Adjustable bus duct

A busway, adjustable technology, applied in the direction of fully enclosed busbar devices, can solve the problems of small scope of application, inability to adjust, fixed space, etc., to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

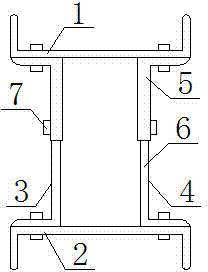

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, an adjustable busway, including an upper cover 1, a lower cover 2, a left side 3 and a right side 4, and the upper cover 1 and the lower cover 2 are respectively connected to the left side 3 and the two ends of the right side board 4, the left side board 3 and the right side board 4 are composed of a mother board 5 and a daughter board 6, the daughter board 6 is inserted in the mother board 5, is slidably connected with the mother board 5, and is fixed by a nut 7 .

[0010] Both the left side panel 3 and the right side panel 4 are designed as a combined structure of the motherboard 5 and the daughter board 6, and are fixed by the nut 7, and the space of the bus duct can be adjusted by the relative sliding of the motherboard 5 and the daughter board 6 to meet different requirements. The assembly requirements of standard busbars greatly expand the scope of application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com