Connecting method of pure electrical vehicle driving system

A technology of drive system and connection method, which is applied to vehicle parts, control devices, transportation and packaging, etc. It can solve the problems of large spline machining error and inaccurate installation and positioning reference, and achieve stable operation, small error, and axial positioning precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

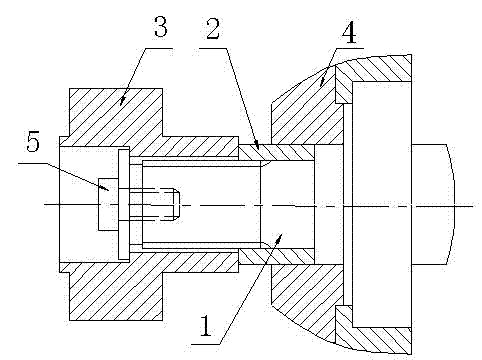

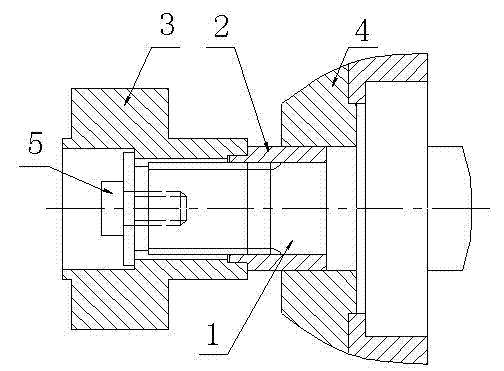

[0021] Further describe the technical scheme of the present invention below in conjunction with accompanying drawing:

[0022] A method for connecting a drive system of a pure electric vehicle, comprising the following steps:

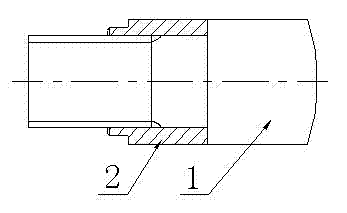

[0023] A. Machining motor rotor spindle 1

[0024] The positioning adopts the double-top clamping method. Use the chuck thimble and the tailstock thimble to support the rotor spindle 1 of the processing motor, and adjust the height of the rotor spindle 1 of the processing motor by adjusting the top of the tailstock to perform alignment and positioning, and then clamp it with jaws The motor rotor main shaft 1 is processed by rotating to detect the axial movement of the motor rotor main shaft 1, and then by adjusting the height of the tiles until there is no axial movement, the axial margin is uniform, and the journal of the motor rotor main shaft 1 is roughly turned. Polish the end journal, CNC finish turning spline sleeve 2 to locate the shaft shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com