Coaxial pressure approaching type hardness detector

A detector and pressure technology, which is applied in the field of coaxial pressure approximation hardness detector, can solve the problems of high user requirements, achieve the effects of improving control accuracy, eliminating gaps, and avoiding errors in force measurement values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

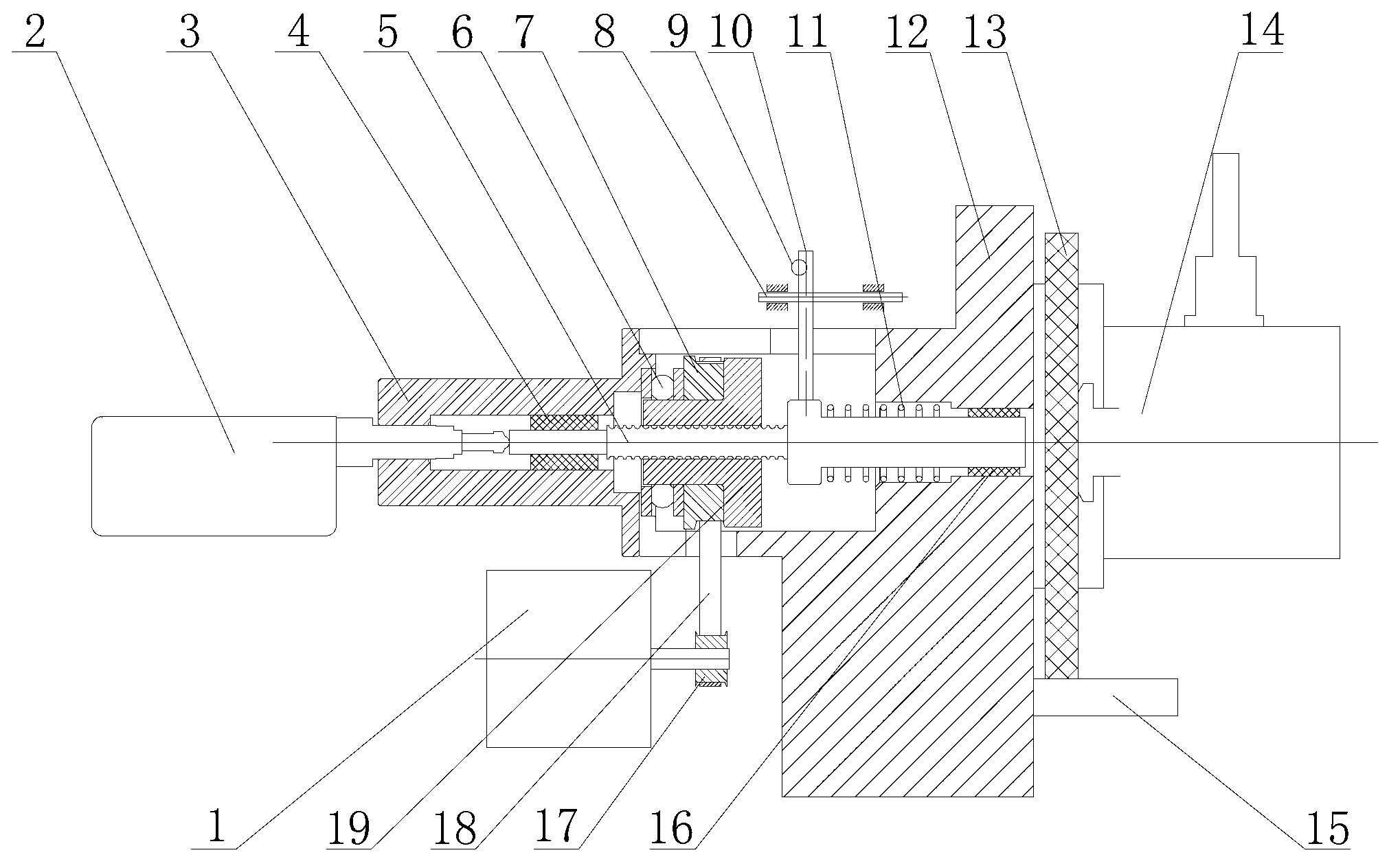

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] Such as figure 1 Shown: the present invention includes motor 1, small synchronous wheel 17, synchronous belt 18, displacement sensor 2, rear fixed cylinder 3, rear bearing 4, pressure rod 5, end face bearing 6, large synchronous wheel 7, spring 11, base 12 , force sensor 14, front bearing 16, screw nut 19, guide cross bar 8, position detector 9 and guide vertical bar 10, the sensing end of displacement sensor 2 passes through rear fixed tube 3 one end and the first end of pressure bar 5 End contact, the section of the pressure rod 5 in contact with the displacement sensor 2 is connected to the rear fixed cylinder 3 through the rear bearing 4, the outer surface of the middle section of the pressure rod 5 is a threaded surface and is matched with the screw nut 19, and the pressure rod 5 can only be straight Movement, its pressure end diameter is 12mm, as the indenter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com