Continuous construction method for fibers at joint of concrete structure

A technology of concrete structure and construction method, which is applied in the direction of building components, building structure, and building materials processing, etc., can solve the problems of increasing the crack strength of joints, reducing the crack strength of joints, and increasing the difficulty of construction, etc. To achieve the effect of reducing project cost, improving joint performance, and good promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

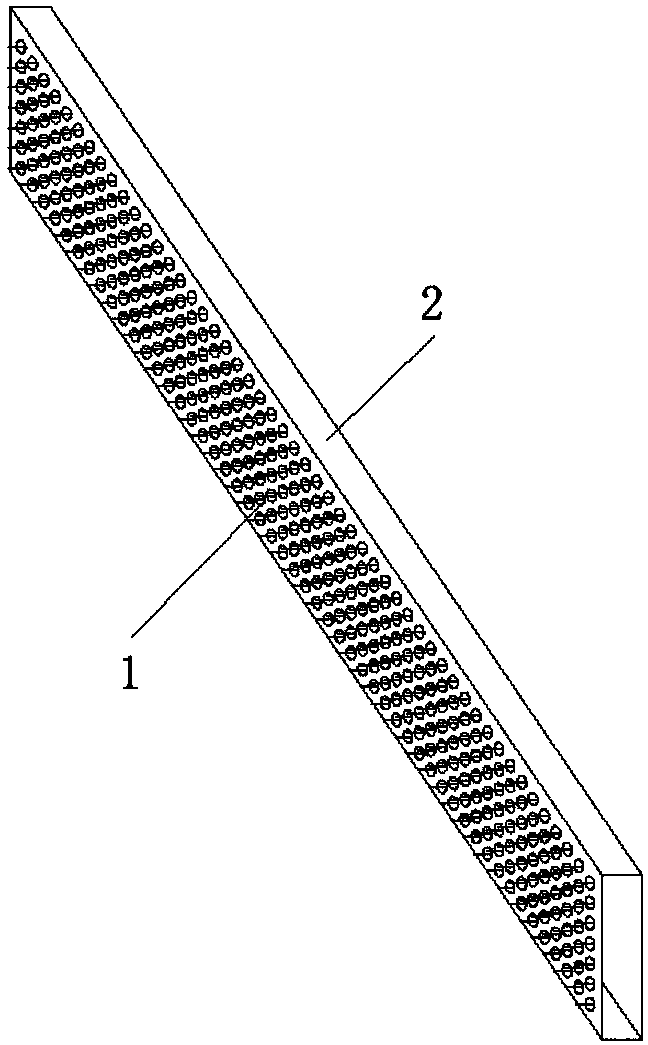

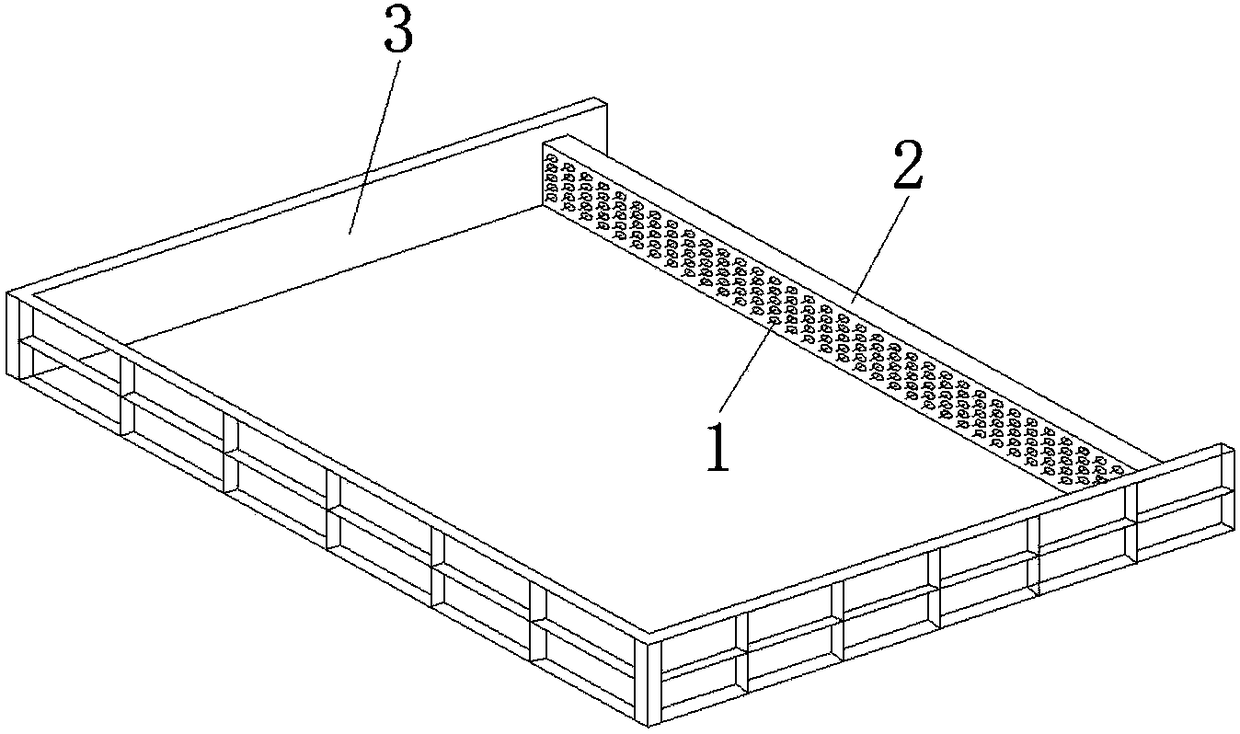

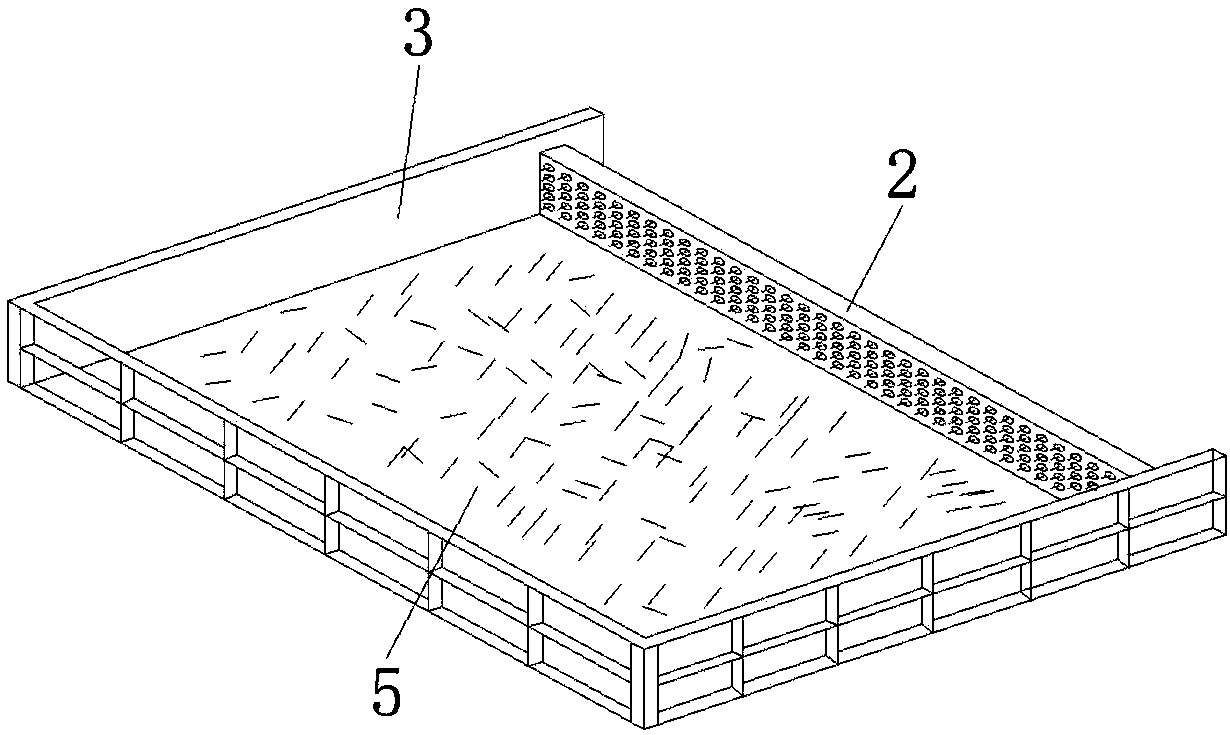

[0030] Example 1, such as Figure 1-7 As shown in one of the above, the fiber-continuous construction method of the concrete structure joint of the present invention is to arrange the fine holes according to the design interval on the formwork of the concrete joint 4 (the formwork of the joint 4 is a steel formwork 2) before pouring. After the concrete pouring is completed and before the initial setting of the concrete 5 near the joint, part of the length of the fiber 1 is inserted into the uncured concrete 5 through the fine hole, and after the concrete 5 is hardened and the steel formwork 2 at the joint 4 is removed, Outside the surface of the joint 4 of the concrete 5, the remaining part of the length not inserted into the concrete 5 is exposed. The fibers 1 at the joints 4 of the poured concrete 5 and 6 are continuous.

[0031] In Example 1, the pore diameter is larger than the fiber 1 diameter, and the pore diameter is less than 2 mm. The fine holes on the steel formwor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com