Assembly equipment and method for steel ball type steering intermediate shaft

An assembly equipment and intermediate shaft technology, applied in the field of parts assembly, can solve the problems that the structure is difficult to meet the high torque requirements, the efficiency of the assembly line is reduced, and the complexity of assembly is increased, so as to save the cost and complexity of measurement , large torque range, and large product design range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

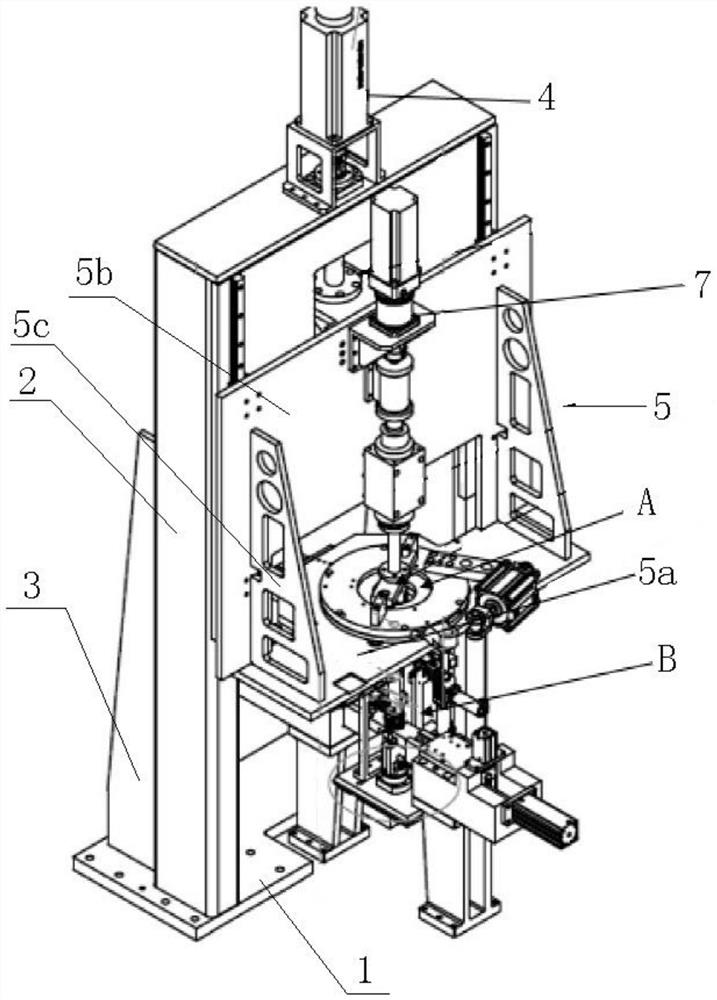

[0047] Such as Figure 1 ~ Figure 3b As shown, an assembly device for a steel ball steering intermediate shaft includes an assembly base 1, a vertical assembly frame 2 arranged on the assembly base, and a fixed rib 3 for fixing the assembly frame, wherein:

[0048] The assembly frame 2 is provided with a servo motor assembly 4 for height adjustment on its top;

[0049] The assembly frame 2 is provided with a liftable yoke clamping mechanism mounting frame 5 on one side of the frame body,

[0050] The installation frame 5 of the yoke clamping mechanism is composed of a horizontal installation platform 5a and a vertical installation riser 5b, which are vertically combined with each other. The two sides of the installation riser are also provided with reinforcing ribs connected with the installation platform. 5c, adjusting the upper and lower heights of the mounting frame of the yoke clamping mechanism through the height adjustment servo motor assembly 4;

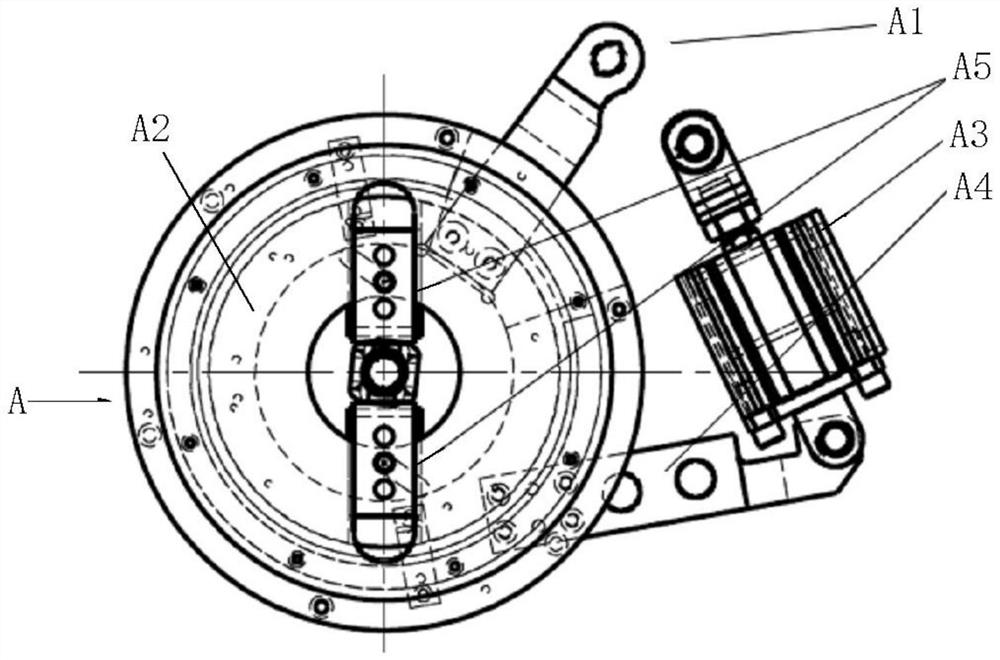

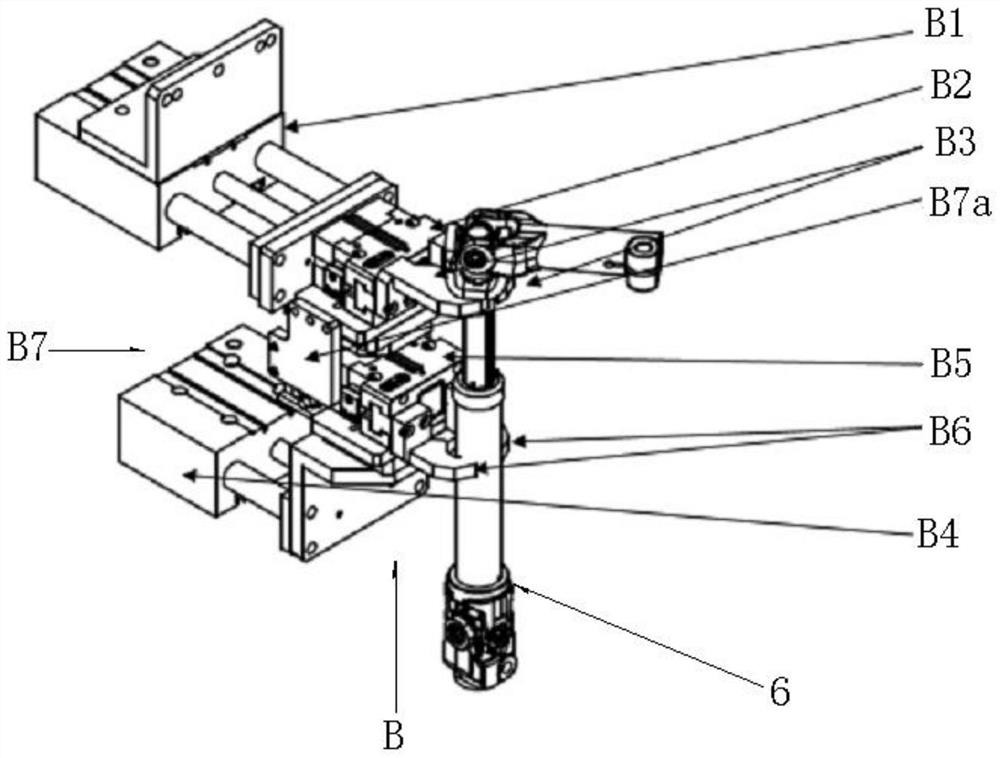

[0051] A fixed yoke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com