Automatic spot welding equipment

An automatic spot welding and equipment technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of hidden safety hazards, low welding efficiency, high labor intensity, etc., to improve safety, reduce labor intensity, improve The effect of welding productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

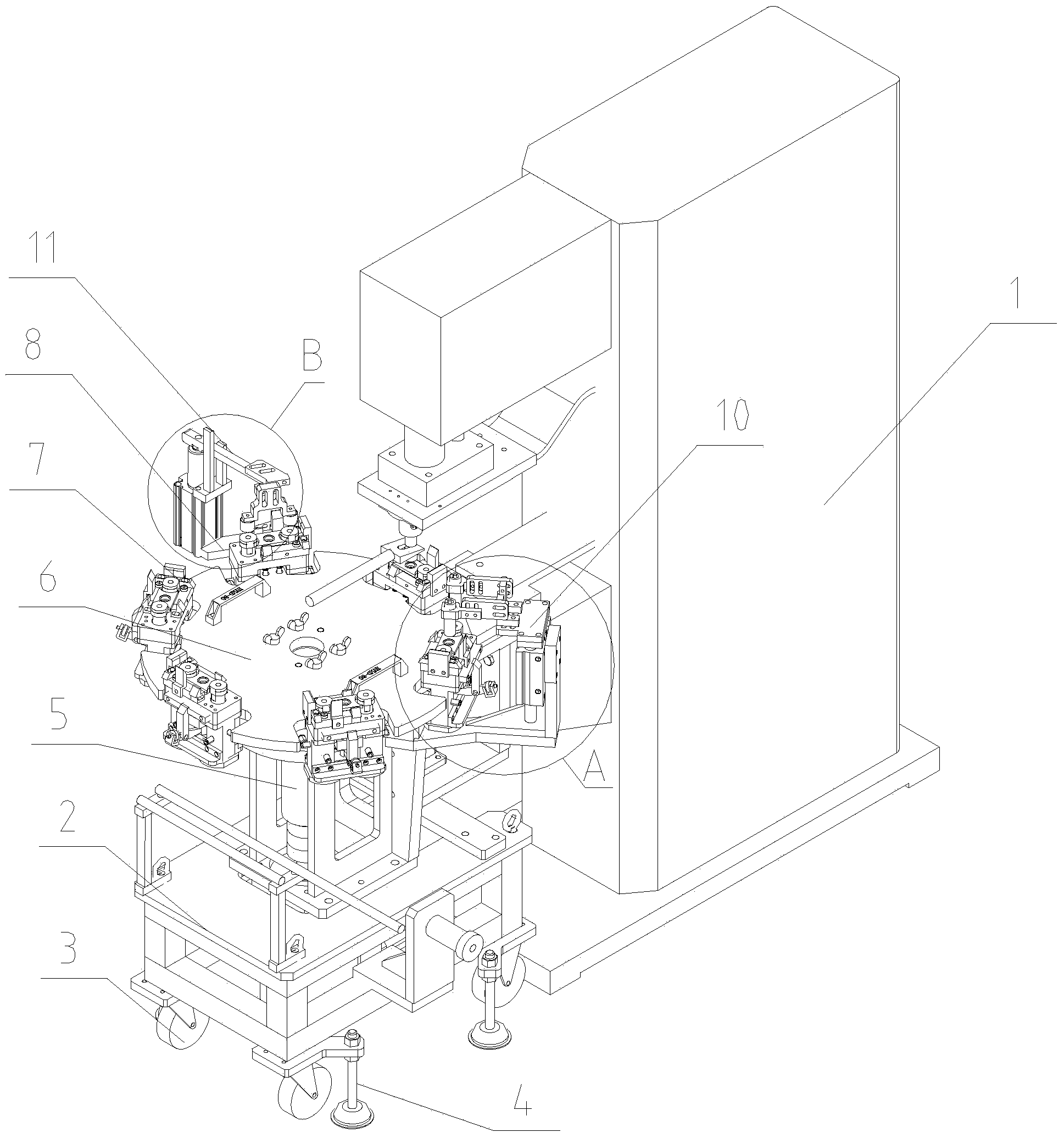

[0032] Such as Figure 1-5 As shown, an automatic spot welding equipment includes a welding machine body 1 and an installation base 2 arranged beside the welding machine body 1, and a lateral lock (not shown in the figure) is also provided between the base 2 and the fixed welding machine body 1 out) to ensure no displacement of the joint. The bottom of the installation base 2 is provided with a number of rollers 3 , and the installation base 2 is provided with four height-adjustable support feet 4 that can prop up the installation base 2 together with the rollers 3 .

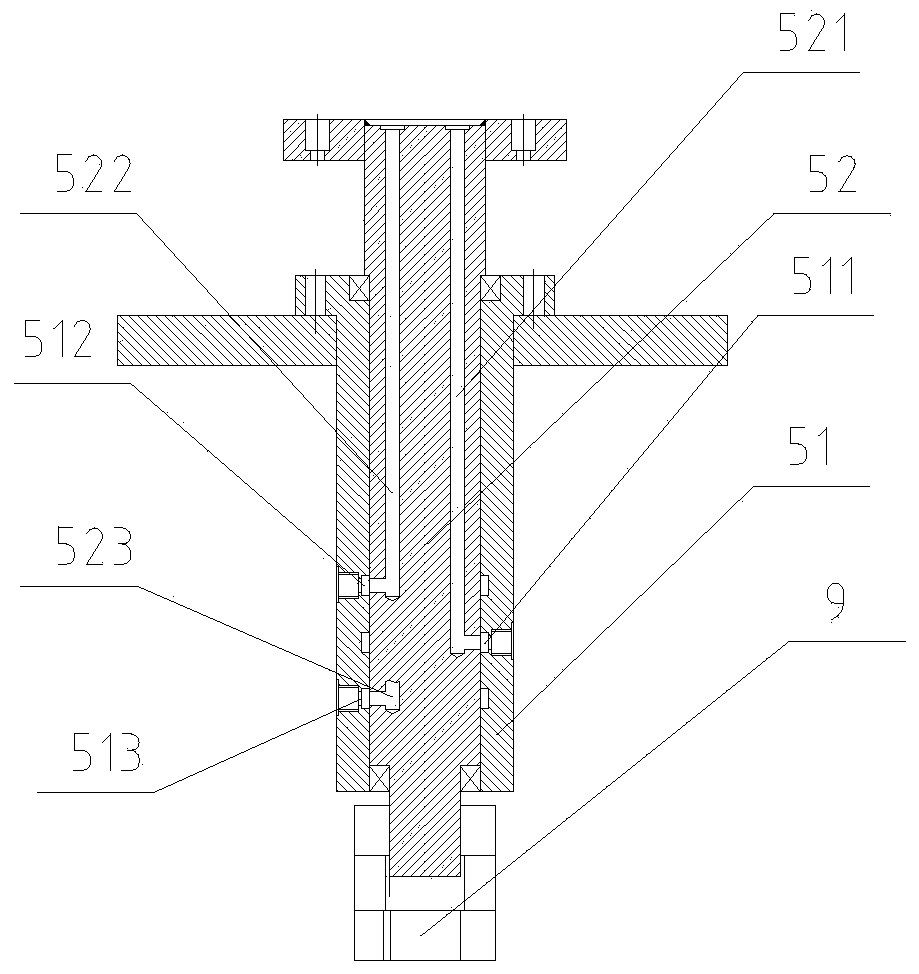

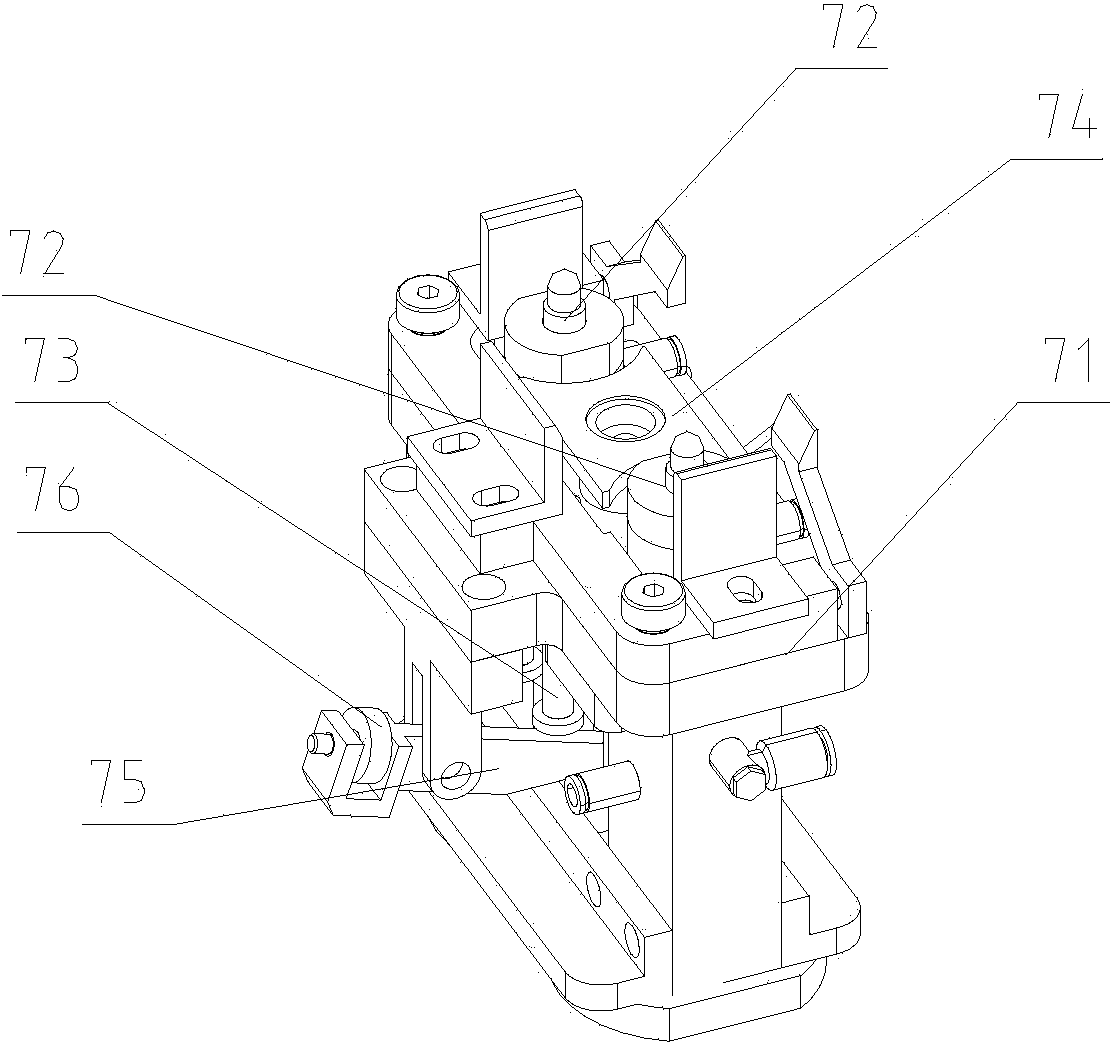

[0033] The installation base 2 is vertically provided with a rotating device 5 driven by a servo motor (not shown in the figure), and the upper part of the rotating device 5 is detachably provided with a mounting plate 6, and the mounting plate 6 is provided with six brackets e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com