MacPherson independent suspension front axle assembly with circulating ball steering mechanism

An independent suspension and steering mechanism technology, applied in the direction of steering mechanism, suspension, elastic suspension, etc., can solve the problem that the rack and pinion steering front axle cannot meet the layout and load requirements, and cannot meet the ride comfort and handling stability. Problems such as poor driving comfort and handling stability, to achieve the effect of improving driving handling stability, solving insufficient steering force, and improving driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

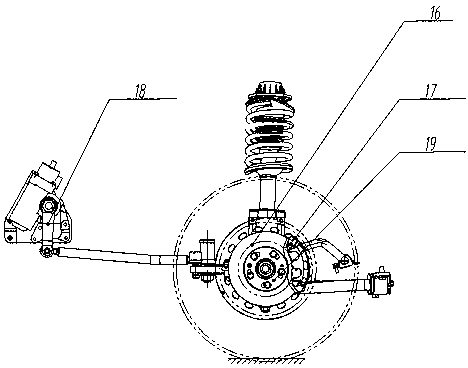

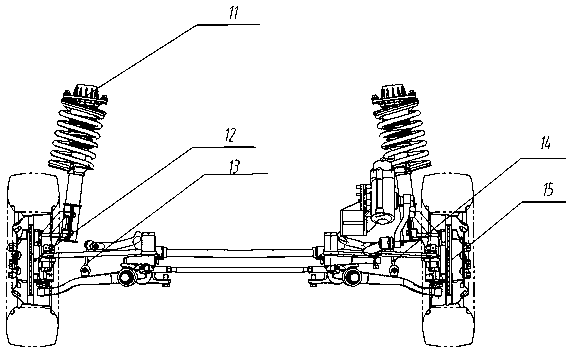

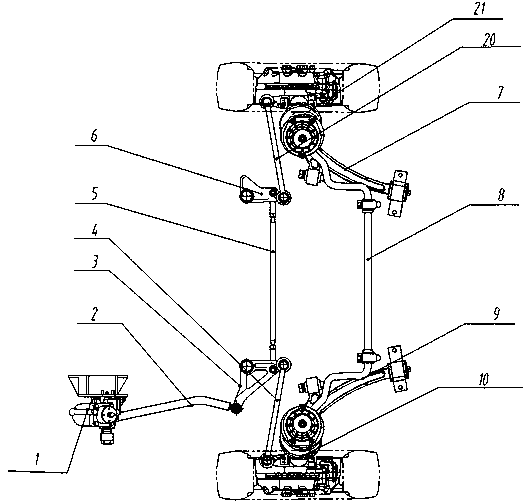

[0023] see figure 1 , figure 2 , image 3 The McPherson independent suspension front axle assembly with recirculating ball steering mechanism is mainly composed of four parts: recirculating ball steering booster 1, steering transmission mechanism, MacPherson independent suspension and hydraulic disc brake system.

[0024] Steering transmission mechanism includes steering drop arm 18, steering straight tie rod 2, steering left rocker arm 3, steering right rocker arm 6, middle tie rod 5, right steering knuckle 12, left steering knuckle 15, left tie rod 4 and right tie rod 20 , wherein the recirculating ball power steering device 1 is connected with the steering drop arm 18 through a spline, the steering drop arm 18 is connected with the steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com