Structural rigidity and precision improving device for hot die forging press

A technology for hot die forging presses and structural rigidity, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problems of inability to adjust the gap or disassembly, affect the positioning accuracy, affect the accuracy of the machine tool, etc. The effect of load-carrying green material saving, improving positioning accuracy, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

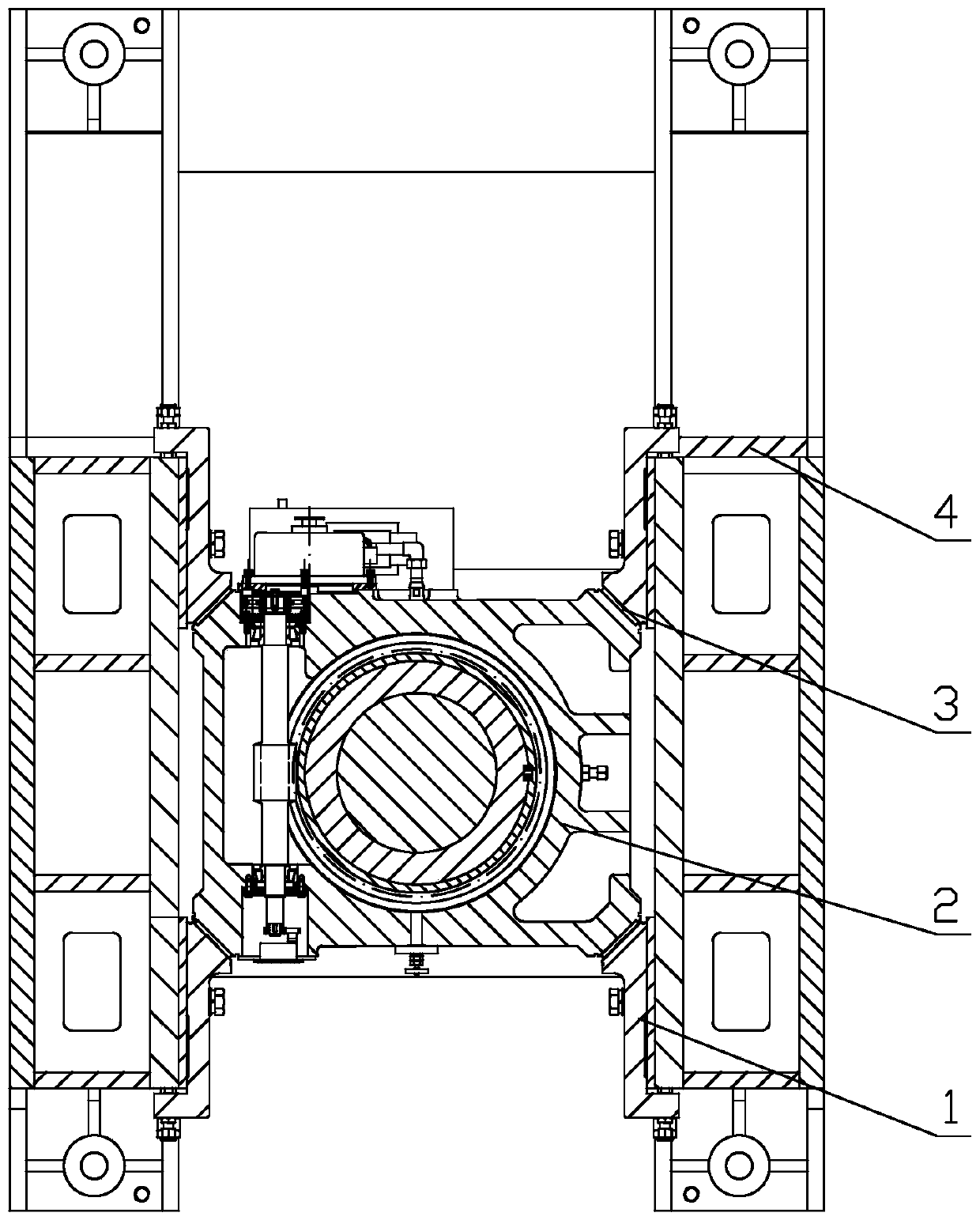

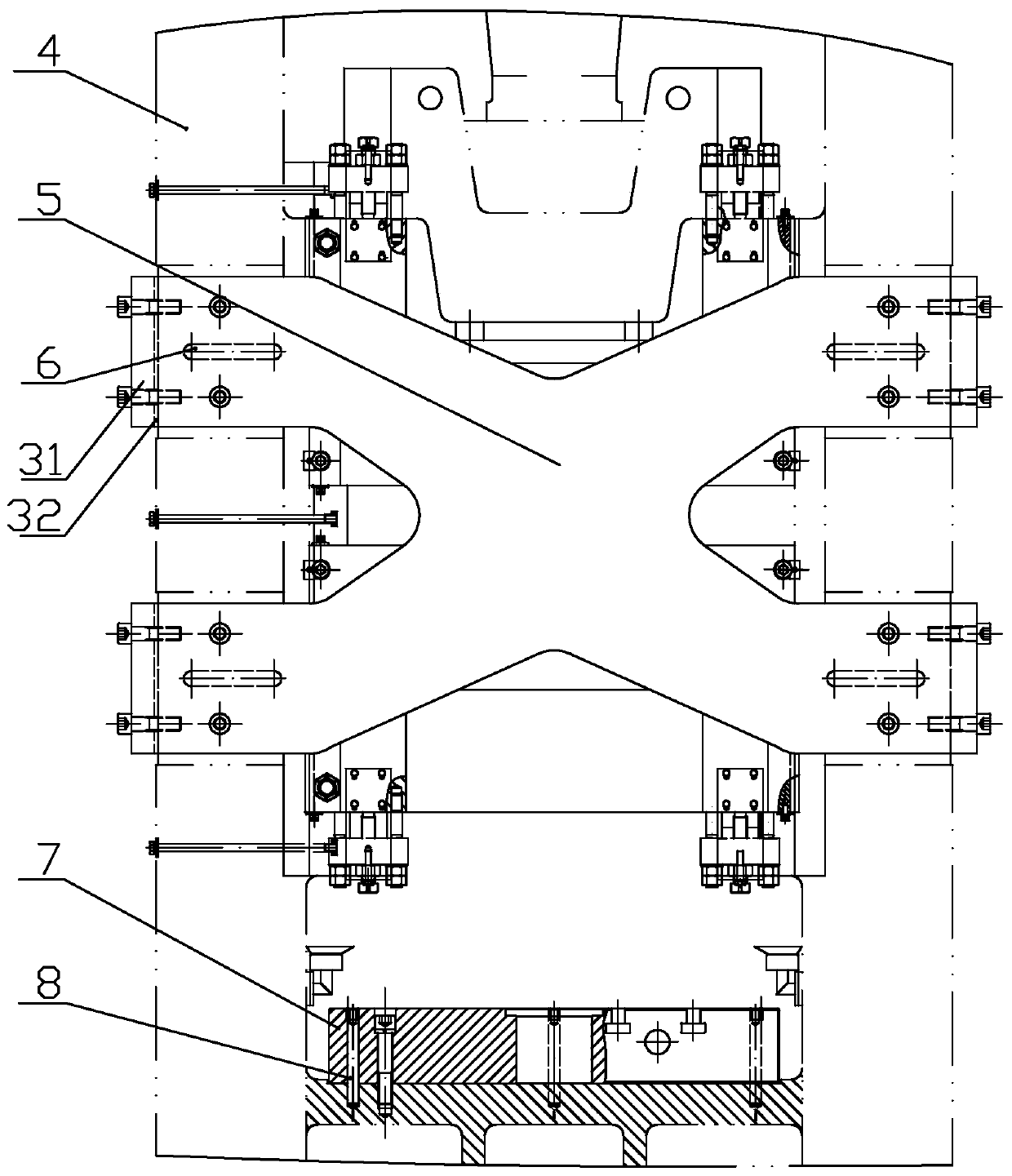

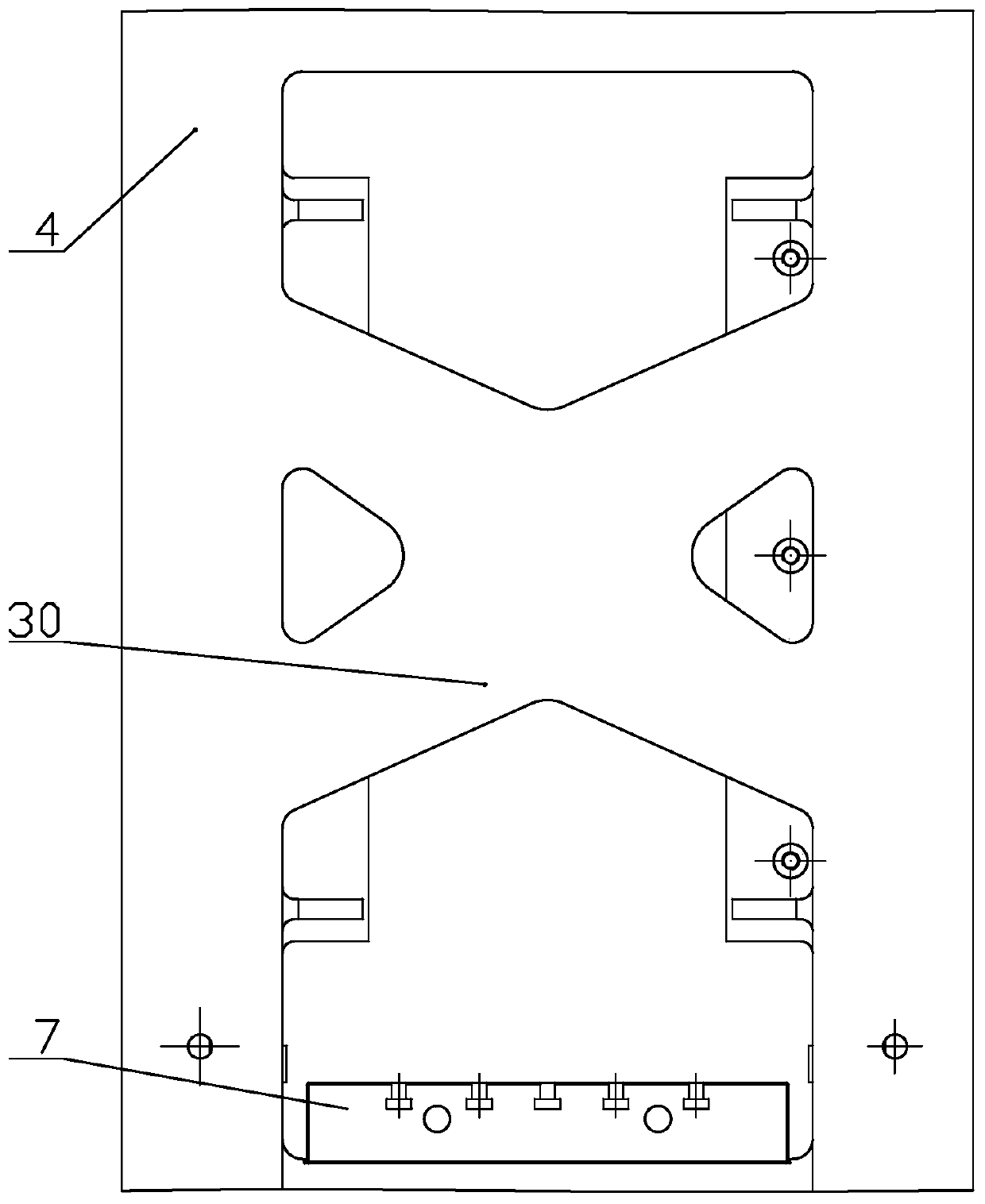

[0034] Such as Figure 2-10 As shown, the structural rigidity and precision improvement device of the hot die forging press includes:

[0035] Frame 4, said frame 4 adopts an integral cast steel box-type frame symmetrical structure, X-shaped connecting ribs 30 are cast on the rear side of frame 4, and the left and right frames on the rear side are connected as one; There is a processing surface, and several horizontal keyways are provided on the processing surface, and a positioning key 6 is arranged in the horizontal keyway, and an X-shaped strengthening connecting plate 5 symmetrical to the X-shaped connecting rib plate 30 is installed on the front side of the frame 4, and the X-shaped strengthening The connecting plate 5 is provided with the same hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com