Laser interfere length measuring system with real time compensation for Abbe error

A technology of real-time compensation and laser interference, applied in measuring devices, optical devices, image data processing, etc., can solve problems such as sharp increase in cost, increase in instrument volume, complex structure, etc., and achieve integration, simple structure and principle , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

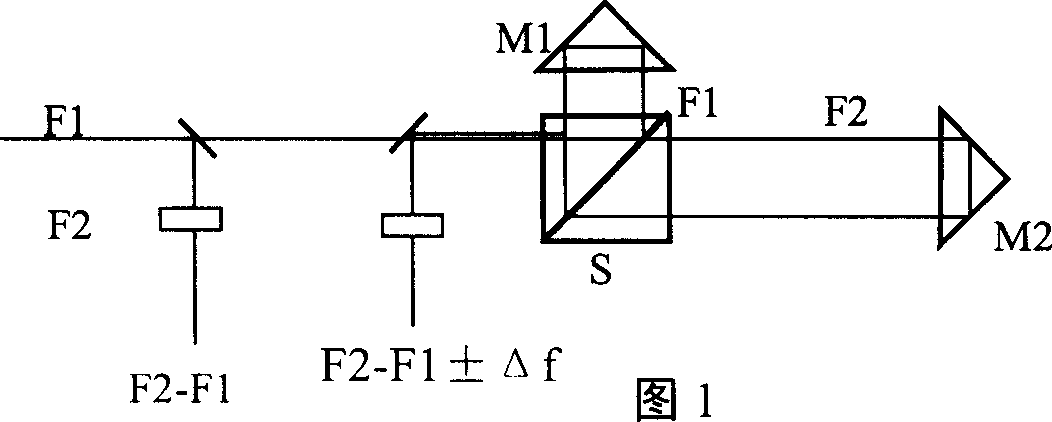

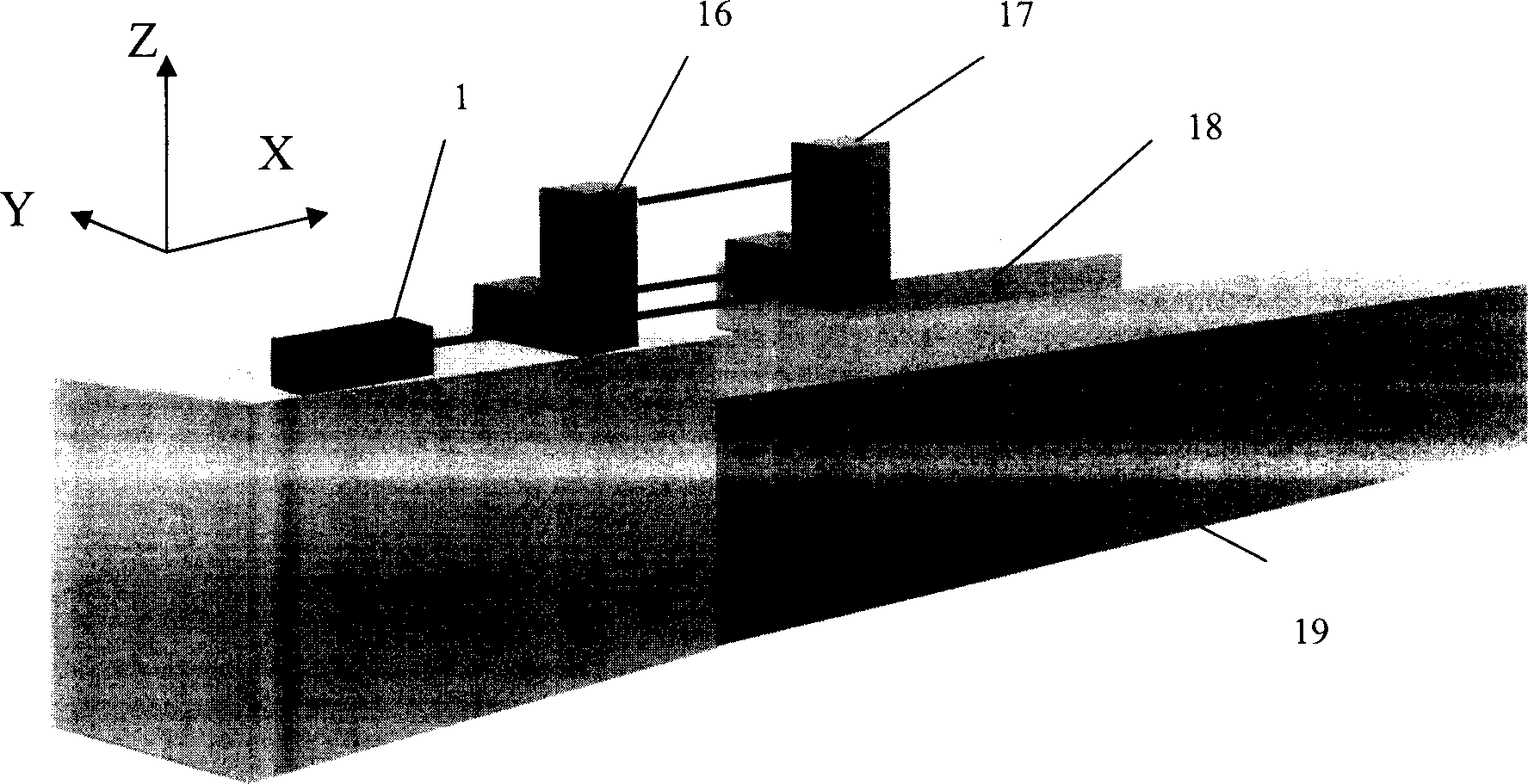

[0032] Figure 5It is a composition system diagram of three-way interference light to realize real-time compensation of Abbe error. The moving directions of the three paths of light are all along the X axis. The laser starts from the HP5527 laser head (1) in the laser (15), and the laser is divided into two beams by a 1 / 3 beam splitter (2), accounting for 1 / 3 of the total energy. A beam of light passes through a 90° beam deflection mirror (3) and an interference mirror (4) and is directed to a corner cube prism (5) on the workbench (the light of this path is in the Z direction). The other beam of light (accounting for 2 / 3 of the total energy) is divided into two beams after passing through the 1 / 2 beam splitter (6), and one of the beams of light passes through the interference mirror (10) and is directly directed to the corner cube prism on the workbench (11) (the light of this path is X direction), and the remaining beam of light passes through the 90-degree beam refracting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com