Large stroke, fast and precise linear feed production line

A technology of linear feed and large stroke, applied in the direction of large fixed members, metal processing equipment, maintenance and safety accessories, etc., it can solve the problems of reduced service life of gears, racks and guide rails, large cumulative errors, slow positioning speed, etc., to achieve Avoid cumulative errors, improve service life, and achieve accurate axial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

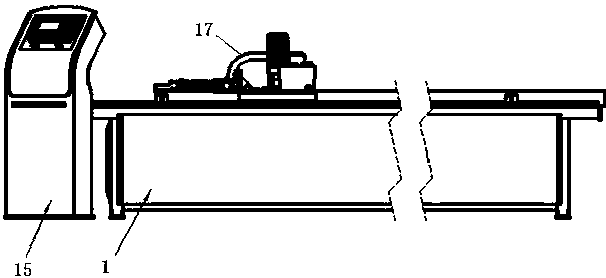

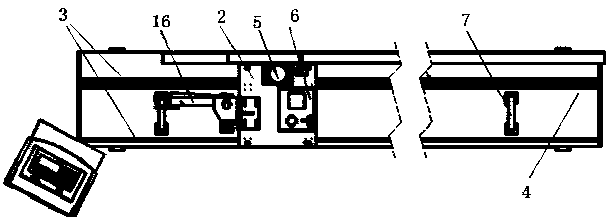

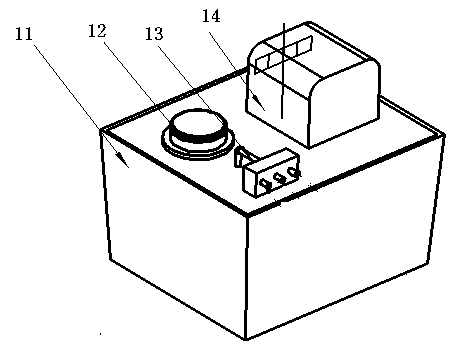

[0022] combine figure 1 with figure 2 As shown, a large-stroke, fast, and precise linear feed production line includes a long bed 1. The bed 1 specifically includes a longer bracket welded and formed, and a flat plate is laid on the longer bracket as an extra-long bed frame. Two parallel linear guide rails 2 are installed on the bed 1, and a rack 4 is fixed on the inner side of one of the linear guide rails 2; linear sliders are slidably installed on the linear guide rail 2, and sliding blocks are fixedly connected to the two linear guide rails. Plate 3; one side on the bed 1 is fixed with a mechanical origin 17 matched with the slide plate 3, and when the slide plate 3 moves each time, the mechanical origin 17 is used as a benchmark to avoid cumulative errors. A servo motor 5 and a workpiece fixture 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com