Method for controlling settlement by horizontally drilling at embankment and injecting light weight replacing material under normal traffic circumstance

A horizontal drilling and embankment technology, which is applied in roads, roads, buildings, etc., can solve problems such as difficult injection into the embankment center, uneven grouting, and waves on the road surface, and achieve low project cost, high radial deformation and rigidity requirements, The effect of reducing the load of the subgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

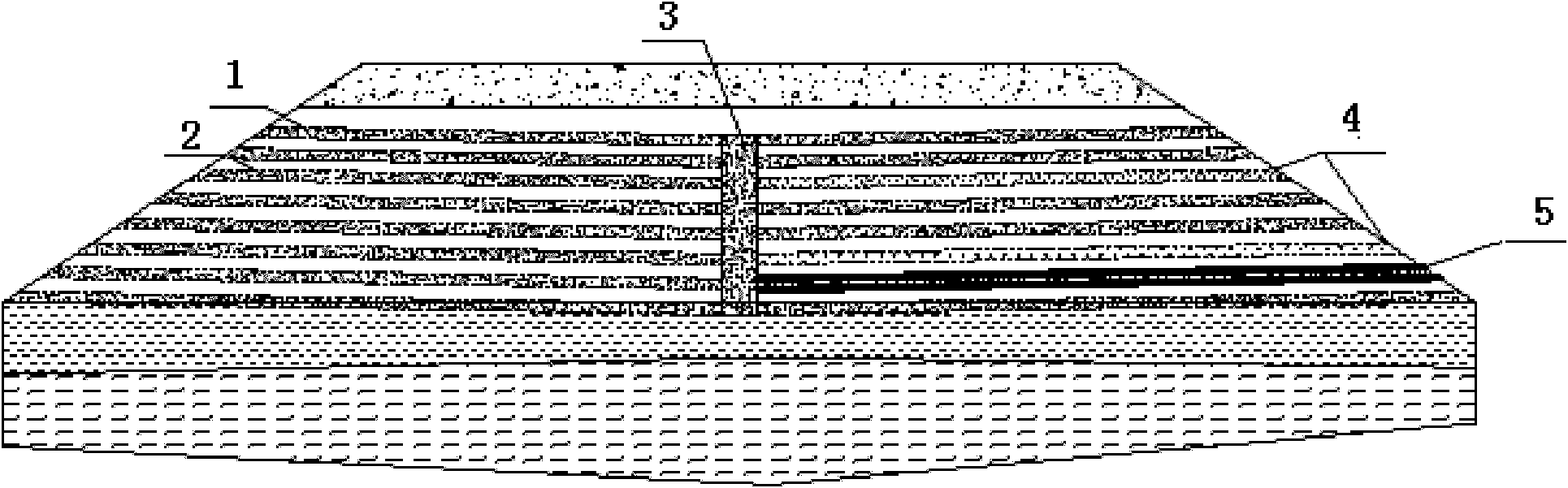

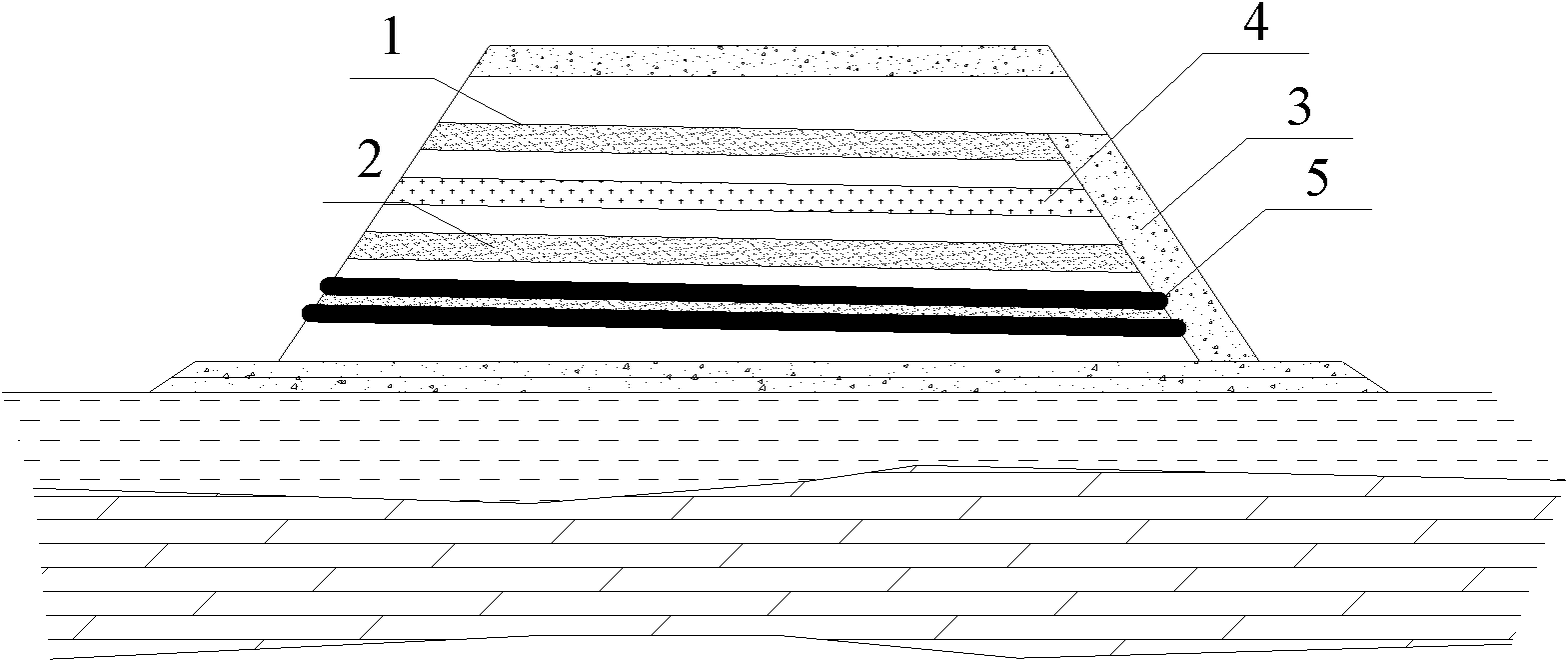

[0026] (1) if figure 1 , 2 As shown, according to the vertical and horizontal spacing of the designed lead holes; place the hydraulic crawler rock drill at the slope toe to lead the holes, and use guided drilling and non-excavation technology to lead holes 1 on one side or both sides of the original embankment, with a diameter of 11.5cm , the hole is inclined 1° to the lower side of the embankment.

[0027] (2) An embankment with a thickness of more than 50 cm is reserved at the non-opening end of the lead hole as the closed end of the lead hole 3; when the vertical and horizontal distances between the lead holes are small, it can be drilled at intervals of more than 2 holes, drilled in stages and poured into air-filled concrete in stages 2;

[0028] (3) If it is difficult to form holes in the subgrade, the holes can be introduced at a distance of 2.5m to 3.0m, and mortar 4 should be poured into the holes, and then the holes should be introduced according to the designed ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com