Patents

Literature

56results about How to "Good seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

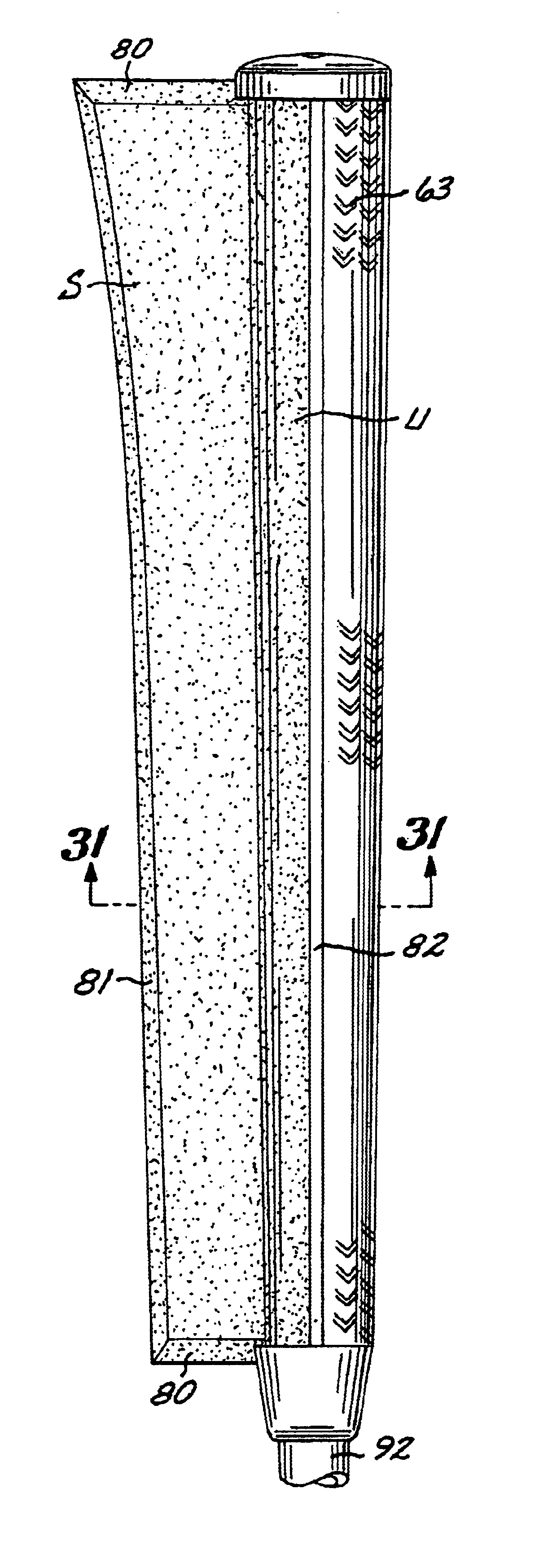

Single panel golf club grip

InactiveUS6857971B2Well mixedSame resistance to shockTextiles and paperGolf clubsEngineeringGolf Ball

A grip for the handle of a golf club having a single polyurethane-felt panel that is wrapped about an underlisting sleeve. The side edges of the panel are adhesively sealed together. The unitary grip reduces impact shock and also provides a feeling of tackiness in the manner of a spirally wrapped polyurethane-felt grip.

Owner:WINN INC

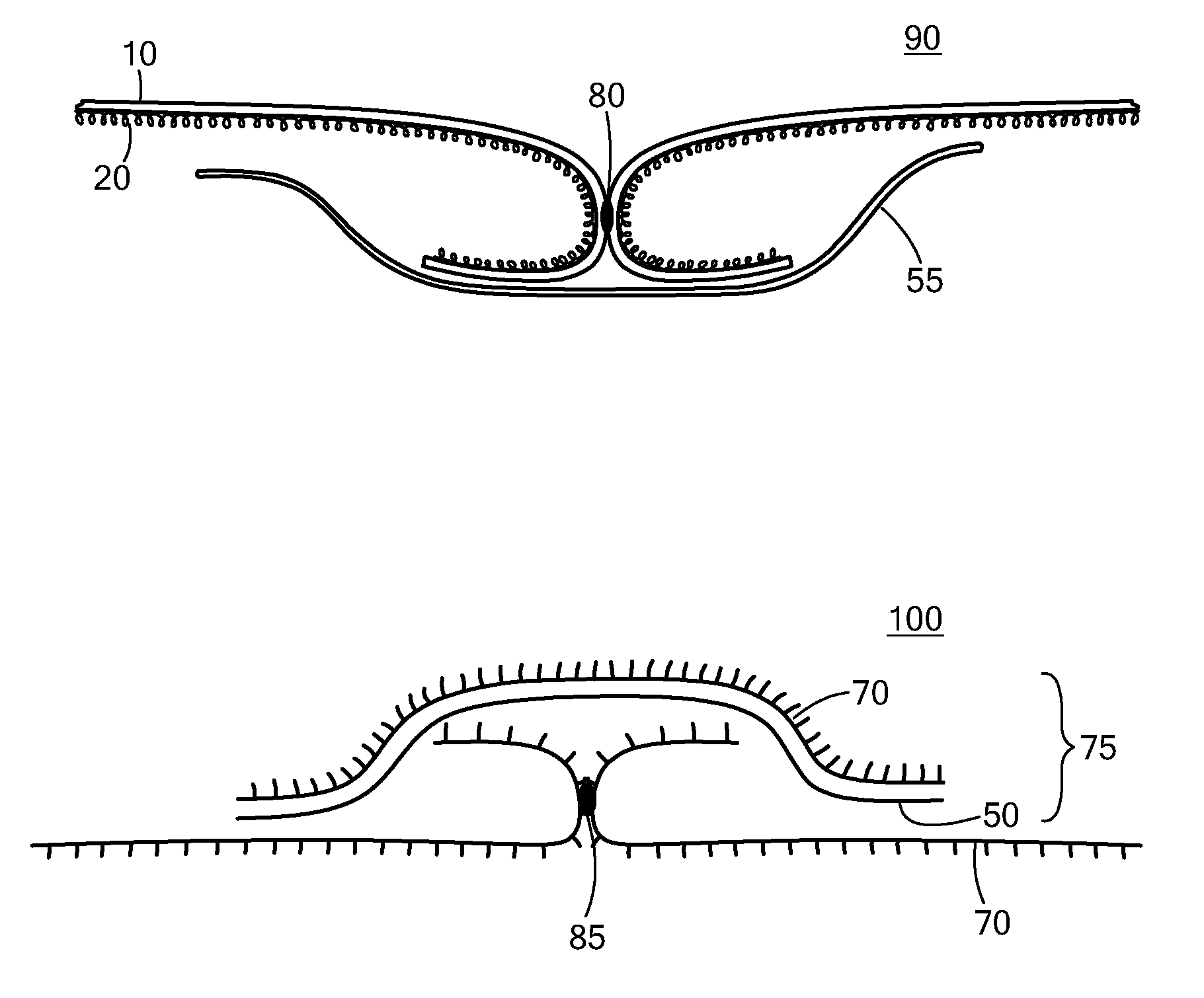

Waterproof garment with invisible barrier seam

InactiveUS20120282425A1Good seamsImprove breathabilityBaby linensThin material handlingMechanical engineeringEngineering

Owner:COHESIVE SYST

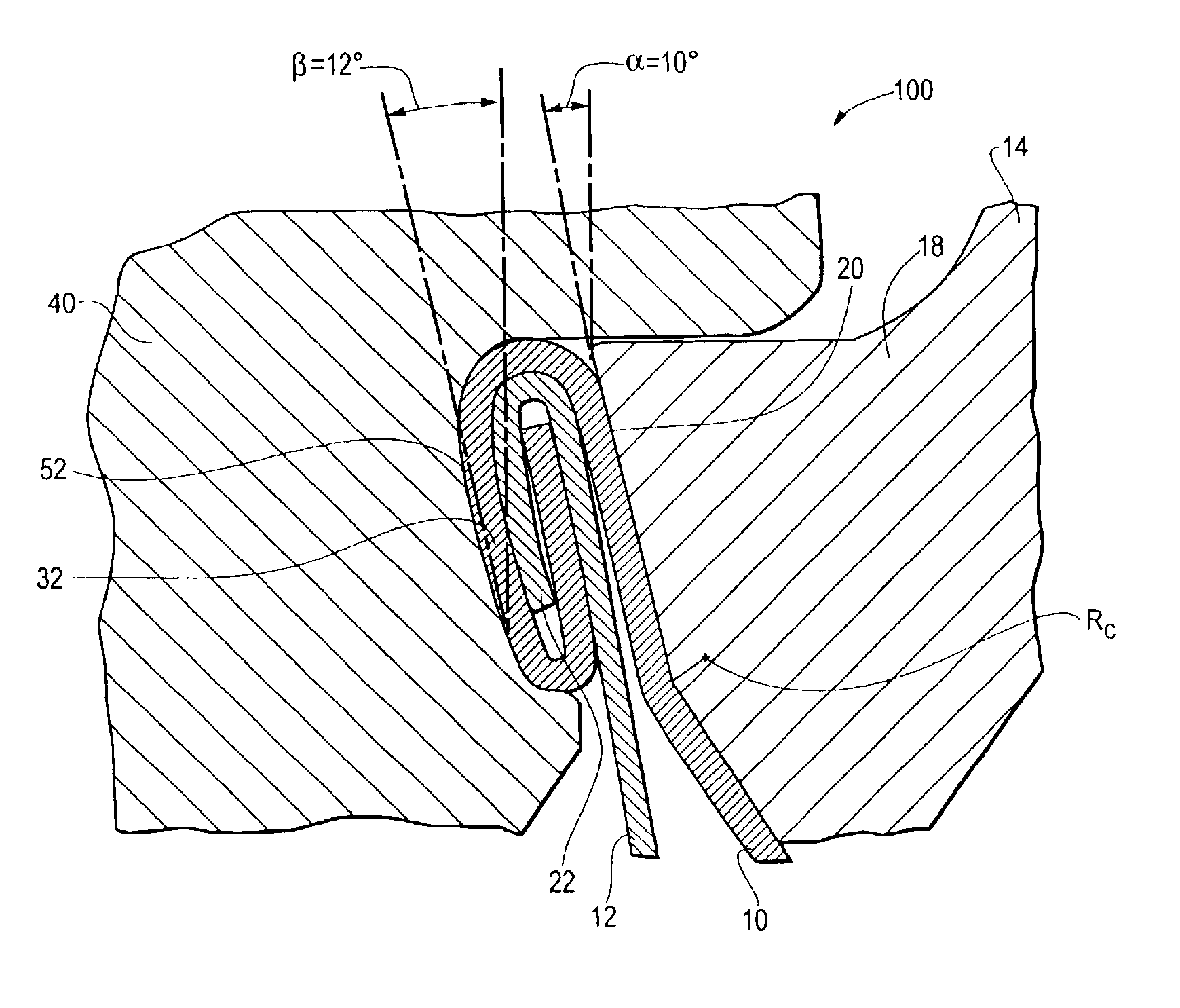

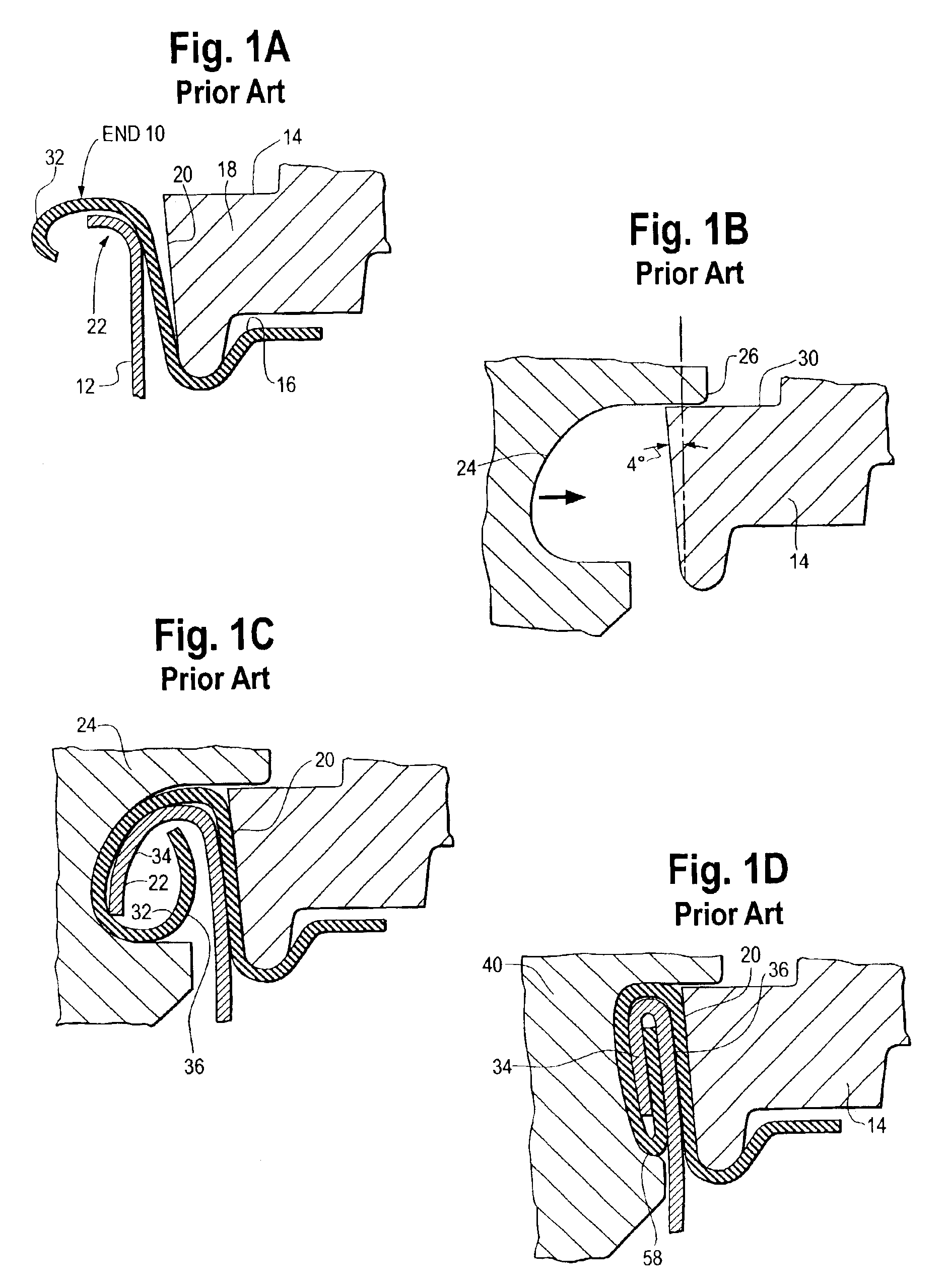

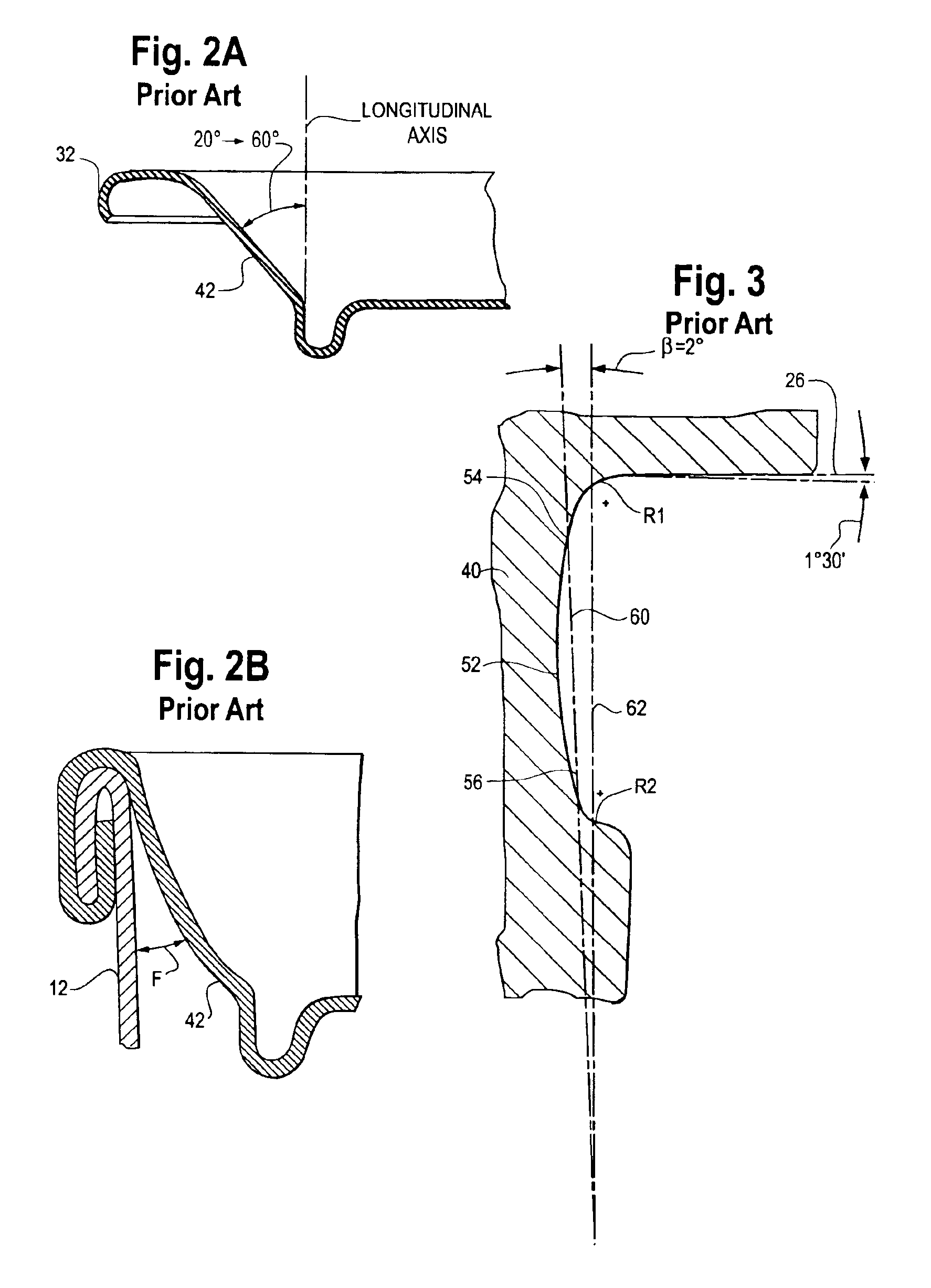

Seaming apparatus and method for cans

InactiveUS6915553B2Less bending of the chuck wallReduced strengthMetal working apparatusHollow articlesEngineeringFlange

Owner:REXAM BEVERAGE CAN

Waterproof garment with invisible barrier seam

InactiveUS20150224738A1Strengthen seamRestrict movementDomestic upholsteryHollow inflatable ballsPliabilityEngineering

Owner:COHESIVE SYST

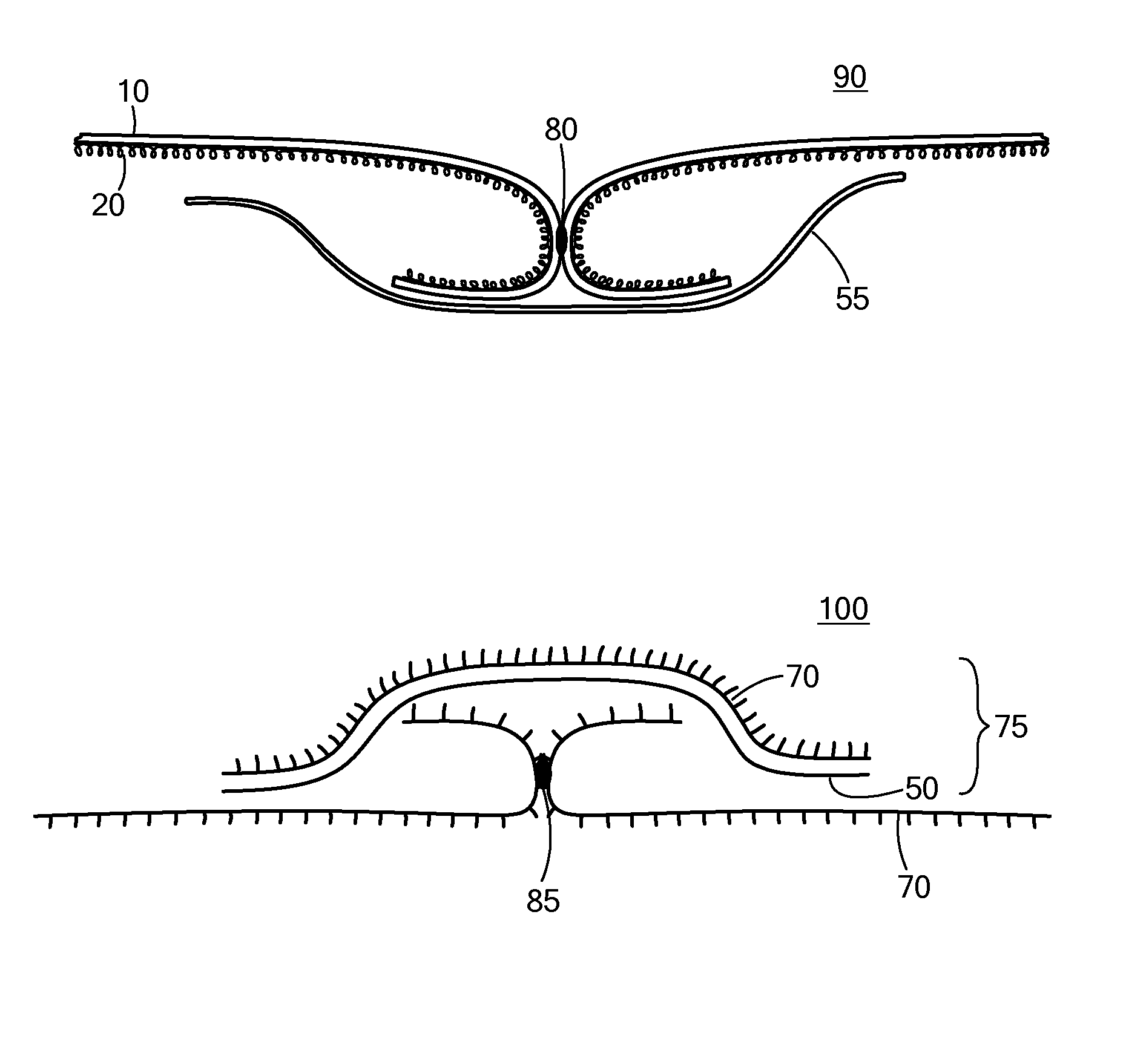

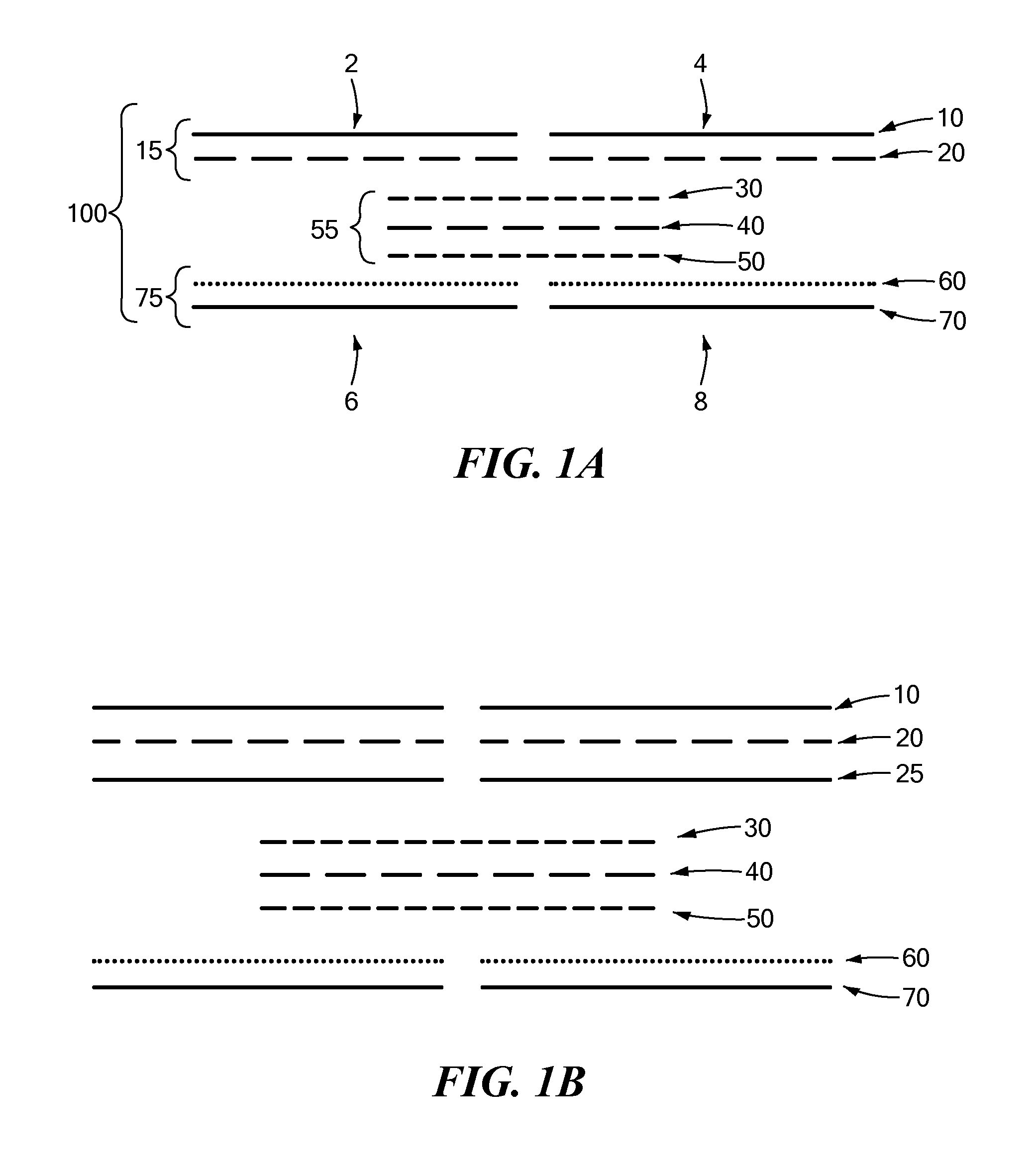

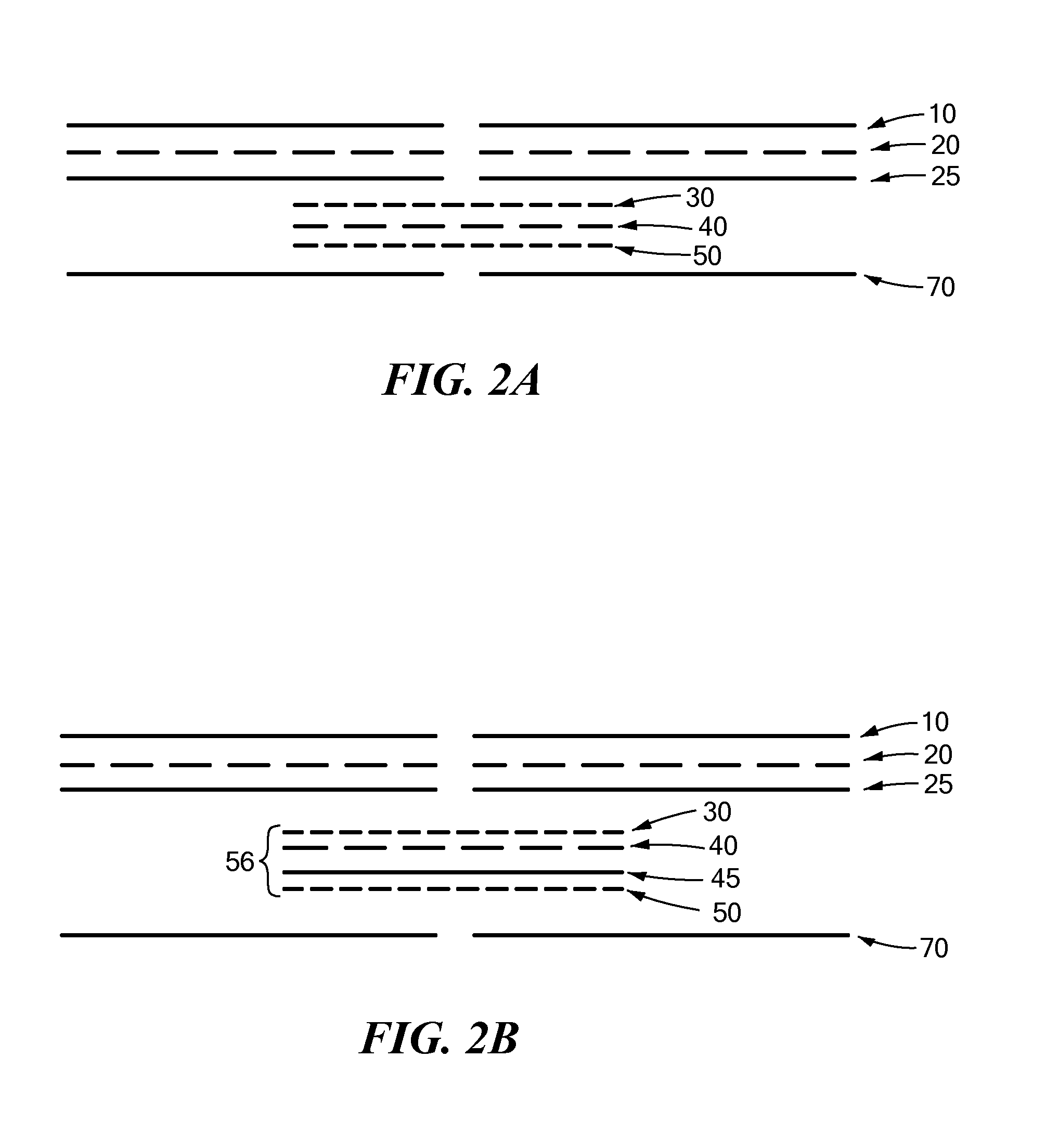

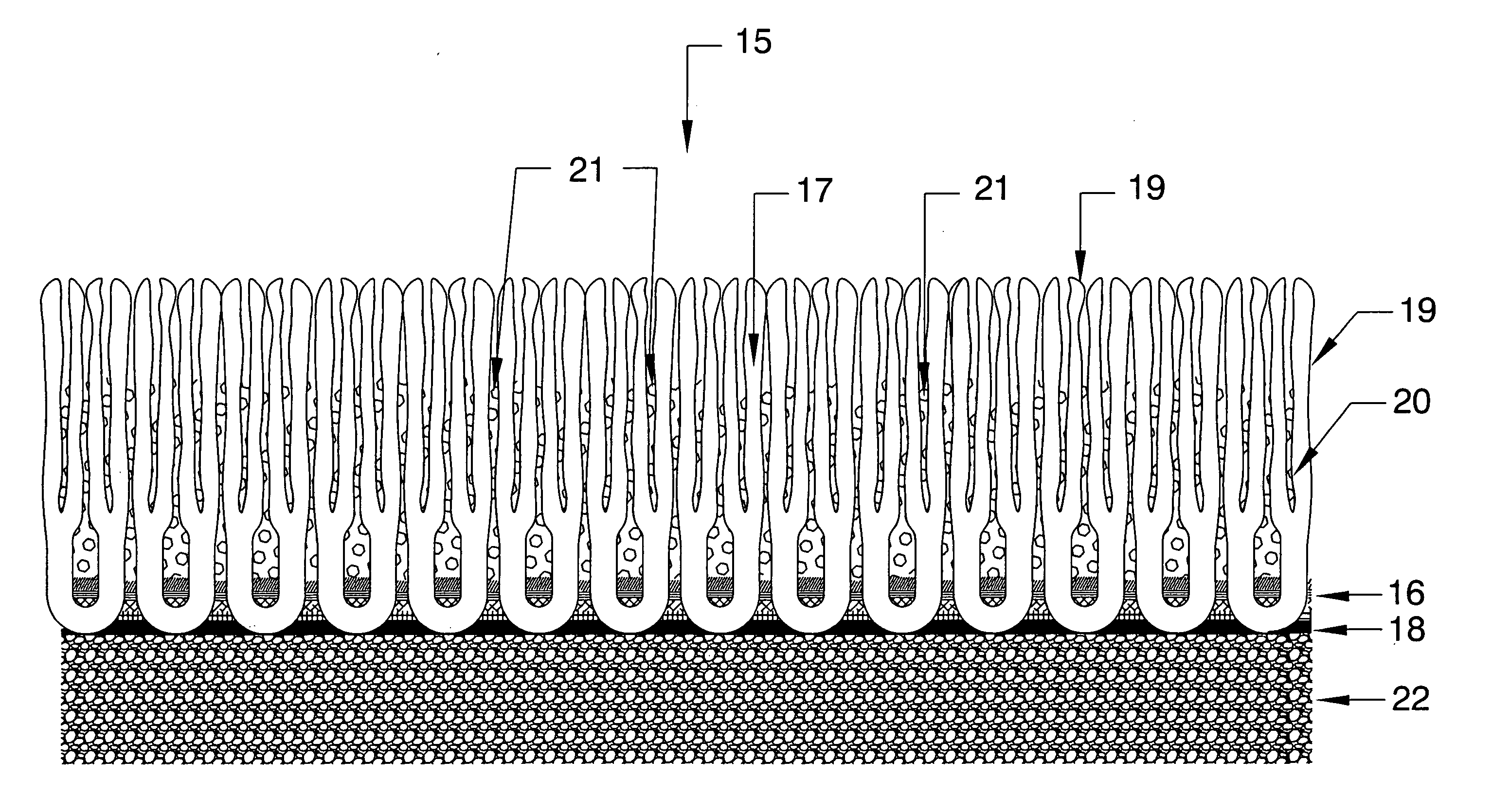

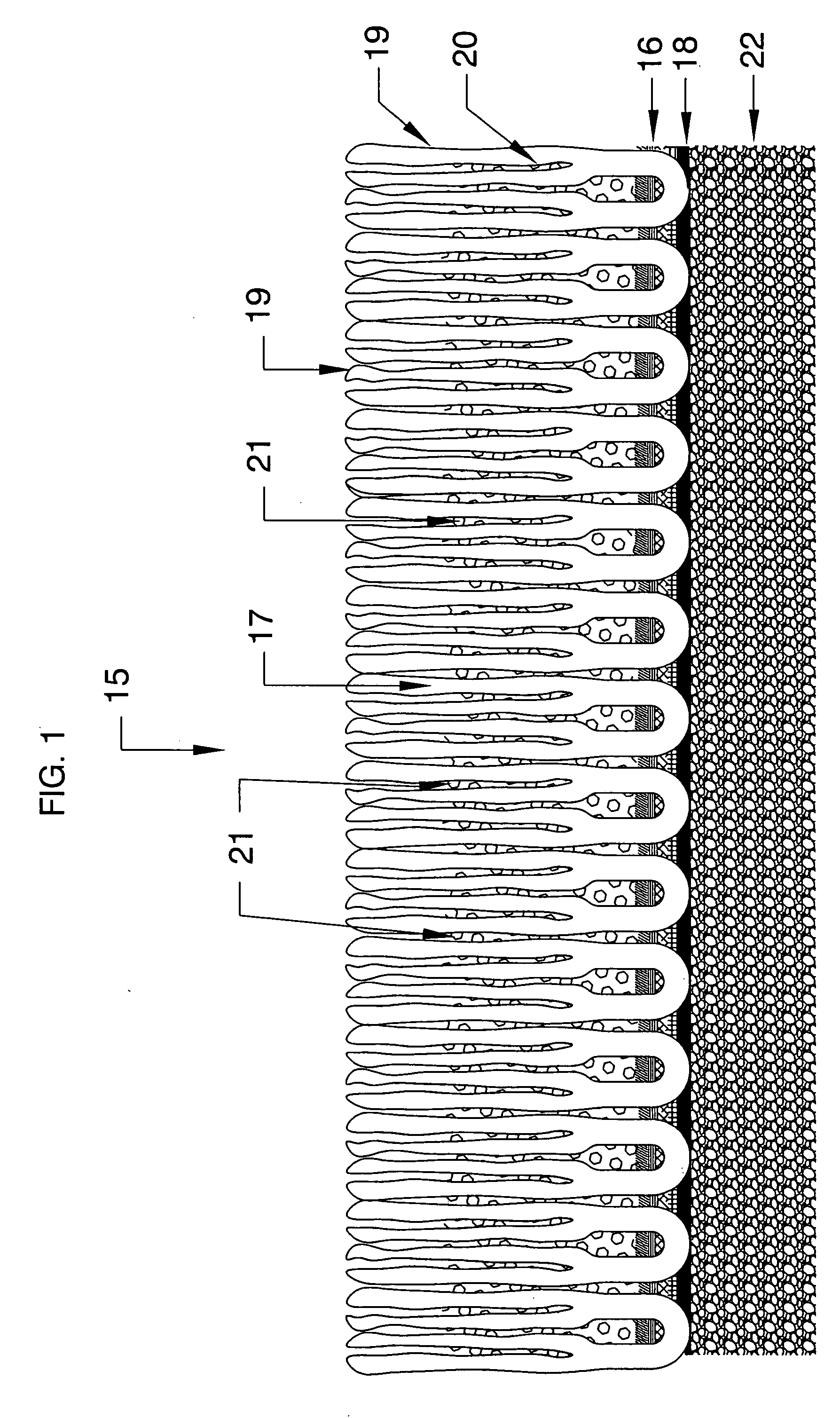

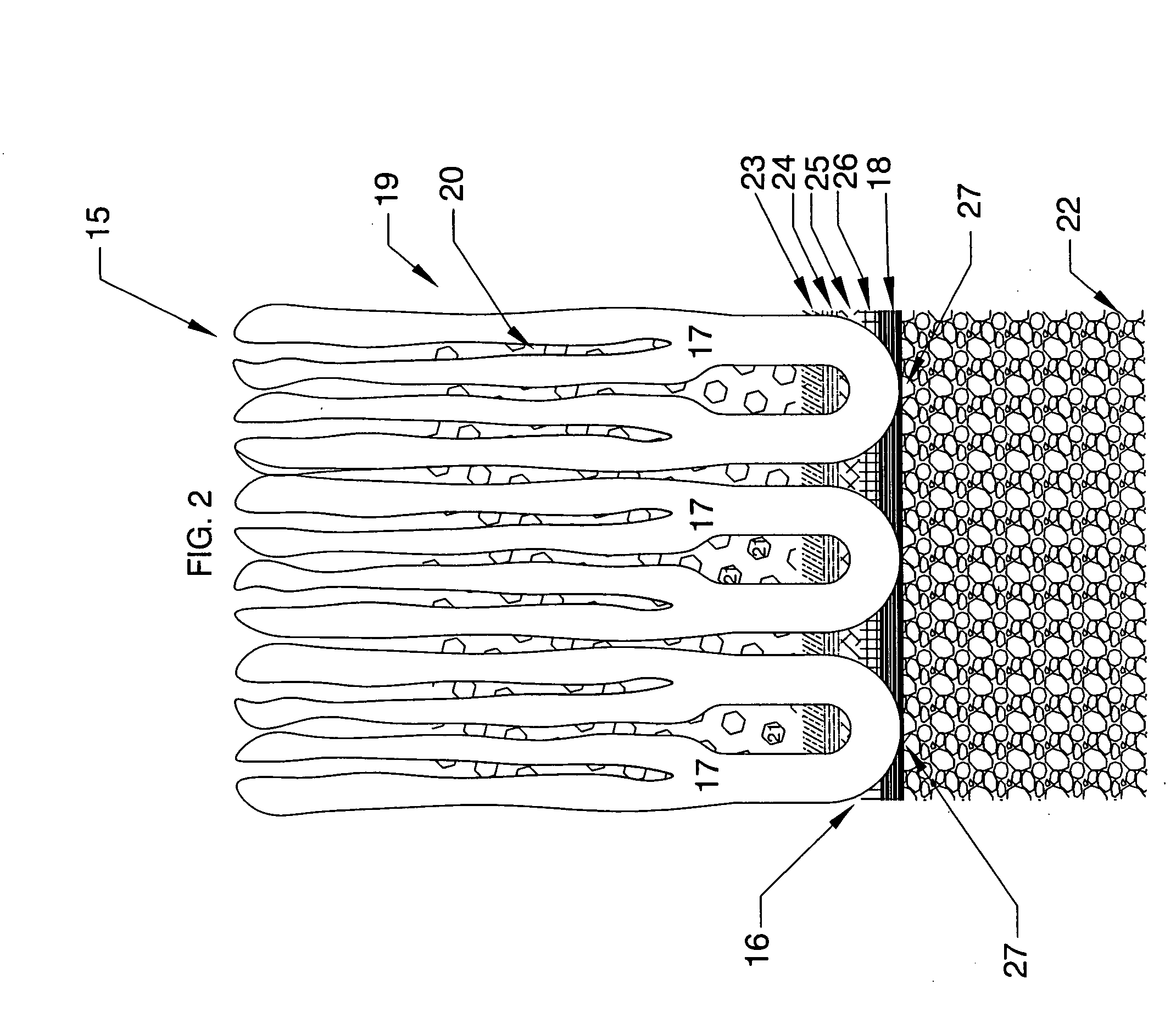

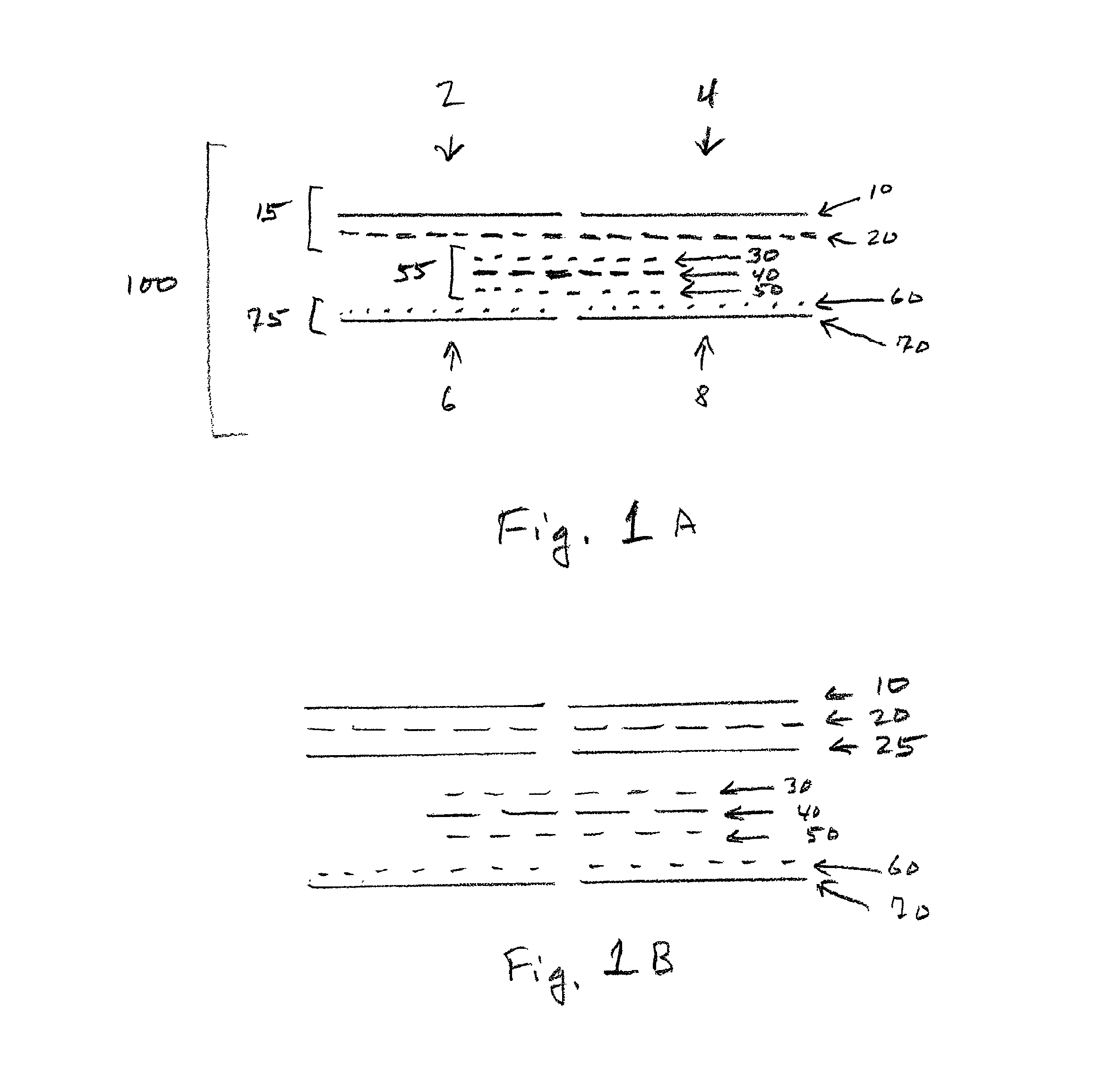

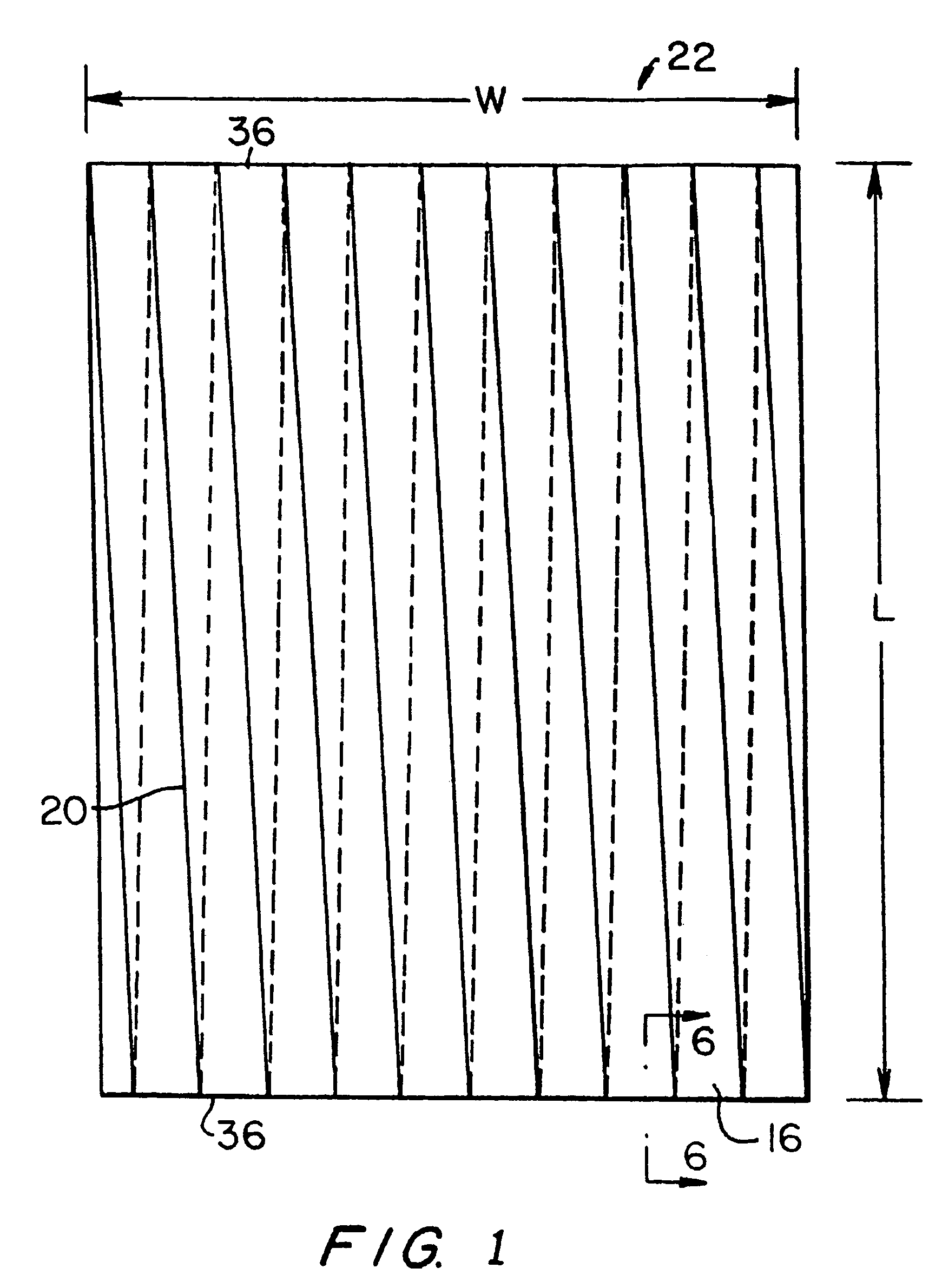

Artificial turf backing

InactiveUS20050064112A1Facilitates tuft bindGood lateral supportDead plant preservationArtificial flowers and garlandsFiberInfill

Artificial turf (15) comprising a primary backing (16) having a first side (52) and a second side (53) and including a first backing layer (23), a second backing layer (24), a third backing layer (25) and a fourth backing layer (26), a plurality of fibers (19) sewn or tufted through the primary backing, and a secondary backing on the second side of the primary backing. The first layer may facilitate tufting, the second layer may facilitate dimensional stability, the third layer may facilitate tufted bind and the fourth layer may facilitate seam strength. The fibers may form upstanding ribbons (17) on the first side of the primary backing and the turf may further comprise an infill layer (20) disposed between the ribbons. The fibers may form a plurality of back stitches (27) on the second side of the primary backing and the secondary backing may cover the back stitches and lock in the fibers.

Owner:TRIEXE MANAGEMENT GROUP

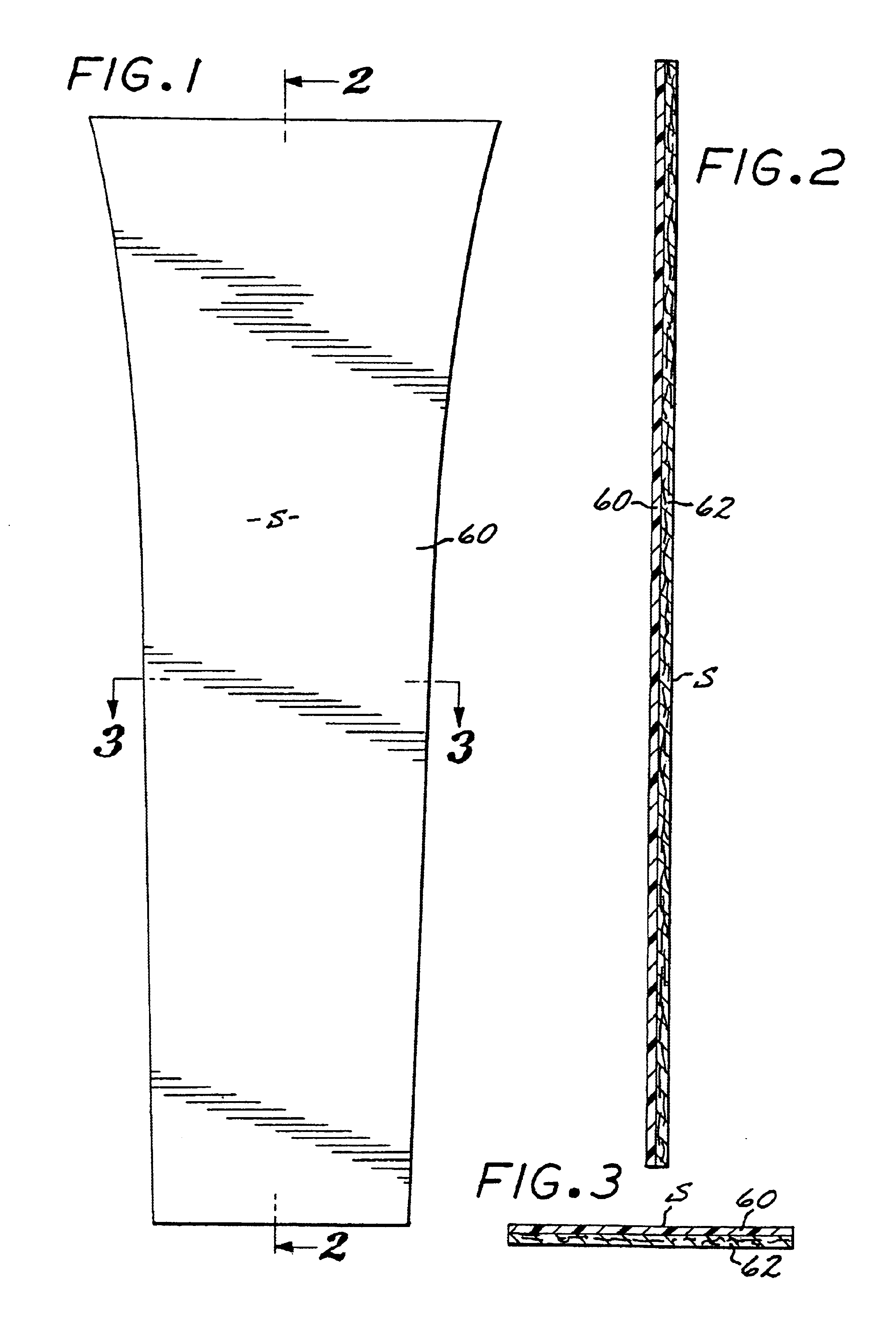

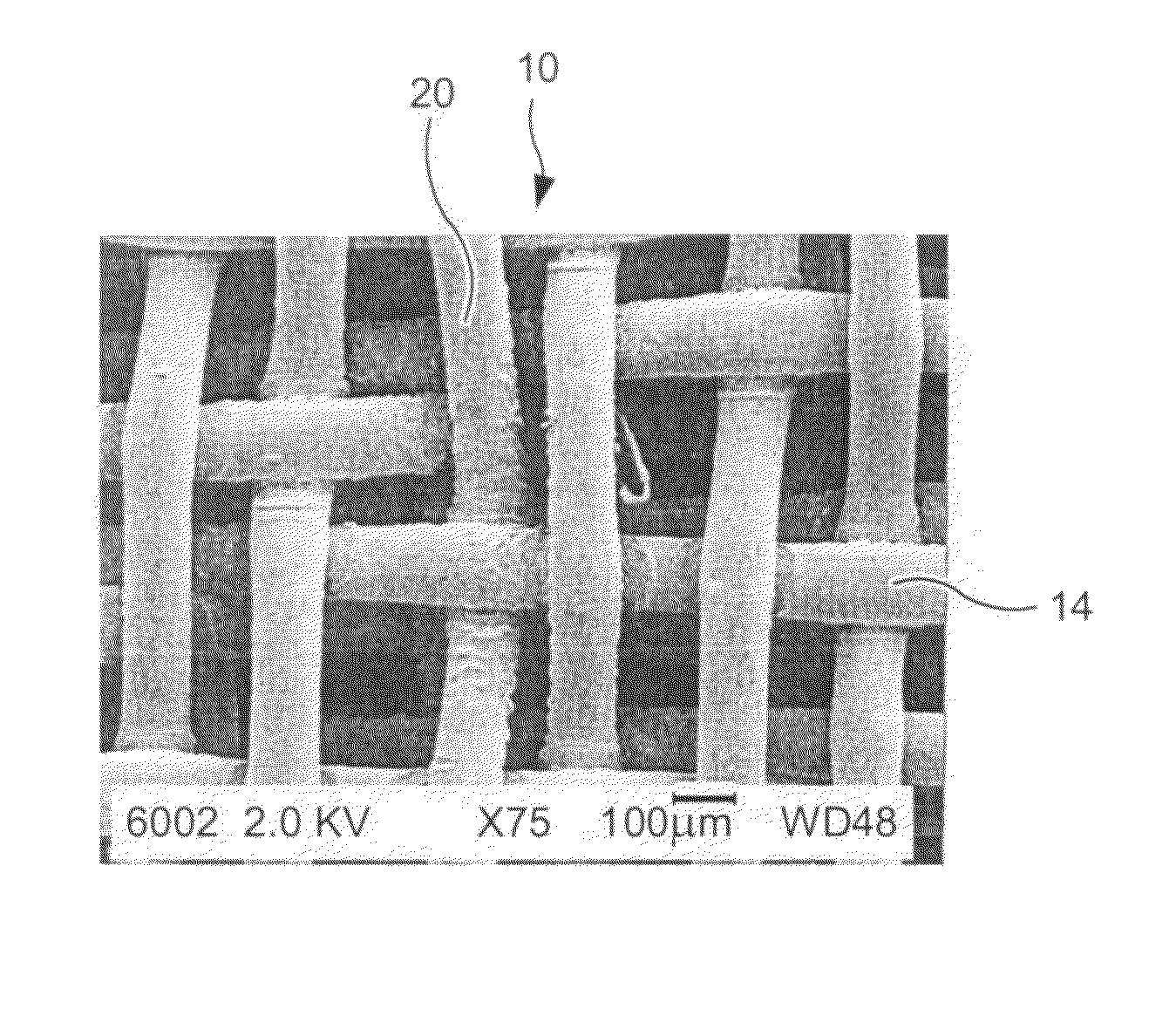

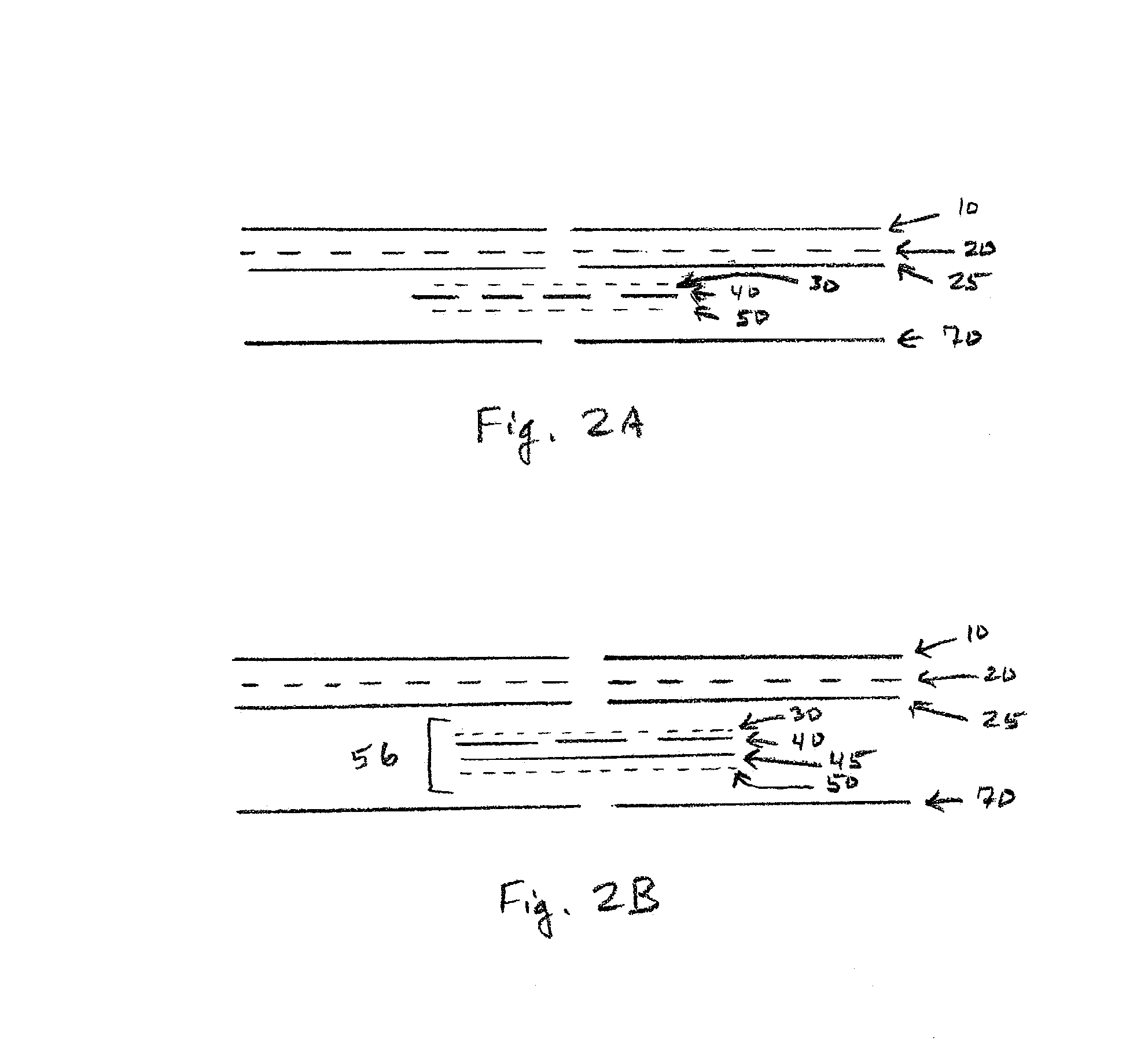

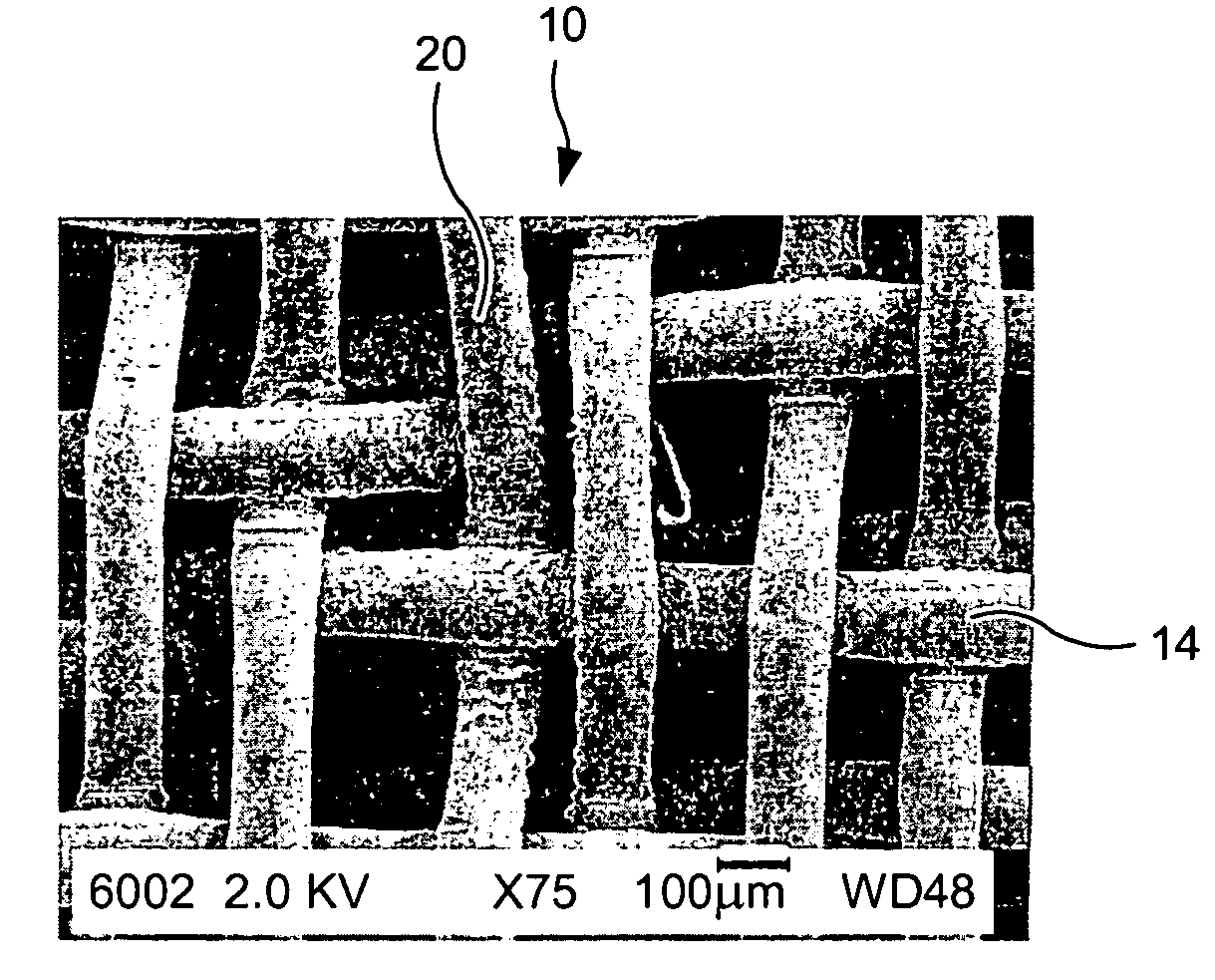

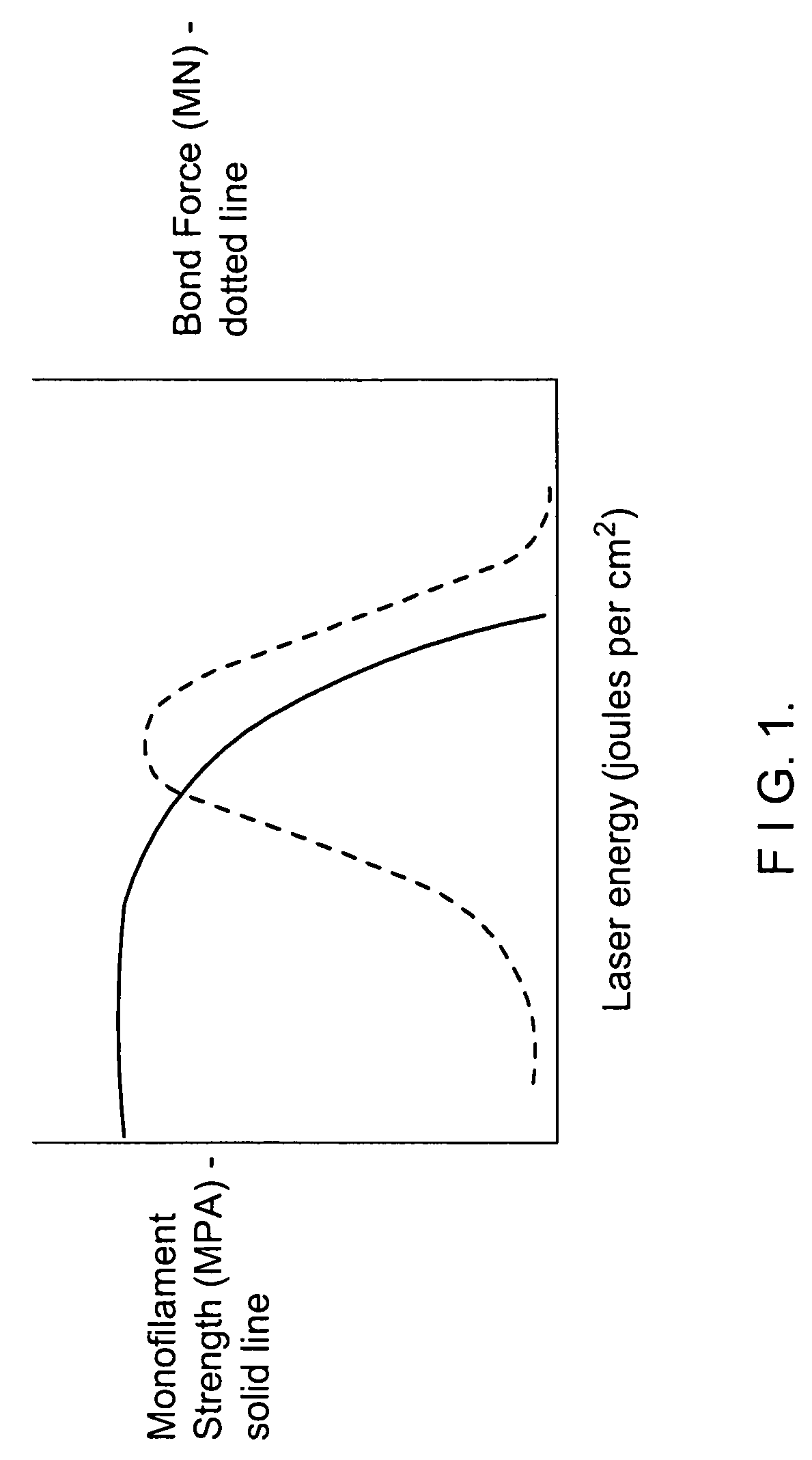

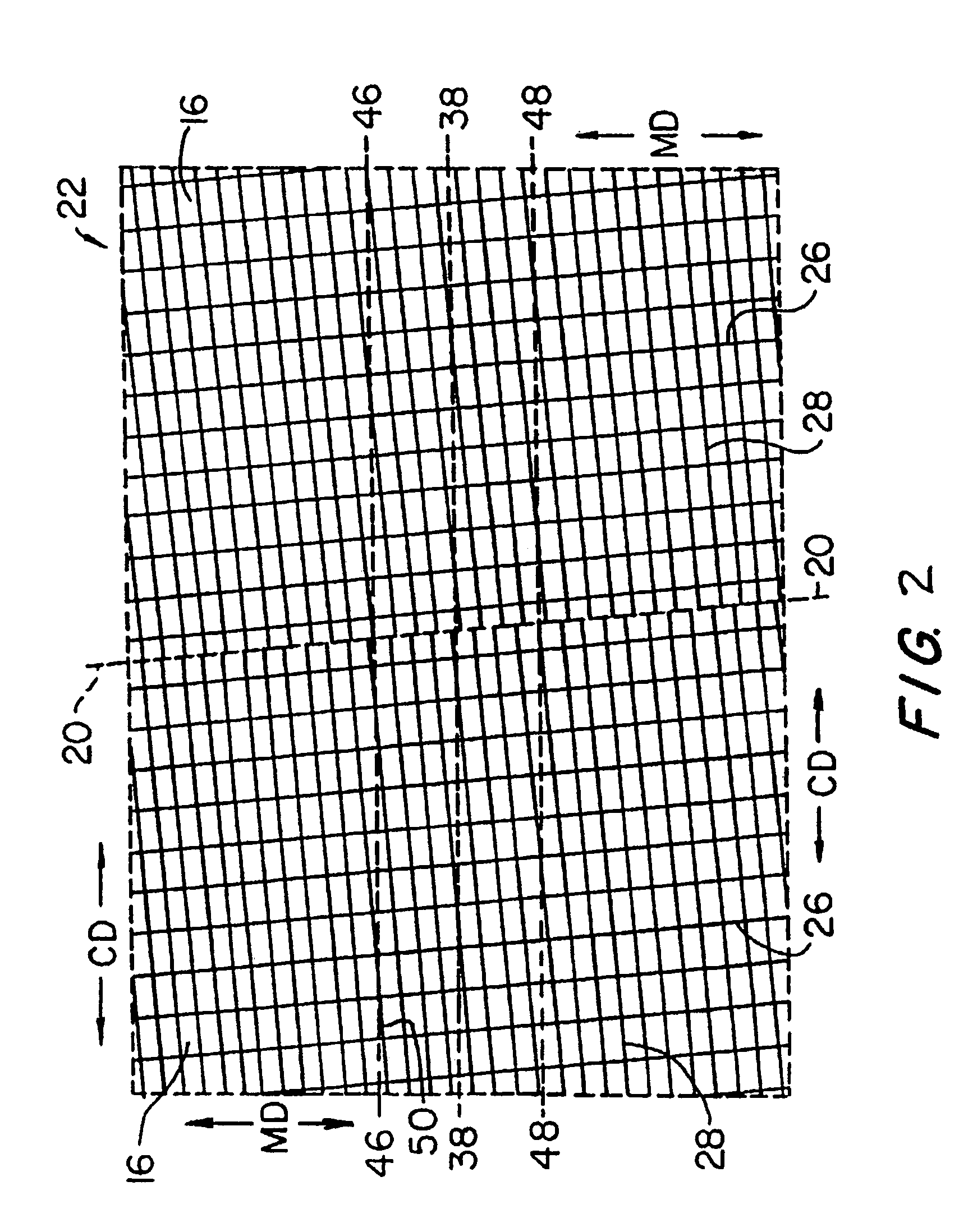

Process for producing papermaker's and industrial fabric seam and seam produced by that method

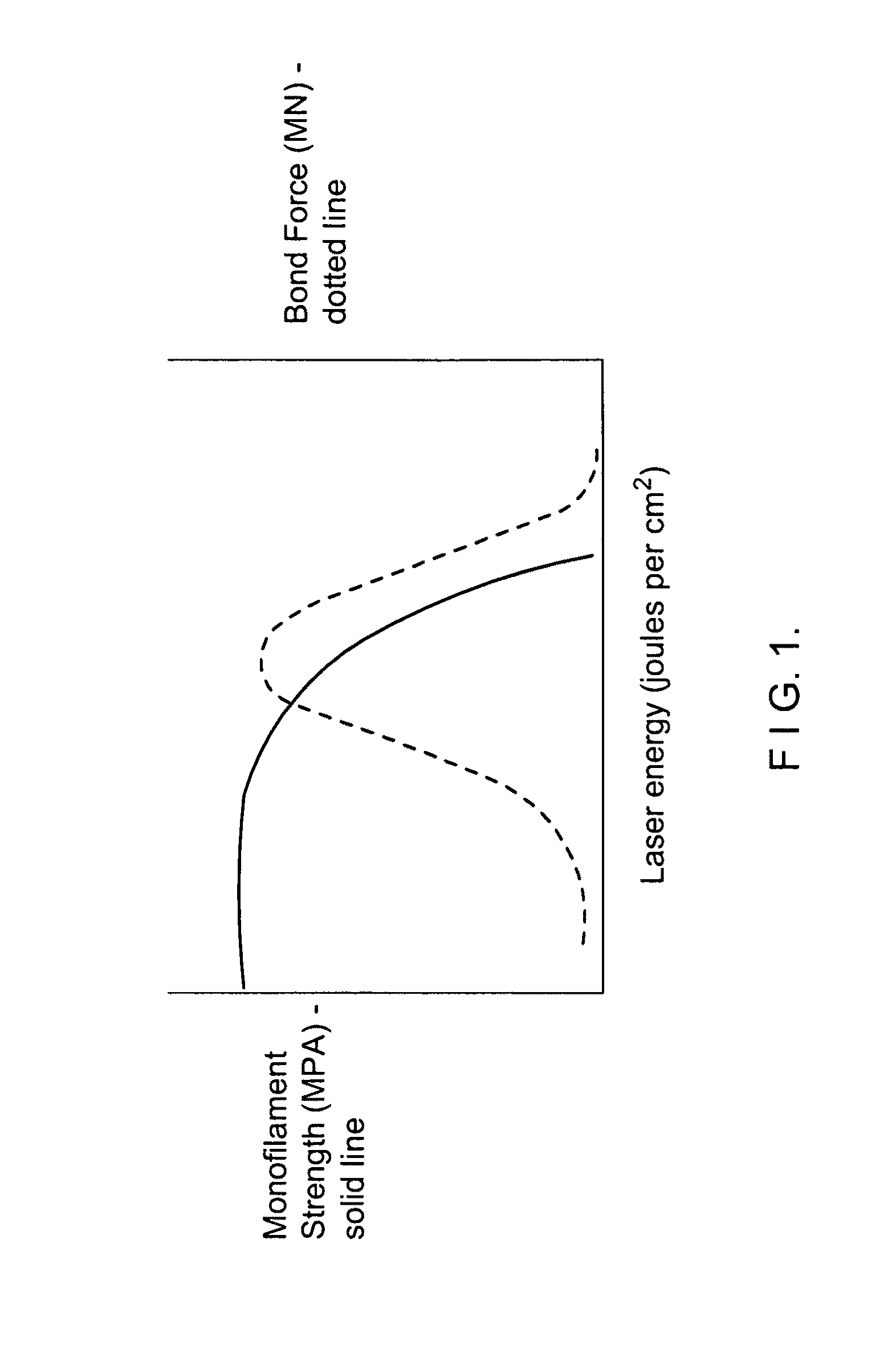

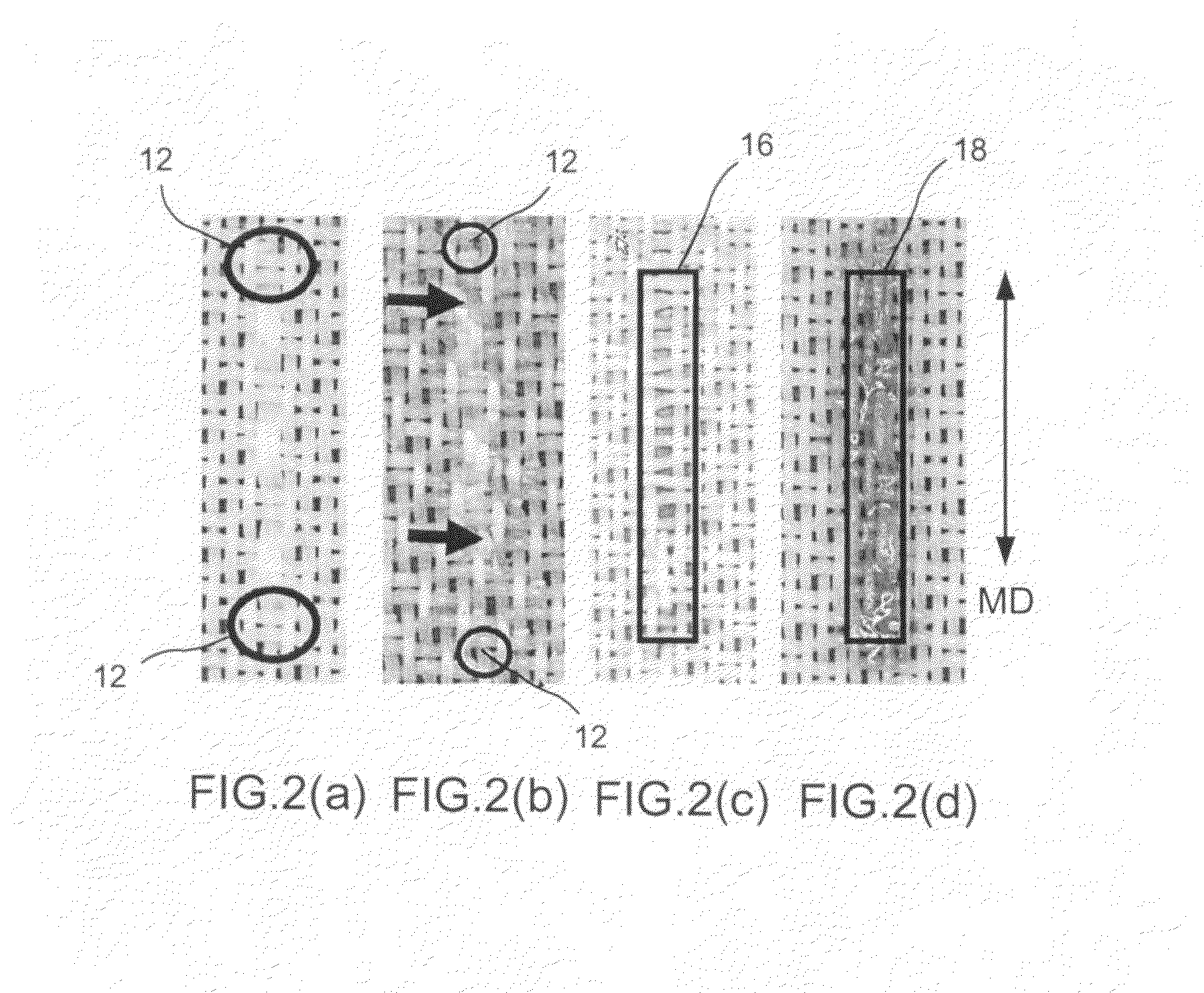

ActiveUS8062480B2Good seamsImprove fusion/bondingLamination ancillary operationsLaminationFiberEngineering

The invention disclosed herein relates to the use of laser energy to weld or melt selected locations in papermachine clothing (“PMC”) and other industrial and engineered fabrics. The invention also relates to an improved seam for a papermaker or other industrial fabric that has properties such as strength, durability, openness, adequate number of support points, and fiber support index (FSI) essentially the same as the fabric body. The invention also relates to a fabric having a durable seam, wherein the seam width as measured in the MD is a fraction of the width of a normal seam or a seam that is formed using a conventional technique of equal strength.

Owner:ALBANY INT CORP

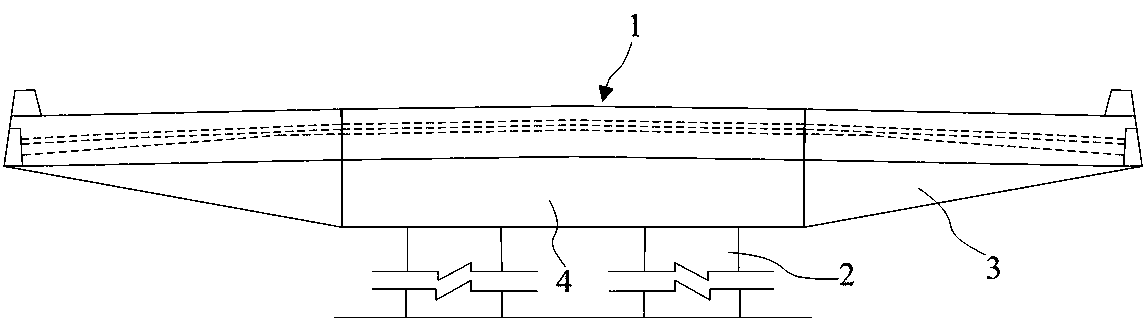

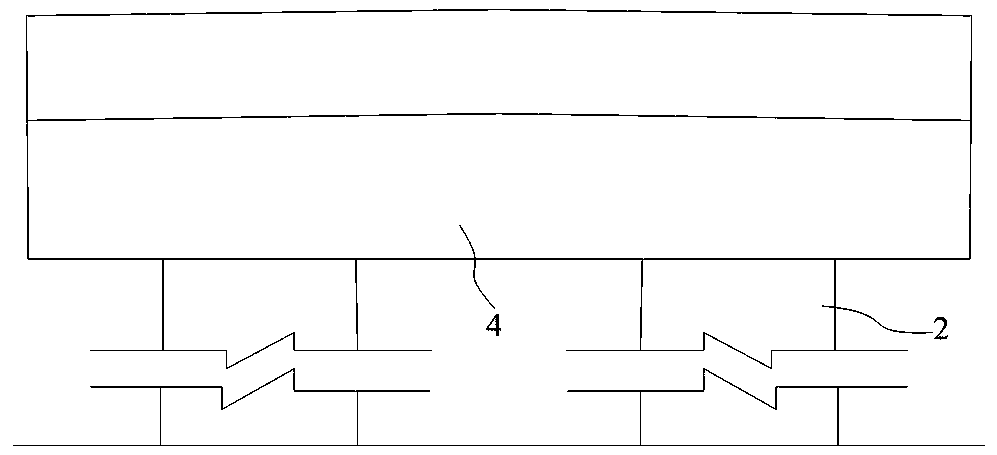

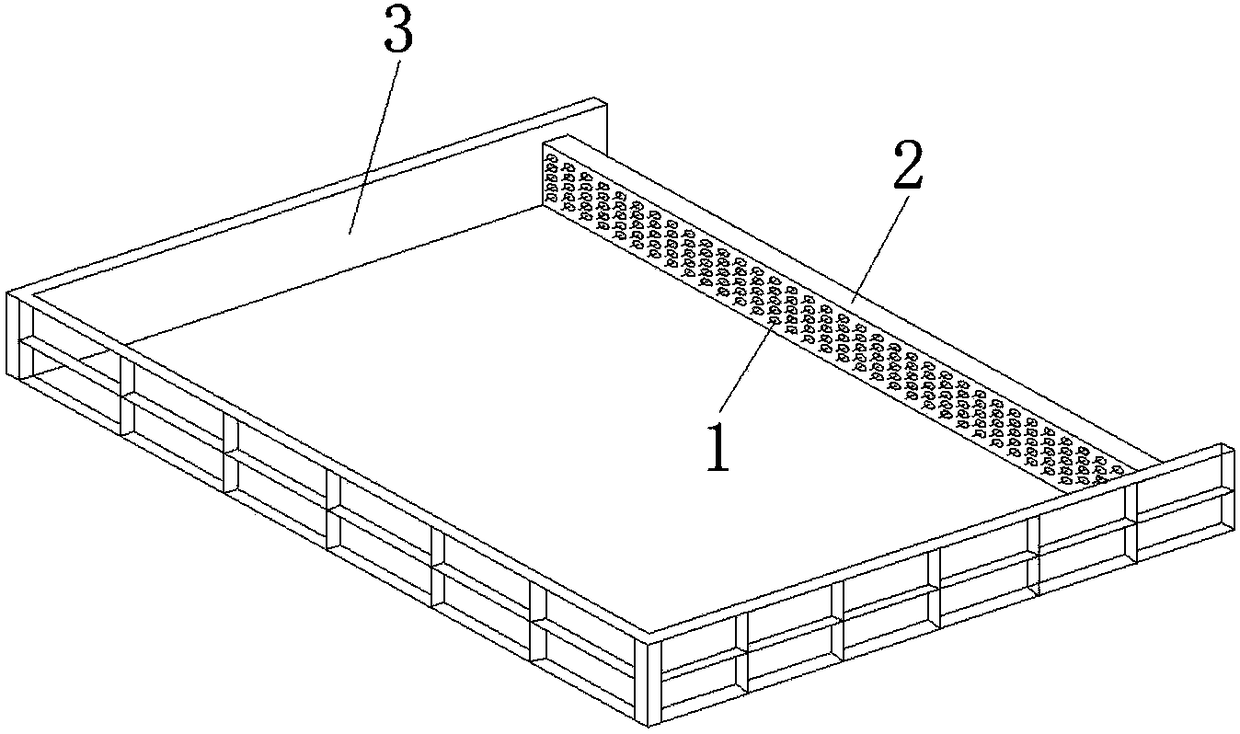

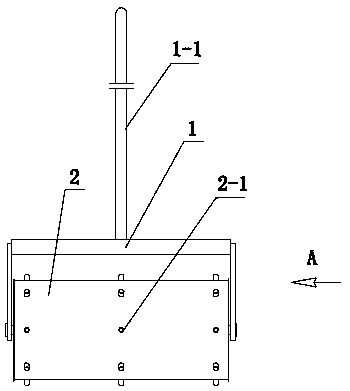

Method for prefabricating and assembling large cantilever cover beam

The invention relates to a method for prefabricating and assembling a large cantilever cover beam, which is characterized by including the steps: lifting and installing the middle section of the coverbeam to the top end of the upright column; Hoisting a cantilever section of the cover beam to an end of a middle section of the cover beam; tightly adhering the splicing surface of the cantilever segment of the cover beam and the splicing surface of the middle segment of the cover beam through an adhesive; the prestressed reinforcement is passed through the cantilever section of the cover beam and the prestressed reinforcement pipe of the middle section of the cover beam in turn, and the prestressed reinforcement is prestressed and tensioned. The invention has the advantages that the integralhoisting has the advantages of simple operation, easy stitching treatment, lower investment, etc. compared with the split hoisting.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

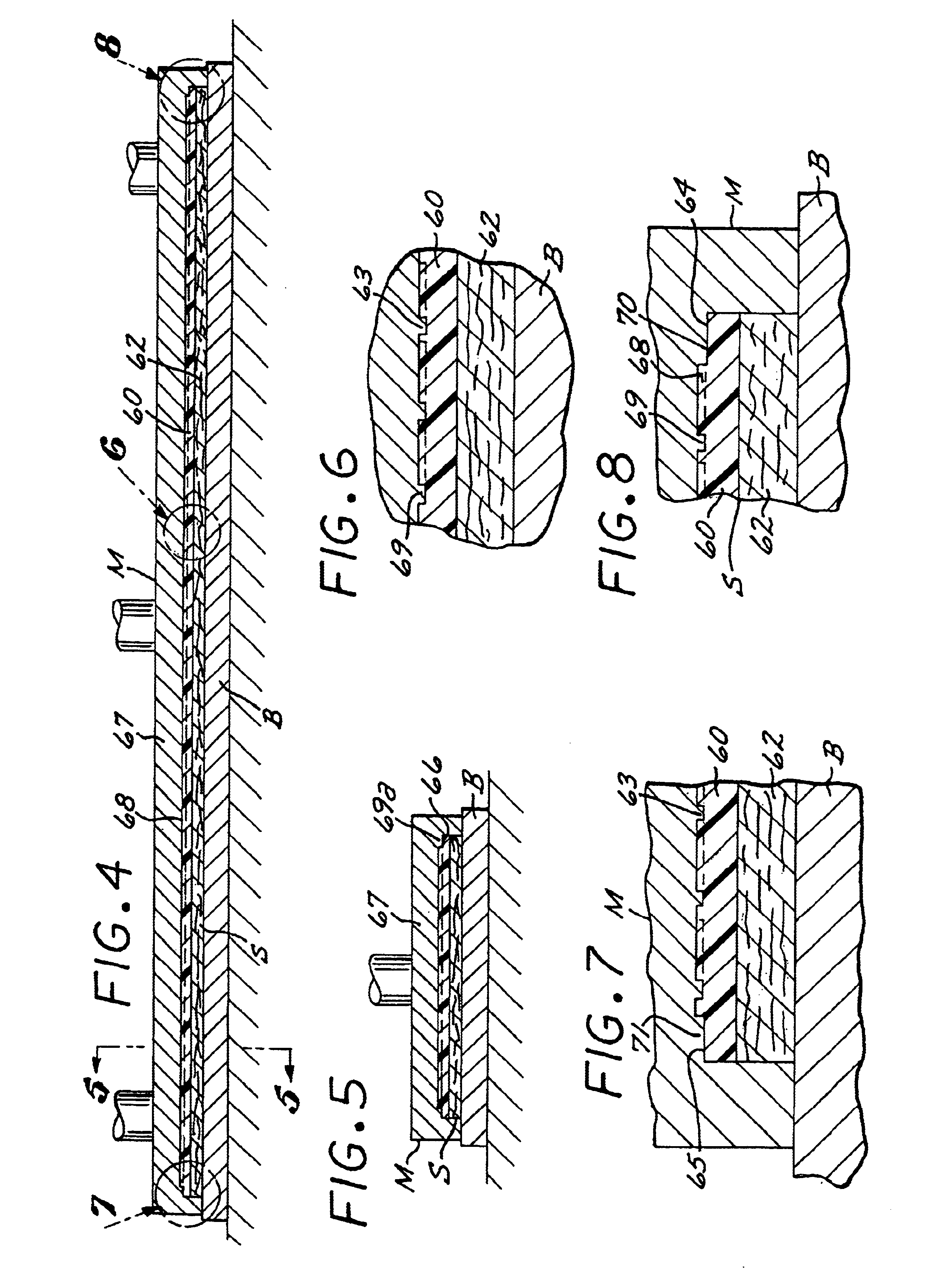

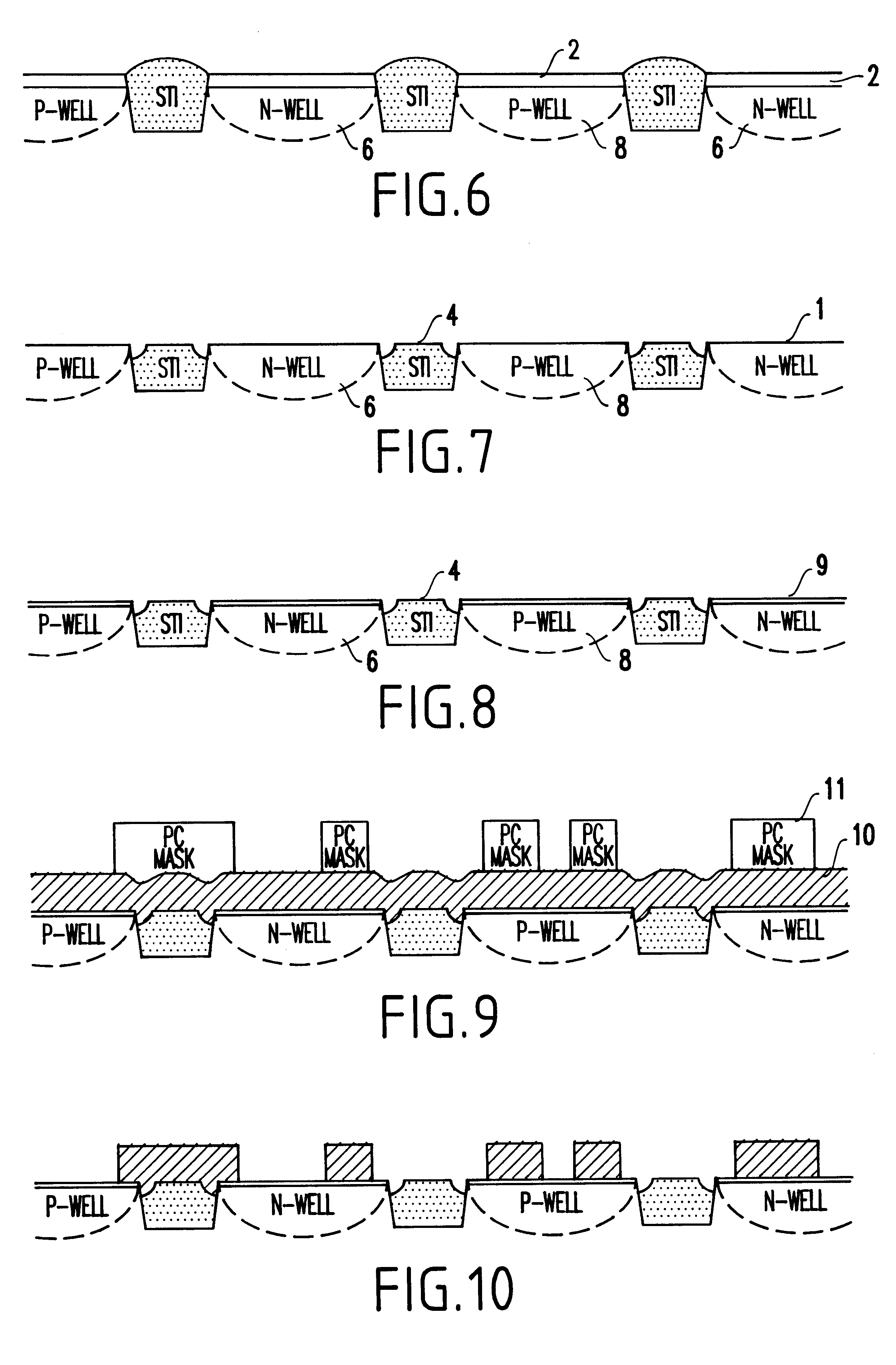

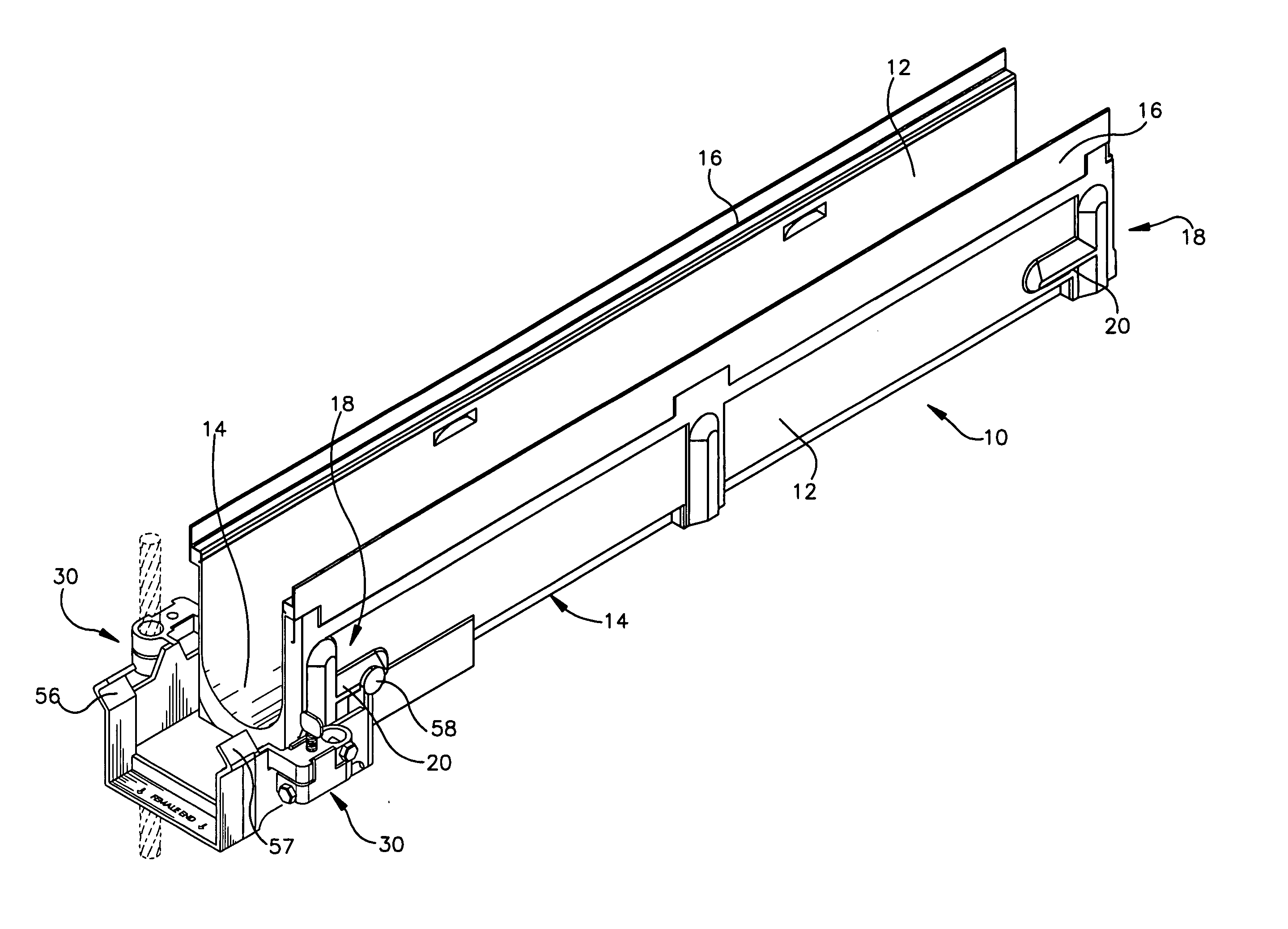

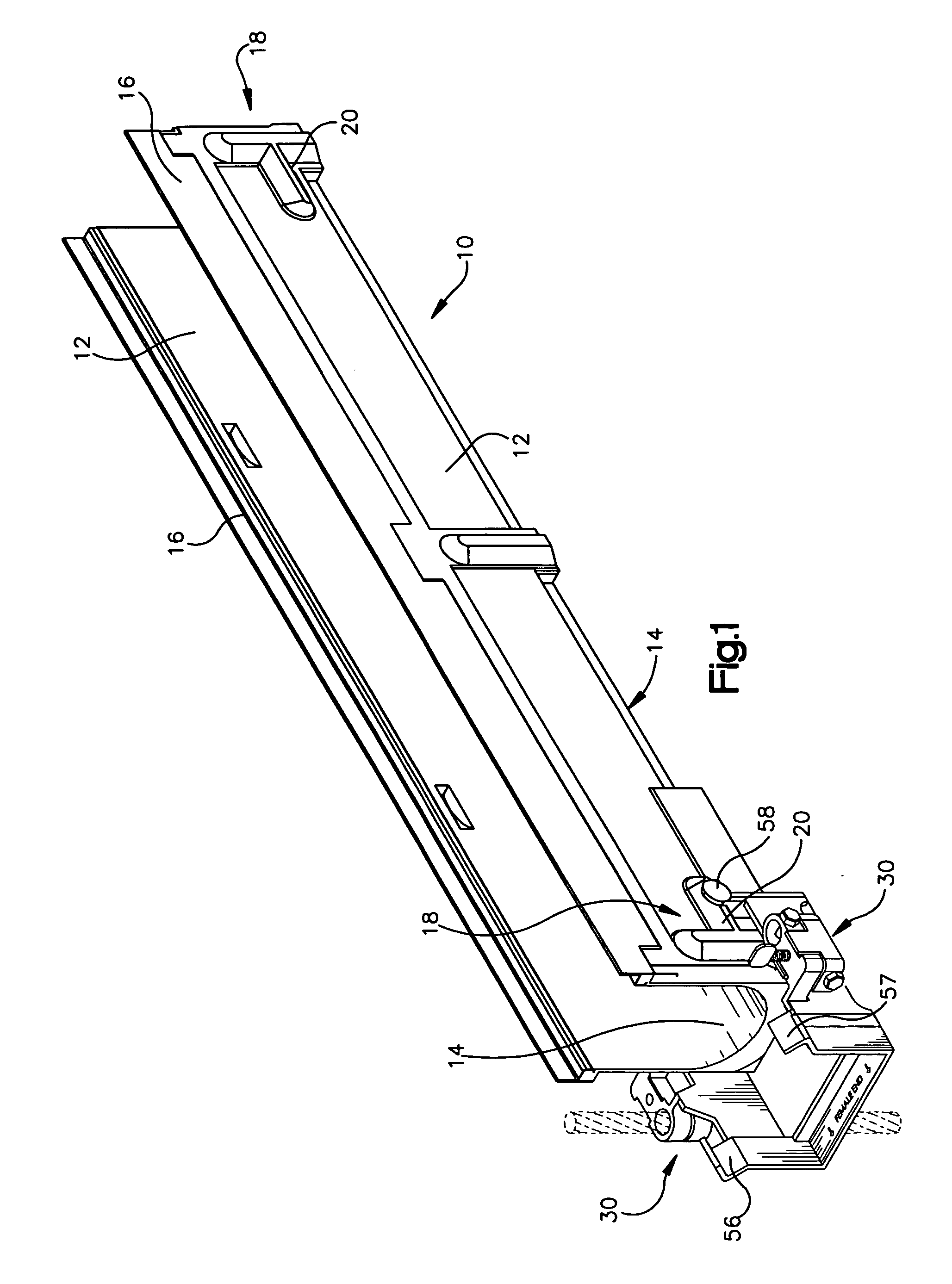

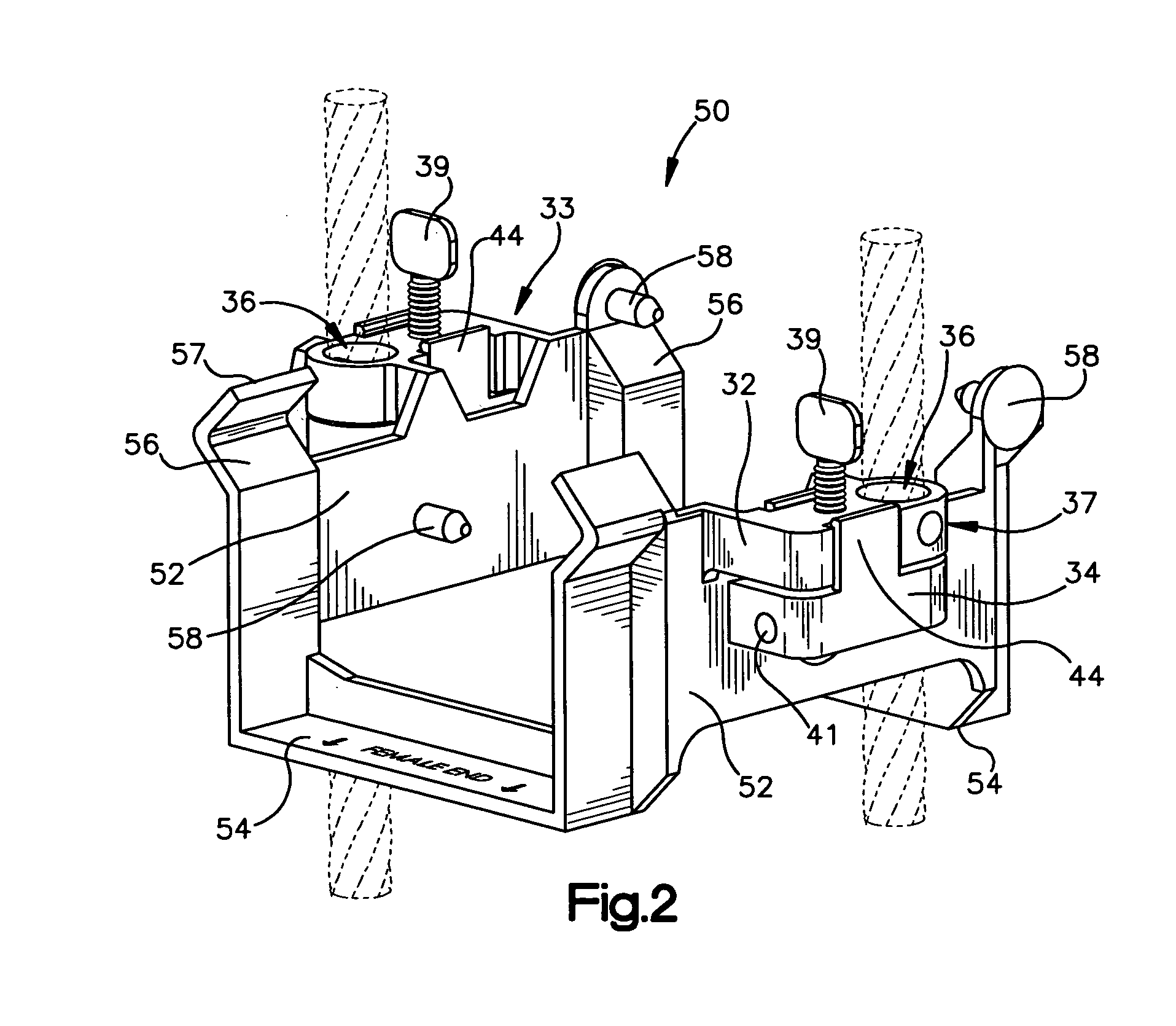

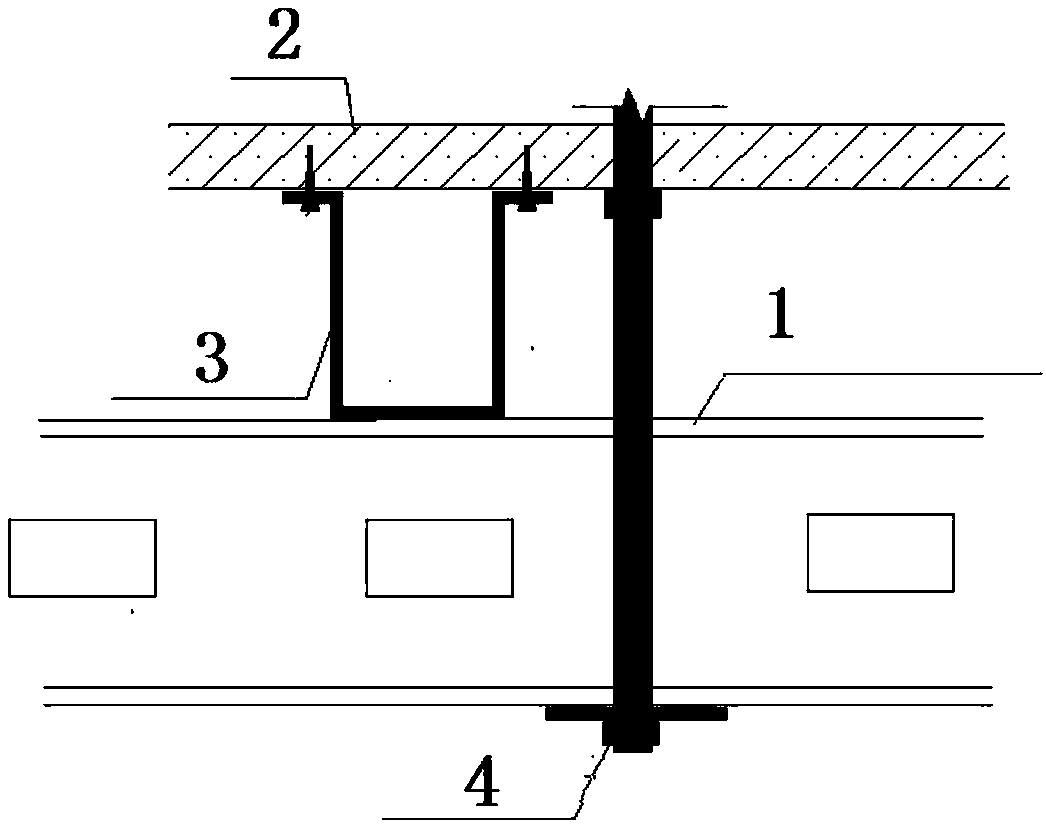

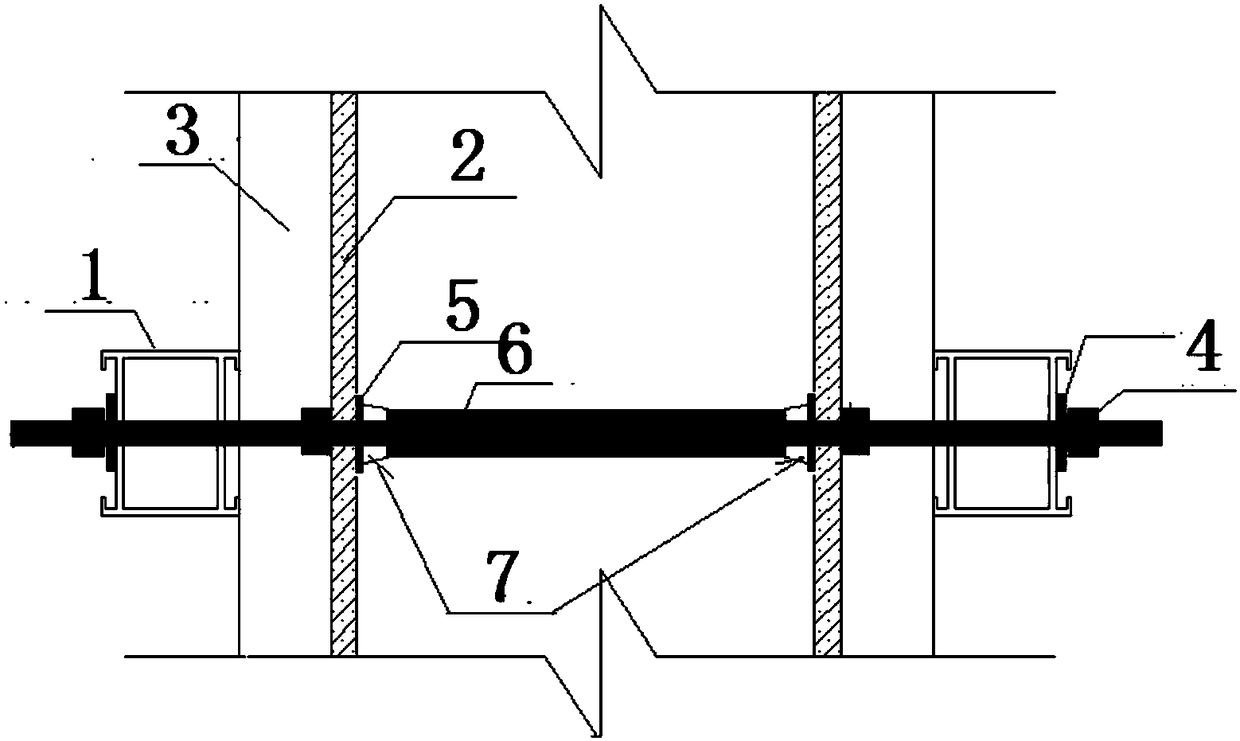

Channel installation device

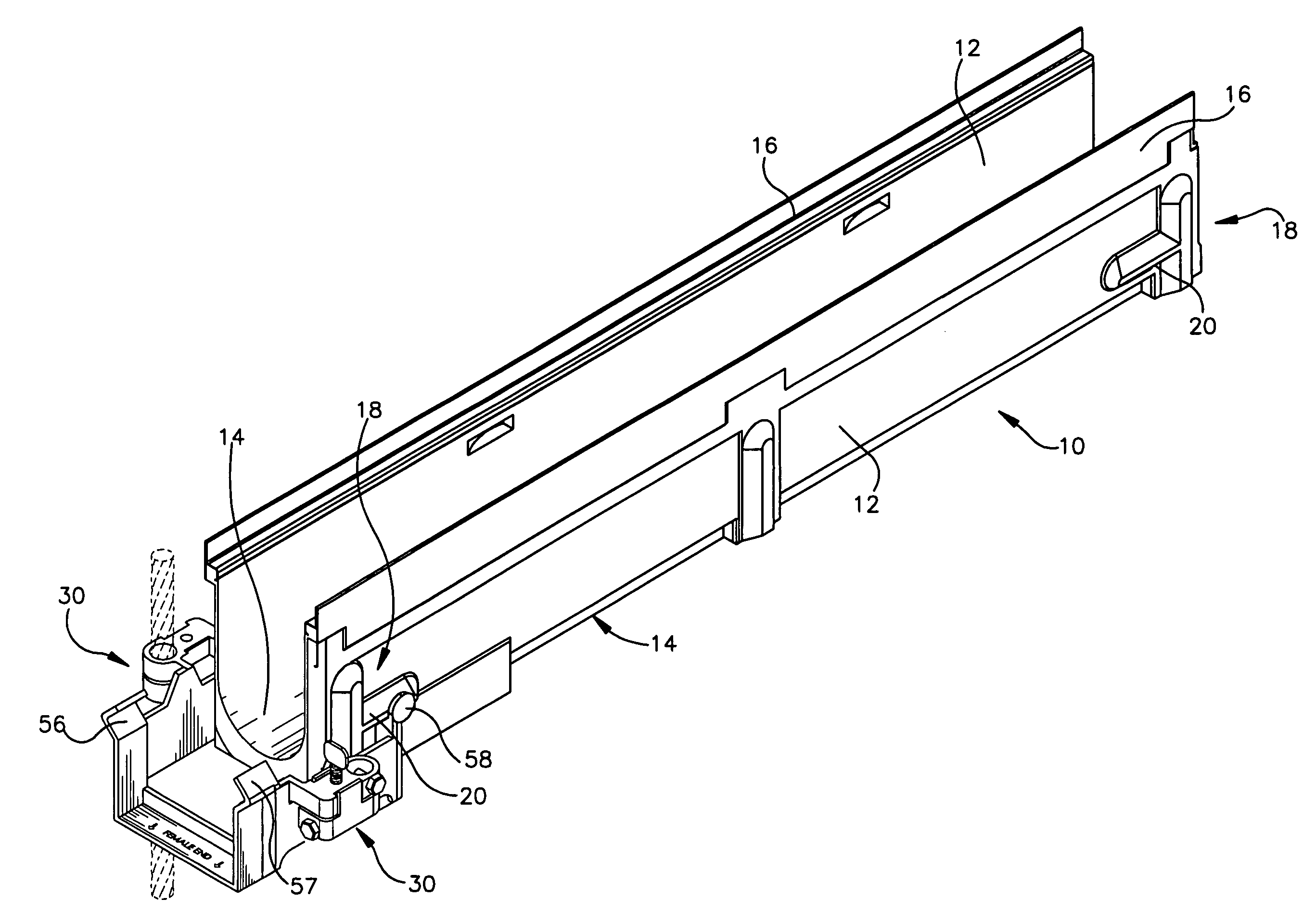

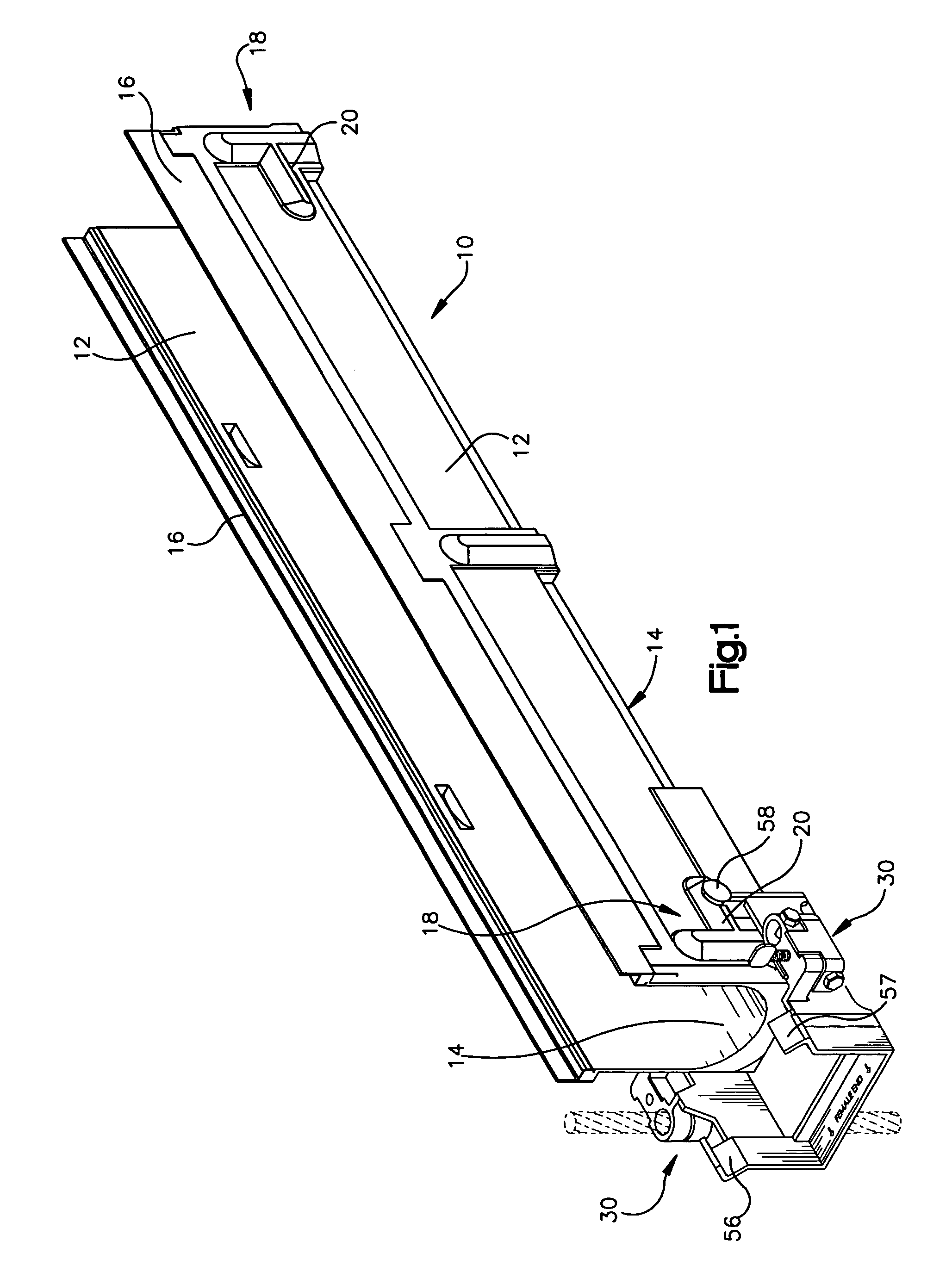

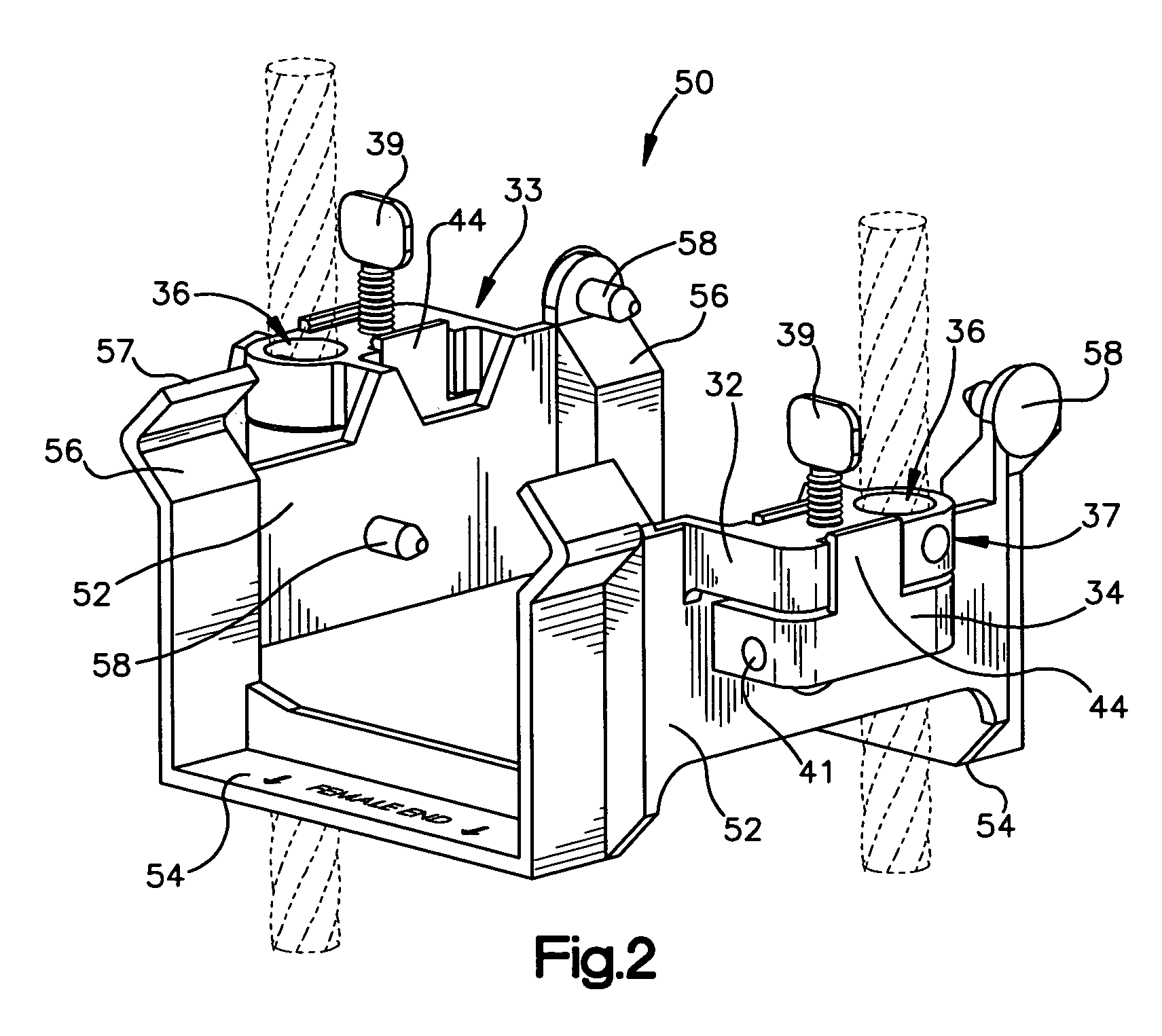

InactiveUS7252457B2Efficient and accurate installationGood seamsRoof coveringBreakwatersEngineeringGuide tube

A cradle assembly for installing trench drain or conduit channels which enables the channels to be suspended from support rods while simultaneously permitting the adjustment of the channel height with in the trench. Because the assembly enables the channel to be supported by the support rods while permitting adjustment of the channel height, final adjustments can be performed by a single worker.

Owner:ACO POLYMER PRODS

Waterproof garment with invisible barrier seam

Owner:COHESIVE SYST

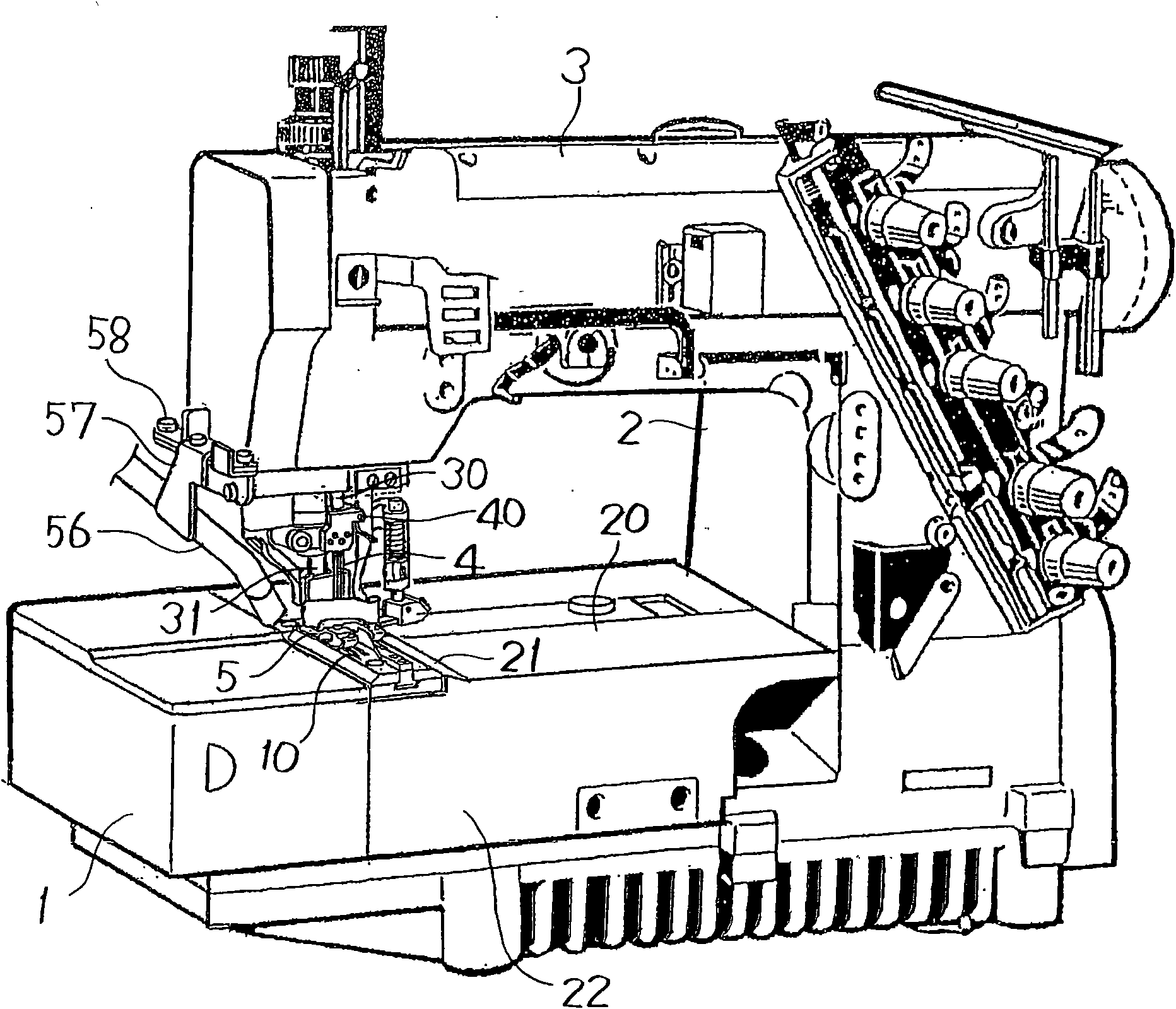

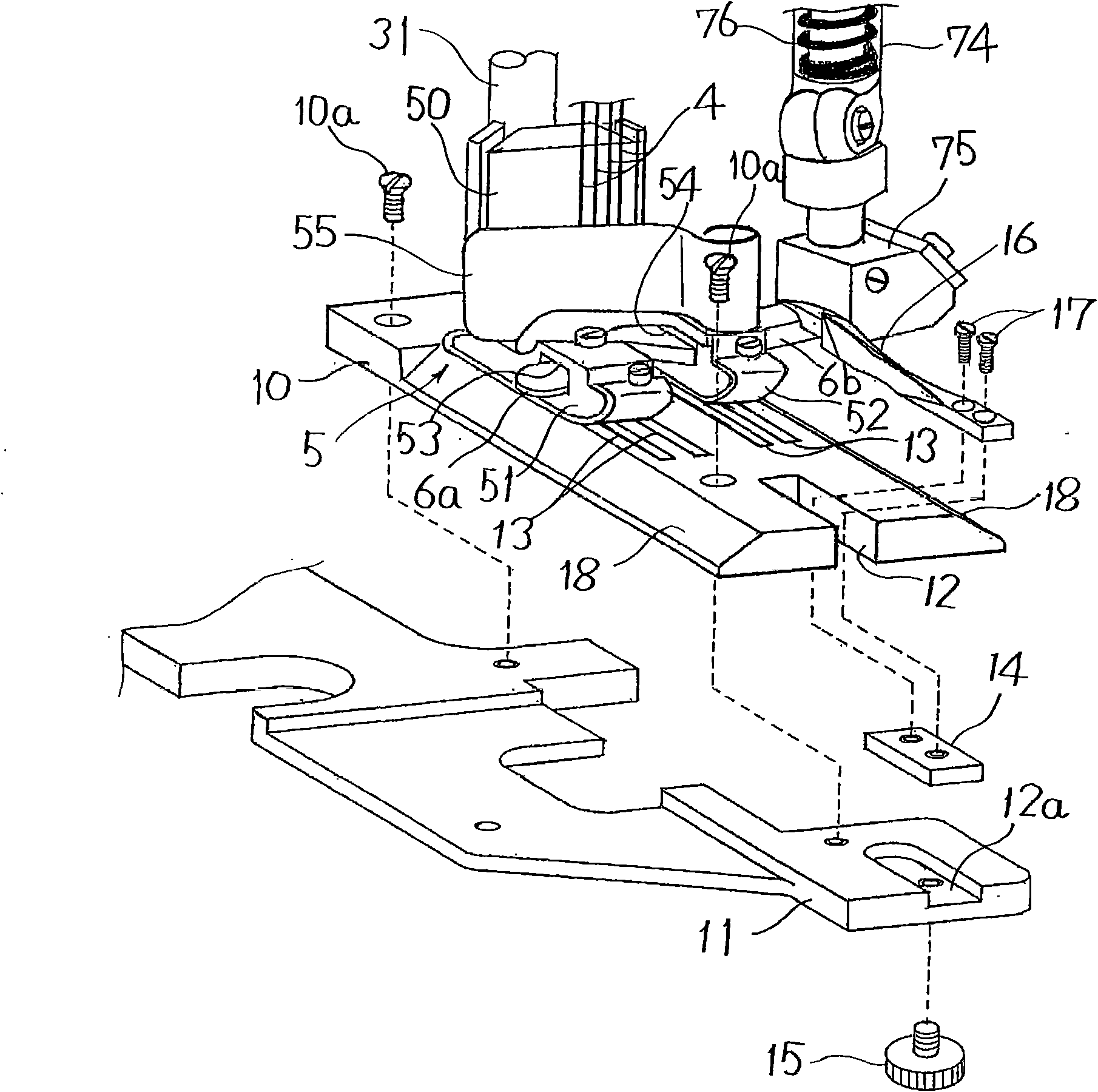

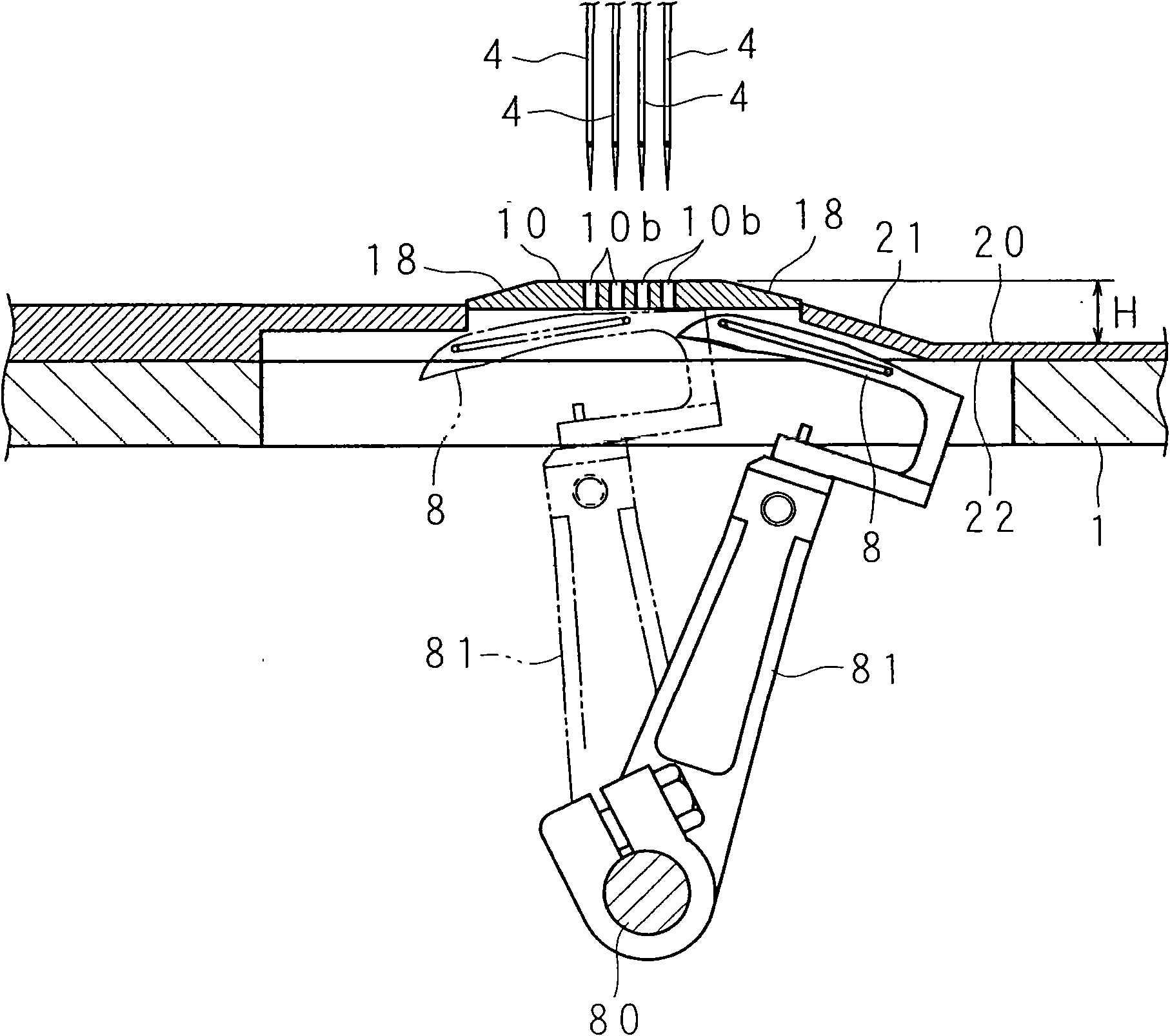

Double-chain stitch sewing machine having box-shaped bed

The invention relates to a double-chain stitch sewing machine having a box-shaped bed, which has a box-shaped sewing machine bed and a presser foot which descends to a needle plate on the sewing machine bed to press the sewing cloth, a knife apparatus is arranged in the presser foot, the sewing cloth is stably supported on a flat upper surface of the sewing machine bed, the edge of the cloth is cut by the knife apparatus, and the sewing cloth is overlapped by certain width to sew. One side or two sides of the needle plate on the upper surface of the sewing machine bed in the width direction is lower than the upper surface of the needle plate to ensure the gap with the projecting part protruding to the knife apparatus outside the presser foot. The operator can utilize the gap to assist theconveying of the sewing cloth by hand in the vicinity of the presser foot, thereby implementing the seam combining of the bulk sewing cloth.

Owner:YAMATO SEWING MASCH MFG CO LTD

Process for producing papermaker's and industrial fabric seam and seam produced by that method

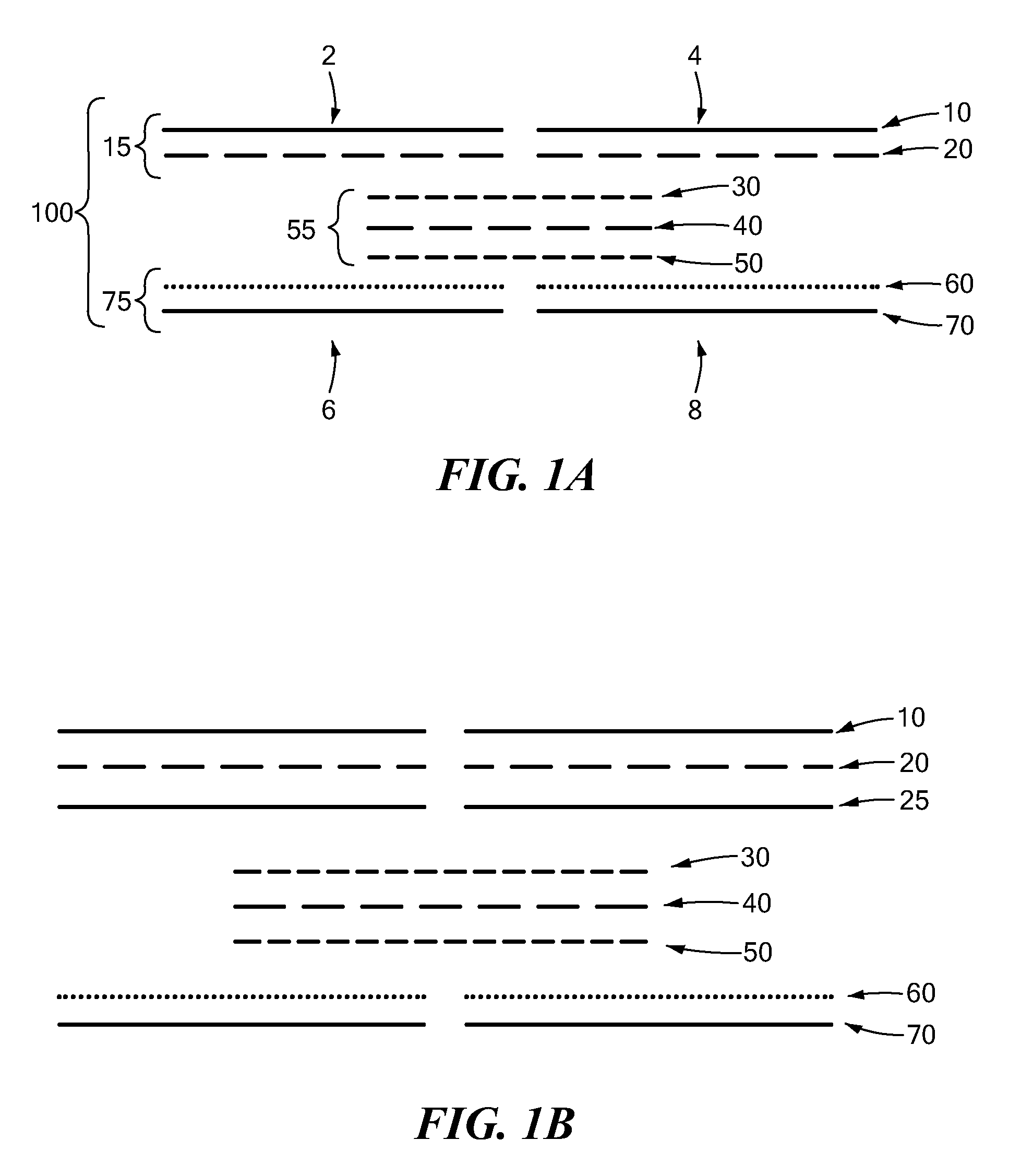

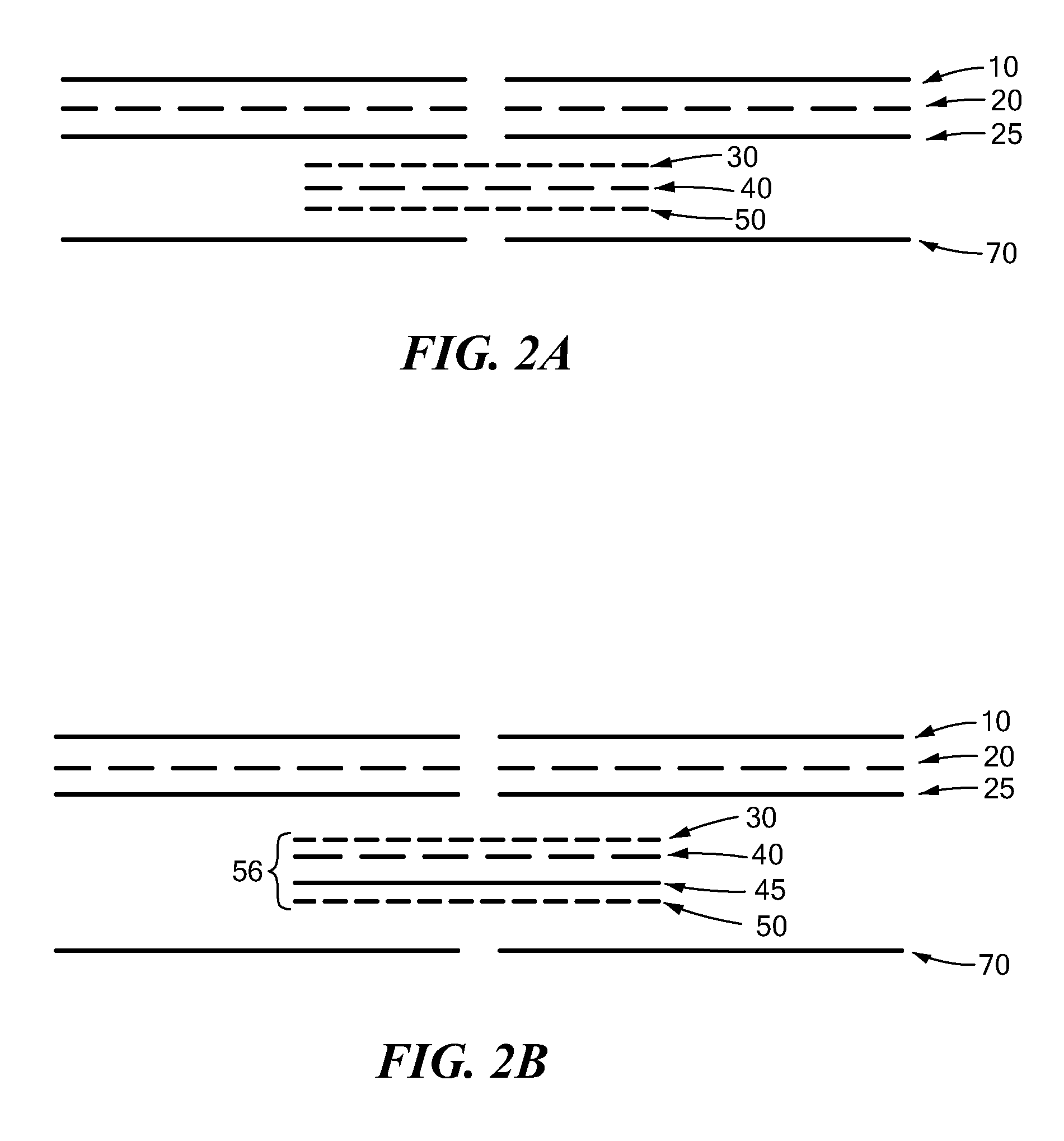

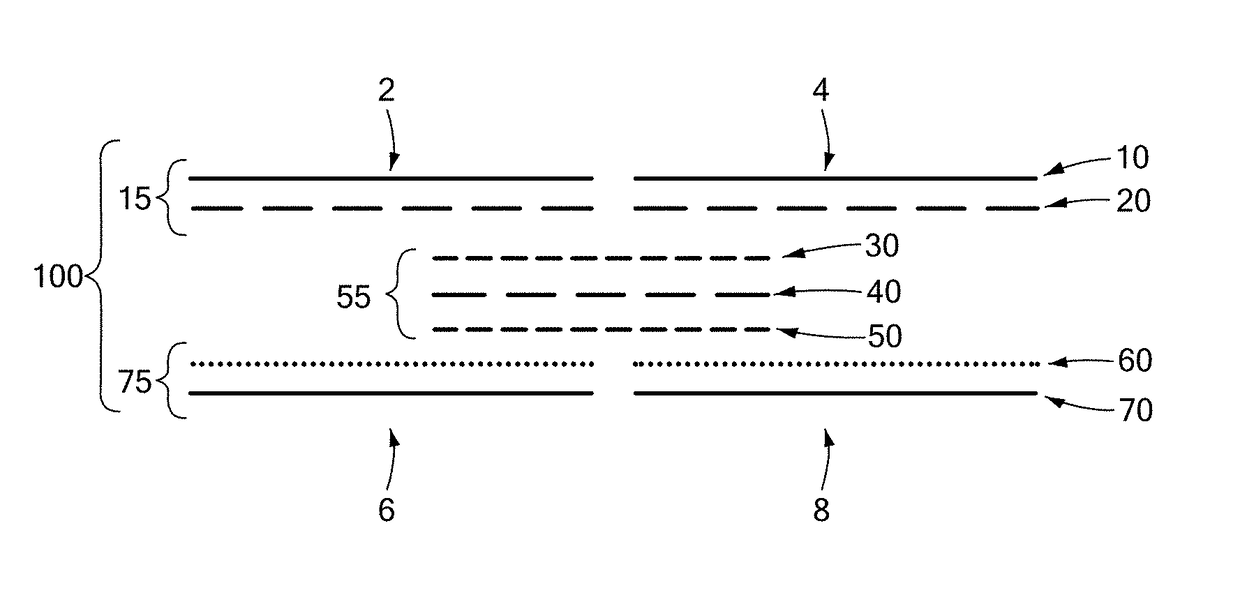

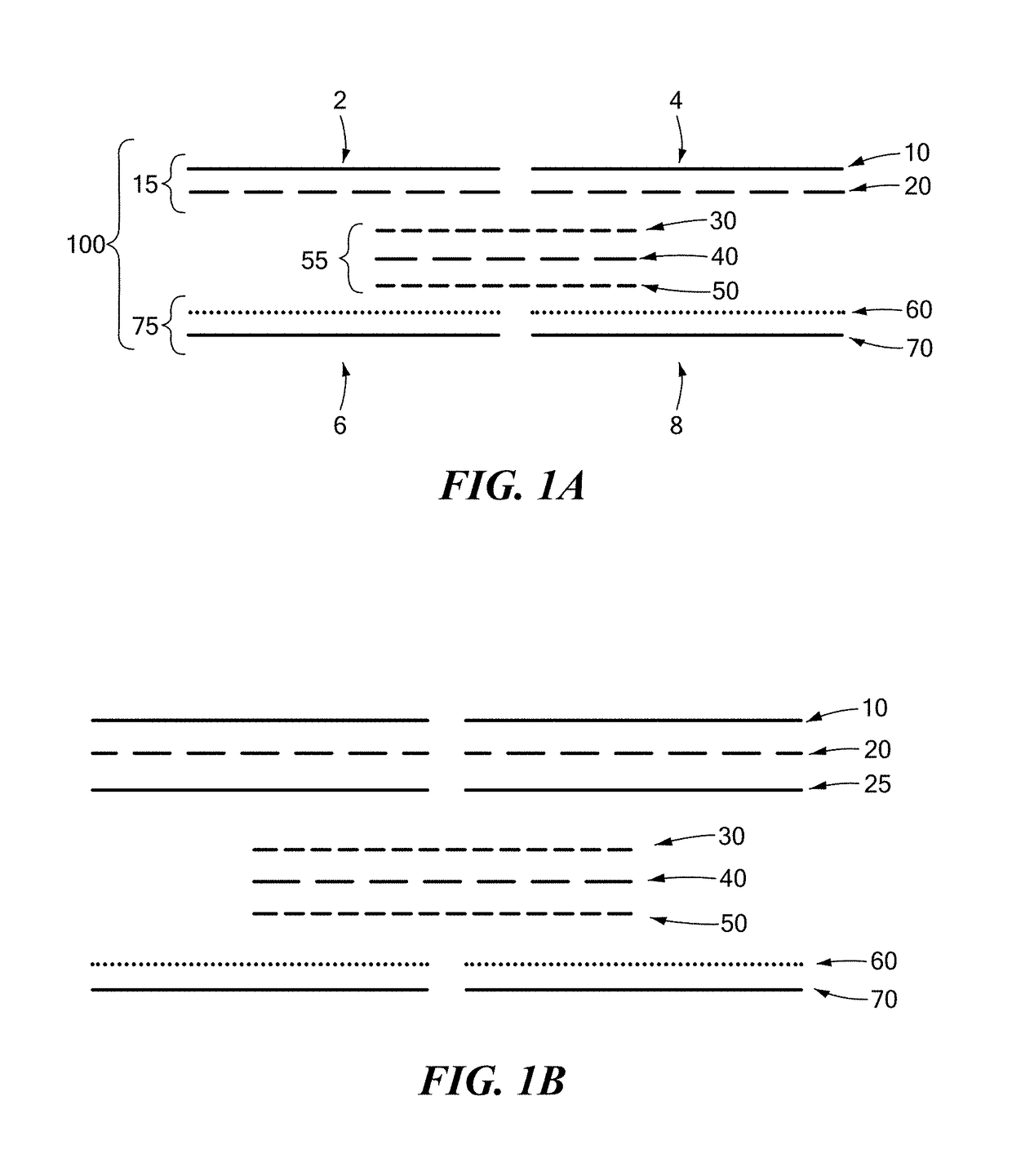

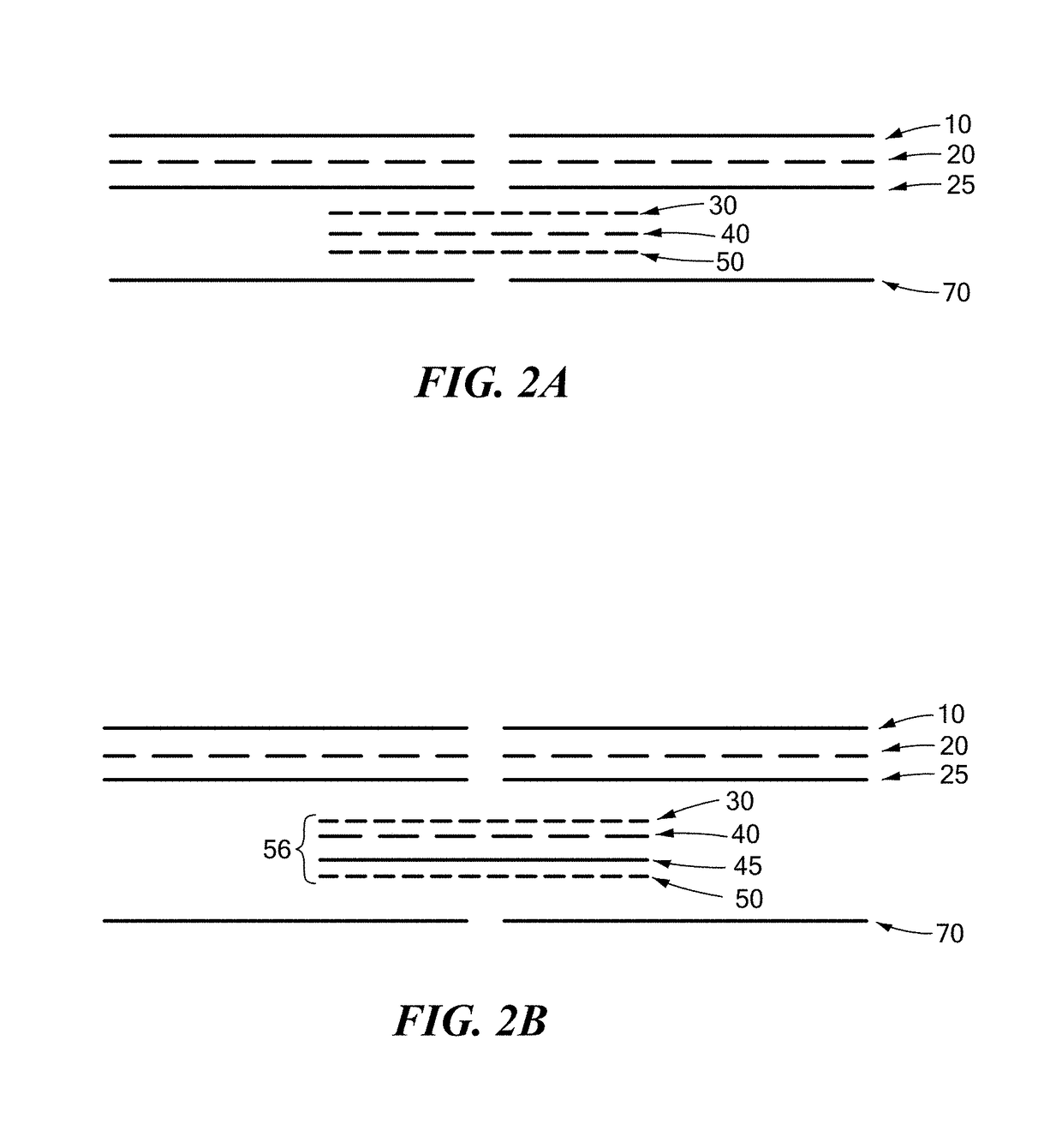

ActiveUS20090139599A1Improve fusion/bondingImproved seam strengthLamination ancillary operationsLaminationFiberEngineering

The invention disclosed herein relates to the use of laser energy to weld or melt selected locations in papermachine clothing (“PMC”) and other industrial and engineered fabrics. The invention also relates to an improved seam for a papermaker or other industrial fabric that has properties such as strength, durability, openness, adequate number of support points, and fiber support index (FSI) essentially the same as the fabric body. The invention also relates to a fabric having a durable seam, wherein the seam width as measured in the MD is a fraction of the width of a normal seam or a seam that is formed using a conventional technique of equal strength.

Owner:ALBANY INT CORP

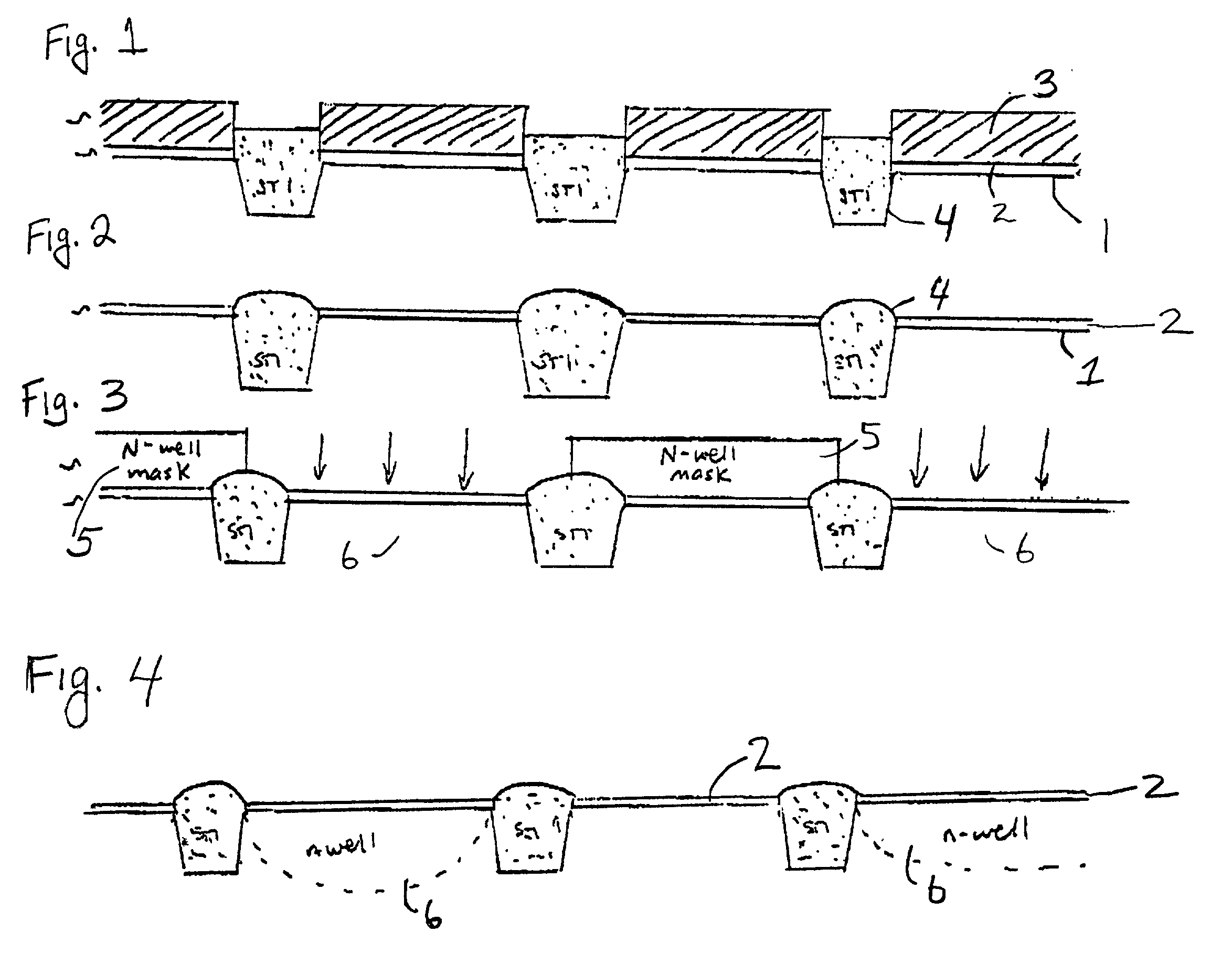

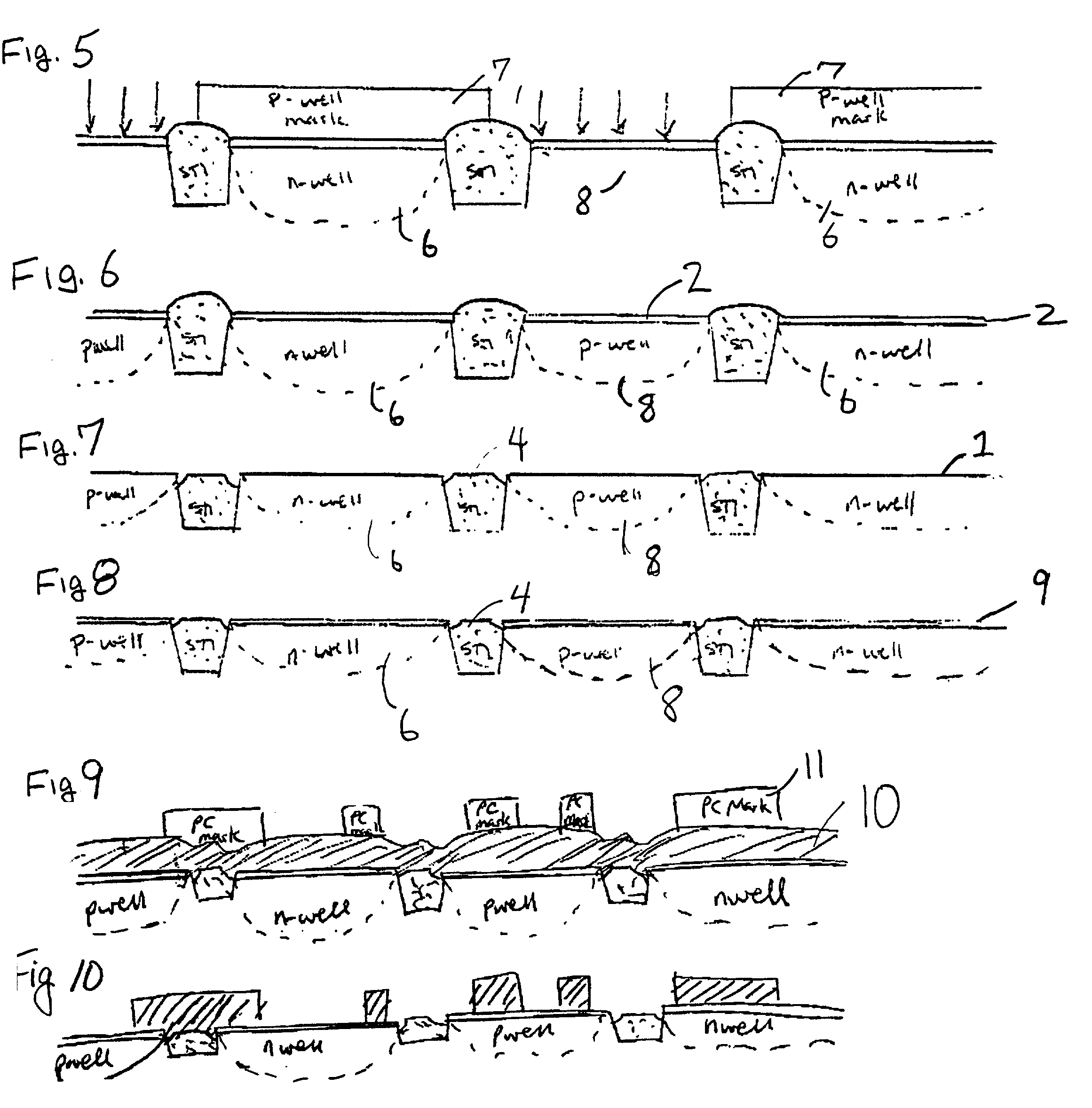

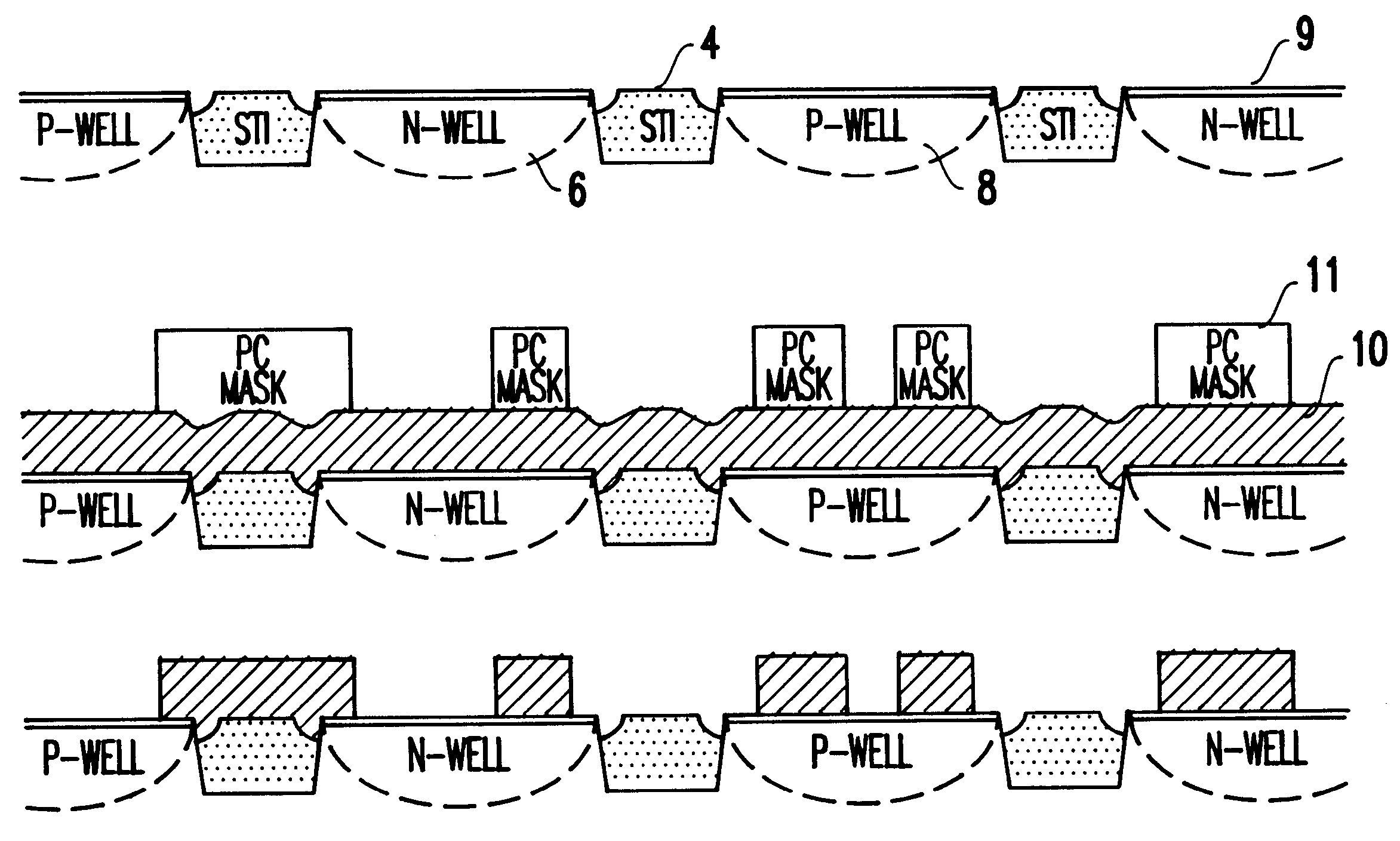

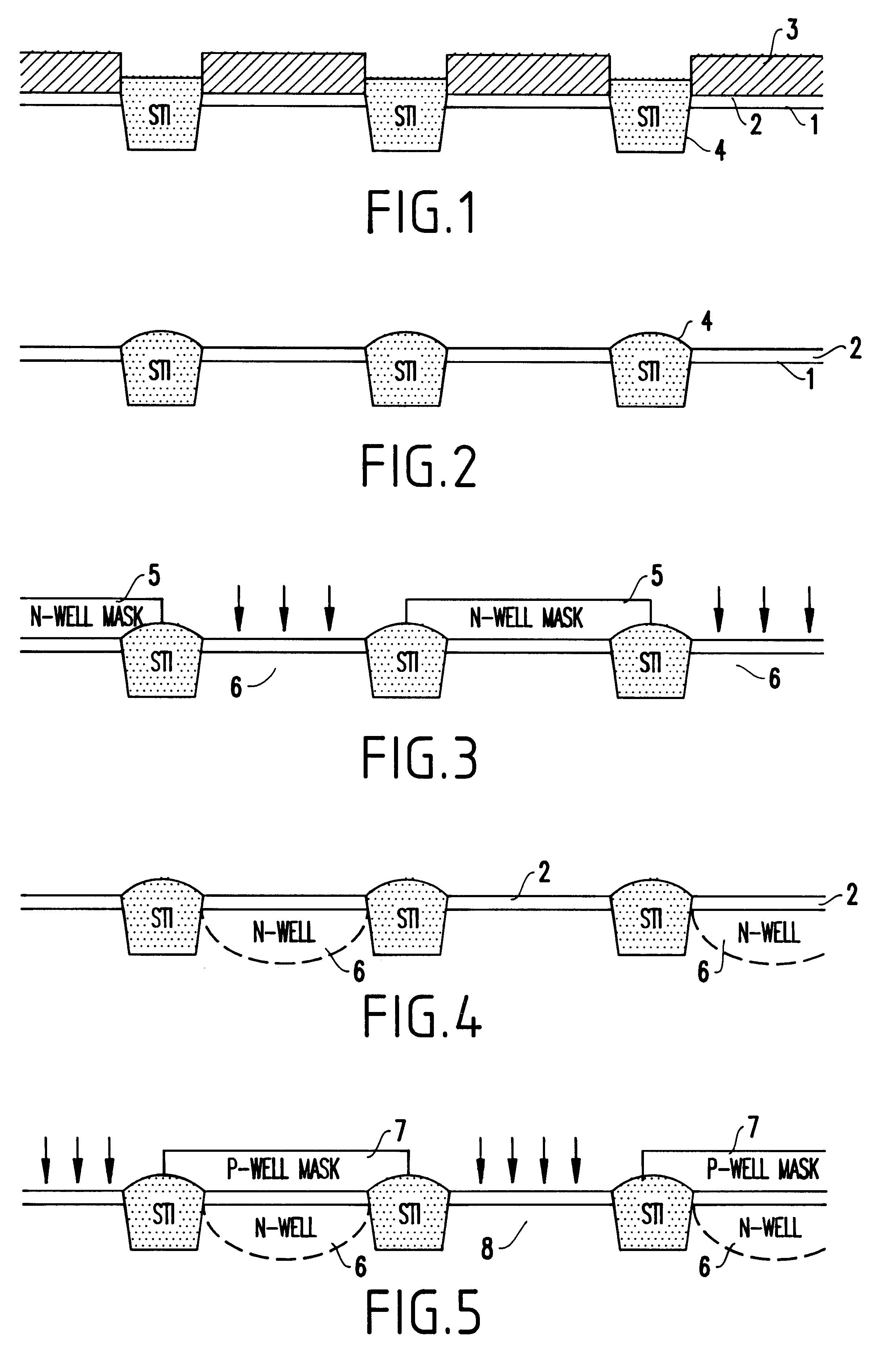

Method for eliminating transfer gate sacrificial oxide

InactiveUS20010021545A1Good seamsReduce leakageSemiconductor/solid-state device manufacturingSemiconductor devicesGate oxideNitride

A method of forming a semiconductor device, includes forming a layer of oxide on a semiconductor substrate, forming a layer of silicon nitride on the oxide layer, forming isolation regions in the substrate using the oxide layer and the nitride layer, removing the silicon nitride layer, ion implanting dopant ions using the original oxide layer as a screen, into the substrate, and removing the oxide layer and forming a gate oxide layer over the substrate. Another method of forming an active area of a semiconductor device, includes using a pad oxide, remaining after removing a film layer thereover of an oxide / film mask stack, for a screen layer for well implants formed in the substrate, removing the oxide layer and forming a gate oxide over the substrate, following defining the well implants, without using a sacrificial oxide.

Owner:IBM CORP

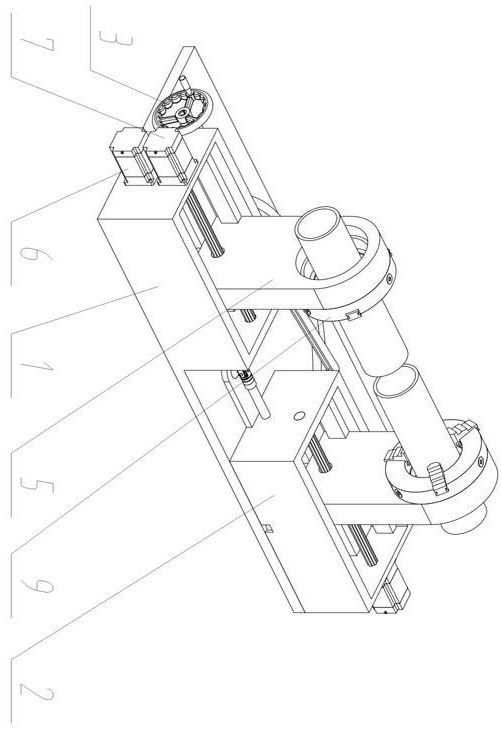

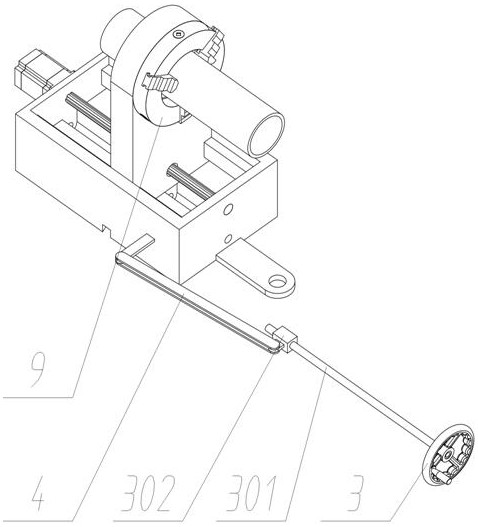

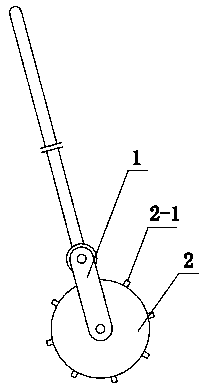

Clamp for heating and ventilation pipe welding

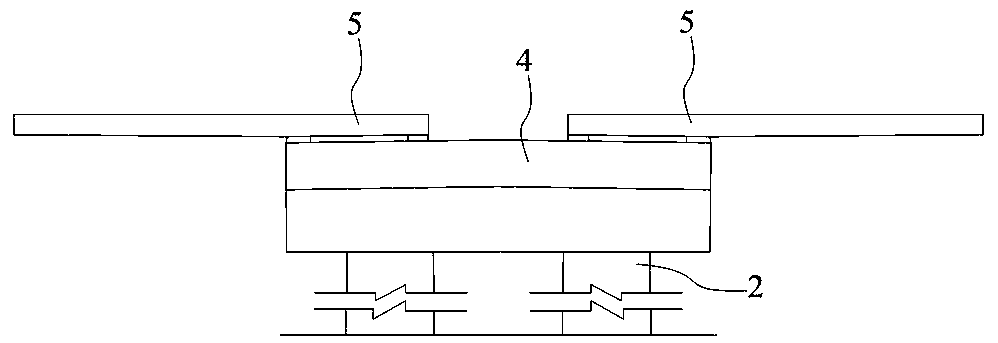

InactiveCN112388242AAdjustable installation angleRealize splicingWelding/cutting auxillary devicesAuxillary welding devicesButt jointStraight tube

The invention discloses a clamp for heating and ventilation pipe welding, and relates to the technical field of heating and ventilation production. The clamp solves the problems that operation is troublesome due to the fact that an existing pipeline welding clamp can only be used in welding of straight pipes, pipelines at other angles are difficult to clamp and weld, and meanwhile manual operationis needed during butt joint, and the welding quality is poor due to the fact that the butt joint requirement is difficult to meet due to low pipeline butt joint precision. The clamp comprises a mounting base, wherein the right side of the upper portion of the mounting base is rotationally connected with a set of swinging seats, and the upper portion of the left side of the mounting base is slidably connected with a set of seam closing sliding piece; and the rear portions of the swinging seats are hinged with a set of swinging connecting rods. According to the clamp for heating and ventilationpipe welding, automatic butt joint action on the pipelines can be achieved, meanwhile, splicing and welding between the pipelines at different mounting angles can be achieved, and the pipelines can be rotated so that the splicing angle of the pipelines can be adjusted, and the splicing precision is higher; and meanwhile, a straight pipe can be welded and rotated at the same time, so that the welding quality is guaranteed.

Owner:沙雨亭

Method for eliminating transfer gate sacrificial oxide

InactiveUS6342431B2Reduce removalGood seamsSemiconductor/solid-state device manufacturingSemiconductor devicesGate oxideNitride

Owner:INT BUSINESS MASCH CORP

Channel installation device

InactiveUS20060013649A1Efficient and accurate installationGood seamsRoof coveringBreakwatersMechanical engineeringDrain tube

A cradle assembly for installing trench drain or conduit channels which enables the channels to be suspended from support rods while simultaneously permitting the adjustment of the channel height with in the trench. Because the assembly enables the channel to be supported by the support rods while permitting adjustment of the channel height, final adjustments can be performed by a single worker.

Owner:ACO POLYMER PRODS

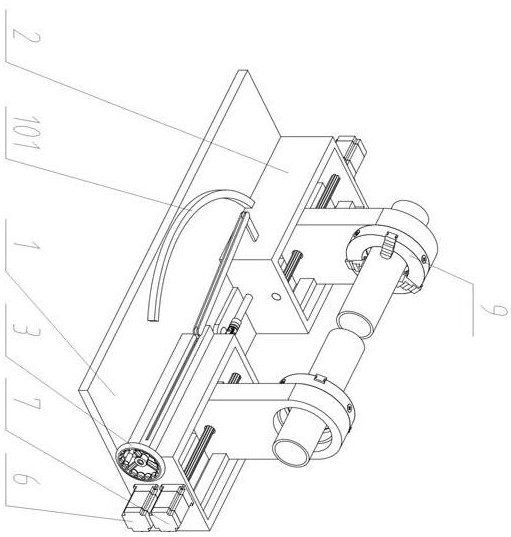

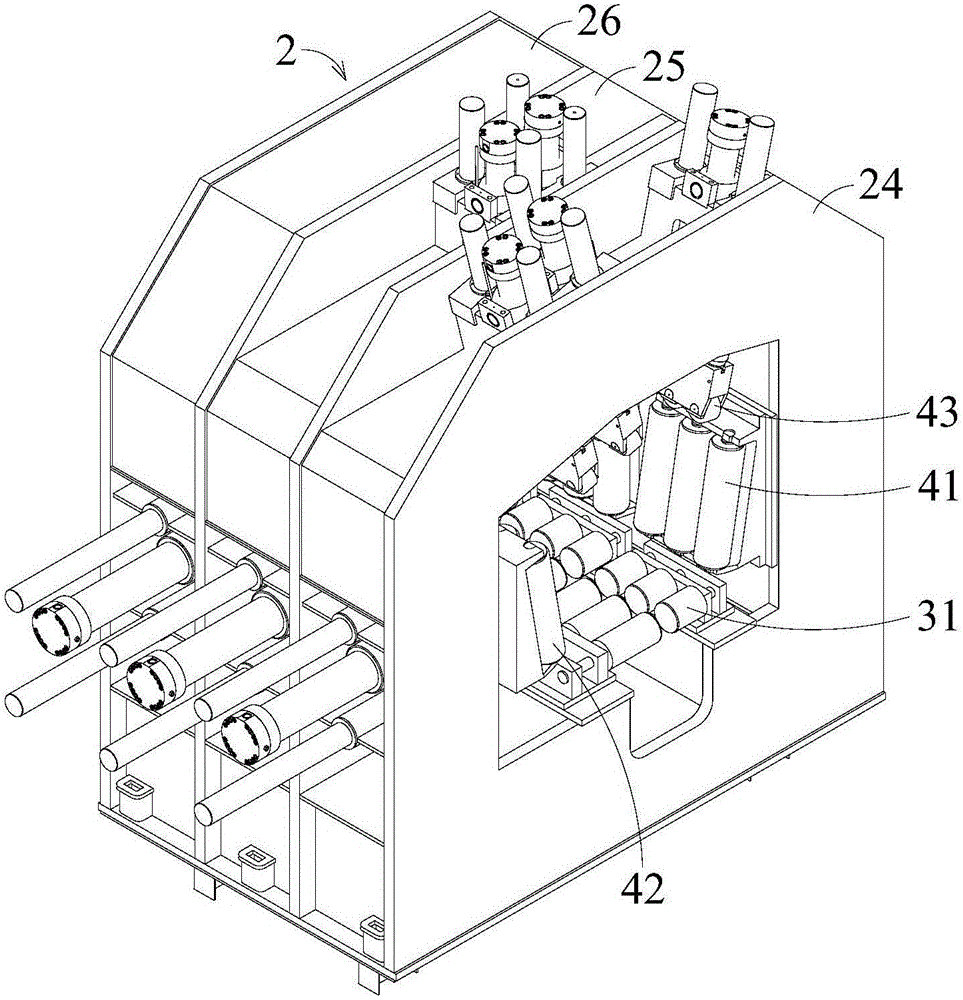

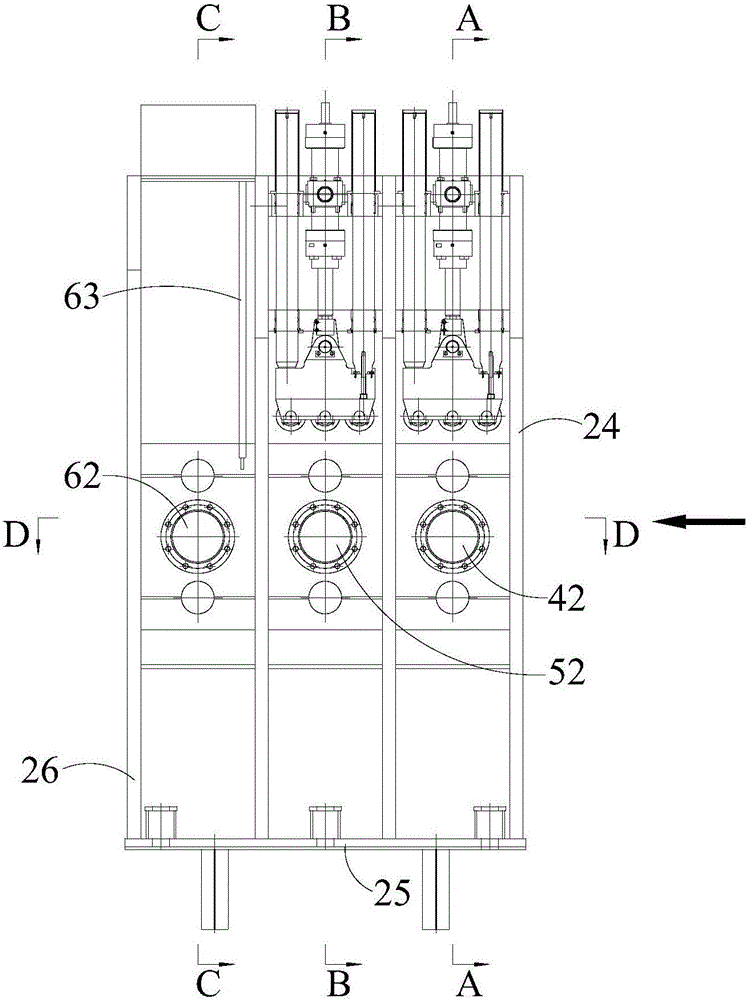

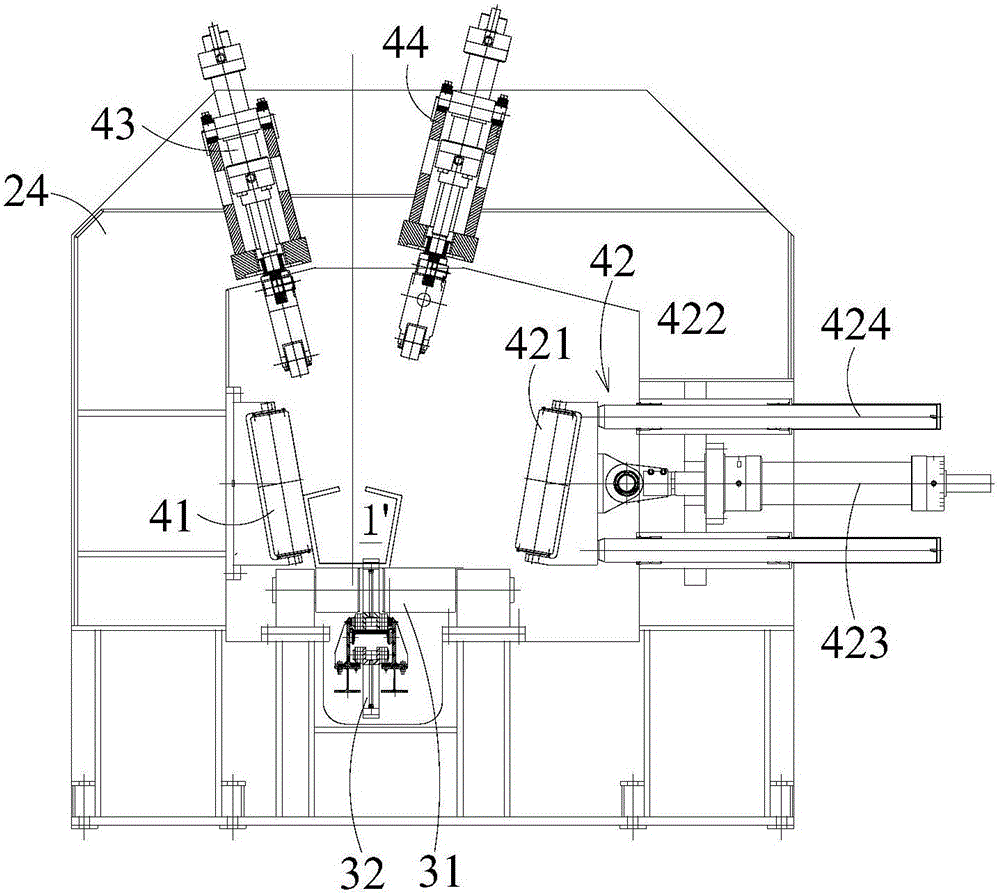

Square and rectangular tube pre-welding machine of JCO unit

ActiveCN105750776AMeet the pre-welding process requirementsReduce the bending stress pointWelding/cutting auxillary devicesOther manufacturing equipments/toolsWelding processEngineering

The invention provides a square and rectangular tube pre-welding machine of a JCO unit.The pre-welding machine comprises a rack, a supporting and conveying mechanism, a joint closing mechanism, a joint pressing mechanism and a pre-welding mechanism; the rack is sequentially provided with a joint closing frame, a joint pressing frame and a pre-welding frame in a first direction; the supporting and conveying mechanism is arranged in the rack in a penetrating mode so as to support and convey tube blanks; the joint closing mechanism is arranged in the joint closing frame and located above the supporting and conveying mechanism so as to conduct joint closing on the tube blanks; the joint pressing mechanism is arranged in the joint pressing frame and located above the supporting and conveying mechanism so as to conduct joint pressing on the tube blanks obtained after joint closing; the pre-welding mechanism is arranged in the pre-welding frame and located above the supporting and conveying mechanism so as to pre-weld the tube blanks obtained after joint pressing into square and rectangular tubes.According to the square and rectangular tube pre-welding machine of the JCO unit, segmented functional areas are arranged, and therefore the pre-welding process requirements of the square and rectangular tubes can be met.

Owner:TAIYUAN HEAVY MACHINERY GRP ENG TECH R & D CO LTD

Wire cloth, in particular paper making wire cloth

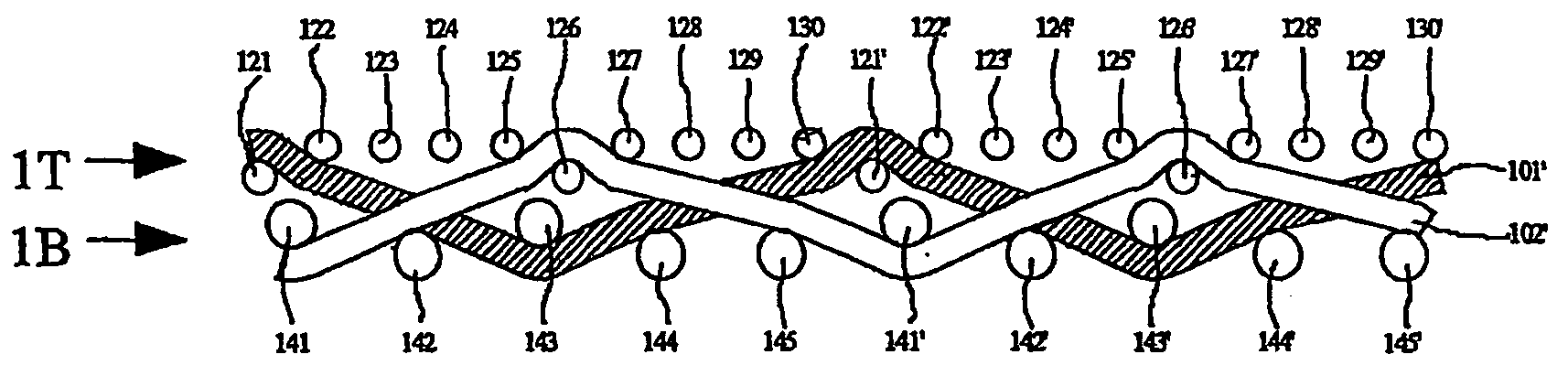

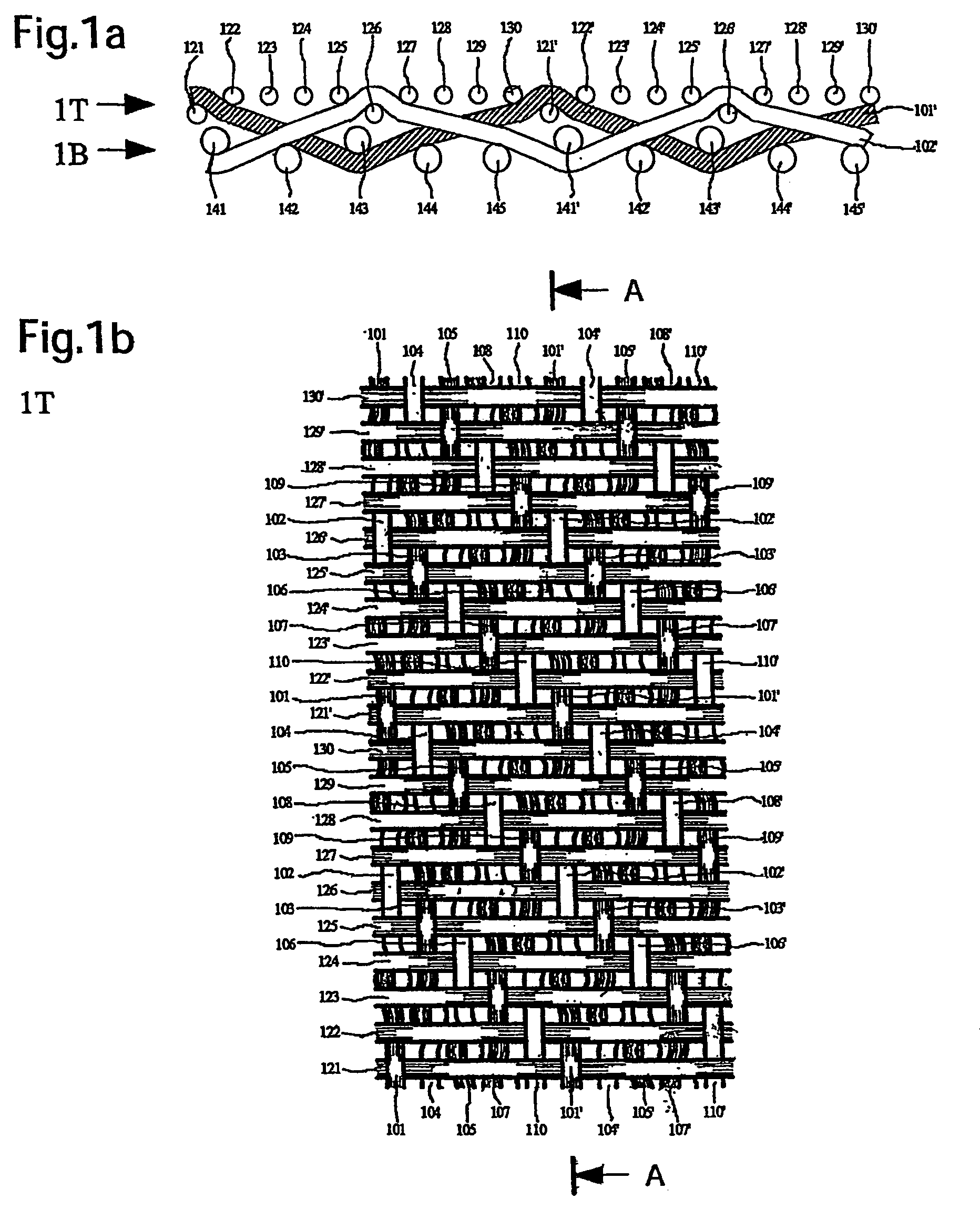

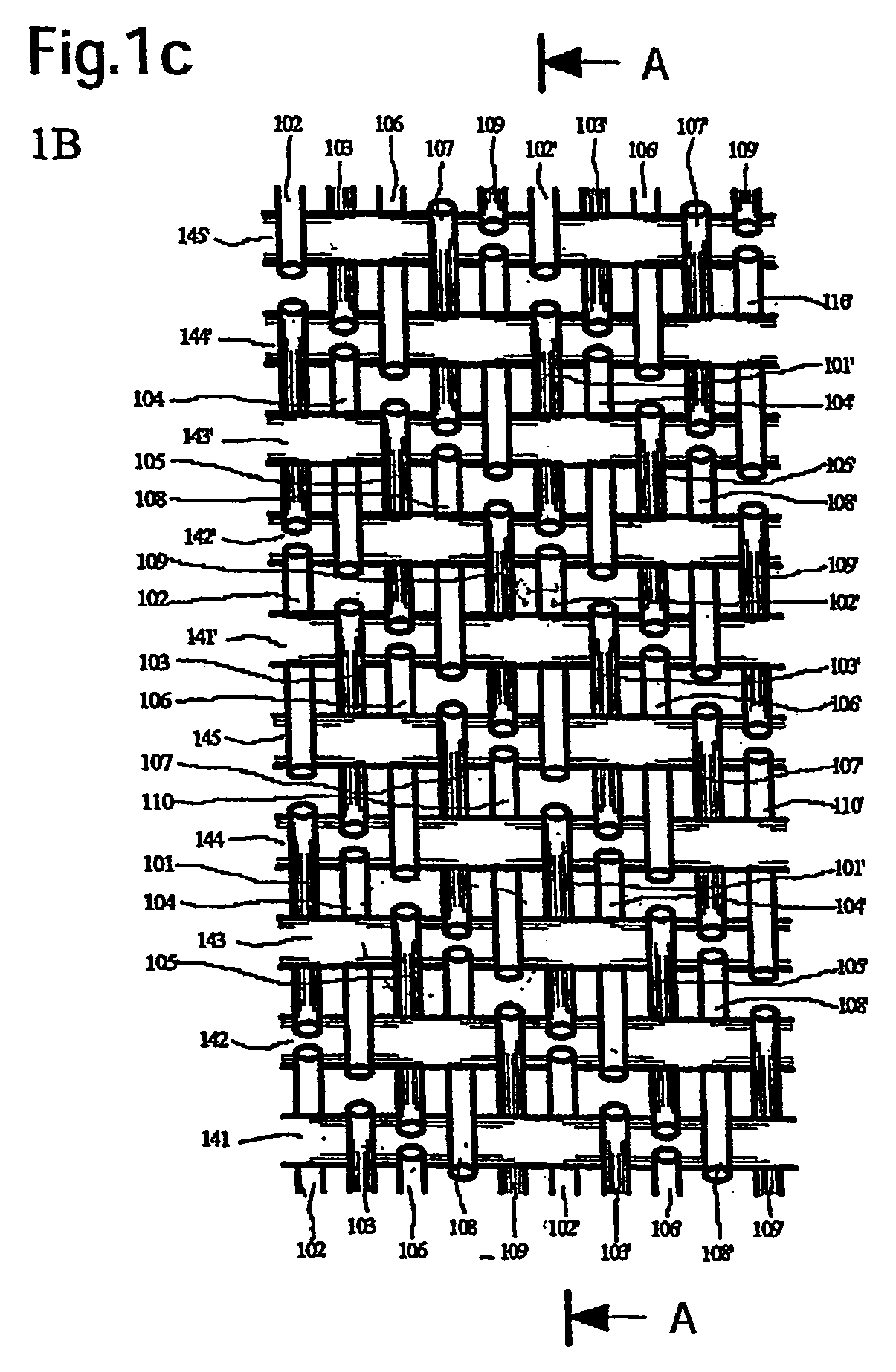

ActiveUS7585394B2Improved wire cloth designImprove dehydration effectWire networkMachine wet endEngineeringMechanical engineering

A wire cloth, in particular a paper making wire cloth, has at least two fabric layers (1B, 1T; 2B, 2T), including an upper fabric layer made of wires in the making direction (101, 110) and wires in the cross direction (121, 130), and a lower fabric layer made of wires in the making direction and wires in the cross direction (141, 145). Wire bridges are formed for the individual fabric layers in such a way that they extend over a predeterminable distance within a pattern repeat without being tied to other wires. The wire bridges of the upper cross direction wires extend within a pattern repeat over at least nine making direction wires and under maximum one making direction wire. The wire bridges of the lower cross direction wires extend within the pattern repeat at least under six and over two making direction wires. Between two making direction wires extending over a cross direction wire, at least one other making direction wire extends under the same cross direction wire.

Owner:ANDRITZ TECH & ASSET MANAGEMENT

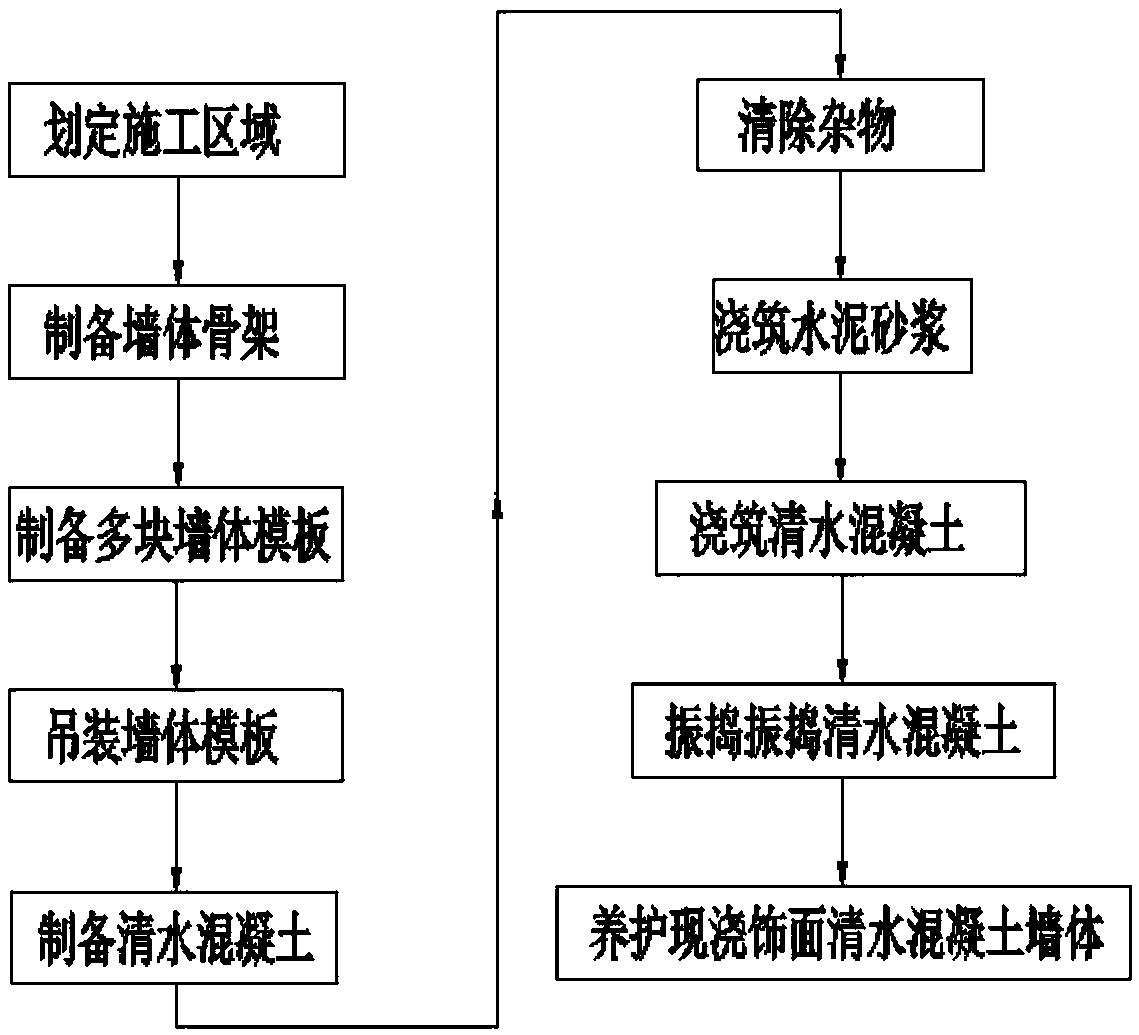

Construction method of cast-in-place decorative finish bare concrete wall

The invention provides a construction method of a cast-in-place decorative finish bare concrete wall. The construction method comprises the steps of delimiting a construction area on the ground, preparing a wall skeleton, preparing a plurality of wall formworks, hoisting the wall formworks, preparing bare concrete, removing all impurities in the wall skeleton and the wall formworks, pouring cementmortar, pouring the bare concrete into the wall skeleton several times, vibrating the bare concrete, curing the cast-in-place decorative finish bare concrete wall, and dismantling protective materials. According to the technique scheme of the construction method, the wall formworks are made from N-shaped steel beams and punched and cold bend C-shaped structural steel, the flatness of a panel is high, at same time, a plurality of wall penetrating screws are adopted, the structural strength of an existing supporting system of the wall formworks is greatly enhanced, the flatness of both sides ofa pouring wall body is effectively ensured, and compared with the prior art, the construction method has the advantages of convenient installation of the wall formworks, good quality of the pouring wall body, low cost, saving of raw materials, shortening of construction time, reduction of environmental pollution and the like.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

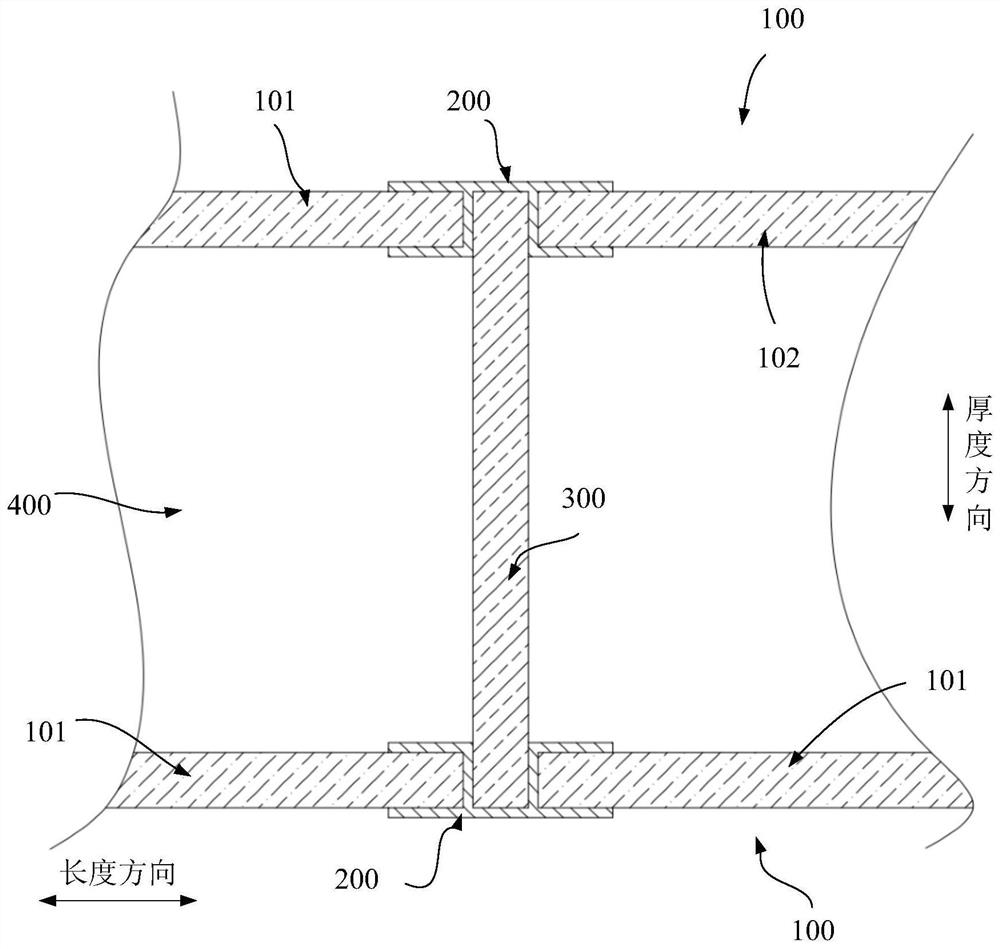

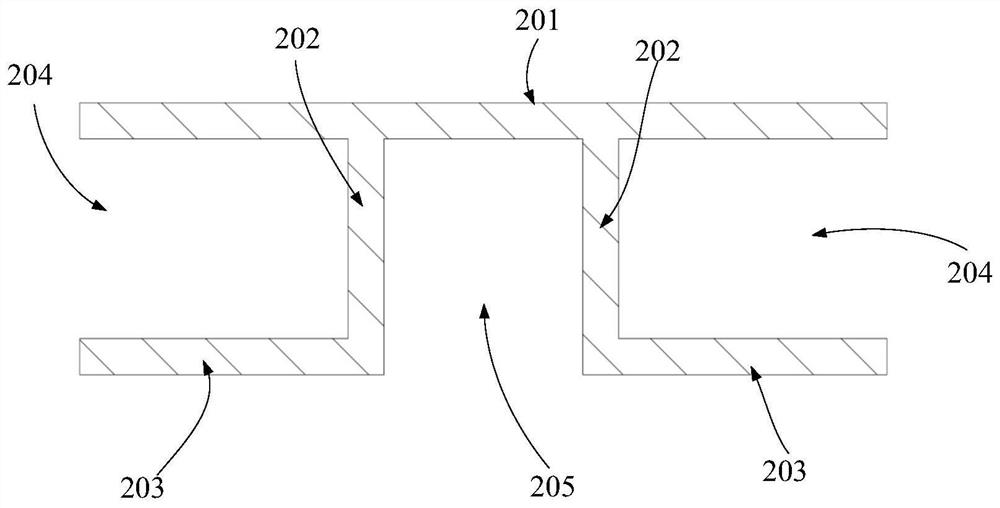

Partition wall with rib plates

ActiveCN113605572AGuaranteed StrengthGuaranteed stabilityWallsHeat proofingMechanical engineeringWall plate

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Magnesium oxysulfate decorative sheet and preparation method thereof

PendingCN109279912AImprove waterproof performanceWill not deform and softenCeramicwareFiberFoaming agent

The invention relates to a magnesium oxysulfate decorative sheet and a preparation method thereof. The raw material components and weight parts of the sheet are as follows: 50-60 parts of magnesium oxide, 50-60 parts of magnesium sulfate aqueous agent, 4-5 parts of a foaming agent, 20-25 parts of bamboo fiber, 50-60 parts of water and 0.5-1 part of a modifier. The above raw materials are subjectedto primary stirring. The magnesium oxysulfate decorative sheet is prepared by physical foaming, re-stirring, molding, curing and trimming. The invention has the advantages of high fireproof and waterproof performance, strong nail holding force, no shrinkage, unfavorable cracking of the joint part and no easy folding.

Owner:BLUETOP JIANGSU NEW MATERIAL

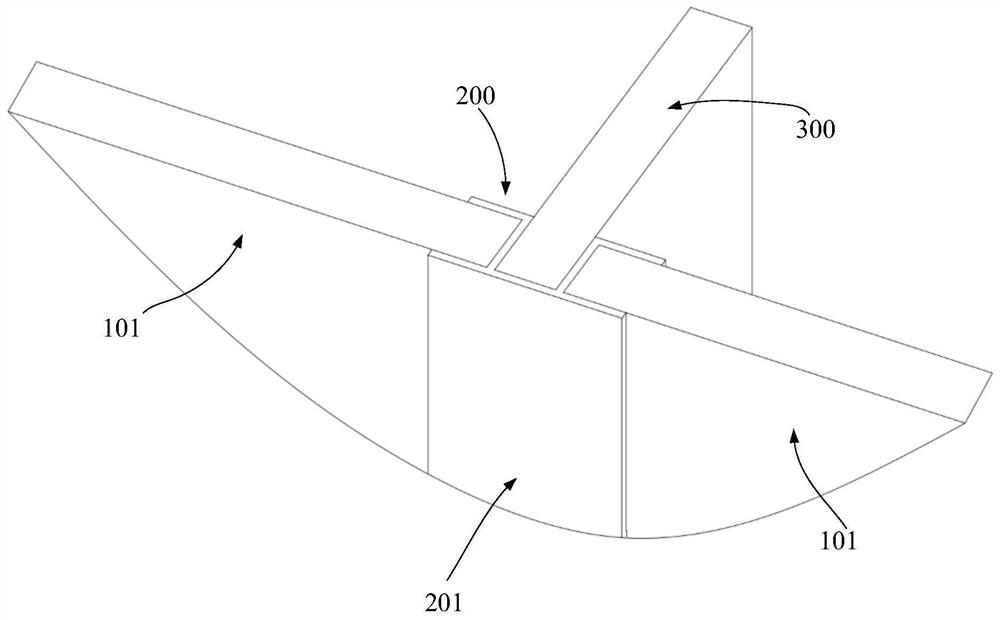

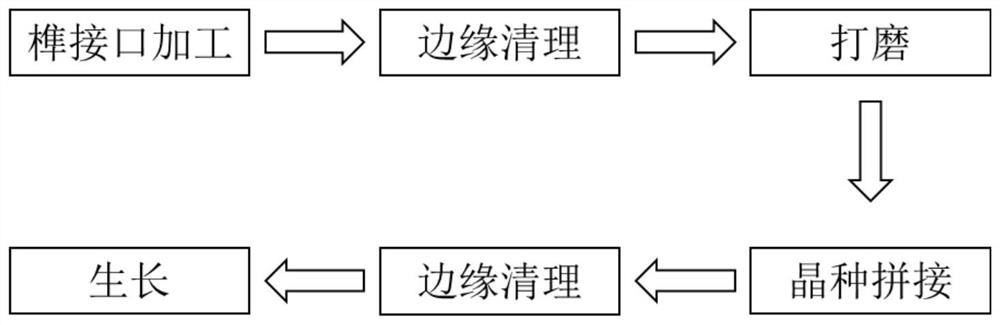

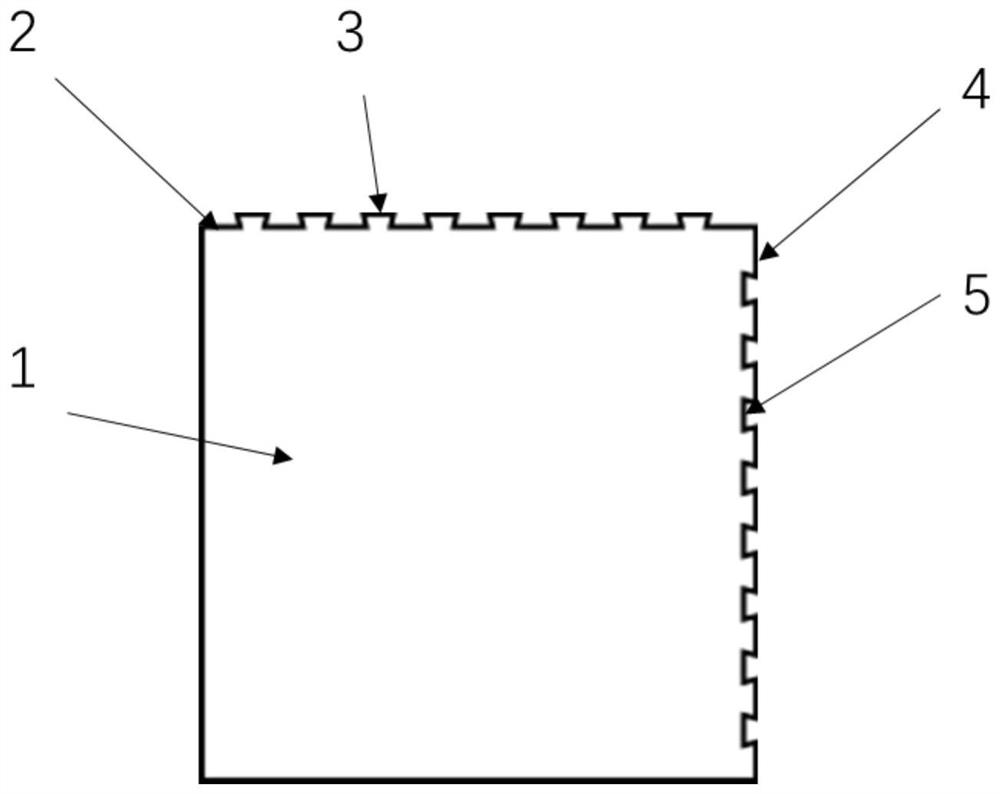

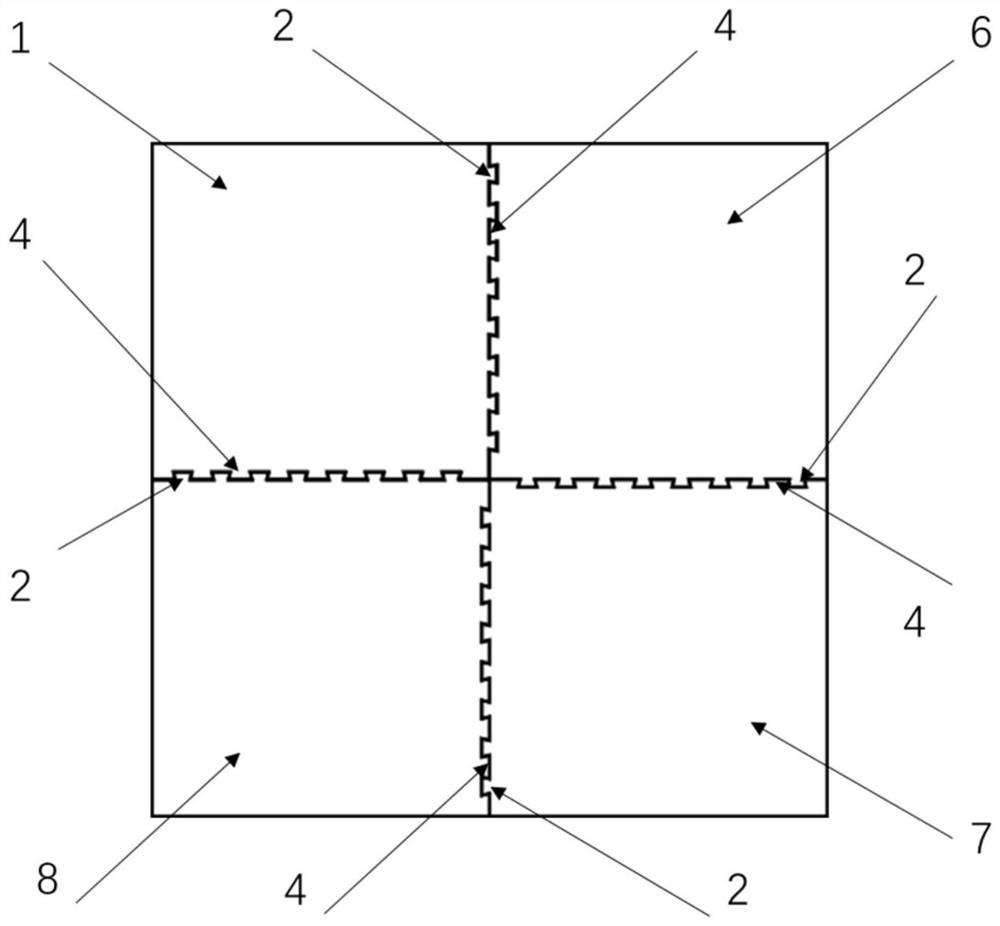

Splicing growth process for large-size monocrystalline diamond

PendingCN112391680AReduce gapImprove growth performancePolycrystalline material growthAfter-treatment detailsMicrowave plasma chemical vapor depositionCondensed matter physics

The invention discloses a splicing growth process for large-size single crystal diamond, and is suitable for epitaxial growth of single crystal diamonds by a microwave plasma chemical vapor deposition(MPCVD) method. The process comprises the following steps of: 1, processing the edges of seed crystal sheets of the single crystal diamonds to be in a tenon joint shape; 2, cleaning an edge interface. 3, carrying out double-sided polishing on the plurality of spliced seed crystals to reduce the height difference. 4, splicing the diamond seed crystals of which the edges are tenon-joint-shaped. 5,growing the spliced and polished crystal seeds of the polished diamond by adopting an MPCVD method. According to the process, through a micron-sized joggle joint gap technology, stress relaxation in the growth process of the monocrystal diamond is achieved, and the growth effect is improved. Splicing growth of the large-size single crystal diamond is achieved through joggling, edge treatment, height difference treatment and other processes, the large-size single crystal diamond obtained through the method has the advantages of being high in flatness, small in splicing part stress and the like,and the high-quality and large-size single crystal diamond can be obtained.

Owner:物生生物科技(北京)有限公司

Quick assembling-disassembling plastic building angle adjustable formwork

InactiveCN103526924ASave resourcesSplicing shortcutForms/shuttering/falseworksForm treatmentClassical mechanicsEngineering

Owner:李德福

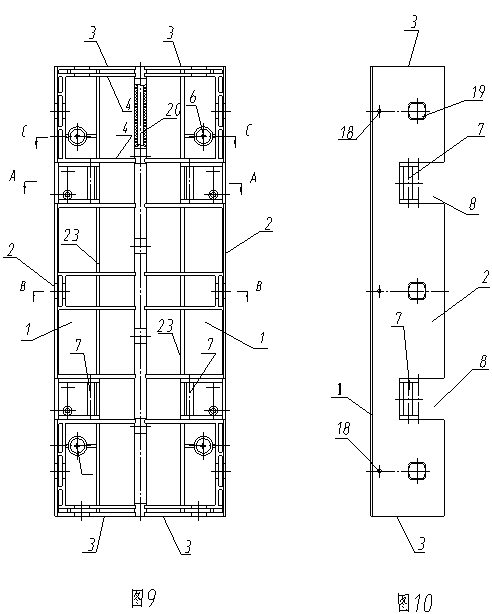

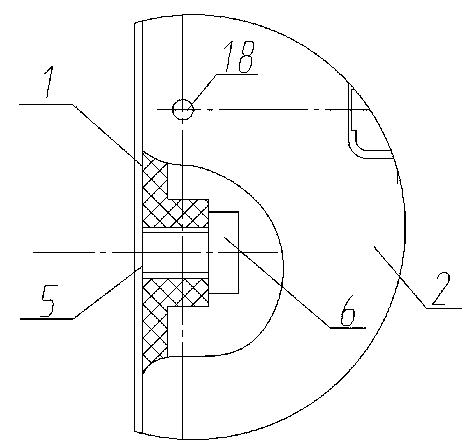

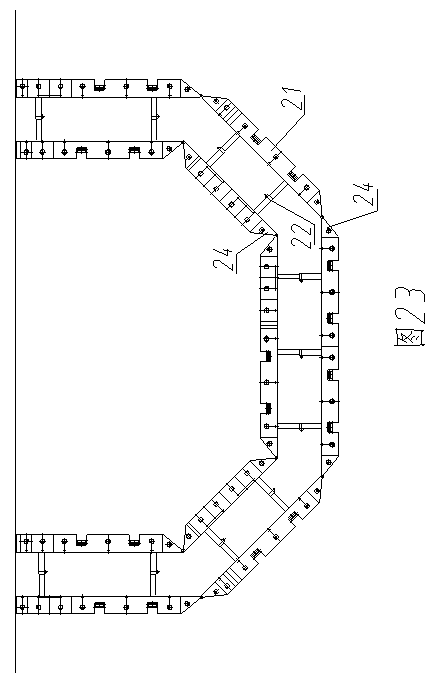

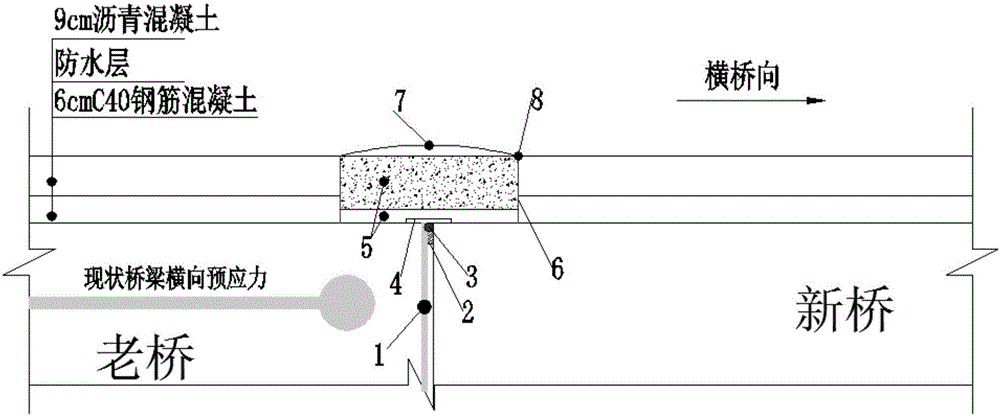

Construction method for longitudinally and flexibly splicing newly-built bridge and current bridge

The invention belongs to the technical field of road bridge construction and relates to a construction method for longitudinally and flexibly splicing a newly-built bridge and a current bridge. The construction method comprises the steps of re-measurement and checking, horizontal and vertical current bridge cutting, asphalt laying, splicing construction, slot bottom processing, waterproof treatment, GD elastic concrete paving and casting, rolling compaction and surface treatment. The construction method has the advantages that normal use of a prestressing system and the integrity of splicing joint structure size of the current bridge are ensured; sudden change of elevation difference is eliminated, the running comfort is improved, and the noise volume of each vehicle passing through splicing joints is reduced; rainwater infiltration is effectively prevented, and the structure durability is improved; the surface roughness of GD elastic concrete is improved; small construction operation surface and uninterrupted traffic can be achieved, the method is easy and quick, a splicing effect is good, the operation and maintenance costs are low, a construction period is short, and opening to traffic can be achieved after 2 hours after construction is completed; the operation is simple, and repair is convenient.

Owner:SINOHYDRO BUREAU 11 CO LTD

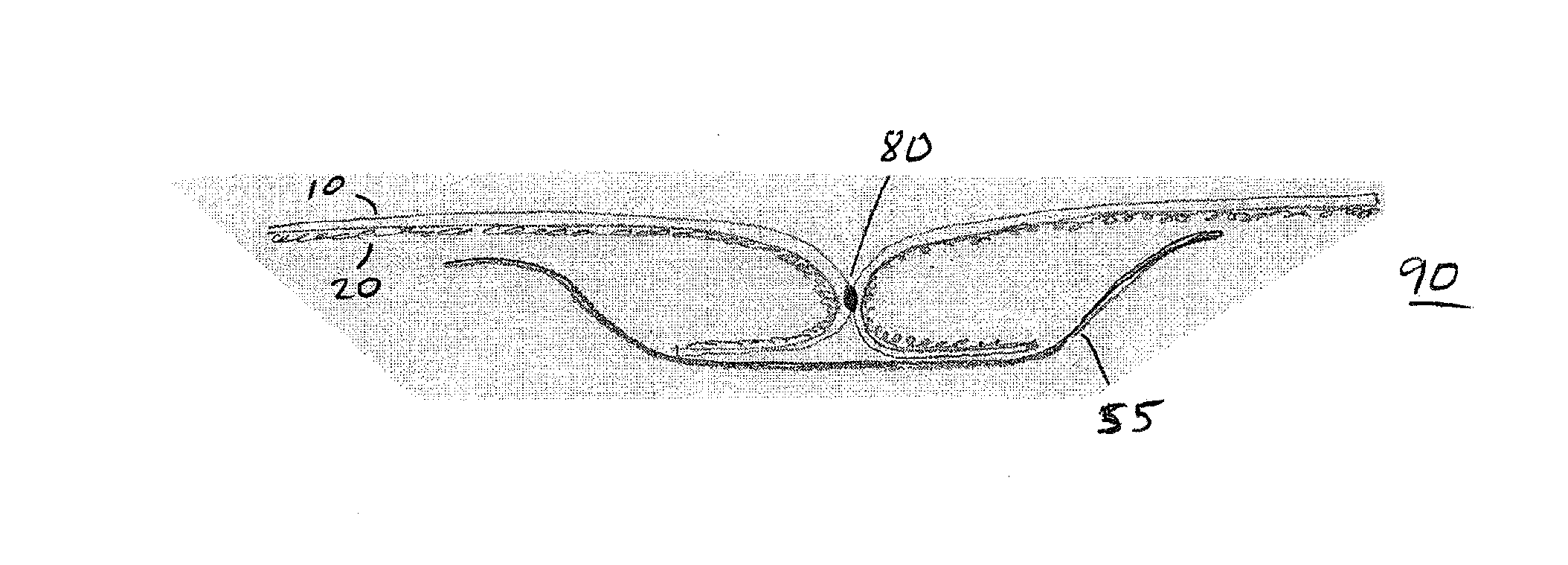

Waterproof garment with invisible barrier seam

InactiveUS9981448B2More appearanceMore flexibleDomestic upholsteryGarmentsMechanical engineeringEngineering

Owner:COHESIVE SYST

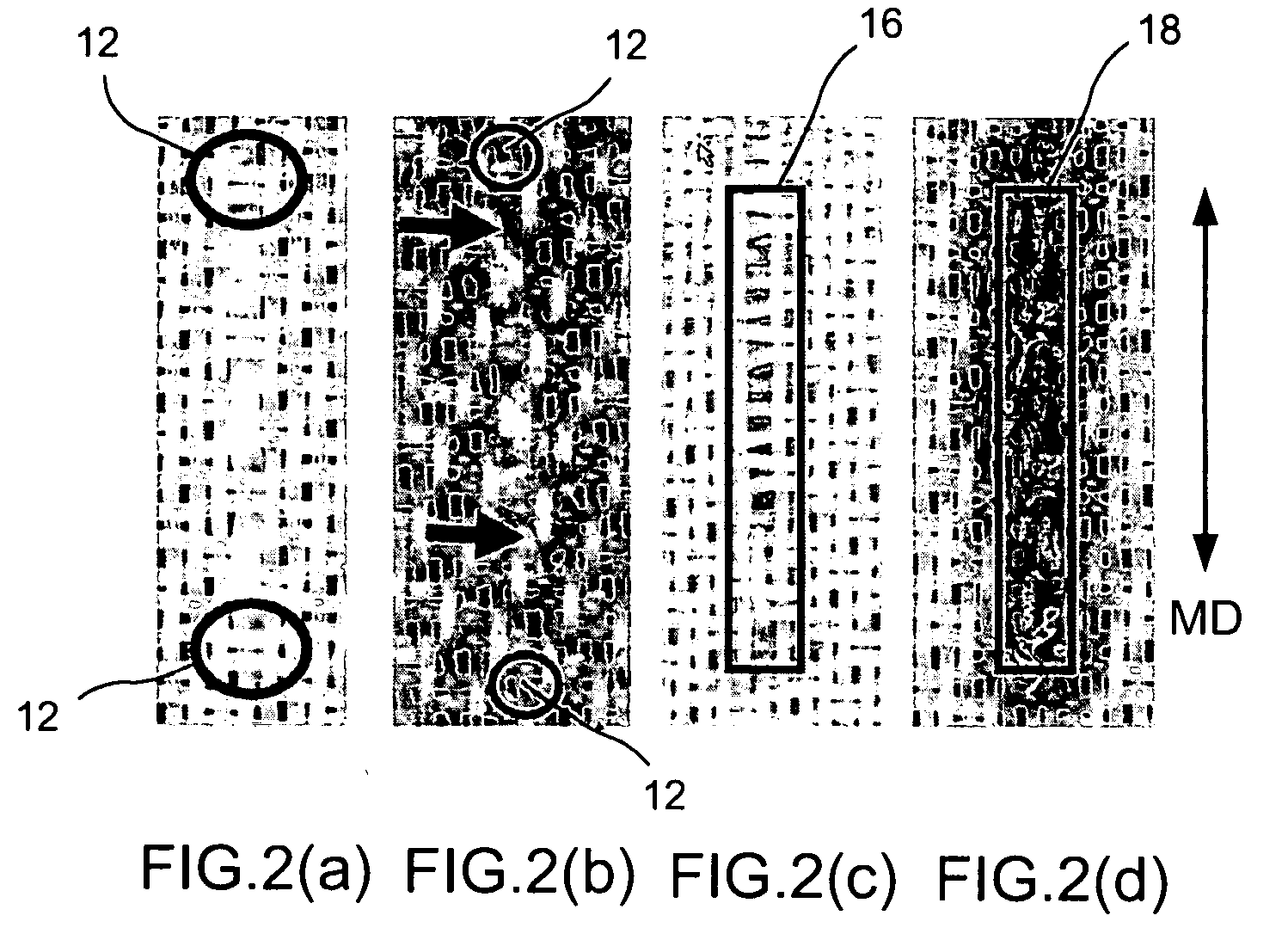

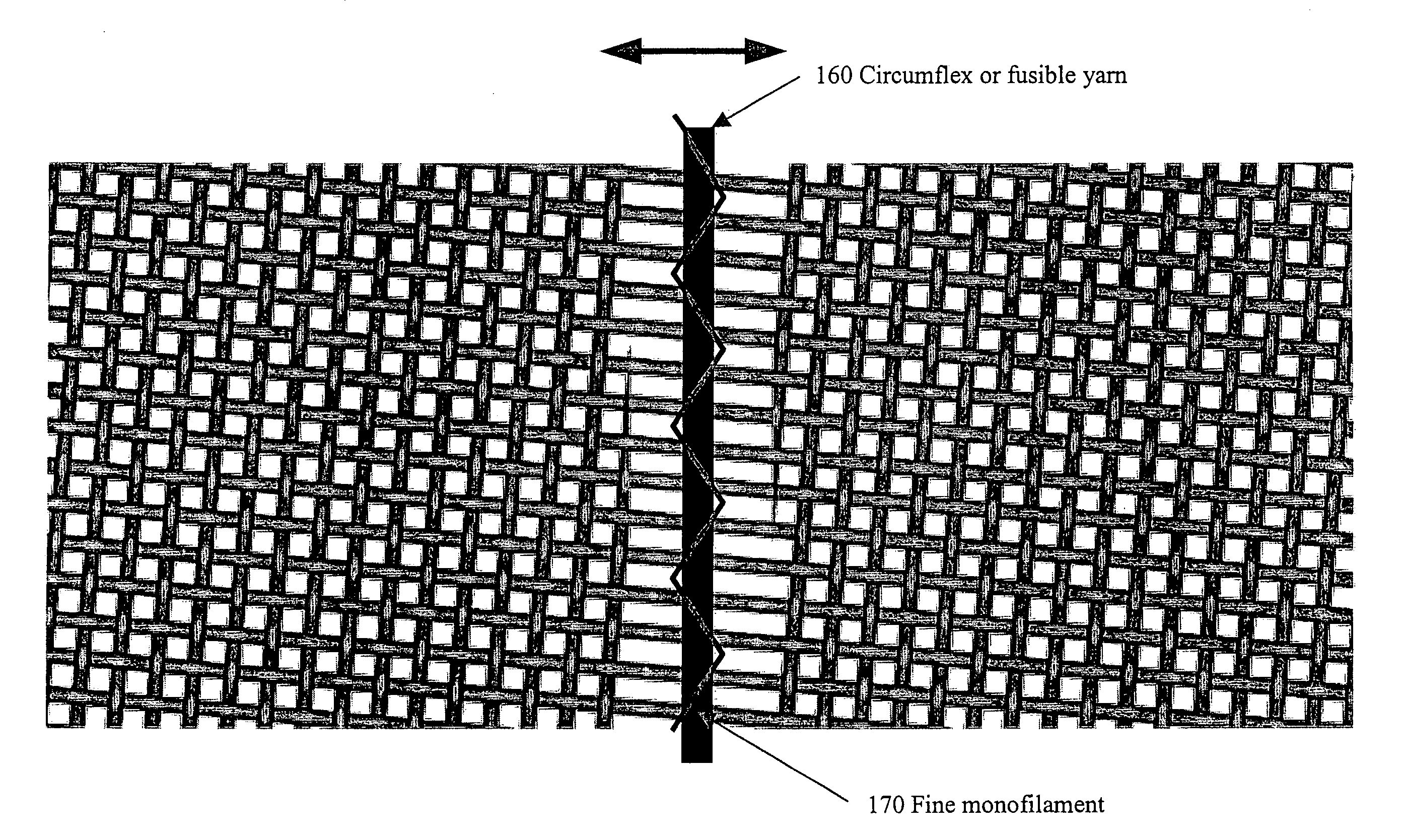

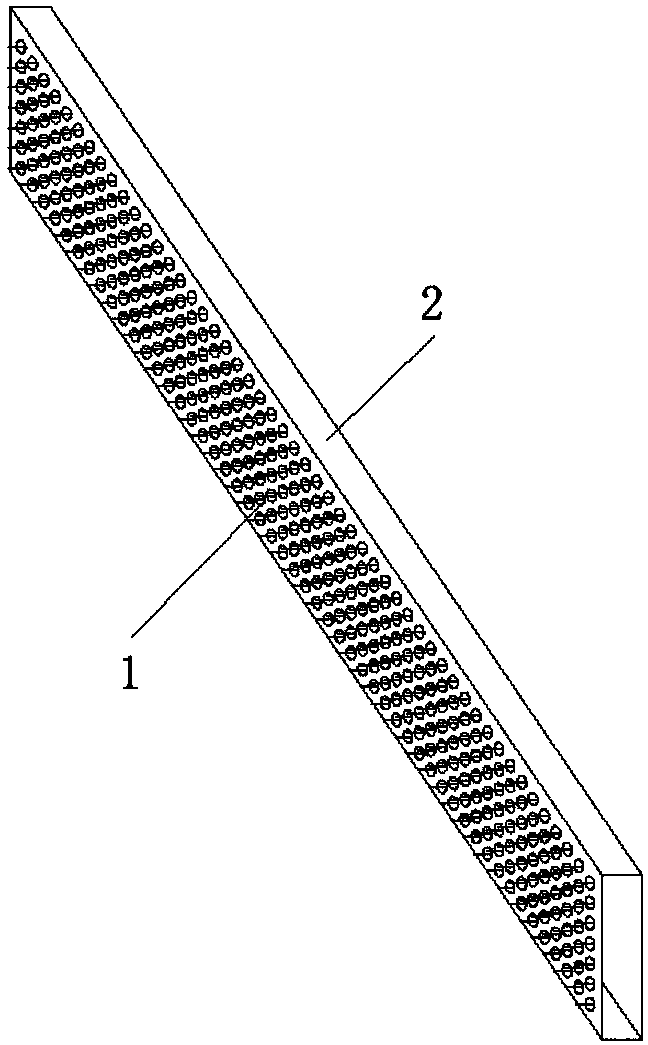

Seam for multiaxial papermaking fabrics

A method of seaming an on-machine-seamable multiaxial papermaker's fabric to prevent yarn migration. The multiaxial fabric is in the form of an endless loop flattened into two layers along fold lines. CD yarns are removed from the folds to create extended ravel areas. This leaves the MD yarns unbound in the ravel areas. Seam loops are then formed from the unbound MD yarns at the folds. CD materials (e.g. continuous CD yarns) are affixed to (rewoven into) the fabric along the edges of the ravel area at each fold. The affixed CD materials bind the CD yarn tails along the edges of the ravel areas to prevent migration of CD yarn tails into the seam area.

Owner:ALBANY INT CORP

Continuous construction method for fibers at joint of concrete structure

InactiveCN108589939AImproved Seam PerformanceReduce project costBuilding material handlingBuilding insulationsSteel platesComplex joint

The invention discloses a continuous construction method for fibers at a joint of a concrete structure. The continuous construction method comprises the steps that thin holes are formed at designed intervals in a formwork at a joint of first-poured concrete, the fibers with certain lengths are inserted into unset concrete through the thin holes after the first-poured concrete is poured and beforethe concrete near the joint is initially set, and after the concrete is hardened and the formwork at the joint is removed, the remaining fibers, with certain lengths, which are not inserted into the concrete are exposed outside the surface of the concrete joint; and when concrete on the other side of the joint is poured again, the fibers are connected between the concrete which is poured by two times to enable the fibers to be continuous at the joint of the concrete which is poured separately. The continuous construction method for the fibers at the joint of the concrete structure fundamentally solves the problem of discontinuity of fibers at the joint of the concrete structure, and it is not necessary to improve joint performance by the complex joint forms such as changing the joint shape, densifying reinforcements or adopting a special-shaped steel plate. The continuous construction method for fibers at the joint of the concrete structure has low engineering cost, convenient construction, material saving, excellent structure performance, and good prospect of popularization.

Owner:FUZHOU UNIVERSITY

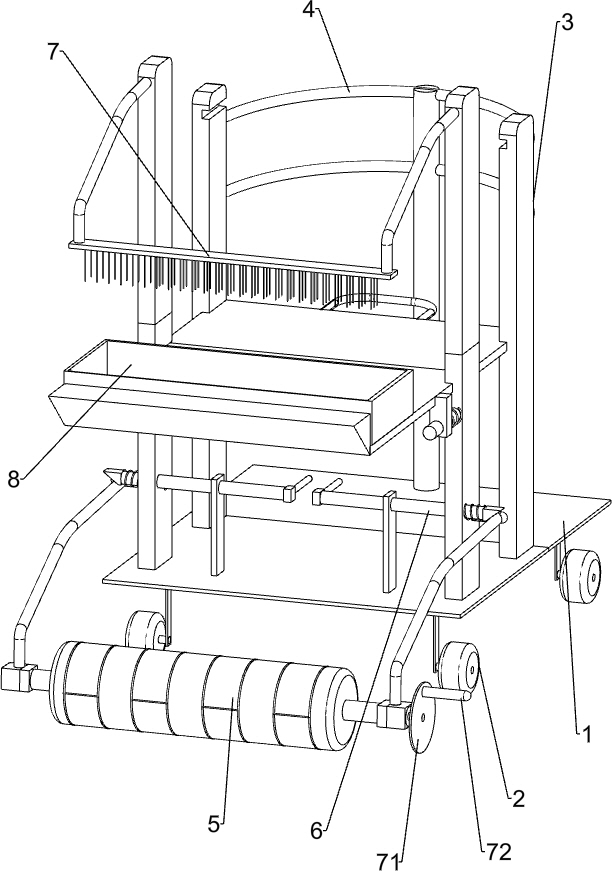

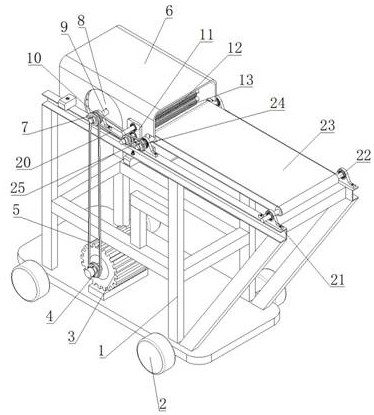

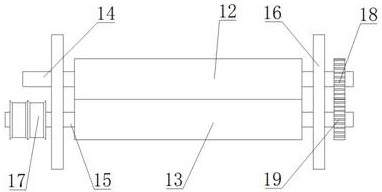

Road surface indentation equipment for road construction

ActiveCN111945534AGood seamsClean up in timeClimate change adaptationDirt cleaningArchitectural engineeringStructural engineering

The invention relates to road construction equipment, in particular to road surface indentation equipment for road construction. The technical problem to be solved by the invention is to provide the road surface indentation equipment for road construction, which is relatively small in labor force, not easy to fatigue after long-time work and high in working efficiency. In order to solve the technical problem, the road surface indentation equipment for road construction provided by the invention comprises a placing plate, wherein the bottom of the placing plate is connected with wheels; a bracket which is connected to the placing plate; a first handle which is connected to one end of the placing plate and is connected with one side of the support; and a seam pressing assembly which is connected to one side of the bottom of the support, and the limiting assembly is connected to the support. The road surface indentation equipment has the advantages that the creasing equipment is moved bypushing the first handle to be matched with the wheels, a road is crewed under the action of the creasing assembly, and a worker can easily perform creasing on the road.

Owner:南联建设集团有限公司

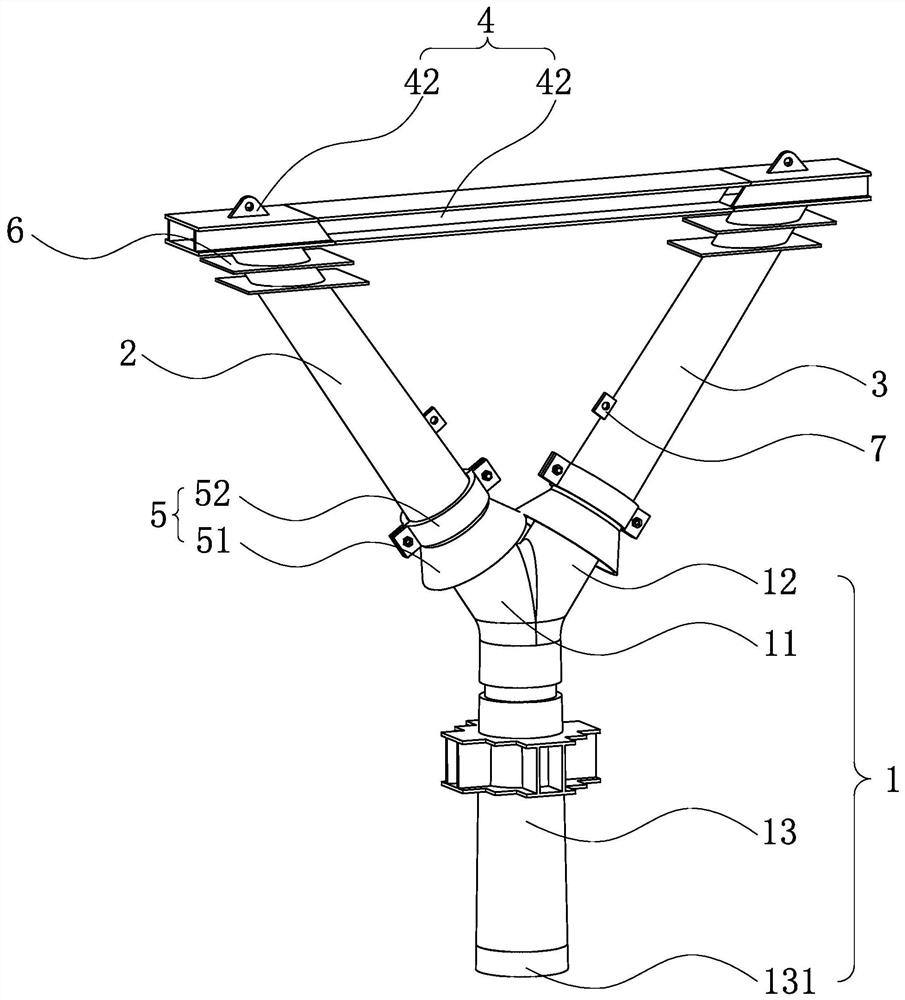

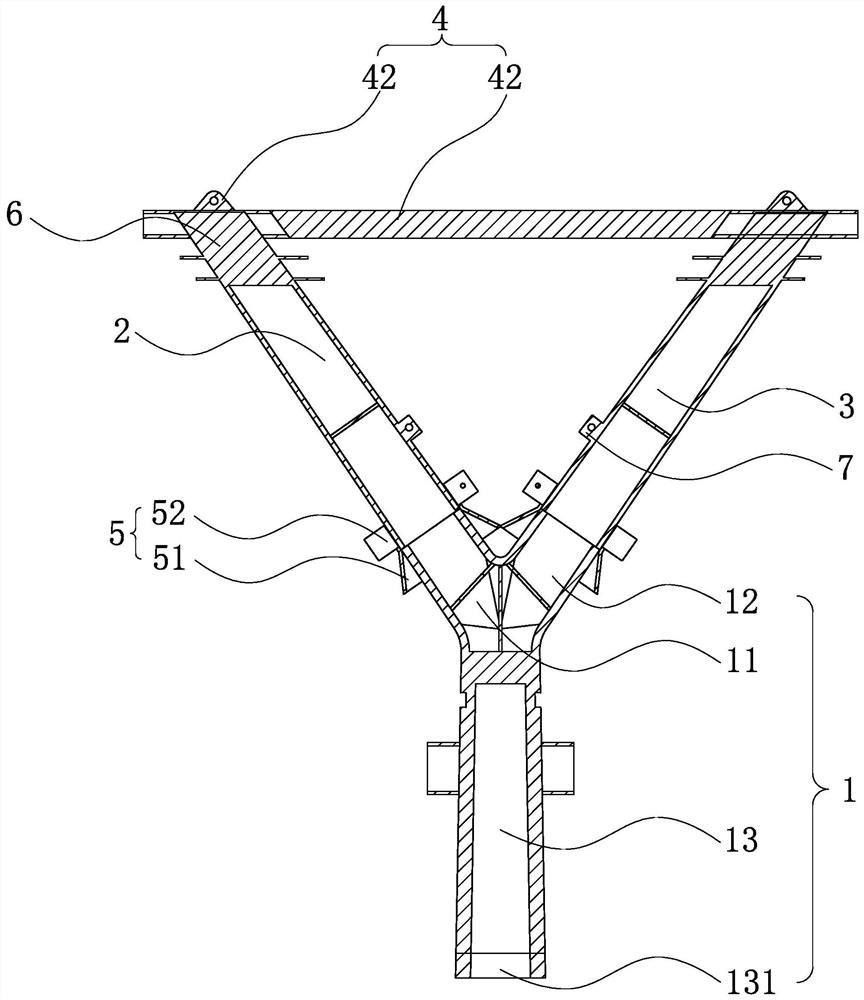

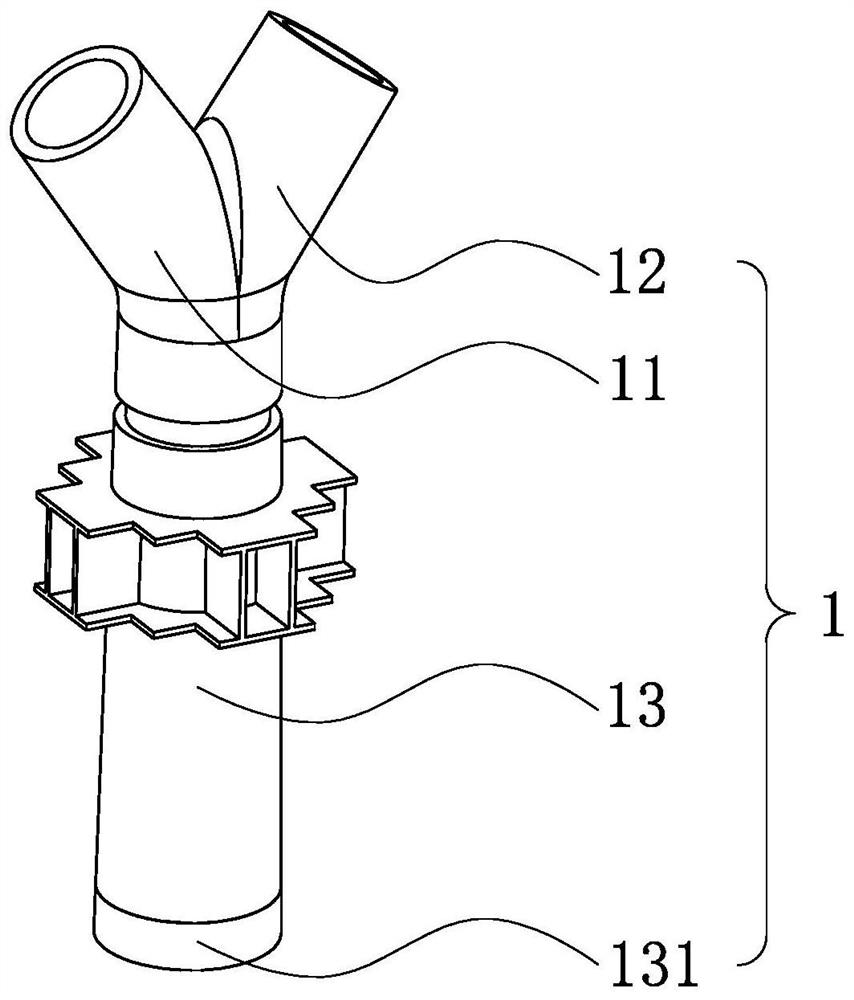

Y-shaped cast steel column and hoisting method thereof

PendingCN113800394AReduce the difficulty of hoisting constructionIncrease contact areaArtificial islandsStrutsSteel tubeSteel columns

The invention relates to a Y-shaped cast steel column and a hoisting method thereof, and belongs to the technical field of cast steel columns and hoisting methods thereof. The Y-shaped cast steel column comprises a three-way pipe arranged on a steel pipe pile, a first branch connected with the three-way pipe, a second branch connected with the three-way pipe and a straining beam; one end of the straining beam is connected with one end, far away from the three-way pipe, of the first branch, and the other end of the straining beam is connected with one end, far away from the three-way pipe, of the second branch. The Y-shaped cast steel column has the advantage of being convenient to hoist.

Owner:北钢建设集团股份有限公司

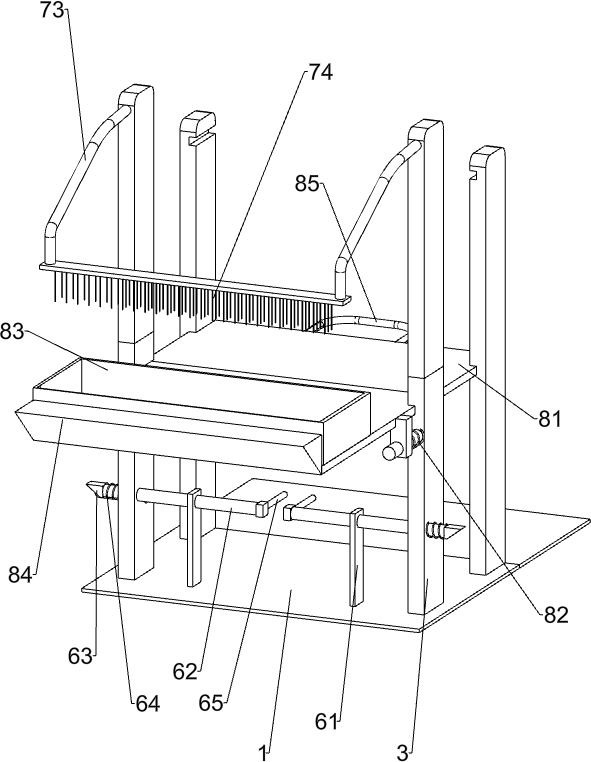

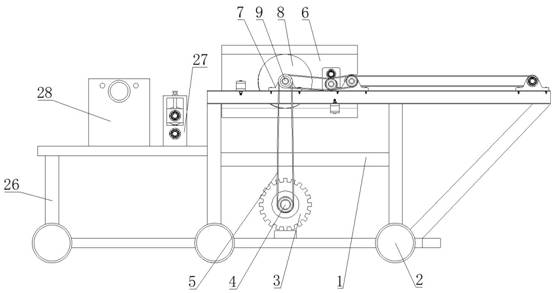

Intelligent cloth sewing processing equipment for electric blanket tippet and working method of intelligent cloth sewing processing equipment

ActiveCN112501799APlay the role of heating and ironingImprove seam qualityProgramme-controlled sewing machinesSewing-machine casingsElectric machineryProcess engineering

The invention discloses intelligent cloth sewing processing equipment for an electric blanket tippet. A plurality of sets of movable trundles are installed at the bottom of a conveying rack, a first motor is fixedly installed on the conveying rack, a first belt wheel is fixedly connected to an output shaft of the first motor, an electric heating pipe is arranged in a heating roller, first connecting shafts are fixedly arranged on two sides of the heating roller correspondingly, two sets of first plummer blocks are fixedly installed on the conveying rack, and the two sets of first connecting shafts are connected to inner rings of the two sets of first plummer blocks correspondingly. According to the equipment and the working method thereof, the cloth is automatically conveyed, the manual operation is effectively saved, the sewing efficiency is improved, the cloth is heated, ironed and leveled before cloth sewing processing, the sewing quality of the cloth is effectively improved, a sewing cover is driven to reciprocate in a horizontal direction through transmission and separation of a lead screw, and sewing processing can be conducted on different positions of the cloth conveniently.

Owner:浙江肯特科技股份有限公司

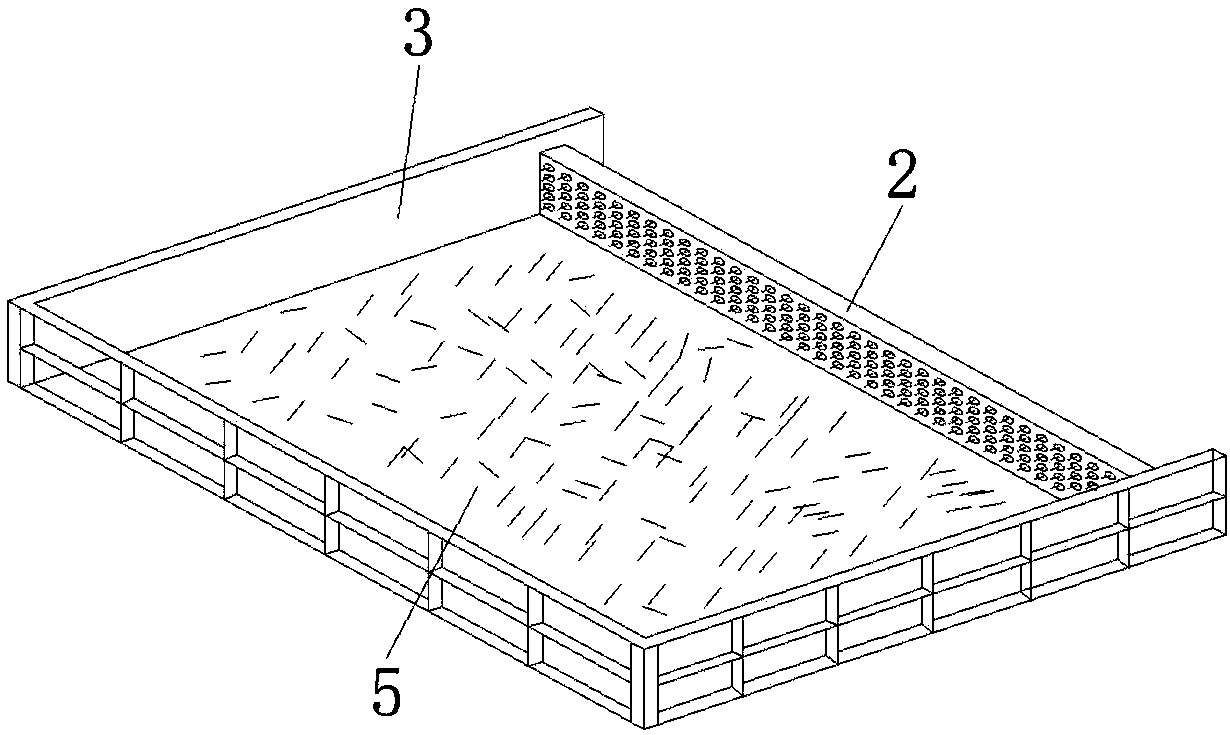

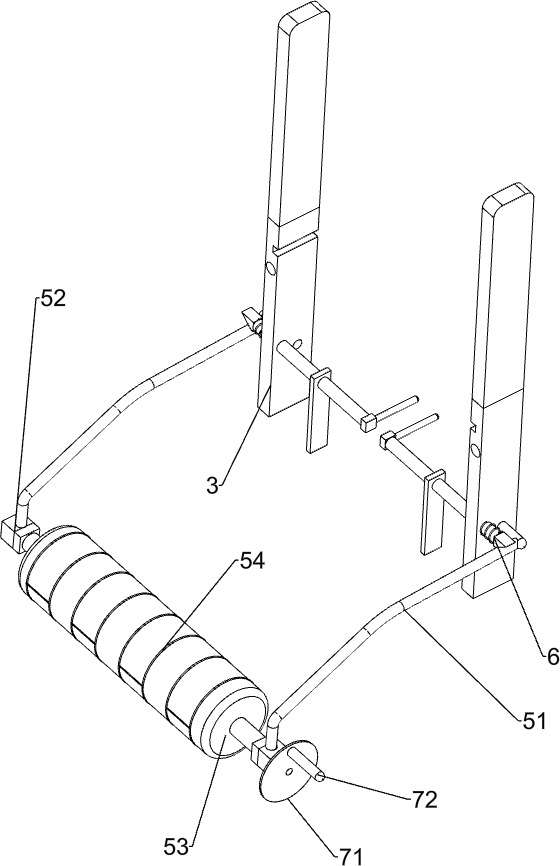

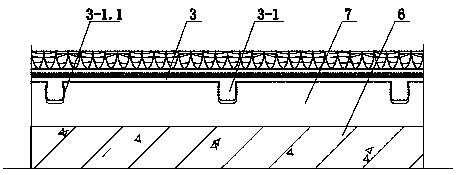

Adhesive-free carpet tile installation construction method and device used and carpet tile structure

The invention discloses an adhesive-free carpet tile installation construction method and device used and a carpet tile structure. The problems of forming of blind holes in carpet tile installation ground, a device used for forming and the structure of adhesive-free carpet tiles are solved. The adhesive-free carpet tile installation construction method comprises the steps that a leveling installation layer is arranged on the ground, the blind holes regularly formed are rolled out after the initial setting of the leveling installation layer, and the carpet tiles are sequentially mounted and fixed to the blind holes. The device used includes a machine frame and a forming press roller, blind hole forming protrusions are regularly arranged on the outer circumference of the forming press roller, and the forming roller is slidably supported on the machine frame. The carpet tile structure comprises a carpet and a mounting fixing layer, a set of elastic protrusions is regularly arranged on thebottom surface of the mounting fixing layer, the carpet is the same size as the mounting fixing layer, and a bottom cloth of the carpet is in press fit with the mounting fixing layer to form an integrated body. The adhesive-free carpet tile installation construction method and the device used and the carpet tile structure have the beneficial effects that an adhesive is not required for fixing, material cost is reduced, the release of harmful substances of the adhesive is overcome, pollution is not produced during construction, simplicity, speediness and convenience are achieved, work efficiency is high, construction period and labor cost are saved, non-destructive disassembly and assembly functions are achieved, the carpet can be reused.

Owner:SHENZHEN RUIHE CONSTR DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com