Length measurement precision calibrating method and device for laser tracker

A technology of laser tracker and calibration device, which is applied in the direction of measuring devices, optical devices, instruments, etc., which can solve the problems of high processing cost, small length measurement range, and low calibration accuracy of ultra-long and high-precision guide rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

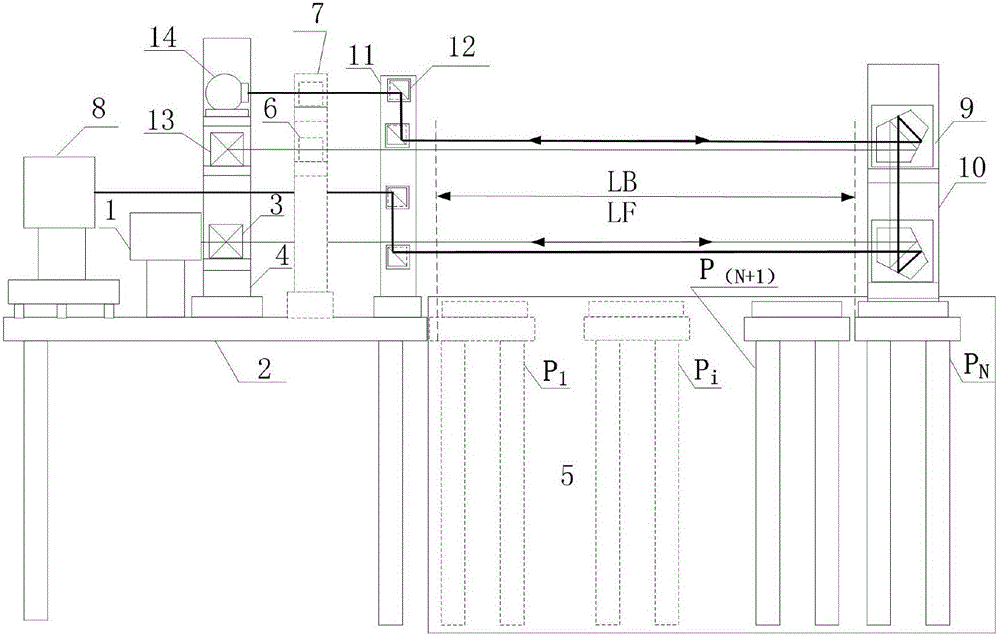

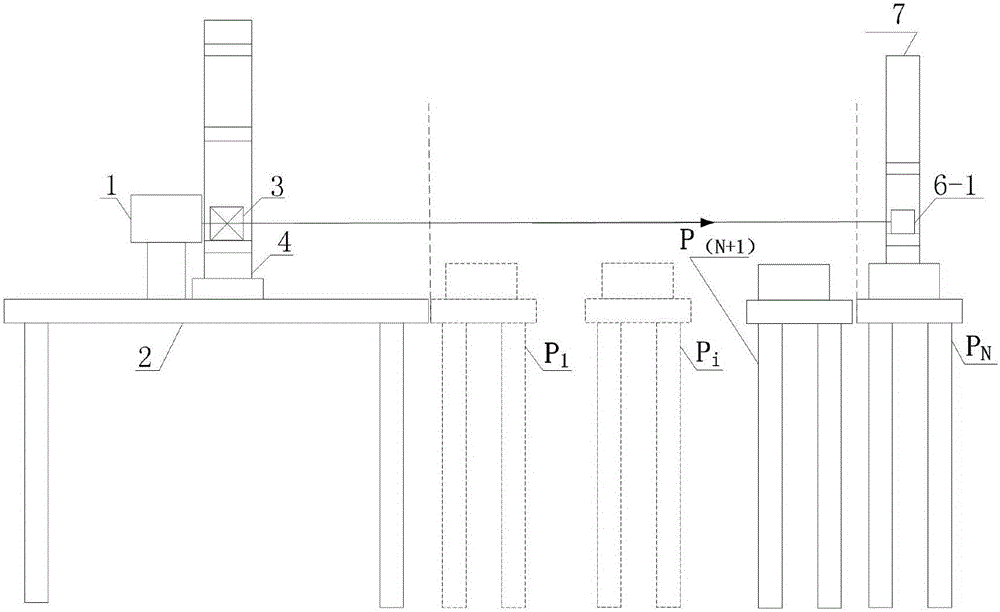

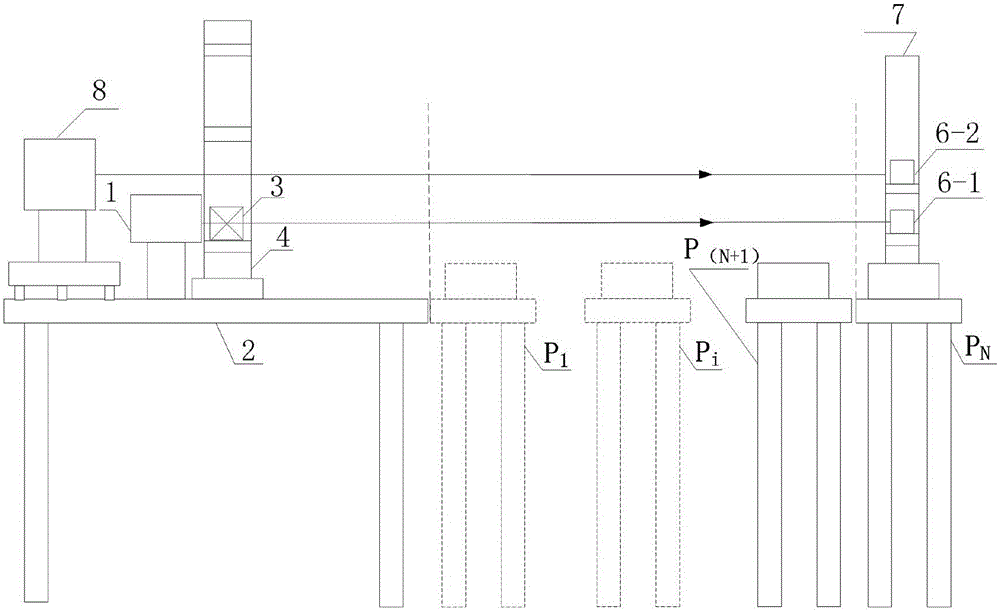

[0039] Such as figure 1 As shown, a laser tracker length measurement accuracy calibration device, the optical platform 2 is provided with a laser tracker 8, a dual-frequency laser interferometer 1, an interference mirror set fixture 4 and a rectangular prism set fixture 11 in sequence from left to right. The interference mirror group fixture 4 places the interference mirror group 3, the dual-frequency laser interferometer target mirror 13 and the laser tracker reflective target mirror group 14 in sequence from bottom to top, wherein the interference mirror group 3 is connected by an interference beam splitter perpendicular to the paper surface 3-1 and interference mirror 3-2. The right-angle prism group 12 is placed on the right-angle prism group fixture 11, and the right-angle prism group 12 is the second right-angle prism 12-2, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com