Patents

Literature

32results about How to "Increased stiffness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

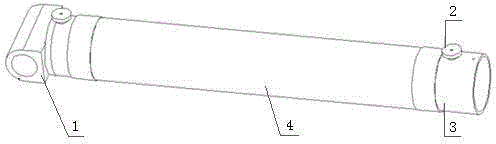

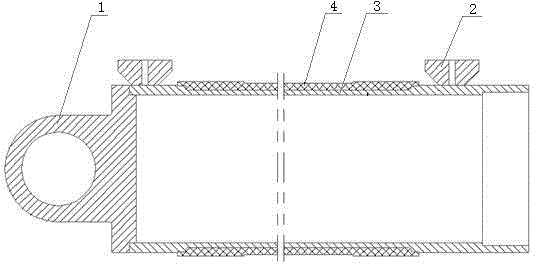

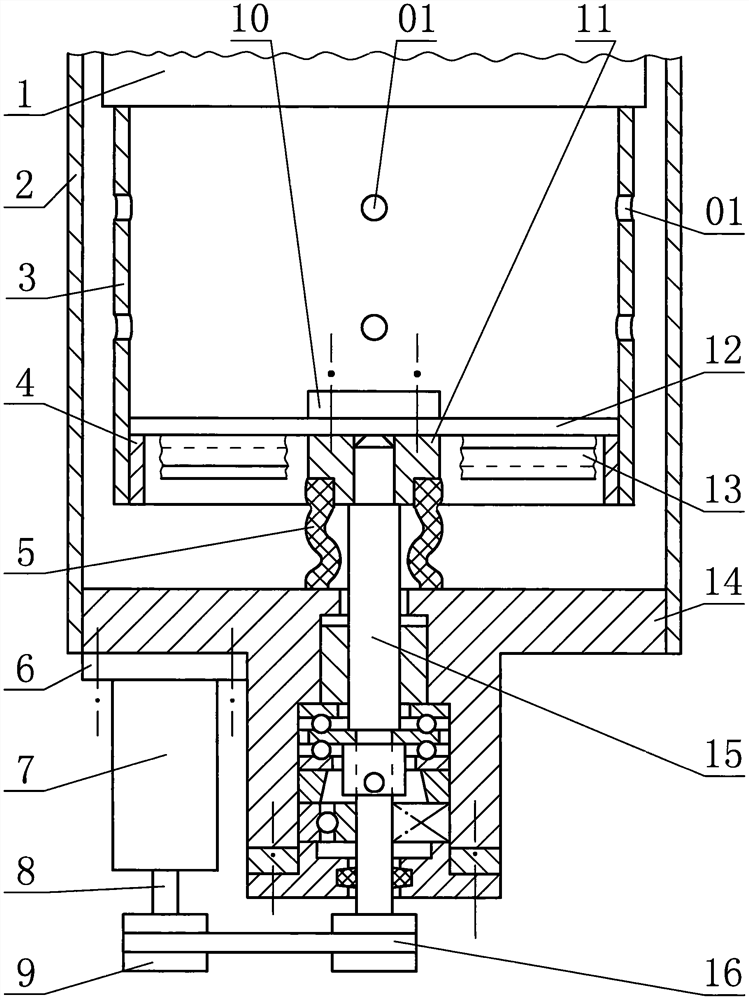

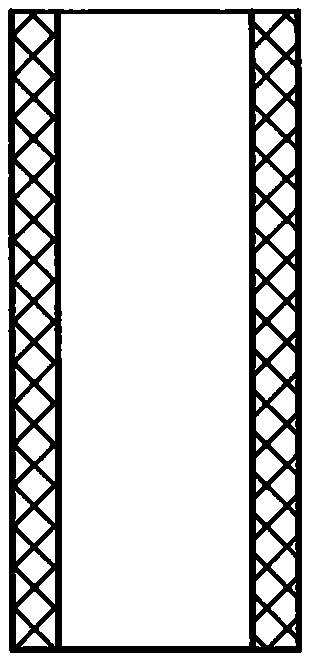

Carbon fiber composite material reinforcing hydraulic oil cylinder

InactiveCN102720721AImprove securityReduce energy consumptionFluid-pressure actuatorsTruckMetal cylinder

The invention provides a carbon fiber composite material reinforcing hydraulic oil cylinder, comprising a base, a cylinder barrel and oil openings. The oil openings are arranged at the both ends of the cylinder barrel; the cylinder barrel is a thinned metal cylinder barrel; a reinforcing layer is coated outside the cylinder barrel; the reinforcing layer is a carbon fiber composite material reinforcing layer; the carbon fiber composite material reinforcing layer uses heat convertible resin as a base body and a carbon fiber as a reinforcing material; and the carbon fiber composite material reinforcing layer contains the resin with a mass ratio of 23-55%. Compared with the full-metal hydraulic oil cylinder in the prior art, the strength, the rigidity and the anti-fatigue property of the carbon fiber composite material reinforcing hydraulic oil cylinder in various working conditions are improved by more than 20%, so that not only can the security of the product be effectively improved in the working conditions, but also more than 30% of the weight is reduced. Therefore, a mechanical pump truck is lightened, and the entire cost is reduced.

Owner:HENGSHEN

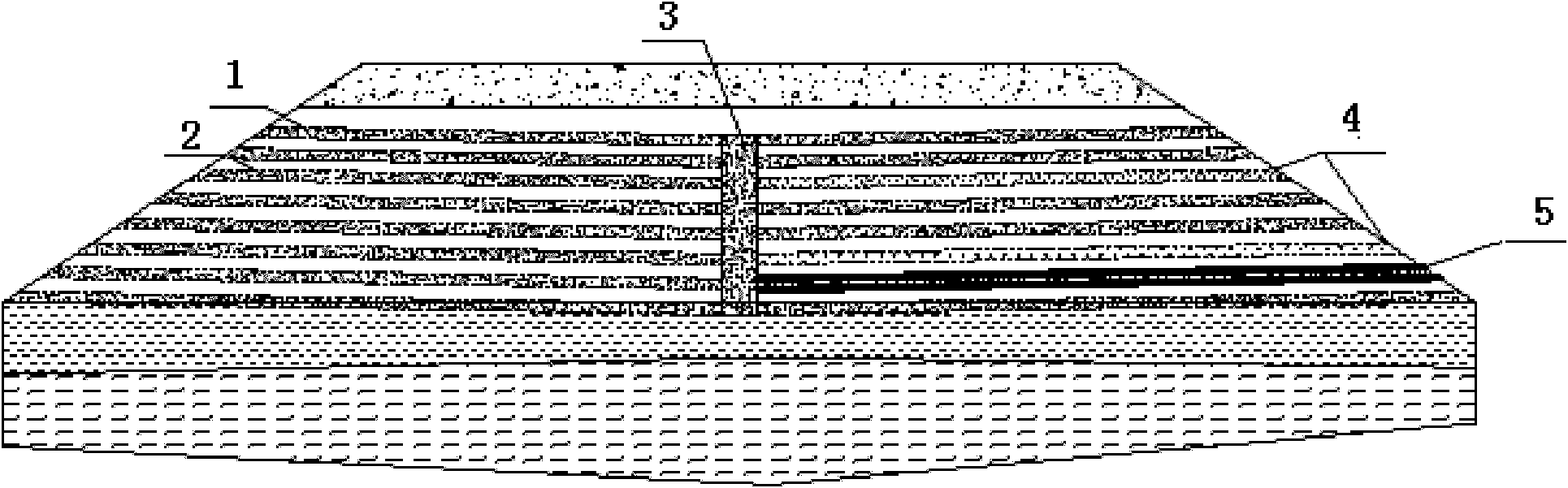

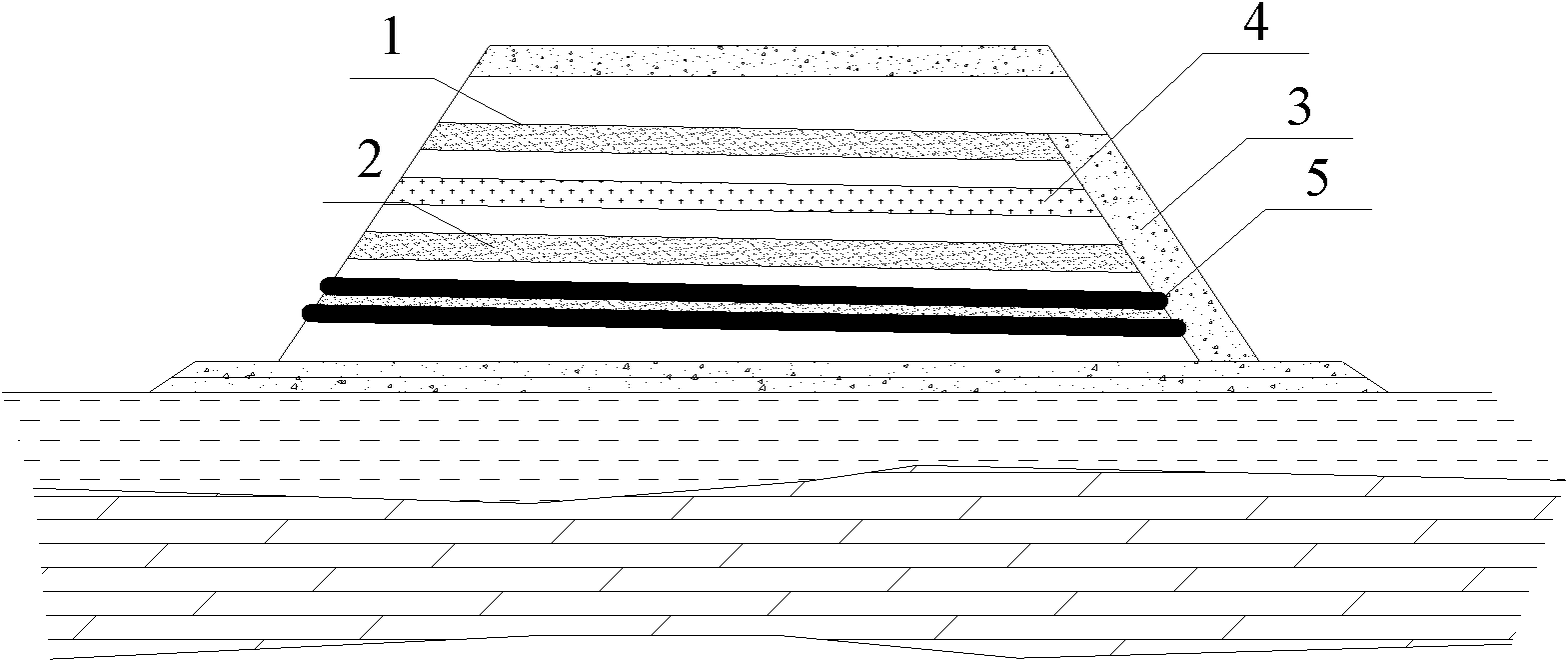

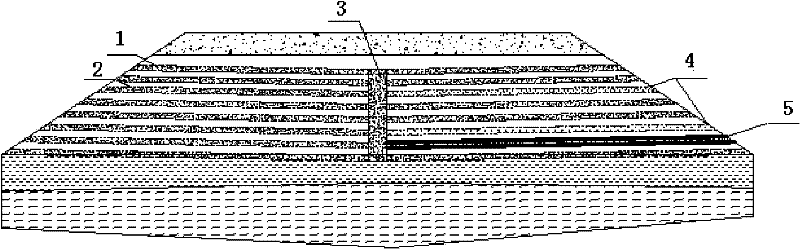

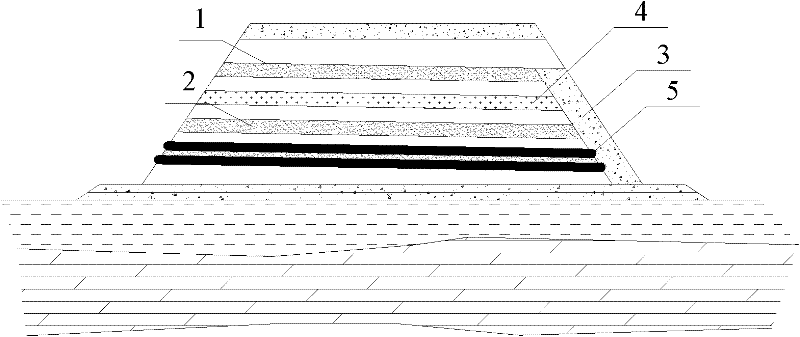

Method for controlling settlement by horizontally drilling at embankment and injecting light weight replacing material under normal traffic circumstance

ActiveCN101949122AIncreased stiffness requirementsIncreased durabilityRoadwaysAccessory structureRoad surface

The invention discloses a method for controlling settlement by horizontally drilling at embankment and injecting a light weight replacing material under the normal traffic circumstance, which is characterized in that: the slope embankment on one side or two sides of roadbed is drilled transversely by a drilling or chiseling pore-forming technique, holes lean a certain angle downwards so as to inject the light weight material; and the light weight material is injected into the holes, and then is solidified in the holes to form the light weight replacing material. A sleeve is also placed into the holes firstly, and then the light weight material or a non-backfill material is injected into the sleeve, so that pore-forming quality is ensured and the diffusion of the light weight material is avoided. The road does not need to be sealed, a pavement structure layer and an upper accessory structure cannot be damaged, and the normal traffic cannot be influenced.

Owner:HOHAI UNIV

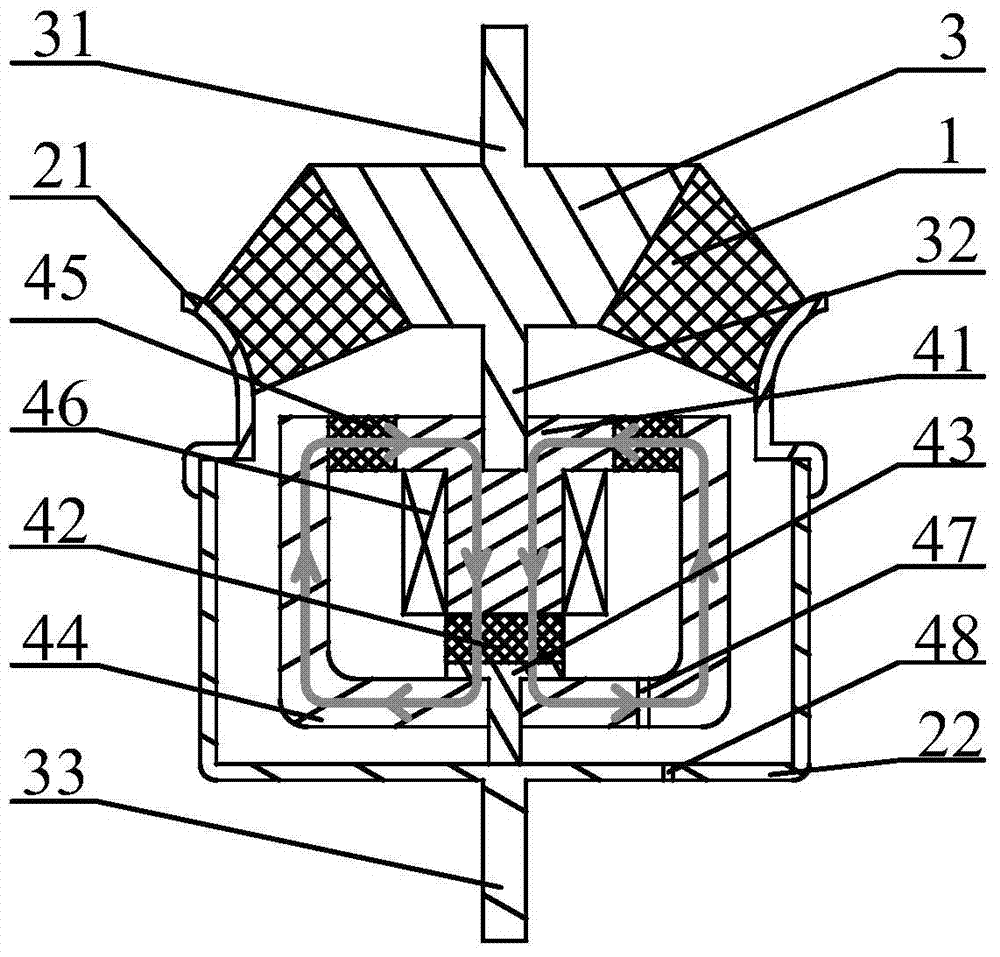

Paralleling model semi-active vibration isolator

ActiveCN104747651AIncrease stiffnessReduce stiffnessSpringsShock absorbersRotary machineMechanical engineering

The invention discloses a paralleling model semi-active vibration isolator. The vibration isolator is characterized in that a cylindrical upper shell is arranged, a rubber main spring is plugged in a top end opening of the upper shell, a main spring framework penetrates through the rubber main spring and is provided with an upper connection stud and a lower connection stud, the upper connection stud is connected with a main vibrating object, the lower connection stud is connected with a column-shaped iron core where an excitation coil is wound, the column-shaped iron core is supported in a magnetism conduction sleeve through a cutting magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, the two ends of the magnetorheological elastomer are extruded to be connected with the top of a T-shaped support and the bottom end of the iron core, and the T-shaped support penetrates through the magnetism conduction sleeve and is fixedly connected; the upper shell is connected with a lower shell, the lower end of the T-shaped support is fixedly connected with the lower shell, and the bottom of the lower shell is provided with a connection bolt used for being connected with a basal body. By means of the vibration isolator, vibrating energy transmitted by a rotary machine to the basal body can be effectively reduced, vibration of relative parts of the rotary machine is reduced, and the service life of the rotary machine and a system of the rotary machine is prolonged.

Owner:HEFEI UNIV OF TECH

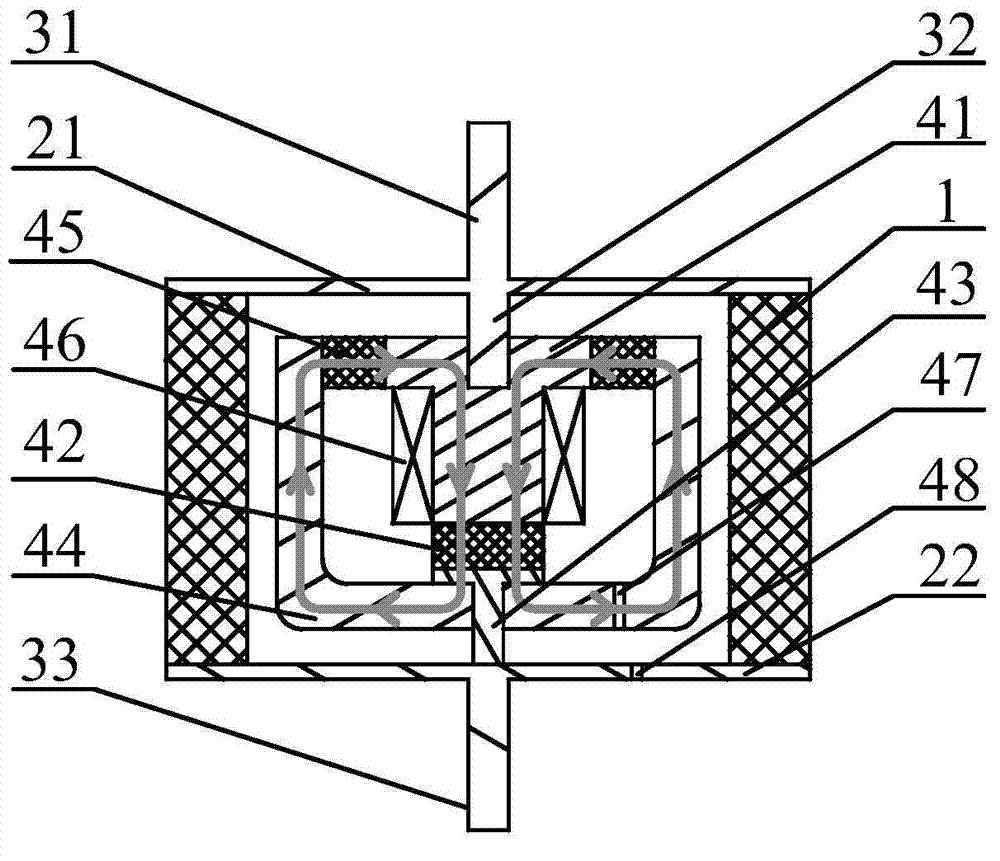

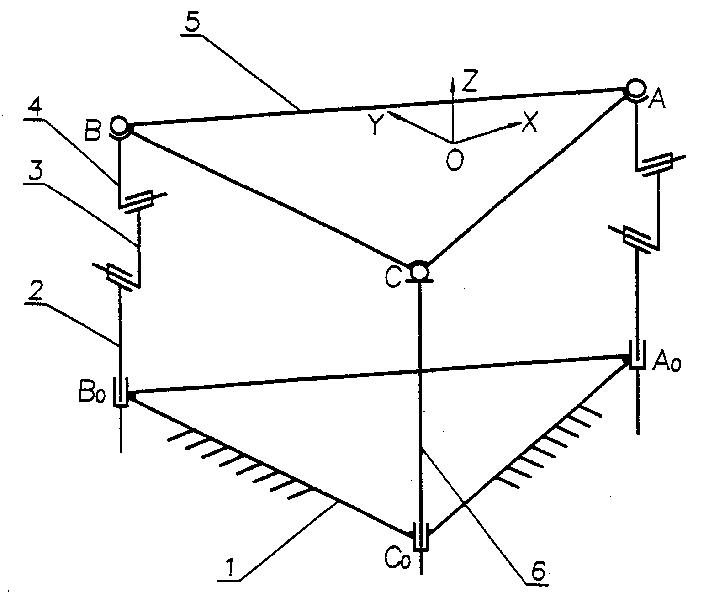

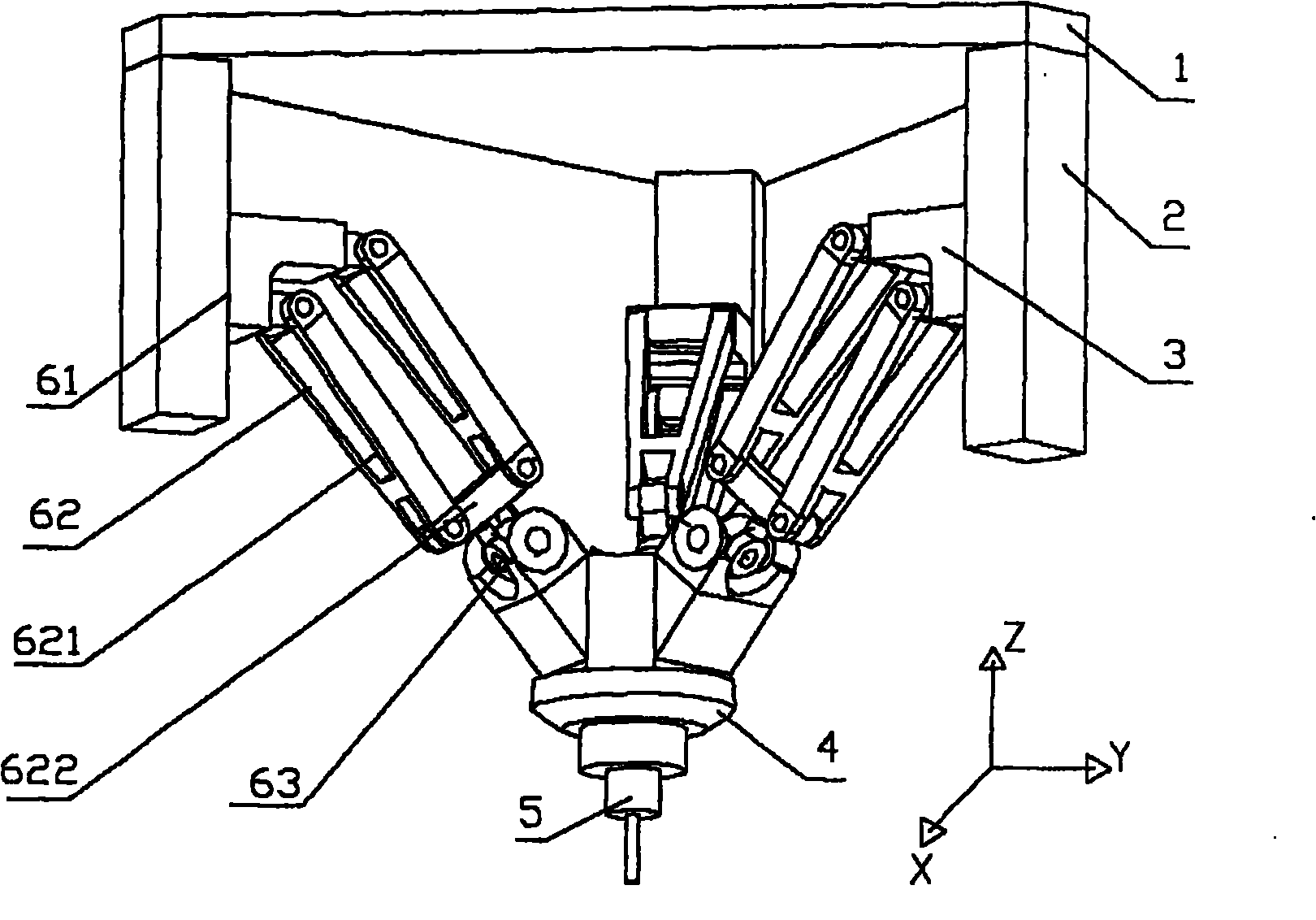

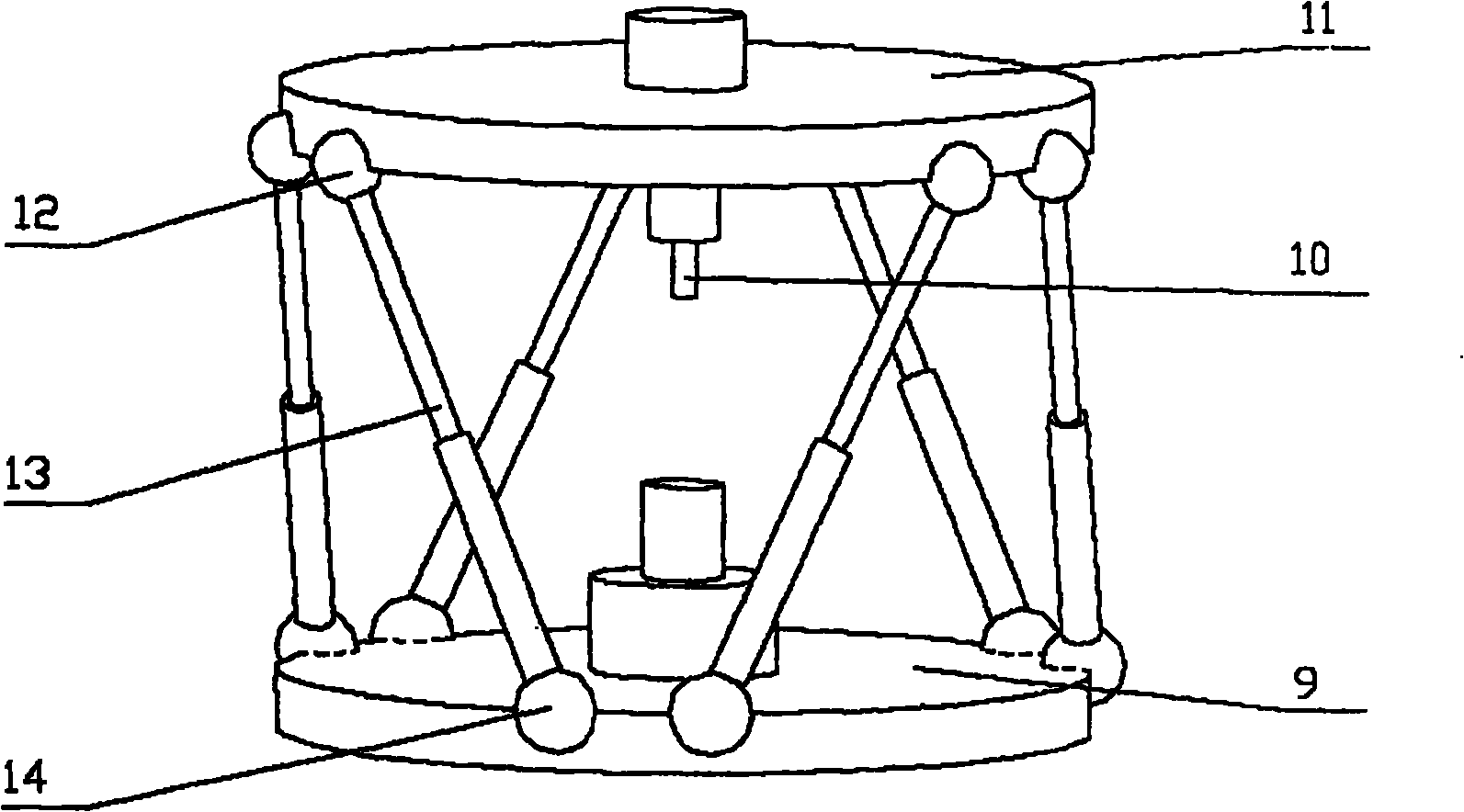

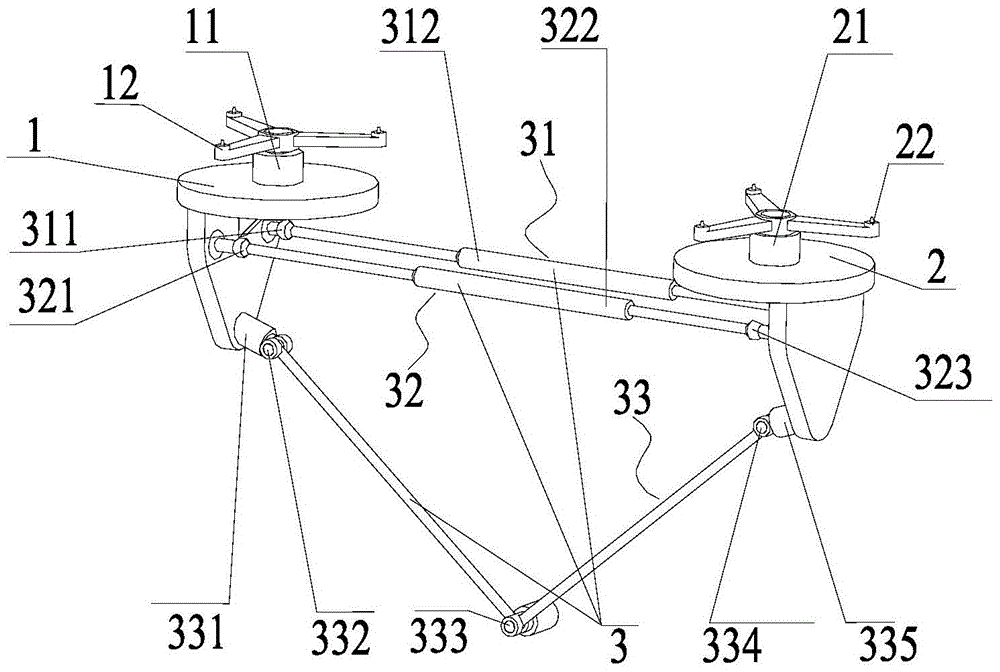

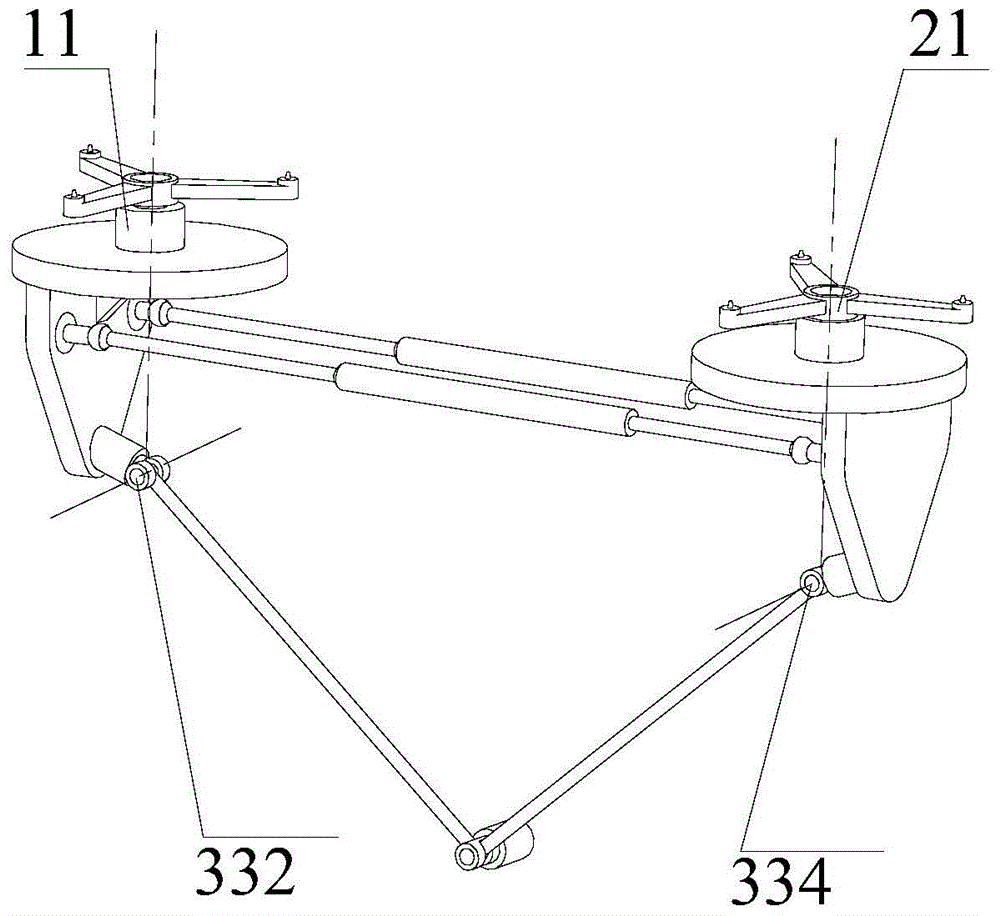

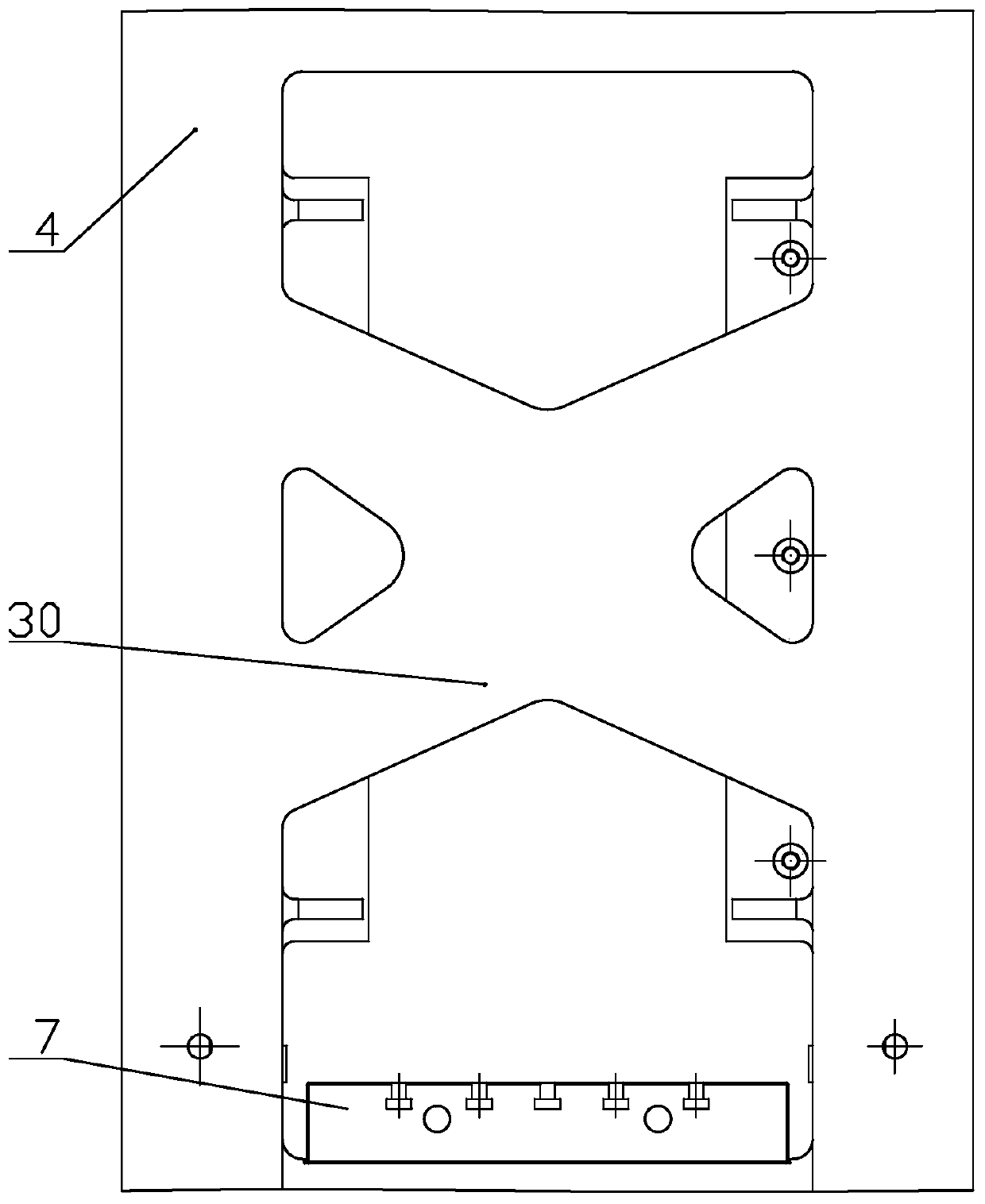

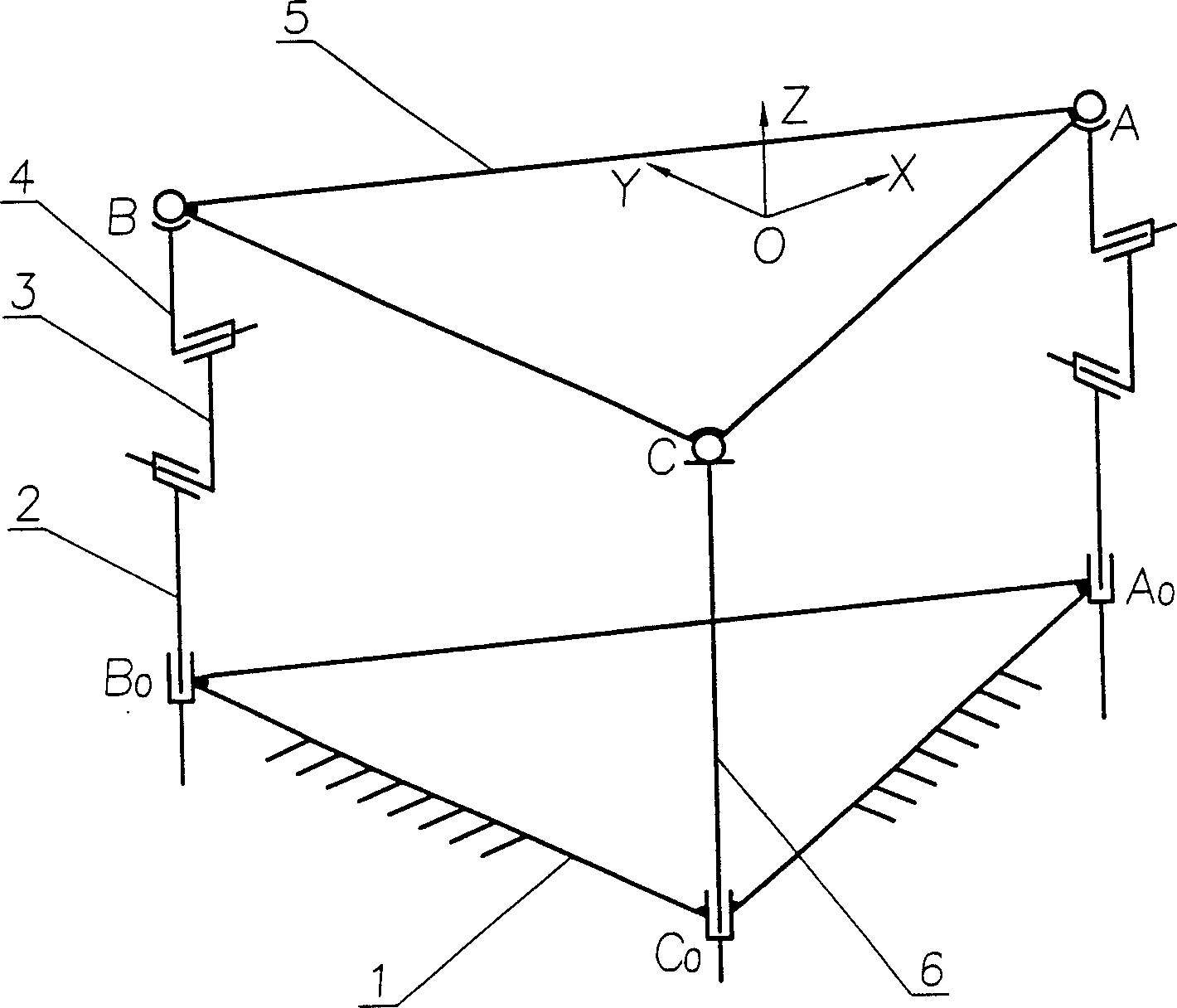

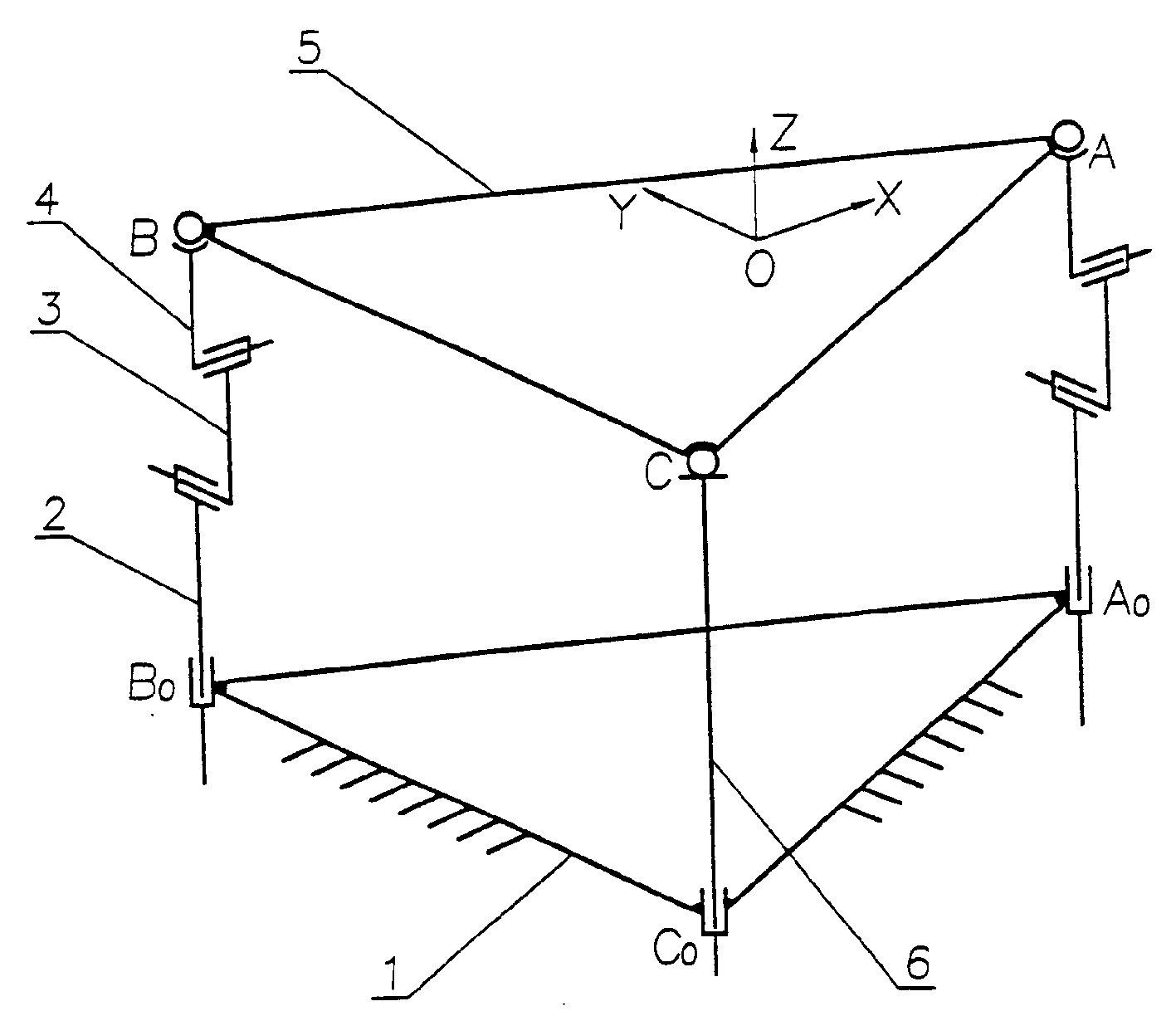

Movable type robot in 6 defree of freedom being connected in series parallel

InactiveCN1462669AEasy to decoupleNo cumulative errorProgramme-controlled manipulatorMovable typeEngineering

A movable six-freedom mixed robot is composed of a static platform, three branch joins AAo, BBo and CCo, and a movable platform. Said branch join AAo (or BBo) has three guide rods: moving rods X, Y and Z, whose moving directions are mutually perpendicular for realizing the movement in X, Y and Z directions. The moving rods X, Y and Z of AAo and the moving rods Y and Z of BBo have drive force but the moving rod X of BBo has not. It can realize 6-freedom movement of movable platform. Its advantages are good decoupling performance of branch joins, high rigidity of movable platform, and no error accumulation.

Owner:SHANGHAI JIAO TONG UNIV

Special HME fiber glass for wind turbine blades

InactiveCN101792267AImprove acid resistanceIncrease high temperature viscosityMachines/enginesWind energy generationElectricityGlass fiber

The invention relates to special HME fiber glass for wind turbine blades, which is mainly prepared by mixing SiO2, Al2O3, Fe2O3, CaO, MgO, NaO2 and K2O according to the proportion; and the special HME fiber glass is characterized in that the following components are added in the components by weight percent: 0.3-2.5% of TiO2, 0.1-0.6% of LiO2, 0-0.8% of WO3, and 0.1-0.6% of CeO2. The special HME fiber glass takes the SiO2, the Al2O3, the CaO and the like as the main components, further adds four important auxiliary components of the TiO2, the LiO2, the WO3 and the CeO2, and mainly uses the TiO2 for replacing B2O3 and F2 which are conventional in alkali-free glass fiber, thereby realizing the environment-friendly property; the WO3 is used selectively, so as to improve the elastic modulus and the acid resistance of the special HME fiber glass for the wind turbine blades while ensuring the cost; particularly, the SiO2 is selected to be more than 58%, so as to improve the high-temperature viscosity of the glass. In short, the special HME fiber glass for the wind turbine blades produced by using the components has the advantages of high elastic modulus, high requirement on product rigidness, good acid resistance and good insulation performance.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

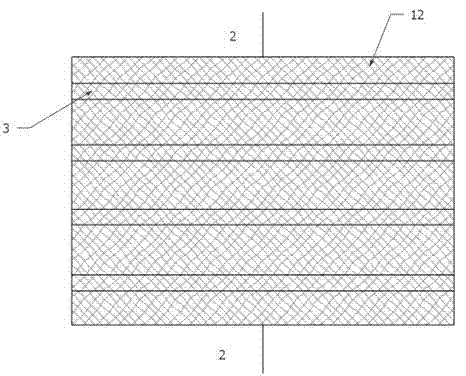

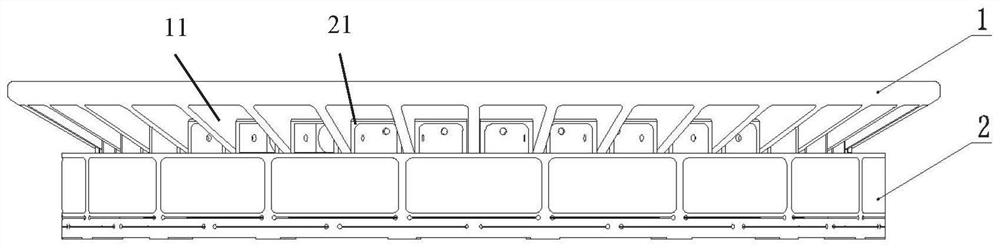

Cast-in-place skeleton net hollow filler wall

InactiveCN102758492AIncreased out-of-plane stiffnessLess materialWallsHeat proofingStructural engineeringMaterials science

The invention discloses a cast-in-place skeleton net hollow filler wall which comprises a skeleton net (1). A cast-in-place surface layer (4) and a seal surface layer (5) are arranged at outer ends of two sides of the skeleton net (1) respectively, and vertical ribs (2) and horizontal ribs (3) are sequentially arranged between the skeleton net (1) and the cast-in-place surface layer (4). According to integration of economic indicators and construction periods, the cast-in-place skeleton net hollow filler wall has an advantage over an existing air-entrapping concrete building block filler wall and a hollow internal mold metal net cement internal partition wall, has the advantages of being high in industrialized production degree and simple in site operation process, and overcomes the shortcomings in the prior art.

Owner:贵州皆盈科技开发有限公司

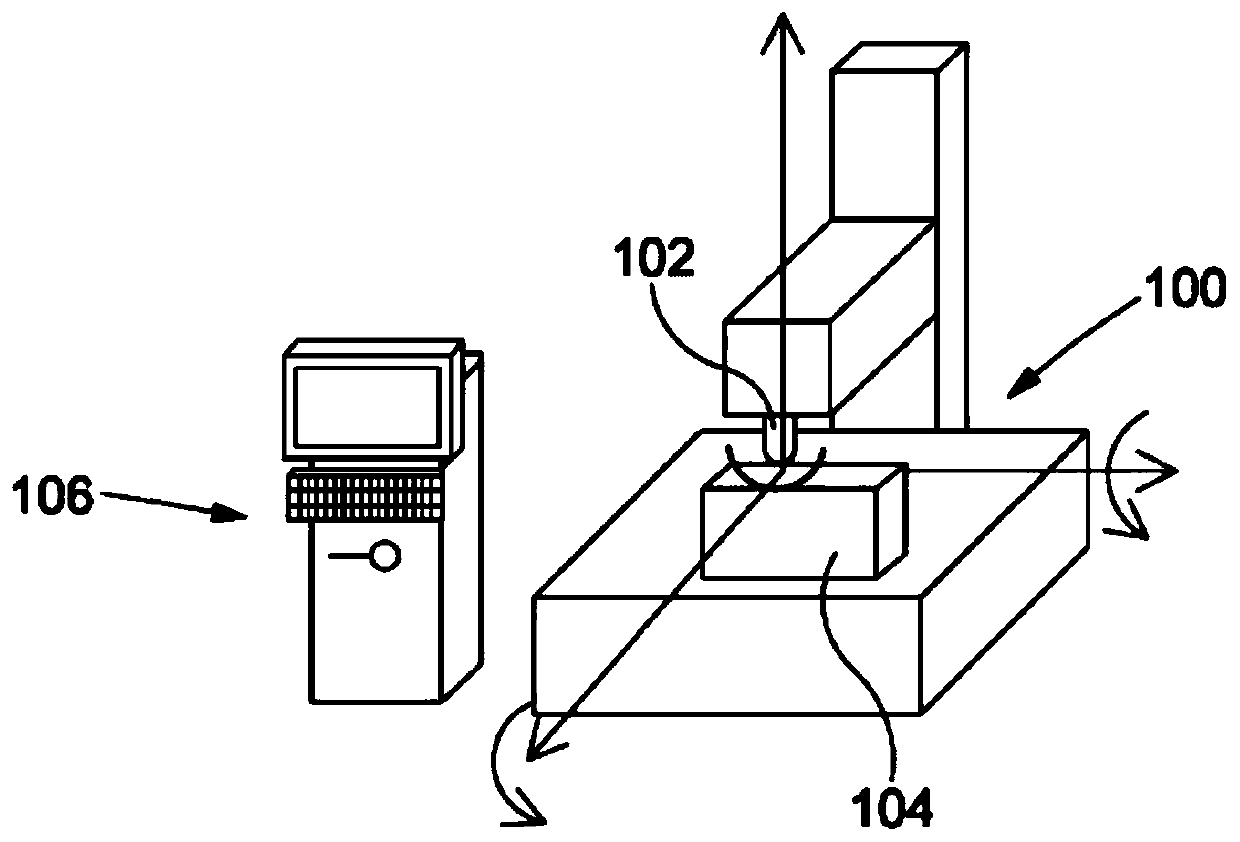

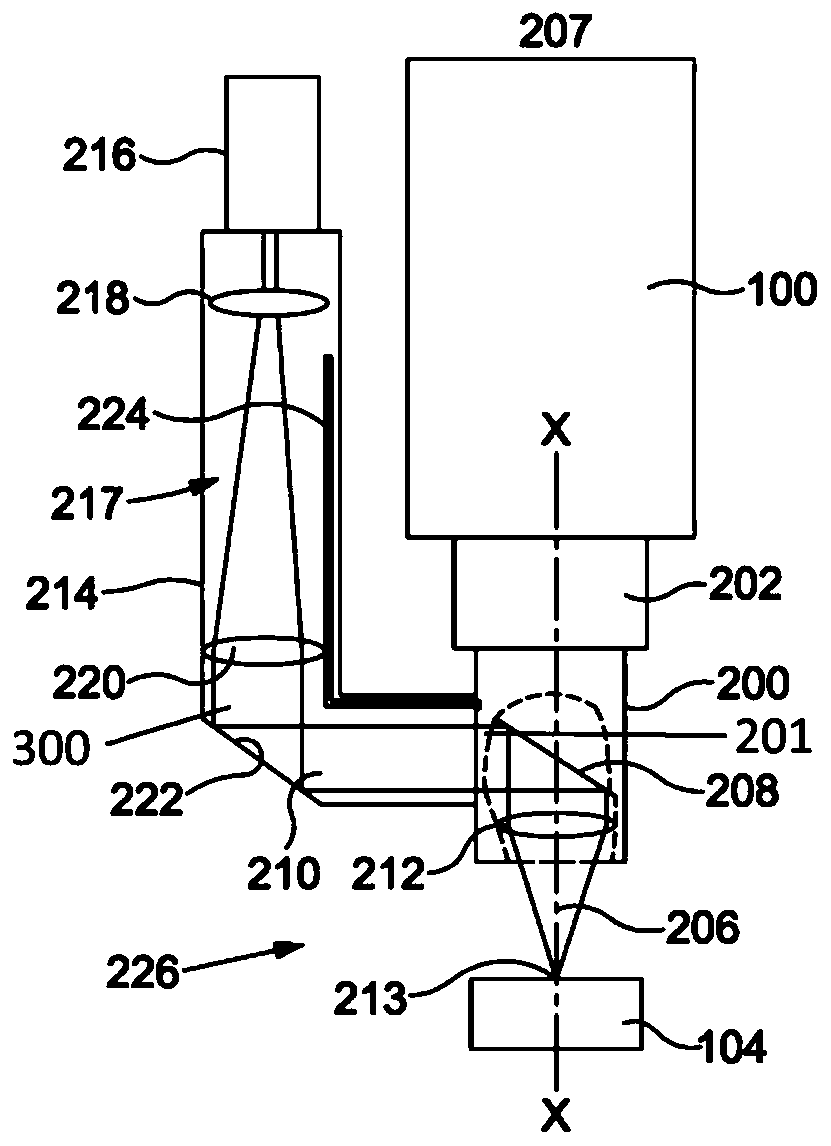

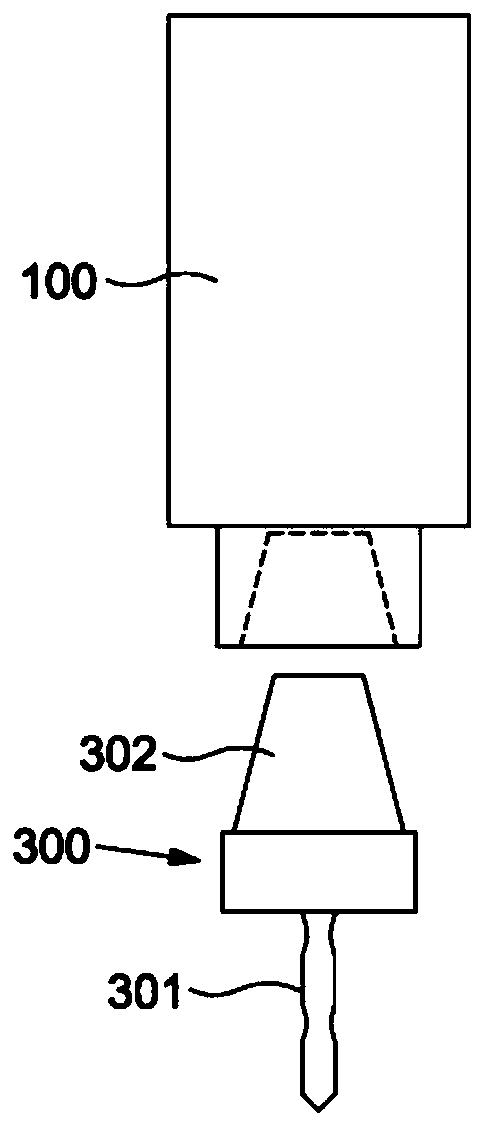

A machine tool

InactiveCN110461574AReduced stiffness requirementsIncreased stiffness requirementsAdditive manufacturing with liquids3D object support structuresEngineeringMulti axis

Owner:HYBRID MFG TECH LTD

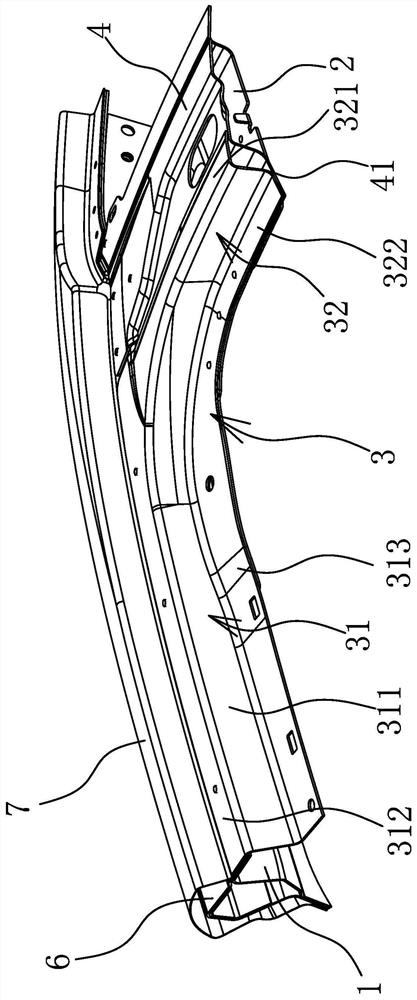

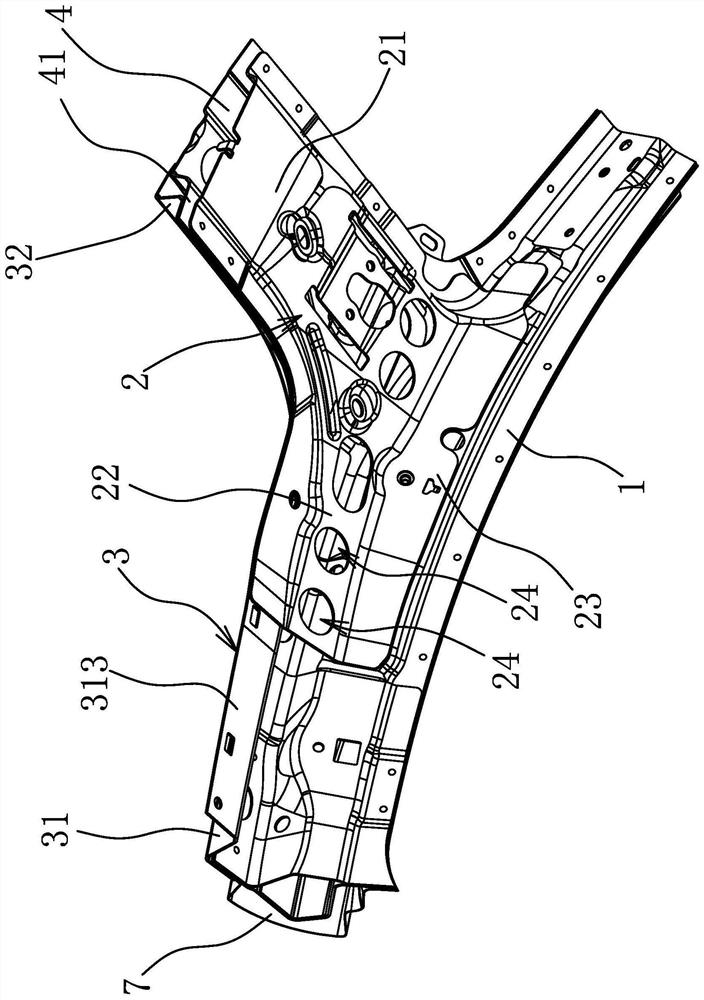

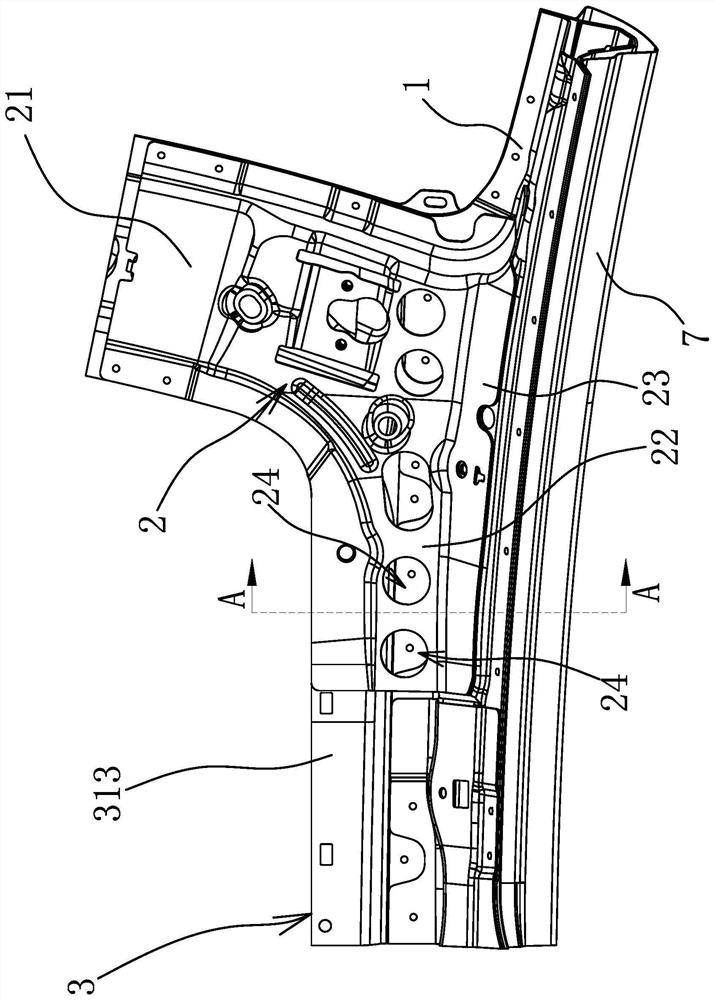

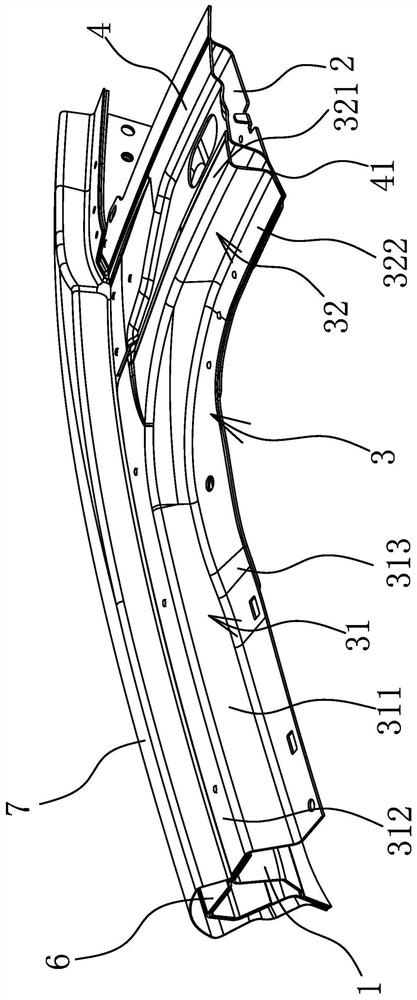

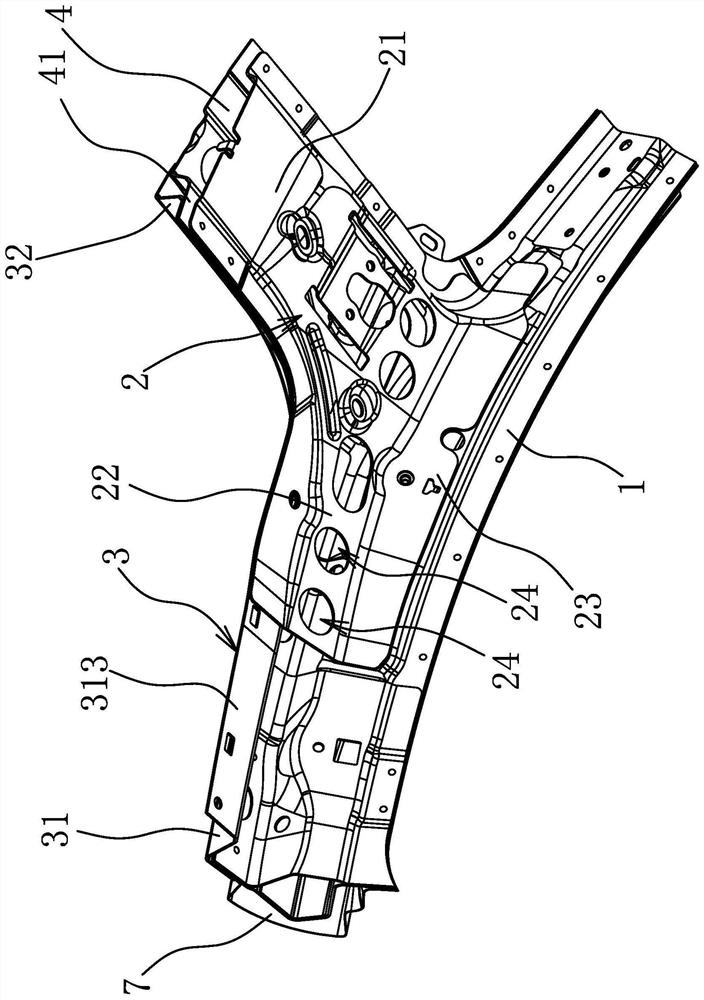

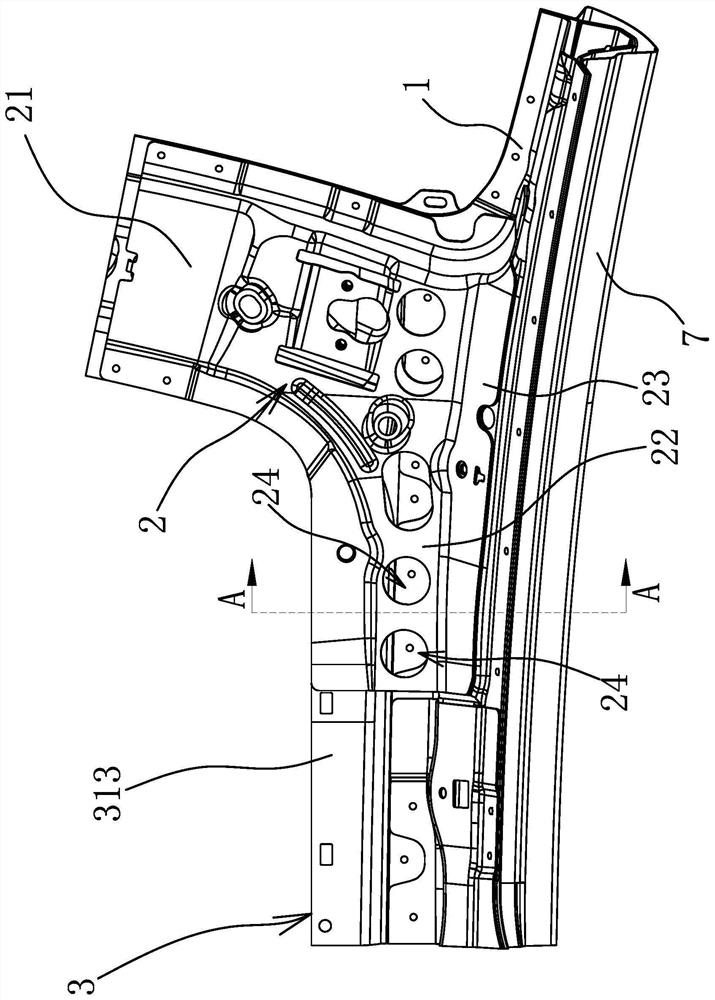

Connecting structure for front cross beam and side wall assembly of automobile roof

ActiveCN112478000AEffective Absorptive CapacityImprove crash performanceSuperstructure connectionsHead-on collisionSkylight

The invention provides a connecting structure of an front cross beam and a side wall assembly of an automobile roof, and belongs to the technical field of automobiles. The problem that the collision performance of the joint of an existing automobile roof front cross beam and a side wall assembly is poor is solved. The connecting structure comprises a connecting plate and a skylight reinforcing plate fixedly connected with the roof front cross beam, the connecting plate is provided with a base plate located on the lower side of the roof front cross beam and welded to the roof front cross beam,and the skylight reinforcing plate is provided with a longitudinal part extending in the front-back direction of an automobile body. The longitudinal part is provided with a main plate body arranged in the height direction of an automobile body, an extending plate body extending towards the rear side of the automobile body is connected to the base plate, the longitudinal part is welded to t he inner plate of the upper edge beam at the upper edge of the main plate body, and the longitudinal part is welded to the inner side edge of the extending plate body at the lower edge of the main plate body. And the outer side edge of the extending plate body is welded with a roof side rail inner plate. According to the invention, the automobile has good head-on collision performance and small offset collision performance.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Grinding device and dismantling method for high-speed rail track milling and grinding car

ActiveCN104074110BAvoid the problem of unstable installation and disassemblyImprove reliabilityGrinding machinesRailway track constructionEngineeringGrinding wheel

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

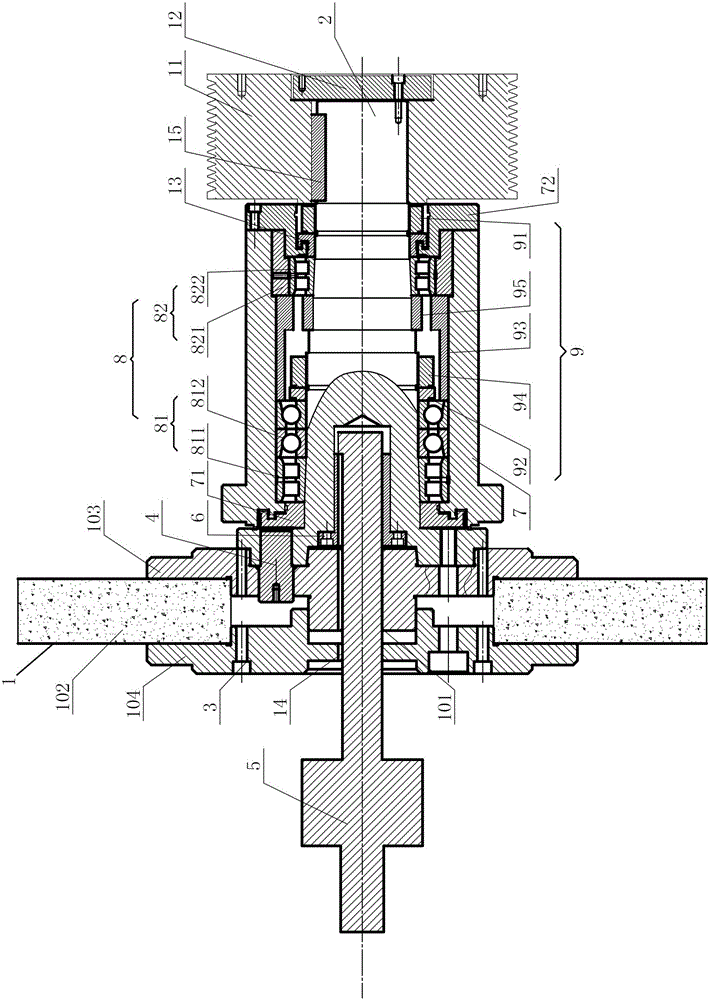

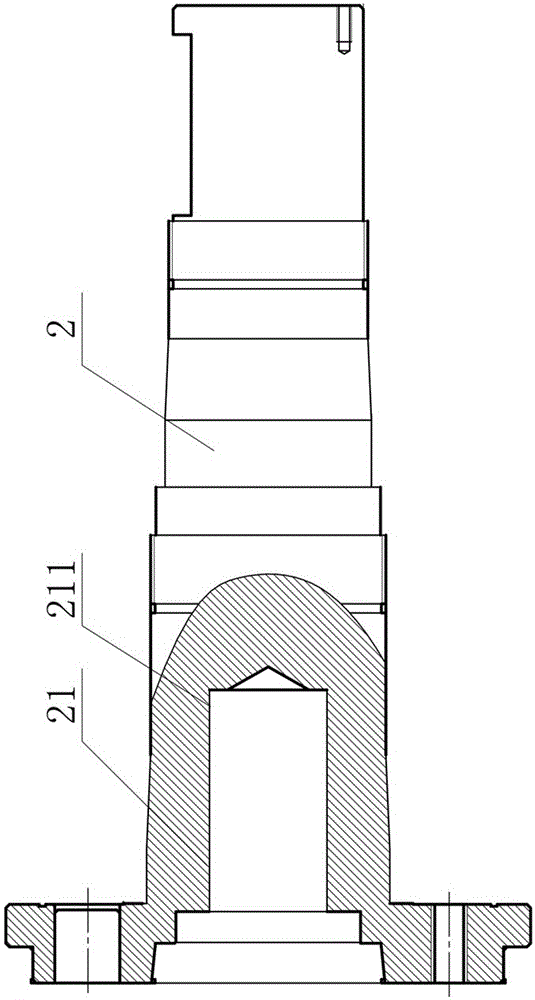

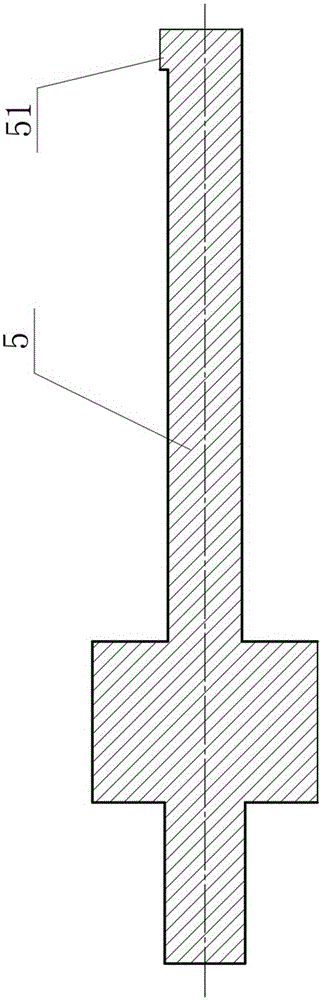

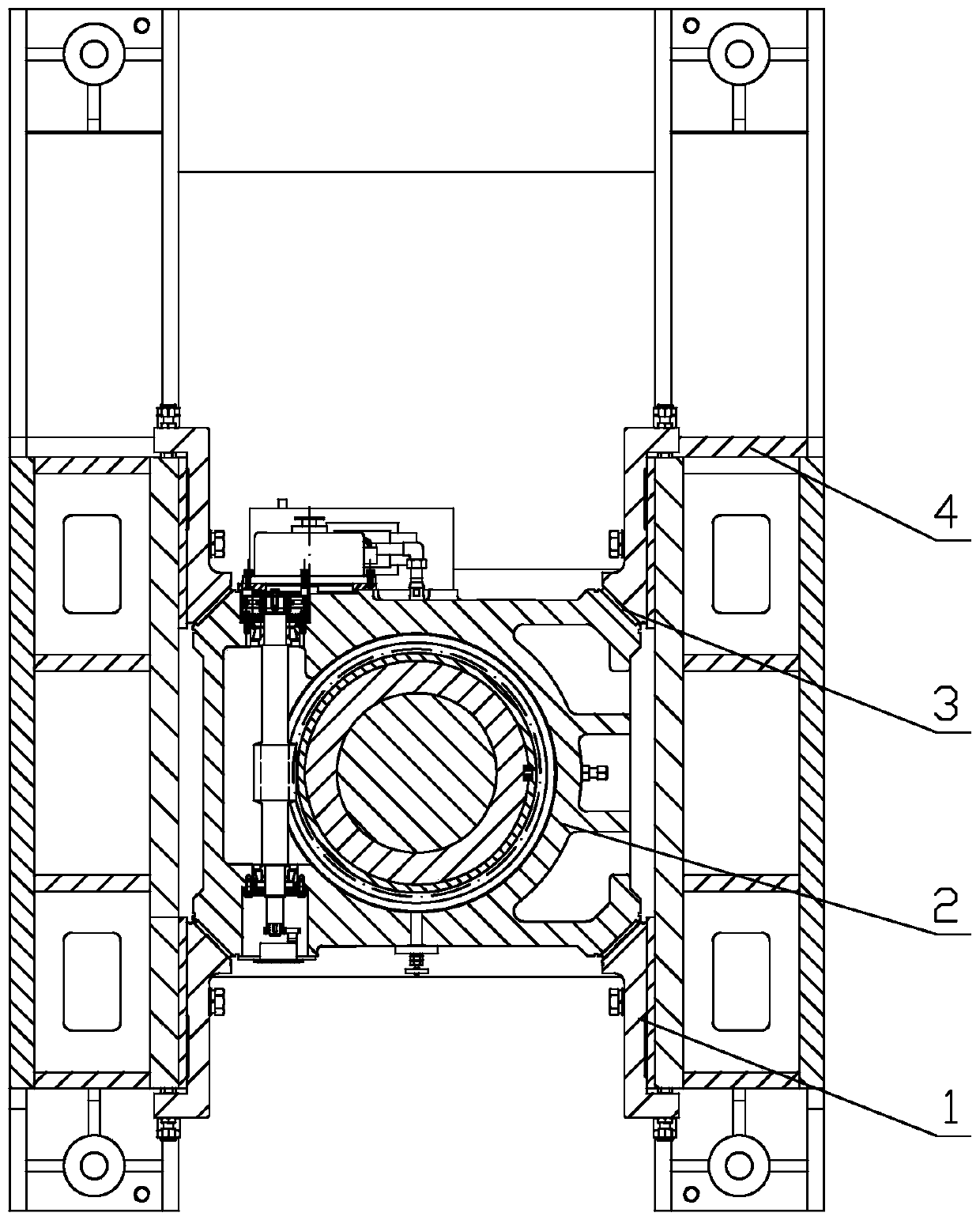

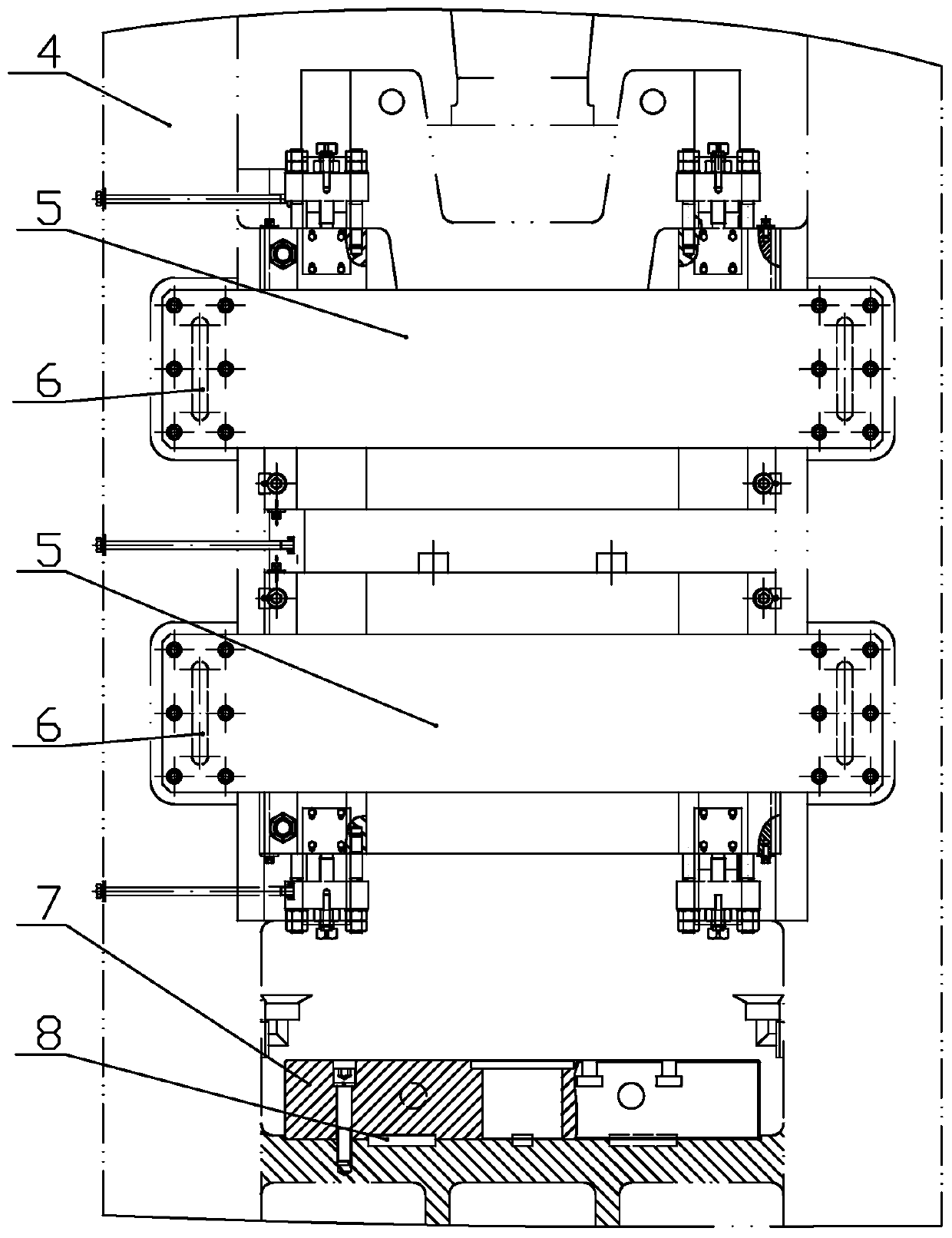

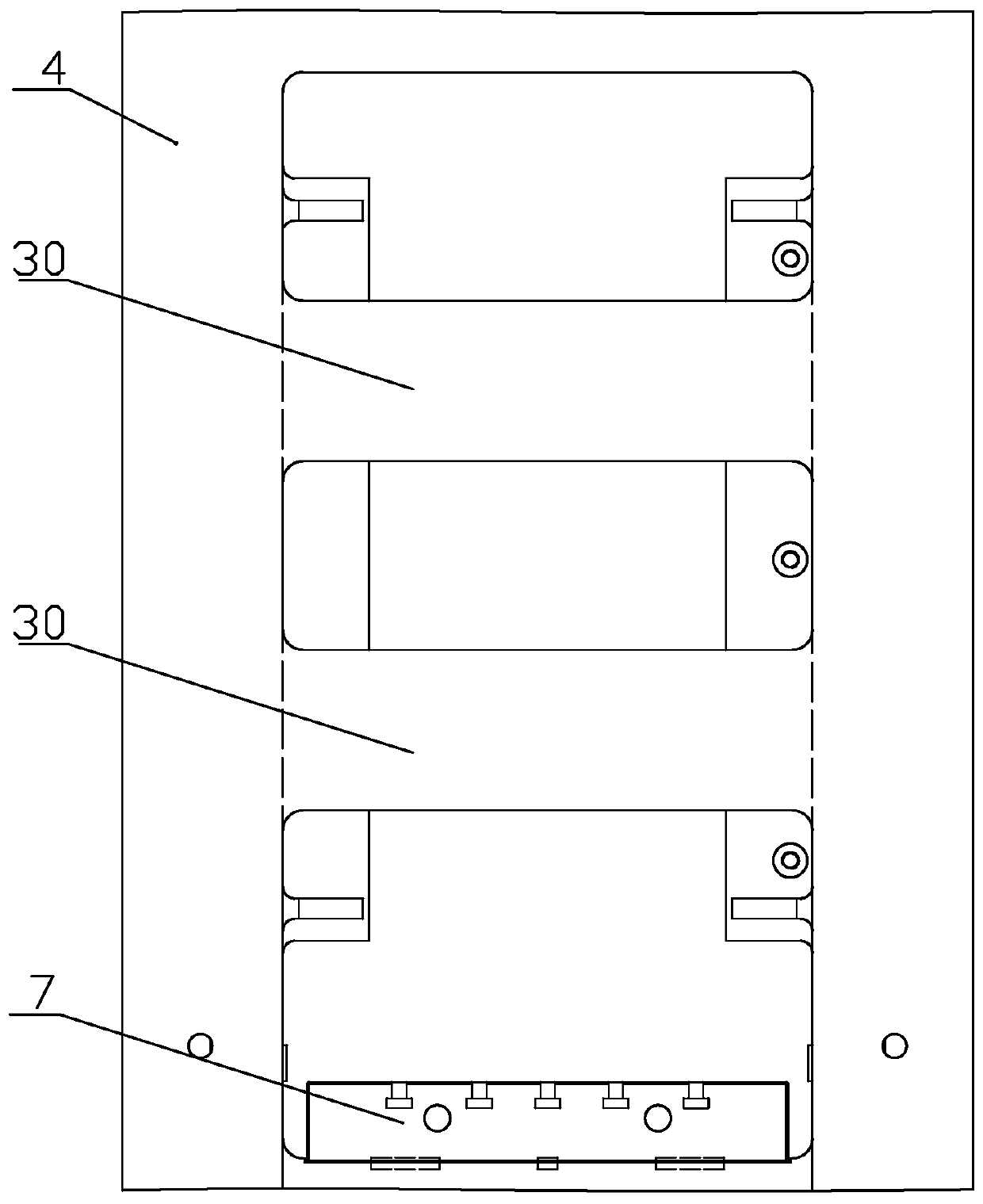

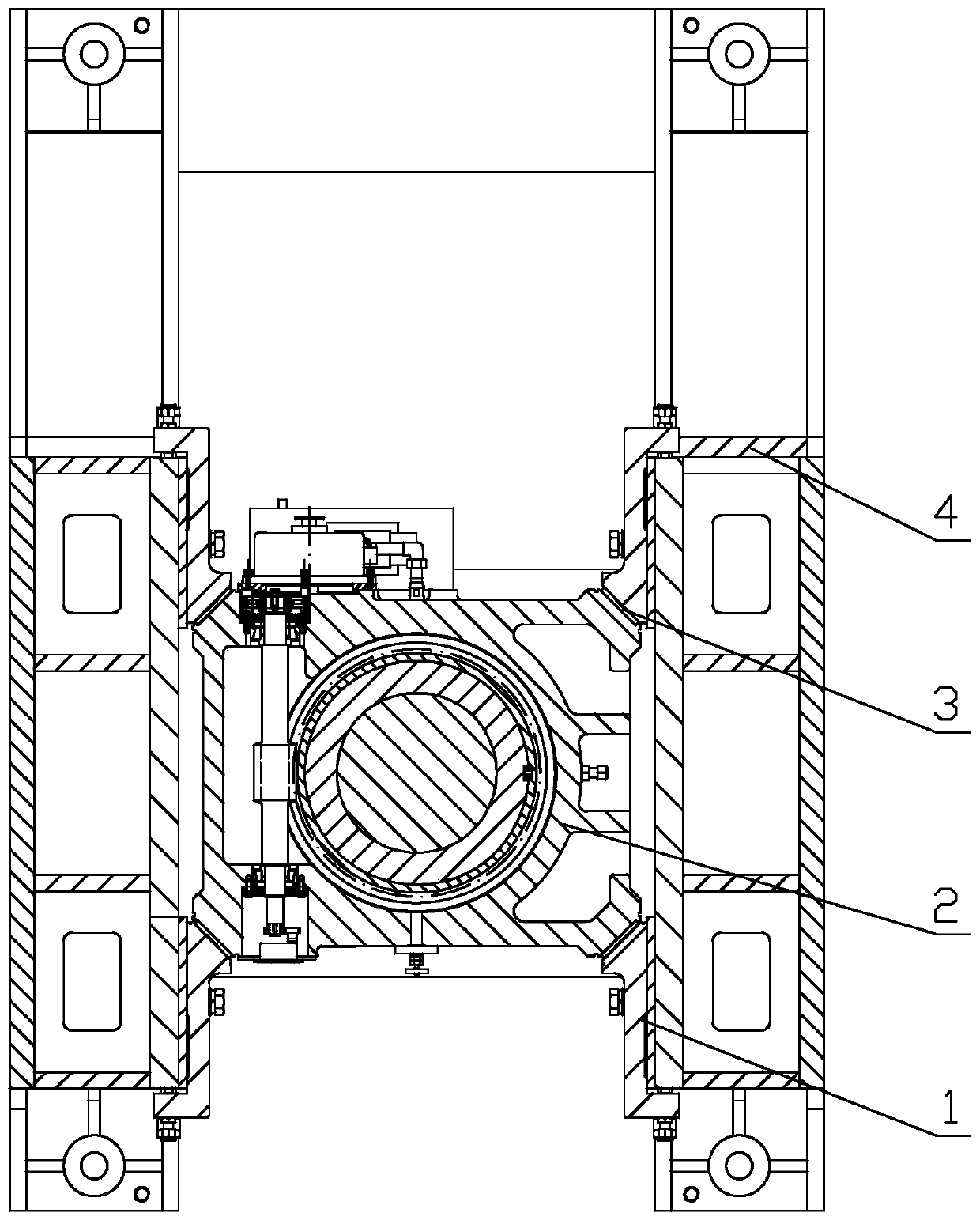

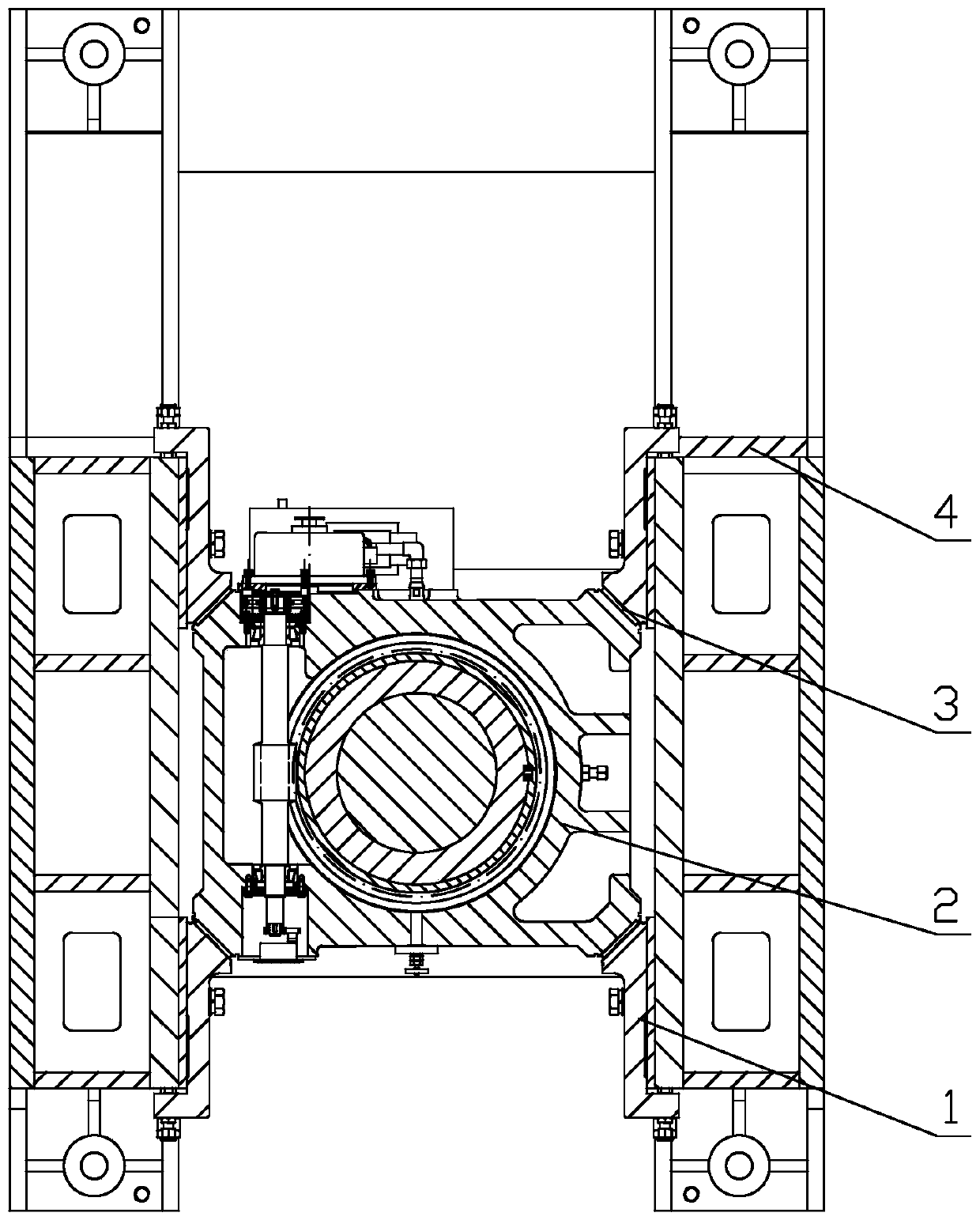

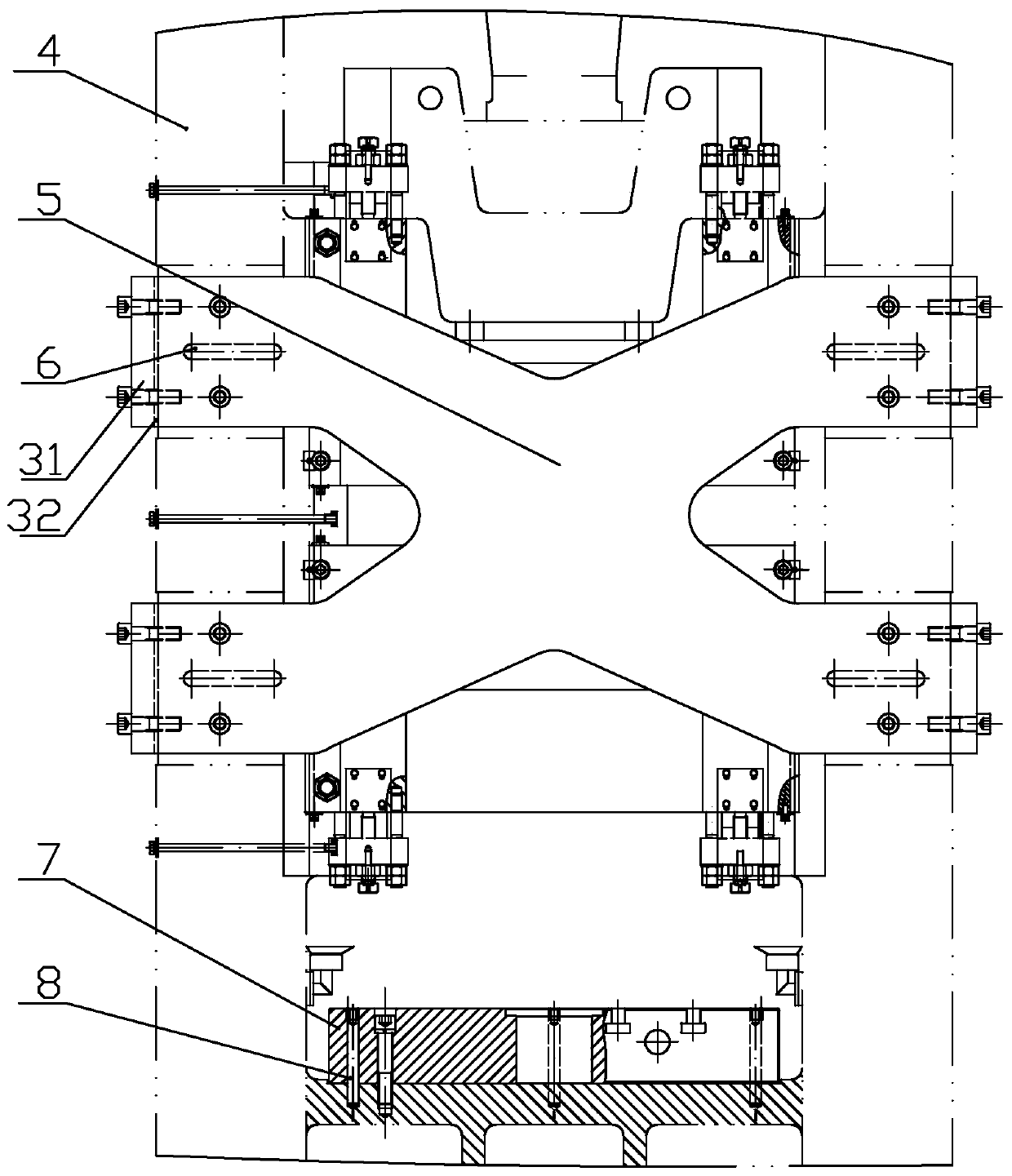

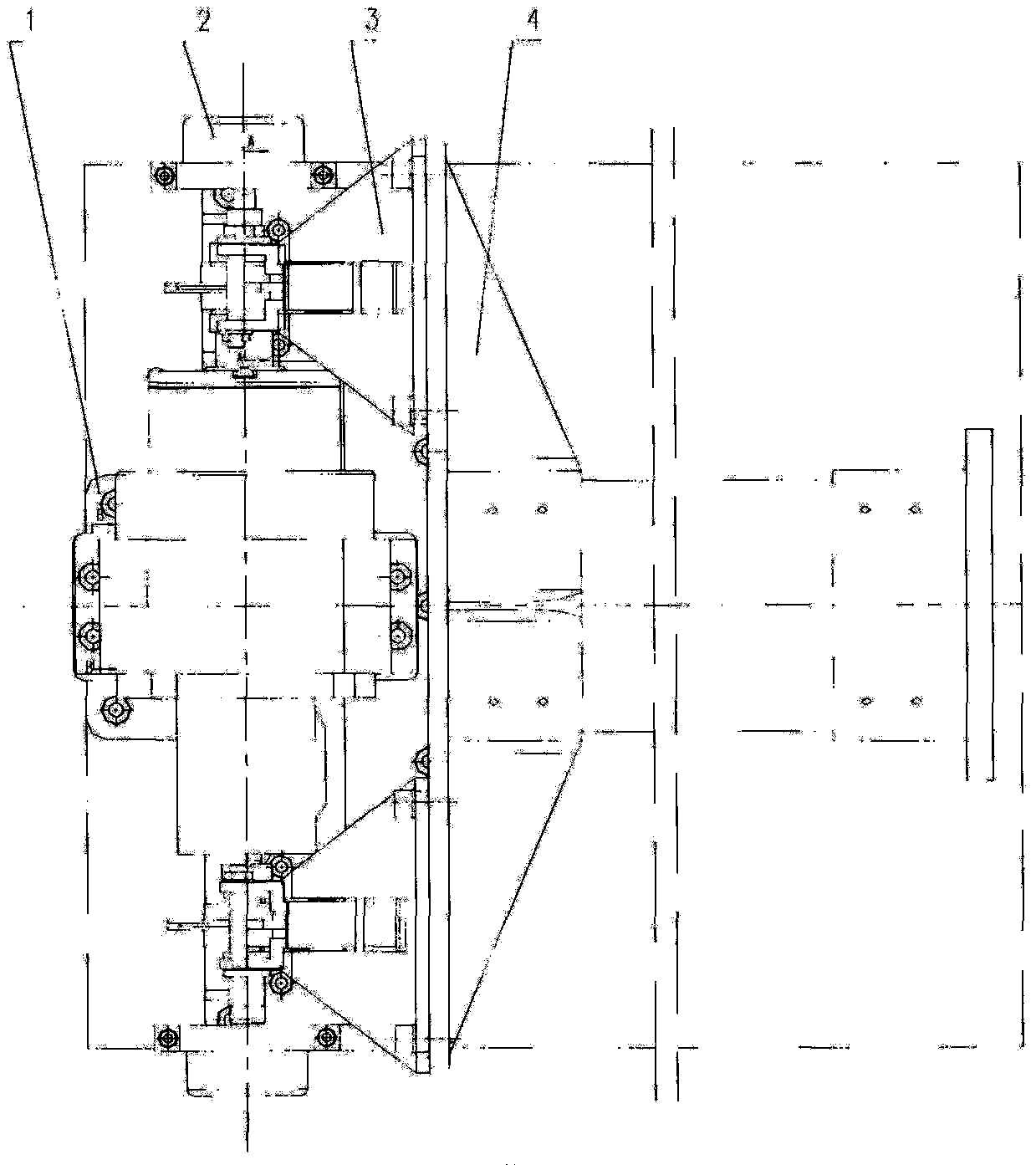

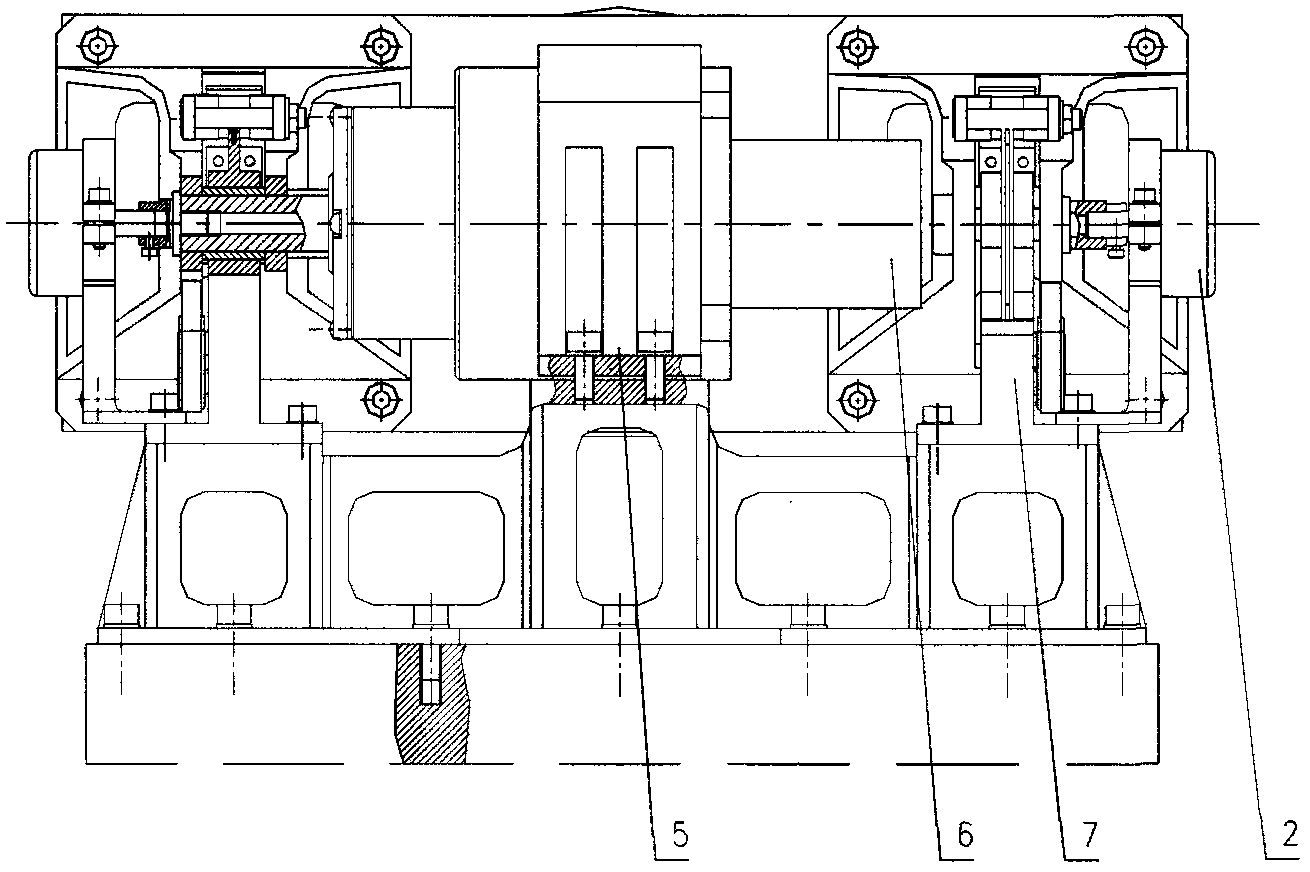

Anti-unbalance-loading device of precise hot die forging press

ActiveCN111036819ANo displacementImprove rigidityForging/hammering/pressing machinesForging press detailsProduction lineGreen materials

The invention relates to the technical field of forging mechanical presses, in particular to an anti-unbalance-loading device of a precise hot die forging press. The anti-unbalance-loading device comprises a rack, a working table plate and a sliding block body, wherein the rack is of an integral cast steel box type frame symmetrical structure, and a symmetrical cage type is formed through a transverse plate; a positioning key is arranged at the bottom of the working table plate and fixed to the rack; the sliding block body is of an integral cast steel structure, and a long octahedral guide rail is arranged on the sliding block body; the guide rail on the front side, the guide rail on the right side and the guide rail on the rear side are 90-degree straight guide rails, and guide rails at the front and the rear of the left side are inclined guide rails; and a left-right gap adjusting mechanism is arranged on the left side of the inside of the rack, and a front-back gap adjusting mechanism is arranged on the front side of the inside of the rack. The anti-unbalance-loading device has the beneficial effects that the rigidity of the whole machine is remarkably improved, the guide precision of the sliding block is improved, and the anti-unbalance-loading capacity is high; and meanwhile, the weight of the whole machine can be reduced, green material saving is achieved, the operation precision and the forging quality are improved, and the remarkable effects of improving the precision, rigidity, efficiency and green material saving of the hot die forging mechanical press and an automatic production line are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +2

A connection structure of a front cross beam and a side wall assembly of an automobile roof

ActiveCN112478000BImprove connection strengthIncrease connection areaSuperstructure connectionsHead-on collisionStructural engineering

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

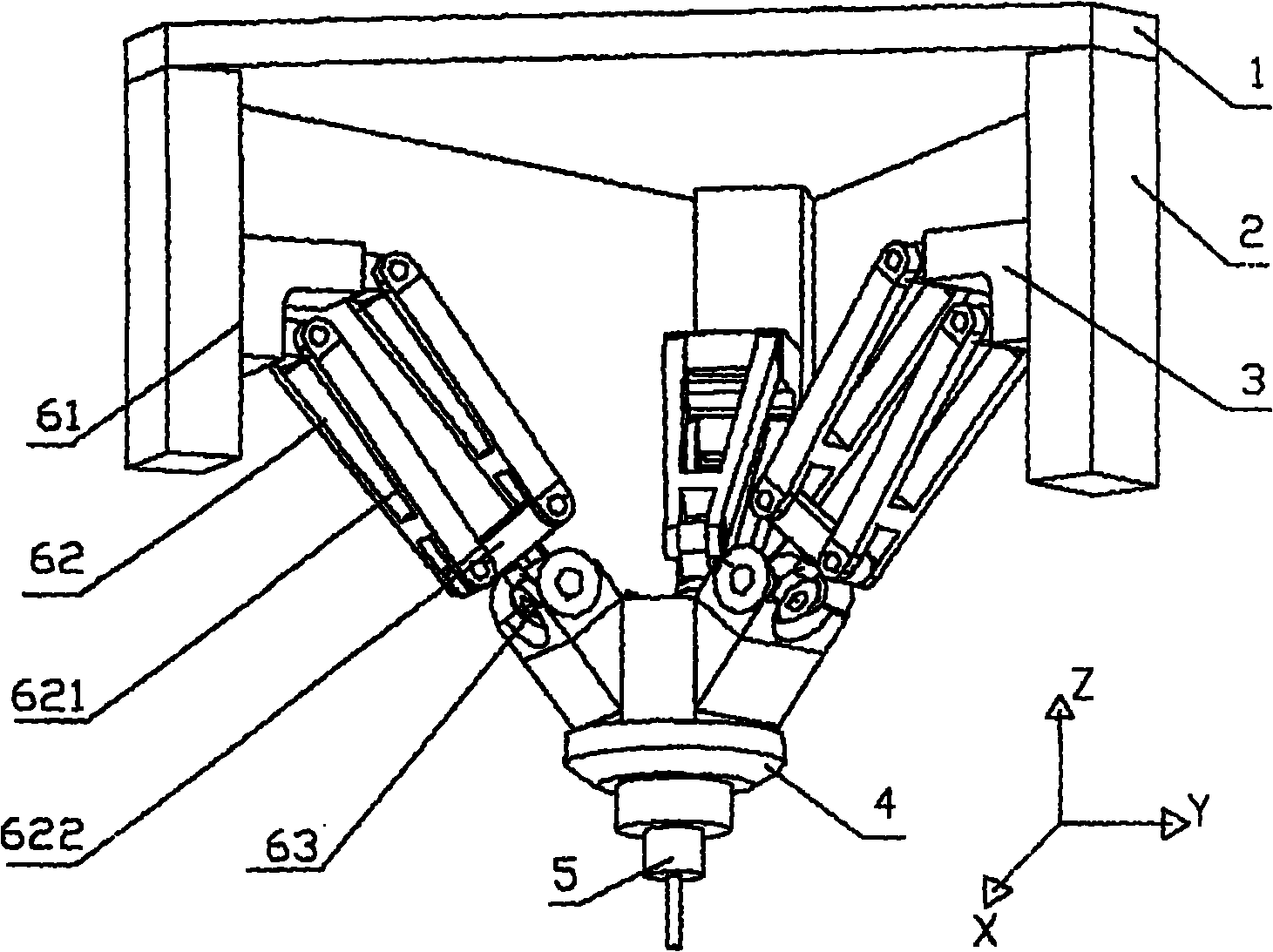

Parallel type three-axis main-shaft head structure

InactiveCN101264576BIncrease stiffnessImprove dynamic performanceLarge fixed membersEngineeringMechanical engineering

The invention relates to a head structure of a parallel triple-axis main spindle, belonging to the technical field of mechanical manufacturing, which comprises a main spindle, a movable platform, a stationary platform, and three identical structural branch mechanisms which are arranged in a triangle for connecting the movable platform and the stationary platform, the main spindle is fixed on the movable platform; each branch mechanism comprises a movement pair, a planar parallelogram mechanism, and a spherical hinge; the planar parallelogram mechanism comprises two parallel long rods with same length and two short rods with one end connected with the long rod via a revolute pair. By adopting the planar parallelogram mechanism, the head structure of the parallel three-axis main spindle hasthe advantages of improving the structural rigidity, realizing the Z axis movement of the platform and rotation around X axis and Y axis by overriding three movement pairs, changing the main spindle working position, and having the possibility to comprehensively machine the big scale complicated structural parts.

Owner:TSINGHUA UNIV

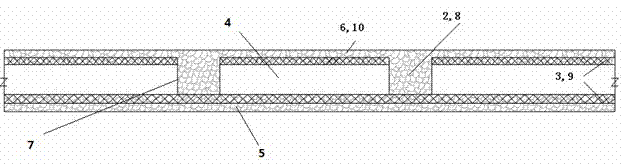

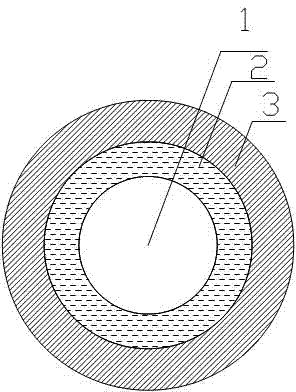

Composite cross arm for power transmission line and preparation method thereof

ActiveCN102261193BLight in massStable modulus of elasticityTowersGlass/slag layered productsGlass fiberEngineering

The invention discloses a composite cross arm for a power transmission line and a preparation method thereof, belonging to the field of members matched with power transmission poles. The structure of the composite cross arm for the power transmission line adopts the cylindrical solid structure, and the cylindrical solid structure is divided into three layers, namely a core layer, an intermediate layer and an outer layer, from inside to outside, wherein the core layer is a composite solid rod which is formed by pultrusion; the intermediate layer made of a glass fiber resin based composite is wound on the outer surface of the solid rod; and the outer layer constituted by an umbrella skirt is coated on the outer surface of the intermediate layer. The preparation method comprises the following steps: performing the pultrusion on glass fiber reinforced thermosetting resins for forming the core layer; winding the resin-based composite on glass fibers for constituting the intermediate layer;and coating the layer of the umbrella skirt outside the intermediate layer for constituting the outer layer. The cross arm prepared by the method is light in weight, good in insulativity and anti-aging performance and convenient to mount, and can effectively improve the safety coefficient of the actual line when being applied on the actual line and reduce the cost.

Owner:北玻电力复合材料有限公司

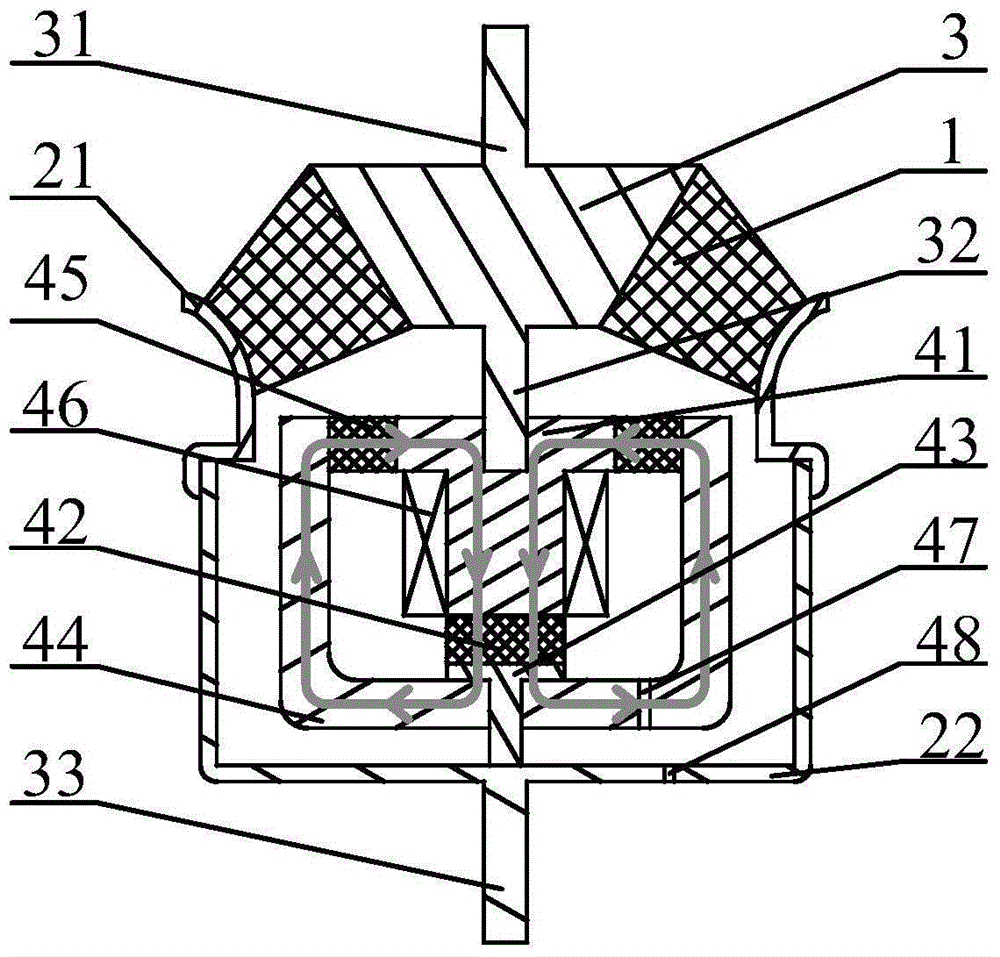

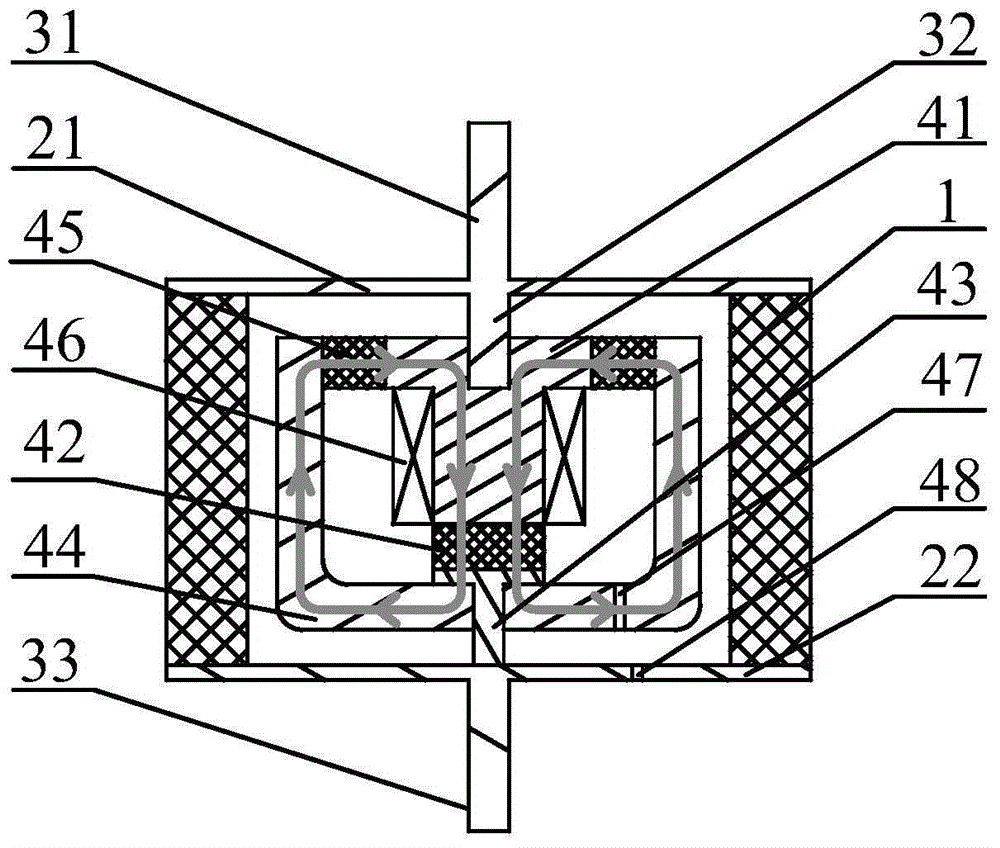

A seven-degree-of-freedom-three-branch parallel symmetrical mechanism for plate splicing

ActiveCN105328693BHigh precisionIncreased stiffness requirementsProgramme-controlled manipulatorMetal working apparatusMirror reflectionDegrees of freedom

The invention provides a seven-freedom-degree three-branch parallel symmetric mechanism for plate splicing. An upper platform 1 and a lower platform 2 of the parallel mechanism are the same. An upper rotating pair and a lower rotating pair which are driven by a motor are arranged in the central normal direction of the upper platform and the central normal direction of the lower platform respectively. The upper platform and the lower platform are connected through two SPS branches and one RRRRR branch, wherein the two SPS branches are each composed of ball pairs at the two ends and a translational pair driven by a middle linear motor; and the RRRRR branch is composed of five rotating pairs, and the first, third and fifth rotating pairs of the RRRRR branch are driven by the motor. The three branches between the upper platform and the lower platform of the mechanism have the mirror reflection symmetric feature, and continuous and efficient movement is achieved on the condition that system complexity is not increased on the basis of high-precision and high-rigidity positioning of the three parallel branches and the mirror reflection symmetric feature between the upper platform and the lower platform.

Owner:SHANGHAI AEROSPACE SYST ENG INST

A Parallel Mode Semi-Active Vibration Isolator

ActiveCN104747651BWide range of stiffnessIncrease stiffnessSpringsShock absorbersSemi activeEngineering

The invention discloses a paralleling model semi-active vibration isolator. The vibration isolator is characterized in that a cylindrical upper shell is arranged, a rubber main spring is plugged in a top end opening of the upper shell, a main spring framework penetrates through the rubber main spring and is provided with an upper connection stud and a lower connection stud, the upper connection stud is connected with a main vibrating object, the lower connection stud is connected with a column-shaped iron core where an excitation coil is wound, the column-shaped iron core is supported in a magnetism conduction sleeve through a cutting magnetorheological elastomer arranged on the outer circumference of the column-shaped iron core, the two ends of the magnetorheological elastomer are extruded to be connected with the top of a T-shaped support and the bottom end of the iron core, and the T-shaped support penetrates through the magnetism conduction sleeve and is fixedly connected; the upper shell is connected with a lower shell, the lower end of the T-shaped support is fixedly connected with the lower shell, and the bottom of the lower shell is provided with a connection bolt used for being connected with a basal body. By means of the vibration isolator, vibrating energy transmitted by a rotary machine to the basal body can be effectively reduced, vibration of relative parts of the rotary machine is reduced, and the service life of the rotary machine and a system of the rotary machine is prolonged.

Owner:HEFEI UNIV OF TECH

Externally-mounted connector of airplane wing

InactiveCN107150787ASimple structureReduce manufacturing costWingsJet aeroplaneUltimate tensile strength

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

An anti-eccentric load device for a precision hot die forging press

ActiveCN111036819BNo displacementImprove rigidityForging/hammering/pressing machinesForging press detailsProduction lineGreen materials

The invention relates to the technical field of forging mechanical presses, in particular to an anti-unbalance-loading device of a precise hot die forging press. The anti-unbalance-loading device comprises a rack, a working table plate and a sliding block body, wherein the rack is of an integral cast steel box type frame symmetrical structure, and a symmetrical cage type is formed through a transverse plate; a positioning key is arranged at the bottom of the working table plate and fixed to the rack; the sliding block body is of an integral cast steel structure, and a long octahedral guide rail is arranged on the sliding block body; the guide rail on the front side, the guide rail on the right side and the guide rail on the rear side are 90-degree straight guide rails, and guide rails at the front and the rear of the left side are inclined guide rails; and a left-right gap adjusting mechanism is arranged on the left side of the inside of the rack, and a front-back gap adjusting mechanism is arranged on the front side of the inside of the rack. The anti-unbalance-loading device has the beneficial effects that the rigidity of the whole machine is remarkably improved, the guide precision of the sliding block is improved, and the anti-unbalance-loading capacity is high; and meanwhile, the weight of the whole machine can be reduced, green material saving is achieved, the operation precision and the forging quality are improved, and the remarkable effects of improving the precision, rigidity, efficiency and green material saving of the hot die forging mechanical press and an automatic production line are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

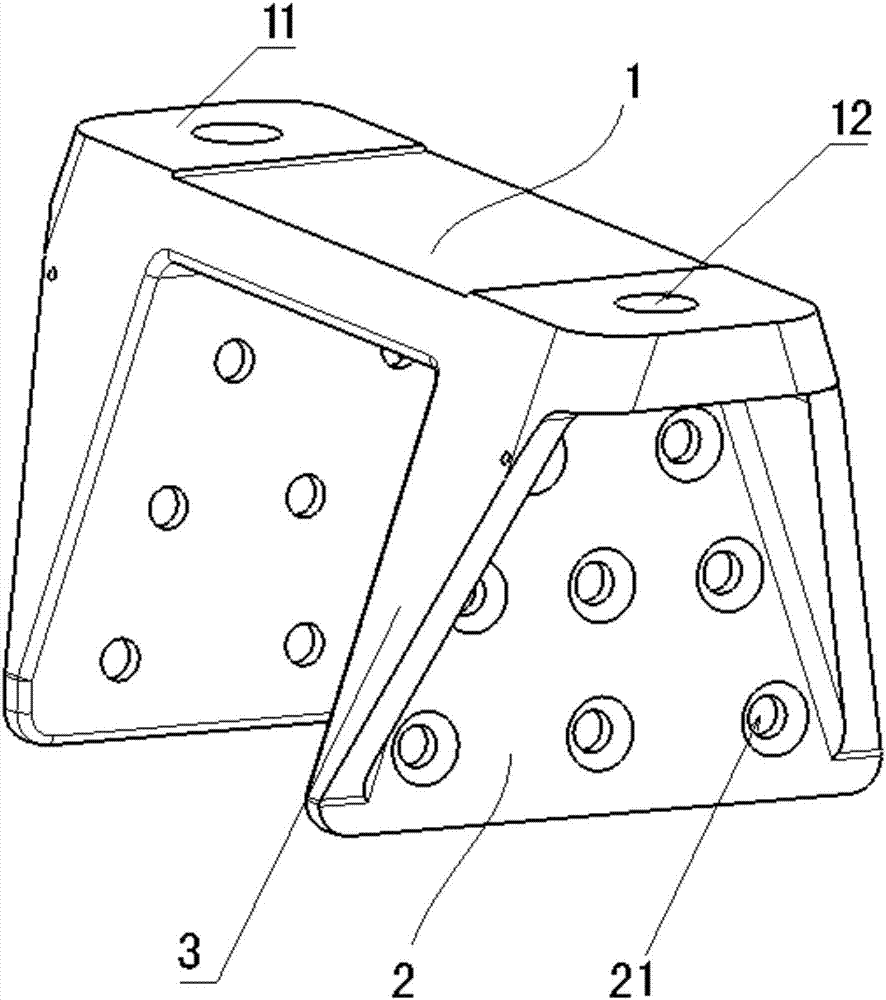

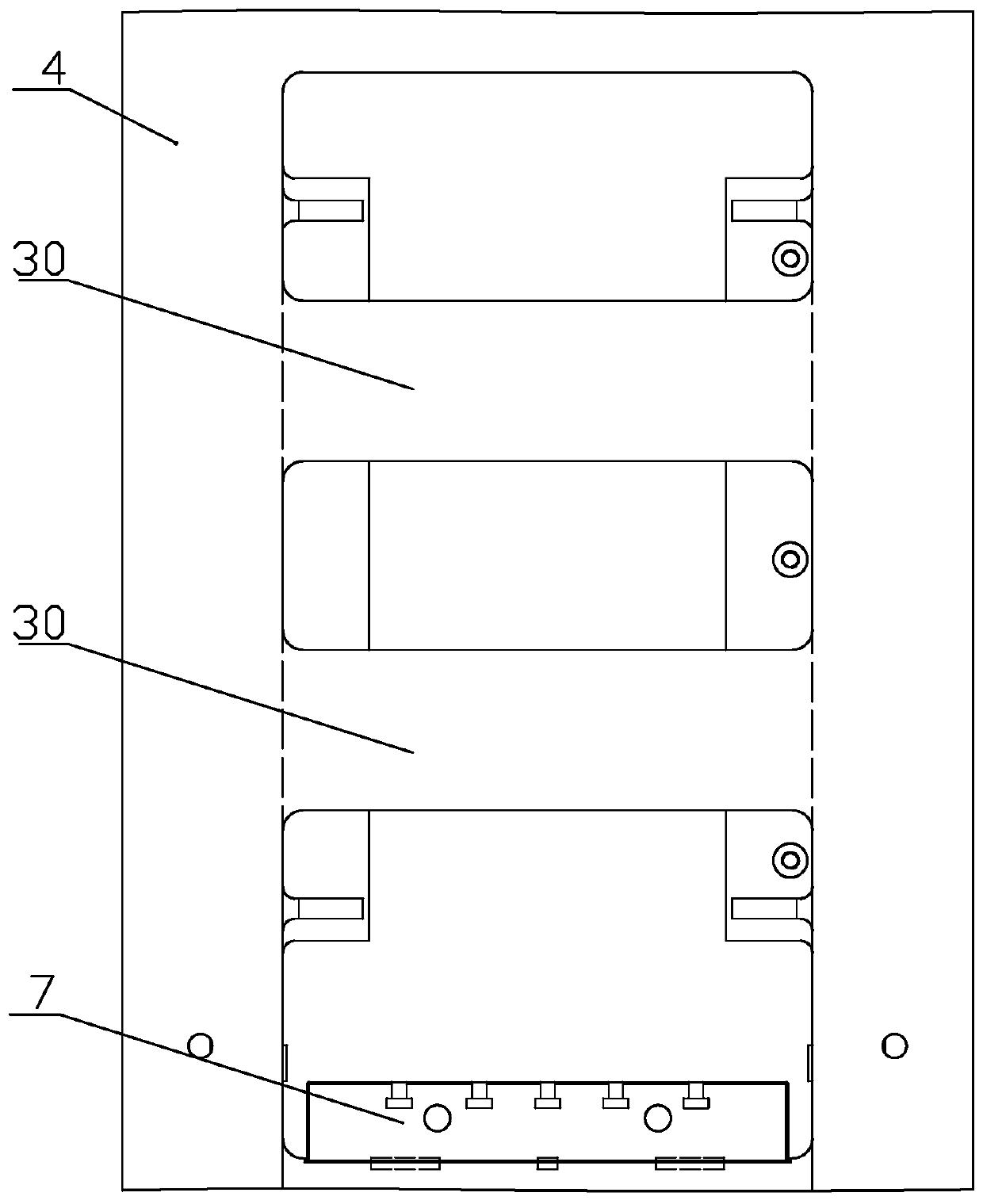

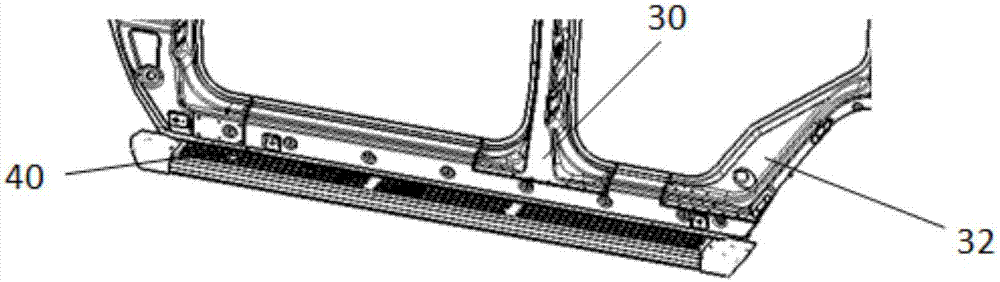

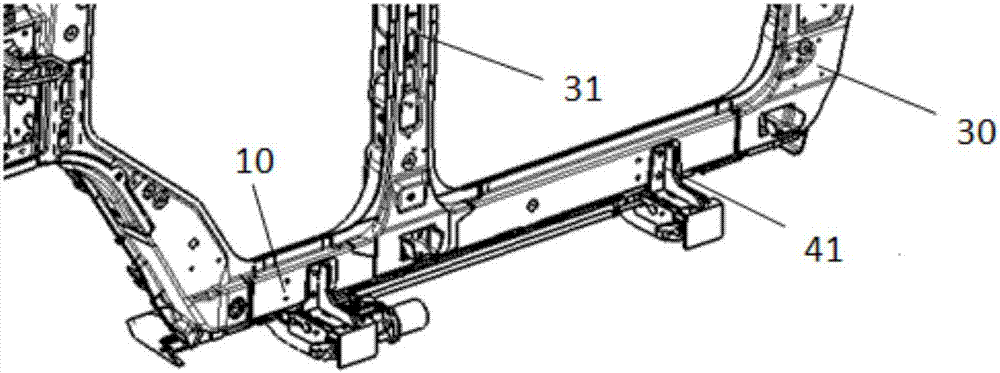

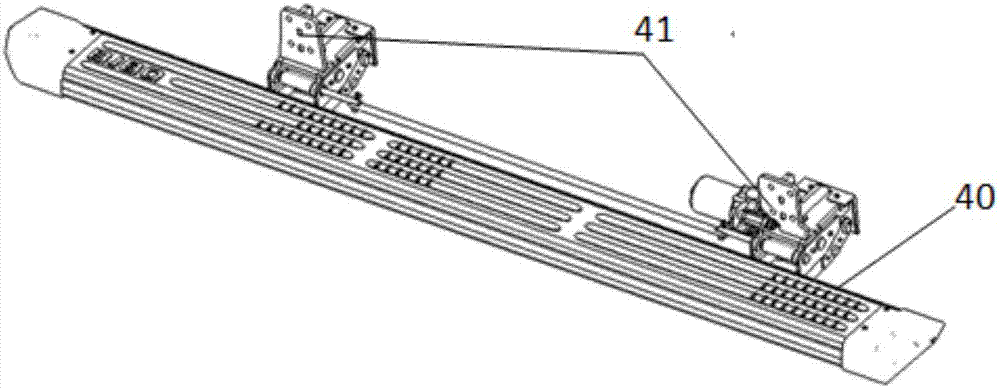

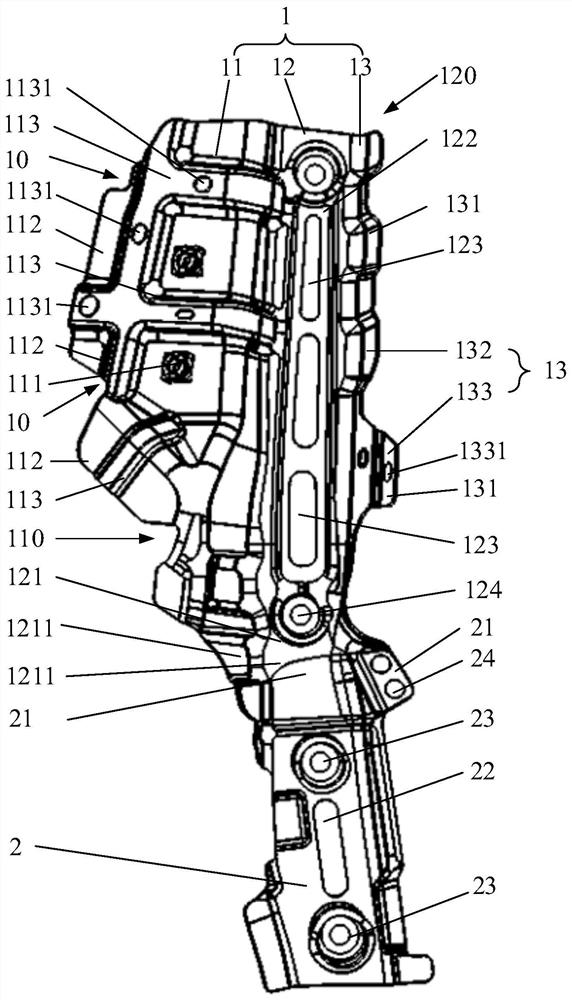

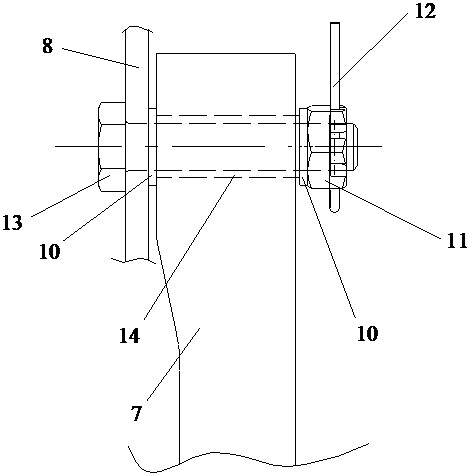

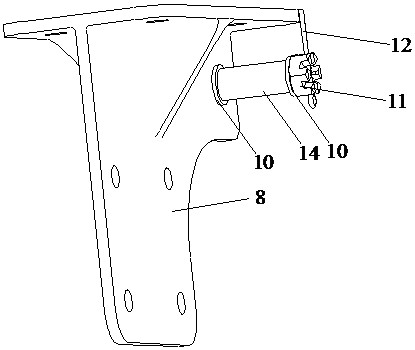

Reinforcing structure used for mounting vehicle stepping bar and vehicle comprising same

ActiveCN107953931AMeet performance requirementsIncreased stiffness requirementsSuperstructure subunitsSteps arrangementAutomotive engineeringPerformance requirement

The invention provides a reinforcing structure used for mounting a vehicle stepping bar and a vehicle comprising the same. The reinforcing structure used for mounting the vehicle stepping bar comprises a doorsill inner plate and a reinforcing plate assembly; the doorsill inner plate is arranged to be matched with a side wall of a vehicle body, so that the doorsill inner plate is fixed to the sidewall of the vehicle body and used for mounting the stepping bar; and the reinforcing plate assembly comprises a reinforcing plate, the reinforcing plate is fixed on the doorsill inner plate so as to improve the mounting strength of the stepping bar. According to the reinforcing structure used for mounting the vehicle stepping bar, the stiffness requirement of the vehicle body is improved, and thestrength requirement of mounting of the vehicle stepping bar and the performance requirement of the vehicle are met.

Owner:BAIC GRP ORV CO LTD

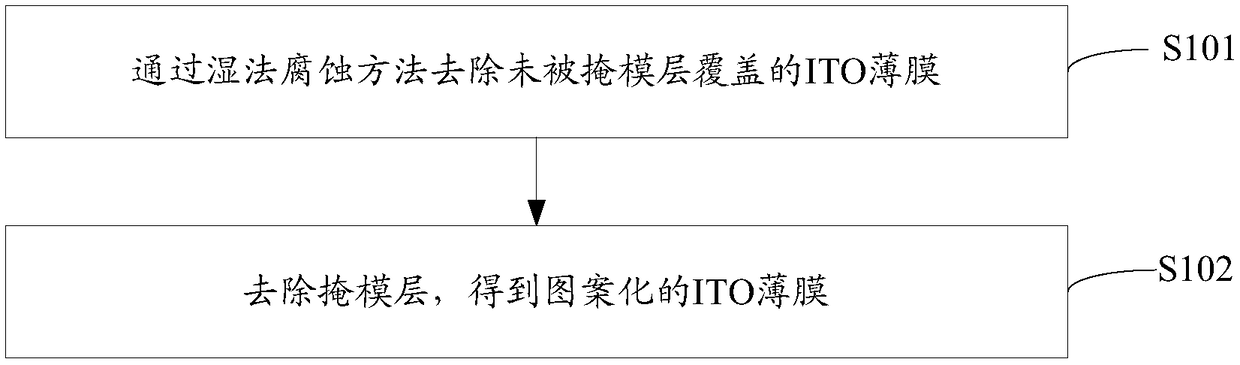

Patterning method of ITO (indium tin oxide) film

InactiveCN108520856AHigh strength requirementsIncreased stiffness requirementsSemiconductor/solid-state device manufacturingSurface treatment compositionsOxidizing acidCorrosion inhibitor

The present application discloses a patterning method of an ITO (indium tin oxide) film. A patterned mask layer is formed on the ITO film. The method includes the following steps that: an ITO film notcovered by a mask layer is removed by means of a wet etching method; and the mask layer is removed, so that a patterned ITO film is obtained. According to the wet etching method, a wet etching solution is a mixed solution composed of oxidizing acid, medium-strength acid and weak acid, and the temperature of the solution is controlled to range from 20 and 60 DEG C; the oxidizing acid and the medium-strength acid can both oxidize ITO, the weak acid is the corrosion inhibitor of the mixed solution, and therefore, the pH value of the mixed solution can be maintained, and a reaction rate can be stable and reliable; and the oxidizing acid, the medium-strength acid and the weak acid have a high etching selection ratio for the mask layer and a substrate, so that the quality of an ITO pattern canbe improved. With the wet etching method adopted, the high selection ratio of the etching solution can be achieved with safety and stability ensured, and the high-quality ITO pattern can be obtained.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Mounting base for mounting automobile back door gas spring

InactiveCN111746243AIncrease profitReduce development costsSuperstructure subunitsDoorsGas springBack door

The invention provides a mounting base for mounting an automobile back door gas spring, and belongs to the technical field of automobiles. The mounting base comprises a reinforcing plate and an extension plate, wherein the reinforcing plate comprises a base plate, a connecting plate and a step plate, a plurality of gas spring mounting holes are formed in the base plate at intervals, one side edgeof the base plate is connected with one side edge of the connecting plate, the other side edge of the connecting plate is connected with one side edge connected with the step plate, and one end of theconnecting plate protrudes out of the base plate and the step plate to extend to form protruding convex extension part; one end of the extension plate is fixed on the convex extension part, and the other end of the extension plate extends along the extension direction of the connecting plate in the same direction; the base plate, the connecting plate, the step plate and the extension plate are all welded to a back door inner plate. By means of the mounting base, the manufacturing cost can be greatly reduced while the rigidity is guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

Pulsator washing machine with multiple washing modes

PendingCN112831970AReduce the number of partsReduce the probability of failureOther washing machinesWashing machine with receptaclesLaundry washing machineDrive shaft

Owner:柴睿明

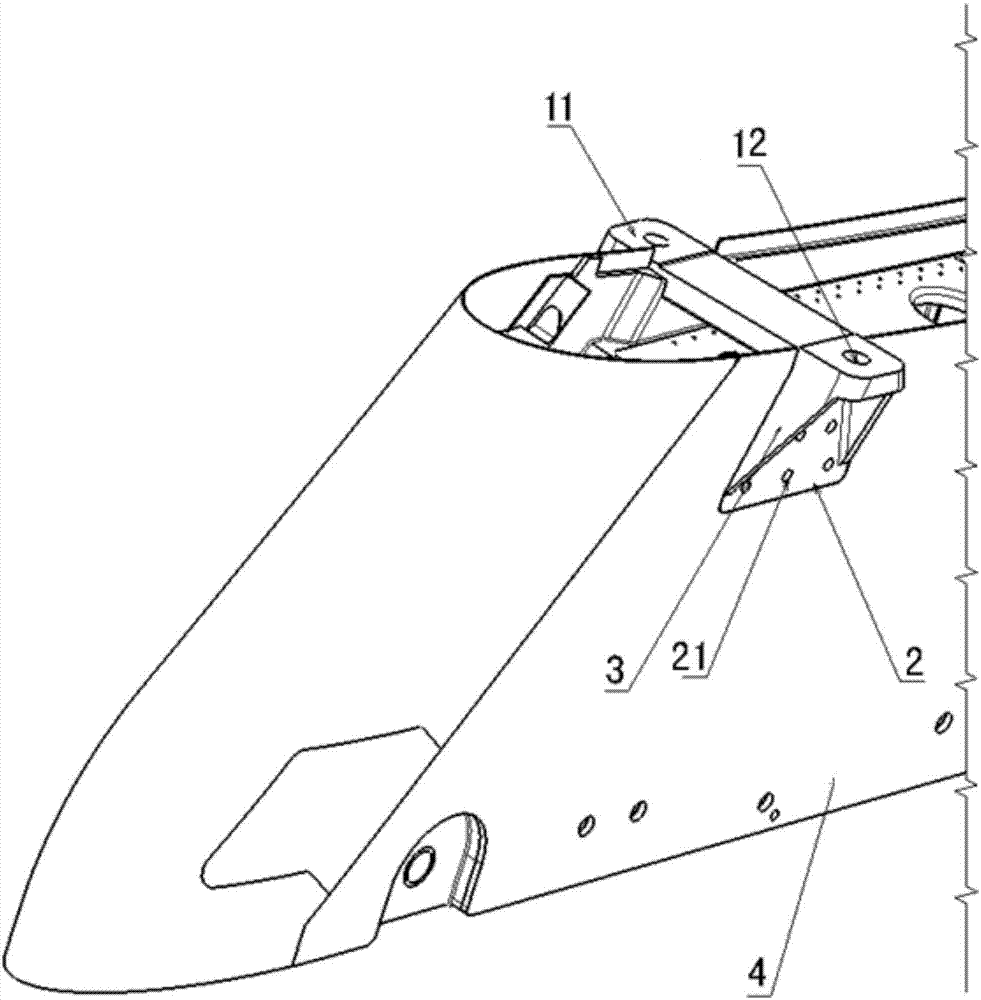

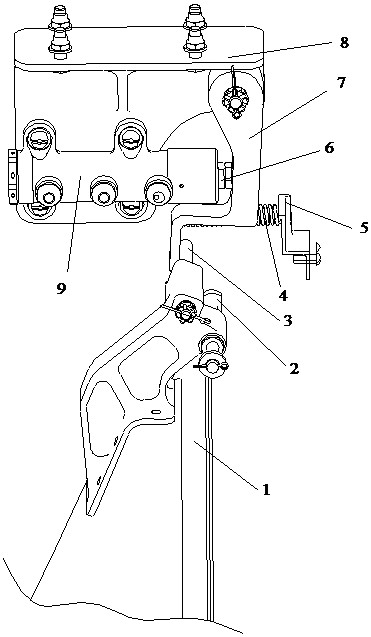

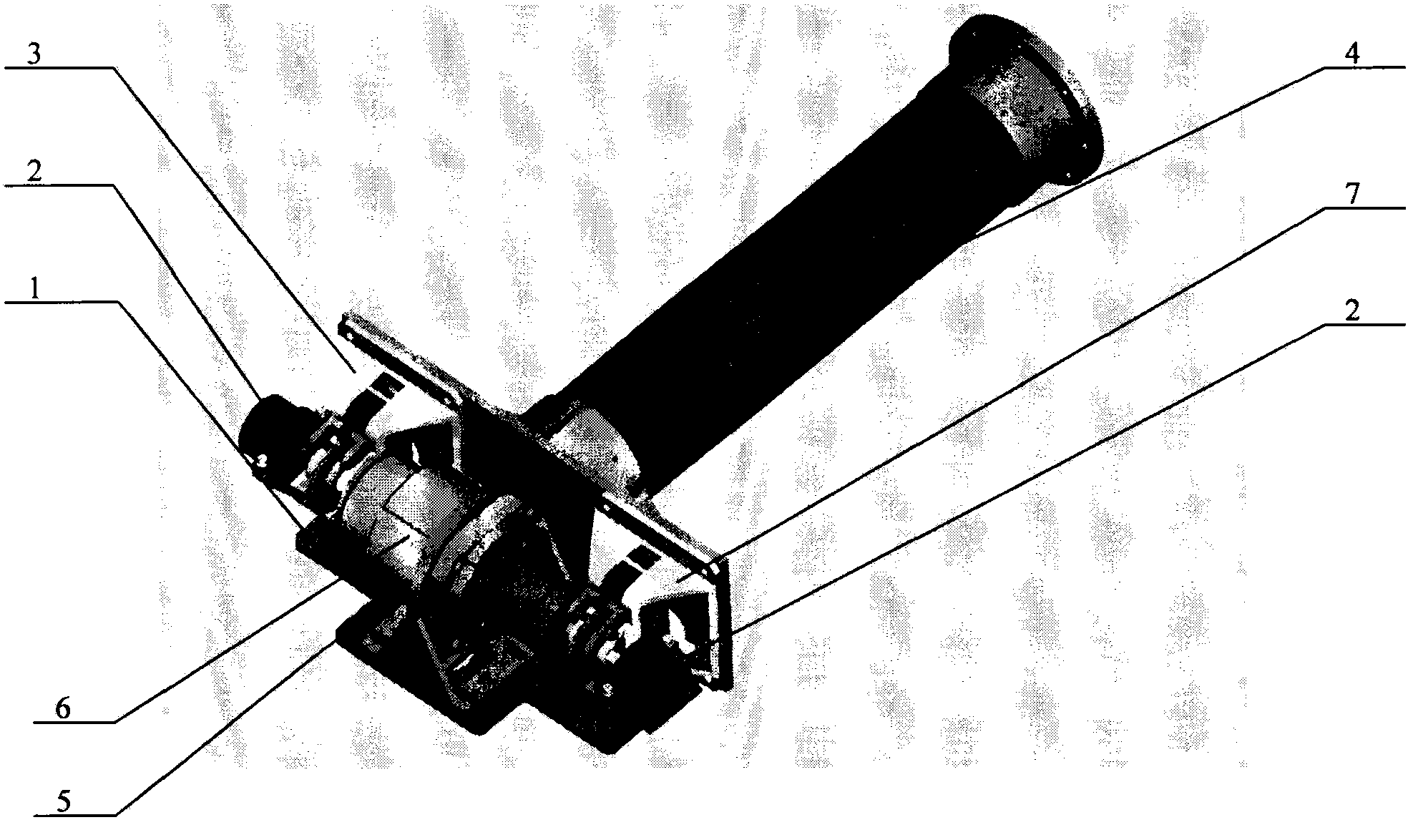

A guard plate landing gear linkage retractable device

ActiveCN105584628BLow installation space requirementCompact structureUndercarriagesMechanical engineeringAircraft manufacturing

The invention relates to the technical field of aircraft manufacturing, in particular to a guard plate and landing gear linkage retracting device. The guard plate and landing gear linkage retracting device comprises a guard plate, a mounting seat, a coordination valve, a support arm and a pressure rod, wherein the coordination valve is fixed to the mounting seat; the pressure rod is arranged on the guard plate and is fixedly connected with the guard plate; one end of the support arm is in contact with the pressure rod, and the other end is movably connected with the mounting seat; the support arm and the coordination valve are positioned in the same mounting plane. The linkage retracting device disclosed by the invention is compact in structure, low in cost, and simple to use and maintain, the retracting reliability for the landing gear can be greatly improved, besides, the requirement for the mounting space of an aircraft is also low, and the retracting device is easy to popularize and use in a hydraulic system of the aircraft.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

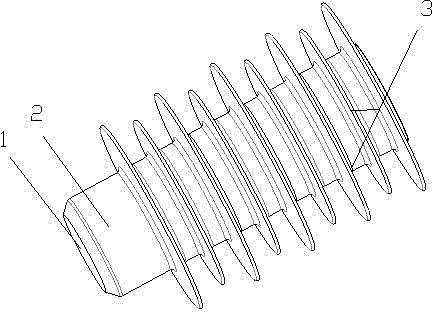

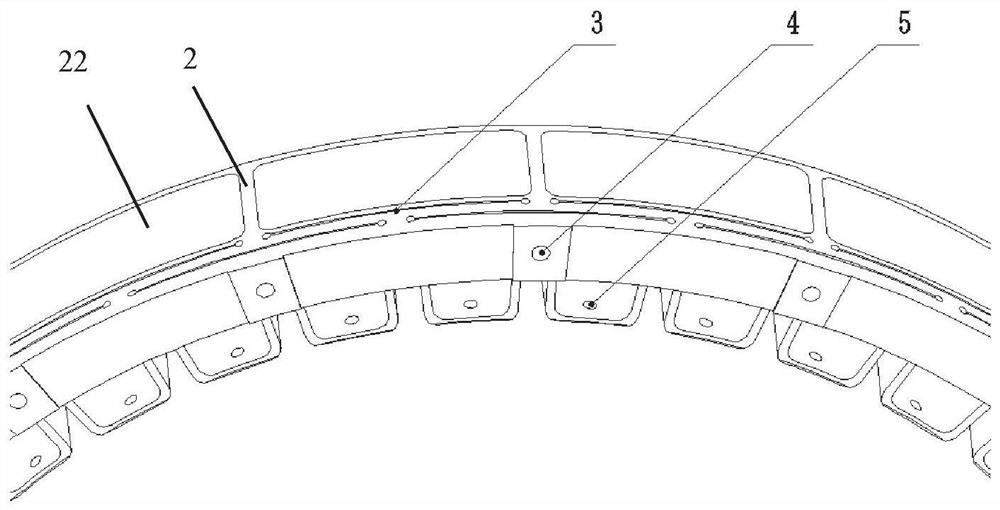

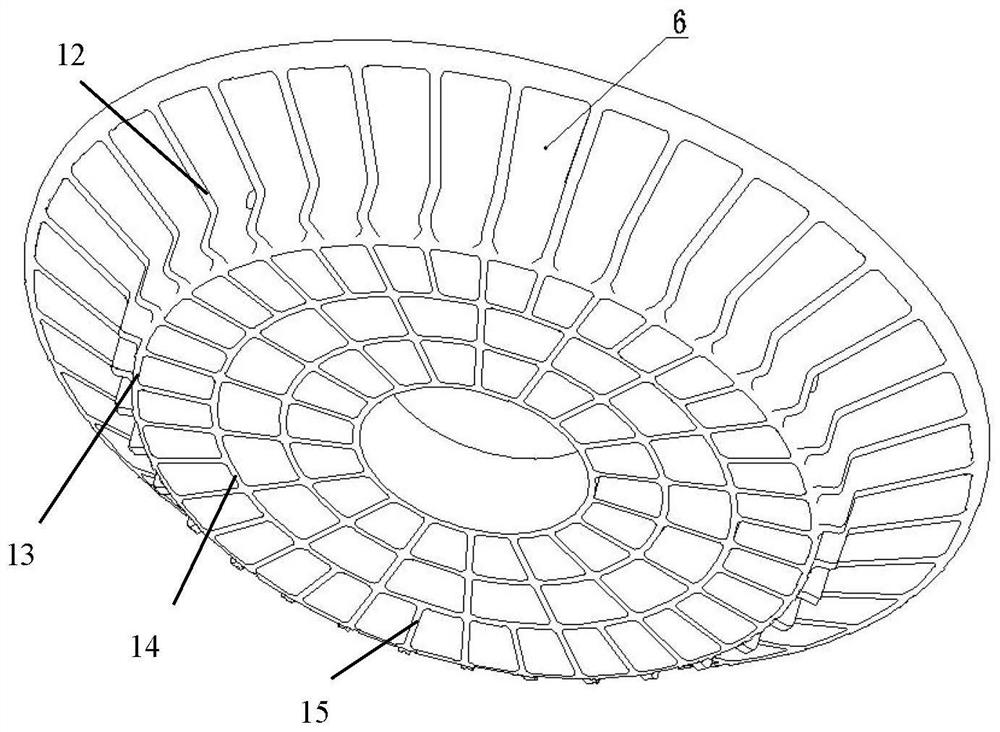

Tooth-shaped reflector integrated supporting frame structure with high force thermal stability

The invention relates to the field of spaceflight optical remote sensors, and particularly discloses a tooth-shaped reflector integrated supporting frame structure with high force thermal stability, which comprises a reflector and a supporting frame, and a plurality of supporting grooves are formed in the supporting surface of the reflector. The supporting groove extends in the direction close to the axis of the reflector along the edge position of the supporting face of the supporting groove of the reflector, the supporting groove comprises a bottom wall, an end wall and two side walls, the bottom wall is located on the supporting face of the reflector, and the end wall extends in the direction parallel to the axis of the reflector from the end, close to the axis of the reflector, of the bottom wall. The side walls are located on the two sides of the bottom wall and the end wall, the side, facing the reflecting mirror, of the supporting frame is provided with a plurality of supporting teeth, the supporting teeth are clamped in the supporting grooves, adhesive layers are arranged between the supporting teeth and the bottom wall and between the supporting teeth and the side walls and between the supporting teeth and the end wall, and the effects that the surface shape of the reflecting mirror can be easily kept, large vibration loads can be borne, and high temperature adaptability is achieved are achieved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Structural rigidity and precision improving device for hot die forging press

ActiveCN111036817BNo displacementHigh dynamic stiffnessForging/hammering/pressing machinesForging press detailsDynamic stiffnessMachine

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +1

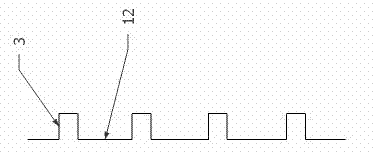

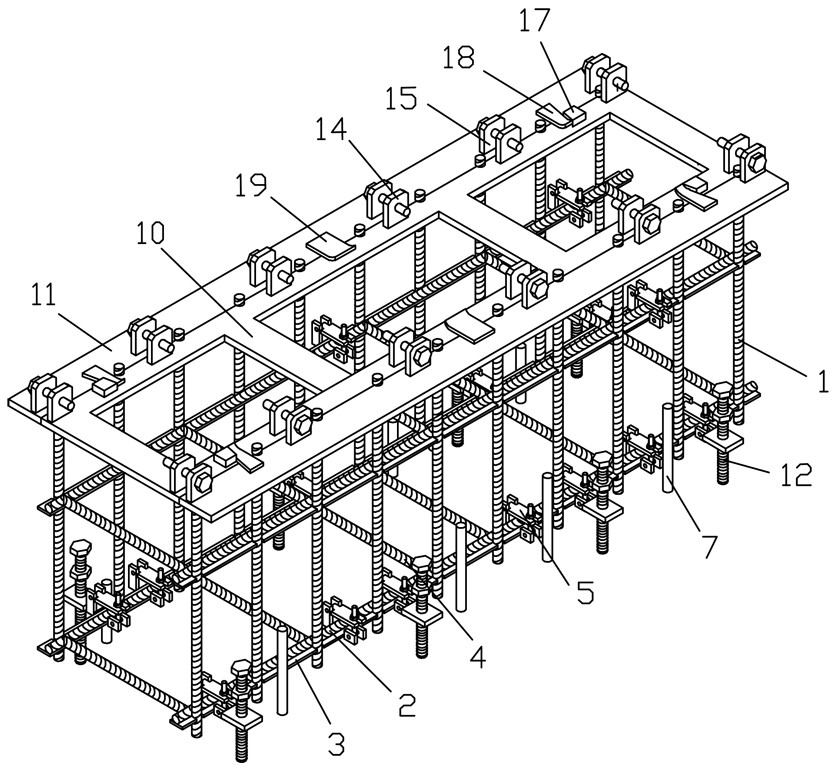

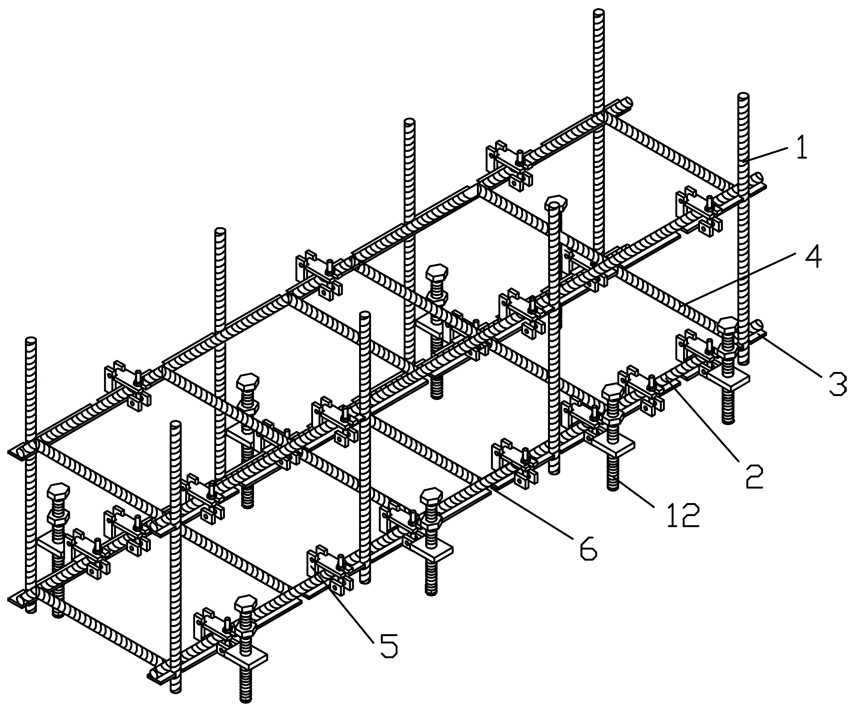

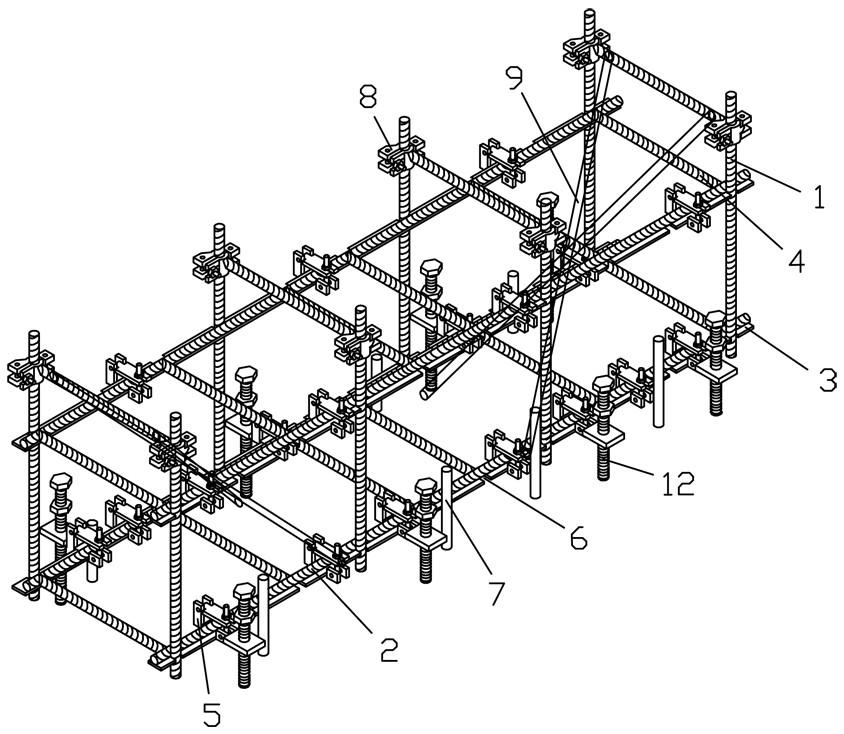

Precise positioning and fixing device for embedded steel bars in cast-in-place bottom plate of fabricated channel side wall and construction method

PendingCN113846607APrecise positioningEasy to installArtificial water canalsBuilding material handlingClassical mechanicsRebar

The invention relates to a precise positioning and fixing device for embedded steel bars in a cast-in-place bottom plate of a fabricated channel side wall. The precise positioning and fixing device comprises a lower-layer horizontal positioning and fixing frame, a middle-layer horizontal positioning and fixing frame, an upper-layer horizontal positioning and fixing verification sleeve plate and a plurality of vertical rods. The lower-layer horizontal positioning and fixing frame comprises two fixing frame long rods, a positioning toothed plate strip and a plurality of transverse rods; the middle-layer horizontal positioning and fixing frame and the lower-layer horizontal positioning and fixing frame are the same in structure; the vertical rods are arranged between the middle-layer horizontal positioning and fixing frame and the lower-layer horizontal positioning and fixing frame; and the upper-layer horizontal positioning and fixing verification sleeve plate is correspondingly arranged above the middle-layer horizontal positioning and fixing frame, and the top ends of the vertical rods exceed the upper-layer horizontal positioning and fixing verification sleeve plate. The invention further relates to a construction method of the precise positioning and fixing device for the embedded steel bars in the cast-in-place bottom plate of the fabricated channel side wall. The problems that in the construction process of cast-in-place bottom plate pre-embedded vertical steel bars, the positioning deviation is large, binding is loose, and fixing is not firm can be solved.

Owner:HENAN PROVINCIAL WATER CONSERVANCY RES INST +3

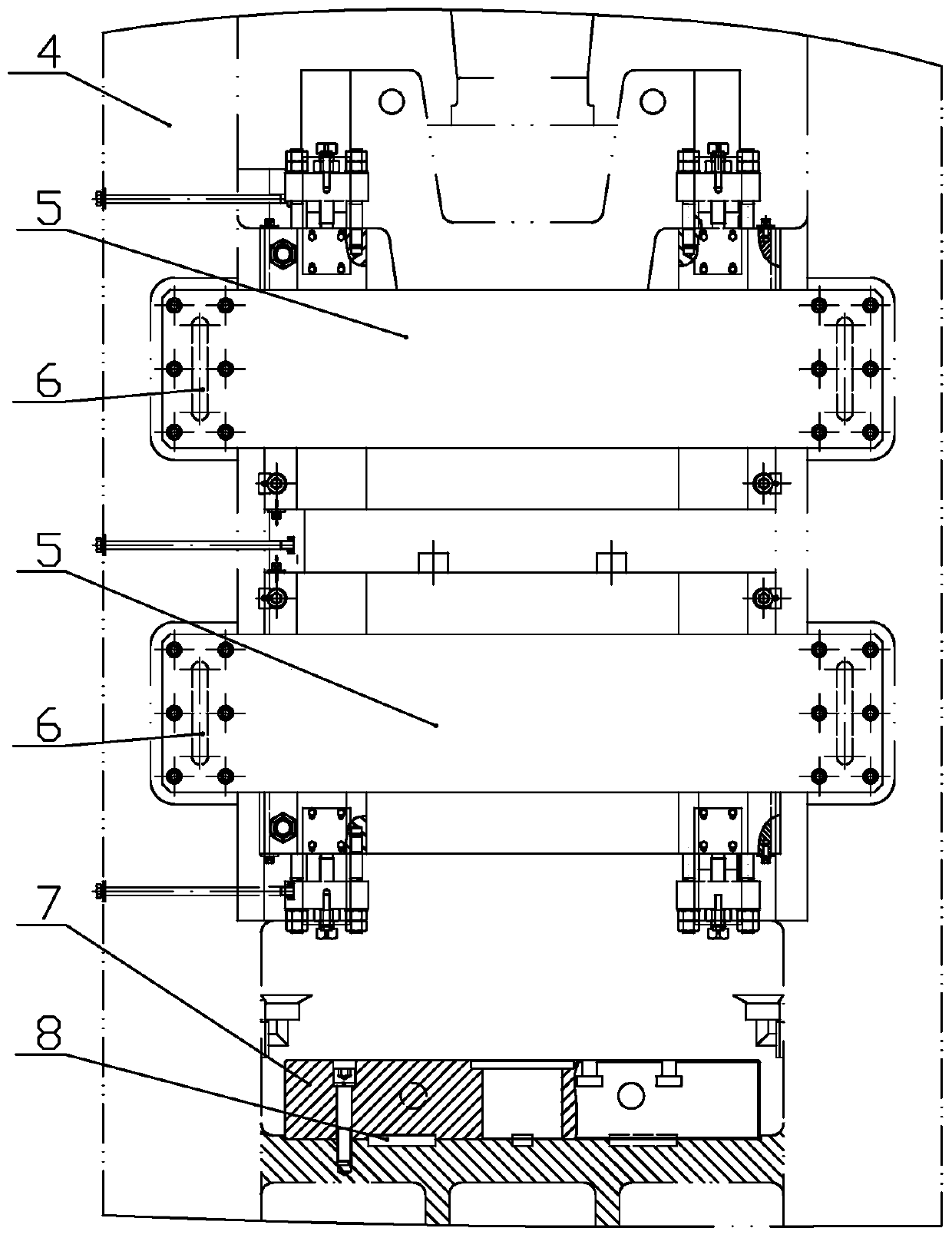

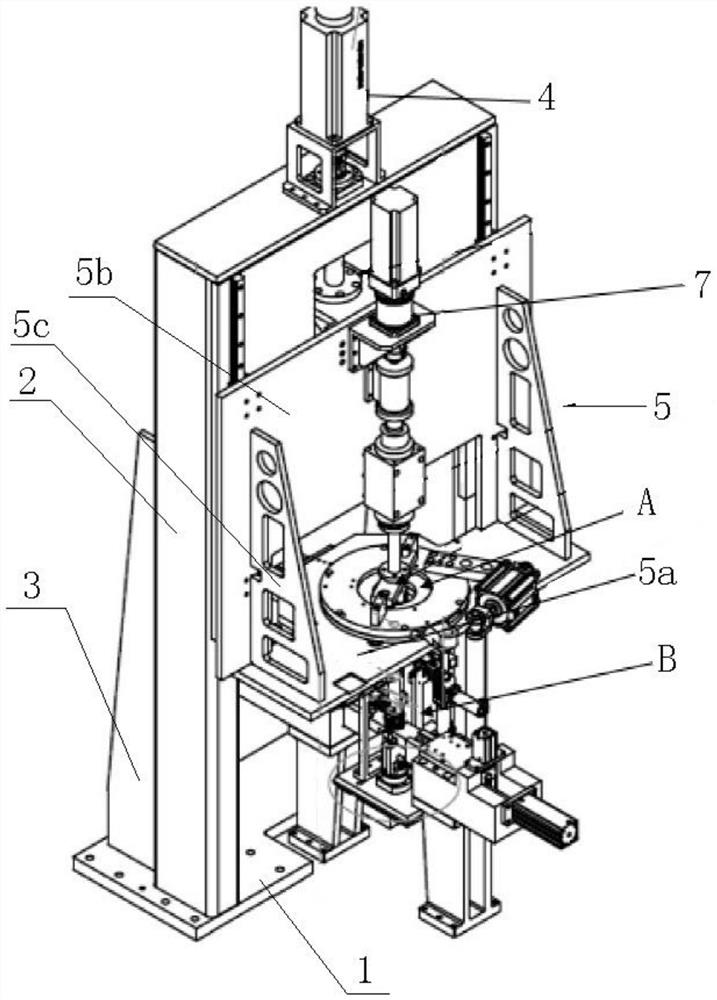

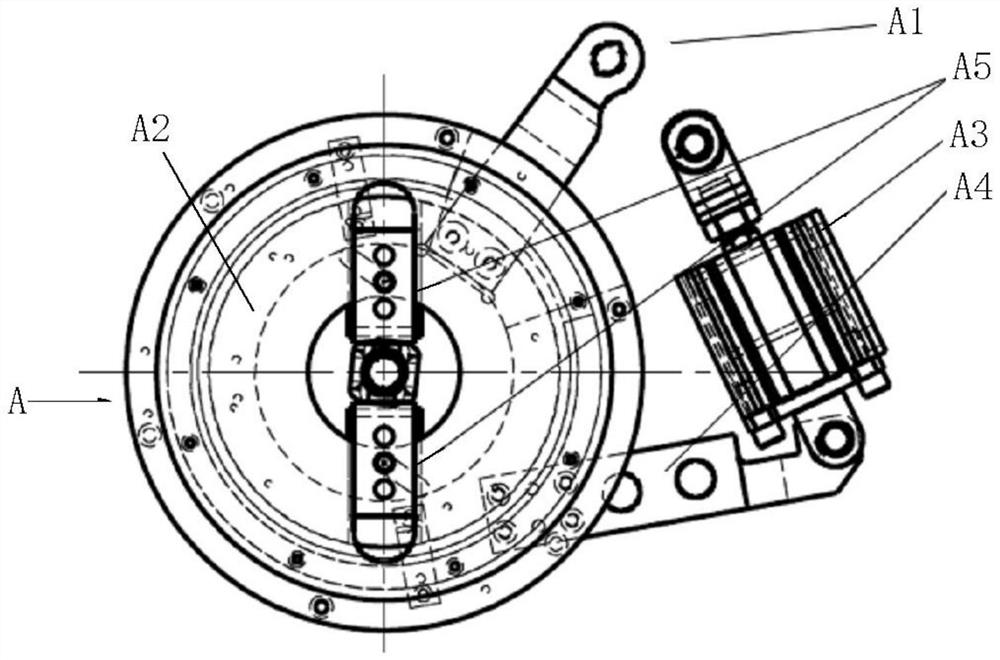

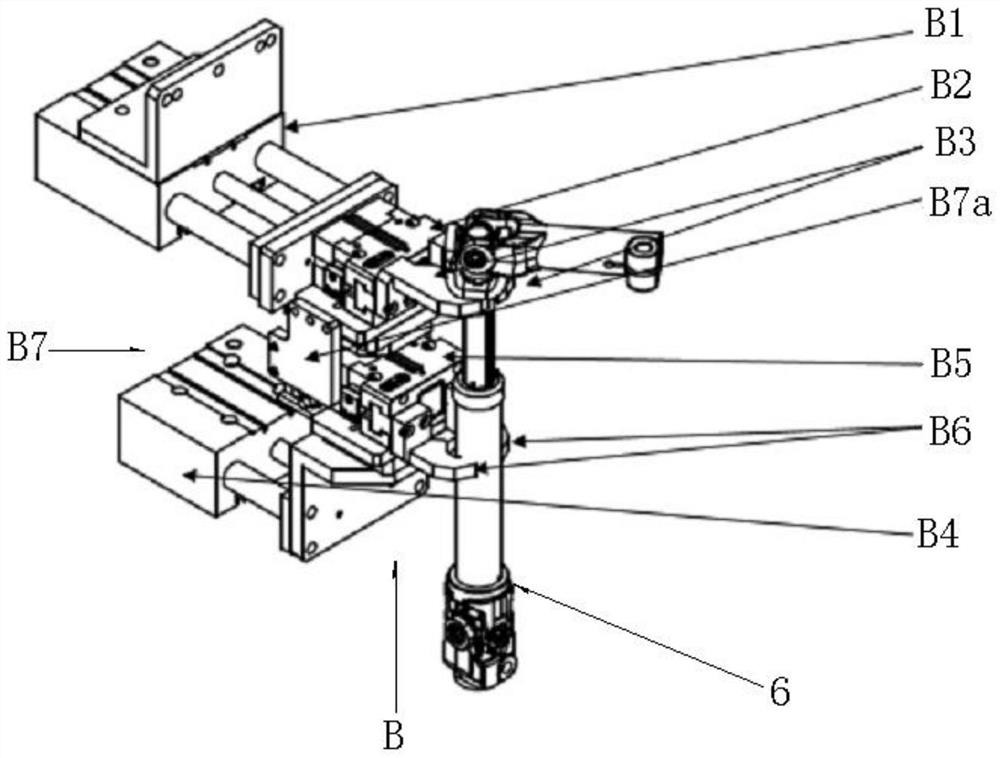

Assembly equipment and method for steel ball type steering intermediate shaft

PendingCN113695897AMeet assembly needsIncreased stiffness requirementsAssembly machinesControl engineeringElectric machinery

The invention discloses assembly equipment and method for a steel ball type steering intermediate shaft. A servo motor component for height adjustment is arranged at the top of an assembly frame, a liftable joint fork clamping mechanism mounting frame body is arranged at one side of a frame body, the frame body is provided with a fixed joint fork clamping mechanism component, and the joint yoke part of a steel ball type steering intermediate shaft to be assembled is clamped through the mechanism component; the lower portion of a motor for applying the torque is connected with the center position of the fixed joint fork clamping mechanism component, and the motor for applying the torque is used for applying the torque to the steel ball type steering intermediate shaft to be assembled clamped by the fixed joint fork clamping mechanism component; and an angular clearance testing mechanism component is arranged on the lower portion of the joint fork clamping mechanism mounting frame body, and the steel ball type steering intermediate shaft to be assembled is clamped through the angular clearance testing mechanism component and an adaptive steel ball is selected to assemble the intermediate shaft. According to the assembly equipment and method, an angular clearance between a shaft and a pipe is effectively and accurately tested, and the optimum matching steel ball is selected to meet the assembly requirements of various steel ball type intermediate shaft assemblies.

Owner:BOSCH HUAYU STEERING SYSTEMS (YANTAI) CO LTD

Method for controlling settlement by horizontally drilling at embankment and injecting light weight replacing material under normal traffic circumstance

ActiveCN101949122BIncreased stiffness requirementsIncreased durabilityRoadwaysAccessory structureRoad surface

The invention discloses a method for controlling settlement by horizontally drilling at embankment and injecting a light weight replacing material under the normal traffic circumstance, which is characterized in that: the slope embankment on one side or two sides of roadbed is drilled transversely by a drilling or chiseling pore-forming technique, holes lean a certain angle downwards so as to inject the light weight material; and the light weight material is injected into the holes, and then is solidified in the holes to form the light weight replacing material. A sleeve is also placed into the holes firstly, and then the light weight material or a non-backfill material is injected into the sleeve, so that pore-forming quality is ensured and the diffusion of the light weight material is avoided. The road does not need to be sealed, a pavement structure layer and an upper accessory structure cannot be damaged, and the normal traffic cannot be influenced.

Owner:HOHAI UNIV

Movable type robot in 6 degree of freedom being connected in series parallel

InactiveCN1242873CEasy to decoupleNo cumulative errorProgramme-controlled manipulatorMovable typeEngineering

A movable six-freedom mixed robot is composed of a static platform, three branch joins AAo, BBo and CCo, and a movable platform. Said branch join AAo (or BBo) has three guide rods: moving rods X, Y and Z, whose moving directions are mutually perpendicular for realizing the movement in X, Y and Z directions. The moving rods X, Y and Z of AAo and the moving rods Y and Z of BBo have drive force but the moving rod X of BBo has not. It can realize 6-freedom movement of movable platform. Its advantages are good decoupling performance of branch joins, high rigidity of movable platform, and no error accumulation.

Owner:SHANGHAI JIAOTONG UNIV

A spacecraft deployment mechanism

ActiveCN105659913BThe overall impact is smallSimple structureCollapsable antennas meansSpace shuttlesLocking mechanismEngineering

The spacecraft deployment mechanism of the present invention adopts a combined form of an active driving assembly and a mechanical locking mechanism. The mechanical locking mechanism includes a first locking assembly and a second locking assembly, and the first locking assembly and the second locking assembly are distributed between the two active driving assemblies. end, the active drive assembly is connected to the second locking assembly, the second locking assembly is connected to the first locking assembly through the connecting bracket, and the active driving assembly, the first locking assembly and the second locking assembly are connected together through the base; when working, The active driving component drives the second locking component to move, and the second locking component drives the first locking component to move through the connecting bracket. After being unfolded in place, the first locking component and the second locking component respectively complete locking. The deployment mechanism also includes a sensor assembly and a micro switch. The invention has a simple and reliable structure, has little disturbance and influence on the spacecraft, can adapt to load requirements in a relatively large range, and can meet the requirements of high precision and high rigidity under space conditions.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

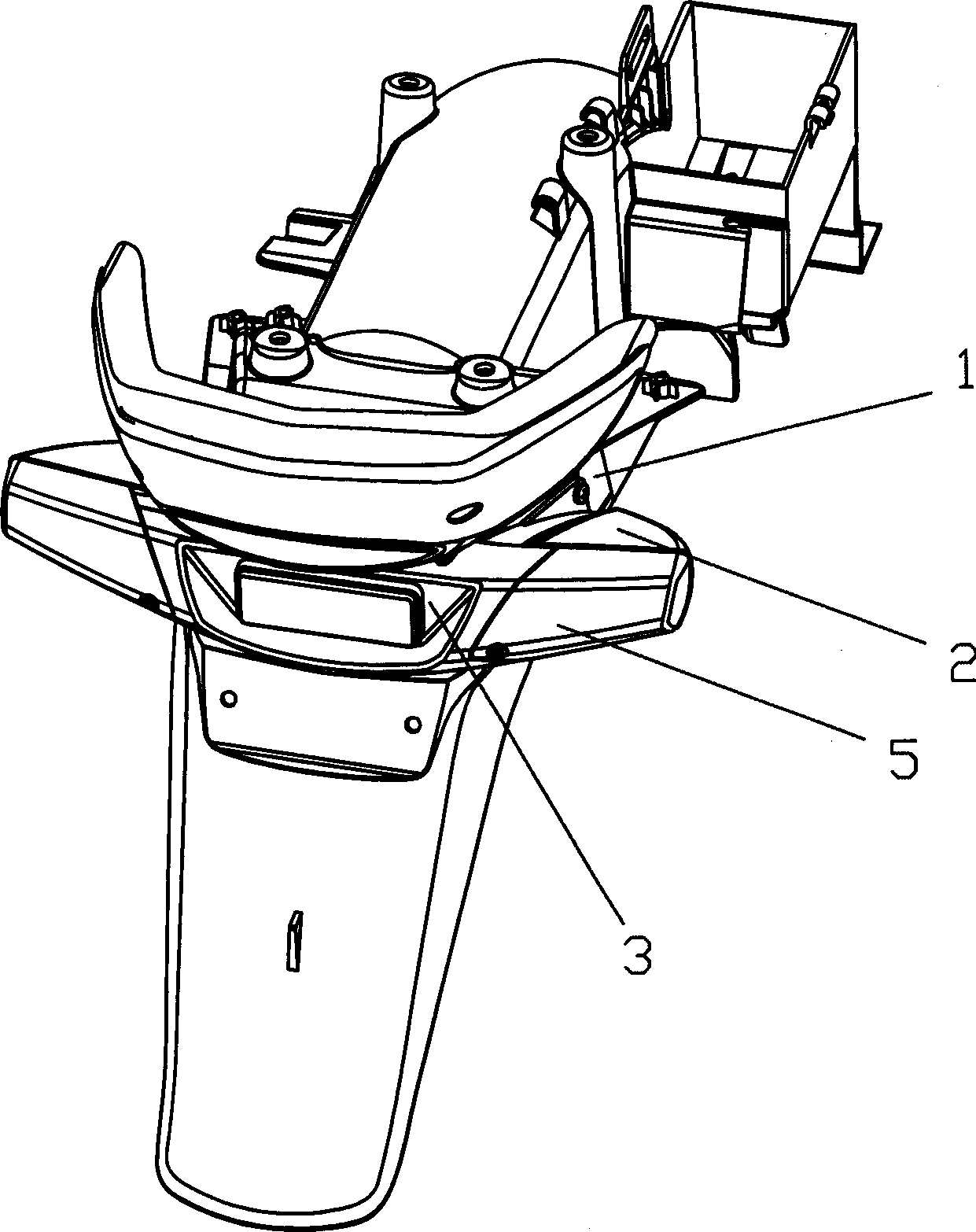

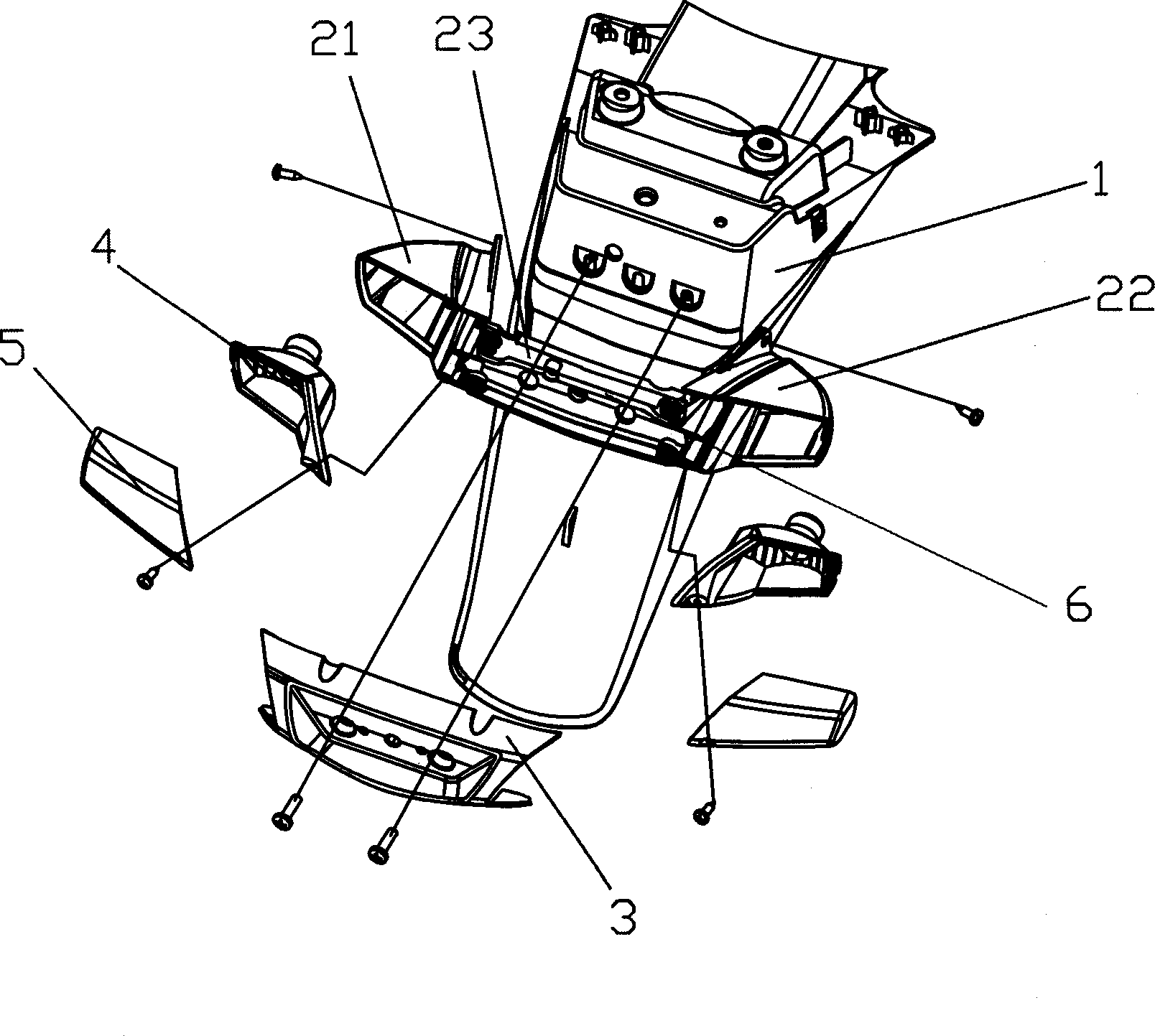

Rear steering indicating light of motorcycle

InactiveCN1880149AImprove management efficiencyImprove assembly efficiencyOptical signalAgricultural engineering

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com