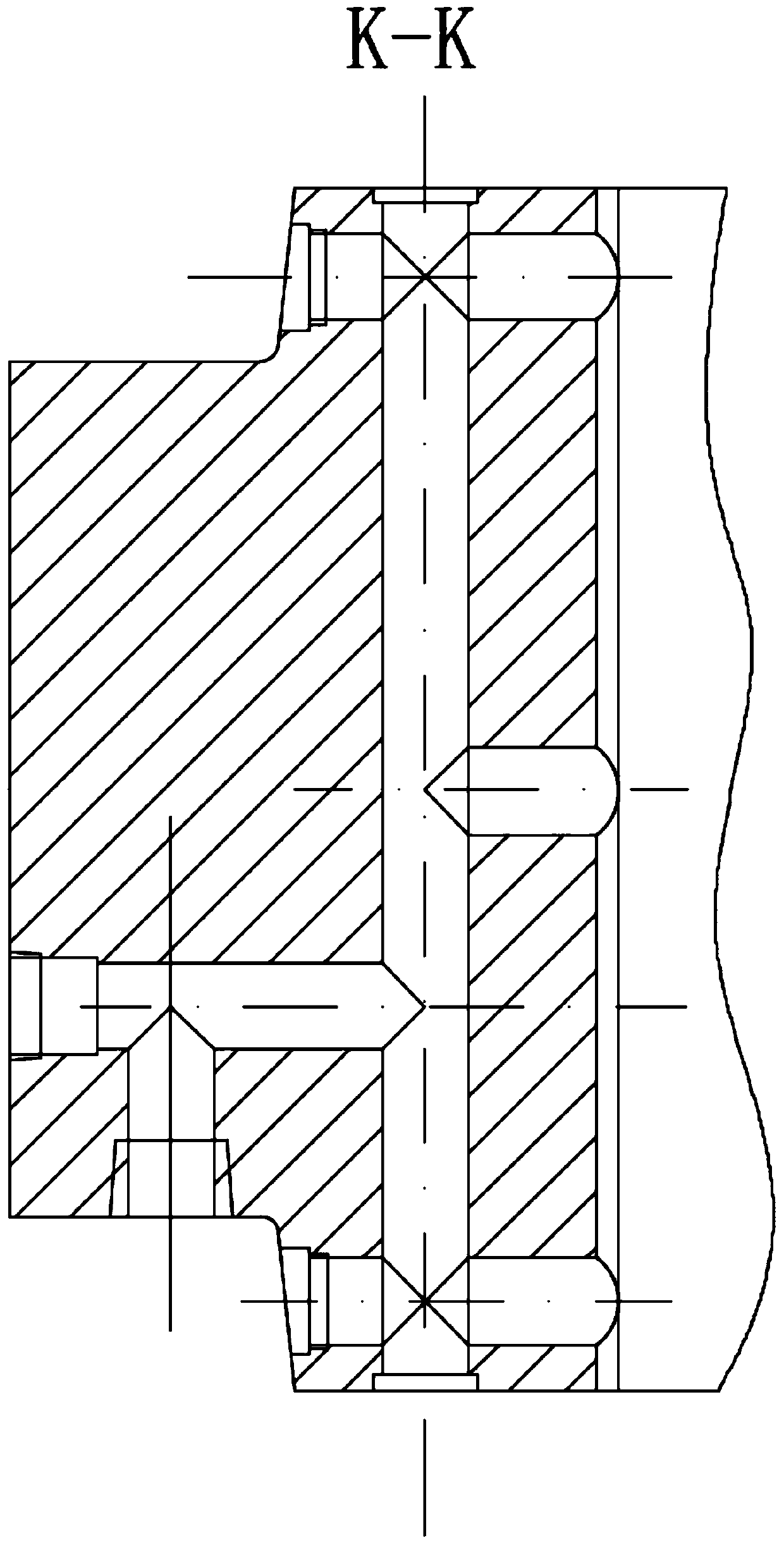

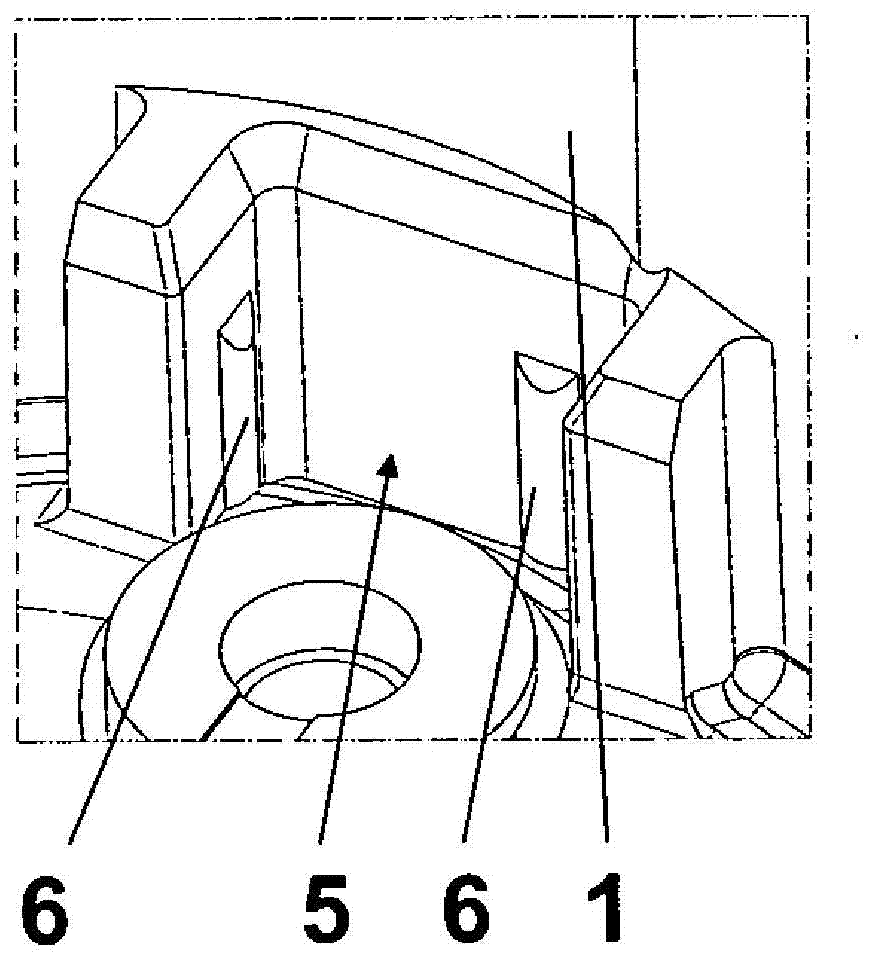

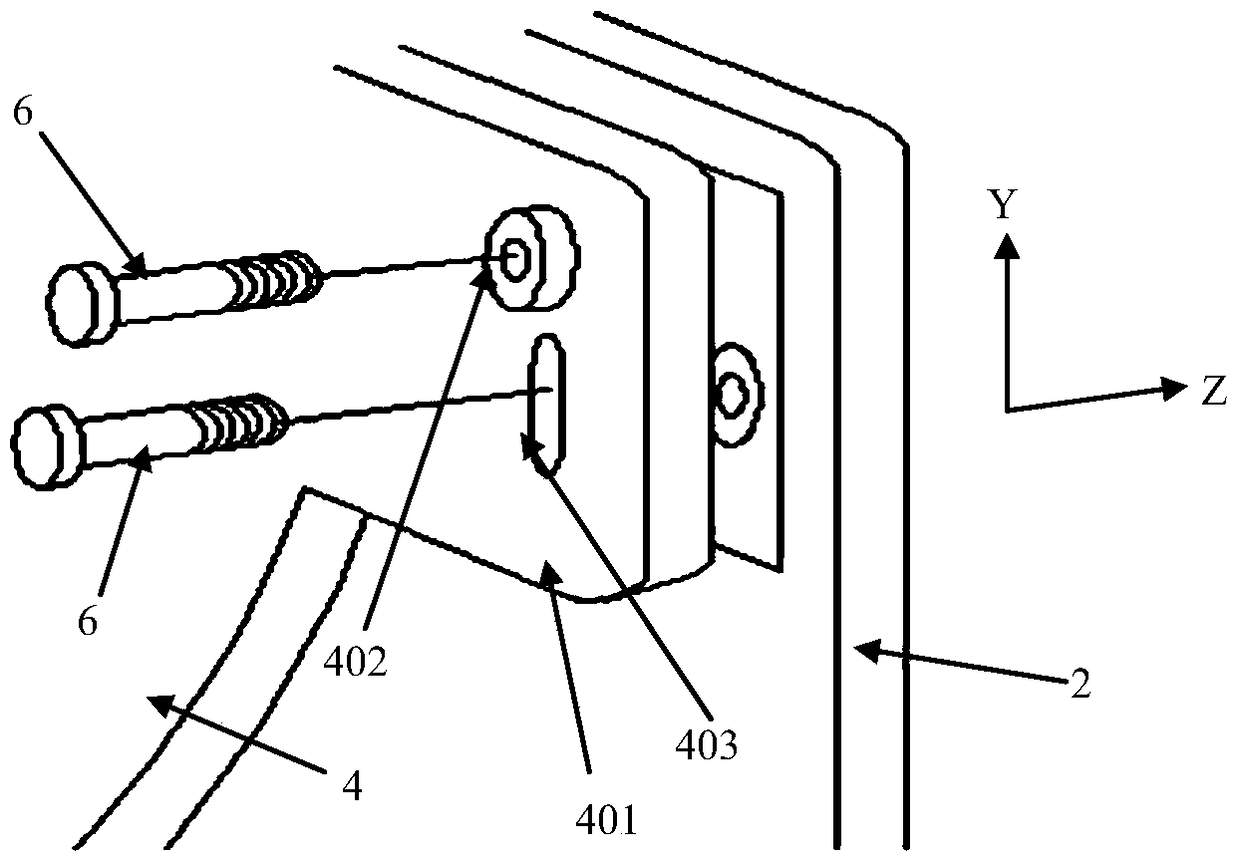

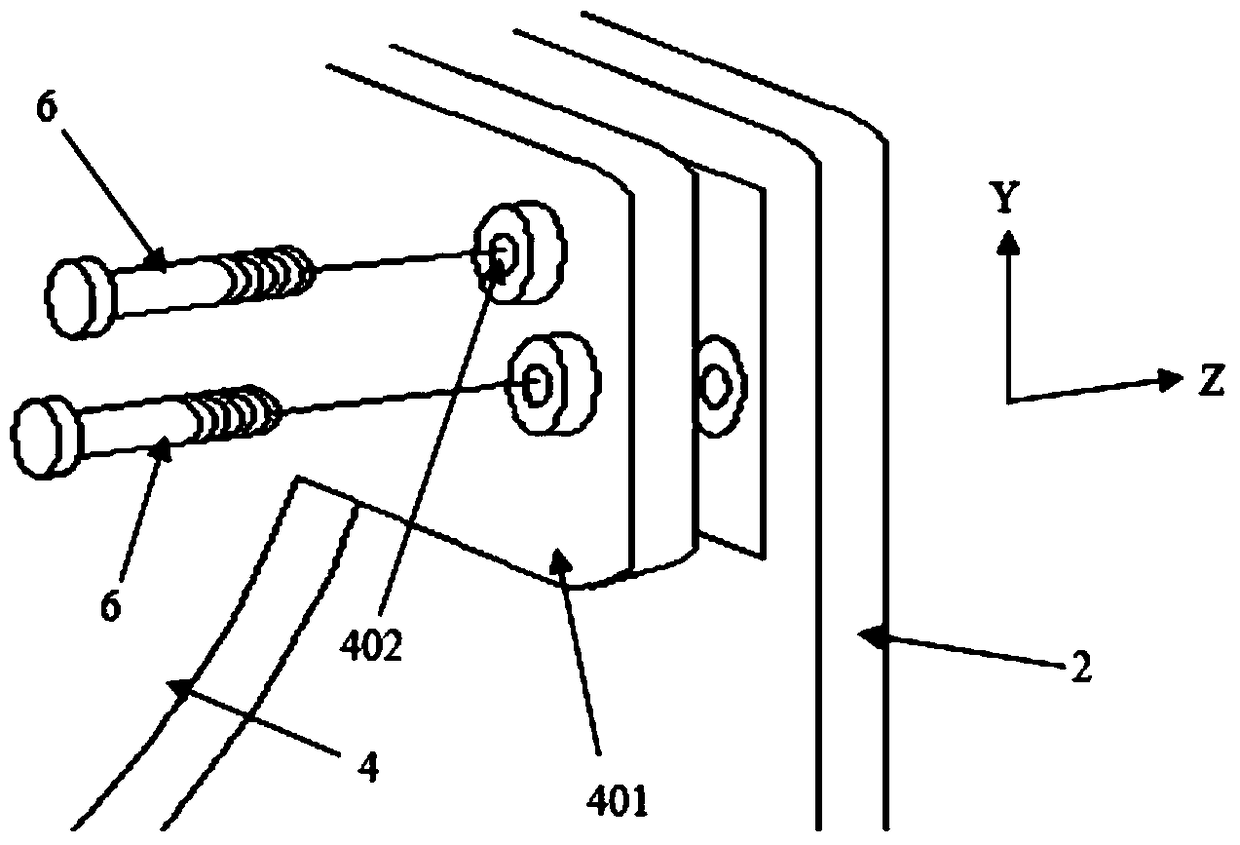

Rolling mill bearing base and manufacturing method thereof

ActiveCN109731916AMeet quick replacement requirementsAxial positioning is accurateMetal rolling stand detailsFurnace typesSurface roughnessSlide plate

The invention discloses a rolling mill bearing base and a manufacturing method thereof. The rolling mill bearing base is forged and processed from high-quality alloy steel, and is mounted at the two ends of a supporting roller of a symmetrical structure on a large rolling mill; the sliding surface which is in contact with a rolling mill memorial gate is equipped with a copper slide plate; precision of a bearing hole is G6, surface roughness of the bearing hole is Ra1.6 and cylindricity of the bearing hole is 0.03mm; precision of a bearing end cover matching hole is H8, surface roughness of thebearing end cover matching hole is Ra3.2, surface roughness of sliding surfaces at the two sides is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, flatness of an upper surface is 0.05mm, perpendicularity, to the sliding surfaces, of a lower surface is 0.2 mm, the two sliding surfaces are symmetrically equipped with dowel pin holes, precision of the dowel pin holes is H7, surface roughness of the dowel pin holes is Ra1.6, degree of symmetry on the bearing hole is 0.1 mm, and center perpendicularity to the bearing hole is 0.1 mm. An intensive lubricating system is adopted, and a ratioof hole depth to hole diameter of an oil inlet and outlet is 20 or higher. The rolling mill bearing base can meet the requirements of quickly replacing and interchanging a supporting roller, is accurate in positioning, is good in cooling and lubricating effect, is high in precision, reduces rolling mill faults, and guarantees the processing quality.

Owner:武汉钢铁有限公司

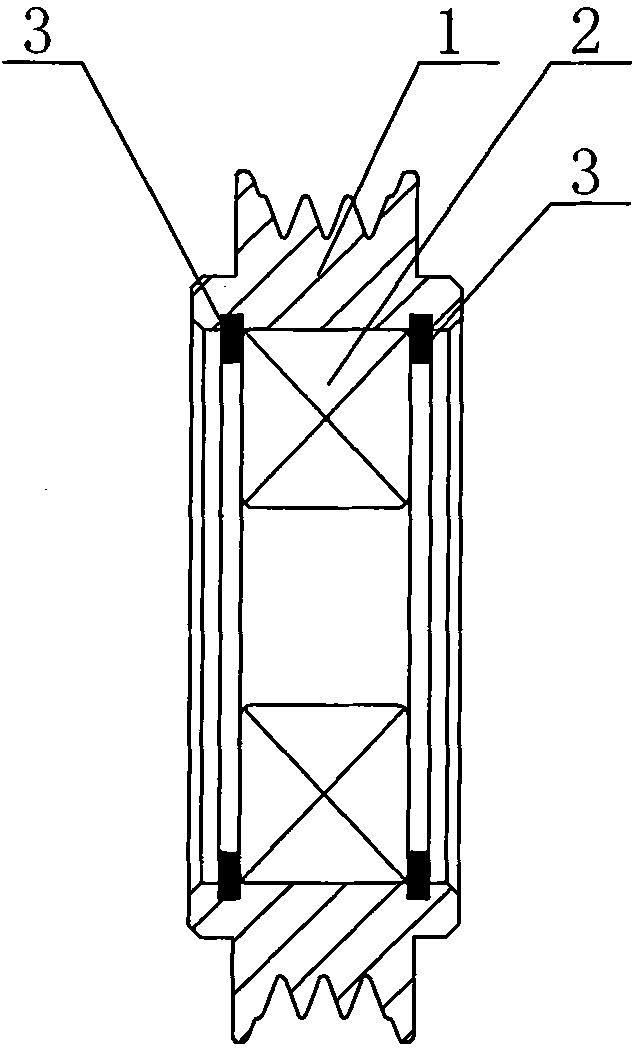

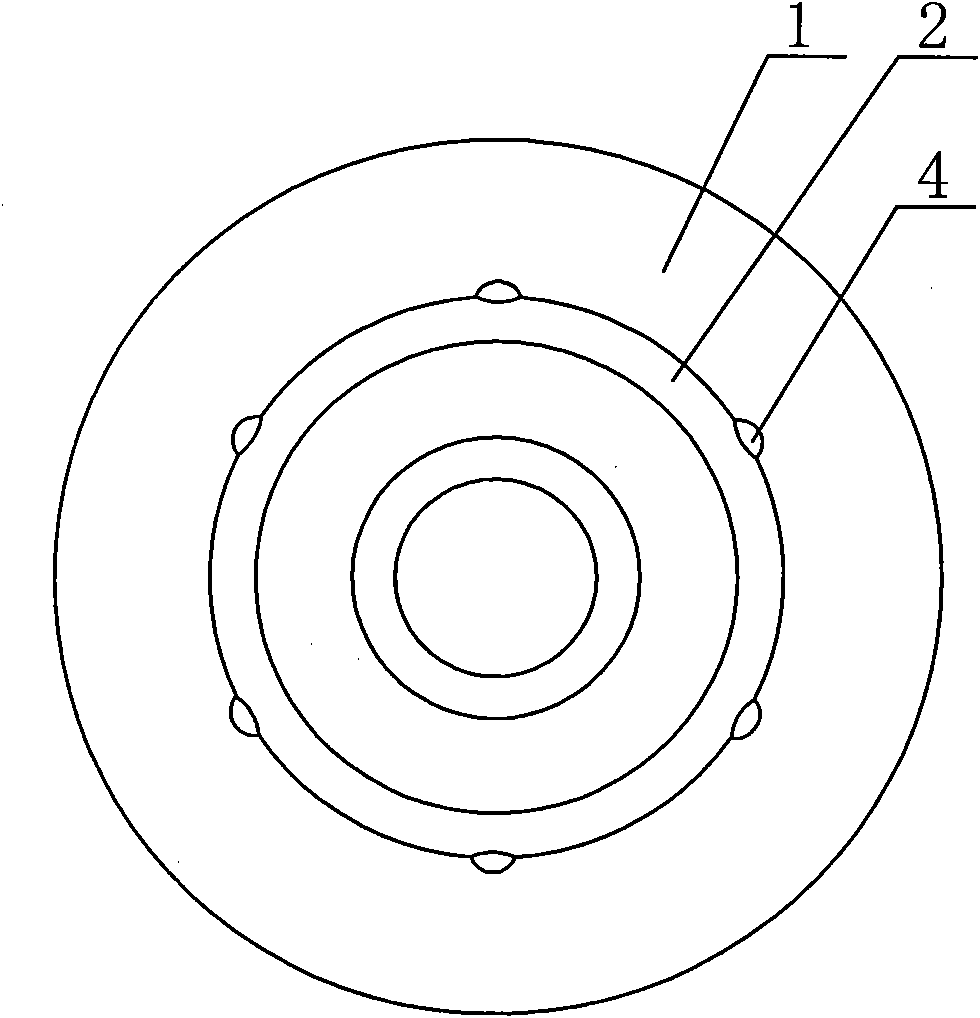

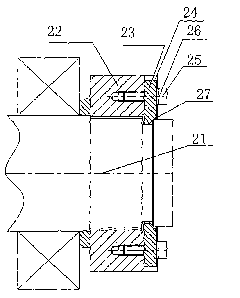

Assembly structure, method and fixture of pulley and bearing

ActiveCN101881304AReduce lossSimple processing technologyPortable liftingGearing elementsInterference fitHigh volume manufacturing

The invention relates to an assembly structure of a pulley and a bearing and a method and fixture for manufacturing the assembly structure. The outer ring periphery of the bearing is in interference fit with the inner bore of the pulley. The assembly structure is characterized in that riveted structures are distributed on the end surfaces at the two sides of the inner bore circumference of the pulley; and part of the pulley materials on the riveted structures is extruded into the rounding portion of the outer ring periphery of the bearing. The assembly structure and method radically change the processing and assembling modes of the conventional steel pulleys, the assembly fixture adopted by the invention can synchronously complete the bearing pressing process and double-sided press riveting process of the pulley conveniently, quickly and accurately, and the press rivet points at the two ends can effectively prevent the bearing from moving axially in the inner bore of the pulley, thus greatly lowering the production cost, saving the production time, improving the assembly efficiency, ensuring the product quality and reliability and meeting the requirement of volume production.

Owner:WUXI YONGKAIDA GEAR

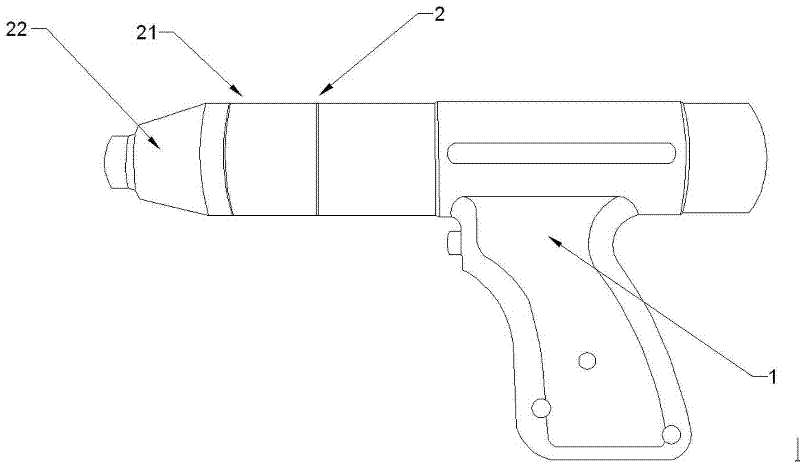

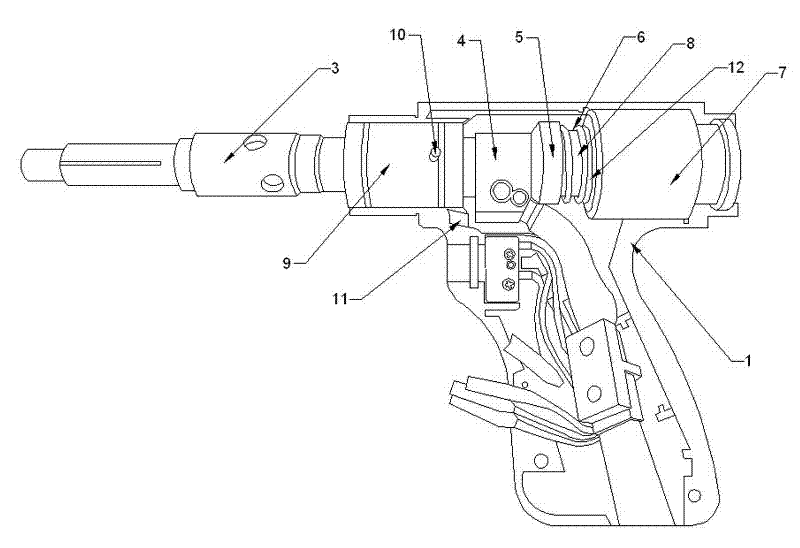

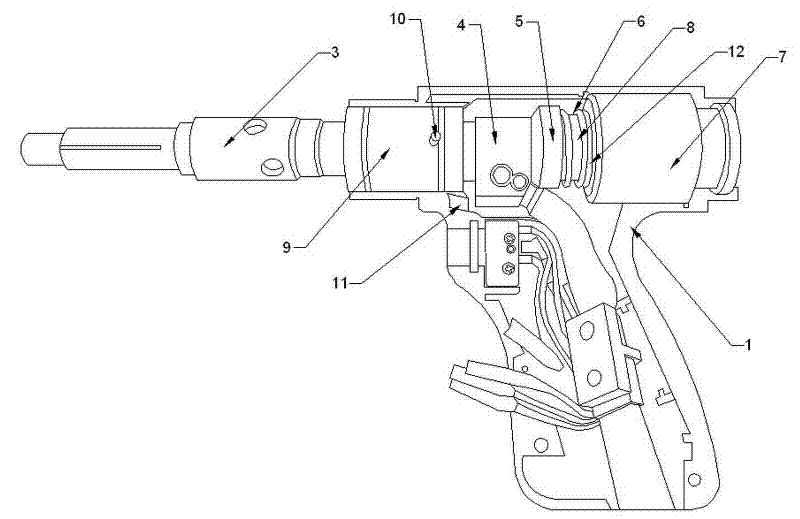

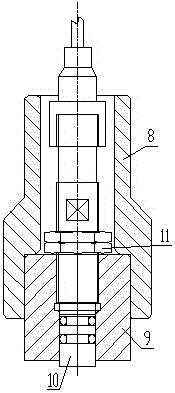

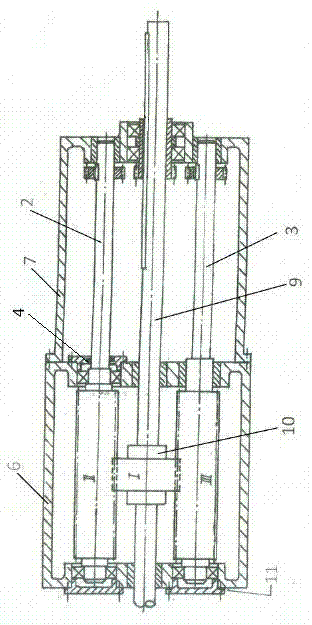

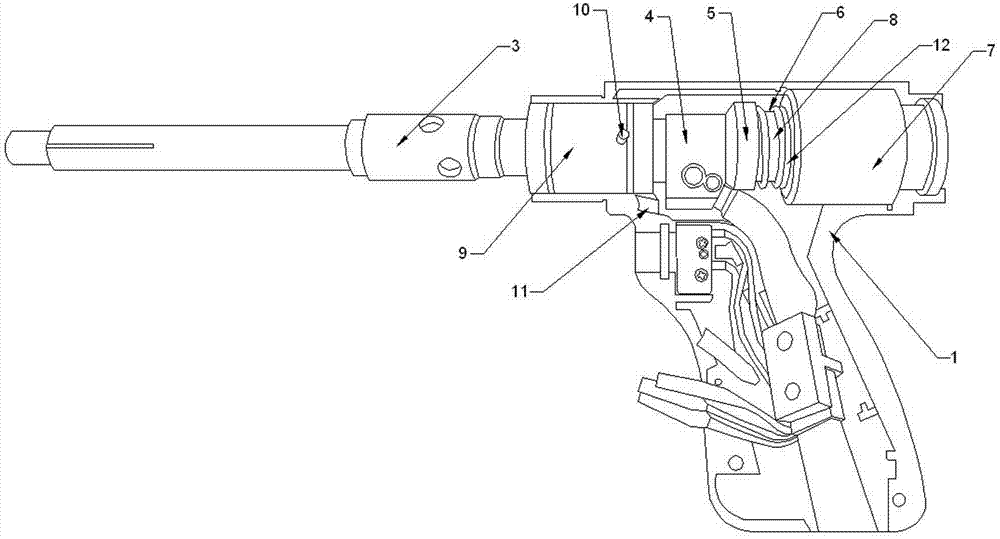

Welding gun

ActiveCN102310252ASmall axial runoutAxial positioning is accurateElectrode supporting devicesStructural engineeringStud welding

The invention discloses a welding gun, which comprises a gun shell and an end cover group arranged on the gun shell, wherein a cavity is formed in the gun shell and the end cover group, a welding gun shaft assembly and a fixed sleeve fixed on the gun shell are arranged in the cavity, an electrification coil is arranged in the fixed sleeve, the front end of the welding gun shaft assembly is provided with an electric conduction chuck, the rear end of the welding gun shaft assembly is detachably connected to the fixed sleeve through an armature, the welding gun shaft assembly is coaxially sleeved with a shaft sleeve, the outer edge of the shaft sleeve is provided with a positioning rod extending outwards, the gun shell is provided with a hole clamped with the positioning rod, the armature isin a cross shape, and the fixed sleeve is provided with a cross hole matched with the armature. The welding gun disclosed by the invention has a compact structure, and the welding operation is easy. The stud welding height can be easily adjusted. The axis of an electric conduction shaft is accurately positioned so as to ensure a stud to be perpendicular to a welding plate.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER

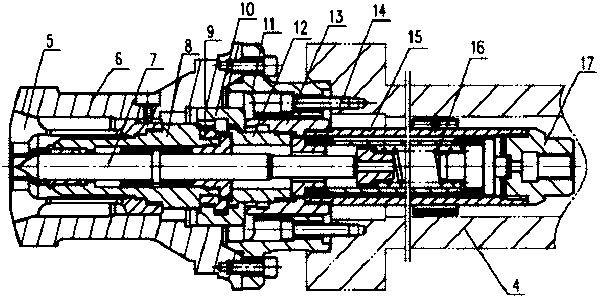

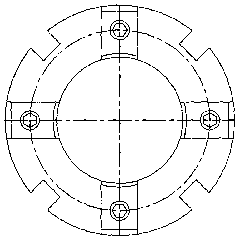

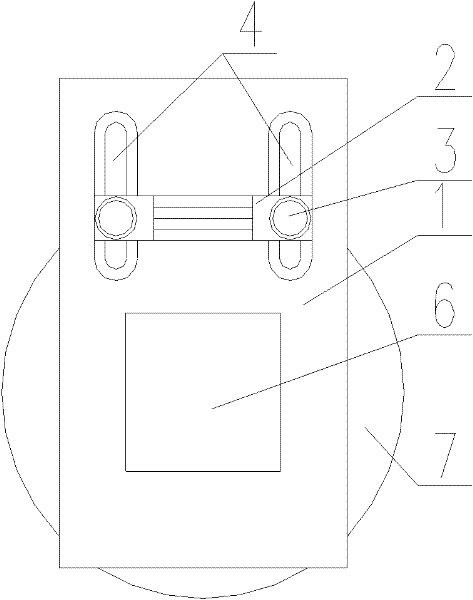

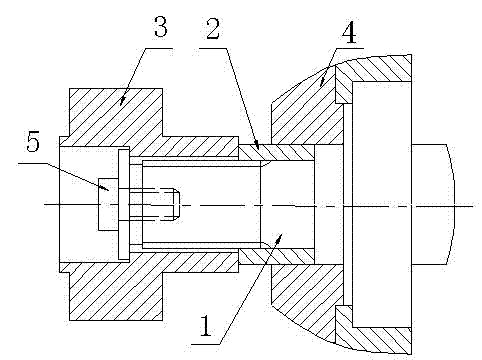

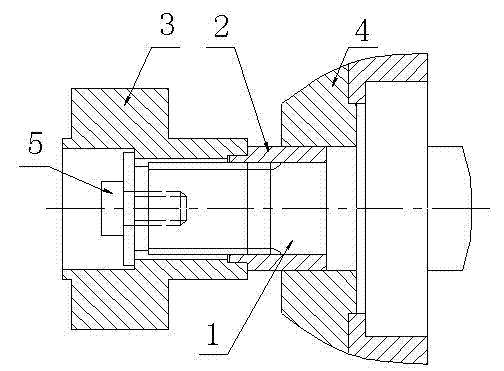

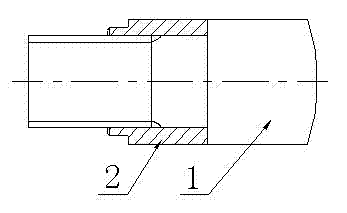

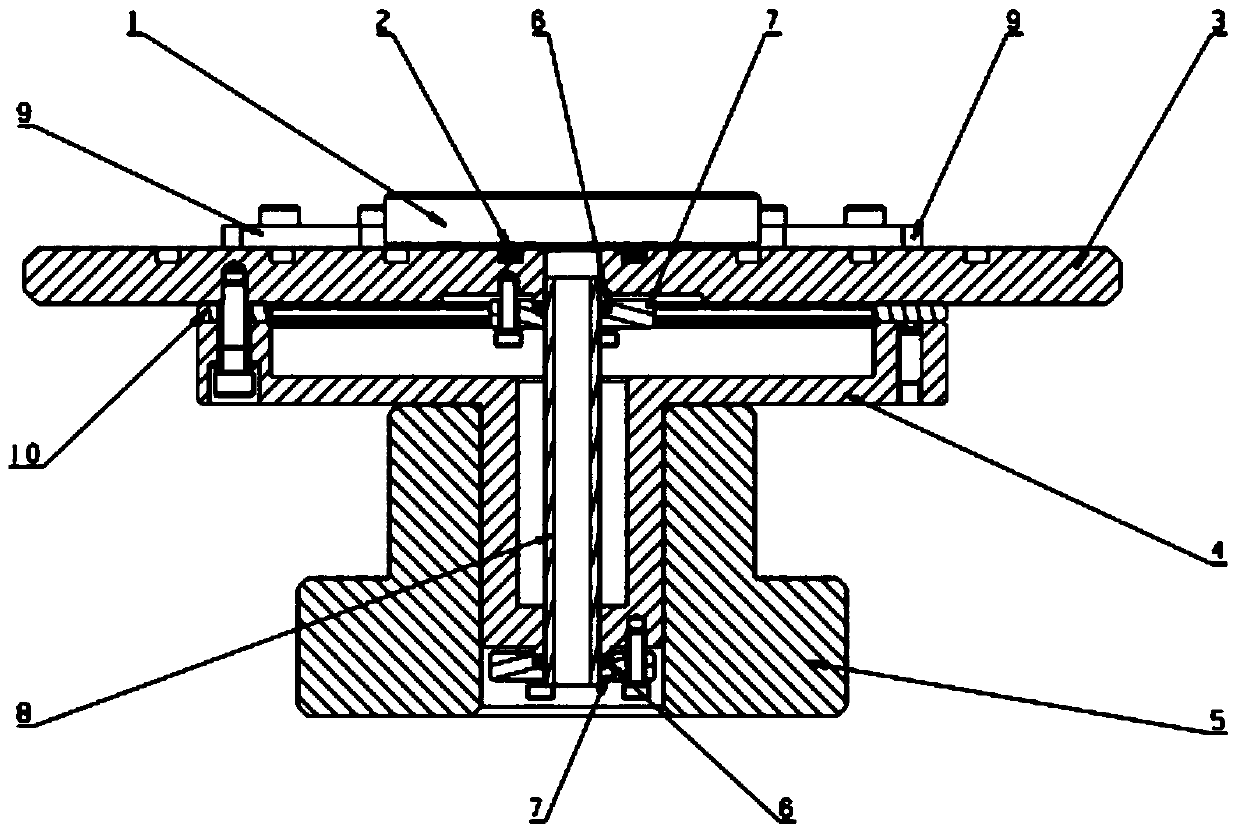

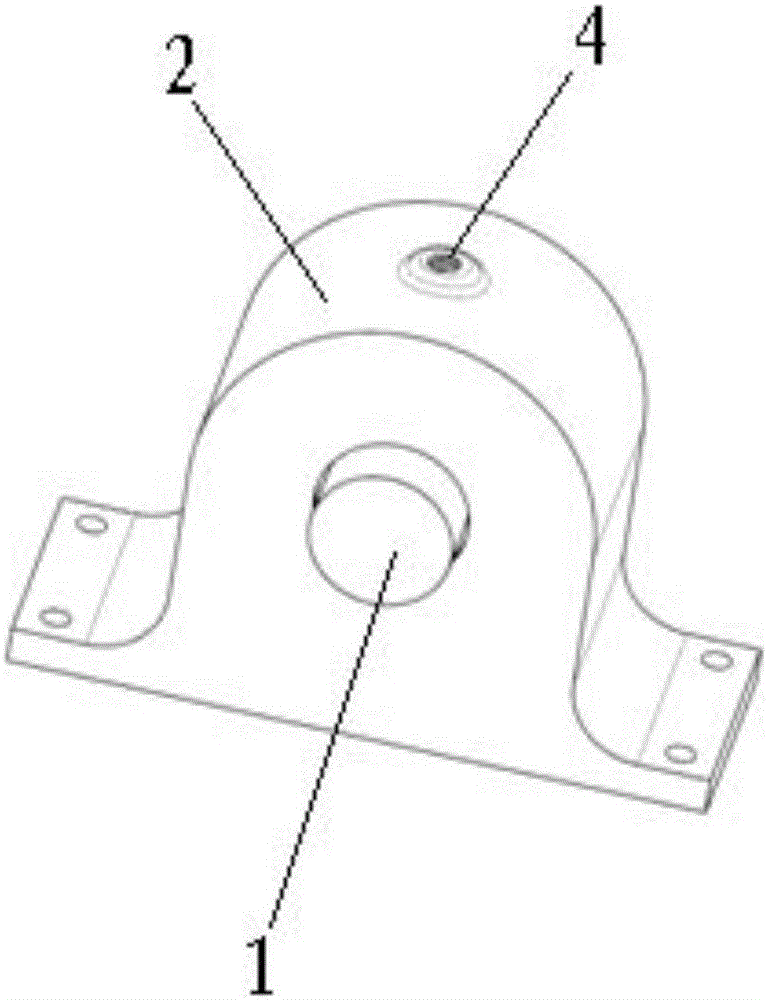

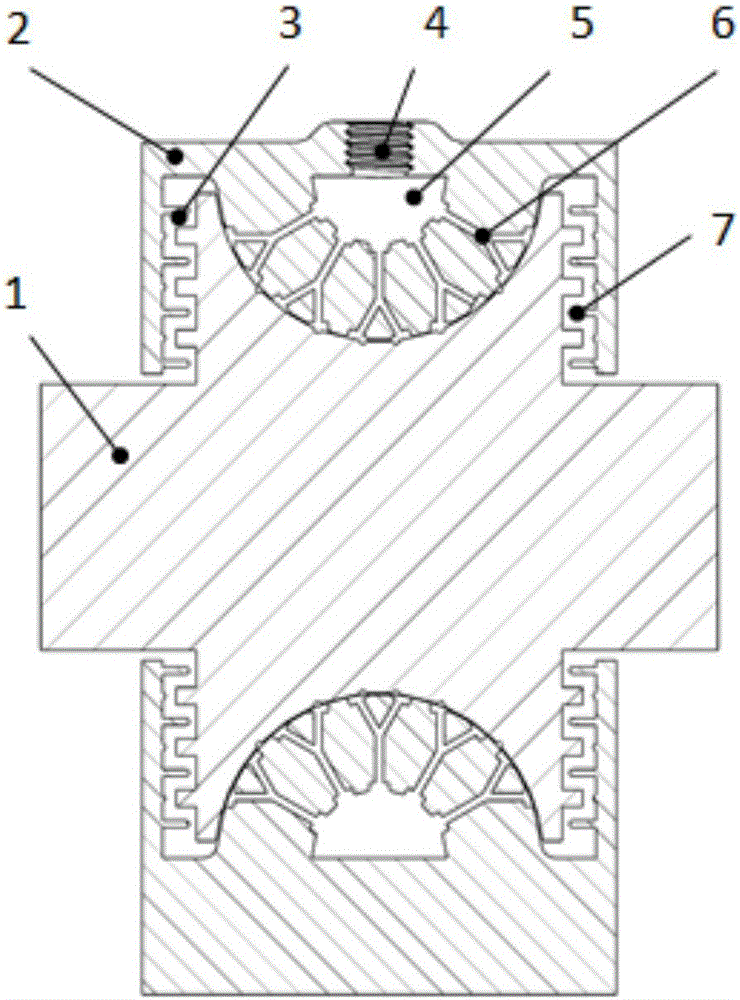

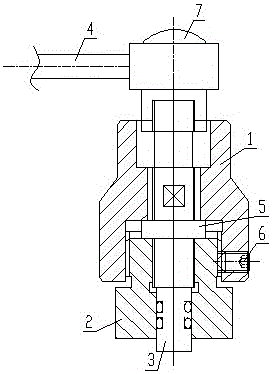

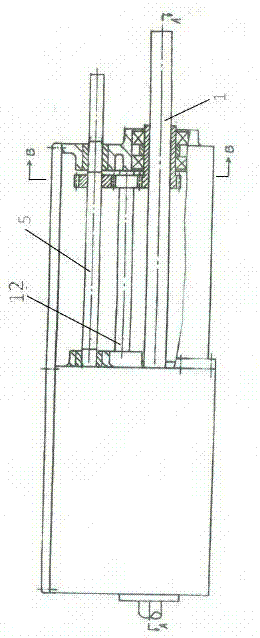

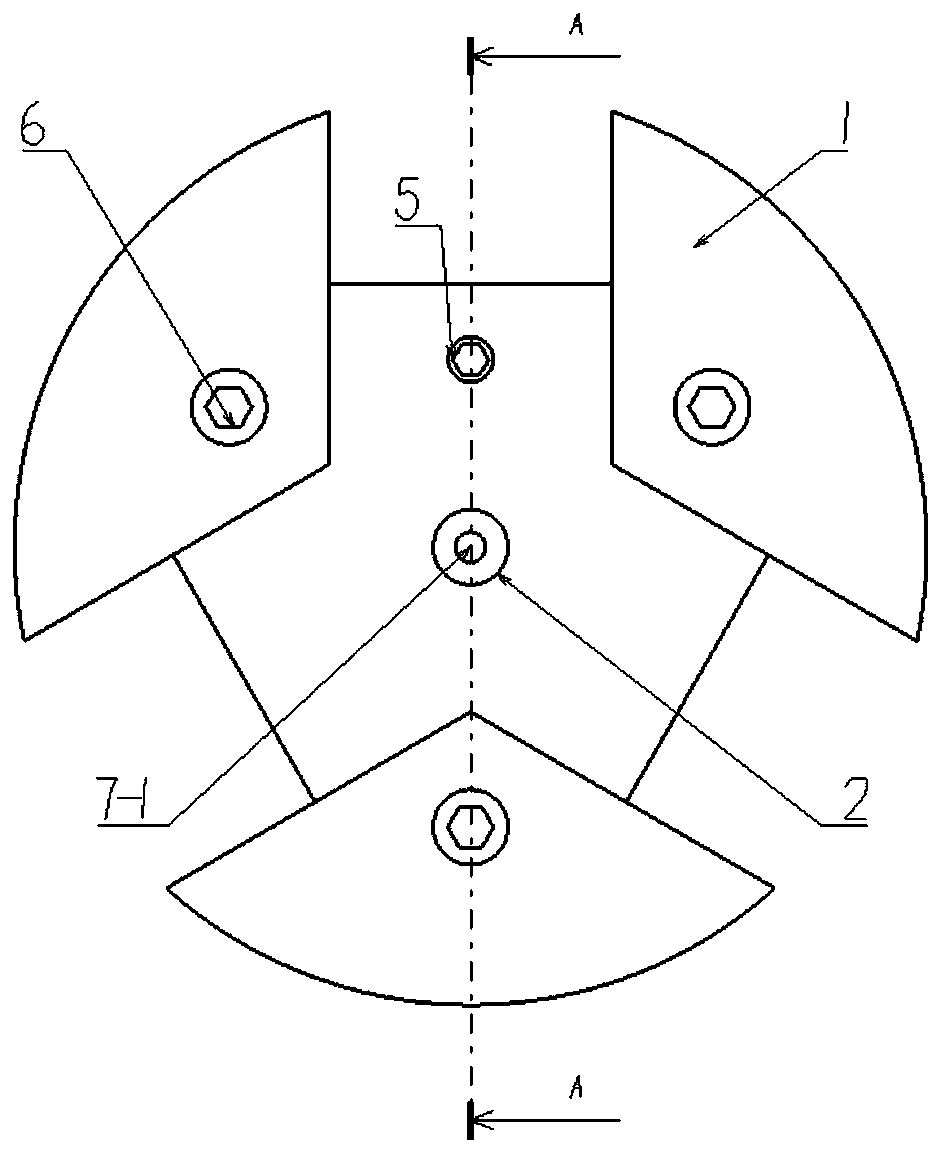

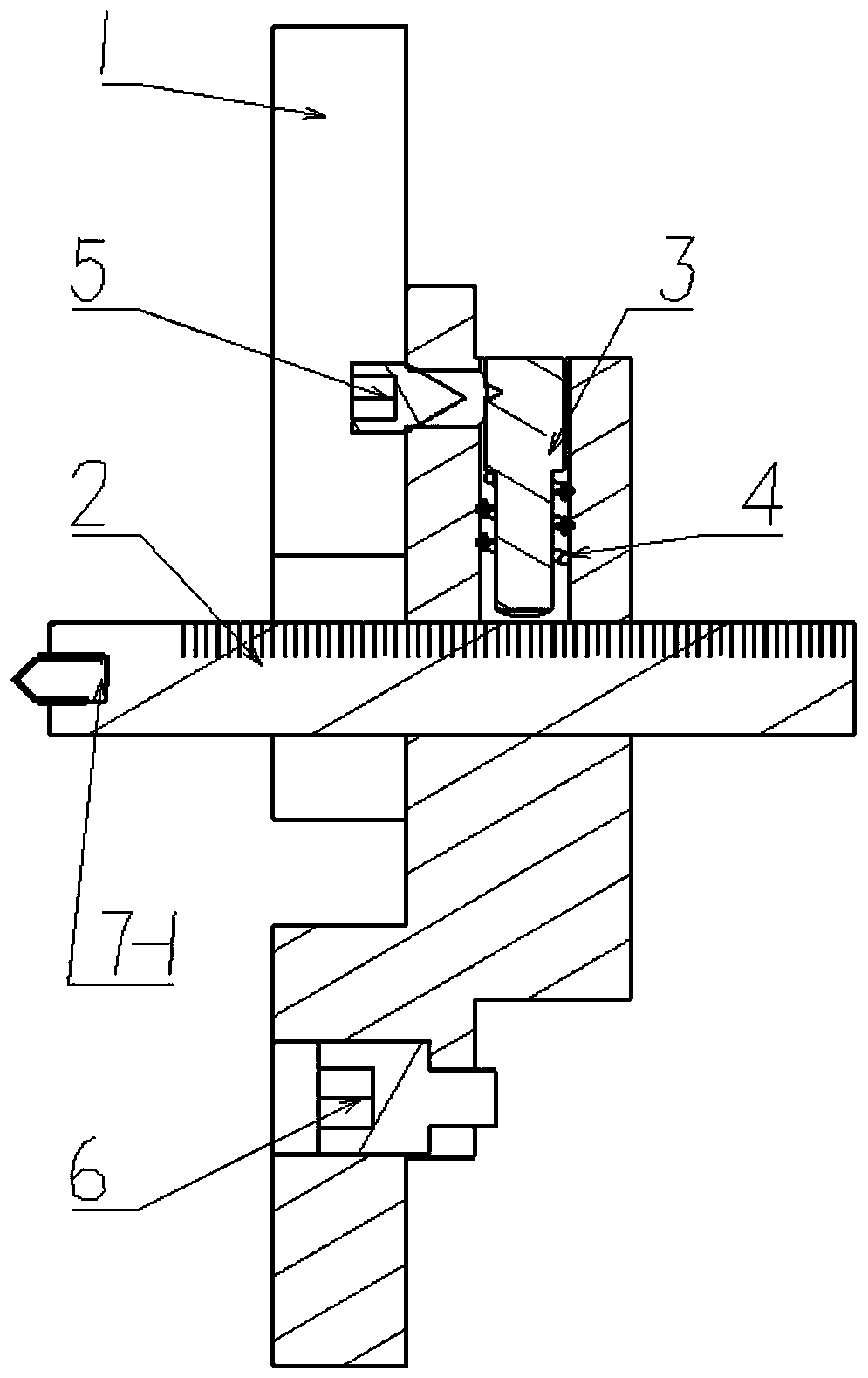

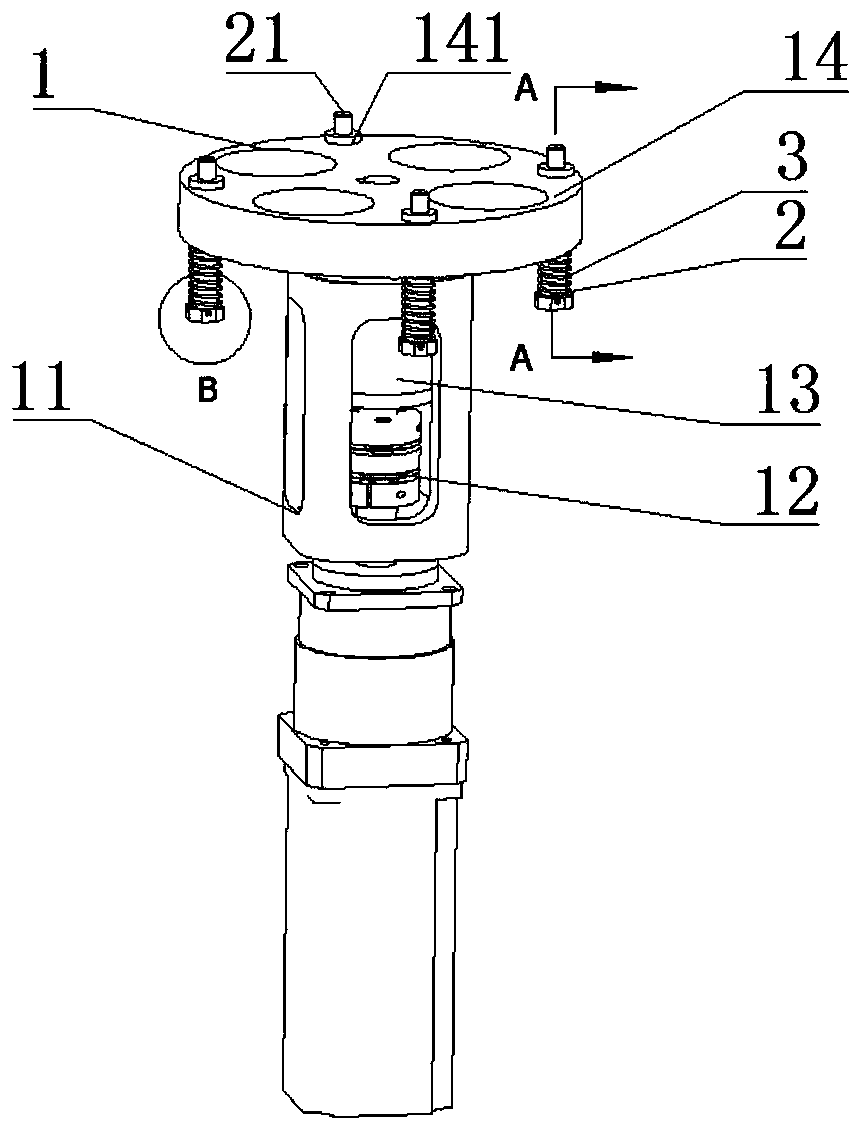

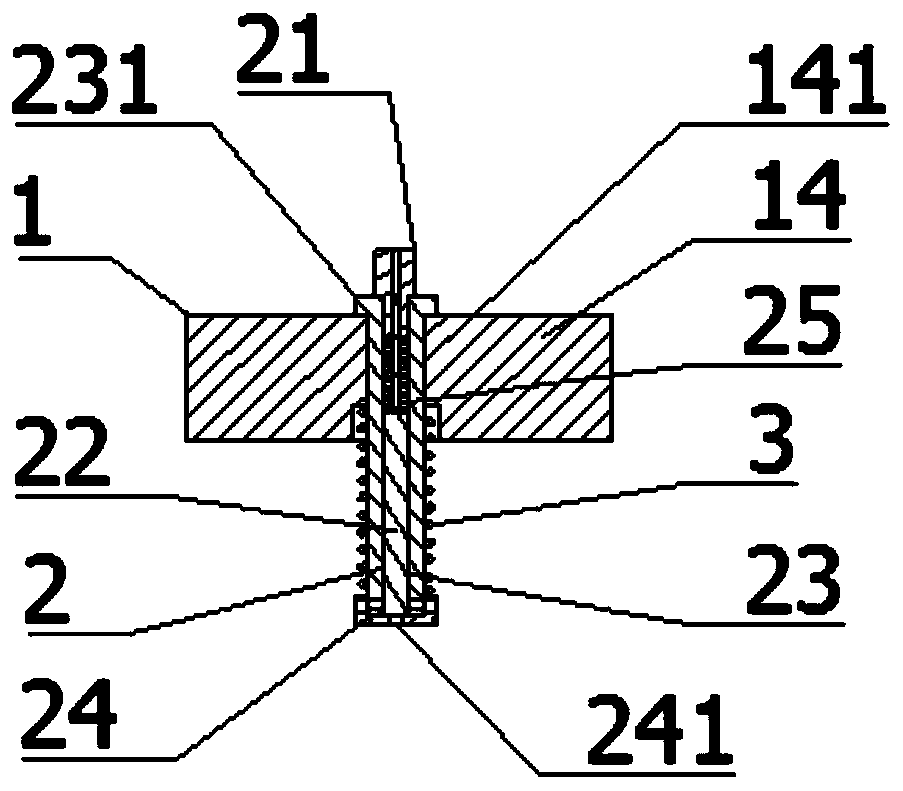

Built-in hydraulic clamping chuck used for spline cold rolling machine tool and assembly machine

InactiveCN103433303AAxial positioning is accurateRemove uncertaintyGuiding/positioning/aligning arrangementsMachine toolAssembly machine

The invention belongs to the technical field of machine manufacturing and discloses a built-in hydraulic clamping chuck used for a spline cold rolling machine tool and an assembly machine. The built-in hydraulic clamping chuck comprises a flange positioning installation component, an axial positioning radial elastic clamping component, a connecting component and a movable center component. The movable center component is located at the central part of the built-in hydraulic clamping chuck; the left end of the movable center component is provided with the axial positioning radial elastic clamping component; the flange positioning installation component is arranged outside the left end of the movable center component; the flange positioning installation component is in threaded screwed connection with the axial positioning radial elastic clamping component by the connecting component; the connecting component is located outside the right end of the chuck. According to the built-in hydraulic clamping chuck disclosed by the invention, not only can accurate axial positioning be realized but also the uncertainty of the strength of a clamping force can be eliminated by using hydraulic clamping. The clamping force is stable and reliable. Moreover, the built-in hydraulic clamping chuck has the advantages that the structure is compact, the occupied length of a machine tool slide guide is small, and the processing range of the machine tool is broadened. The built-in hydraulic clamping chuck is easy to manufacture and install, and is very good in use value.

Owner:CHINA YITUO GROUP

Welding tool fixture for electrolytic bath cathode steel rod and explosion block

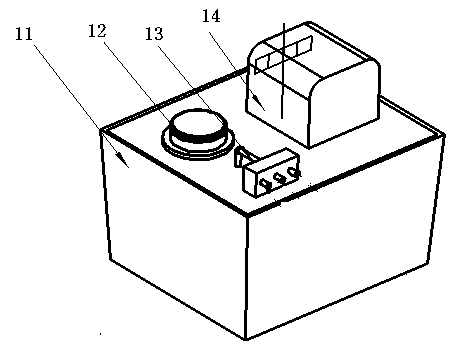

ActiveCN106078063ASolve complex and tedious problems with low efficiencyEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesFixed frameWorking environment

The invention discloses a welding tool fixture for an electrolytic bath cathode steel rod and an explosion block. The welding tool fixture comprises a fixed frame 5, a rotary hanging hook 6, a welding steel piece box 8, a lifting handle cover 10, an extension rod 3, a first spanner 2 and a second spanner 11; the fixed frame 5 consists of a door-shaped front frame 15, a side plate 17 and a cross beam 16; the rotary hanging hook 6 is fixed up and down through penetrating through one end of the cross beam 16 and a base 19 on the side plate 17; the welding steel piece box 8 is hung on the cross beam 16 through a cylinder pin 9; the first spanner 2 and the door-shaped front frame 15 can enable the explosion block 14 to fix with the fixed frame 5; and the second spanner 11 and the rotary hanging hook 6 can enable the cathode steel rod 7 to fix with the fixed frame 5. The welding tool fixture is convenient for installation, easy to dismount, simple in whole structure and easy to operate, improves the labor intensity and the working environment, is easier to realize automatic welding through matching with a welding machine, and improves the welding efficiency.

Owner:GUIYANG AL-MG DESIGN & RES INST

Limit locking nut and limit locking device

ActiveCN101825134APrecise positioningAxial positioning is accurateNutsBoltsEngineeringMechanical equipment

The invention relates to a limit locking nut and a limit locking device. The limit locking nut comprises a nut which can be screwed into a shaft, wherein at least two grooves into which limit plates can be inserted are arranged at one outer side of the nut, and each limit plate passes through the side wall of the nut on which at least one bolt is fixed. The limit locking device is characterized in that the nut is screwed into a preset position of the shaft, and the limit plate is radially inserted from the groove at the outer side of the nut and is contacted with a shoulder; and the limit plate is fixed on the nut by the bolt or the bolt along with a gasket. The limit locking device has the characteristics of simpler processing and assembly, more reliable locking and the like, and can be applied in mechanical equipment requiring high reliability.

Owner:HANGZHOU ADVANCE GEARBOX GRP

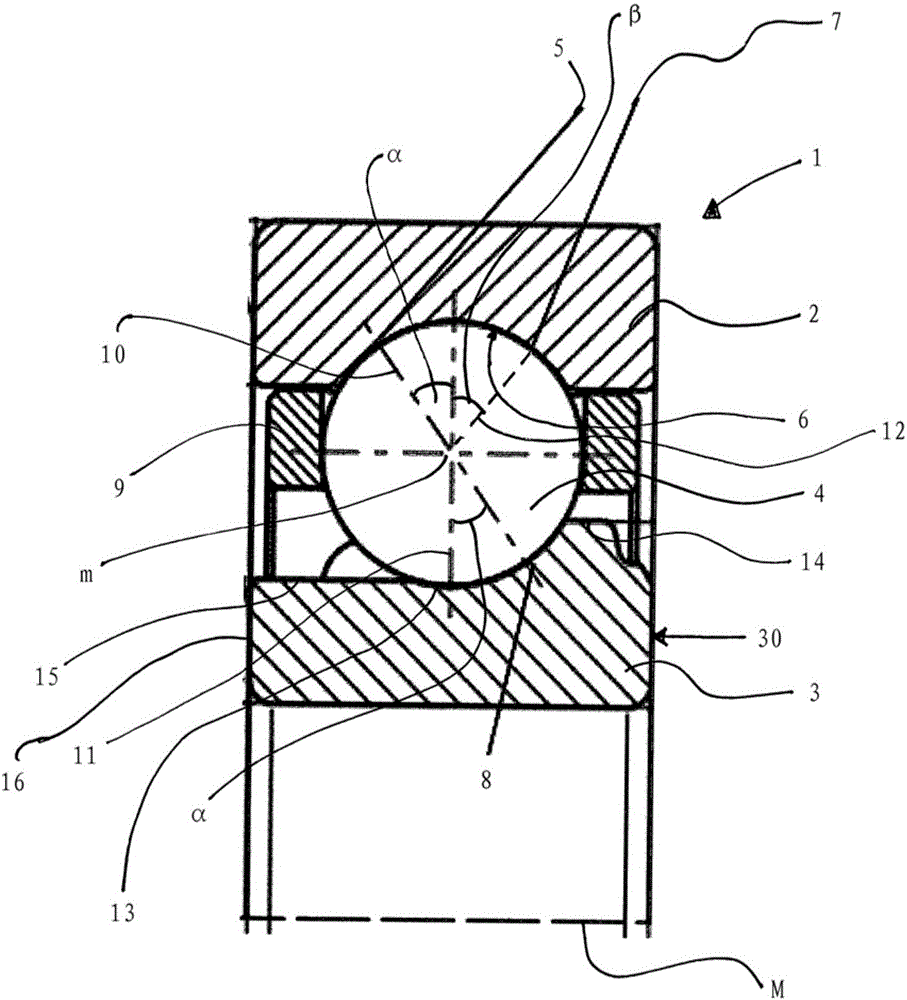

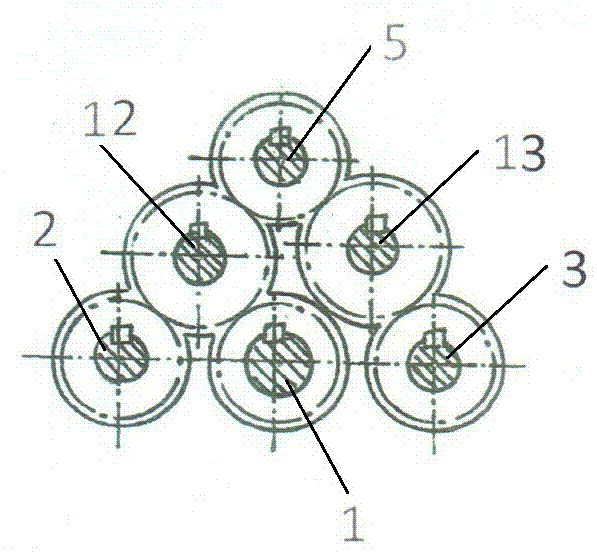

Rolling bearing, high-speed bearing device and compressor

InactiveCN106065899AAvoid or at least minimize changeEasy to undertakeShaftsBall bearingsEngineeringMechanical engineering

An embodiment relates to a rolling bearing (1) having at least one outer ring (2) and at least one inner ring (3). A plurality of rolling bodies (4) is provided between the outer ring and the inner ring to support the inner ring (3) in a rotary mode with respect to the outer ring (2). The outer ring (2) has at least one more rollaway nest (5, 7) for the plurality of rolling bodies (4) than the inner race (3).

Owner:AB SKF

Adjustable multipurpose fracture reduction outer fixing frame

ActiveCN102670290AAxial positioning is accurateAccurate Horizontal OrientationExternal osteosynthesisFunctional exercisesFracture reduction

The invention discloses an adjustable multipurpose fracture reduction outer fixing frame which comprises at least one set of fixing frame body. The fixing frame body comprises an axial adjusting screw, two axial adjusting devices arranged at the two ends of the axial adjusting screw, two main brackets, two horizontal adjusting devices, two vertical adjusting devices as well as a main needle clamp and an auxiliary needle clamp which are fixed with the horizontal adjusting device and vertical adjusting device on the same side; a fracture fixing needle is arranged on the main needle clamp and the auxiliary needle clamp respectively; the horizontal adjusting device drives the main needle clamp and the auxiliary needle clamp to move in a horizontal direction; the vertical adjusting device drives the main needle clamp and the auxiliary needle clamp to move in a vertical direction; and the axial adjusting device drives the main needle clamp and the auxiliary needle clamp to move in an axial direction. The adjustable multipurpose fracture reduction outer fixing frame disclosed by the invention realizes convenient and accurate alignment and adjustment, has better generality and universality in treating fracture, and is firm and reliable and small in volume; and moreover, the needle through hole is flexibly adjusted, and the functional exercise of the joint can be taken at the early stage after operation.

Owner:左中男

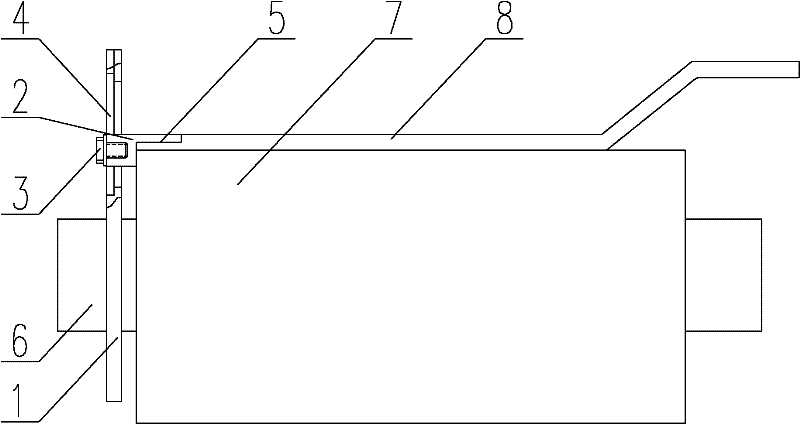

Device for positioning and clamping leading-out wire of transformer foil coil

InactiveCN102254670ARealize clamping positioningAxial positioning is accurateTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses a device for positioning and clamping a leading-out wire of a transformer foil coil. The device comprises a fixing plate, a positioning sliding plate and a bolt, wherein the positioning sliding plate is vertically fixed on the fixing plate by the bolt; a sliding slot is formed on the fixing plate; and the bolt passes through the sliding groove. The device has the advantages that: the height of the positioning sliding plate is adjusted in the sliding slot of the fixing plate so that the positioning sliding plate is concavely and convexly occluded with the leading-out wire; and the bolt is fastened so as to position and clamp the leading-out wire. The axial positioning of the leading-out wire is accurate and is not influenced by styles of a mold; a dry transformer or an oil immersed transformer can be applicable no matter the dry transformer or the oil immersed transformer is poured or not; and the operation is simple.

Owner:JIANGSU BAOHENGXIN ELECTRIC

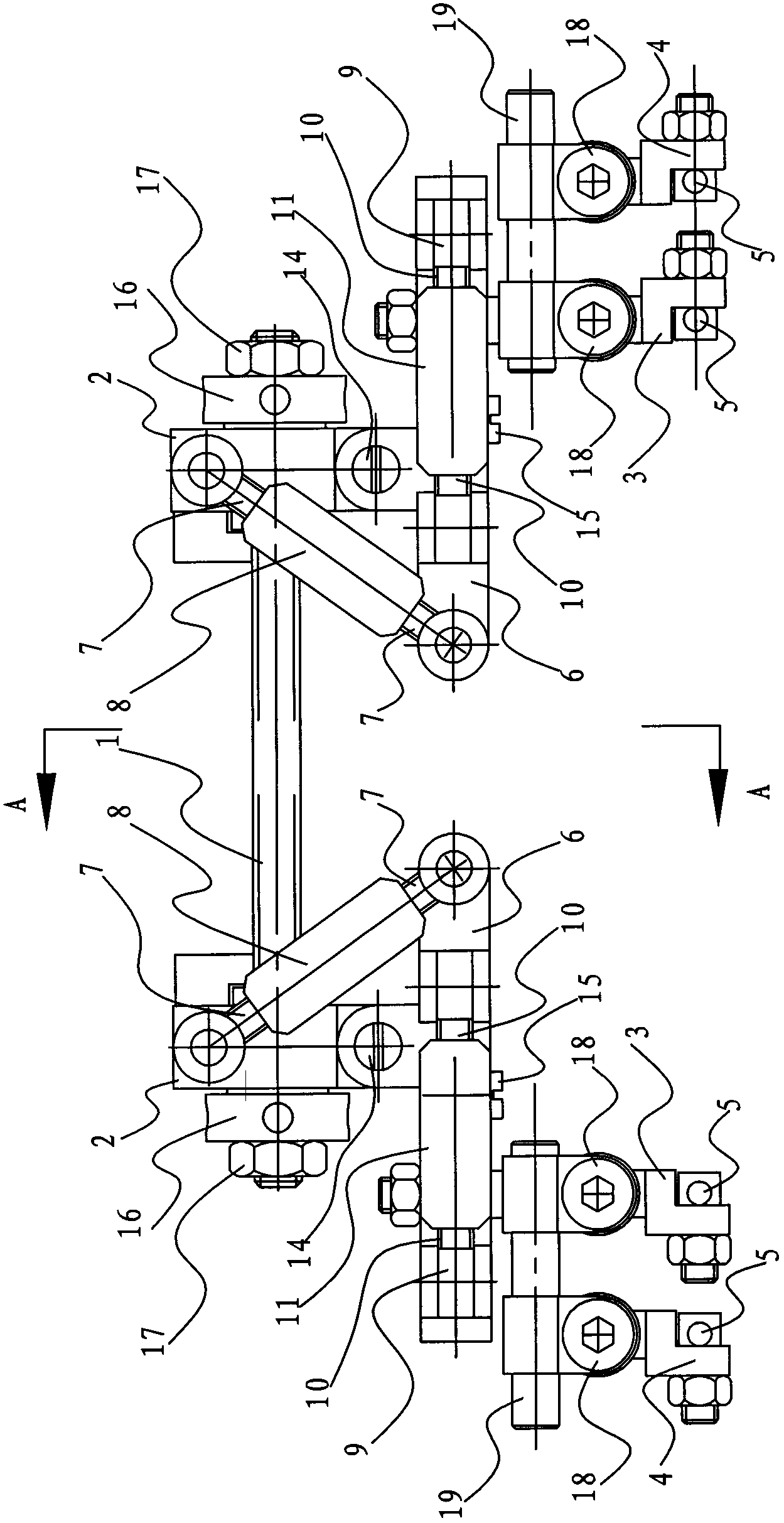

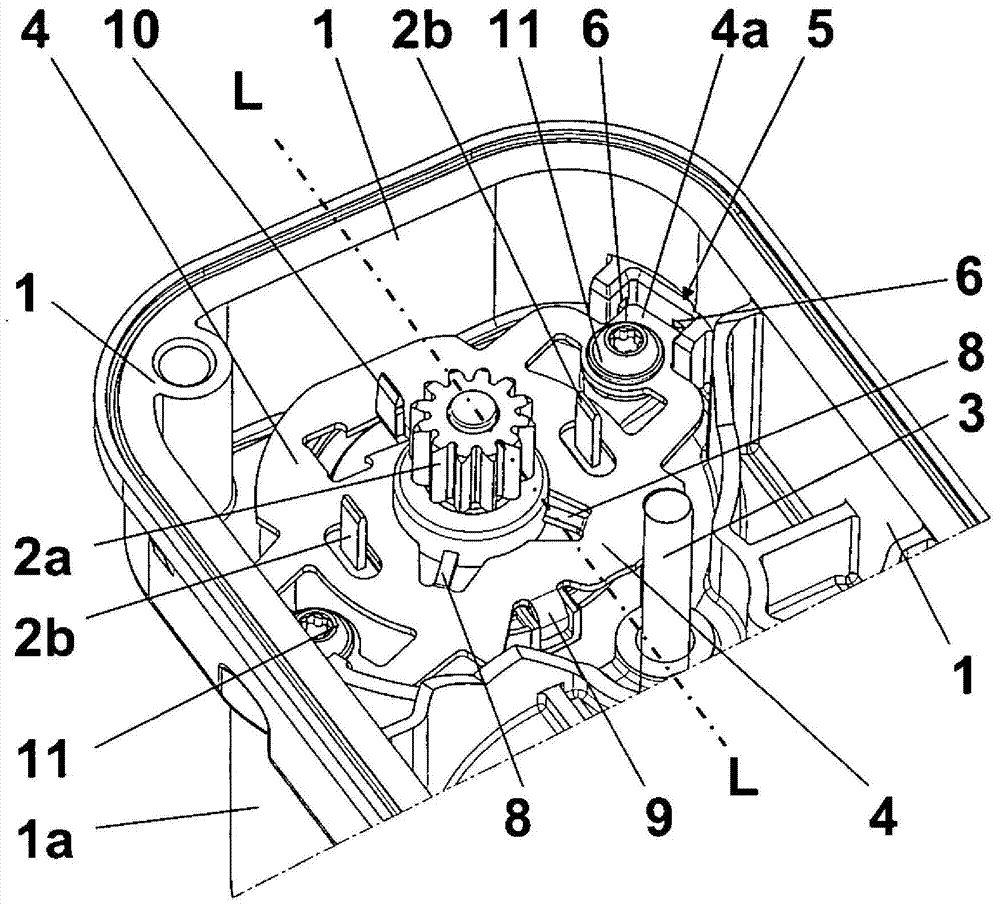

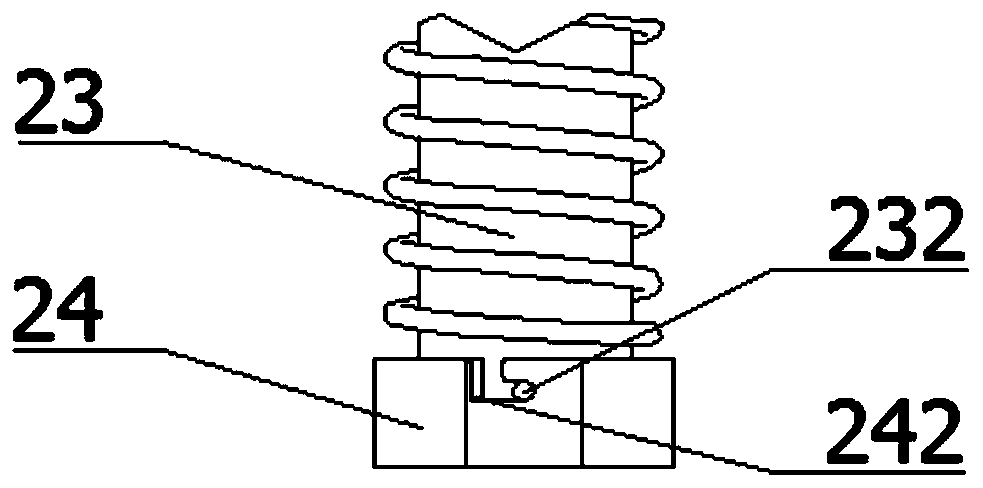

Large-sized pressure spring loading and unloading machine

InactiveCN104511742AAxial positioning is accurateImprove wear resistanceMetal working apparatusGear wheelWear resistant

The invention discloses a large-sized pressure spring loading and unloading machine. A left lead screw cylinder shaft is connected with an upper spring fixing seat, a lower spring fixing seat, a left lead screw nut and a nut; a right lead screw cylinder shaft is connected with the upper spring fixing seat, the lower spring fixing seat, a right lead screw nut and a nut; the upper spring fixing seat and the lower spring fixing seat are provided with a wear-resistant lining; an upper spring pushing support plate is connected with the wear-resistant lining and the upper spring fixing seat; a lower spring pushing support plate is connected with the wear-resistant lining and the lower spring fixing seat; a left lead screw gear is connected with the upper spring fixing seat and the left lead screw nut and is engaged with a middle gear; a right lead screw gear is connected with the right lead screw nut and is engaged with a driving gear. The driving bevel gear is engaged with a driven bevel gear. A spring pulling plate is connected with the upper spring pushing support plate and the lower spring pushing support plate; a gearbox casing is connected with the upper spring fixing seat.

Owner:王荣

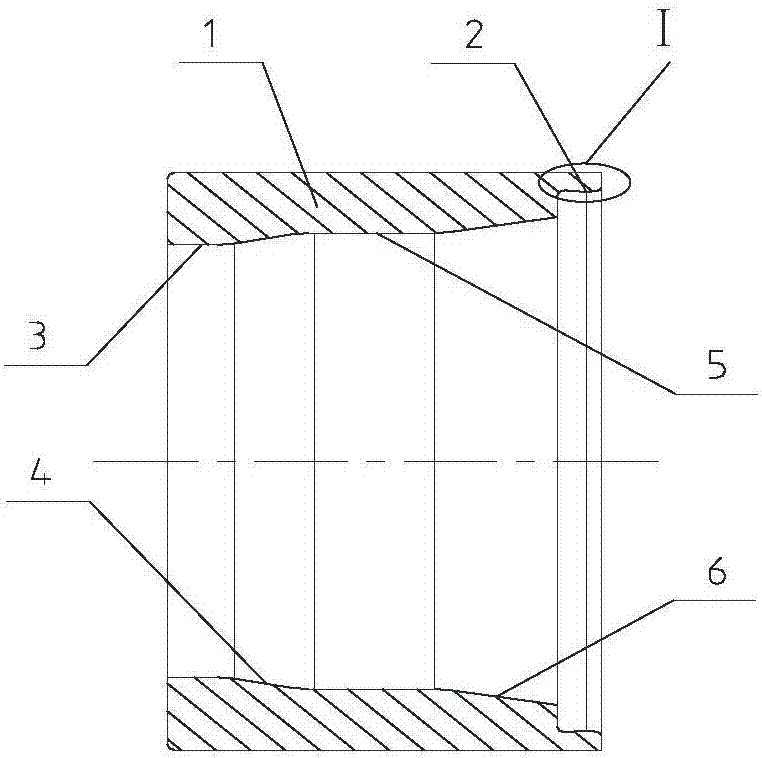

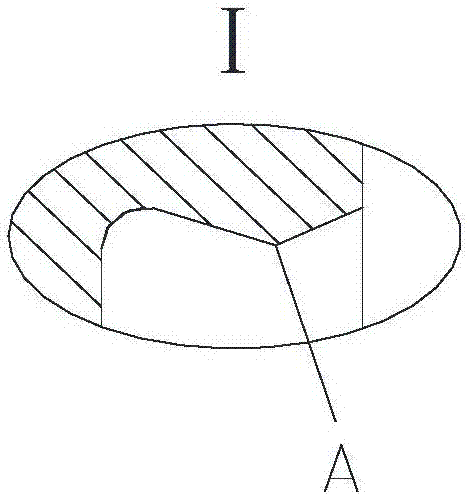

Mandrel component

ActiveCN104827068AAxial positioning is accurateAchieving preliminary axial positioningExpansion mandrelsMechanical engineeringWedge shape

Owner:TSINGHUA UNIV +1

Round positioning clamp and using method thereof

The invention discloses a round positioning clamp and a using method thereof. The round positioning clamp comprises a first clamp, a second clamp, a regulating bolt and a plurality of pressing mechanisms, wherein the first clamp is fixedly arranged at one side of the upper part of a clamp base; the second clamp is arranged at the other side of the upper part of the clamp base in a sliding mode; the first clamp and the second clamp are symmetrically arranged, and are of semi-cylindrical structures; the first clamp is matched with the second clamp to form a clamp datum positioning circle; a partdatum circle of the processed part sleeves the clamp datum positioning circle; one end of the regulating bolt is connected to the second clamp, and the other end of the regulating bolt is connected to the clamp base; and the pressing mechanisms are uniformly arranged on the outer side periphery of the clamp datum positioning circle, and are used for vertical positioning of the processed part. According to the round positioning clamp disclosed by the invention, the first clamp and the second clamp define the clamp datum positioning circle; and the regulating bolt is screwed up to regulate a gap between the clamp datum positioning circle and the part processing datum circle, so that the precise positioning clamping effect on the processed part and a quick dismounting function on the processed part are realized.

Owner:AECC AVIATION POWER CO LTD

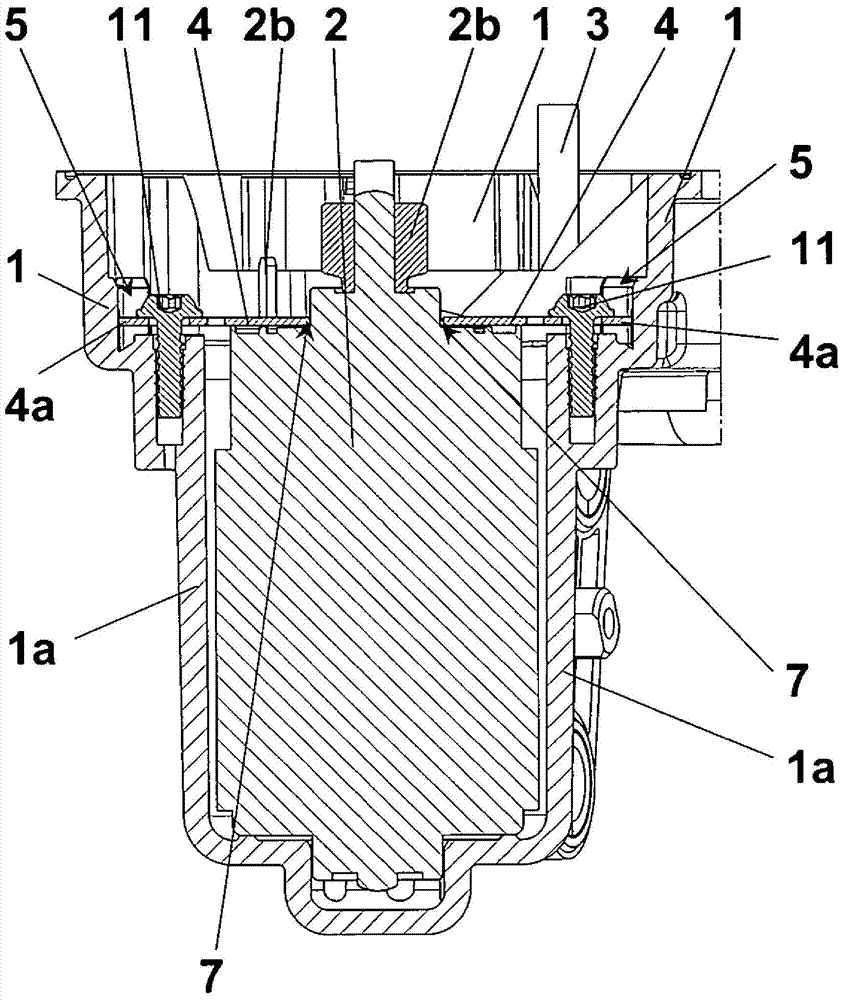

Actuating drive

ActiveCN103683643ALow priceImprove operational reliabilityMechanical energy handlingSupports/enclosures/casingsEngineeringMetal sheet

Owner:海拉有限双合股份公司

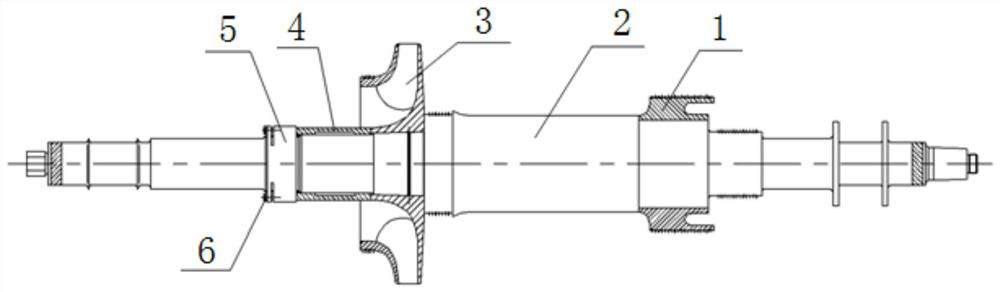

Connecting method of pure electrical vehicle driving system

InactiveCN102211520AAxial positioning is accurateAvoid stress concentrationControl devicesElectric machineryProcessing accuracy

The invention discloses a connecting method of a pure electrical vehicle driving system, comprising the following steps of: A, processing a motor rotor main shaft (1); B, processing a spline sleeve (2); C, processing a connecting flange (3); and D, connecting and assembling. The method has the advantages of accuracy and convenience in positioning, high processing precision, and little error; the matching quality of connecting pieces is ensured; and the whole system is stable in running.

Owner:DONGFANG ELECTRIC CORPLESHAN NEW ENERGY EQUIP

A vacuum adsorption adjustment table for milling and grinding

ActiveCN107443200BCompensation for errors in uneven distribution of axial deformationGuaranteed positioning accuracyOptical surface grinding machinesEngineeringMachining process

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

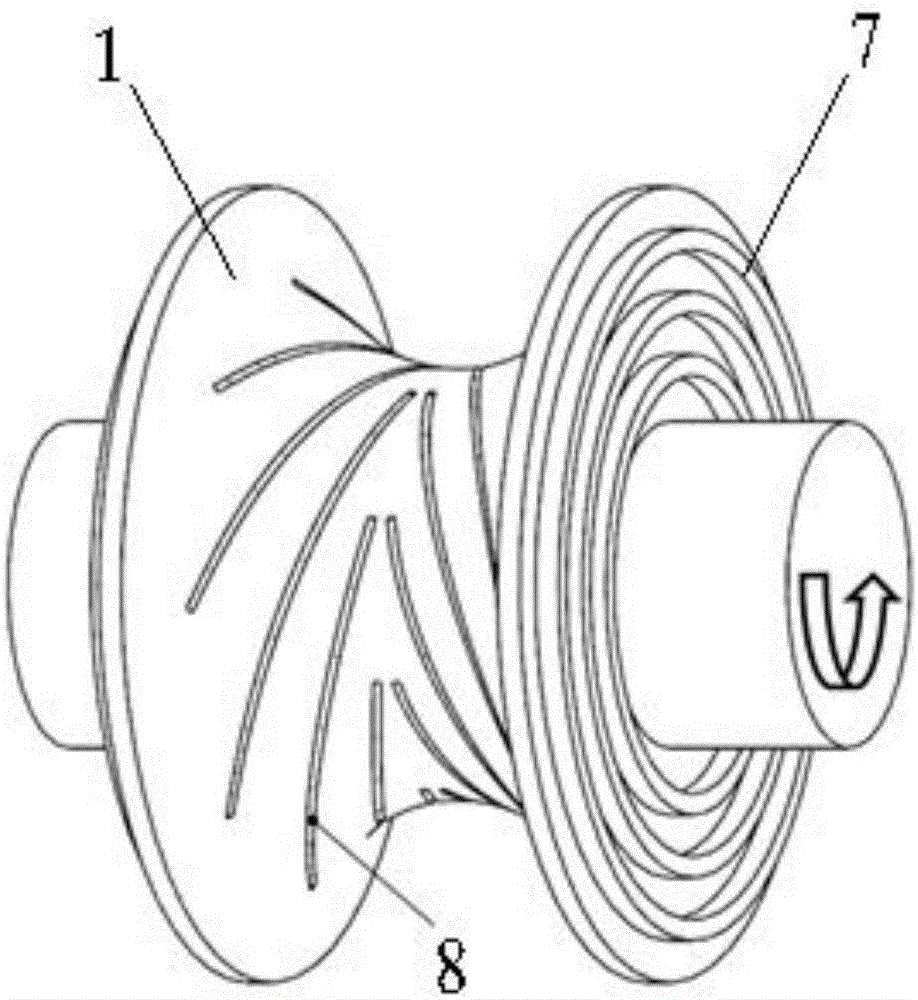

Centrifugal compressor rotor capable of hydraulically assembling and disassembling impeller and impeller assembling and disassembling method

PendingCN113357168AAvoid deformationAvoid heatingPump componentsRadial flow pumpsCentrifugal compressorPhysics

The invention discloses a centrifugal compressor rotor capable of hydraulically assembling and disassembling an impeller and an impeller assembling and disassembling method. The centrifugal compressor rotor comprises a main shaft, a balance disc, the impeller, a shaft sleeve and a locking nut, the balance disc, the impeller, the shaft sleeve and the locking nut are sequentially installed on the main shaft, and the locking nut is in threaded connection with the main shaft; the impeller is sleeved on the main shaft; and an annular oil passing groove is arranged on a matched conical surface of the main shaft, an axial oil injection hole is arranged at the axis of the main shaft, one end of the axial oil injection hole is located in a shaft head of the main shaft, and the other end of the axial oil injection hole is communicated with the annular oil passing groove through a radial oil inlet hole. The impeller does not need to be heated by flames in the impeller assembling and disassembling process, operation is simple and safe, and meanwhile, the impeller is prevented from deforming and bluing due to heating in the hot charging process; the impeller is axially positioned and locked through the locking nut, the shaft sleeve and a shaft shoulder structure on the main shaft, so that the axial movement of the impeller in the rotation of the rotor is avoided; and accurate positioning of impeller installation is achieved through a hydraulic tool, damage to the matching face of the impeller and the main shaft caused by disassembly and assembly is avoided, and repeated disassembly and assembly can be achieved.

Owner:XIAN SHAANGU POWER

Bearing and manufacturing method thereof

ActiveCN106812798AAxial positioning is accurateSimple structureGas cushion bearingsBearing componentsStatorStructural engineering

The invention relates to the technical field of bearings, in particular to a bearing and a manufacturing method thereof. The bearing comprises a stator and a rotor, wherein the rotor is arranged inside the stator; annular bulges which are arranged in a circumferential direction are arranged on the inner wall of the stator; annular grooves matched with the annular bulges are formed in the outer wall of the rotor. Diameters of two ends of the bearing provided by the invention are larger than that of the middle part, precise radial support can be achieved after the rotor and the stator are integrally molded and used, precise axial direction can be achieved as well, the bearing is simple in structure, furthermore production and manufacturing processes can be simple, and the production efficiency can be relatively high.

Owner:嘉兴意动能源有限公司

Proximity switch for oil cylinder

InactiveCN106438577ANot easy to looseAxial positioning is accurateFluid-pressure actuator testingServometer circuitsSet screwHigh pressure

The invention discloses a proximity switch for an oil cylinder. The proximity switch comprises a protective sleeve, a mounting base, a probe arranged in the protective sleeve and the mounting base, and a connecting line connected with the rear end of the probe. The proximity switch for the oil cylinder is characterized in that the protective sleeve is provided with a stepped hole; a shaft shoulder is arranged in the middle of the probe; the mounting base and the protective sleeve are connected through a thread and a radial set screw; the probe is located in inner holes of the protective sleeve and the mounting base; and the shaft shoulder of the probe is clamped between the end face of the stepped hole of the protective sleeve and the rear end face of the mounting base. The proximity switch for the oil cylinder has the advantages of being easy and convenient to mount, good in interchangeability, resistant to high pressure and not prone to loosening. The normal work can be guaranteed, and the working state of the proximity switch can be monitored.

Owner:泸州合成液压件有限公司

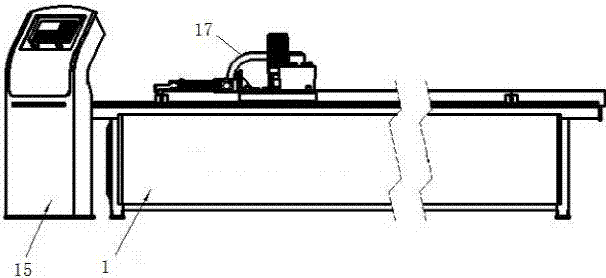

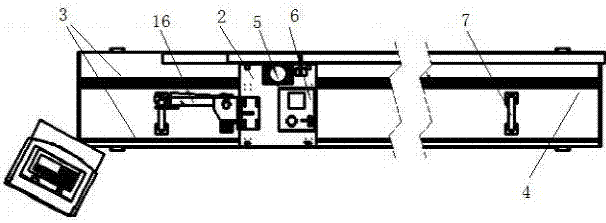

Large-stroke, rapid and accurate linear feeding production line

ActiveCN107962439AAvoid Cumulative ErrorsRapid positioningLarge fixed membersMetal working apparatusProduction lineEngineering

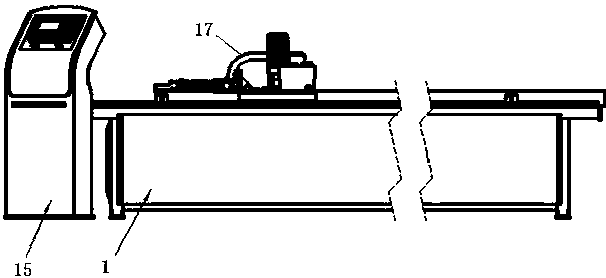

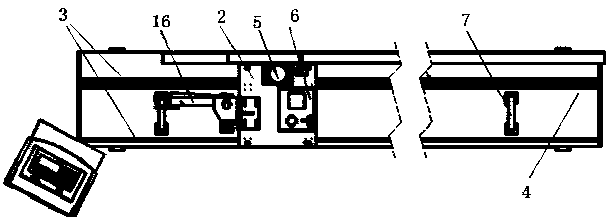

The invention discloses a large-stroke, rapid and accurate linear feeding production line, and belongs to the technical field of servo positioning control. Two parallel linear guide rails are installed on a tool body, and a rack is fixed on the inner side of one of the linear guide rails; linear sliding blocks are slidably installed on the linear guide rails, and a sliding plate is fixedly connected to the two linear sliding blocks; a servo motor is installed on the sliding plate, and the servo motor is connected with the rack through a transmission mechanism; an automatic lubricating device is further installed on the sliding plate; and two ends of the tool body are provided with adjustable tug mechanisms respectively. According to the linear feeding production line, when the sliding plate works every time, a mechanical zero point serves as a reference, so that the accumulative error is avoided, and rapid and accurate positioning is realized; a gear, the rack, linear guide rails and aplanetary gear are adopted, so that large rigidity power is provided for the production line, and axial positioning can be accurately realized; and the automatic lubricating device provides continuous lubricating oil for the gear, racks, the linear guide rails and the like, so that the service life is greatly prolonged.

Owner:江苏众利达自动化设备有限公司

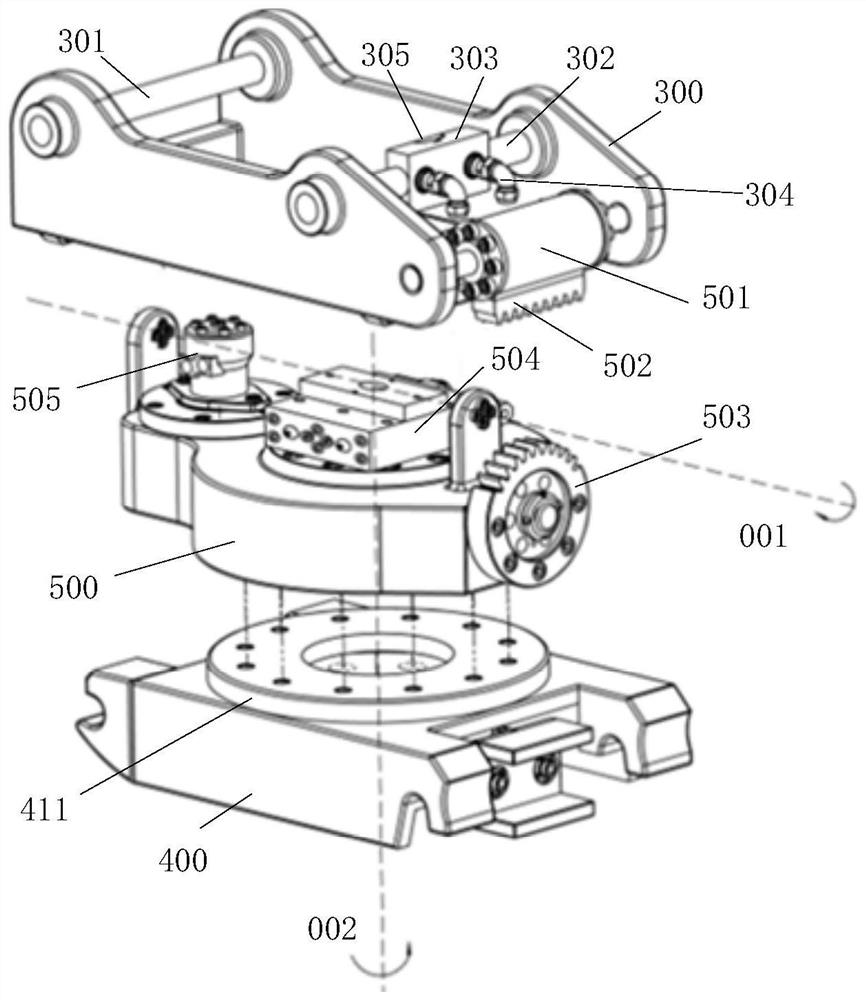

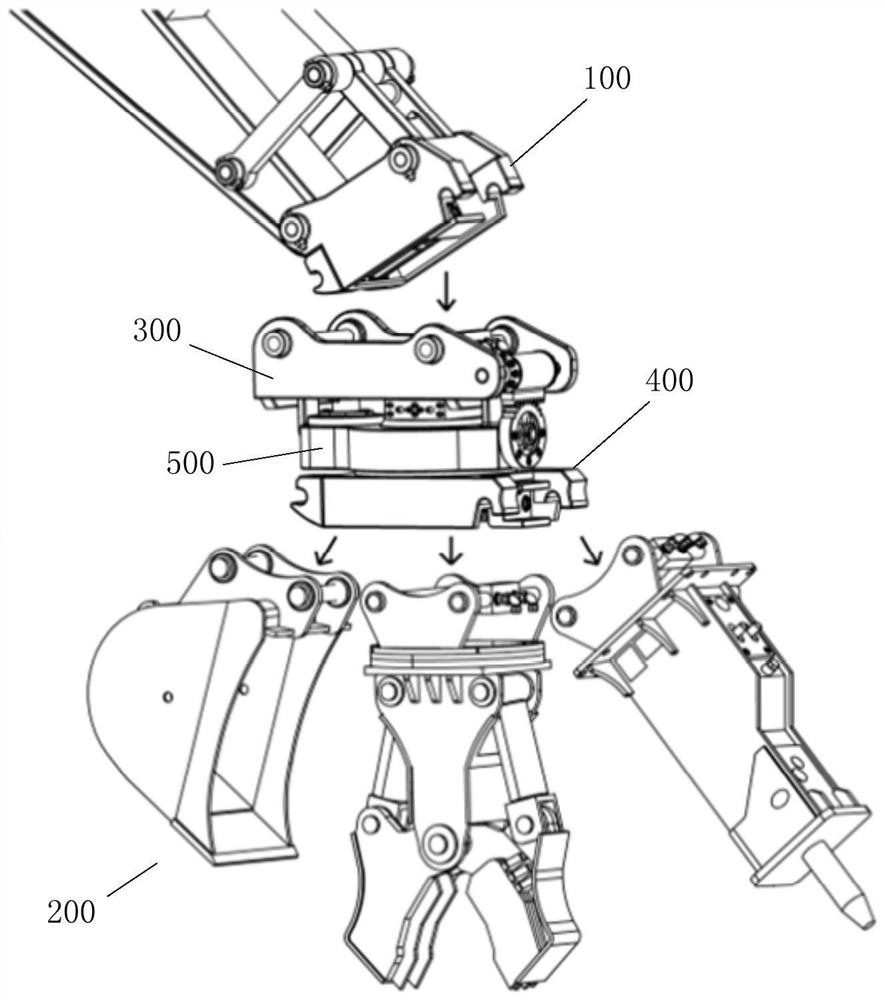

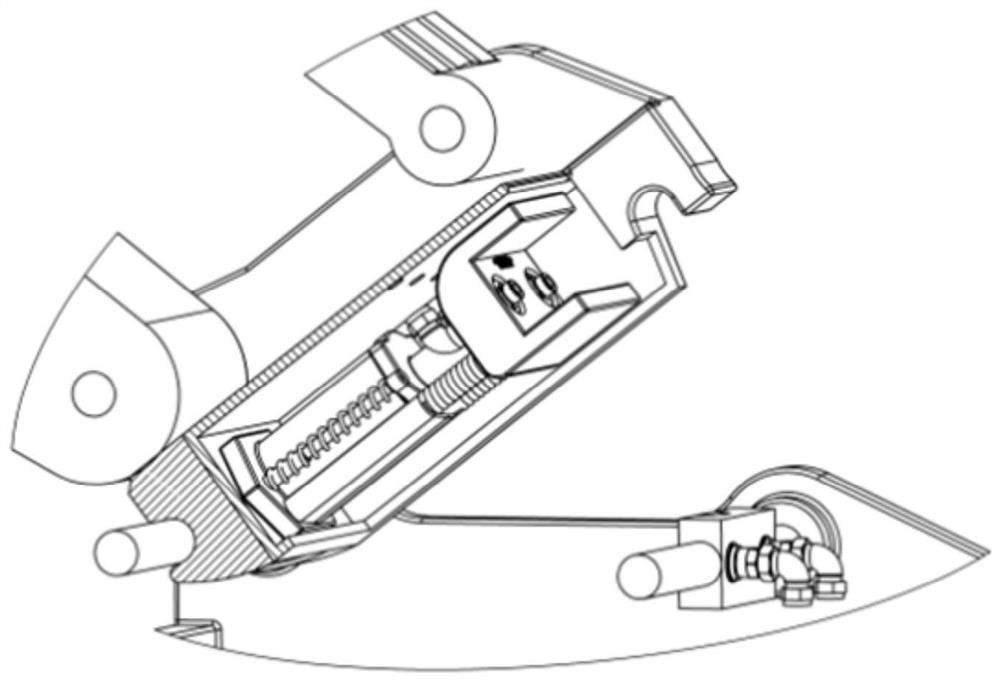

Full-automatic quick-switching device for emergency rescue engineering equipment

ActiveCN113123385ARealize automatic turn-onNeutral goodMechanical machines/dredgersEmergency rescueButt joint

The invention discloses a full-automatic quick-switching device for emergency rescue engineering equipment. An upper connecting device of the device is provided with a first front pin shaft and a first rear pin shaft which are connected with a first pin hook of a main machine bucket rod and a first locking butt joint mechanism. A lower connecting device of the device is provided with a second pin hook and a second locking butt joint mechanism which are connected with a second front pin shaft and a second rear pin shaft of a lower connecting accessory. A rectangular block is arranged in the middle of the rear pin shaft, and through holes for mounting female connectors are symmetrically formed in two ends of the rear pin shaft. A locking head is arranged at the telescopic end of each locking butt joint mechanism, a butt joint groove is formed in the middle of each locking butt joint mechanism, and through holes for installing male connectors are formed in the two ends of each butt joint groove. The pin hooks are connected with the front pin shaft and the rear pin shaft, and after the locking butt joint mechanisms lock the rear pin shaft, the female connectors in the rectangular block are in butt joint with the male connectors in the butt joint grooves. According to the technical scheme, the rescue requirements of quick switching and multi-degree-of-freedom operation of various machines and tools are met, and the problems that an existing quick switching device is complex in structure and high in manufacturing cost are solved.

Owner:HUNAN UNIV

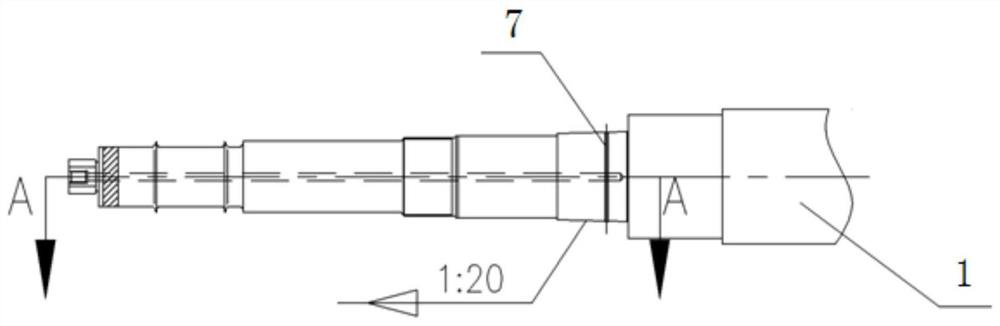

Precise axial displacement transmission device

InactiveCN104265852AIncrease the minimum precision scaleReduce wearGearingAxial displacementDrive shaft

A precise axial displacement transmission device of a box body structure comprises a box body, an input shaft, two transmission shafts and a parallelly-meshed threaded transmission pair consisting of three axis-coplaner screw shafts, namely two long threaded screw shafts and one short threaded screw shaft. One of the two long threaded screw shafts is supported in a front box body bearing hole to serve as a positioning reference for displacement transmission. The other one of the two long threaded screw shafts is supported in the front box body bearing hole to play a meshing gap eliminating role. The short threaded screw shaft is of a split structure formed by a taper pin connecting screw and a mandrel, and the mandrel is supported in the front box body bearing hole to play a displacement transmission role. The upper gear of an input shaft supported at the upper portion of a rear box body drives gears located at the rear ends of the three screw shafts respectively though gears on two middle transmission shafts so as to achieve differential rotation of the three screw shafts. Compared with a traditional screw and nut transmission pair, the minimum precision scale of axial displacement can be remarkably improved.

Owner:李想

Adjustable axial positioning device of lathe

InactiveCN111421368AAxial positioning is accurateEasy to operatePositioning apparatusMetal-working holdersPhysicsEngineering

The invention discloses an adjustable axial positioning device of a lathe, and belongs to the technical field of machines. The adjustable axial positioning device of the lathe comprises a main body disc, a positioning rod, a clamping pin, a spring, a locking screw, a fastening bolt and a positioning cap. According to the adjustable axial positioning device of the lathe, the positioning cap is replaced, so that the positioning requirements of parts of different structures can be met; the fastening bolt is connected with a three-jaw chuck of the lathe, so that the device can be disassembled without disassembling the three-jaw chuck, the operation is convenient, and the labor is saved; and the fastening screw is adjusted through a small stroke, the tightness and the loosening of the positioning rod is realized through the cooperation of the spring force and the conical surface, the adjustment of axial positioning is completed, the structure is exquisite, and the operation is simple.

Owner:SHENYANG AIRCRAFT CORP

Mechanical splice

InactiveCN106870840AInhibit sheddingIncrease vibration amplitudeJoints with sealing surfacesAviationMechanical splice

The invention discloses a mechanical splice comprising two main bodies, two sleeves and a bushing, wherein the bushing is arranged in the bore of the two main bodies arranged symmetrically, and the two sleeves are sheathed on the periphery of the main bodies; a stepped excircle I, a shaft shoulder, a stepped excircle II and a stepped excircle III are arranged on the periphery of the main bodies in turn from front to back, and the shaft shoulder is raised and annular, and is provided with a triangular, concave and annular drop-proof slot; a cylindrical surface I, a conical surface I, a cylindrical surface II, a conical surface II and a drop-proof ring are arranged in the bores of the sleeves from small ends to big ends in turn, the bushing is cylindrical, the middle part is thick and both sides are thin; the middle of the outside surface of the bushing is provided with a triangular annular bulge. The diameter, volume and weight of the mechanical splice disclosed by the invention are reduced obviously, so that the space occupation and total weight of a pipeline system are reduced, which is especially important for those aviation and aerospace fields with high requirements for the volume and weight.

Owner:TIANJIN SINO SWISS BONLOK PIPE CONNECTION TECH

Large stroke, fast and precise linear feed production line

ActiveCN107962439BAvoid Cumulative ErrorsRapid positioningLarge fixed membersMetal working apparatusProduction lineGear wheel

Owner:江苏众利达自动化设备有限公司

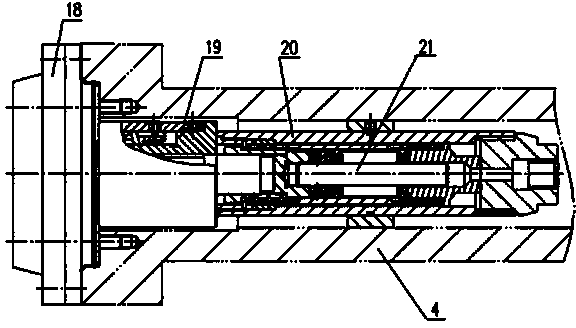

Stud welding gun

ActiveCN102310250BCompact structureConvenient welding operationElectrode supporting devicesStud weldingScrew thread

The invention discloses a stud welding gun, which comprises a gun shell and an end cover group arranged on the gun shell, wherein the end cover group comprises two aluminum sleeves and a positioning ring, the aluminum sleeve positioned at the rear end of the end cover group is clamped with the gun shell, the aluminum sleeve positioned at the front end of the end cover group is connected with the positioning ring through screw threads, two guide rods parallel to the axis of an electric conduction shaft are arranged on the aluminum sleeve positioned at the rear end of the end cover group, the aluminum sleeve positioned at the front end of the end cover group can be arranged on the guide rods in a relatively sliding mode, the gun shell and the aluminum sleeve positioned at the rear end of the end cover group constitute a cavity, the electric conduction shaft, a connecting body, an insulation sleeve, a male connection sleeve and a female connection sleeve are arranged in the cavity, the front end of the electric conduction shaft is provided with an electric conduction chuck, the rear end of the electric conduction shaft, the connecting body, the insulation sleeve and the front end of the male connection sleeve are sequentially connected, the rear end of the male connection sleeve is provided with an armature, the female connection sleeve is fixed on the gun shell and is sleeved onthe armature in a relatively sliding mode, and an electrification coil is arranged in the female connection sleeve. When the electrification coil is electrified, the male connection sleeve is lifted to slide to the female connection sleeve, and when the electrification coil is powered off, the male connection sleeve falls down to be far away from the female connection sleeve.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER

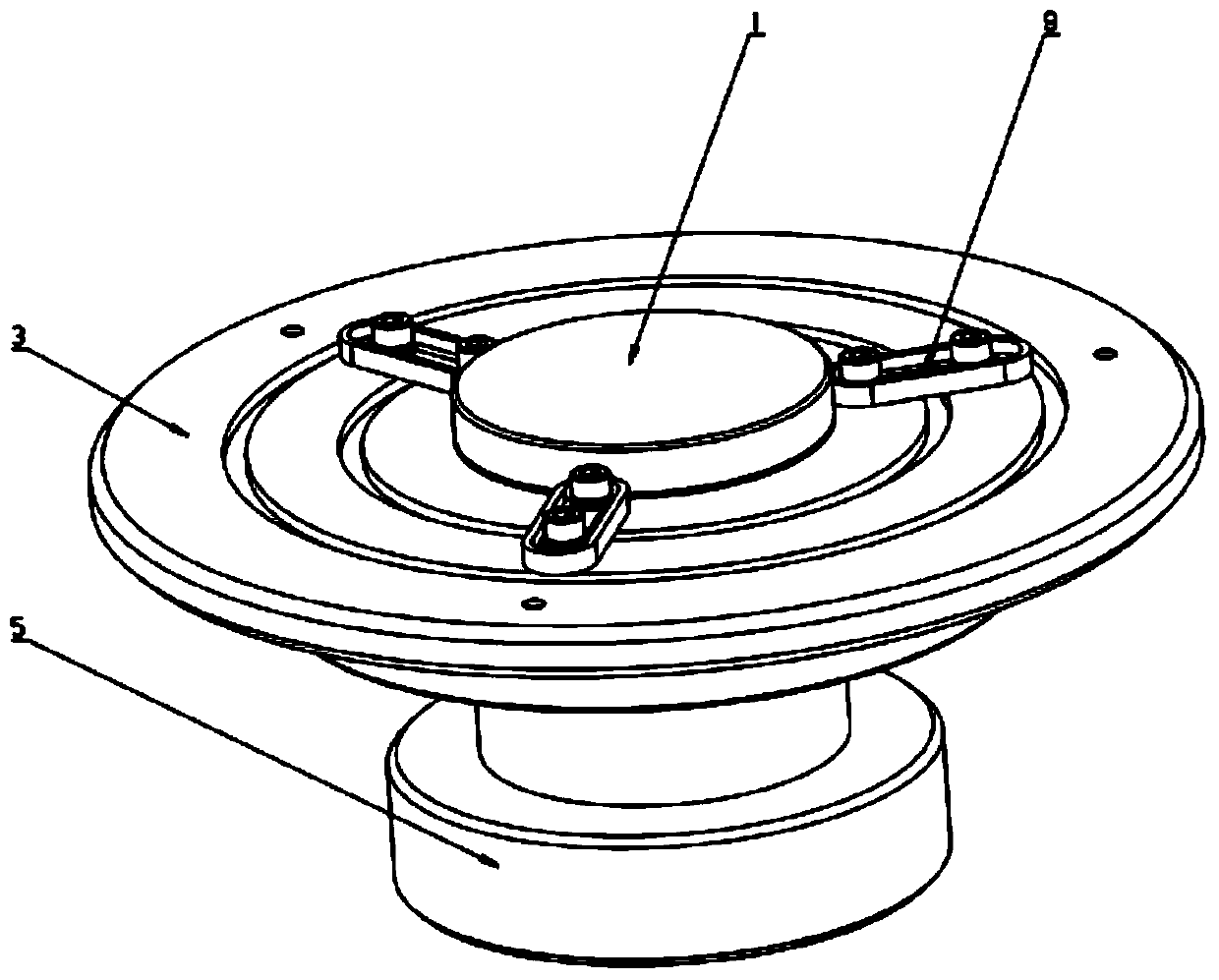

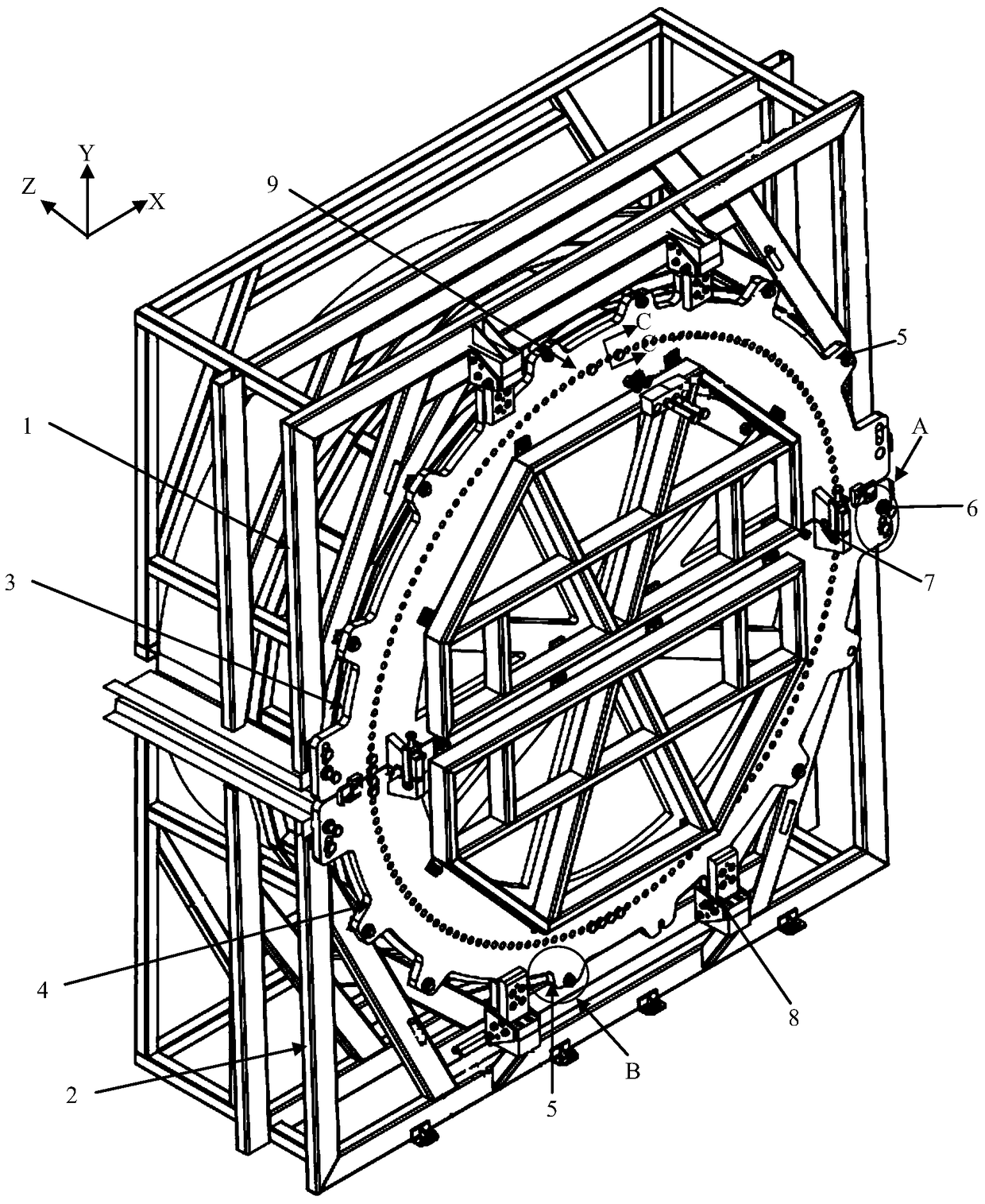

Circular rotating disc mechanism for transferring microneedles

ActiveCN110451242ANo scratchesAxial positioning is accurateConveyorsConveyor partsEngineeringRotating disc

The invention discloses a circular rotating disc mechanism for transferring microneedles. The circular rotating disc mechanism comprises a driving platform, a chuck assembly and a second spring. The circular rotating disc mechanism adopts structures of the driving platform and the chuck assembly, wherein the driving platform is provided with a circular rotating disc and four chuck assembly seats,the chuck assembly is arranged on the chuck assembly seats, the circular rotating disc on the driving platform rotates to drive the chuck assembly to be circulated in a reciprocating mode between a feeding station and a conveying station, feeding and conveying work on the corresponding stations is completed through a chuck of the chuck assembly, a feeding jacking rod and a carrying table, and no abrasion and scratch is caused to the microneedles in the feeding and conveying processes. The circular rotating disc mechanism has the advantages that the structure is simple, universality is high, station conversion is fast and stable, and axial positioning of the microneedles is precise.

Owner:SHANGHAI WORKPOWER TELECOM TECH

A fan blade pre-embedded root flange device

Owner:SINOMATECH WIND POWER BLADE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com