Patents

Literature

79 results about "Abbe error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

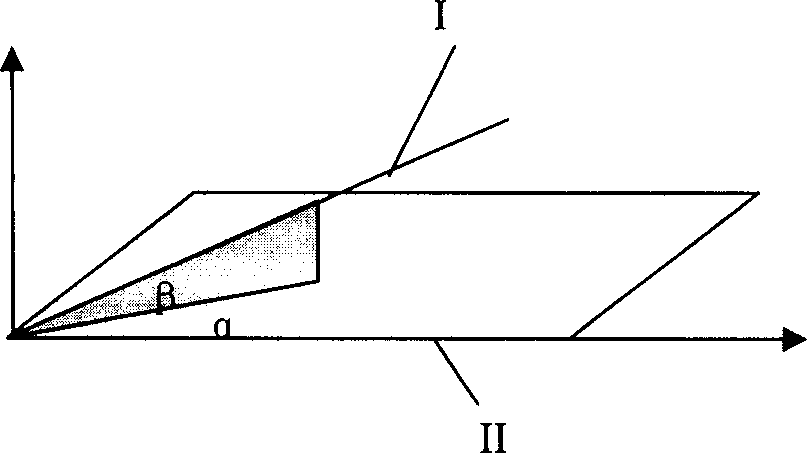

Abbe error, named after Ernst Abbe, also called sine error, describes the magnification of angular error over distance. For example, when one measures a point that is 1 meter away at 45 degrees, an angular error of 1 degree corresponds to a positional error of over 1.745 cm, equivalent to a distance-measurement error of 1.745%. In machine design, some components are particularly sensitive to angular errors.

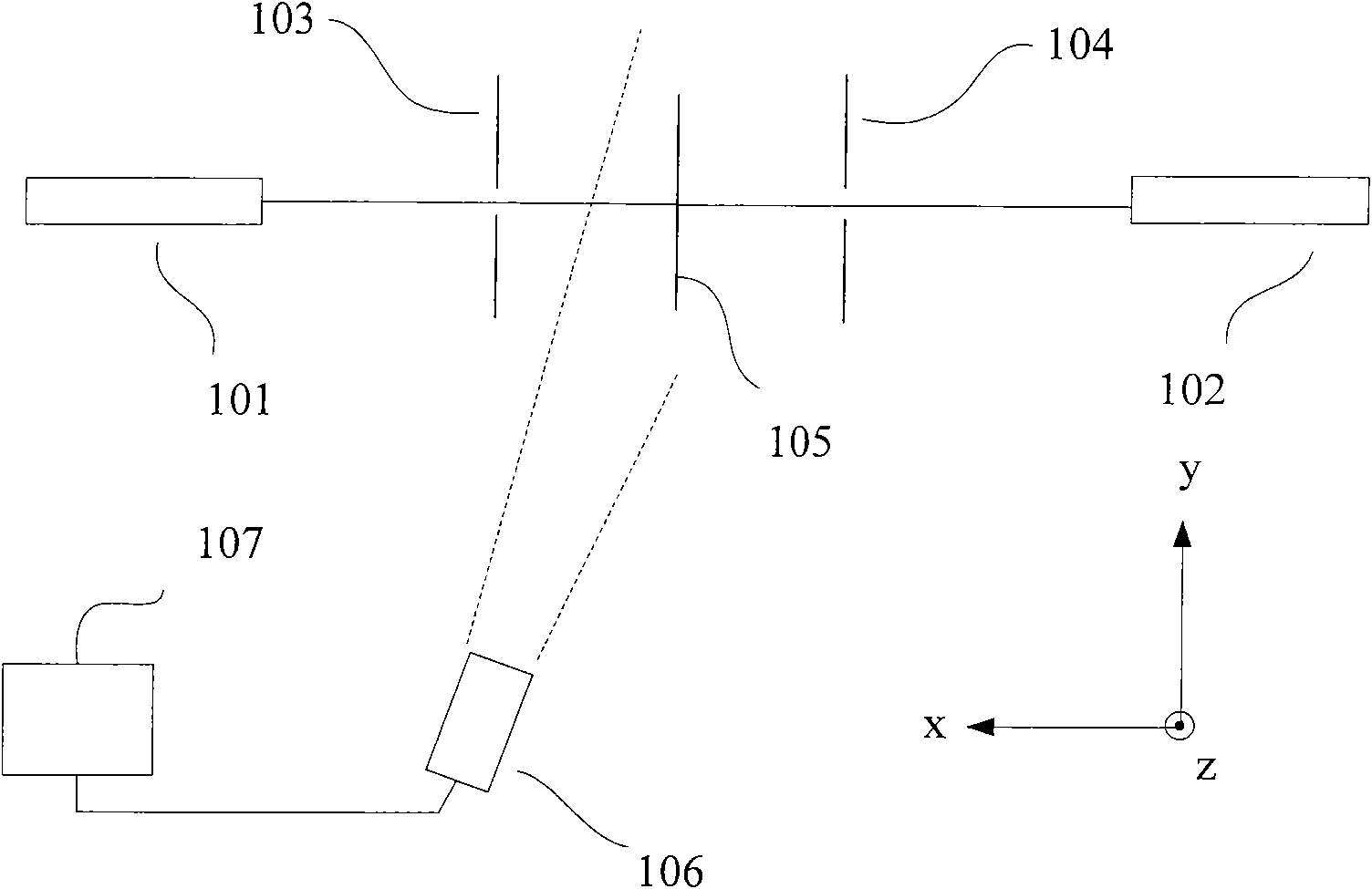

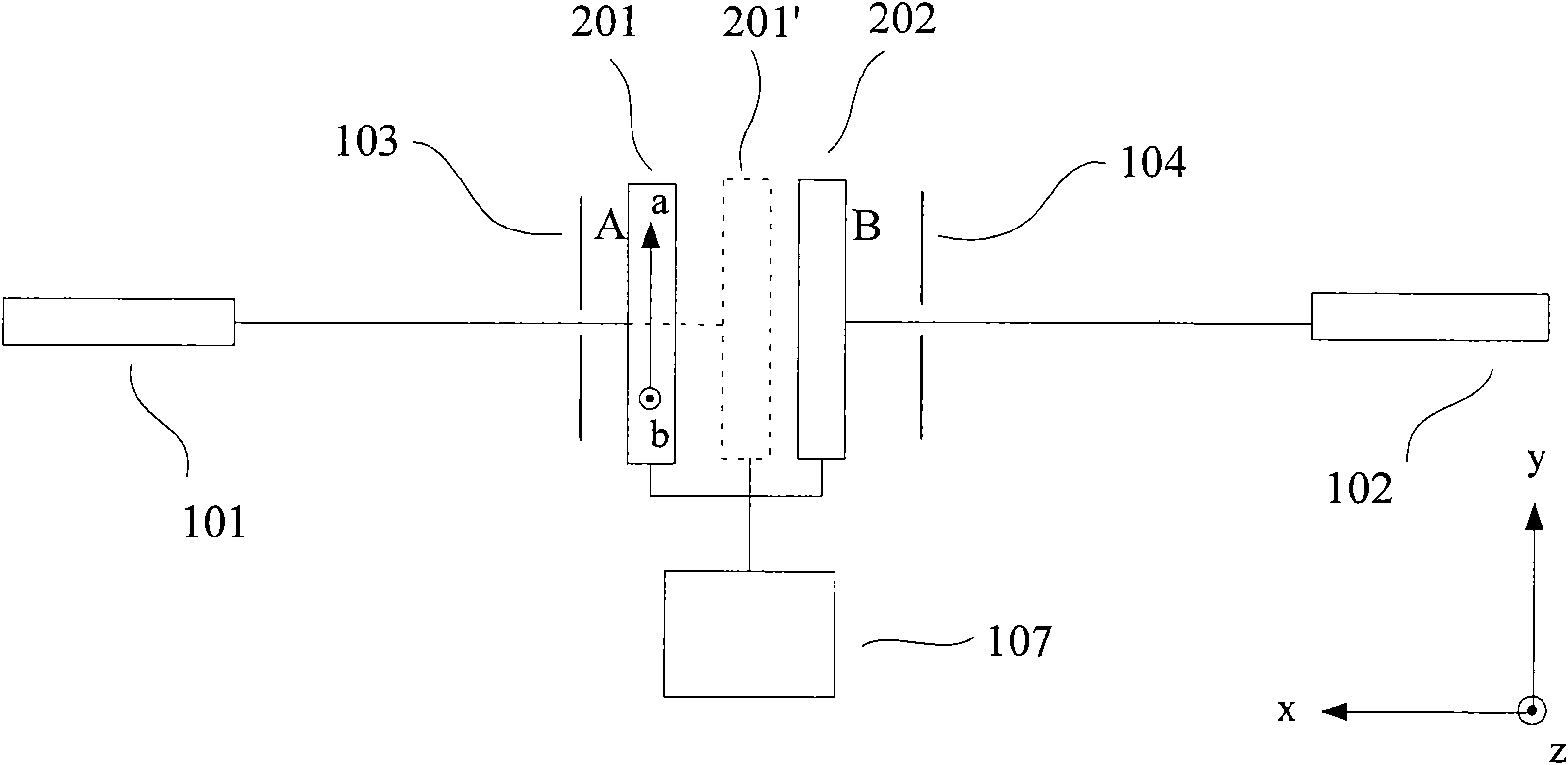

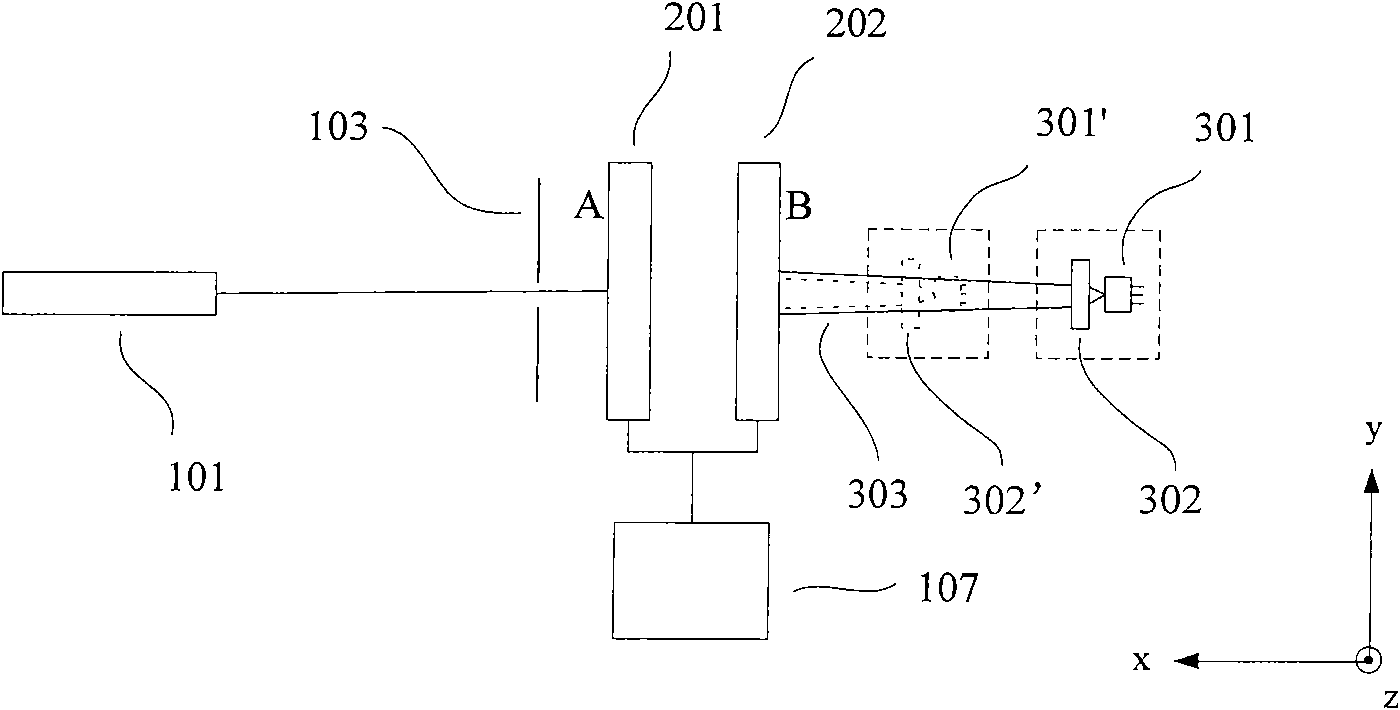

Device for adjusting light path and method thereof

InactiveCN101592787AHigh adjustment accuracyEliminate Abbe errorOptical elementsLight spotLight beam

The invention provides a device for adjusting light path and a method thereof. The invention comprises a laser, a light spot detector and a monitor, wherein, the laser is used for generating laser beams irradiated to the light spot detector; the light spot detector is used for receiving the laser beams and then converting the received laser beam information to electrical signals and transmitting the electric signals to the monitor; and the monitor is connected with the light spot detector so as to convert received electrical signals to images. The light path adjusting method based on the device is characterized in coaxial measurement, and compared with traditional methods, the light path adjusting method of the invention is capable of eliminating Abbe error, improves adjustment precision, is easier to operate and is favorable to practically popularize.

Owner:PHOEBUS VISION OPTO ELECTRONICS TECH +1

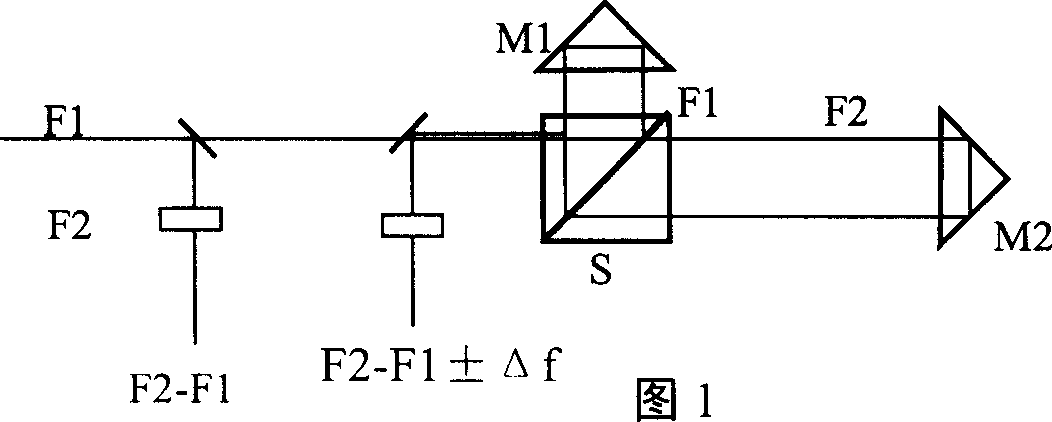

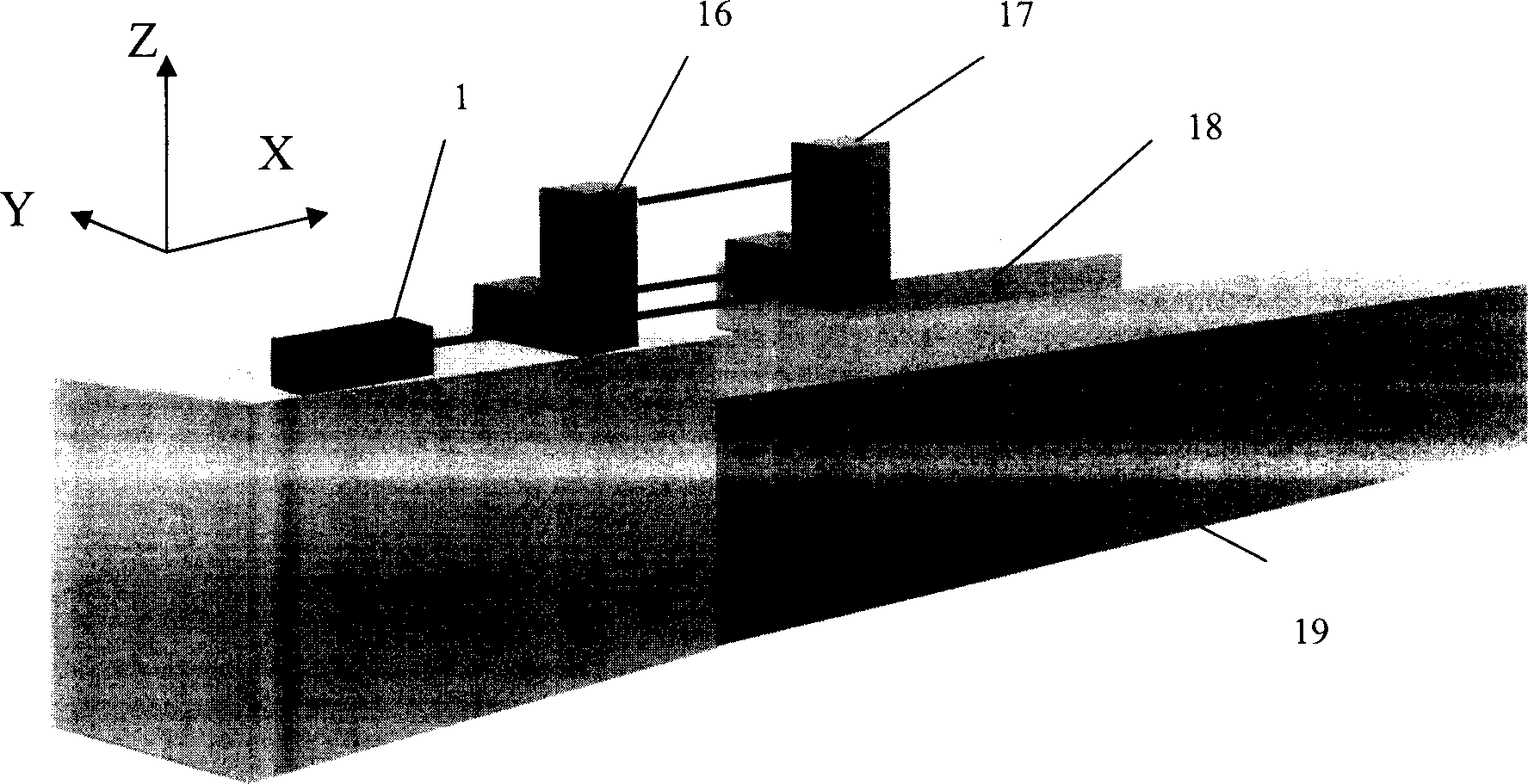

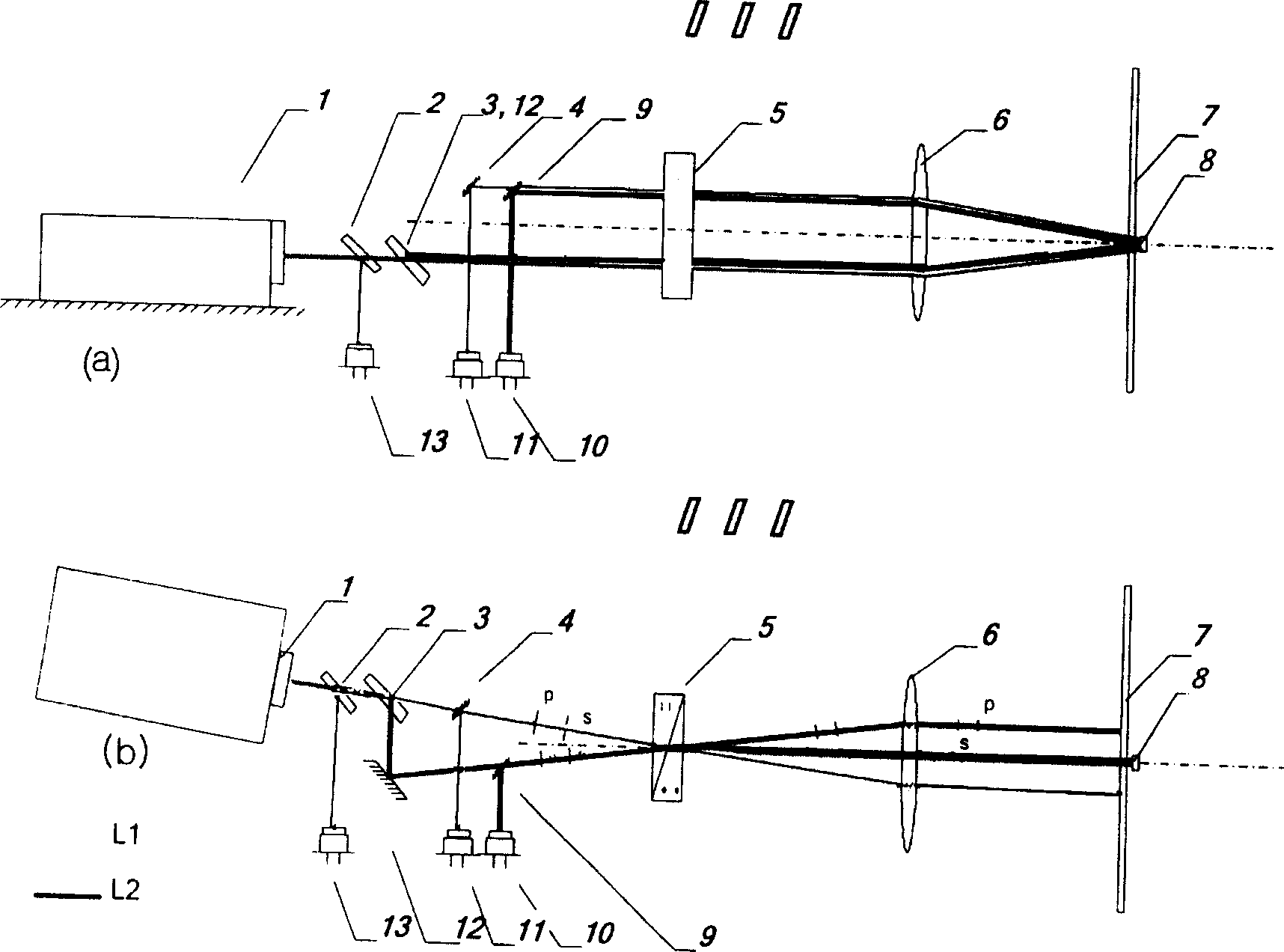

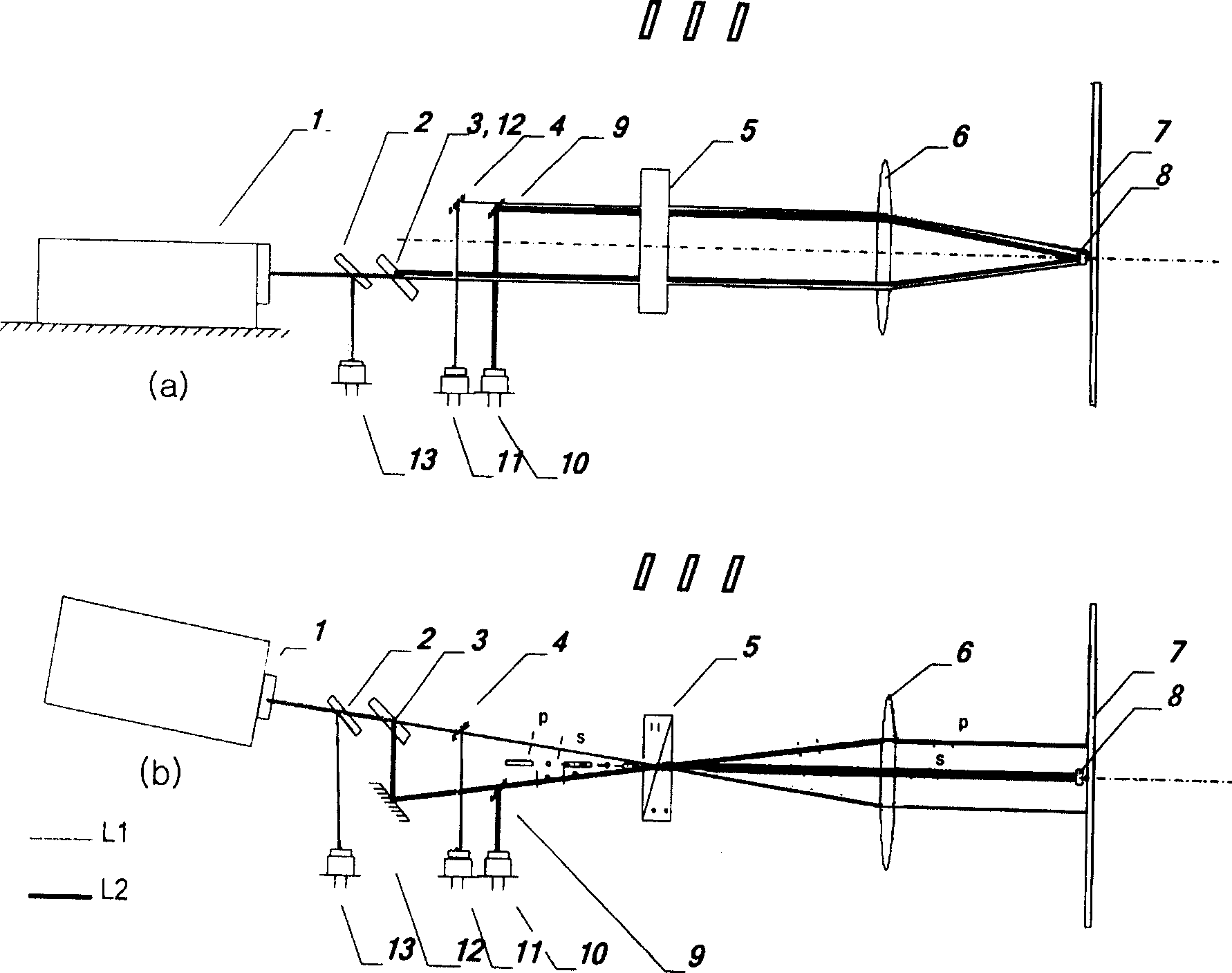

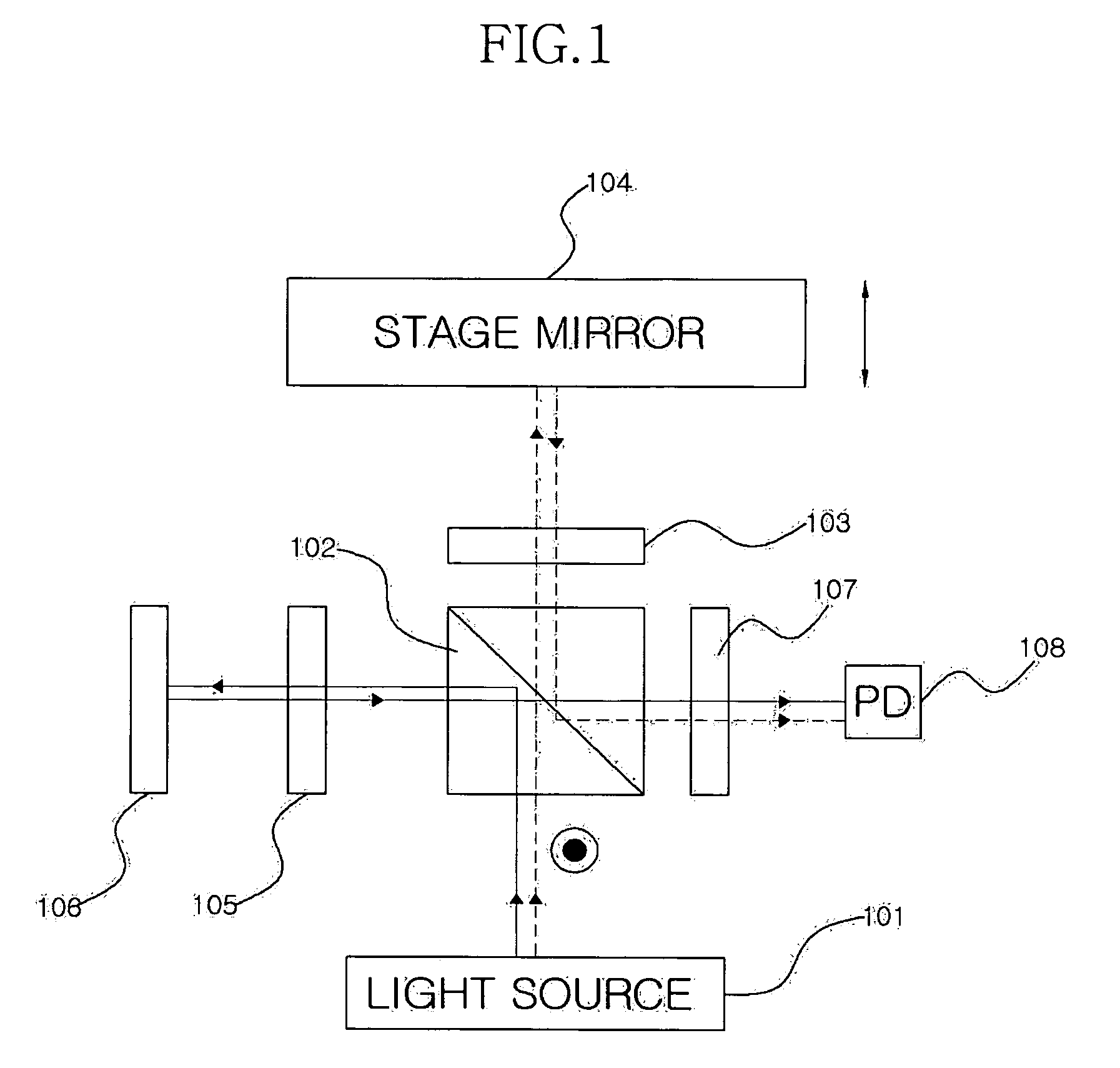

Laser interfere length measuring system with real time compensation for Abbe error

InactiveCN1510390AImprove accuracyHigh precisionUsing optical meansImage data processing detailsBeam splitterClassical mechanics

The length measuring system utilizes a two-frequency laser projector, two beam splitters and two light-beam refractors of 90 degree to carry on length measurement for three pathes of interferometric light simultaneously so that two-dimensional Abbe angle for guide track can be obtained on real time, and thereby real time compensation for Abbe error can be achieved.

Owner:中国航空工业总公司第三〇四研究所

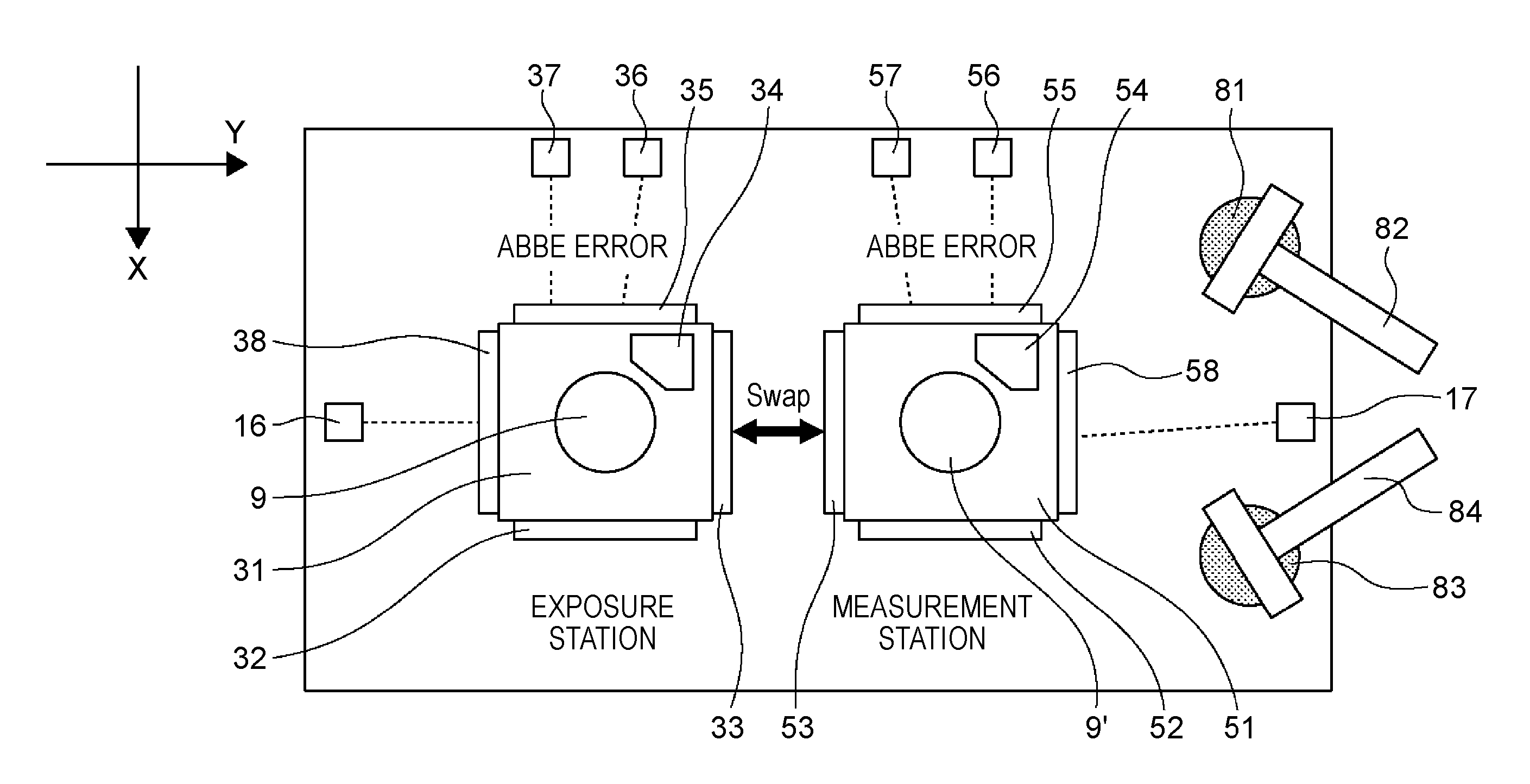

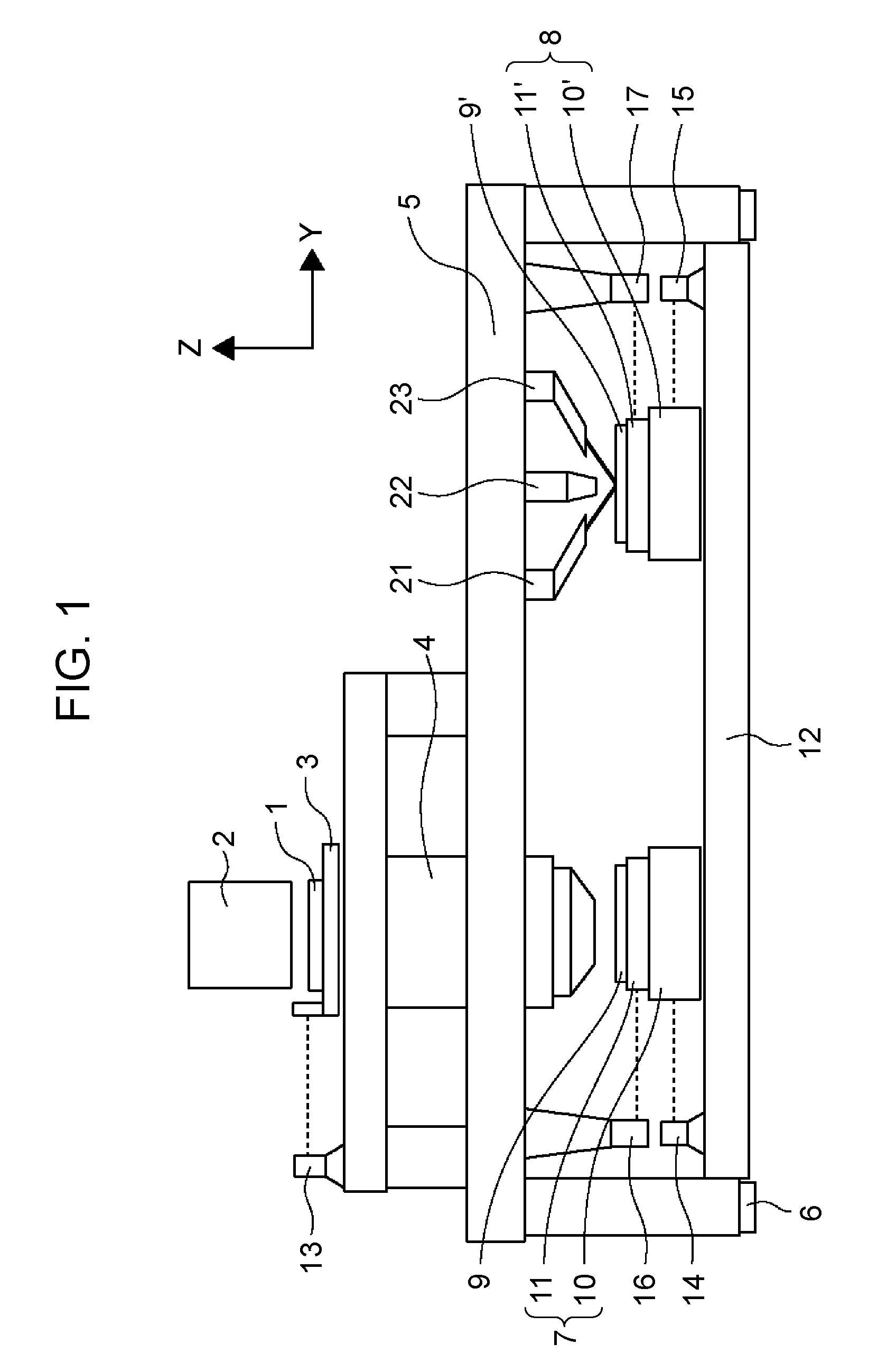

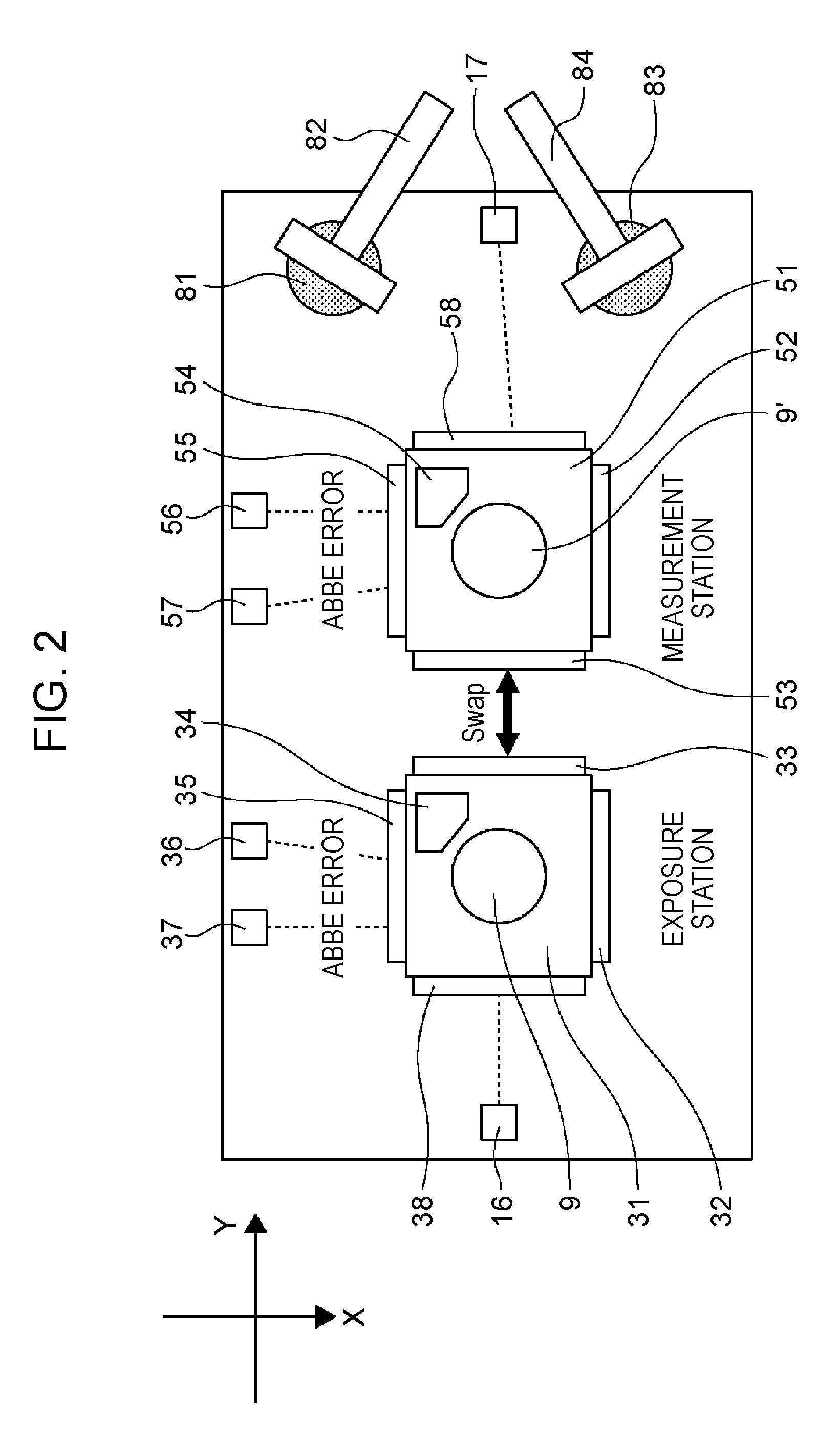

Exposure apparatus

InactiveUS20080013099A1Reduce positioningImprove throughputPhotomechanical apparatusUsing optical meansEngineeringPosition error

In an exposure apparatus having a plurality of substrate stages moving between a plurality of stations, errors due to the combination of the stage and a position measuring unit, such as Abbe error and errors due to the surface configuration of a reflection mirror, are precisely corrected to reduce the position error of the substrate stage. The exposure apparatus includes a control device having a storage unit and a correction unit. The storage unit stores the correction information established every combination of the plurality of substrate stages and a plurality of position measuring units, and the correction unit corrects the result measured by the plurality of position measuring units on the basis of the correction information corresponding to the combination of the substrate stages and the position measuring units among pieces of correction information stored in the storage unit.

Owner:CANON KK

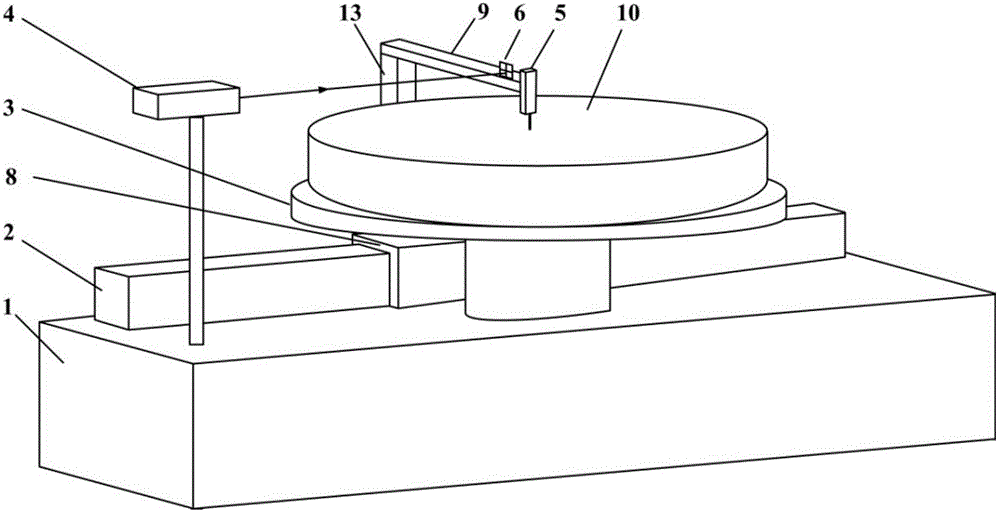

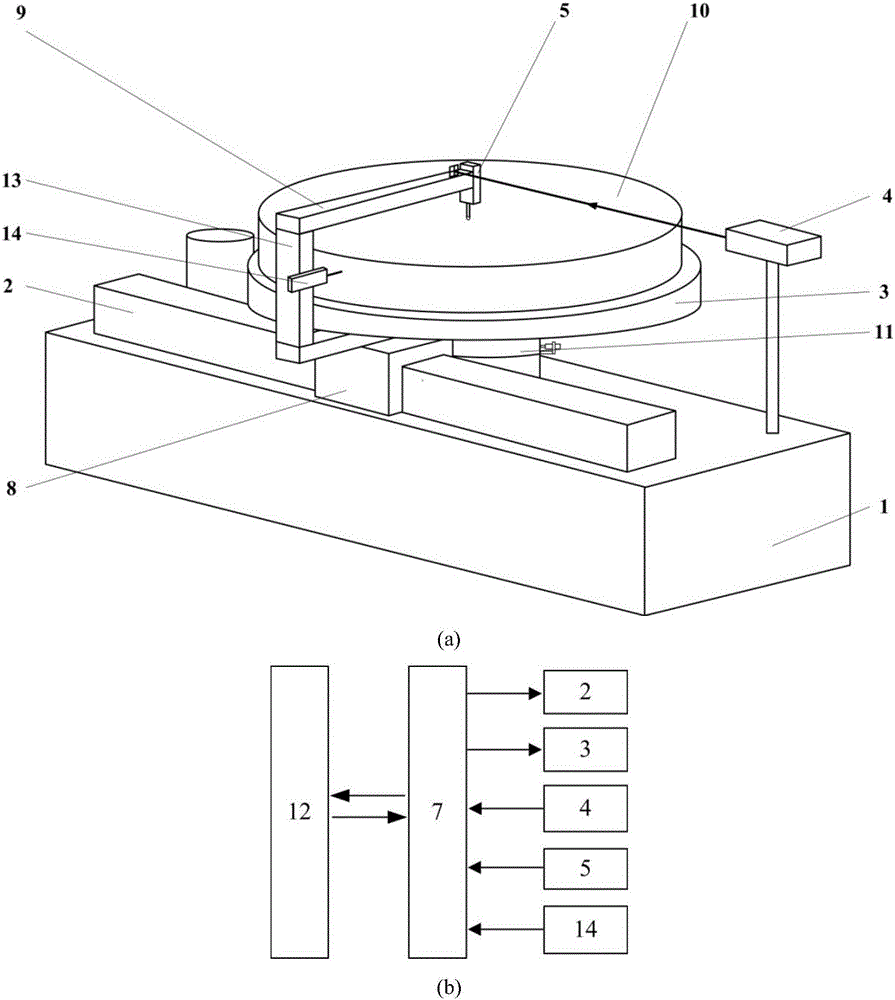

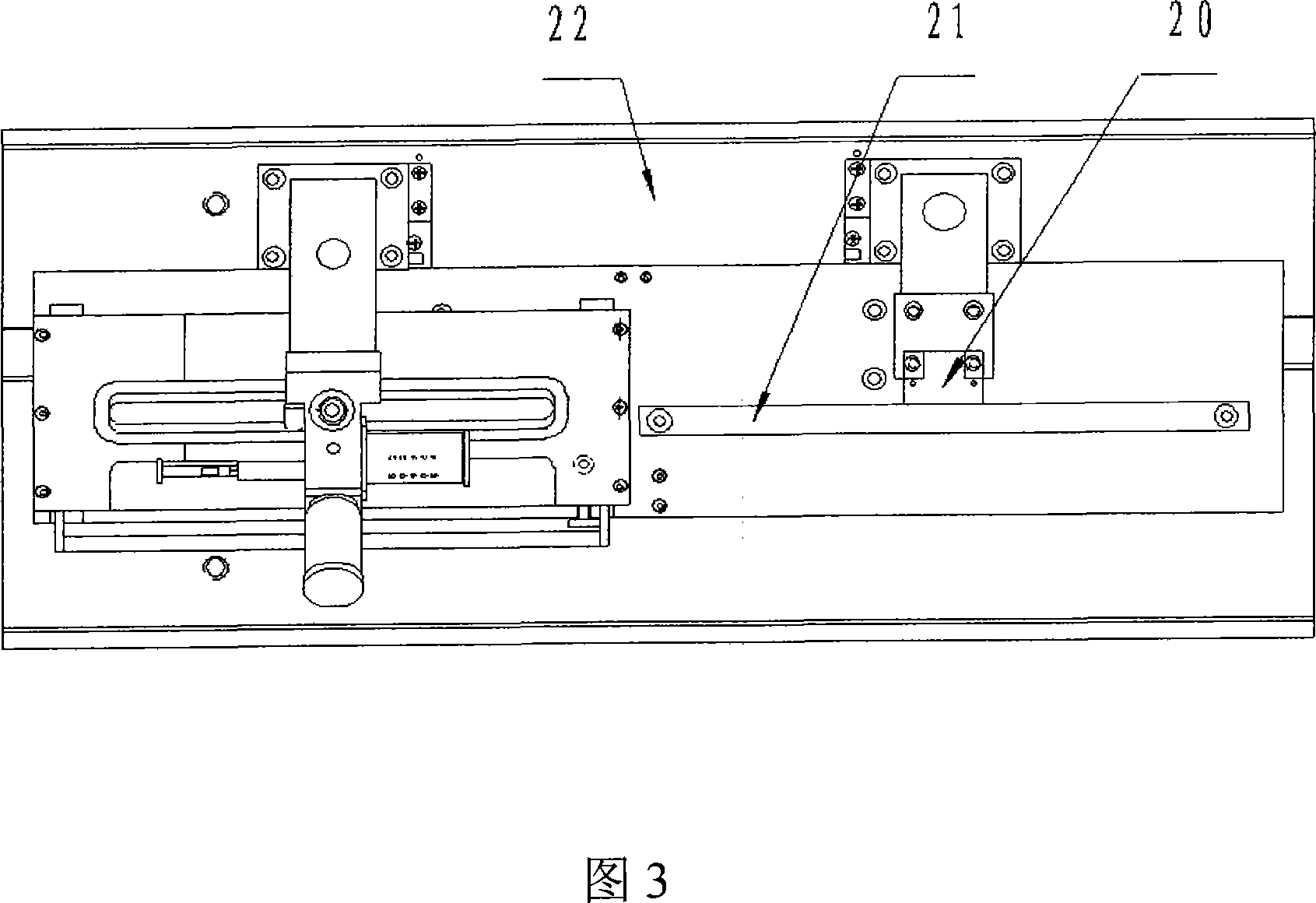

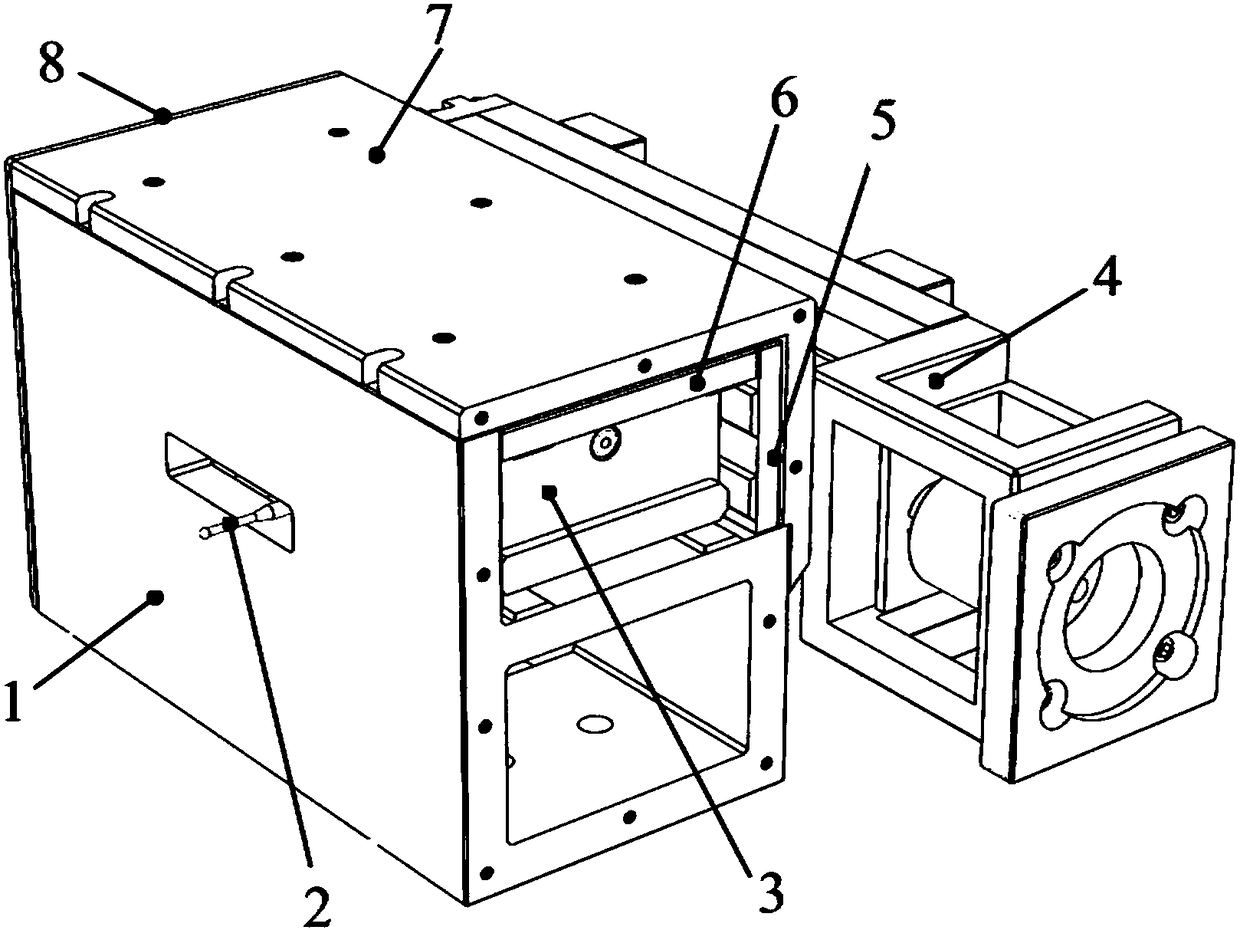

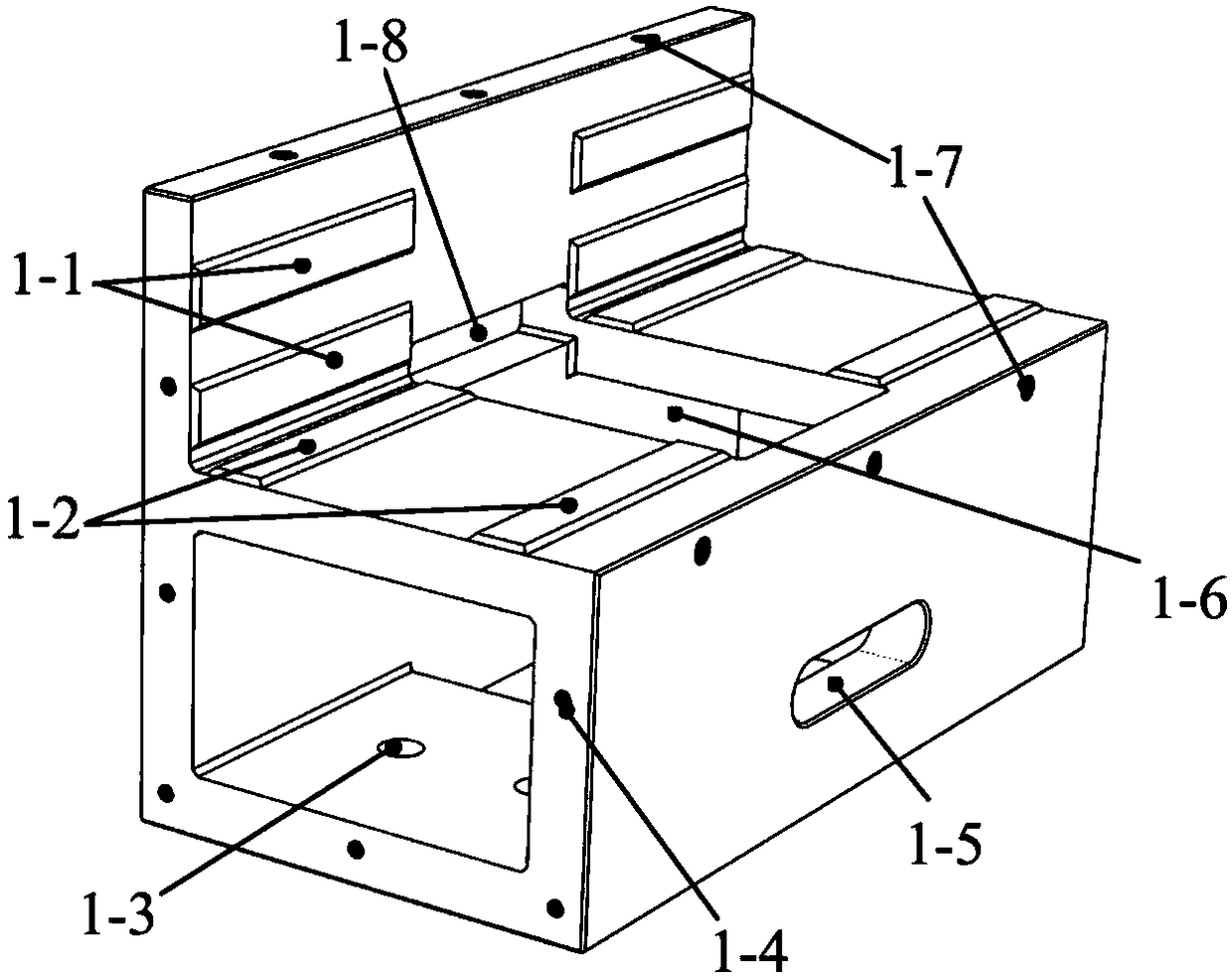

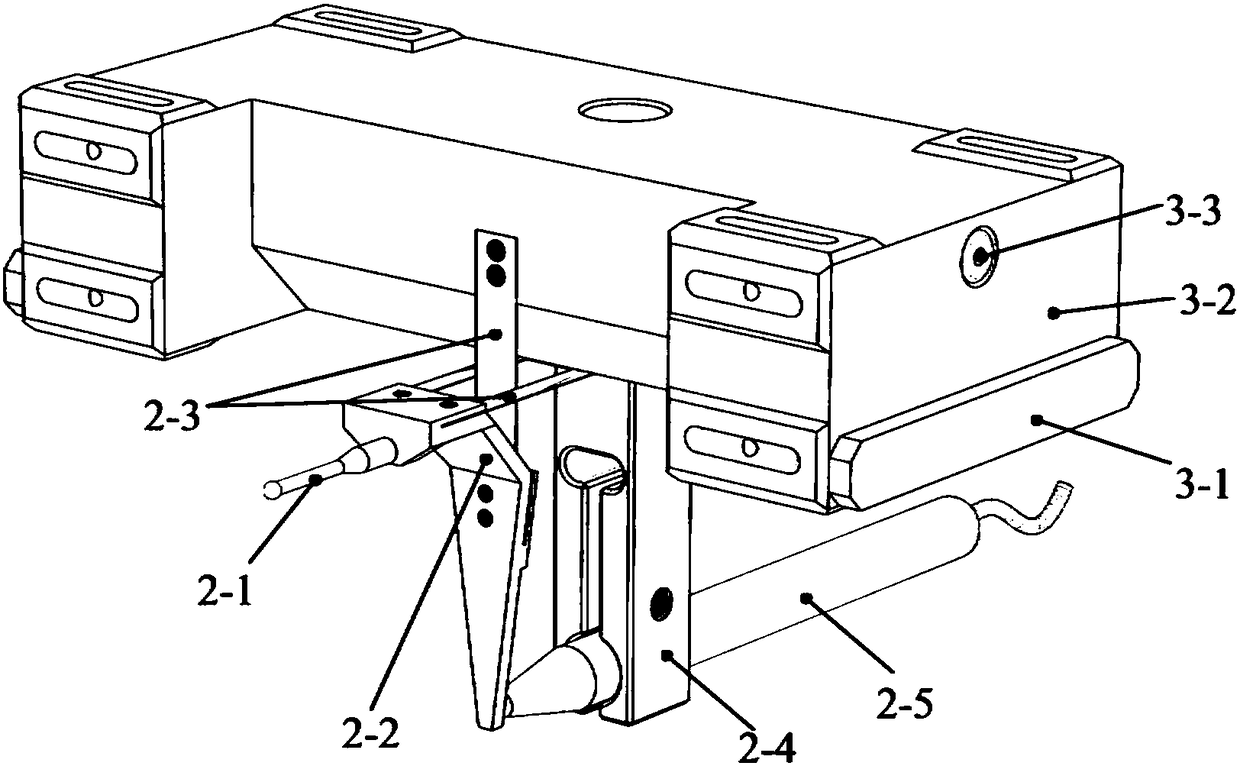

Device and method for detecting contours of large-caliber aspheric surface components

ActiveCN106441153ARealize high-precision detectionReduce mistakesUsing optical meansCommon baseMotion accuracy

The invention belongs to the technical field of optical precision tests, and relates to a device and a method for precisely detecting large-caliber aspheric surfaces. The device and the method can be used for detecting the contours of large aspheric surface components in precision optical systems in a high-precision manner. The device is of an open type contour instrument structure with rotary-linear datum common base planes on the basis of linear / rotary datum technologies and the like, so that the contours of the large-caliber aspheric surface components can be detected on the basis of precision flotation rotary centers in the high-precision manner. The device and the method have the advantages that common base plane designs for rotary-linear datum systems, turning designs for measurement frames and designs for open type non-gantry structures are adopted, Abbe errors of instruments can be reduced, the movement precision of a precision linear flotation guide rail can be realized to the greatest extent, and parameters of the contour of a mother line of each to-be-detected aspheric surface can be directly measured by a sensing measuring system which synchronously moves with the precision linear flotation guide rail; the contours of multiple mother lines of the to-be-detected aspheric surfaces can be measured by the aid of precision flotation rotary technologies, and the contours of the large-caliber aspheric surfaces can be quickly detected in the high-precision manner by means of fitting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

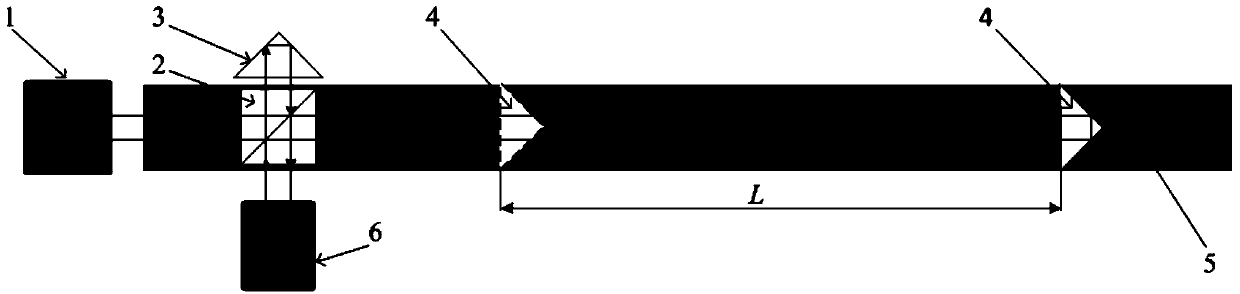

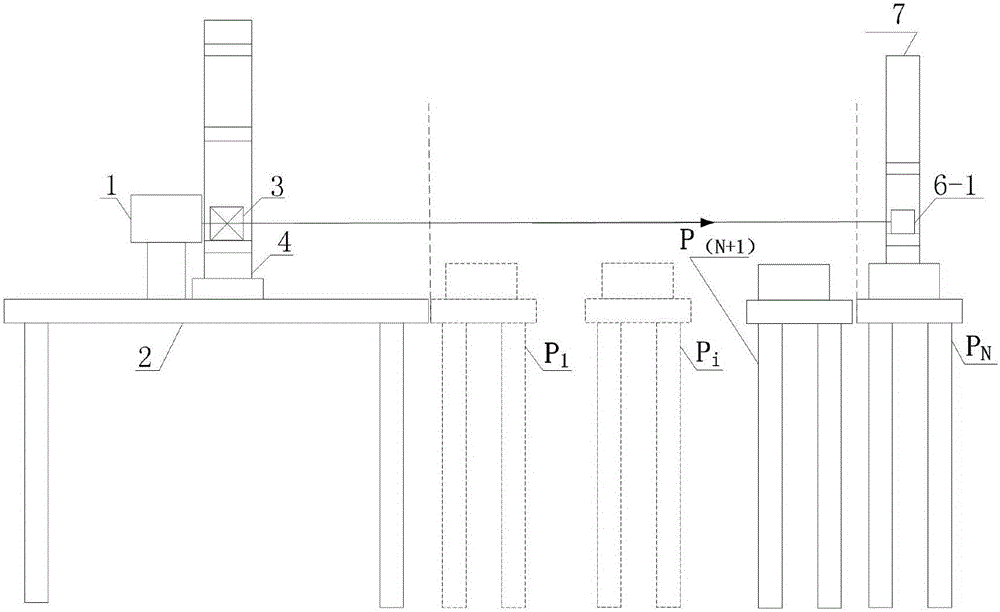

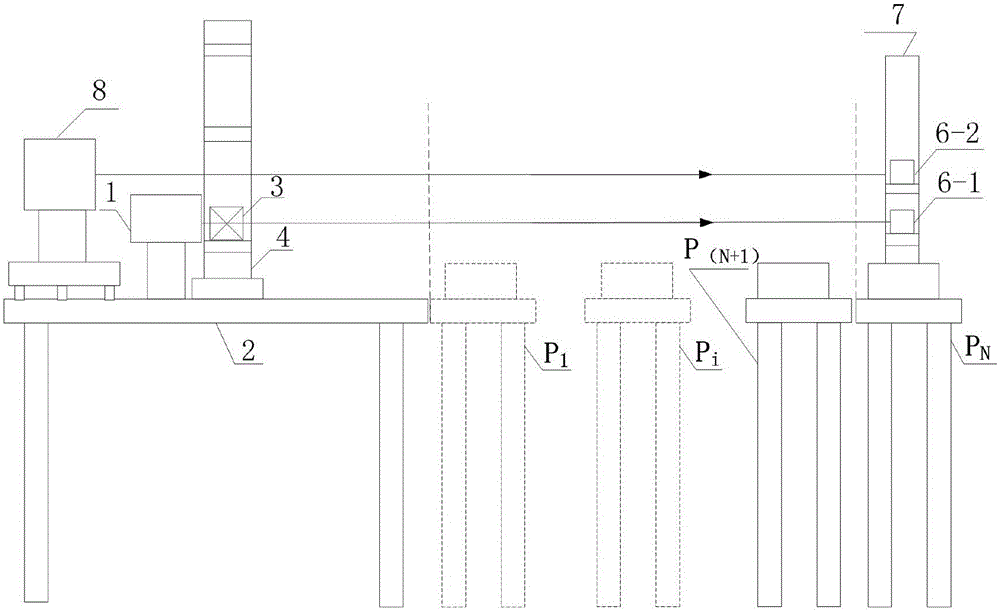

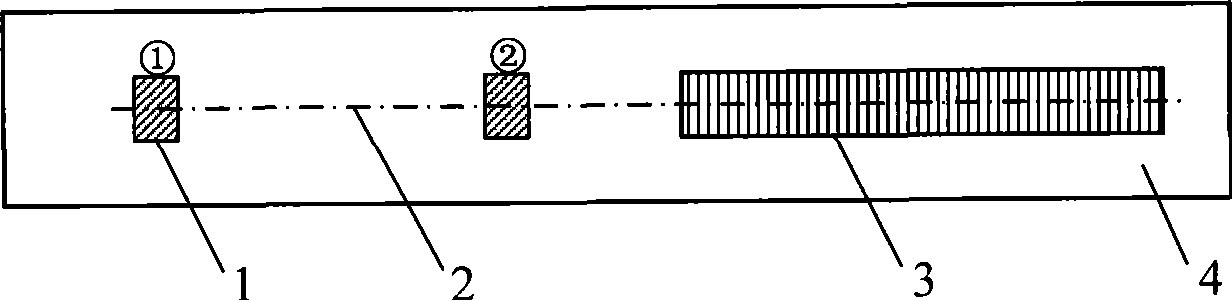

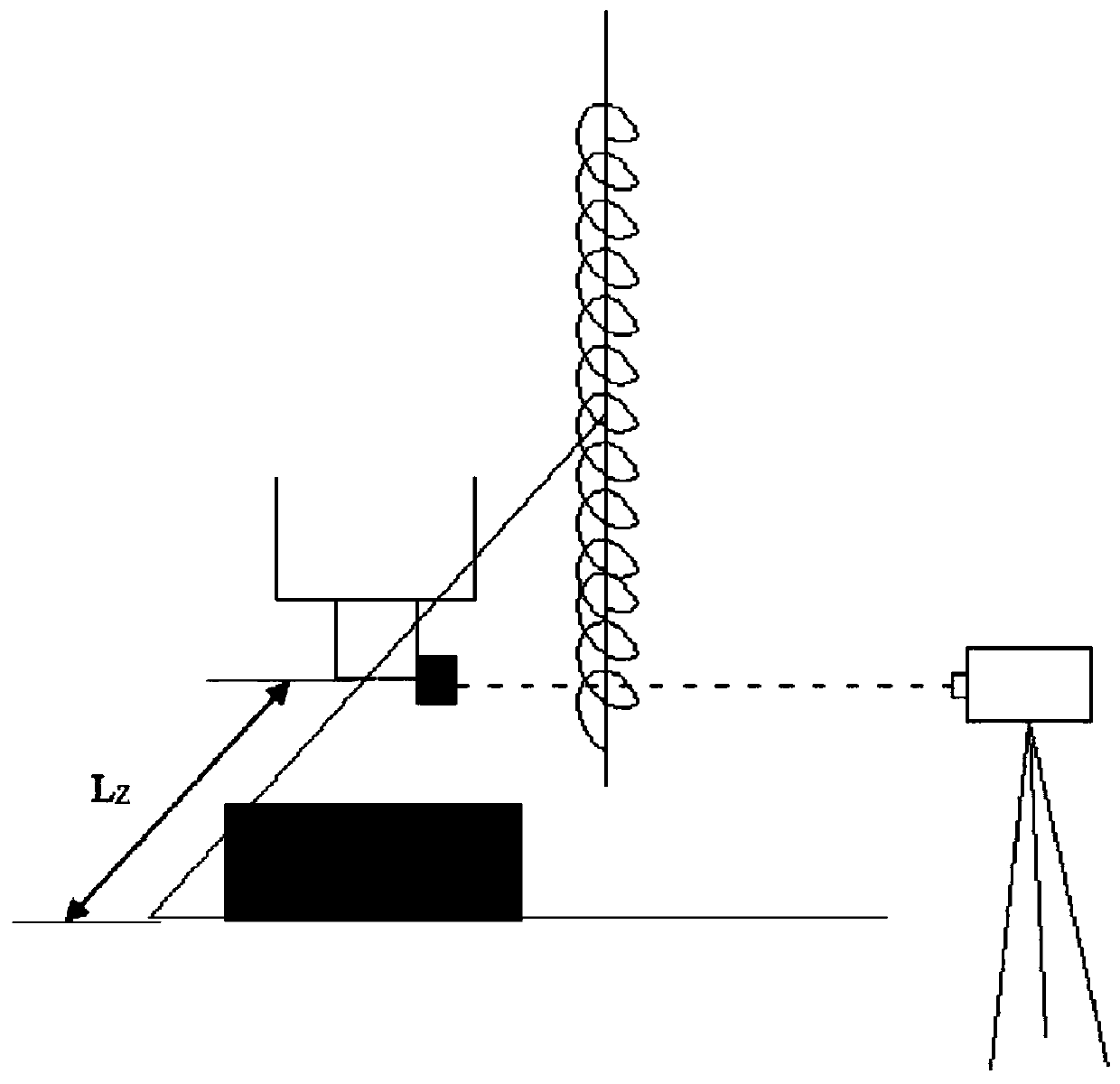

Large-length laser interferometer measurement system for eliminating Abbe error

ActiveCN104215181AHigh precisionThe principle is simpleUsing optical meansOperabilityLaser interference

The invention discloses a laser interferometer measurement system for eliminating Abbe error. The system comprises three independent laser interference length measuring systems and a high-precision long guide rail. With the use of the three independent laser interference length measuring systems which are placed in an arbitrary triangle, equivalent measuring optical paths with a starting point at any position of an the initial plane are constructed. Meanwhile, with the three independent laser interference length measuring systems having the same optical path with a device under test, measurement uncertainty caused by the fact that an Abbe principle is not met. The laser interferometer measurement system for eliminating Abbe error has the advantages of being simple in technical principles, low in costs, strong in operability and capable of improving accuracy of the large-length laser interferometer measurement system.

Owner:NAT INST OF METROLOGY CHINA

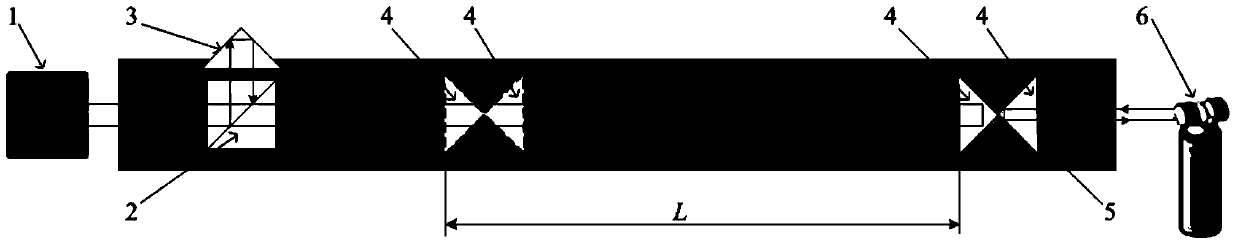

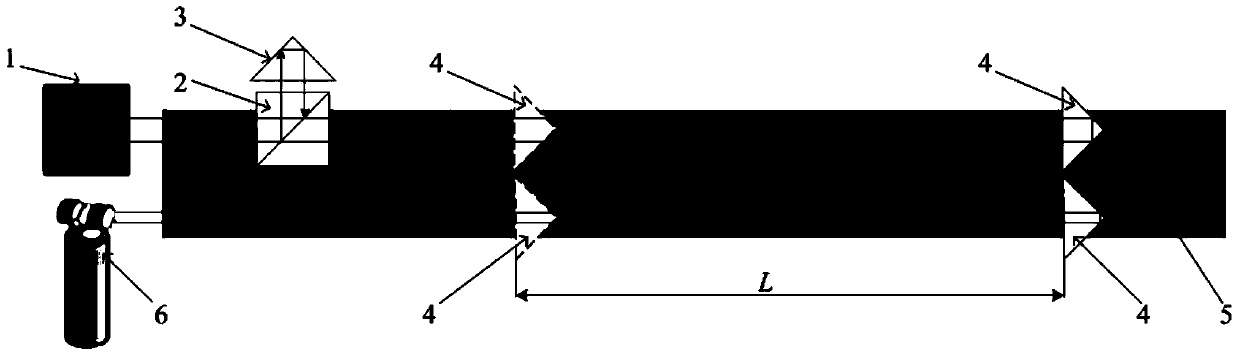

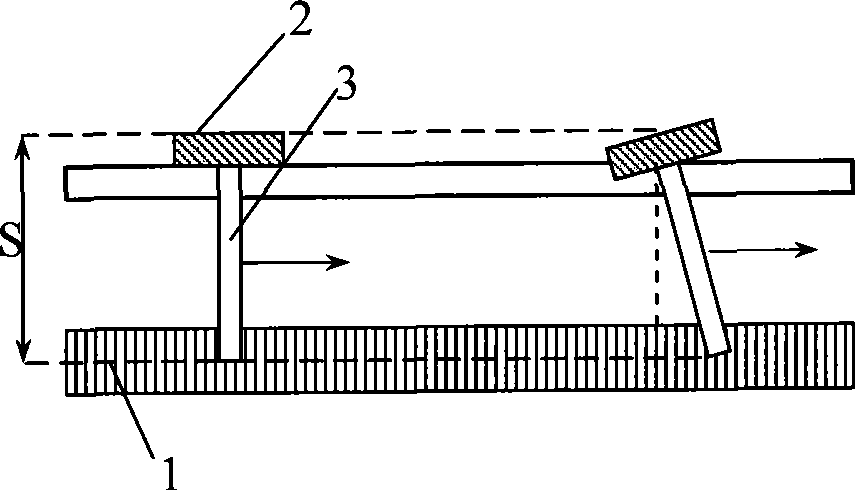

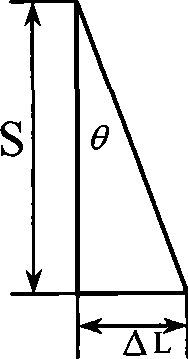

Length measurement precision calibrating method and device for laser tracker

ActiveCN105157574AAvoid Cumulative ErrorsEasy calibration of length measurement accuracyUsing optical meansOptoelectronicsPrism

A length measurement precision calibrating method and device for a laser tracker belongs to the measurement and calibration field of optical instruments, and are aimed at solving the problems of the prior art that the calibrating precision of an ultra-long high-precision guide rail is low, the machining cost is high, the length measurement range is small and the occupation space is large. An interference length of a double-frequency laser interferometer is taken by the calibrating device as a length basis. Platforms spaced from each other at certain intervals within the measurement range and an adjustable pedestal above the platforms together form a high-precision virtual guide rail. Right-angle prism units are utilized to adjust the space of two measurement light beams, and five prism units are utilized for turning of light paths. In this way, length measurement precision calibration is conducted on a laser tracker within the ultra-long measurement range in a limited space. The calibrating method includes the steps: leveling a light beam of a laser interferometer; adjusting the virtual guide rail to realize flatness and linearity that are needed by calibration; adjusting an emitting light beam of the laser tracker to enable the emitting light beam to be parallel to the light beam of the laser interferometer; forming a measurement optical path; fixing a reflector, and adjusting the two measurement light beams and enabling the two light beams to parallel to each other so that an Abbe error is eliminated; conducting measurement; and performing data processing.

Owner:CHANGCHUN UNIV OF SCI & TECH

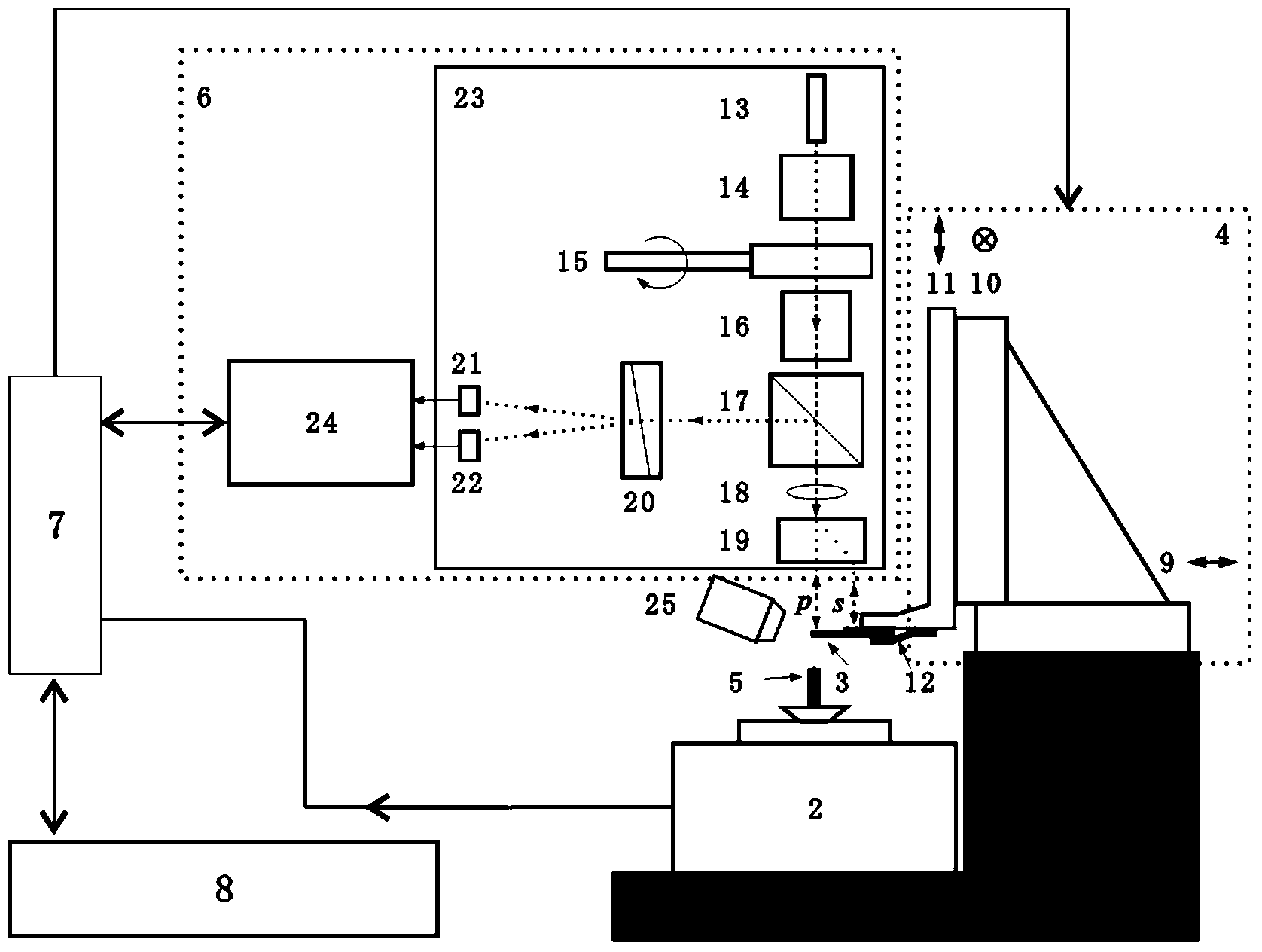

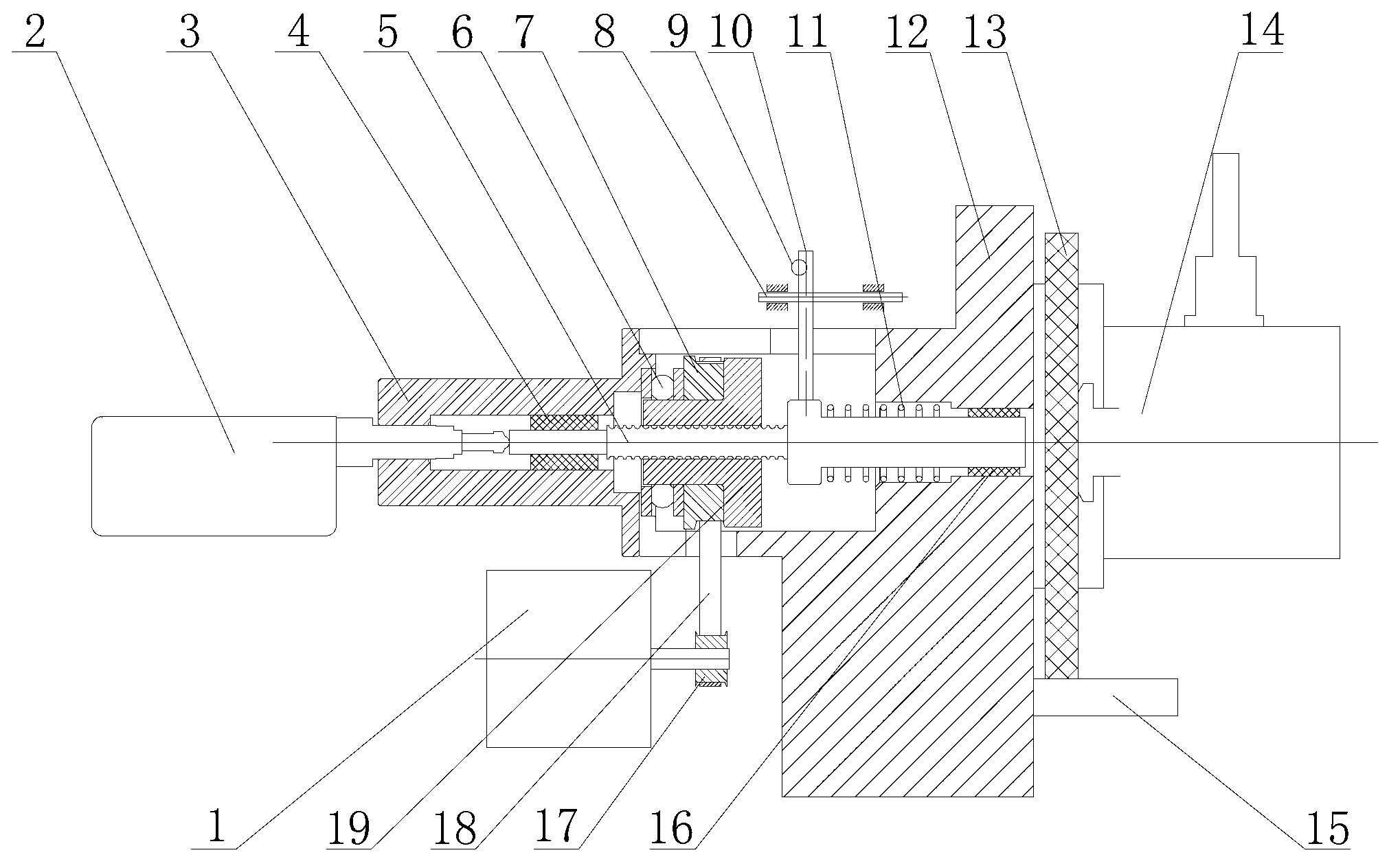

Source tracing calibrating device and source tracing method for micro cantilever beam elastic constant

InactiveCN103616127AGuaranteed measurement accuracyGuaranteed uniformityFluid pressure measurementForce/torque/work measurement apparatus calibration/testingMicro nanoLight beam

The invention provides a source tracing calibrating device for a micro cantilever beam elastic constant. The source tracing calibrating device structurally comprises a marble frame, a nanometer balance, a micro cantilever beam, a three-dimensional micro-nano displacement platform, a force loading rod, a polarization difference interferometer, an instrument controller, a computer and measuring and controlling software. The invention meanwhile provides a source tracing method of the source tracing calibrating device for the micro cantilever beam elastic constant. The source tracing calibrating device and source tracing method have the advantages that an elastic constant value can be directly traced to the international system of unit SI when the device is used, micro light spots, formed on the upper surface of the free end of the micro cantilever beam, of measuring light beams of the polarization difference interferometer completely coincide with force loading points when the lower surface of the free end of the micro cantilever beam is loaded by the force loading rod on the nanometer balance through the device, so that the Abbe arm is zero, the Abbe principle of displacement measuring is abided by, generation of Abbe errors is avoided, and the measurement accuracy of a source tracing instrument is ensured. Uniformity, reliability and comparability of micro force measuring by using the micro cantilever beam in different labs can be ensured.

Owner:TIANJIN UNIV

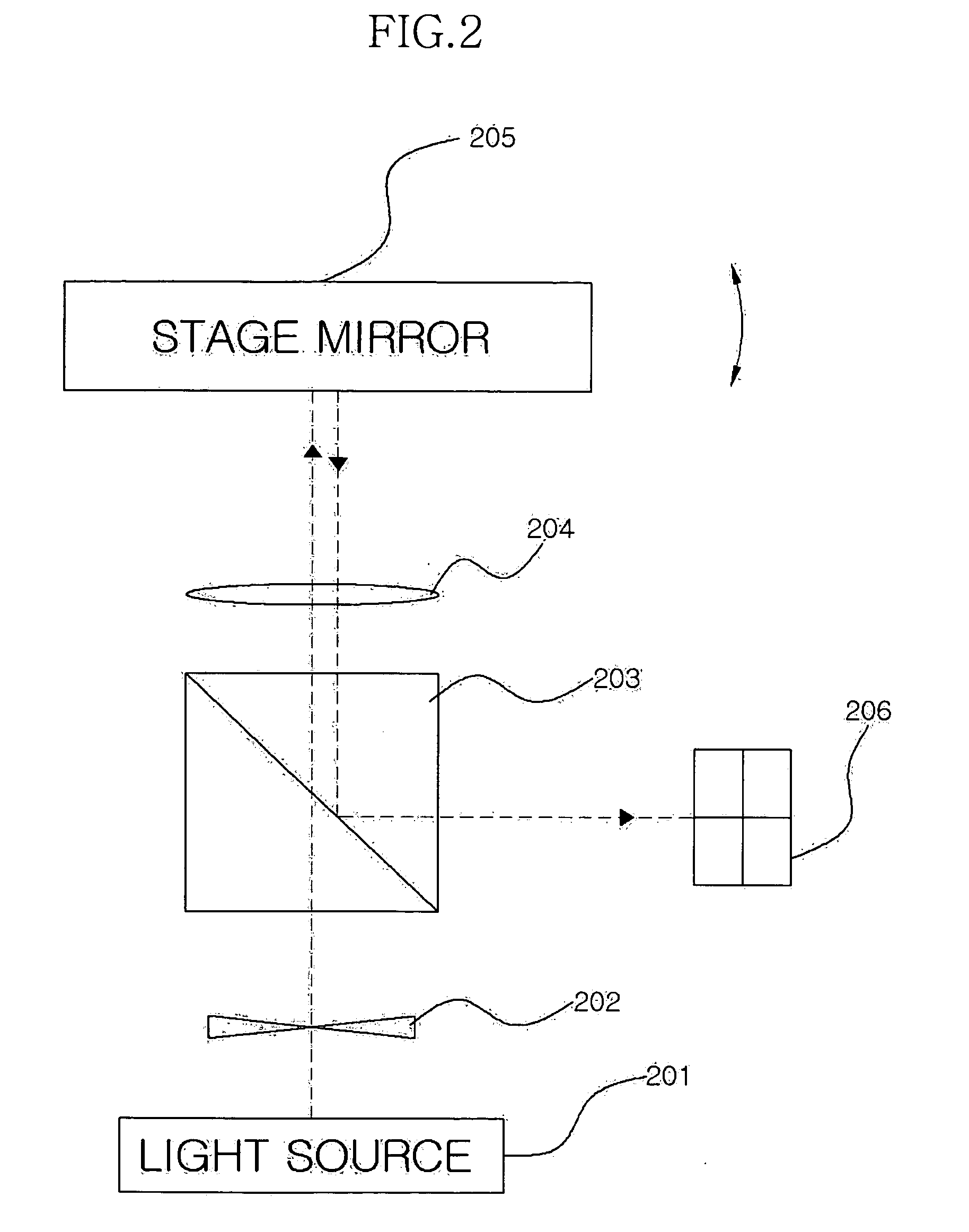

System for measuring hard disk magnetic head flight height and common-path dual-frequency laser interference measuring method

InactiveCN1844847AGood effectImprove stabilityDisposition/mounting of recording headsUsing optical meansDevice formOptical measurements

The invention relates to a system for measuring disc magnetic head flying height and a share-path dual-frequency laser interference measure method, belonging to the optical measure technique. It comprises a transverse Zeeman laser, a low-reflective divide plate on the axes of laser sender, an adjustable splitting angle device formed by a semi-reflect divide plate and a reflector, a Woraston polarize splitting lens, a big diameter long focus lens, a magnetic head disc at the back focal plane of lens, two paths of interference and reference lights, a high-reflector, a deflection checker, and a optical-electric detector. The invention can improve the measure accuracy, resolution and sampling frequency, improve and compensate the Abbe error caused by the stable position change of disc, meet the demand of flying height that magnetic head relative to the glass simulate disc, and on the producing line, check the flying state of magnetic disc relative to the actual disc. The invention has lower cost, which it can be used in disc checking, and micro mechanical device vibration checking.

Owner:TSINGHUA UNIV

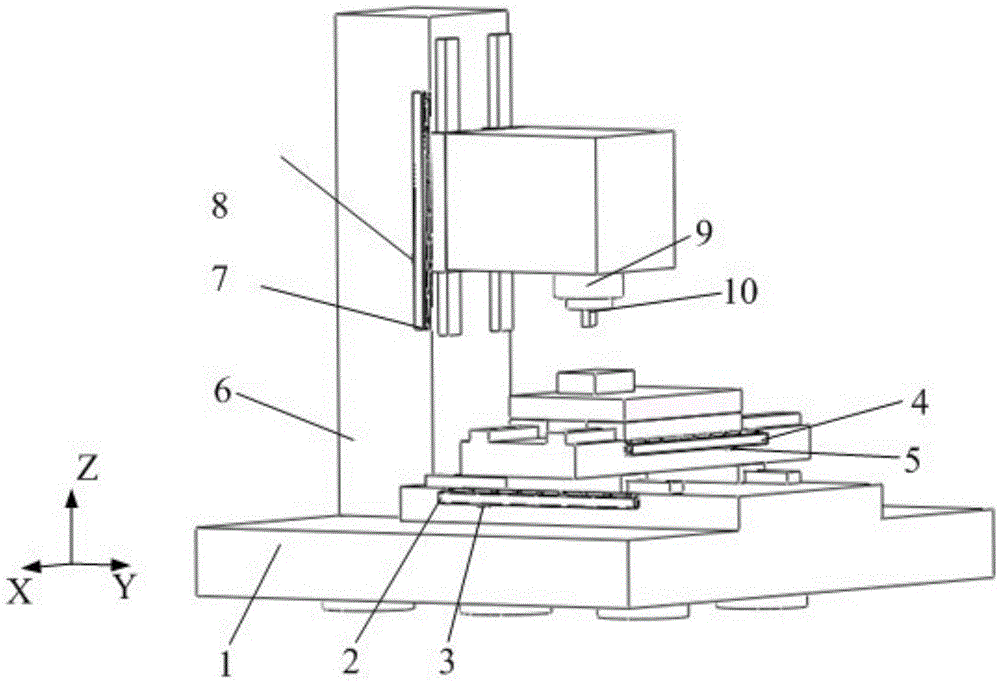

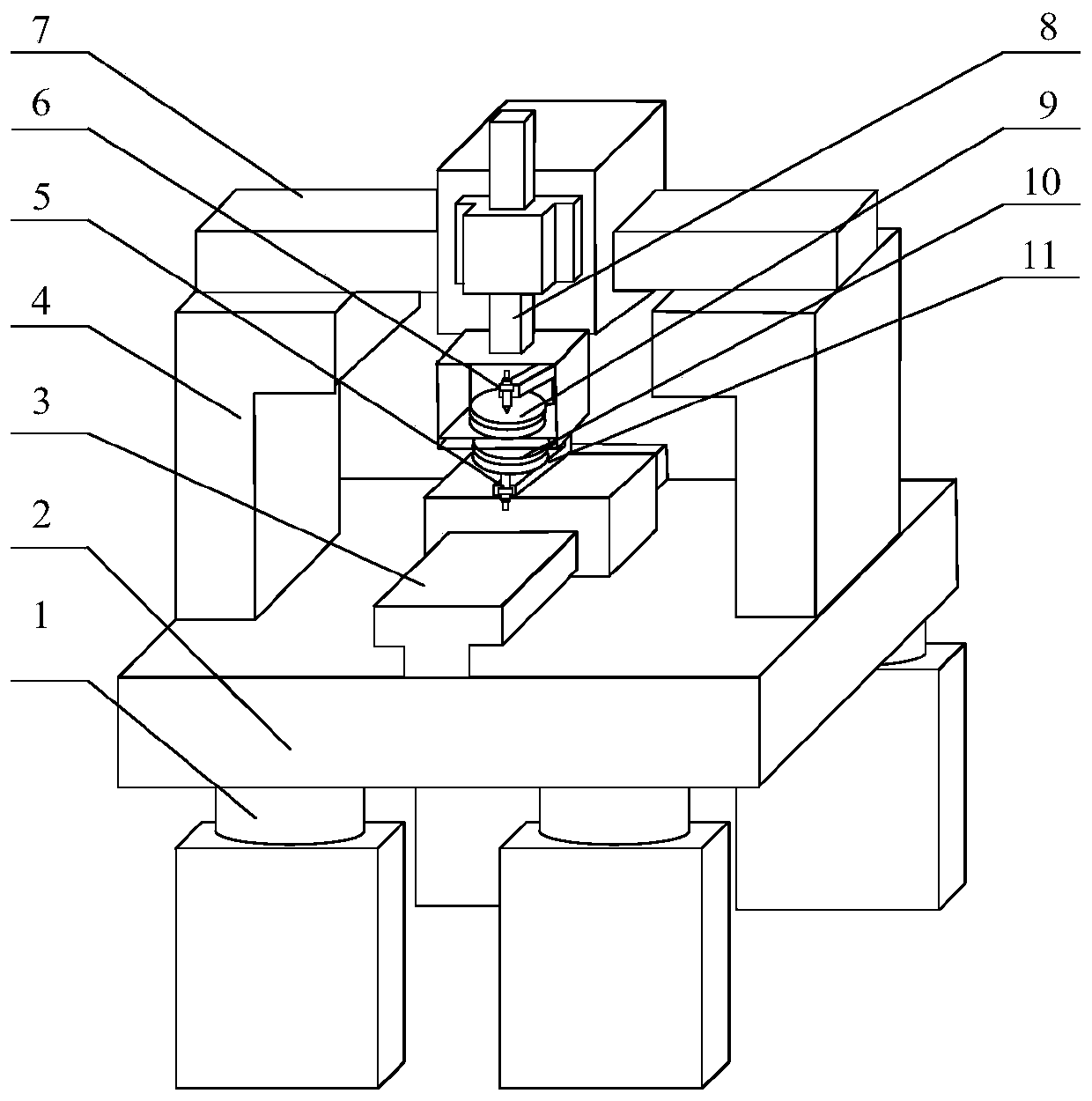

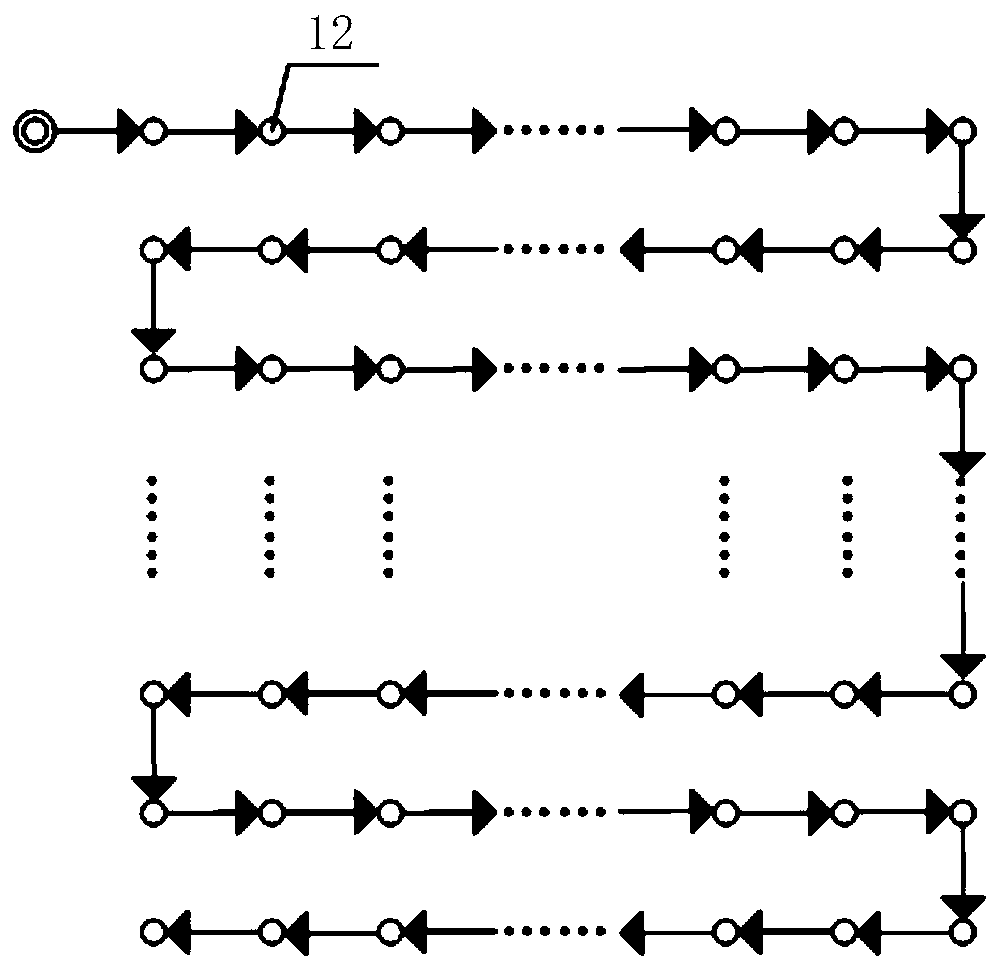

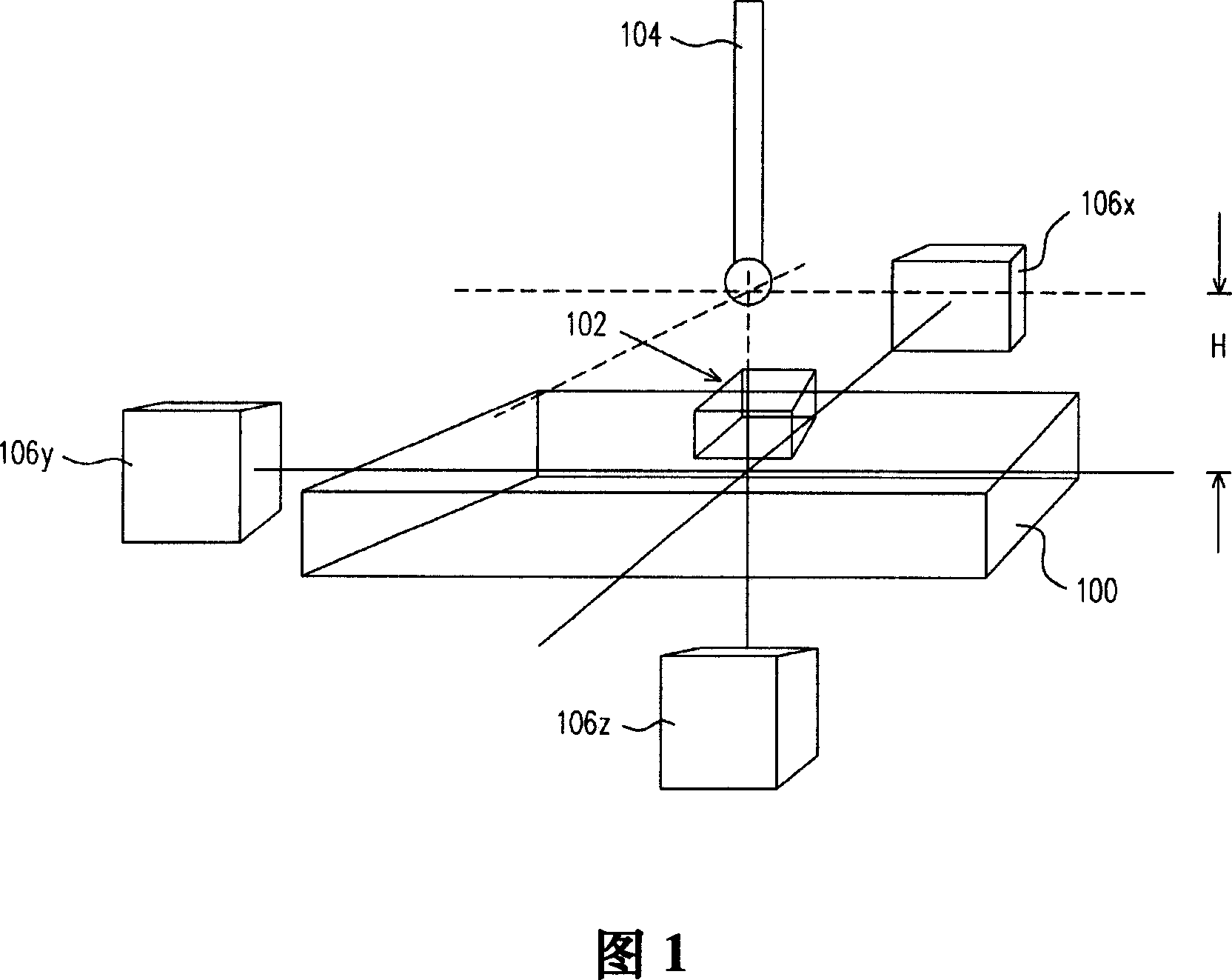

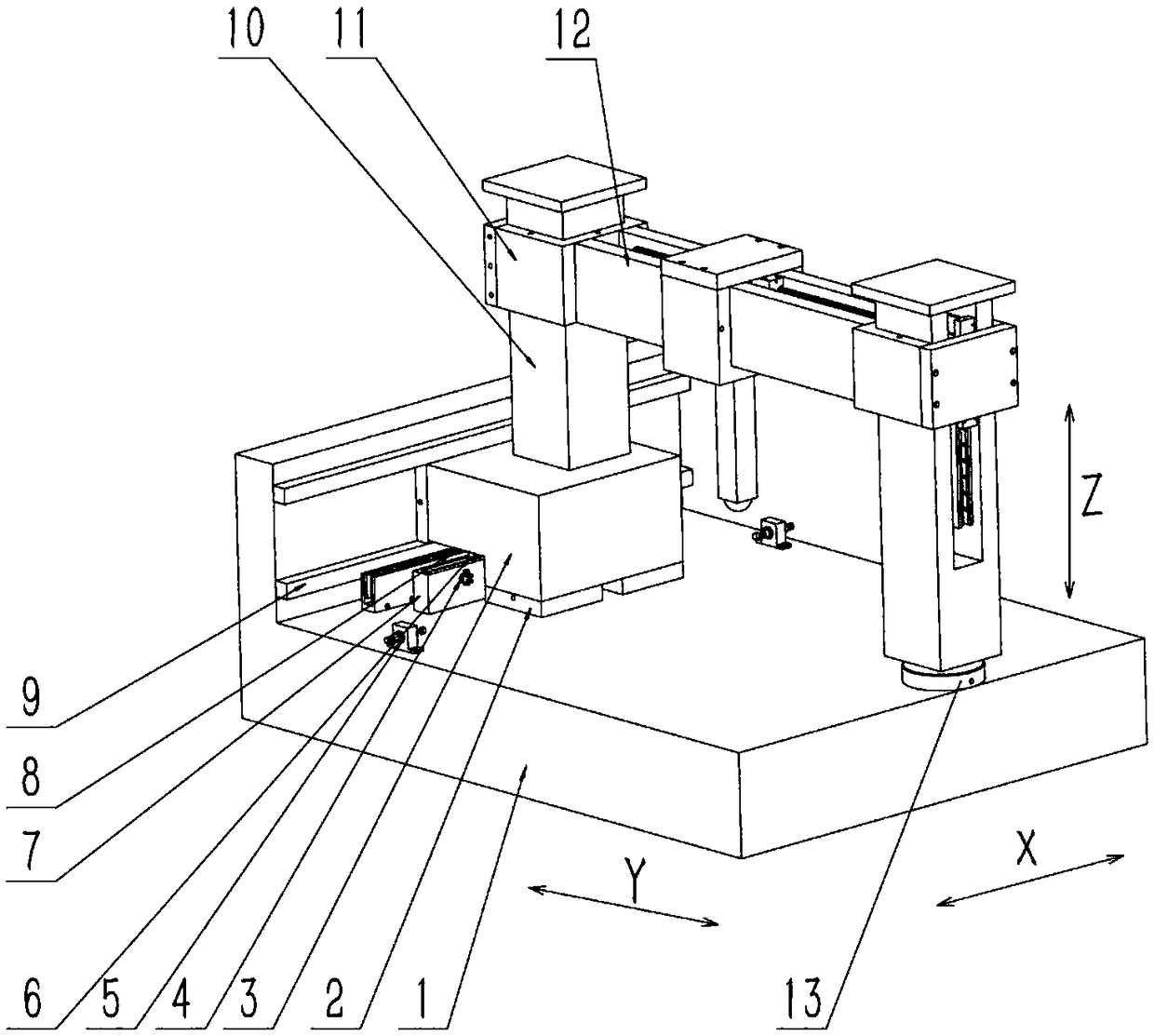

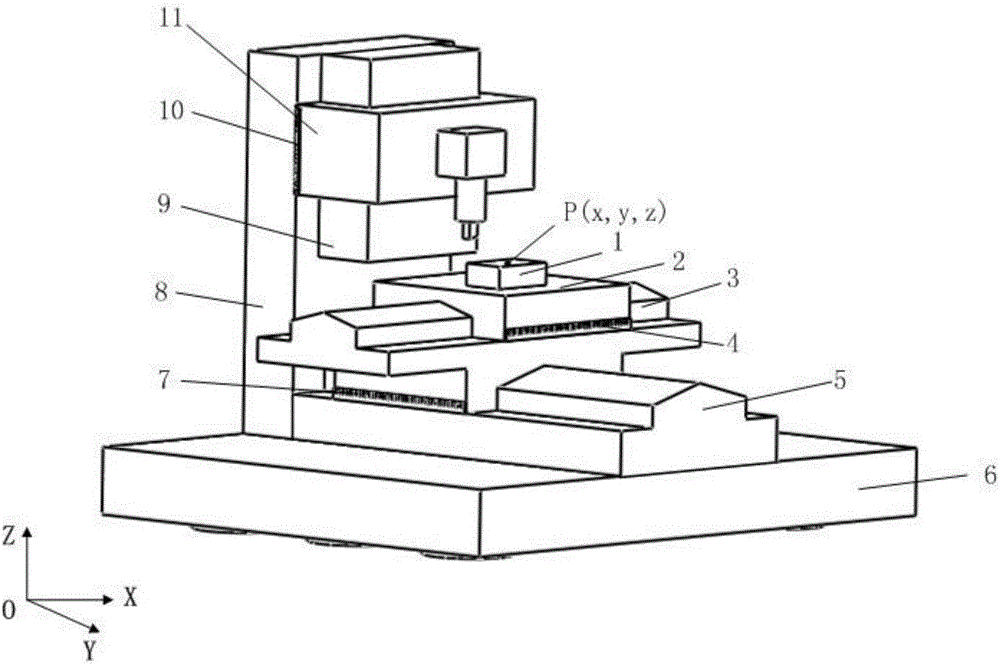

Micron-nano grade three-dimensional measurement '331' system and measurement method thereof

InactiveCN101419044AAvoid Abbe errorNo measurement errorMechanical measuring arrangementsMicro nanoThree dimensional measurement

The invention provides a micro-nano level 3-D measurement '331' system and a measurement method thereof. The system is characterized in that X, Y and Z-axis standard-measure dimension lines or extended lines thereof of the 3-D measurement system are arranged to be perpendicular to one another and intersect at one intersection point, so as to establish a 3-D coordinate system taking the intersection point as a coordinate origin; an X-axis guide-rail guide plane and a Y-axis guide-rail guide plane of a measurement platform in the measurement platform are arranged to be coplanar with a measurement plane where a measuring-head central point is, so as to form a coincidence plane; the intersection point of the X, Y and Z-axis standard-measure dimension lines or the extended lines thereof is on the coincidence plane of the measurement platform; meanwhile, the X and Y-axis standard-measure dimension lines or the extended lines thereof are also arranged to coincide with three planes, so as to ensure that X and Y coordinate planes of the established coordinate system coincide with the measurement plane; and the measuring-head central point is arranged to coincide with the intersection point of the three standard-measure dimension lines or the extended lines thereof. The invention satisfies the Abbe principle in 3-D direction, thereby effectively avoiding Abbe errors and guaranteeing high measurement precision.

Owner:HEFEI UNIV OF TECH

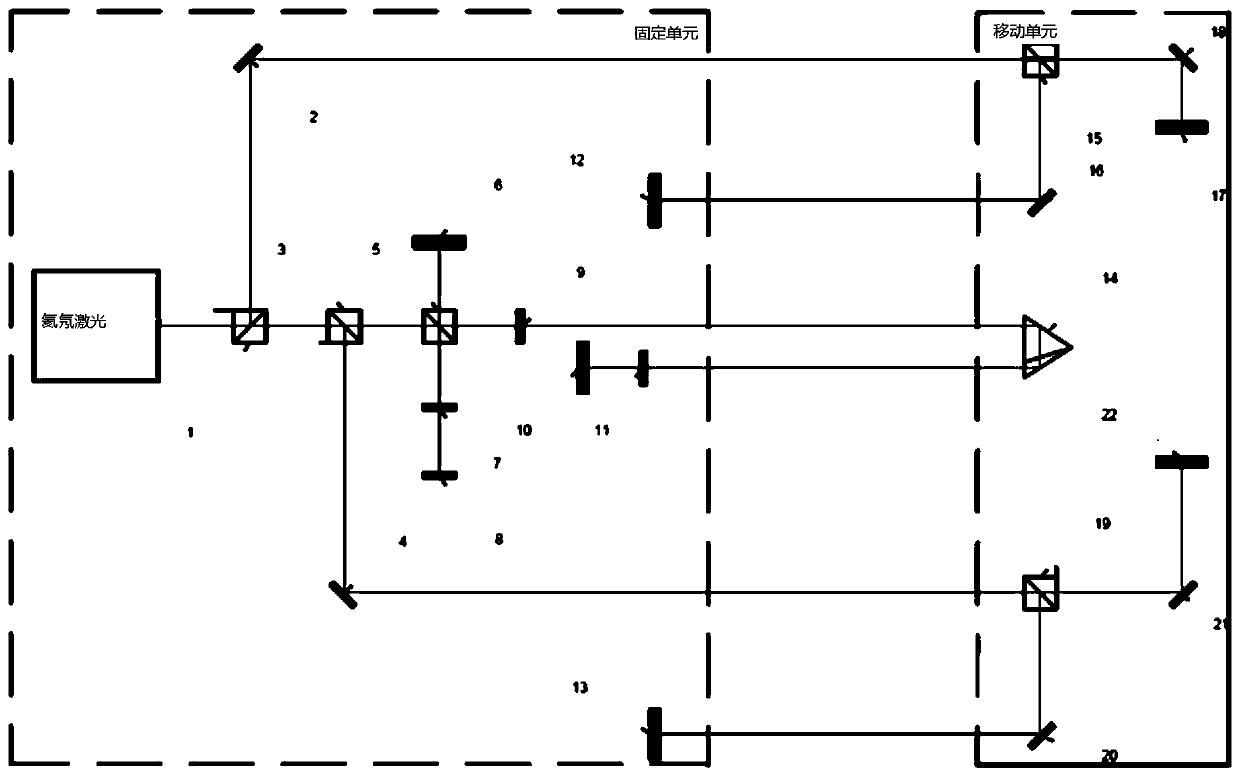

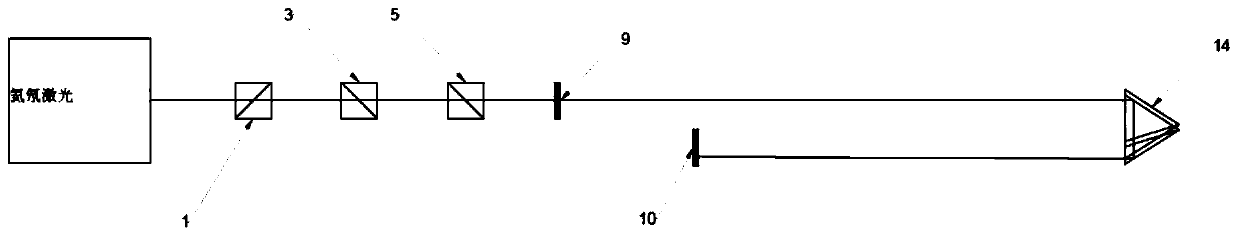

Error measurement system and method for high-precision linear guide rail

InactiveCN110160471AReduce the impactAvoid crosstalkUsing optical meansNumerical controlObservational error

The invention belongs to the field of geometric accuracy detection, and particularly discloses an error measurement system and method for a high-precision linear guide rail. The system comprises a fixed unit and a mobile unit, wherein the fixed unit is arranged on a fixed plane of a numerical control machine tool and comprises a helium-neon laser, a first beam splitter prism, a second beam splitter prism, a polarization beam splitter prism, a first 1 / 4 wave plate and a first four-quadrant detector; and the mobile unit is arranged on a mobile workbench of the numerical control machine tool andcomprises a pyramid prism. According to the invention, the pyramid prism which is insensitive to angles is adopted to measure the straightness error, so that the crosstalk and the measurement error caused by the angle change can be effectively avoided; meanwhile, the pyramid prism is arranged on the axis or the paraxial line, so that the influence of the Abbe error on the measurement result can beeffectively reduced, and the precision of the straightness measurement is improved; and the six-degree-of-freedom synchronous measurement can be realized by arranging other devices, and each error isdecoupled and separated, so that the accuracy of the measurement result is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

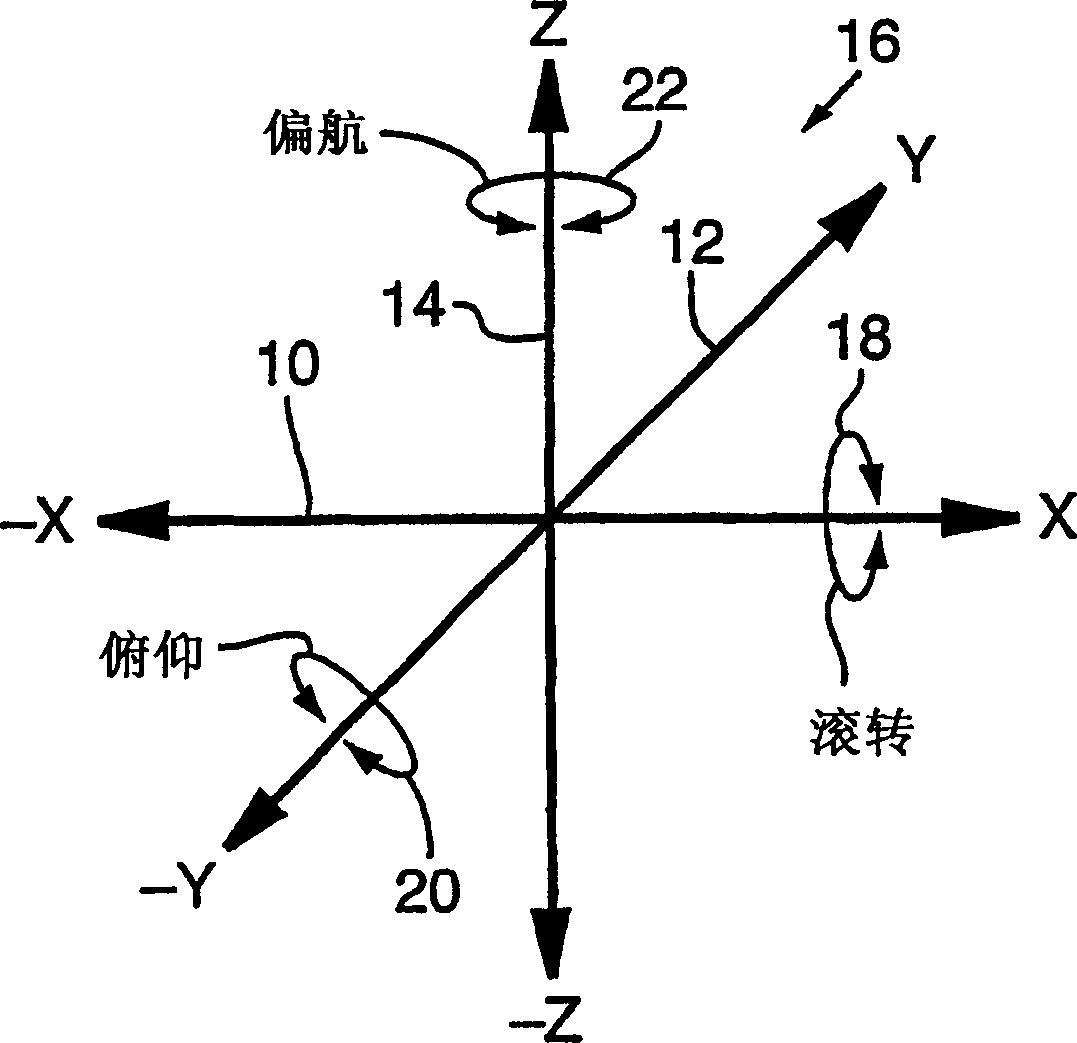

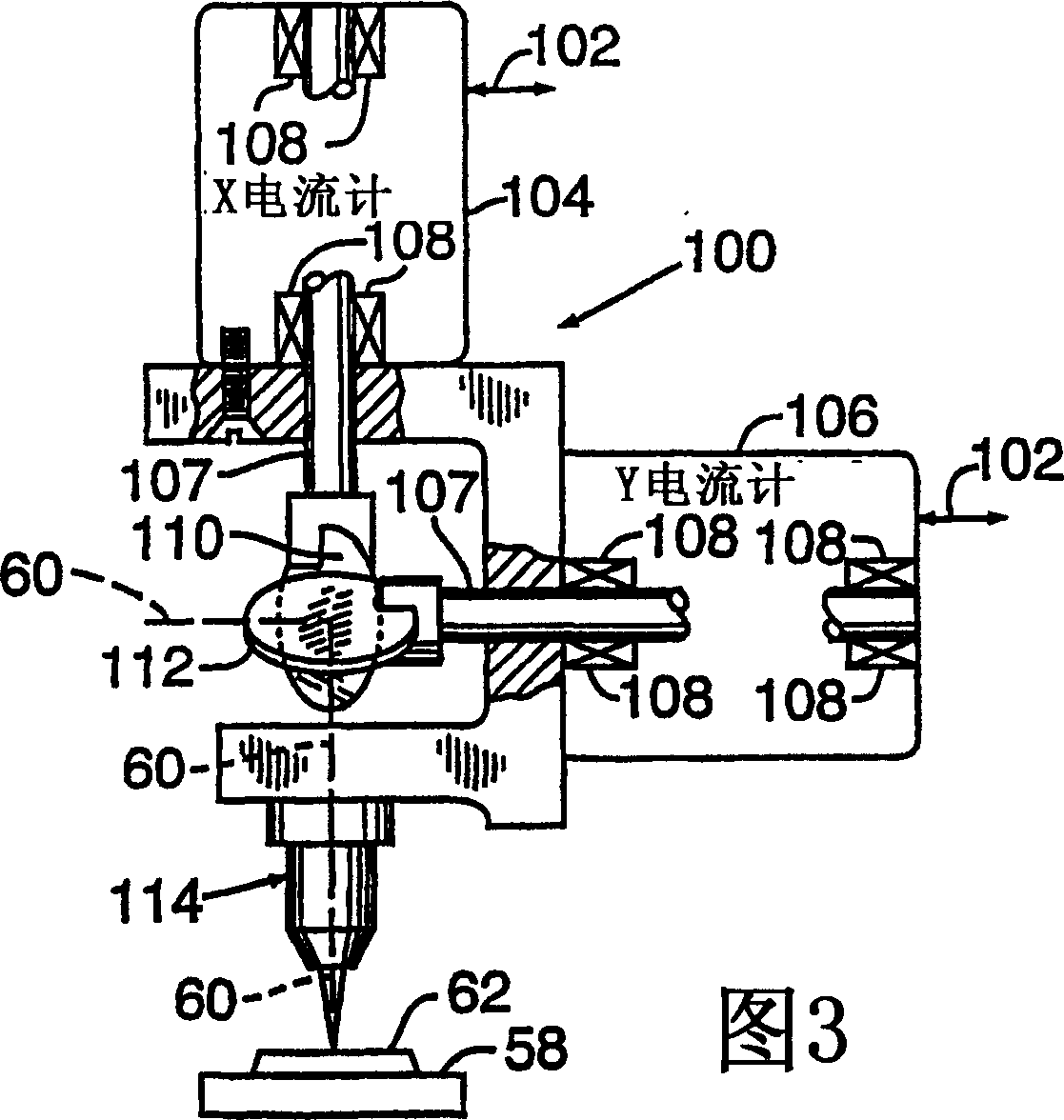

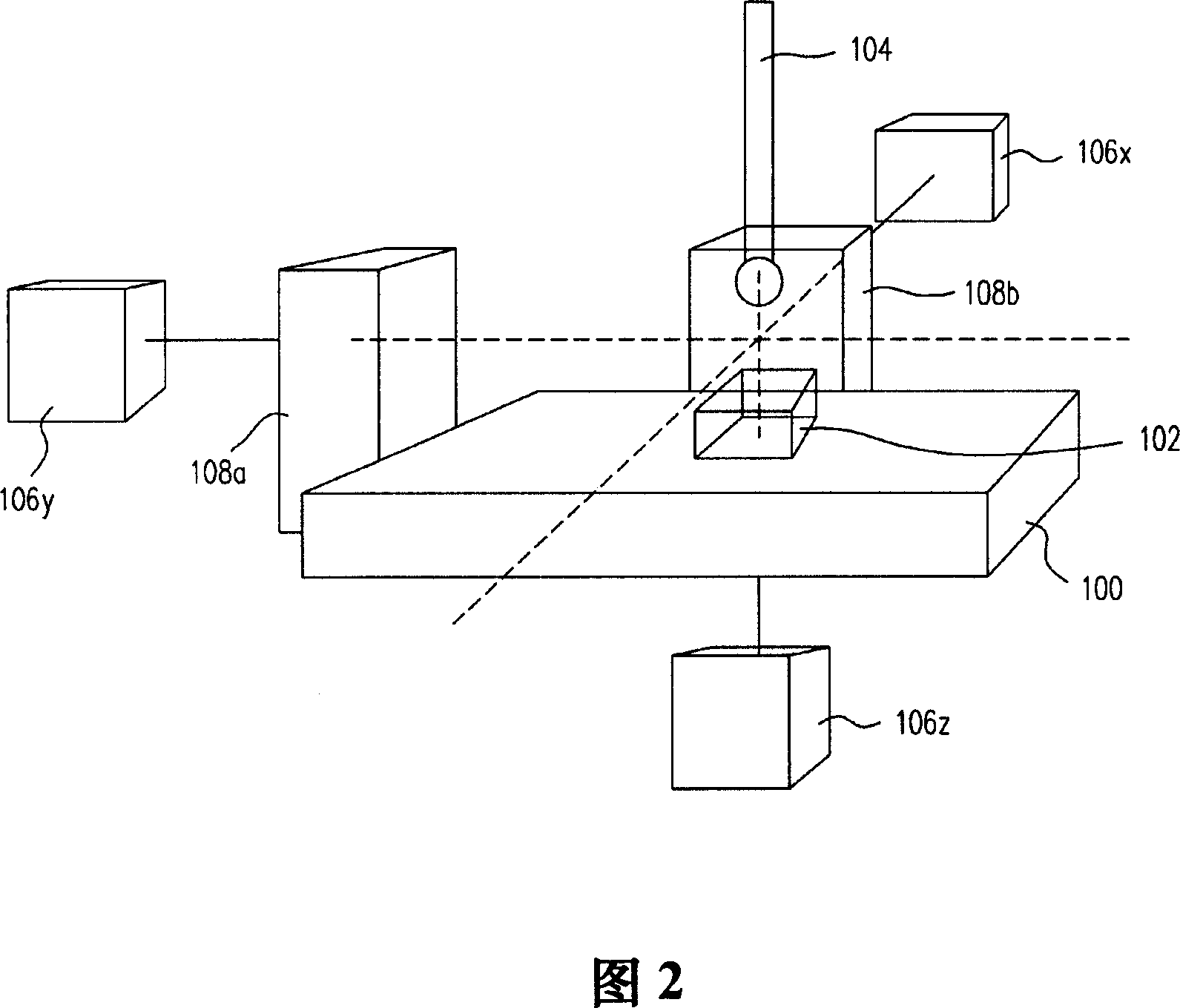

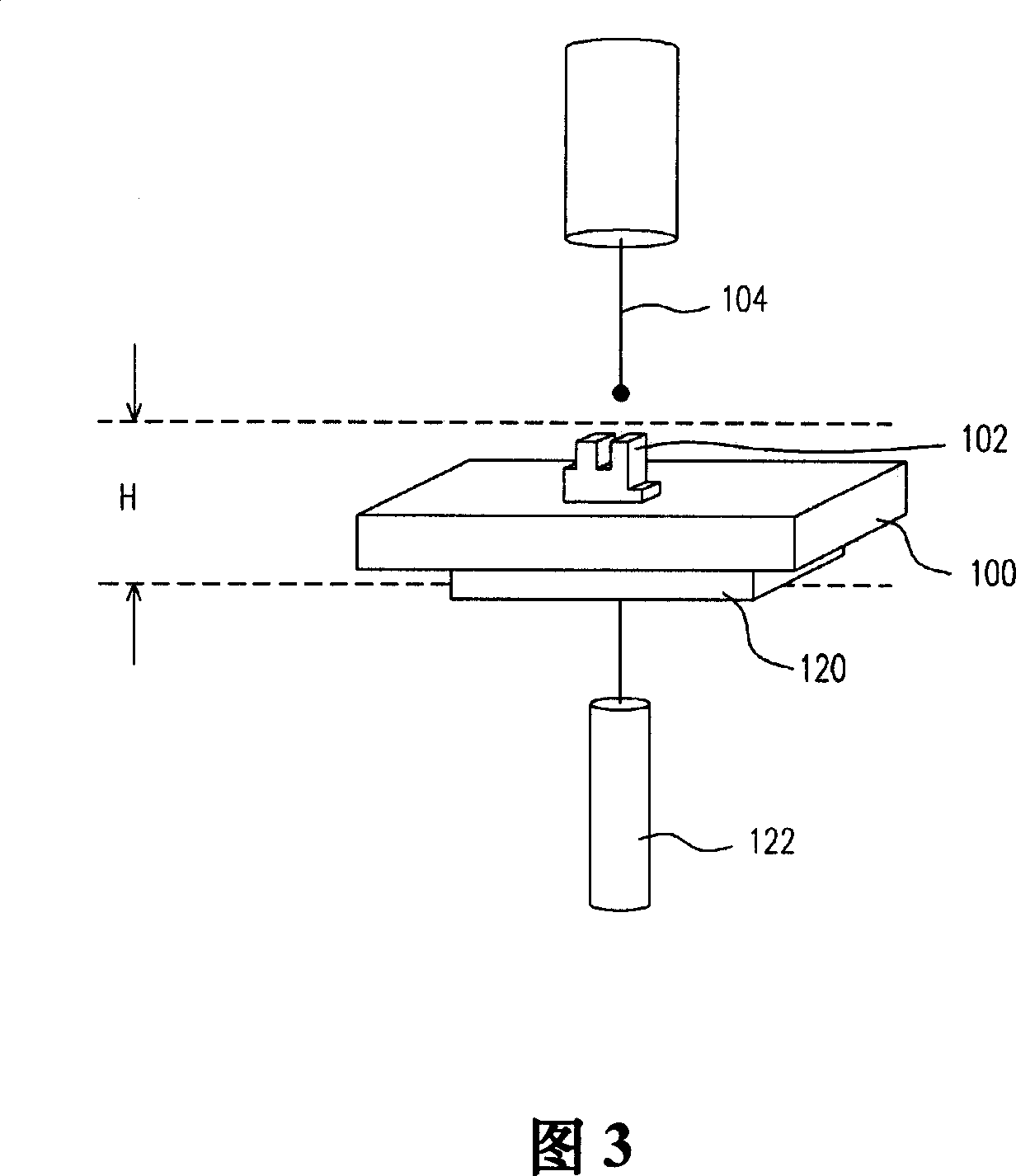

Abbe error correction system and method

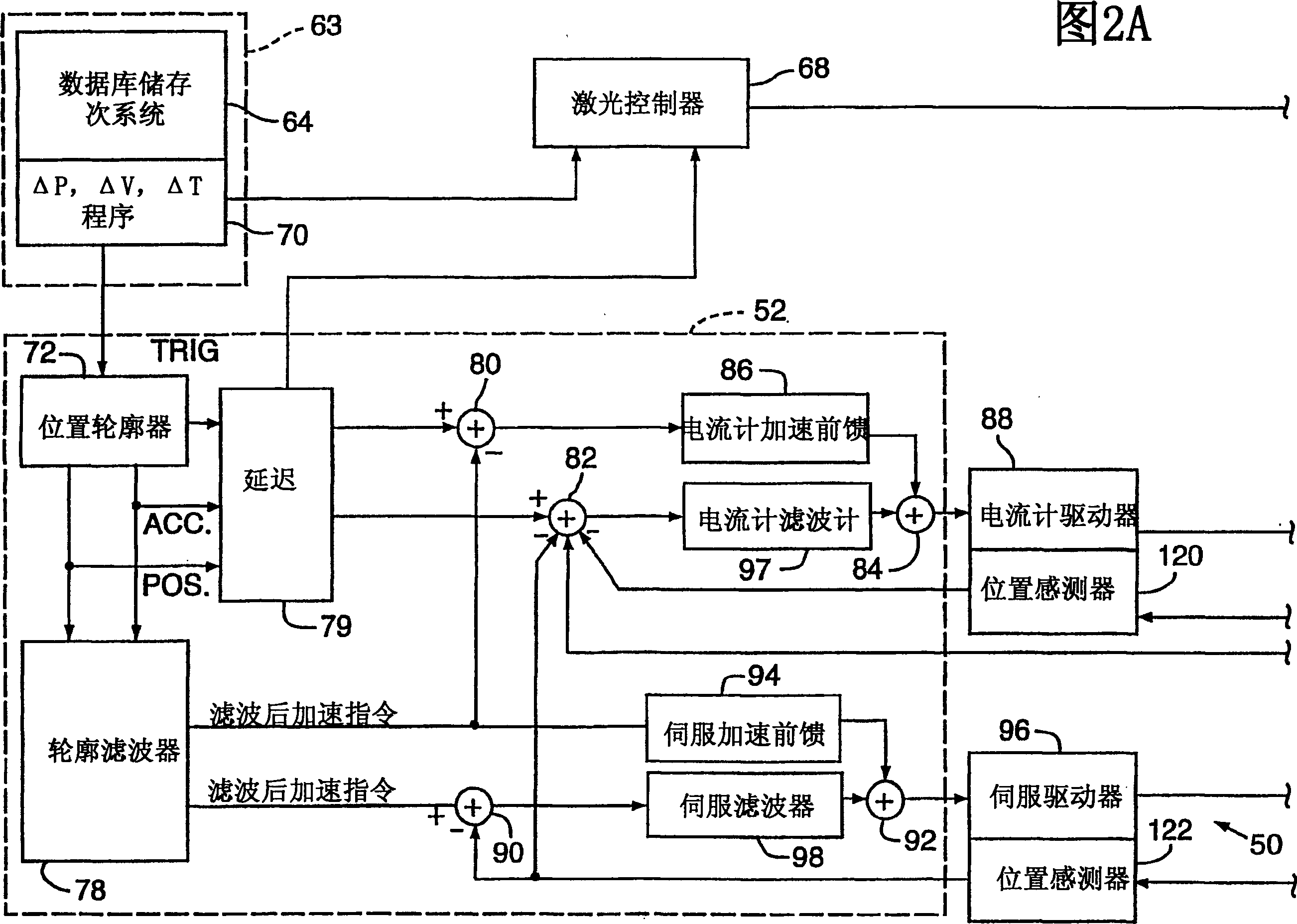

The present invention preferably employs non-contact, small-displacement, capacitive sensors (124, 128, 130, 131, 132) to determine Abbe errors due to the pitch (20), yaw (22), or roll (18) of a near linear mechanical stage (56, 58) that are not indicated by an on-axis position indicator, such as a linear scale encoder or laser interferometer. The system is calibrated against a precise reference standard so the corrections depend only on sensing small changes in the sensor readings and not on absolute accuracy of the sensor readings. Although the present invention is preferred for use in split-axis positioning systems (50) with inertially separated stages (56, 58), the invention can be employed in typical split-axis or stacked stage systems to reduce their manufacturing costs.

Owner:ELECTRO SCI IND INC

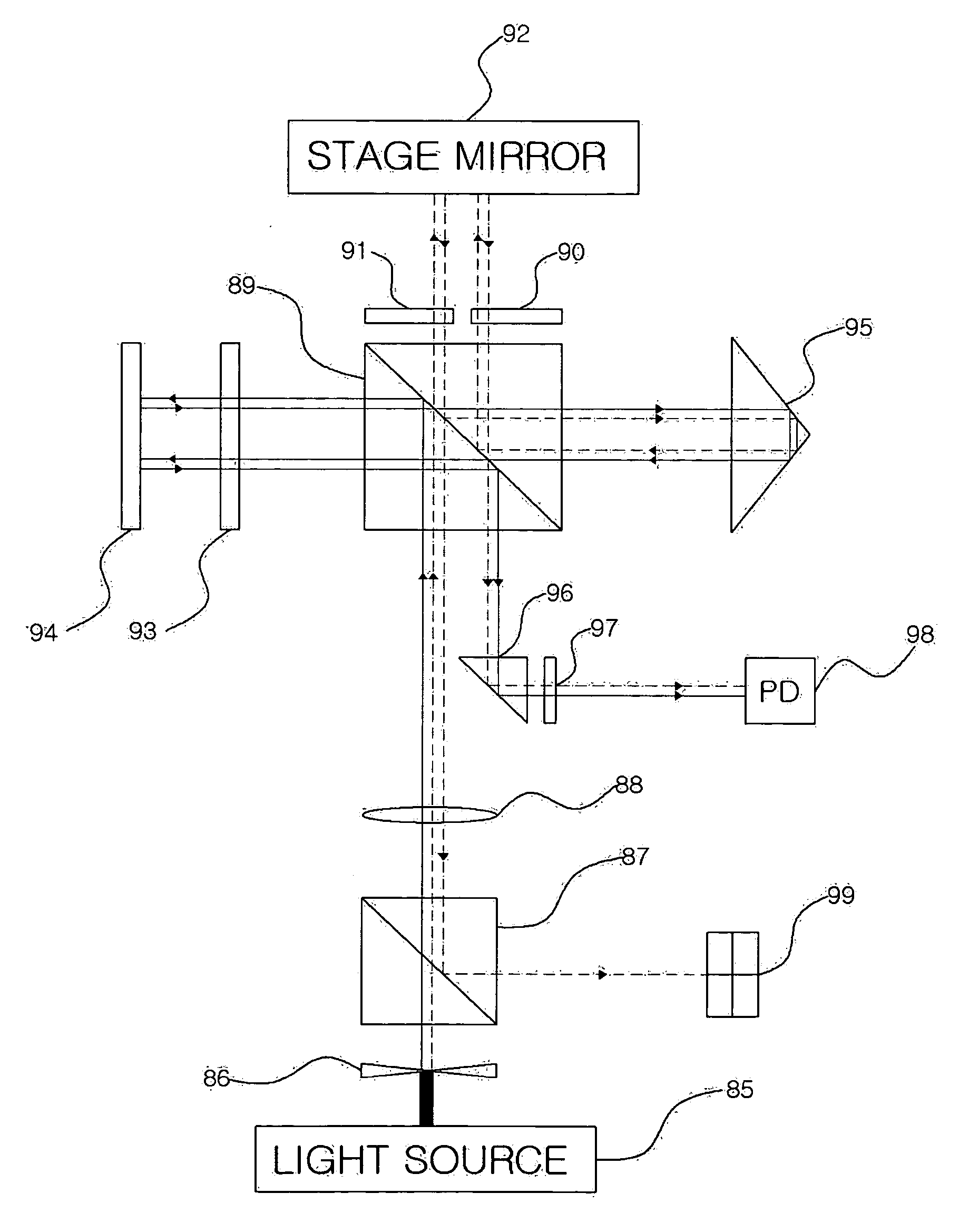

Method and apparatus for simultaneously measuring displacement and angular variations

InactiveUS20050157310A1Avoid mistakesSimple structureInterferometersMaterial analysis by optical meansMeasurement deviceOptical axis

Disclosed herein is a method and apparatus for simultaneously measuring a displacement and angular variations. The method and apparatus of the present invention allows light radiated from a single light source to be placed along a light axis so as to simultaneously measure a distance (displacement) and angular variations that are different physical quantities, so that the displacement and angular variations of the measuring device of a precision measuring apparatus or machining device of a machine tool moved by a stage can be simultaneously measured without an Abbe error.

Owner:KOREA RES INST OF STANDARDS & SCI

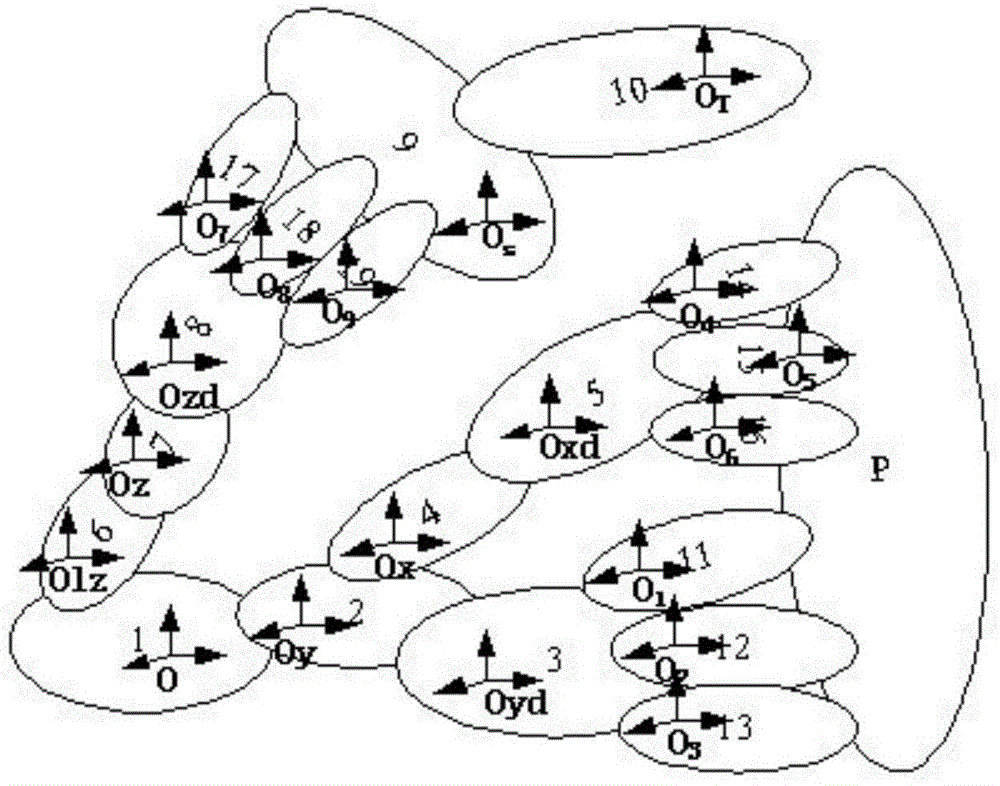

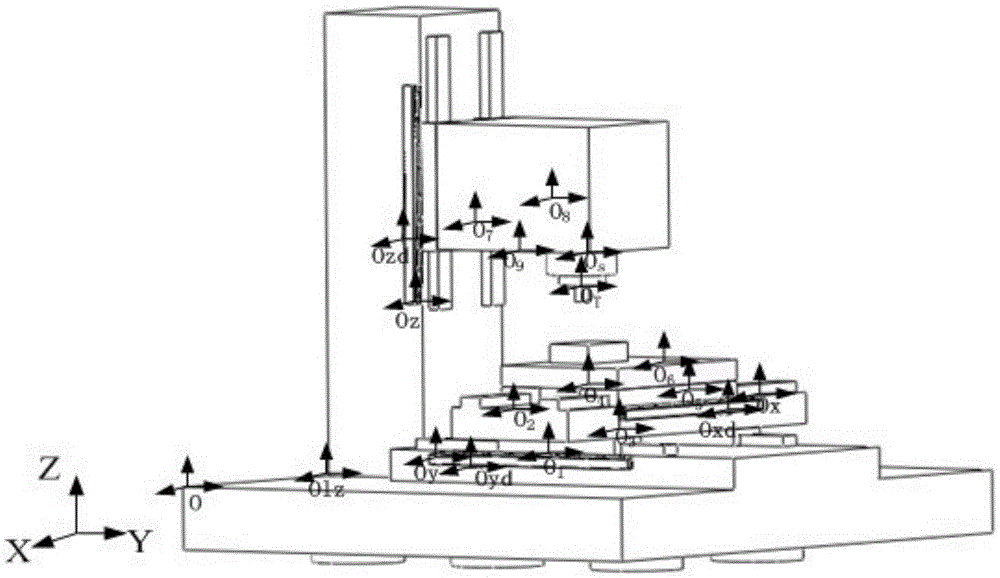

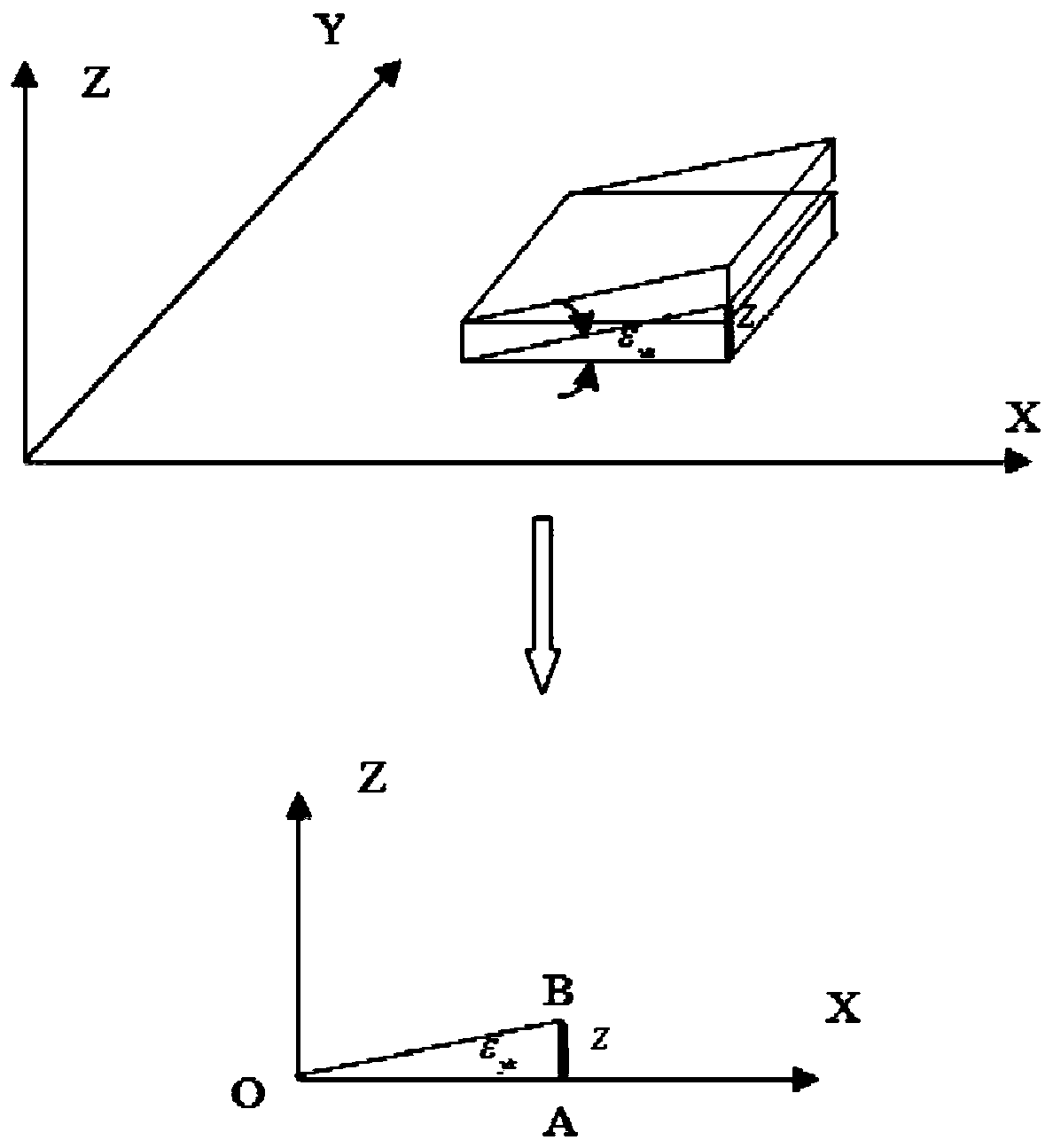

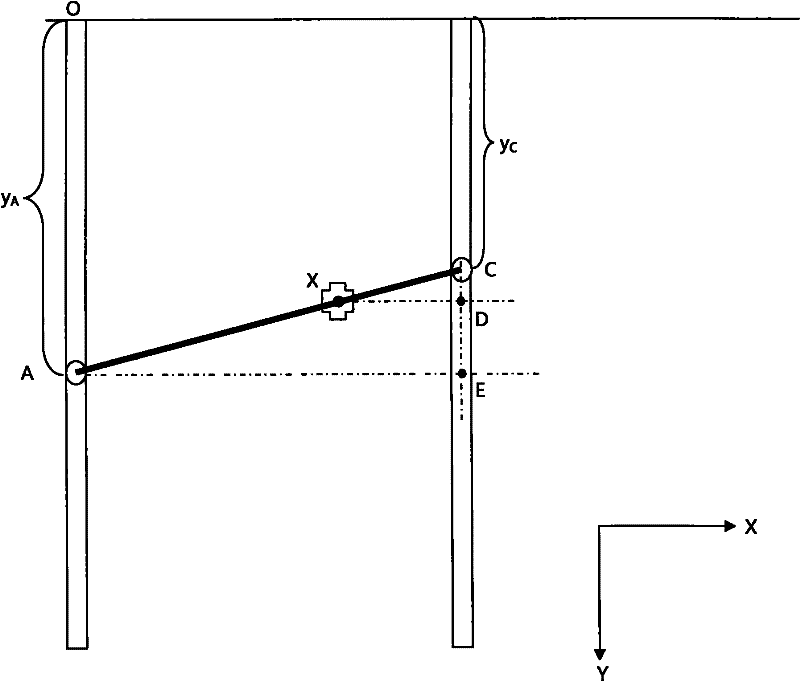

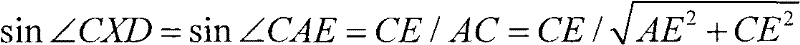

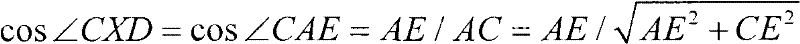

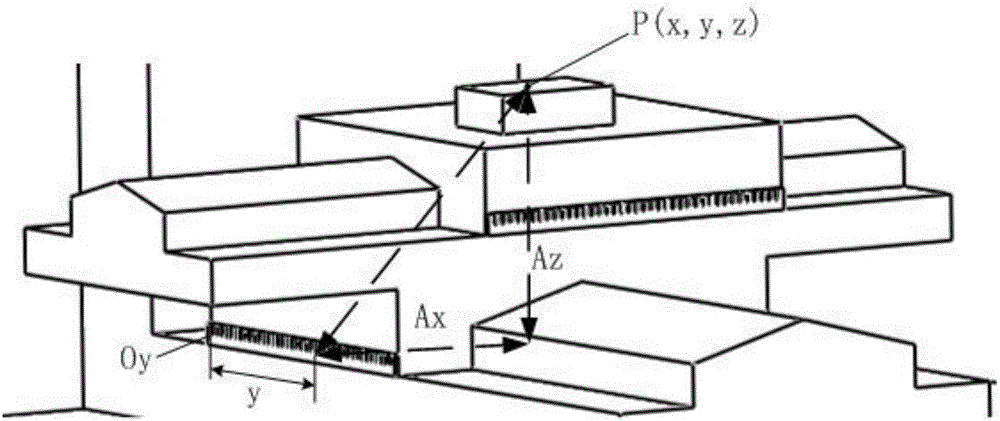

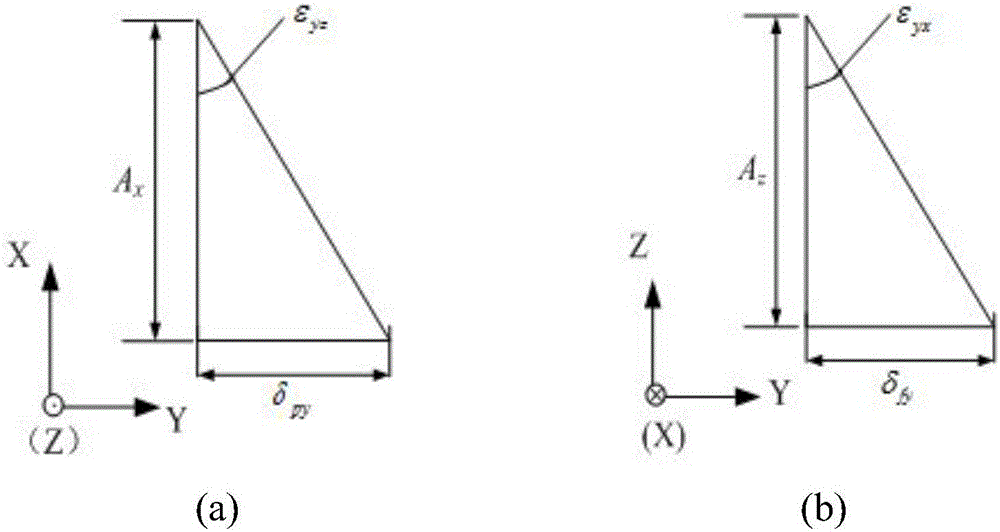

Machine tool error modeling method based on two-dimensional Abbe error and instantaneous movement center

ActiveCN105574287AIn line with the actual work situationImprove machining accuracyGeometric CADSpecial data processing applicationsNumerical controlGrating

The invention discloses a machine tool error modeling method based on a two-dimensional Abbe error and an instantaneous movement center, and relates to the technical field of machine tool error compensation. The machine tool error modeling method comprises the following steps: analyzing a deflection instantaneous center, a pitching instantaneous center and a rolling instantaneous center of an X and Y-axis guide track system of a stack working table; analyzing the deflection instantaneous center, the pitching instantaneous center and the rolling instantaneous center of a Z-axis guide track system; establishing corresponding deflection-Abbe error, pitching-Abbe error and rolling-Abbe error models. By adopting the machine tool error modeling method, the deflection instantaneous center, the pitching instantaneous center and the rolling instantaneous center of guide track systems in different motion directions can be analyzed, and the corresponding deflection-Abbe error, pitching-Abbe error and rolling-Abbe error models can be established. The zero drift error, the indication error and the guide track system Abbe error of a grating measurement system can be comprehensively considered according to the multi-body dynamic theory, a comprehensive numerically-controlled machine tool error model can be established, basis can be provided for next error compensation, and thus the processing precision of a numerically-controlled machine tool can be effectively improved.

Owner:ANHUI UNIV OF SCI & TECH

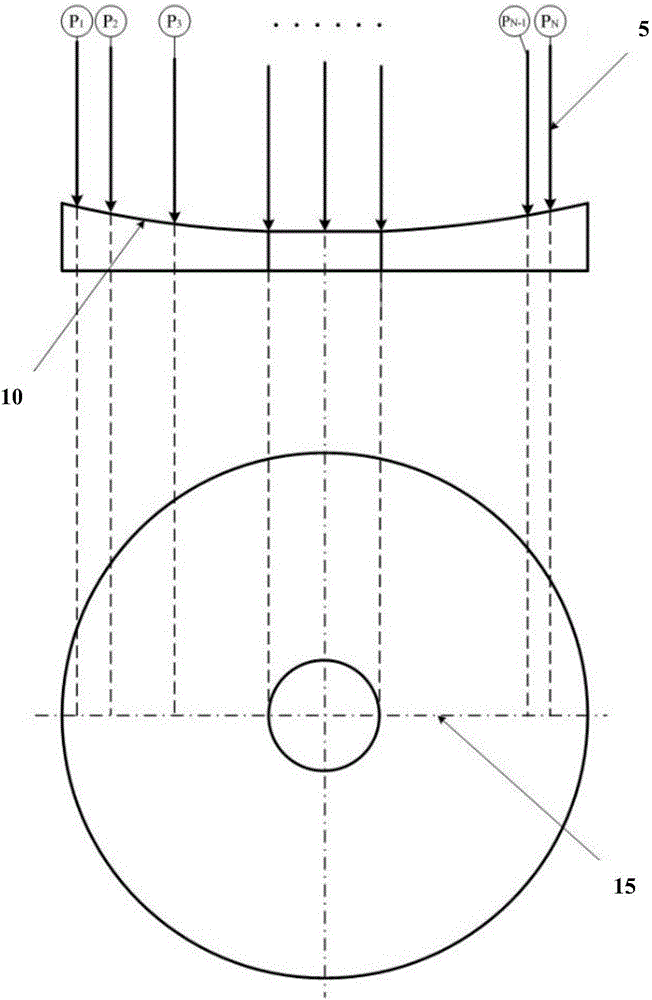

Method and device for measuring free-form surface based on reference plane comparative measurement

ActiveCN110057337AImproved scan detection accuracyAbbe's error is smallUsing optical meansFree formSurface level

The invention discloses a method and a device for measuring a free-form surface based on reference plane comparative measurement, and belongs to the technical field of optical precision detection. Themethod uses the high-precision plane flat crystal as a reference plane of an X-Y surface, utilizes the high-precision height measurement sensor and the free-form surface measurement sensor which arecoaxially installed to detect the high-precision plane flat crystal and the surface height information of the measured free-form surface respectively, utilizes the high-precision height measurement sensor to acquire the surface height information of the high-precision plane flat crystal to monitor and compensate the straightness error of an X-direction air-floatation guide rail and a Y-direction air-floatation guide rail, performs dimension reduction error separation on the surface appearance of the free-form surface, and realizes the nanometer precision detection of the appearance of the free-form surface. The method and the device for measuring the free-form surface based on reference plane comparative measurement can realize the detection of the free-form surface, provide high-precisionthree-dimensional linear positioning and scanning measurement, inhibit the influence of the straightness error of the movement of the X-direction guide rail and the Y-direction guide rail on the measurement of the free-form surface, reduce the influence of the Abbe error of the Z axis on the measurement, and realize the large-range and nanometer precision measurement of the free-form surface.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

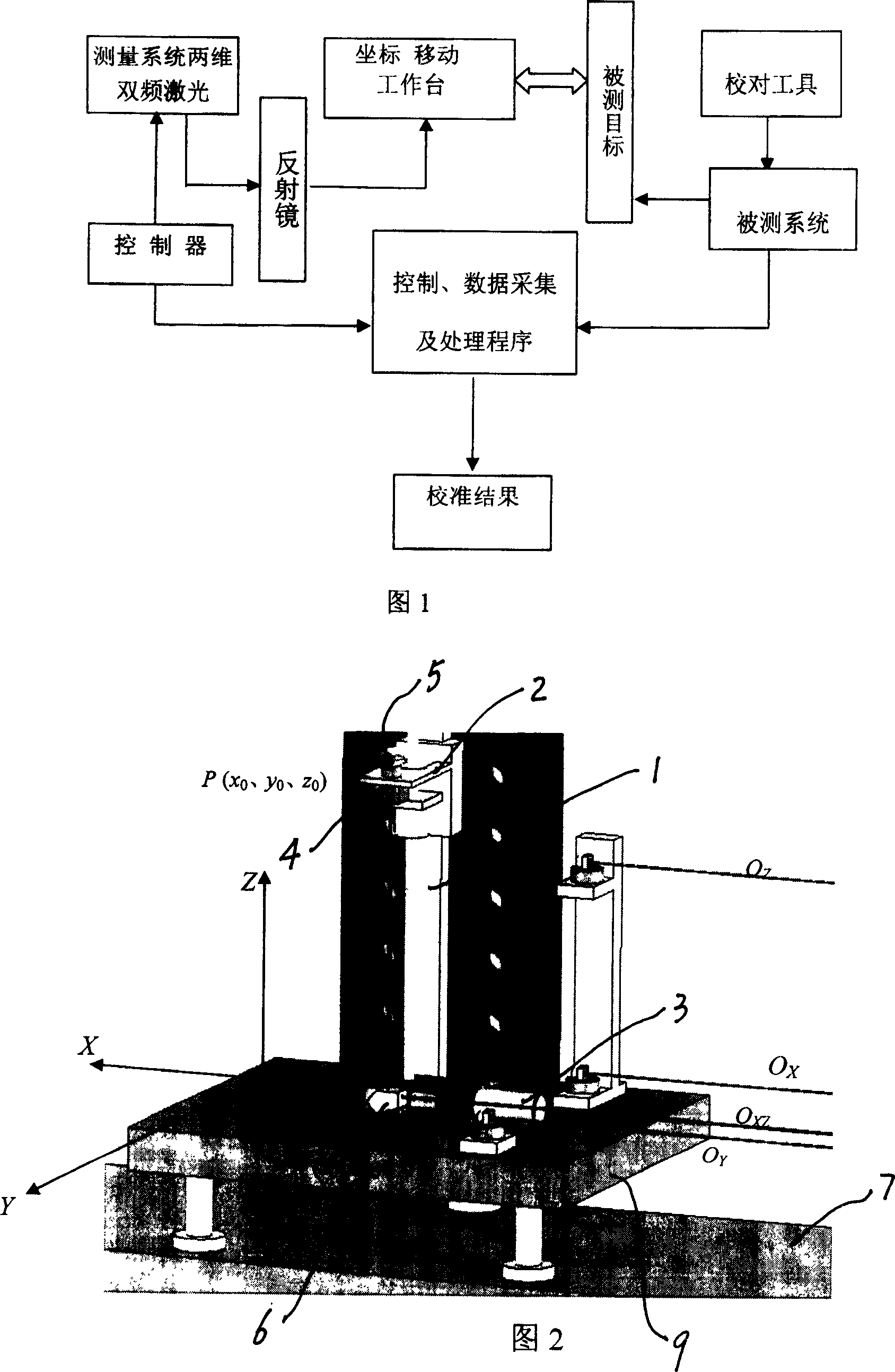

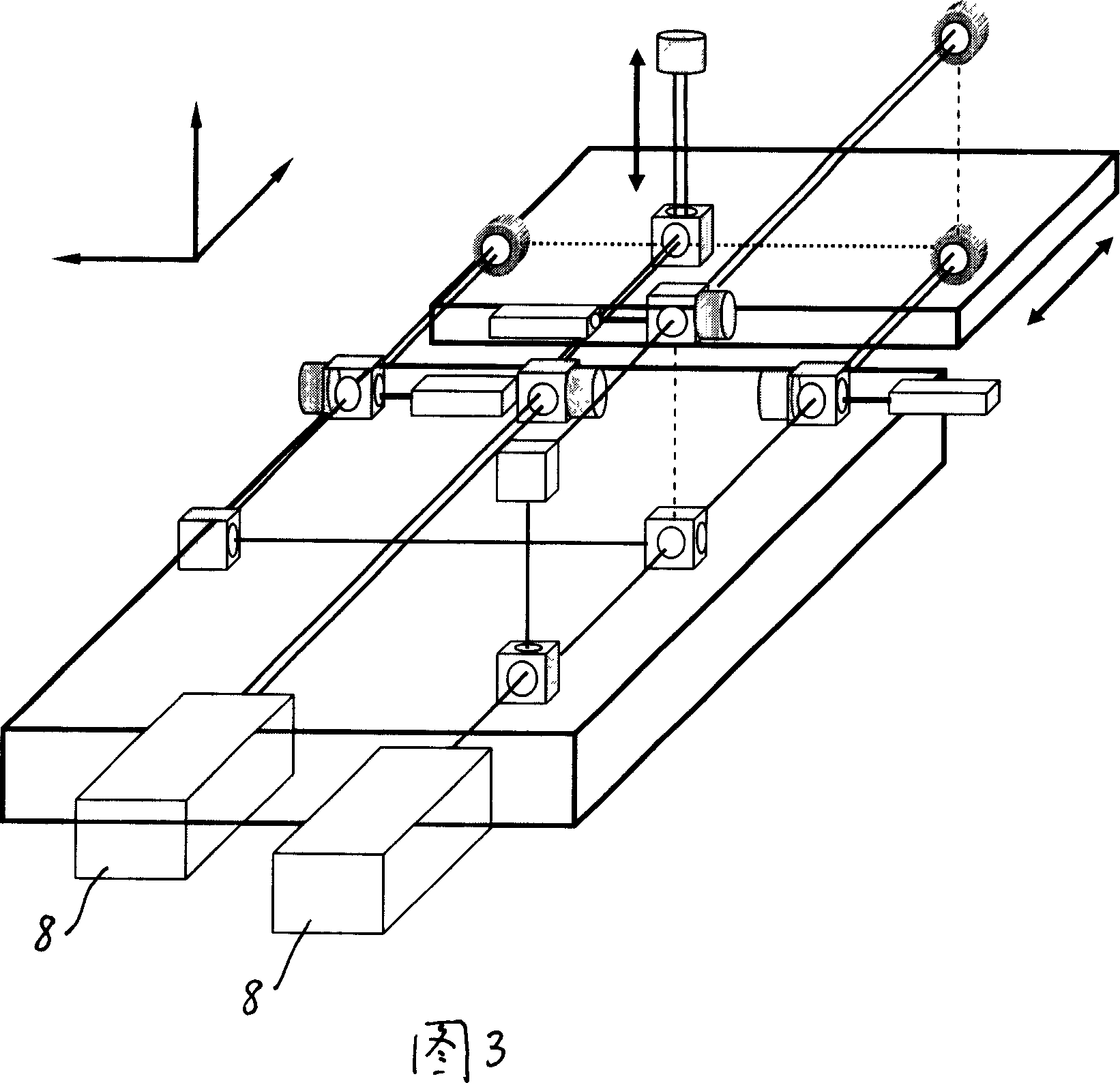

Laser plane coordinate calibration device

InactiveCN1971210AReduce straightness requirementsEliminate the effects ofUsing optical meansCoordinate-measuring machinePrism

An invention of laser plane coordinate standard device contains three laser interferometry optical paths which measures the horizontal axial coordinate, it characterized in that a set of laser interferometry optical path which measures vertical axial coordinate is added, the interferometry optical path includes a vertical axis, object operating platform is located on the vertical axis and moves along the vertical axis drive by motor, pyramid reflector and survey target are mounted on the operating platform, a rotating prism which deflects the light path from horizontal axial to vertical axial is set on lower of operating platform. The device builds laser plane standard coordinate plane with two sets of mutually perpendicular laser interferometry optical paths, the structure is simple, accuracy of Abbe error compensation is high, measurement precision is high, direct calibration and error evaluation which is based on the coordinate points of large scale portable three-coordinate measuring machine are realized for the first time.

Owner:BEIJING CHANGCHENG METERING TEST TECH INST NO 1 GRP CO CHINA AVIATION IND

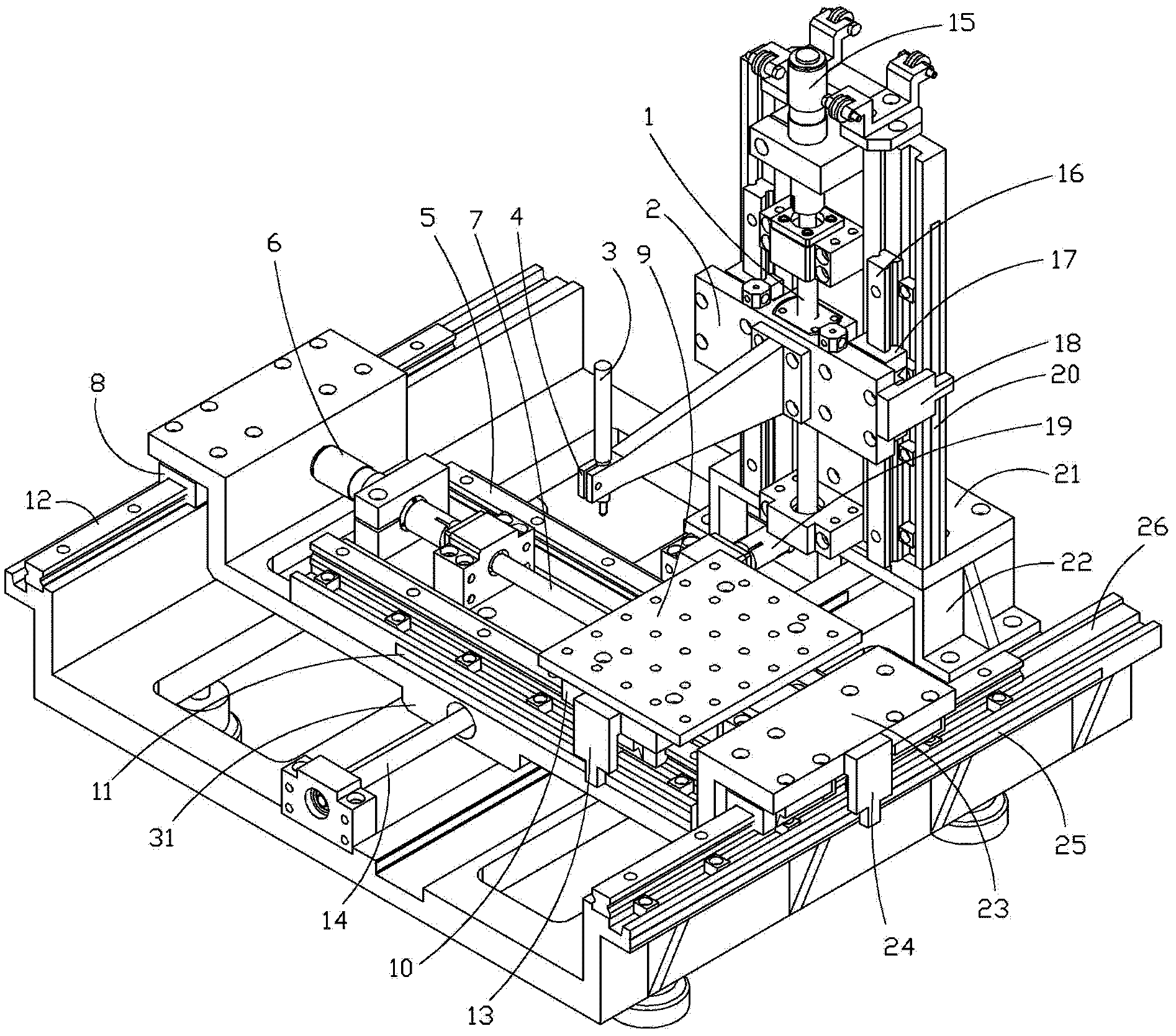

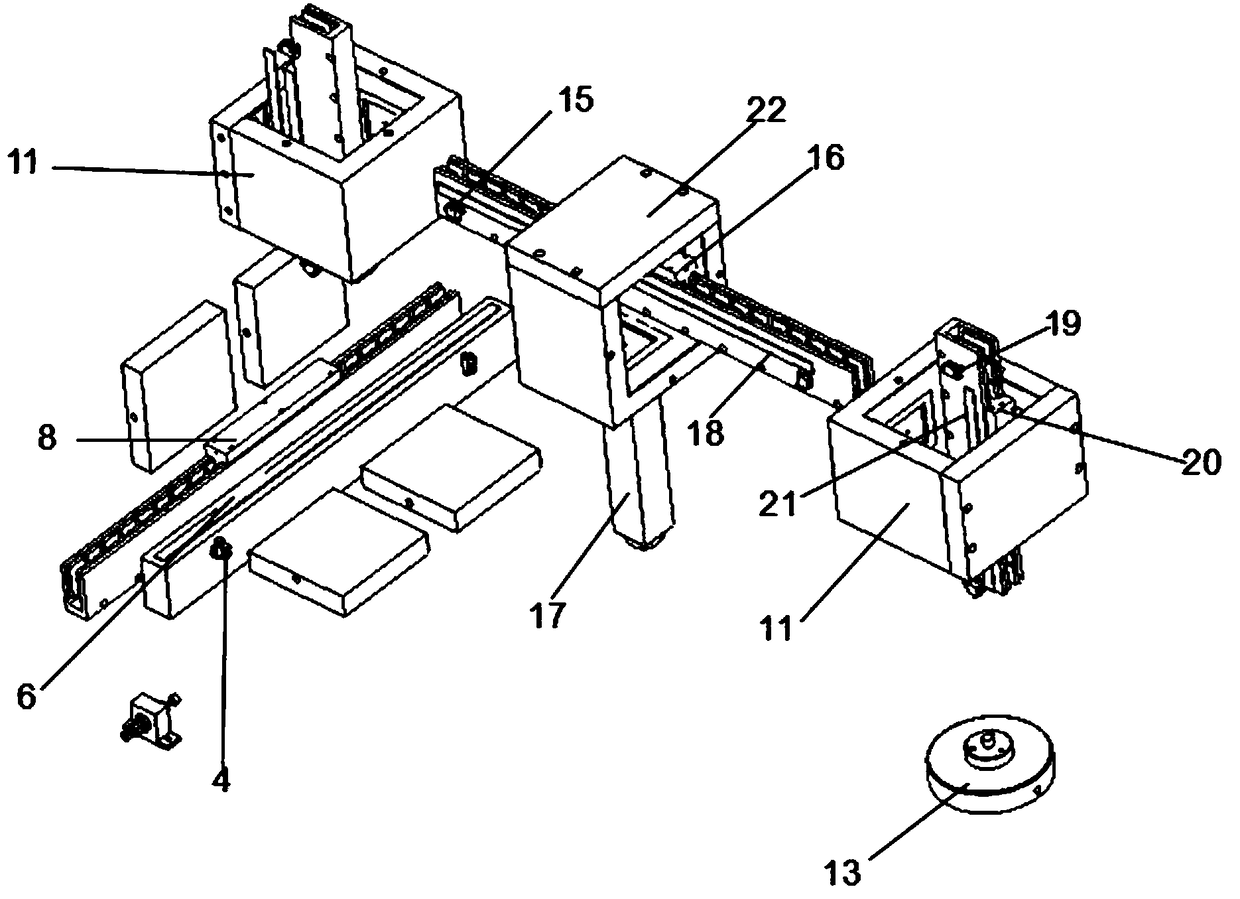

Small-Abbe-error three-dimensional measurement system

The invention discloses a small-Abbe-error three-dimensional measurement system, which is characterized in that the small-Abbe-error three-dimensional measurement system is arranged in a mechanical transmission unit and comprises an X-direction assembly, a Y-direction assembly and a Z-direction assembly, a Z-direction clamp head used for clamping a sensor is fixedly arranged on a Z-direction slide seat arranged in the Z-direction assembly, and gratings consisting of grating rulers and grating heads respectively comprise an X-direction grating assembly, a Y-direction grating assembly and a Z-direction grating assembly. The small-Abbe-error three-dimensional measurement system has the technical effects of high efficiency, accuracy and simplicity when being applied to the thermal deformation detection, and the Abbe errors can be effectively reduced.

Owner:HEFEI UNIV OF TECH

Zero-Abbe error measuring system and its method

InactiveCN1991333AEliminate Abbe errorLow costSurface/boundary effectInstrumental componentsClassical mechanicsAbbe error

A zero Abelian error measuring system is disclosed that includes: moving platform, detecting equipment, the first and second three-dimensional optical rulers. The moving platform is used to load the sample to be measured. The detecting equipment is used to detect the sample and measure the perpendicular height of observation point relative to sample. The first and second three-dimensional optical rulers are mounted separately on the moving platform face to face secluded by the sample; the height of the first and second three-dimensional optical rulers can be adjusted tiny along the perpendicular height, the perpendicular height of the first and second three-dimensional optical rulers relative to the moving platform is same as the perpendicular height of observation point to measure the sample.

Owner:IND TECH RES INST

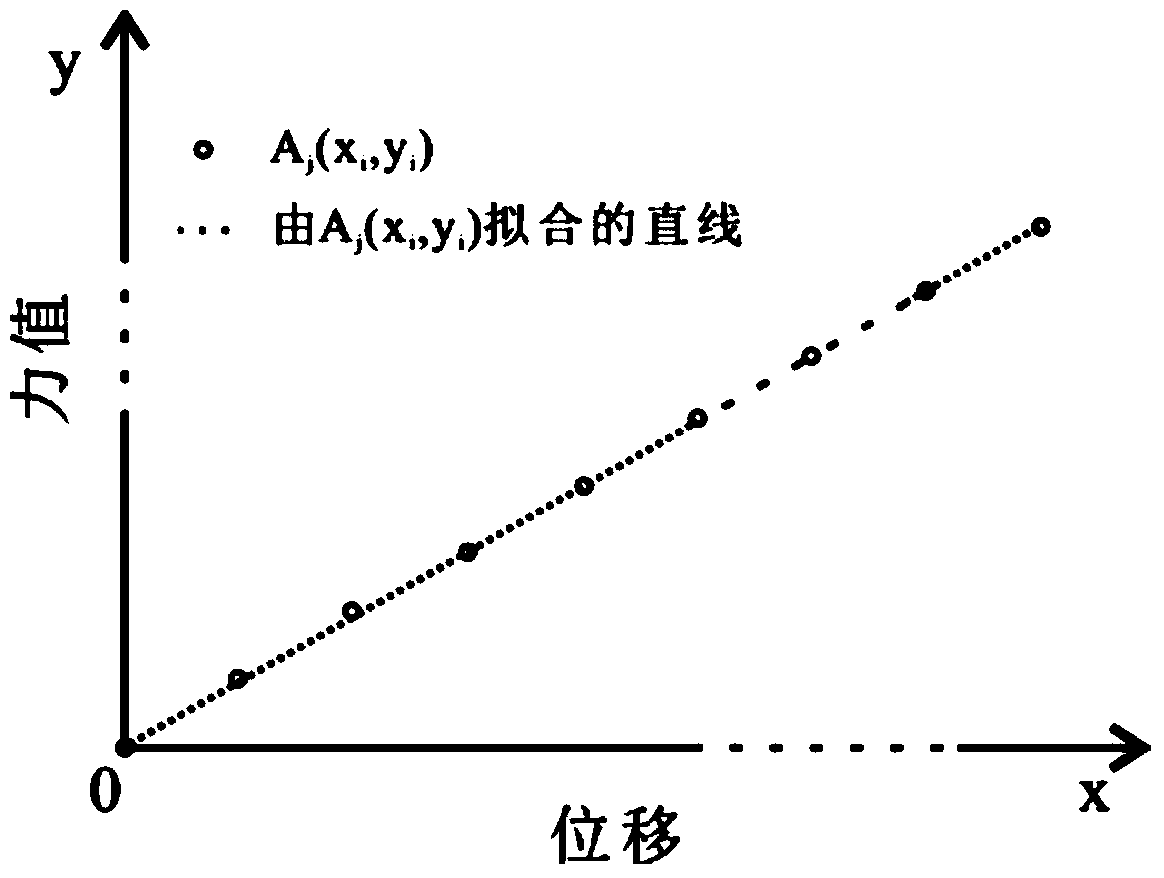

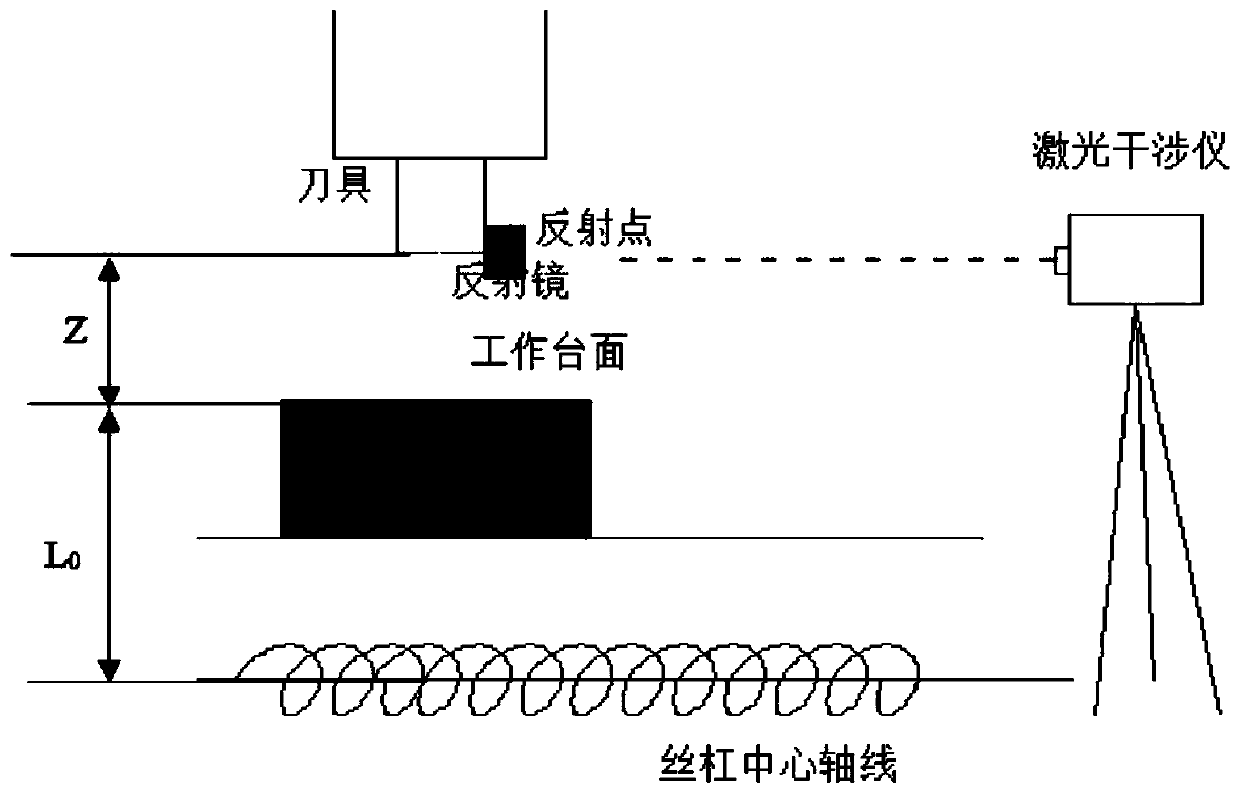

Abbe error compensation method and system based on machine tool positioning precision measurement

ActiveCN111338291AImproved final positioning accuracyProgramme controlComputer controlMeasurement deviceControl engineering

The invention discloses an abbe error compensation method and system based on machine tool positioning precision measurement. The method comprises the steps: arranging a laser interferometer of a measurement device on a machine tool, carrying out the optical debugging, and enabling the laser interferometer to be in a to-be-measured state; recording a measurement program of the numerical control system to enable the program of the numerical control system to be consistent with measurement parameters of the laser interferometer; measuring the positioning error of the machine tool, and generatingan error compensation parameter table; measuring the distance between the emitted light of the laser interferometer and the central axis of the corresponding transmission lead screw, and recording the data as Abbe arm length; and the numerical control system performs superposition operation according to the error compensation parameter table and the abbe error value to generate a compensated positioning error compensation value, and drives the servo motor to perform feeding movement according to the positioning error compensation value to perform error compensation. The method has the advantages that the Abbe error generated in the measurement process is considered, the Abbe error is superimposed on the compensation value to serve as the final positioning precision of the machine tool, and the compensation precision is greatly improved.

Owner:HUBEI UNIV OF ARTS & SCI +2

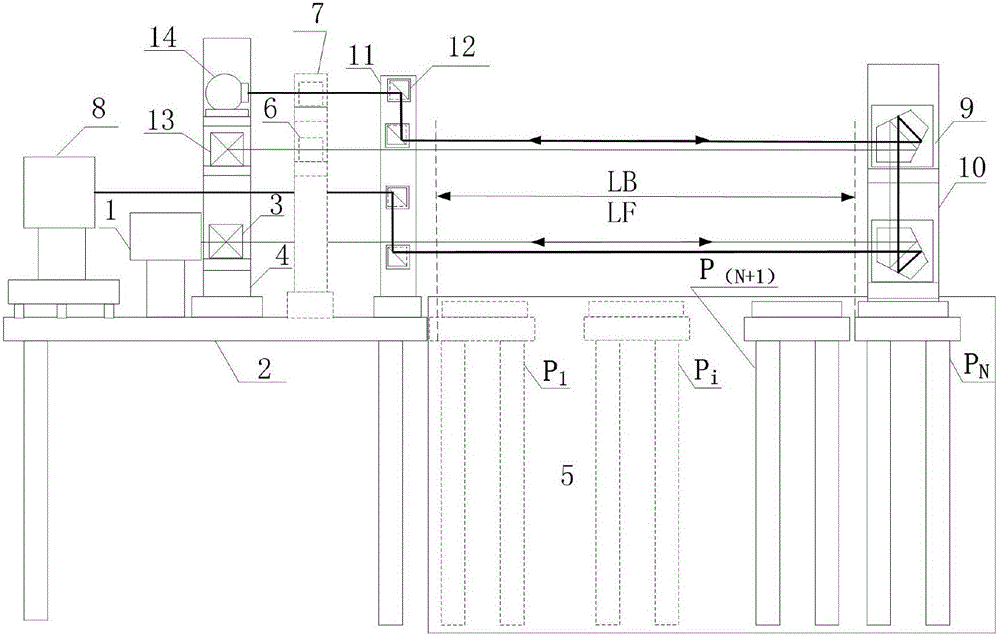

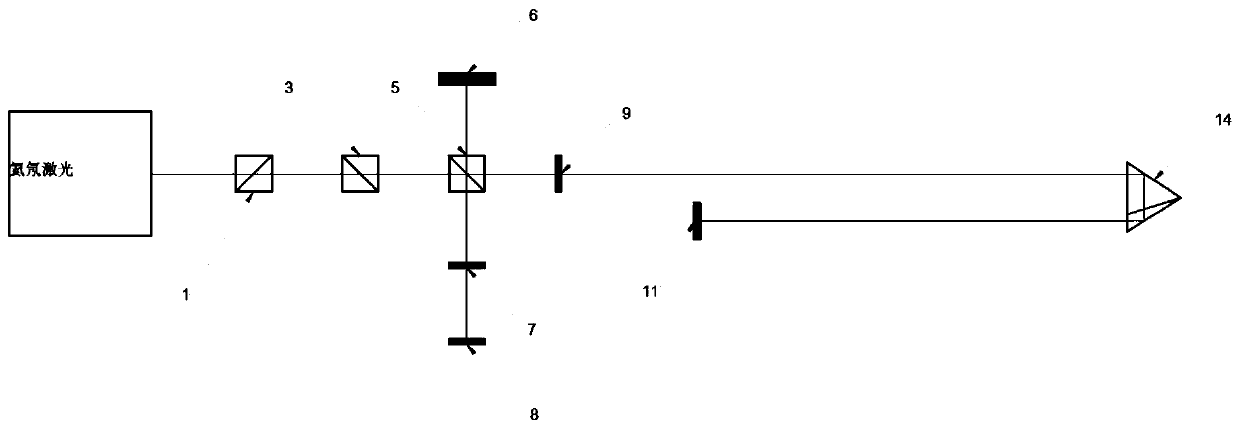

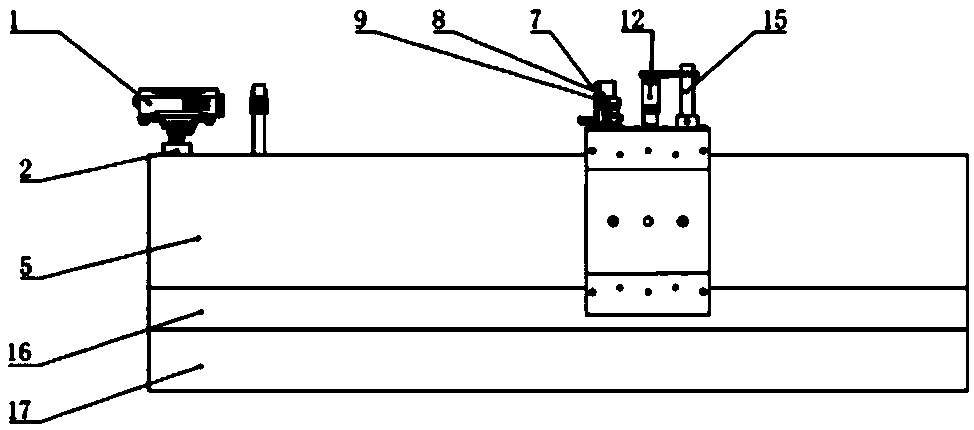

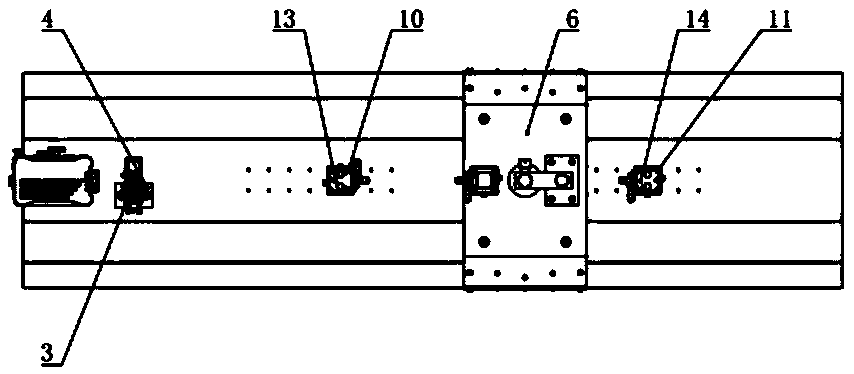

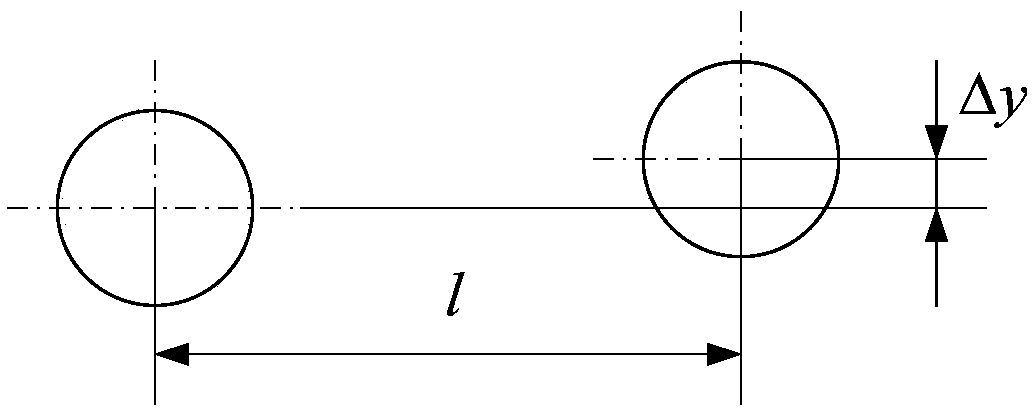

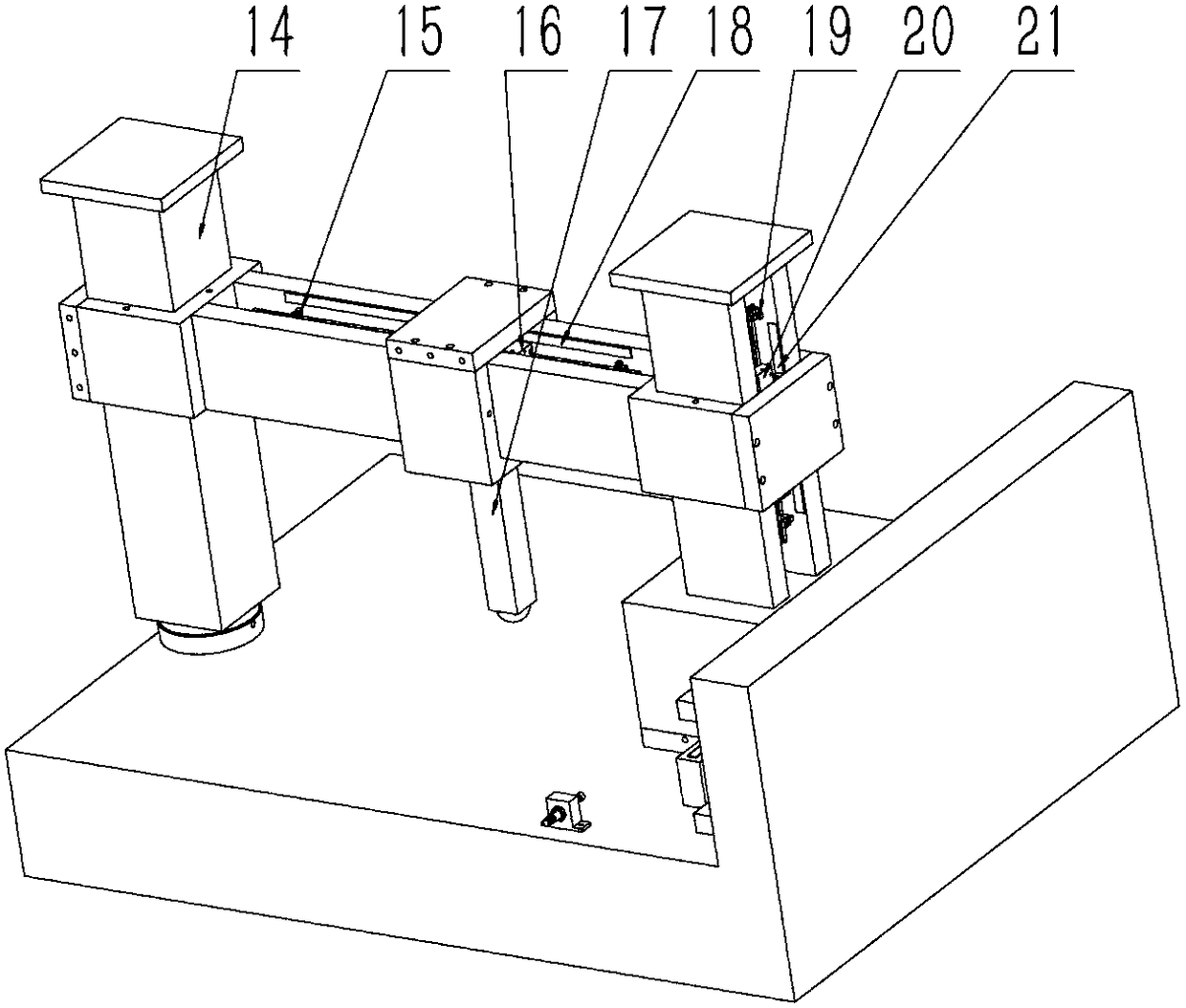

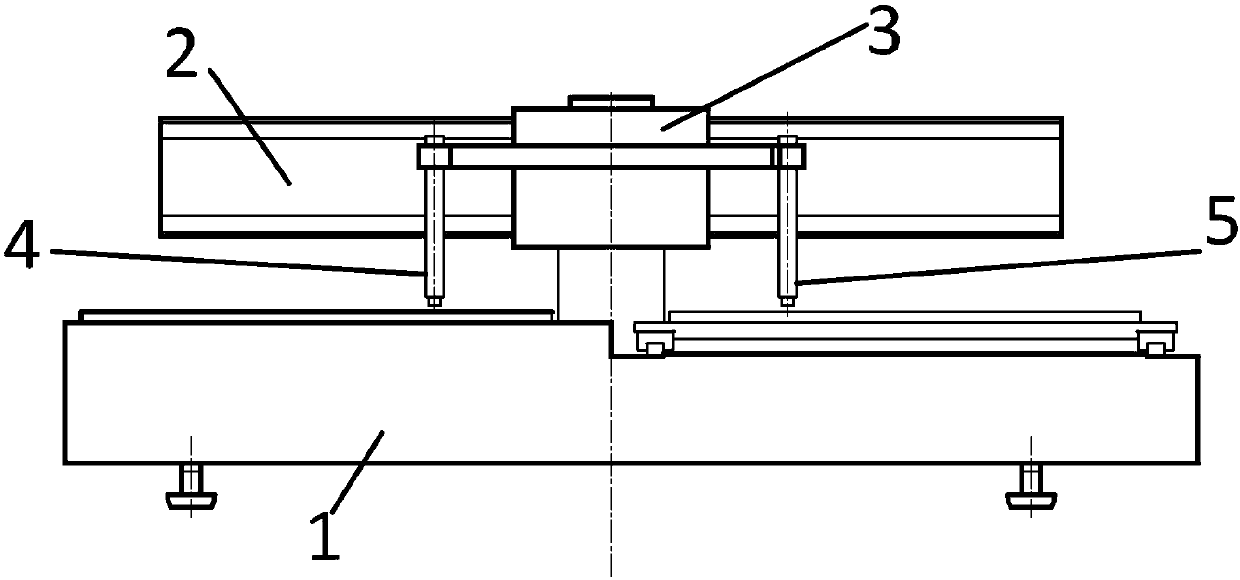

Length calibration device for photogrammetric reference ruler and using method thereof

ActiveCN108871207AGuaranteed accuracyEliminate Abbe errorUsing optical meansBeam splitterMultiple modes

The invention discloses a length calibration device for a photogrammetric reference ruler and a using method thereof. The length calibration device effectively eliminates Abbe errors in the y direction of a conventional device, is easier to assemble and adjust, and is suitable for calibration of reference rulers with multiple modes. The length calibration device includes an air float slide block located on a granite long guide rail with a rectangular groove, a laser interferometer located at one end of the rectangular groove of the granite long guide rail, a beam splitter and an interference lens group, a reflector located on the air float slide block, and a zoom camera. On the basis of the length of a to-be-calibrated reference ruler, a reference ruler support is adjusted in position before measurement and is fixed to support the to-be-calibrated reference ruler, and the reference ruler is calibrated by moving the air float slide block to a corresponding mark point. The length calibration device for a photogrammetric reference ruler is applicable to high-precision calibration of the lengths of various reference rulers using circular mark points, thereby effectively ensuring the industrial photogrammetric accuracy.

Owner:FOSHAN TIANMU IND MEASUREMENT TECH CO LTD

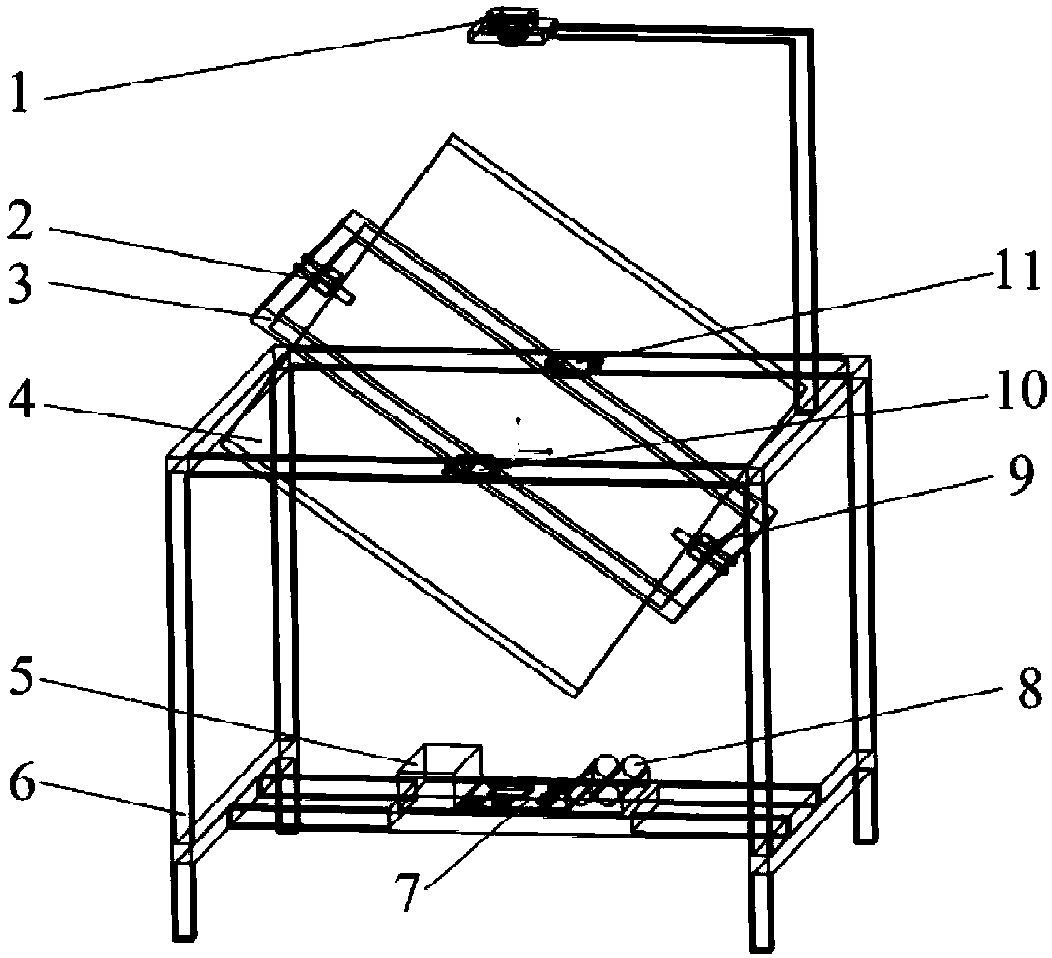

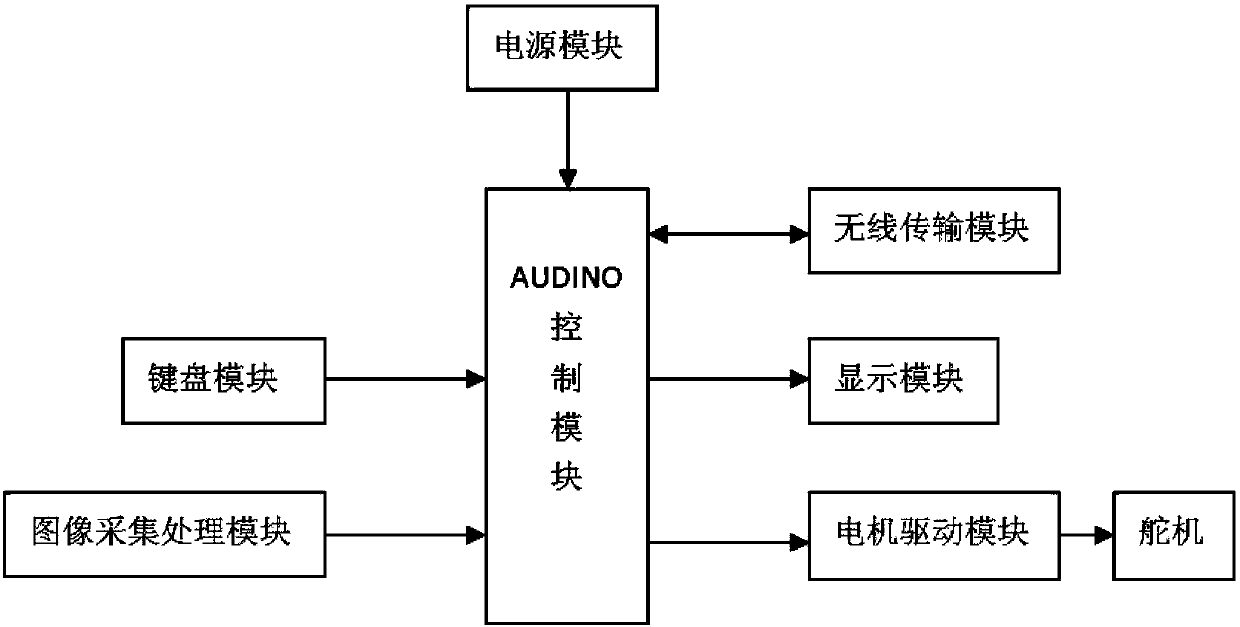

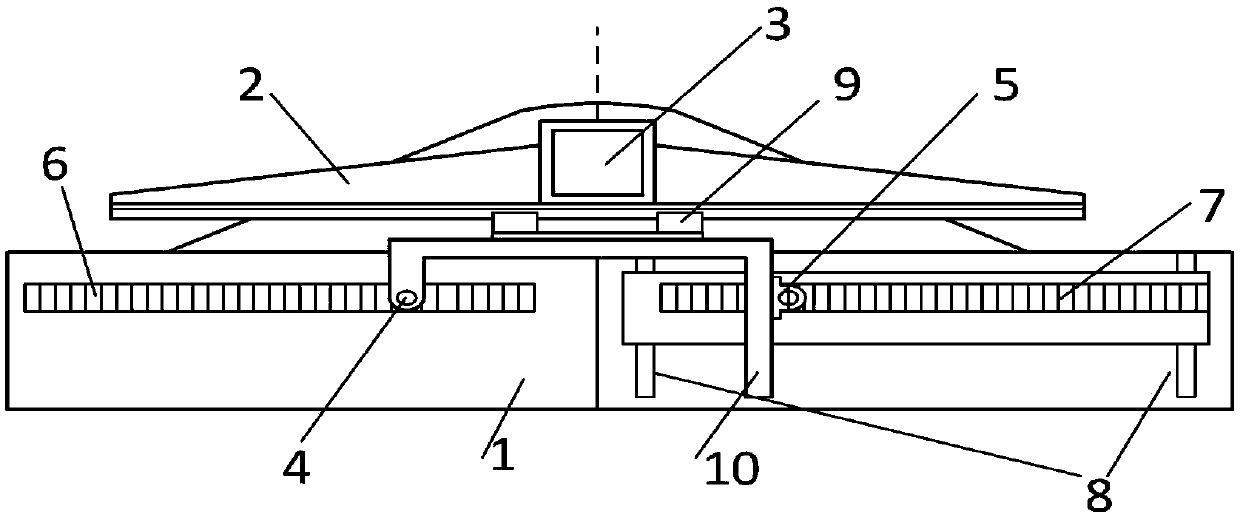

Image processing based coplanar ball-plate experiment system and operating method thereof

PendingCN107632559AAchieve zero errorAvoid disadvantagesProgramme controlComputer controlImaging processingComputer science

The invention relates to an image processing based coplanar ball-plate experiment system and an operating method thereof. The image processing based coplanar ball-plate experiment system adopts a coplanar structure form, and is characterized in that a steering engine used for controlling two-dimensional movements of a flat plate is arranged on a plane, thereby reducing the Abbe error, reducing theerror source, achieving zero error of a platform geometric structure, and effectively overcoming defects of a stack structure.

Owner:SHANDONG UNIV OF SCI & TECH

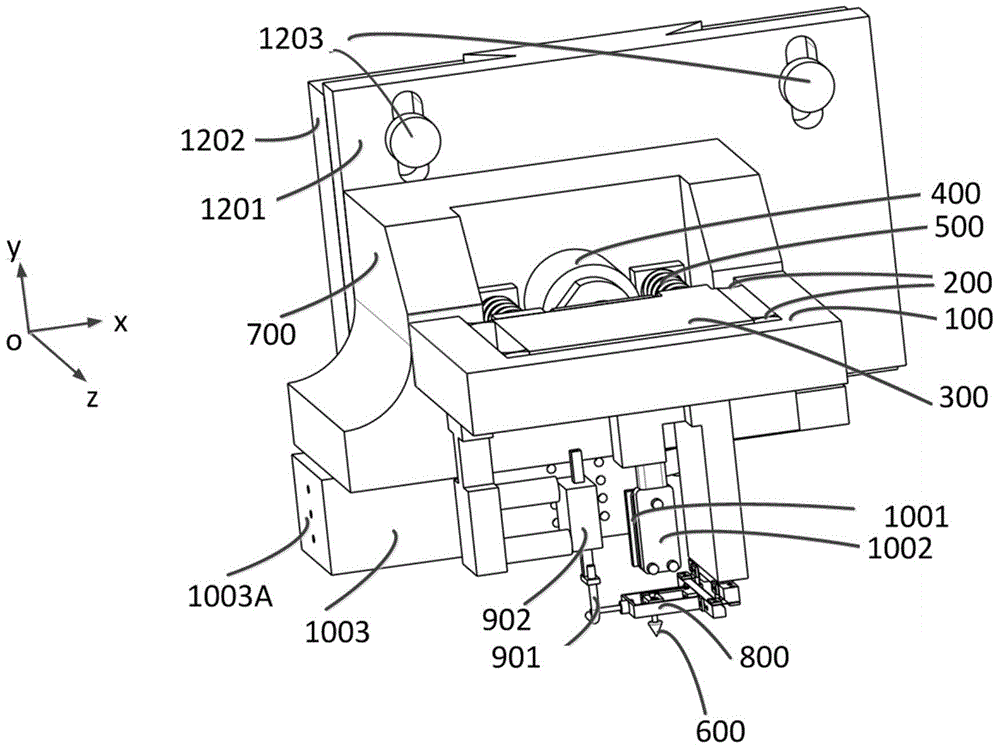

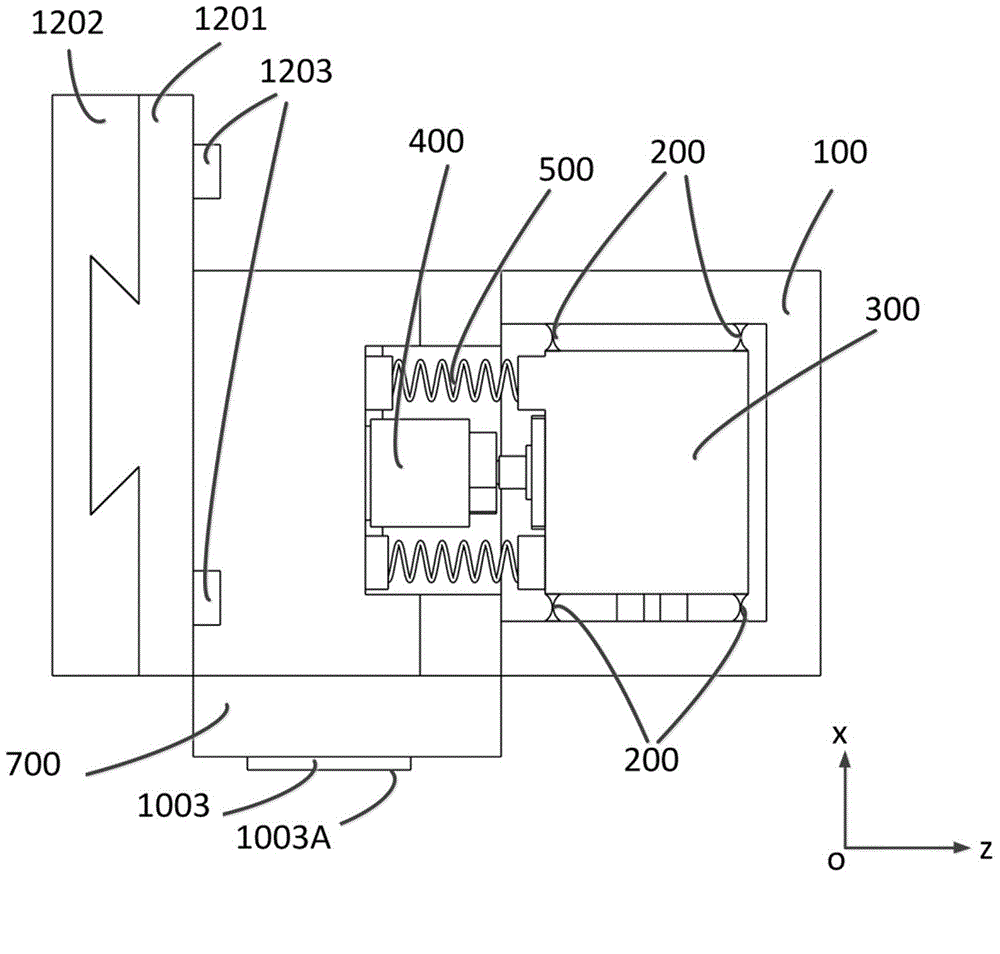

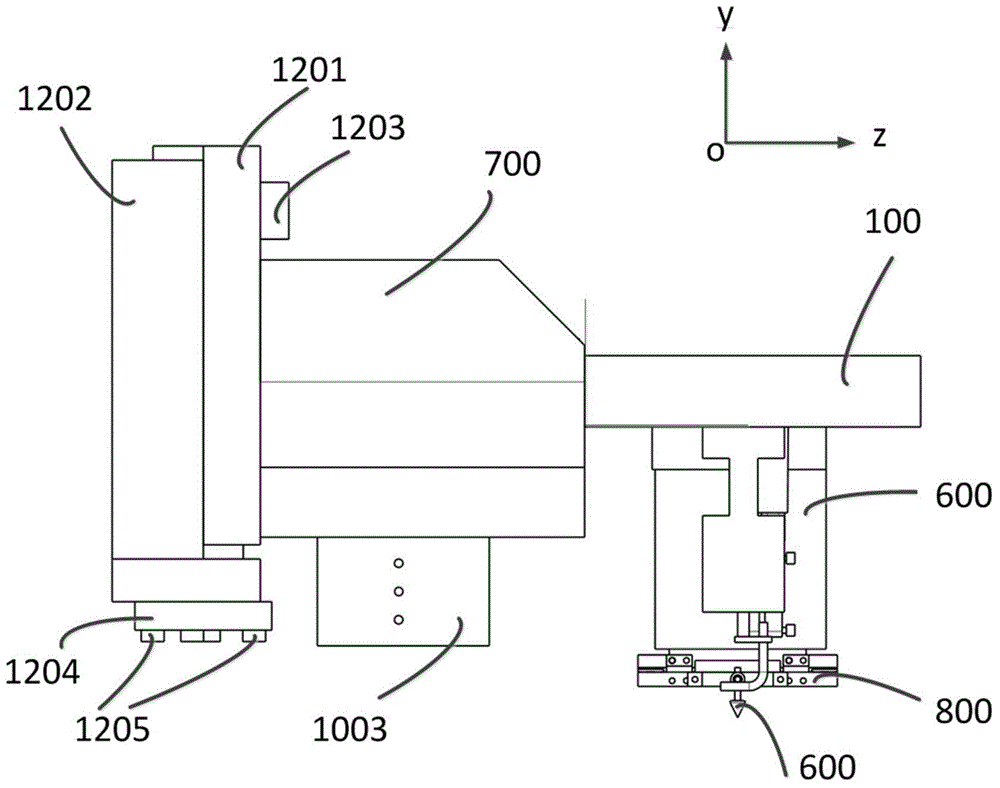

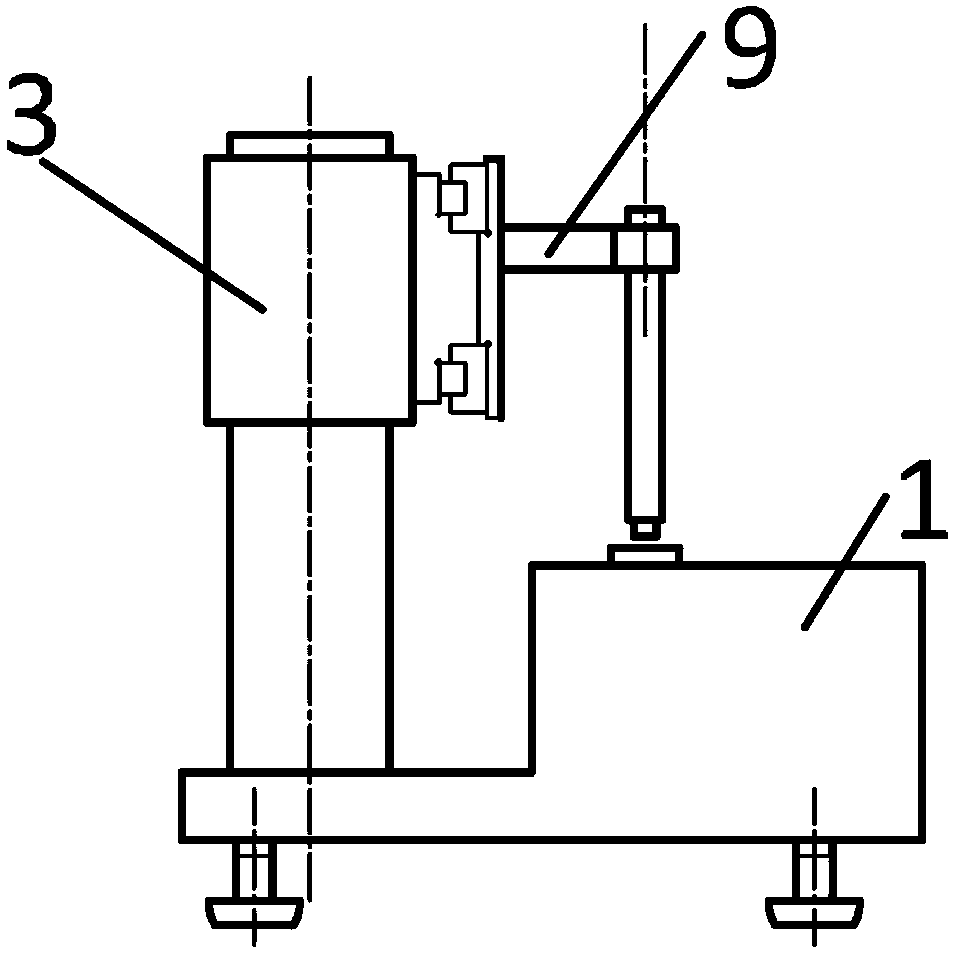

Grating ruling tool initiative adjusting device having abbe error correcting function

ActiveCN104536073AReduce displacement deviationReduce positioning accuracyDiffraction gratingsObservational errorGrating

The invention relates to the technical field of grating ruling and particularly discloses a grating ruling tool initiative adjusting device having an abbe error correcting function. The grating ruling tool initiative adjusting device comprises a tool rest lifting mechanism, a tool rest supporting frame, a micro positioning worktable, a worktable installation seat, flexible hinges, piezoelectric ceramics, tension springs, a small tool rest and a diamond ruling tool. The piezoelectric ceramics and the micro positioning worktable are in contact through friction, and the four symmetrical flexible hinges enable the micro positioning worktable to have large rigidity in direction except the Z-axis direction. The micro positioning worktable conducts micro positioning movement in the Z-axis direction under the stretching movement of the piezoelectric ceramics, and thus the displacement deviation between the actual position and the ideal position of the diamond ruling tool can be minimized. According to the grating ruling tool initiative adjusting device, a double-axis interferometer is used for measuring the position of the diamond ruling tool in real time, the influence of abbe measurement errors caused by using a one-axis interferometer on the positioning precision of the diamond ruling tool is avoided, the positioning error of the diamond ruling tool can be easily reduced, the grating ruling quality can be improved, and the performance index can be increased.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Dynamic revising method of three-coordinate measuring machine

InactiveCN102175147AReasonable designLow application costUsing optical meansCoordinate-measuring machinePhysics

The invention relates to a dynamic revising method of a three-coordinate measuring machine, and the method comprises: displacement measuring devices are respectively arranged at the side of the two parallel Y-axial guide rails of the three-coordinate measuring machine; when the measurement is carried out by the three-coordinate measuring machine, the displacement measuring devices respectively obtain the data of the two displacements of an X-axial movement beam on the Y-axial guide rails and the displacement measuring device on the X-axial movement beam also synchronously obtains the data of the displacement of a measuring probe on the X-axial movement beam; and the calculation is carried out through the three-coordinate measuring machine according to the data of the three displacements to obtain the real-time displacement data of the measuring probe on a Y-axial guide plane. The dynamic revising method of the three-coordinate measuring machine provided by the invention has the advantages of reasonable design and low application cost, can be suitable for the improvement of the existing three-coordinate measuring machine and the manufacture of a new three-coordinate measuring machine, and can be used for effectively eliminating the influence of Abbe errors on the measuring result and also effectively improving the speed and efficiency of the measurement.

Owner:昆山双虎电子科技有限公司

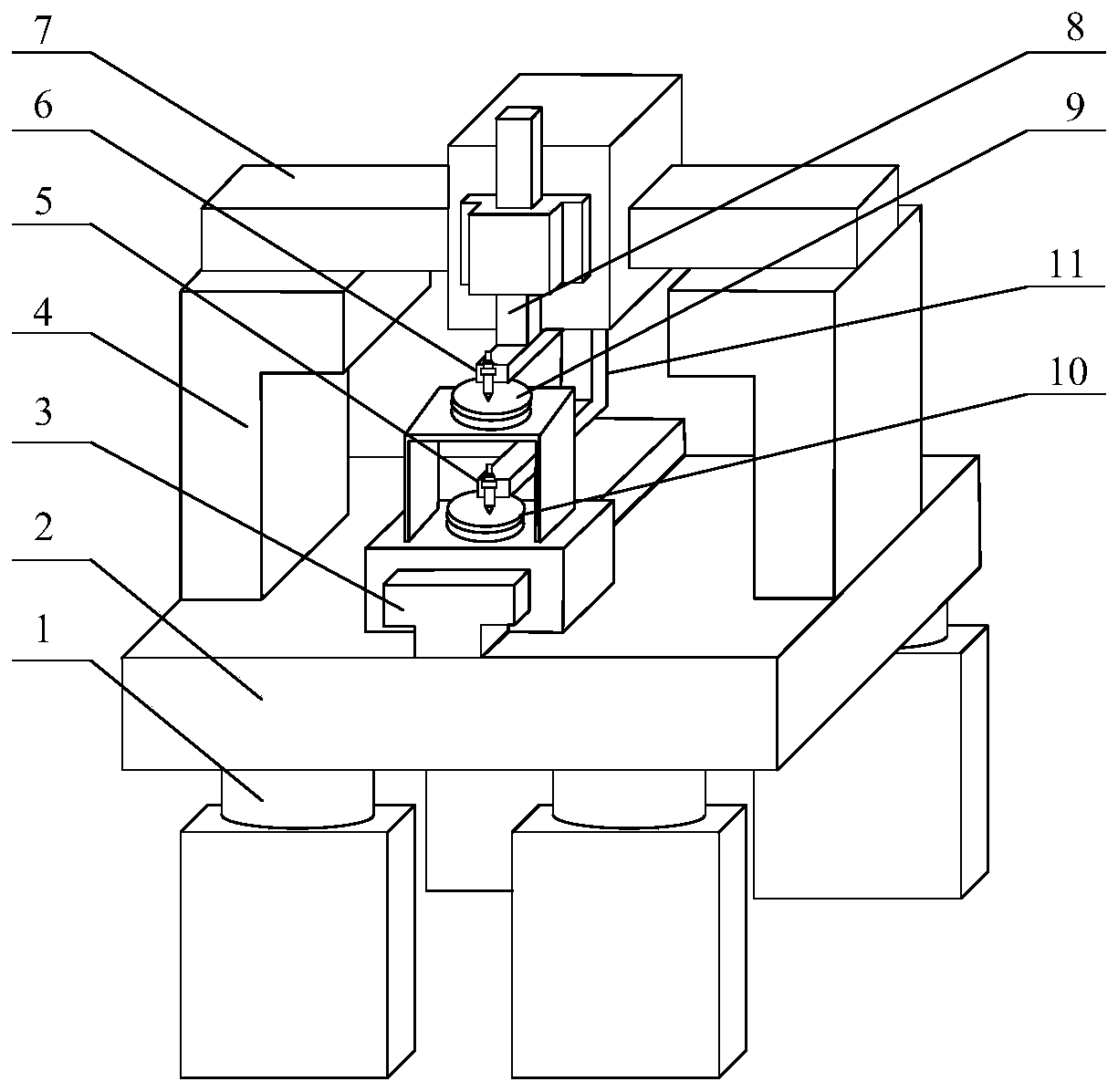

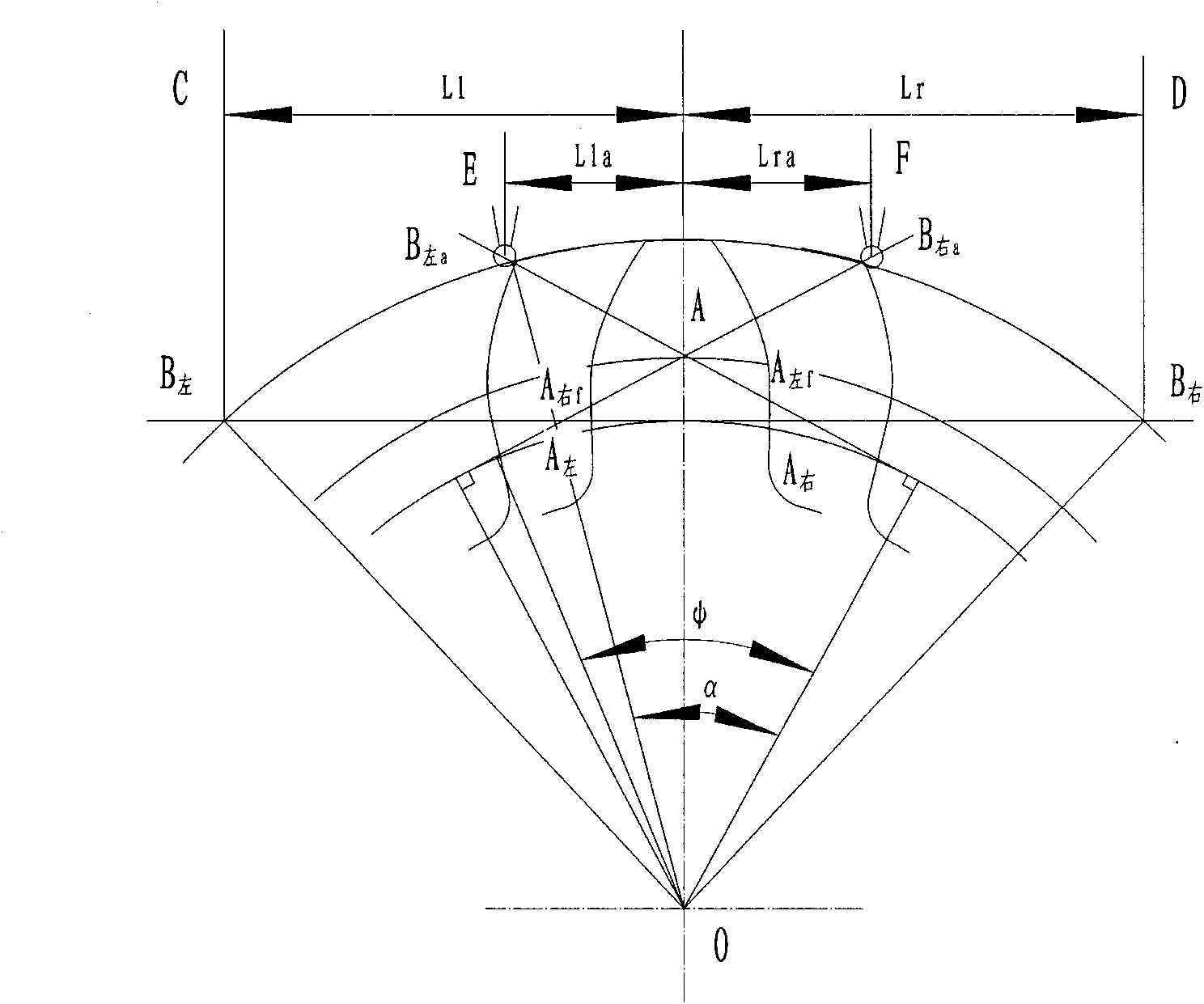

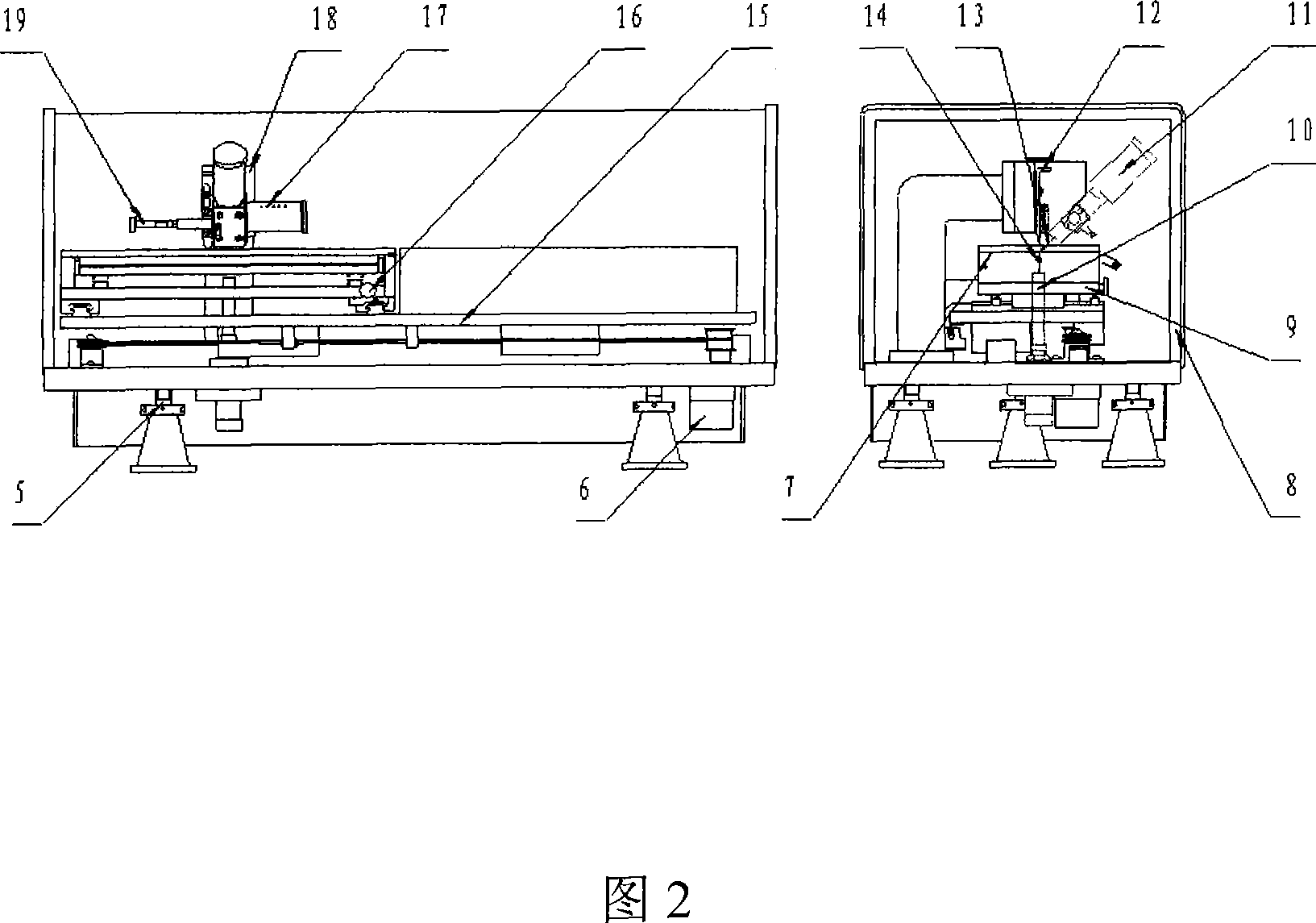

Meshing line large-specification gear measurement center

The invention overcomes the defect of overlarge tangential travel of a gear measurement center when the error of a gear tooth form of a large gear is measured by adopting base circle generating method, thereby providing a meshing line large-specification gear measurement center which has the advantages of optimized layout and high measurement precision and comprises a C shaft used for fixing a gear to be measured, wherein the C shaft is a rotating shaft. The meshing line large-specification gear measurement center also comprises a sensor probe used for acquiring data of the gear tooth form to be measured, wherein the sensor probe is controlled to move along the meshing line of the gear to be measured by a control system. According to the invention, the tangential guide rail size of a measurement apparatus is remarkably shortened, the abbe error of the gear measurement center is effectively reduced without a measurement head alignment error, the tangential travel when the error of the gear tooth form is measured is reduced, the tangential direction and the radial direction of the apparatus are in the vertical coordinate axis, thus the influence of the abbe error is furthest reduced, the optimized layout of the apparatus structure is effectively realized, the measurement precision is improved, and the advantages of simple structure and convenience for installation location and operation are realized.

Owner:HARBIN JINGDA MEASURING INSTR

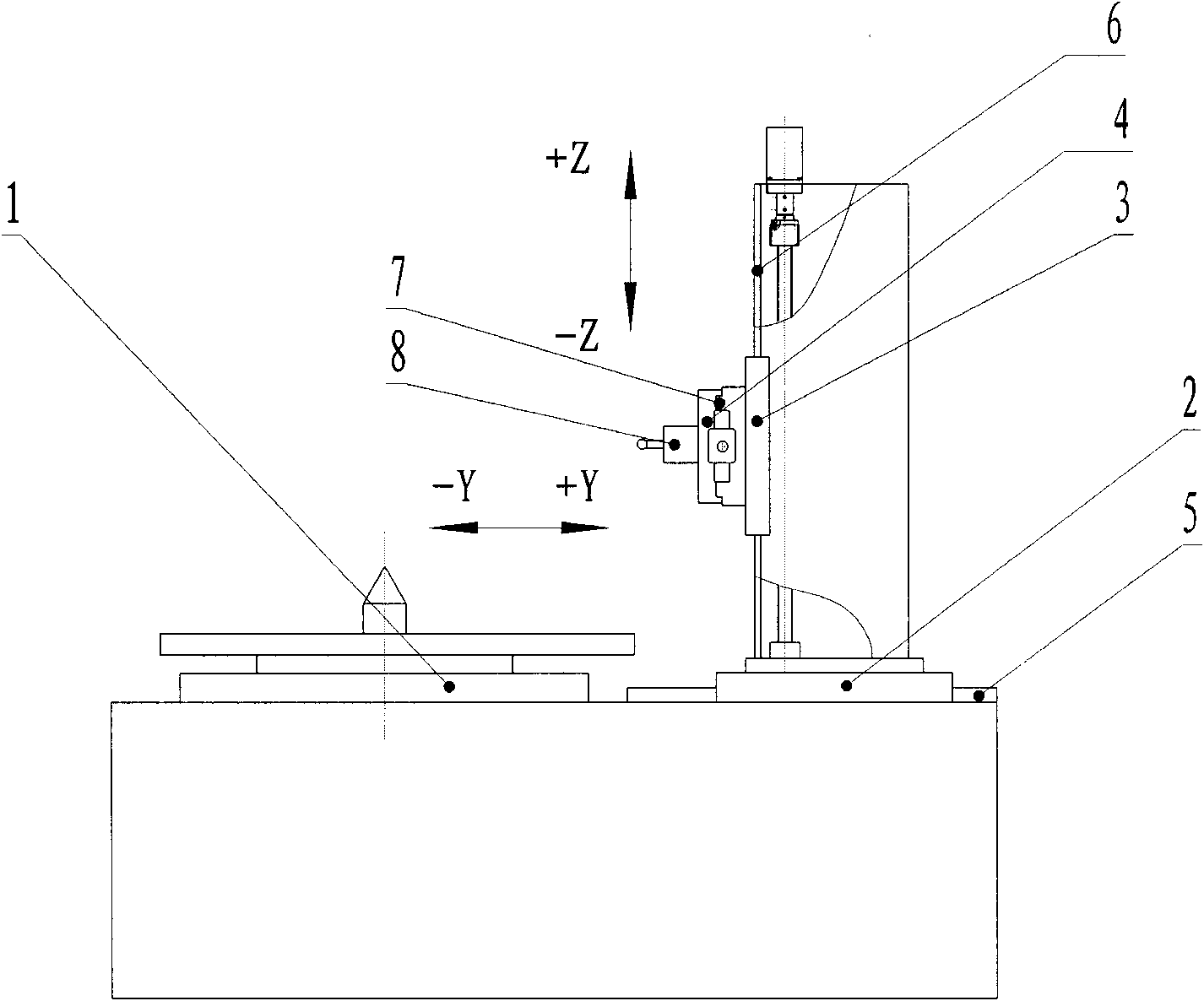

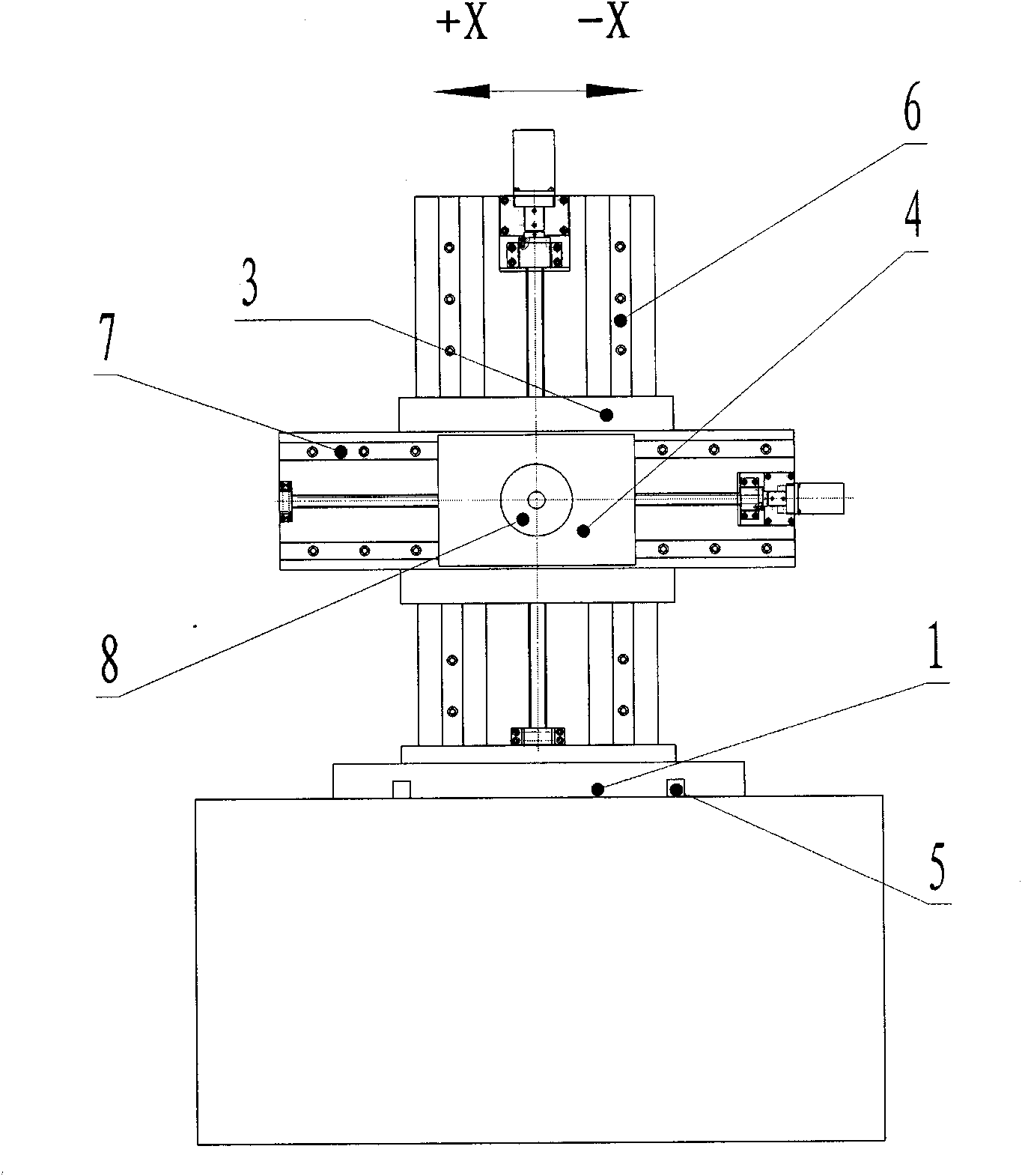

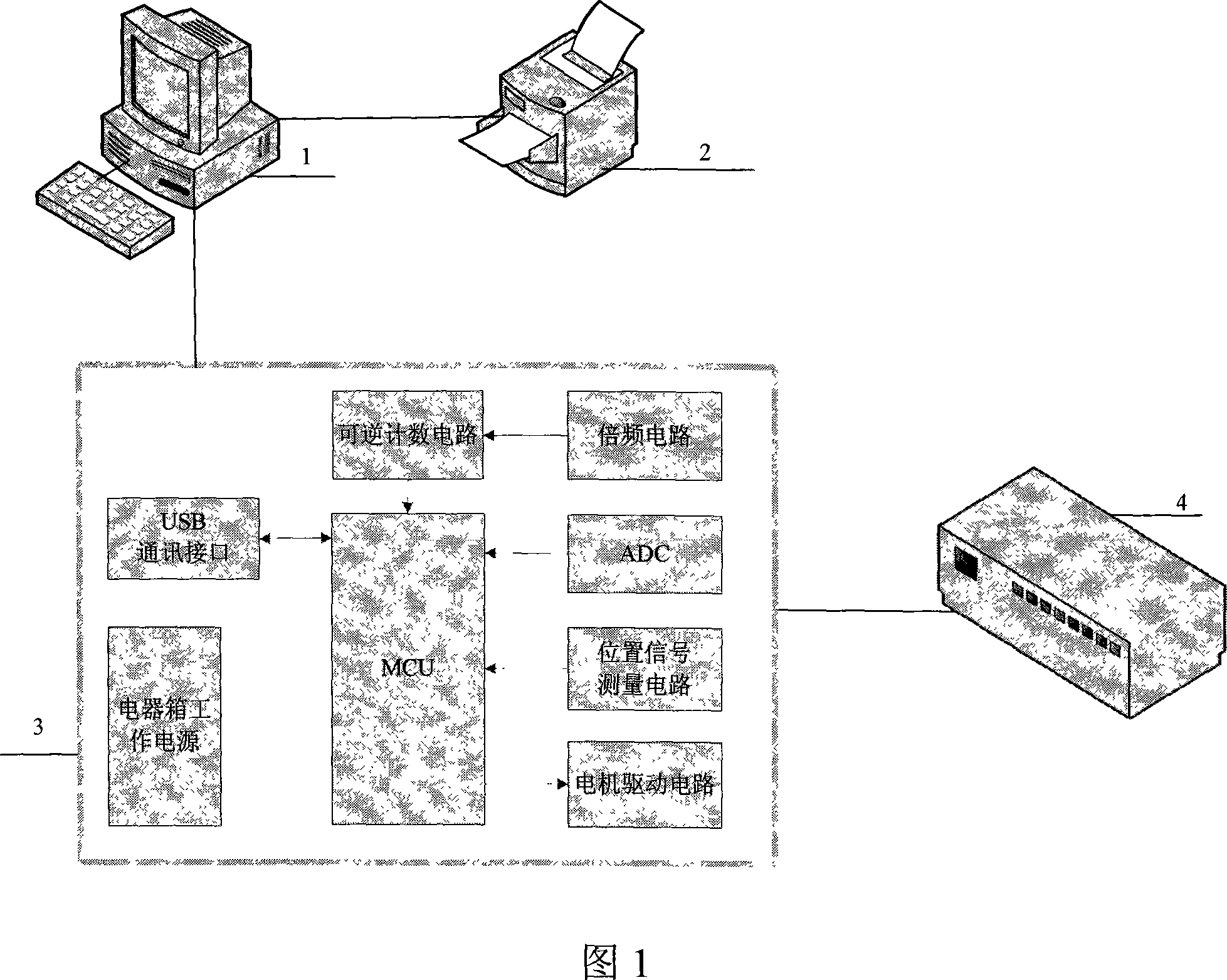

Table type bar code detector

InactiveCN101021431AOvercome structural deficienciesReduce mistakesMaterial analysis by optical meansUsing optical meansGratingElectric machinery

A stage bar-code detecting apparatus is composed of host computer and computer connected by electrical box. Host computer is connected with electric engine, transmission source, probe bracket, read head bracket and longitudinal guide separately by scan platform. Longitudinal operating platform connects longitudinal and lateral guide and grating ruler brace. Probe bracket connects N-average pointer, reflectance source and adjust handle. Grating ruler brace connects grating ruler. Read head connects bracket and electrical box which is connected with doubling circuit and single chip by reversible counting circuit. Single chip connects communicating interface, analog-to-digital conversion, channel optical coupling, electrical engine and driving circuit. The device can detect printed bar-code and bar-code production acetate, has Abbe error eraser and high testing precision, can realize average measurement for one bar-code, parallel moving, data collecting, simple operation, can detect merchandise bar-code, cross two-five bar-code, logistics bar-code and 128 bar-code etc.

Owner:BEIJING DONGFANG JIE CODE SCI & TECH DEV CENT +1

Ultra-precise three-coordinate testing platform

PendingCN108592839AStructural solutionAbbe's error is smallMeasurement devicesElectric machineryArchitectural engineering

The invention provides an ultra-precise three-coordinate testing platform, comprising a base, a support connector and a first Z-direction upright post and a second Z-direction upright post. A square flat-plate vacuum preloading air-flotation support is mounted on the support connector; the support connector is driven by an X-direction linear motor; the first Z-direction upright post is fixed on the top of the support connector, the second Z-direction upright post is mounted at one side, and a circular-plate vacuum preloading air-flotation support is mounted at the bottom of the second Z-direction upright post; a Z-direction linear motor is mounted on the Z-direction upright post and is connected with two first vacuum preloading air-flotation assemblies; a gantry cross beam is fixed betweentwo first vacuum preloading air-flotation assemblies, and a Y-direction linear motor is mounted on the gantry cross beam and connected with a second vacuum preloading air-flotation assembly. By the vacuum preloading air flotation technology, the testing platform can move rapidly without any friction on the X,Y and Z directions respectively, the moving on the Z direction is driven directly by thelinear motor and the two-way vacuum preloading air-flotation assemblies, and thus Abbe error on the Z-direction is reduced.

Owner:深圳市金园智能科技有限公司

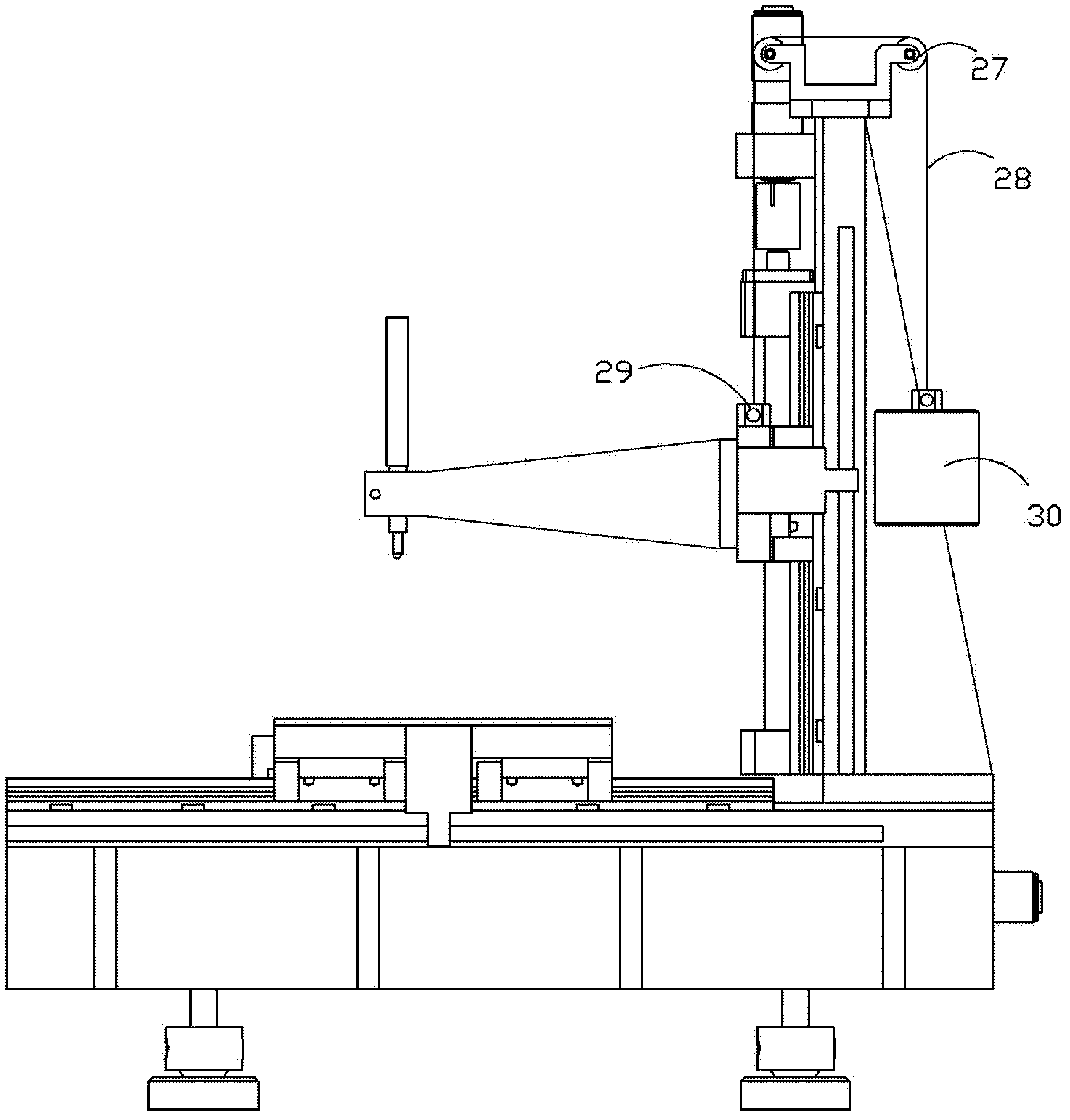

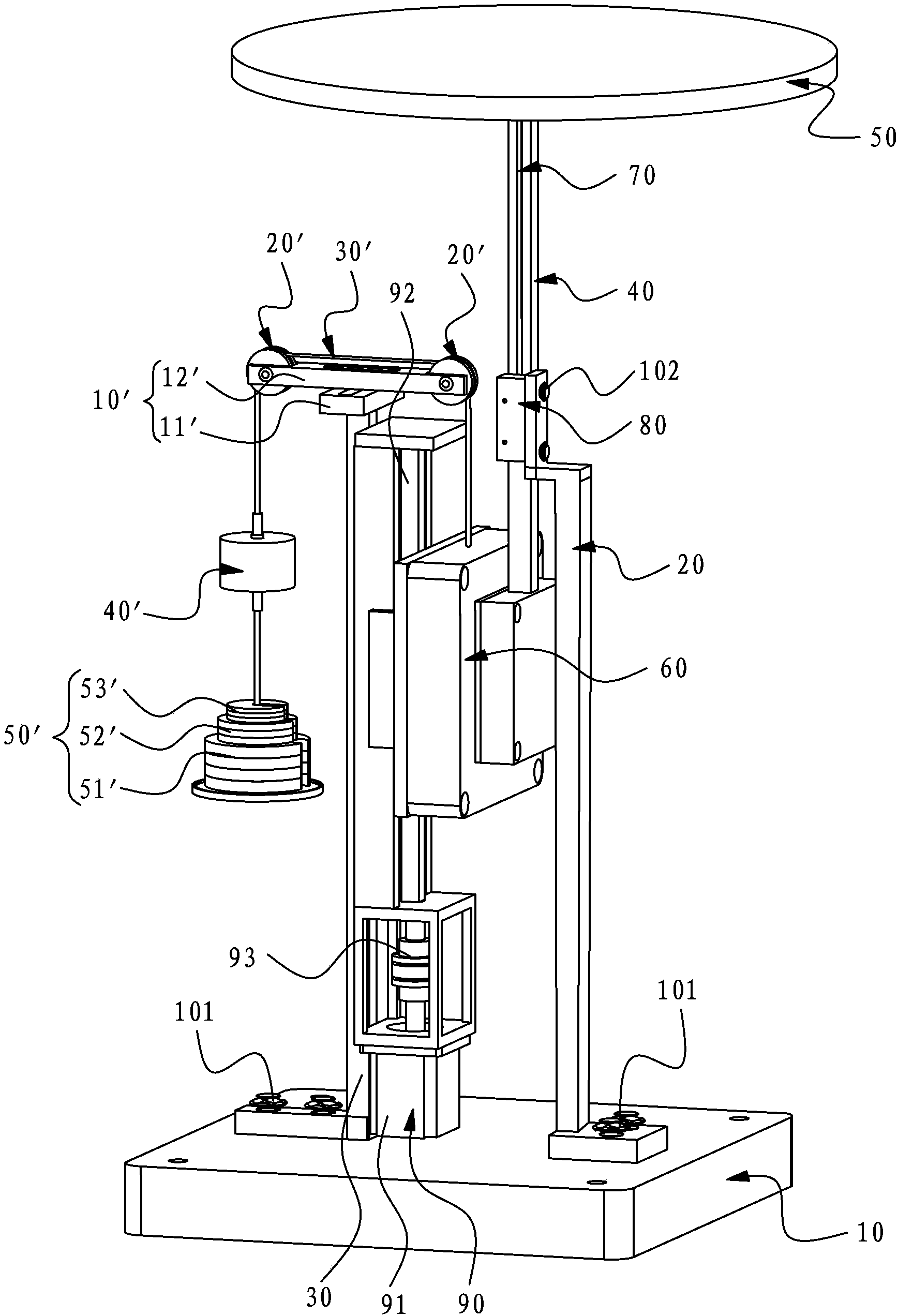

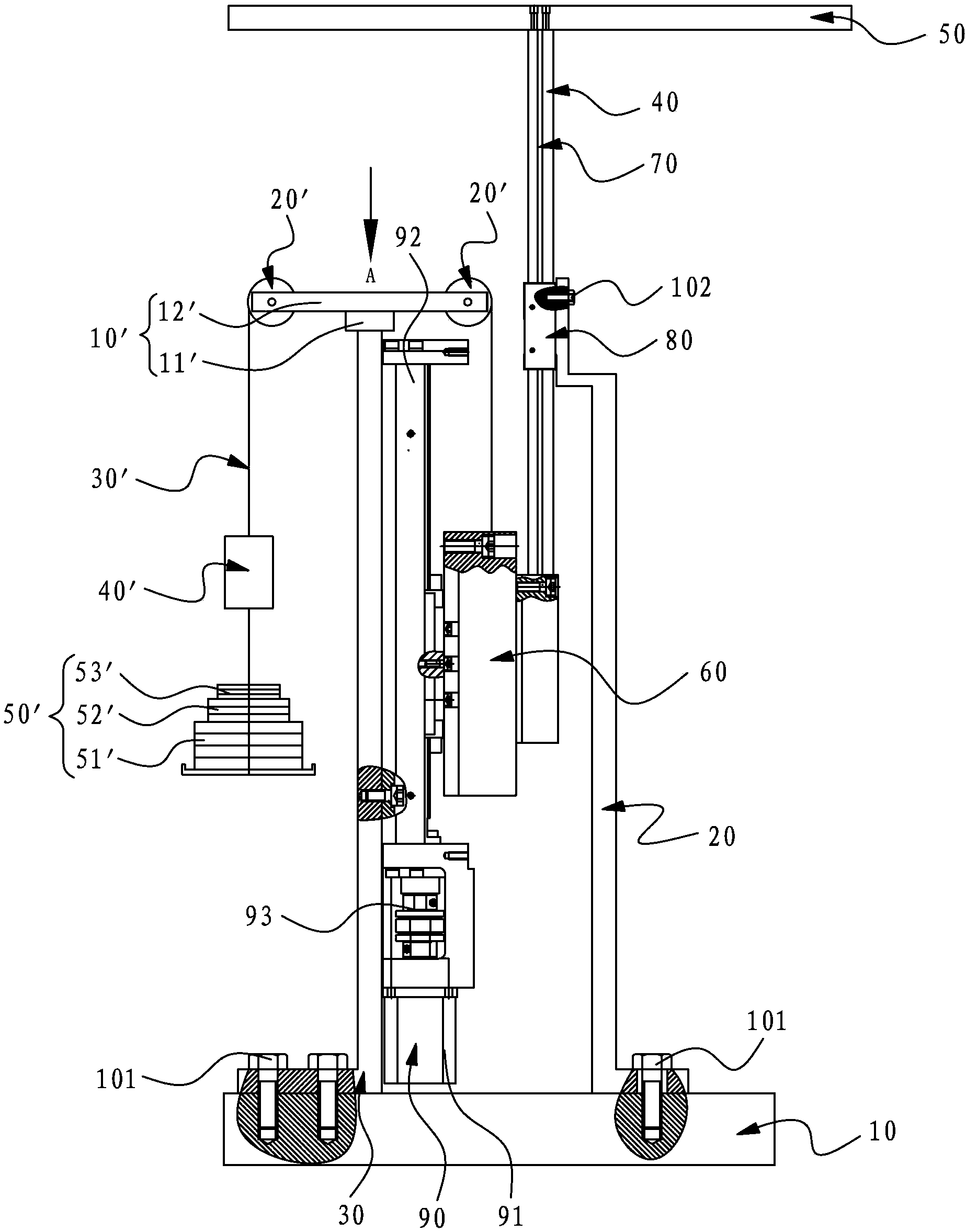

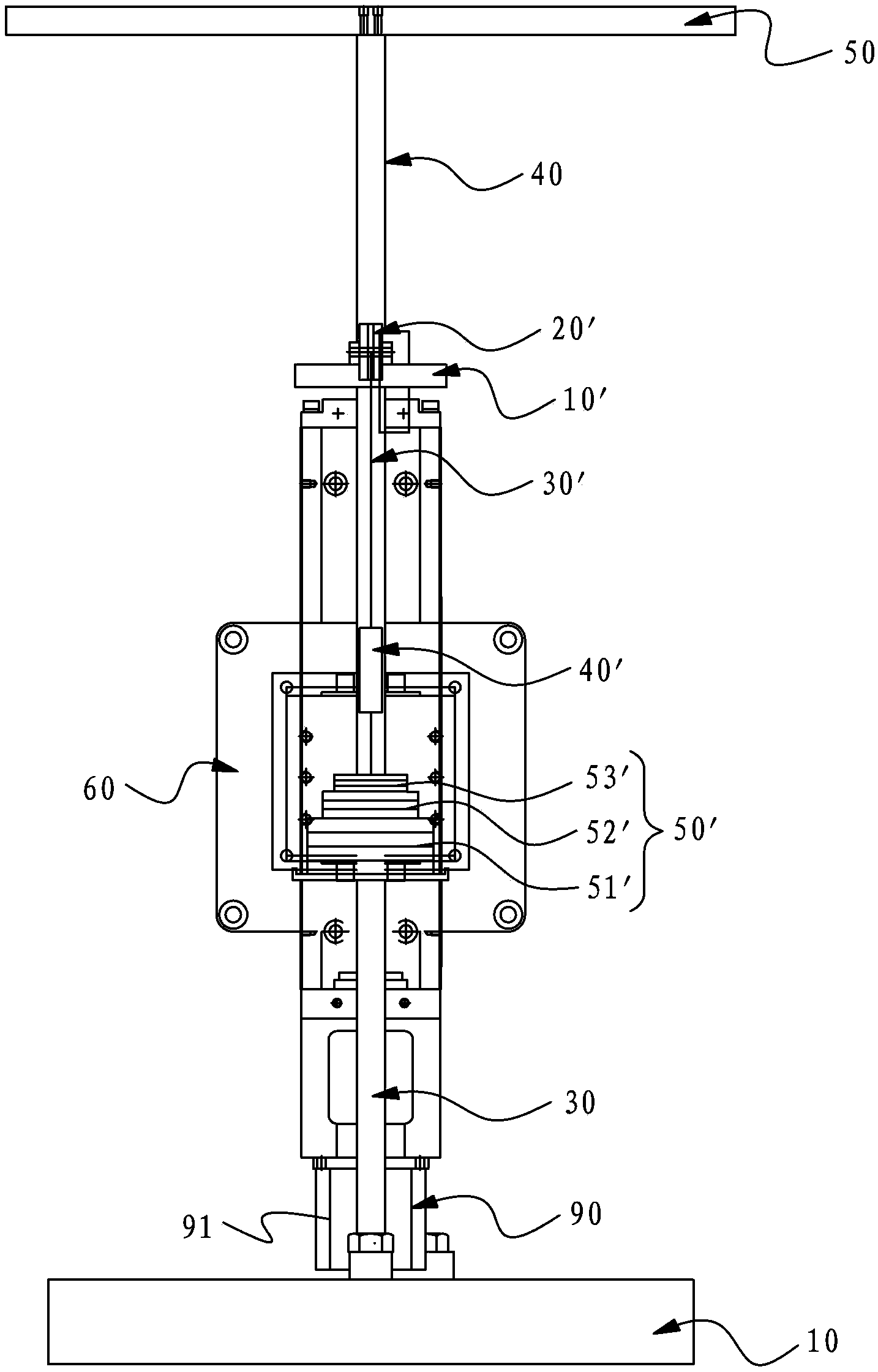

Large-stroke high-precision Z-axis worktable with novel structure

ActiveCN103506855AAbbe's error is smallSimple structureMeasurement/indication equipmentsCounterweightsMicro nanoGrating

The invention discloses a large-stroke high-precision Z-axis worktable with a novel structure. The worktable comprises a base, a first support, a second support, a movable supporting rod, a worktable body and a precise movable positioning table. The first support and the second support are arranged on the base, the movable supporting rod is arranged on the first support in an upward and downward movable mode, the movable supporting rod is fixedly provided with a grating ruler extending vertically, the first support is provided with a grating reading head, the precise movable positioning table is arranged on the second support in an upward and downward movable mode, the lower end of the movable supporting rod is fixedly connected with the precise movable positioning table, and a drive device is arranged on the precise movable positioning table. Due to the fact that the center of the worktable body, the center of the grating ruler, the center of the grating reading head and the center of the precise movable positioning table are located on the same line, zero abbe errors of a system can be achieved theoretically, abbe errors of the system are reduced to the largest extent, and micro-nano measuring and micro-nano processing requirements can be met.

Owner:HUAQIAO UNIVERSITY

High-precision probe device used for linearity error measurement

ActiveCN108519046ASmall static and dynamic friction coefficientGood anti-climbing effectUsing electrical meansLinearity errorMeasurement precision

The invention belongs to the technical field of precision machining and testing, and discloses a high-precision probe device used for linearity error measurement. The device comprises a guide seat, amicro-displacement lever transmission system, a slide block system, a slide block driving system, a side pressure plate, an upper pressure plate, a cover plate, and a side baffle. According to the device, a polytetrafluoroethylene guide rail soft tape is adopted as a friction auxiliary material, and the motion stationarity of a slide block and a probe can be substantially improved in a lubricationstate; the position of a measuring point is located above an extending surface of a guide rail work surface so that the direction has no measuring Abbe error, and the measuring precision can reach the submicron magnitude; by employing a high-sensitivity crossed reed micro-displacement transmission lever, the micro-displacement acquired by a ball probe is transmitted to a high-precision inductionprobe in an equivalent manner, and the device is applicable to the measurement of high-precision linearity errors without direct adoption of an axial probe. The device is advantageous in that the structure is simple, the deformation is symmetric, the influence of the driving precision on the motion precision of the probe is small, measuring Abbe errors can be avoided, the measuring precision of linearity errors is high, and the application range is wide.

Owner:DALIAN UNIV OF TECH

Coaxial pressure approaching type hardness detector

ActiveCN103308406AEliminate gapsSatisfy the requirement of not being able to rotateInvestigating material hardnessEngineeringHardness

The invention discloses a coaxial pressure approaching type hardness detector which comprises a motor, a small synchronizing wheel, a synchronous belt, a displacement sensor, a rear fixing barrel, a rear bearing, a pressing rod, an end-face bearing, a large synchronizing wheel, a spring, a base, a force sensor, a front bearing, a lead-screw nut, a guide cross rod, a position detector and a guide upright rod. By the adoption of the mode of directly checking a sample by using the force sensor, and the force measurement value error caused by frictional force and the like is avoided; when the nut is fixed and axially positioned through the spring, a gap of a lead screw is eliminated, and the control precision of a pressure head is improved; moreover, due to the coaxial design of the displacement sensor, the pressure head and the lead screw, an Abbe error is avoided.

Owner:CHENGDU RETOOL SCI & TECH CO LTD

Error compensation control method for stack worktable

ActiveCN104965958AIn line with the actual working statusImprove machining accuracySpecial data processing applicationsAngular degreesControl theory

The present invention discloses an error compensation control method for a stack worktable. The method is applied to the technical field of error compensation of machine tools and comprises: analyzing an Abbe error in the Y direction of a machining point caused by a swing angle and a pitch angle of a Y-axis guide rail of a stackable worktable, and building an Abbe error model; analyzing correlation and compensatory impacts of an angular error of the Y-axis guide rail of the stackable worktable on an angular error of an X-axis guide rail; building an Abbe error model in the X direction of the machining point under the combined effects of the angular error of the X-axis guide rail and the angular error of the Y-axis guide rail; and applying the model to perform compensation control on a two-dimensional Abbe error of unidirectional motion of the stackable worktable. The model is higher in accuracy, conforms better to the actual operating state of the worktable, and provides the basis for further error measurement and error compensation, thereby effectively improving machining accuracy of machine tools.

Owner:ANHUI UNIV OF SCI & TECH

Precision measurement teaching instrument based on Abbe principle

PendingCN107655410AFully reflect and verify the classic Abbe errorFully reflect and verify the errorUsing optical meansEducational modelsGratingComputer science

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com