Elevator traction belt and elevator

An elevator traction and traction belt technology, which is applied in the field of traction elevators, can solve the problems of affecting the service life of the bearing body, affecting the comfort of elevator operation, adverse noise, etc. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

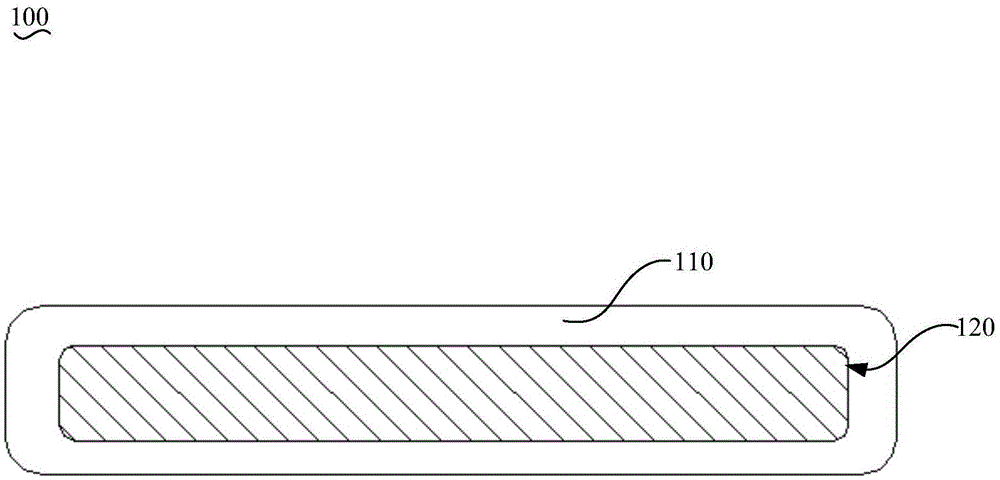

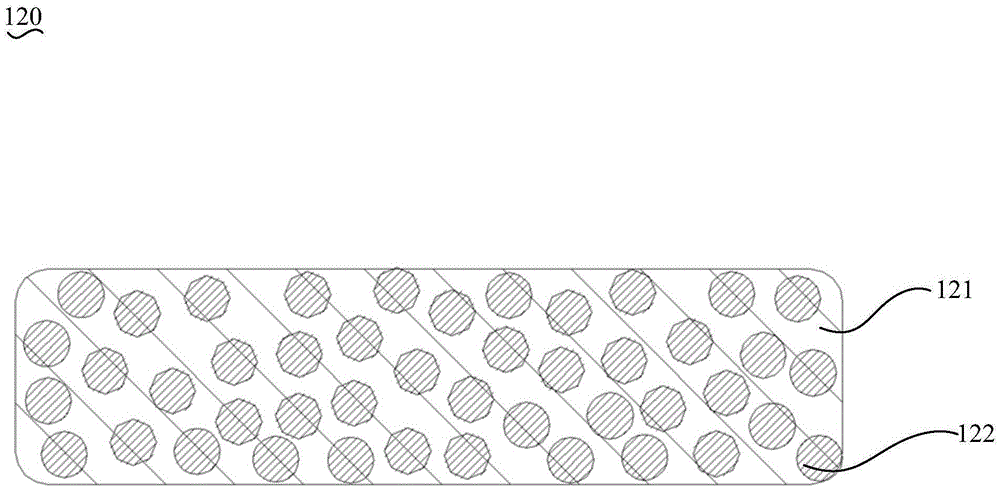

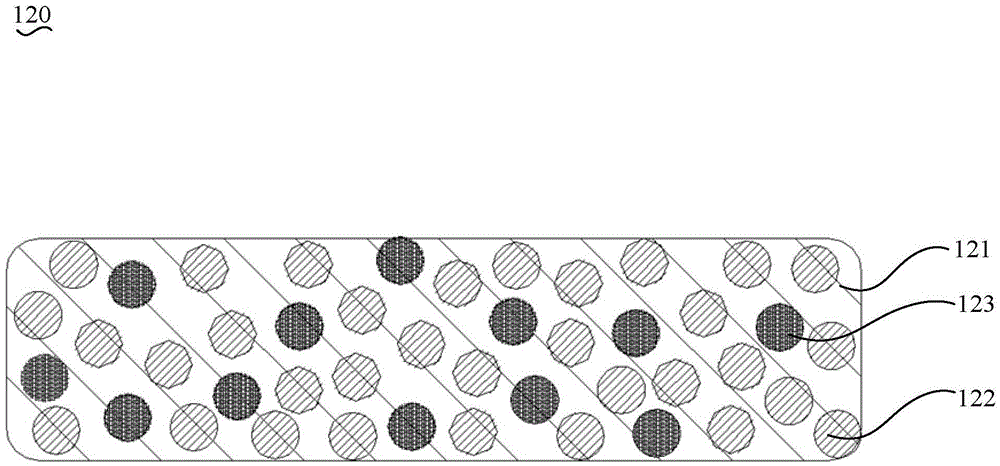

[0036] Such as figure 1 and figure 2 As shown, an elevator traction belt 100 includes a wrapping layer 110 and at least one carrier 120 sheathed in the wrapping layer 110, and the carrier 120 includes a composite resin matrix 121 and basalt fiber, the The basalt fiber includes a plurality of basalt fiber filaments 122 arranged in parallel. Both the traction belt 100 and the carrier 120 are designed to be flat in cross-section, forming a flat traction medium. Because basalt fiber and resin density are smaller than steel wire, and the tensile strength of basalt fiber is high, under the condition of the same breaking tension, the weight per meter of the elevator traction belt 100 is about 25% to 35% of the weight of the steel wire rope. The invention effectively reduces the weight of the traction belt 100, facilitates its use on elevators with super high lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com