Road surface indentation equipment for road construction

A road construction and indentation technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of small labor force, large labor force, easy fatigue, etc., and achieve the effect of beautiful appearance, long life and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

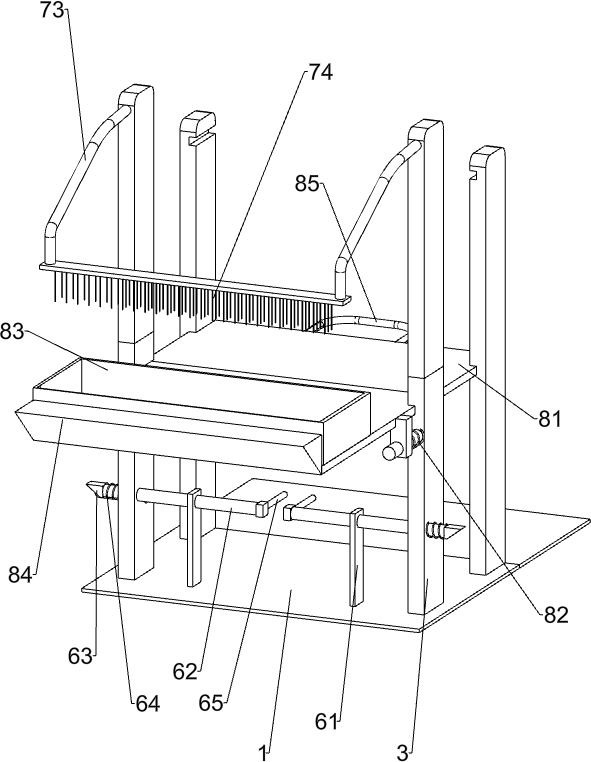

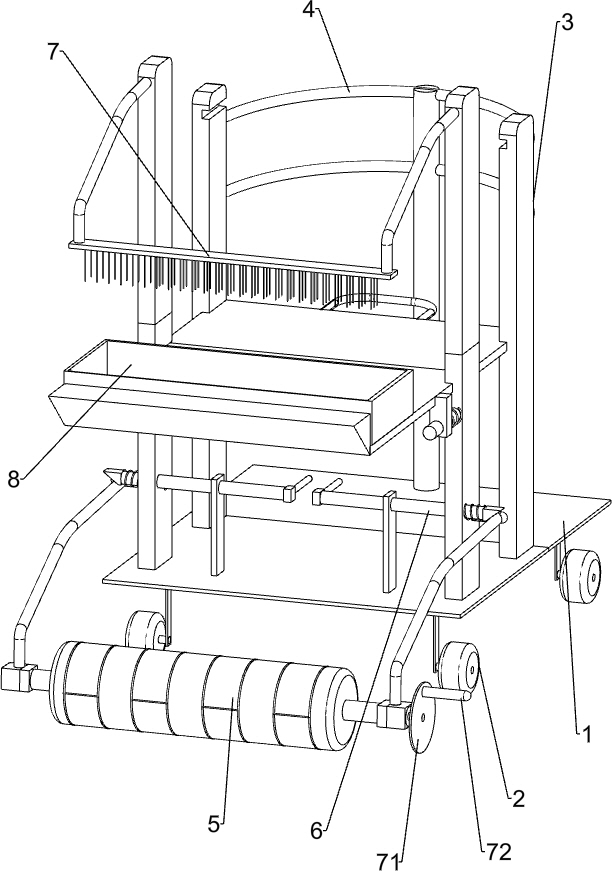

[0024] A road surface indentation equipment for road construction, such as Figure 1-3 As shown, it includes a placement board 1, wheels 2, bracket 3, first handle 4, seam pressing assembly 5 and limit assembly 6, the bottom of placement board 1 is connected with wheels 2, and the top of placement board 1 is provided with two Bracket 3, the first handle 4 is connected to the rear end of the placement plate 1, the front end of the first handle 4 is connected to the two brackets 3 on the rear side, the front side of the bottom of the bracket 3 is provided with a crimping assembly 5, and the lower sides of the two brackets 3 at the front end are connected Limit component 6.

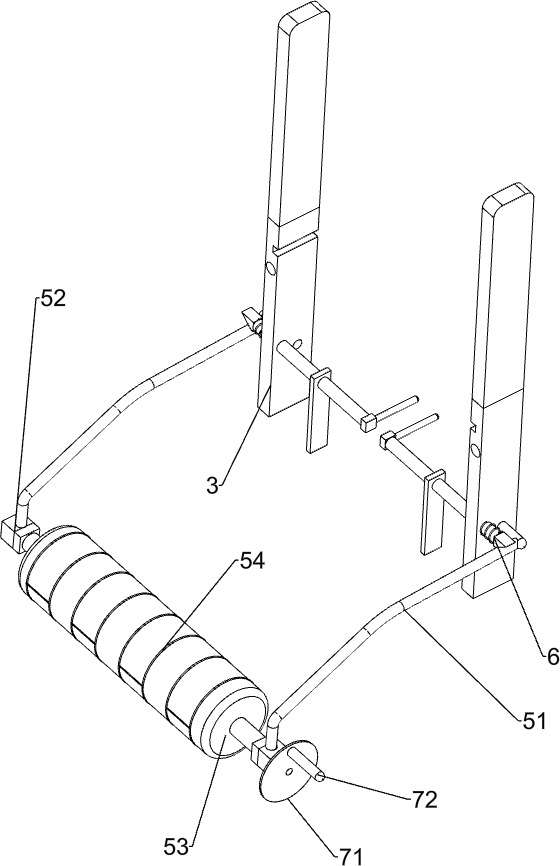

[0025] The seam pressing assembly 5 includes a first curved rod 51, a briquetting block 52, a cylinder 53 and a seam leaving mold 54. The bottoms of the two supports 3 on the front side are rotatably connected with the first curved rod 51, and the front ends of the first curved rod 51 are provided with Ther...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 2-3 As shown, a cleaning assembly 7 is also included. The cleaning assembly 7 includes a disc 71, a handle 72, a second curved rod 73 and a brush 74. The right side of the cylinder 53 is fixedly connected with a disc 71, and the eccentric position on the right side of the disc 71 is A handle 72 is connected, and two second curved rods 73 are arranged on the top front ends of the two brackets 3 on the front side, and a brush 74 is installed between the front ends of the two second curved rods 73 .

[0030] When the short inclined block 63 blocked the first curved bar 51, the hairbrush 74 was in contact with the cylinder 53 and the seam leaving mold 54, and the staff rotated the disc 71 by turning the handle 72, and the cylinder 53 and the seam leaving mold 54 rotated thereupon. Under the action of the brush 74, the cement adhering to the roller 53 and the seam leaving mold 54 is brushed off, and the roller 53 and the seam leavin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com